Development of 3D-Printed MWCNTs/AC/BNNTs Ternary Composite Electrode Material with High-Capacitance Performance

Abstract

:1. Introduction

2. Experimental

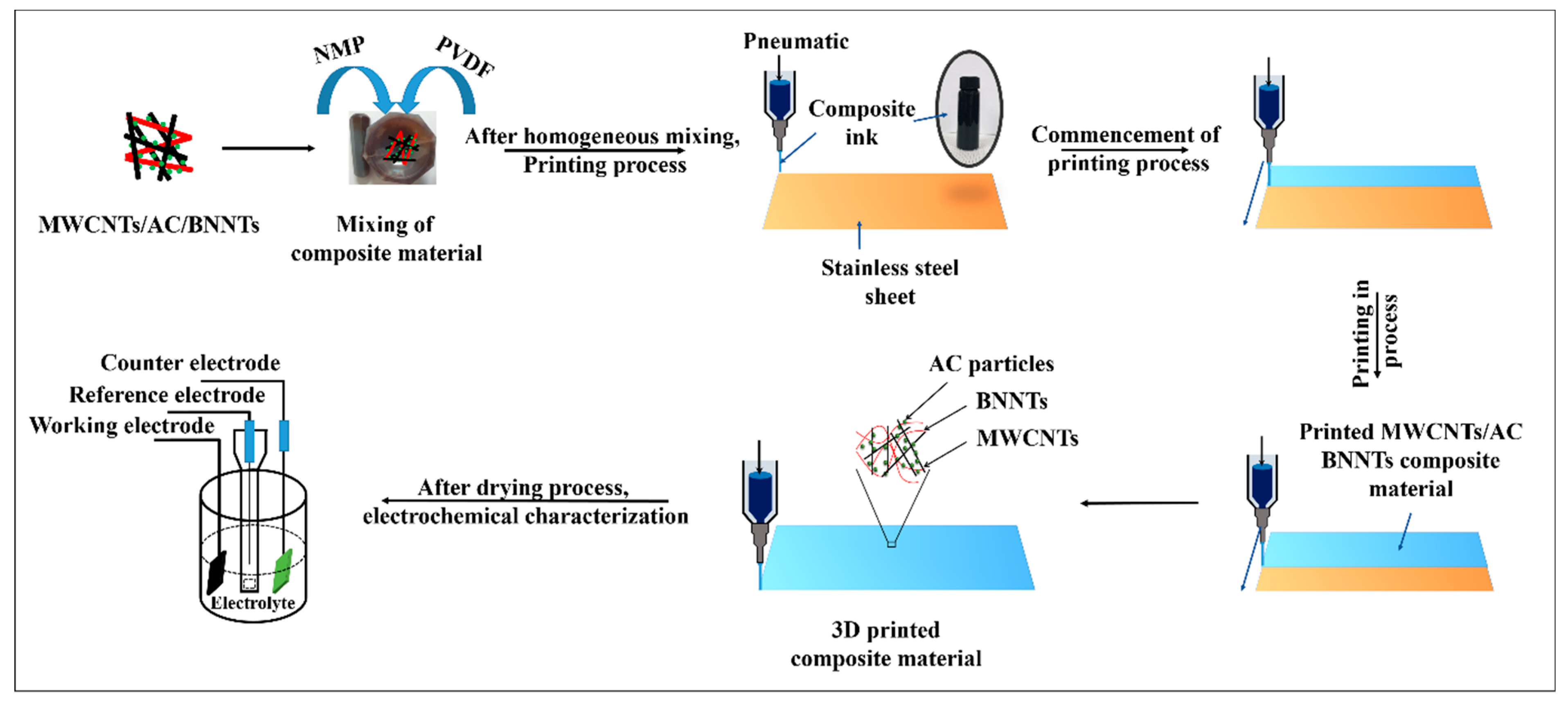

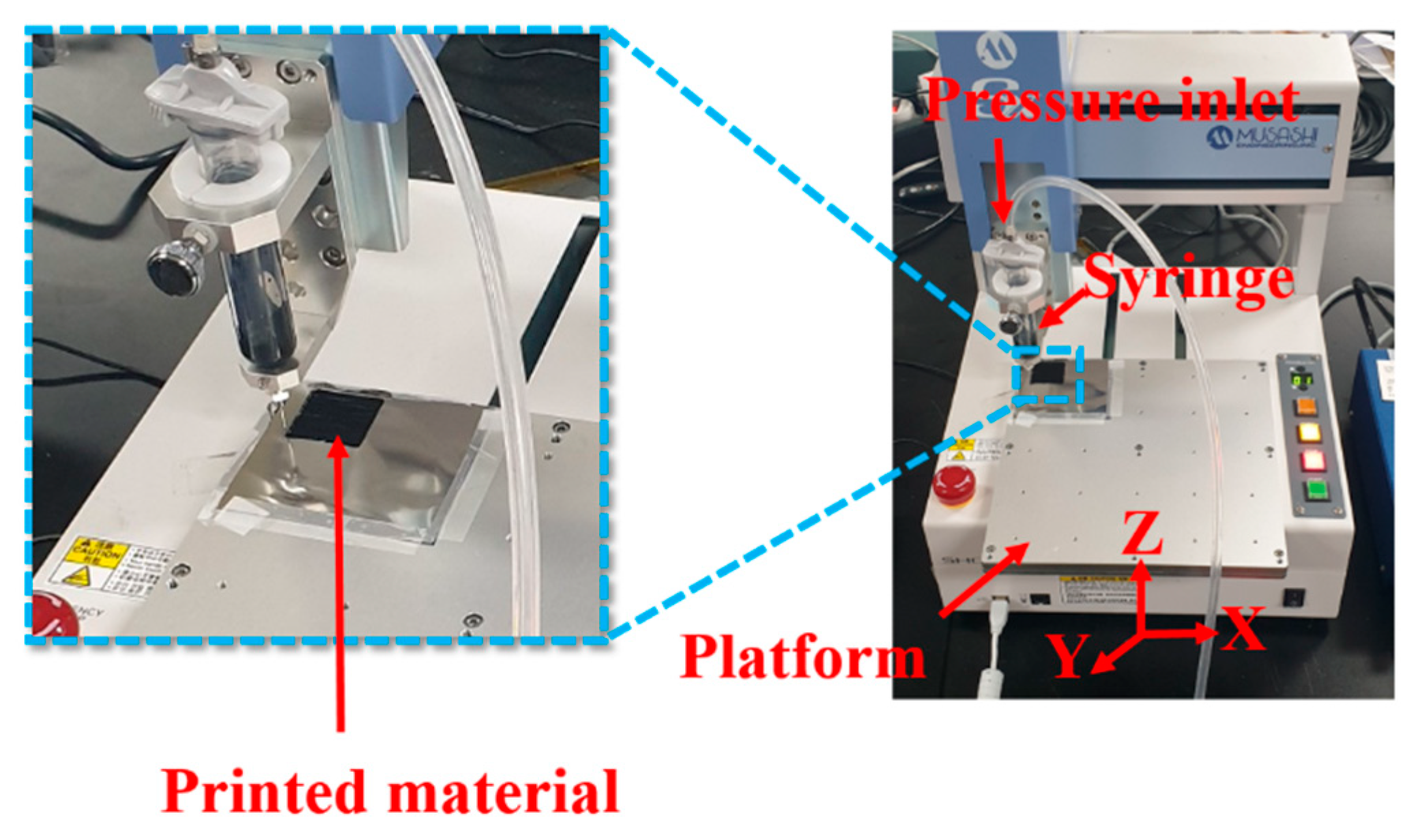

2.1. Fabrication of Printed MWCNTs/AC/BNNTs Ternary Composite Material

2.2. Material Characterizations

2.3. Electrochemical Testing

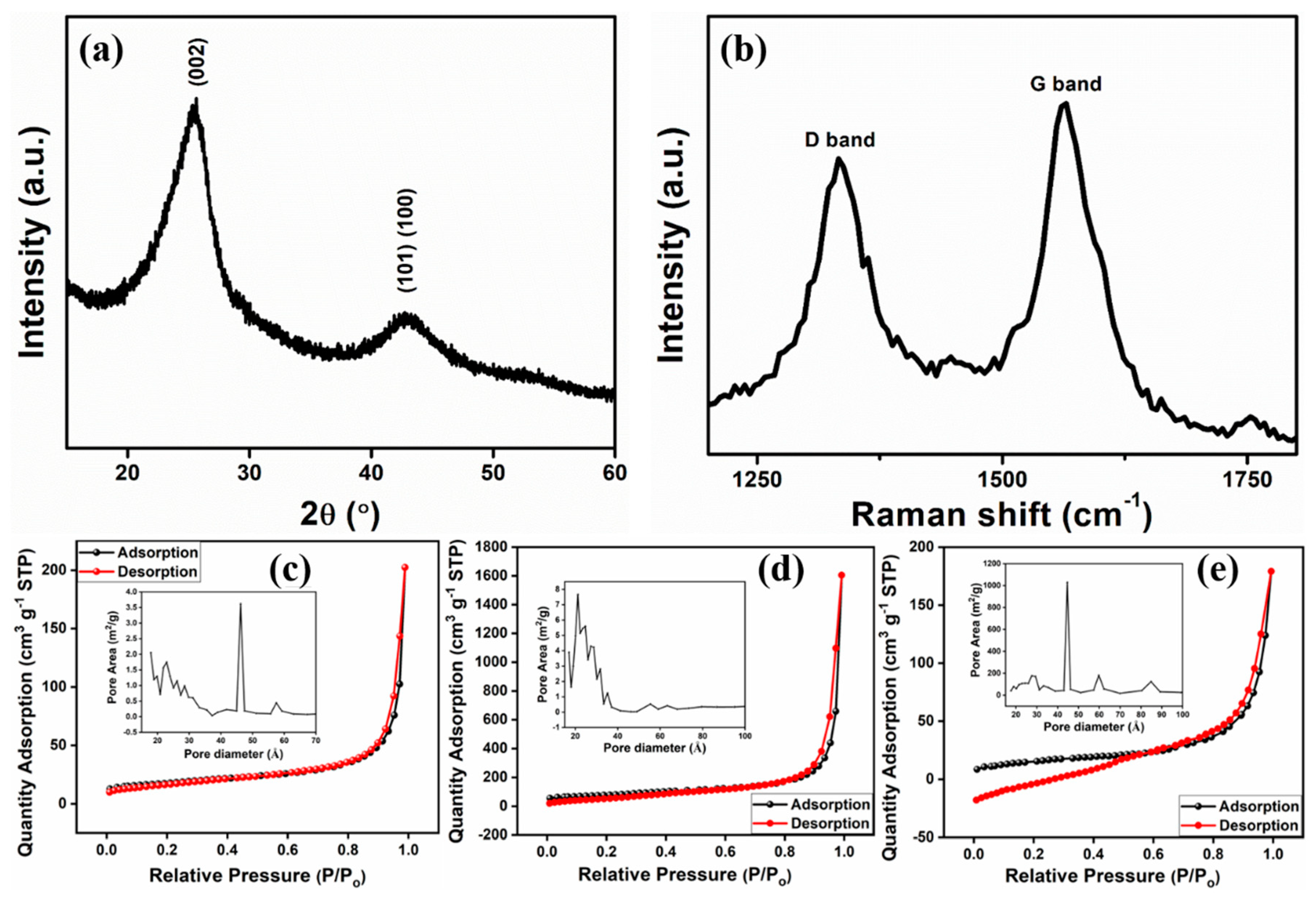

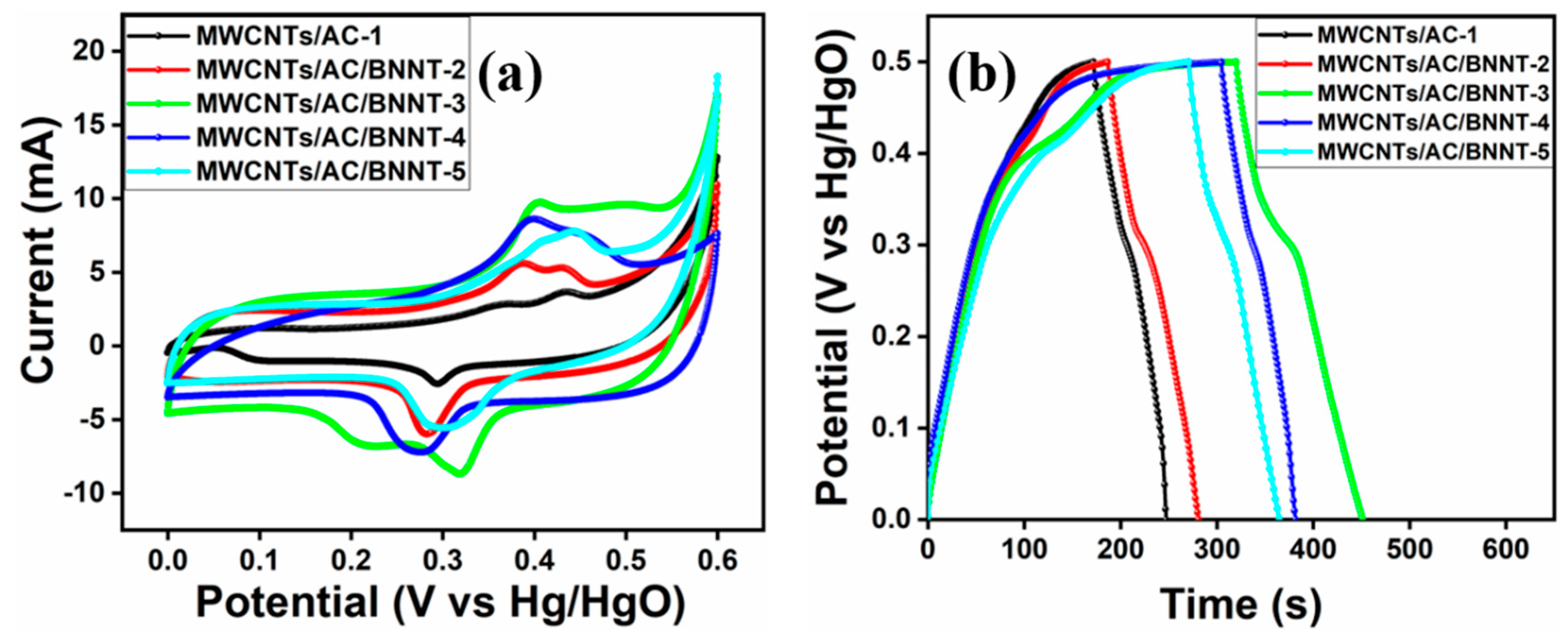

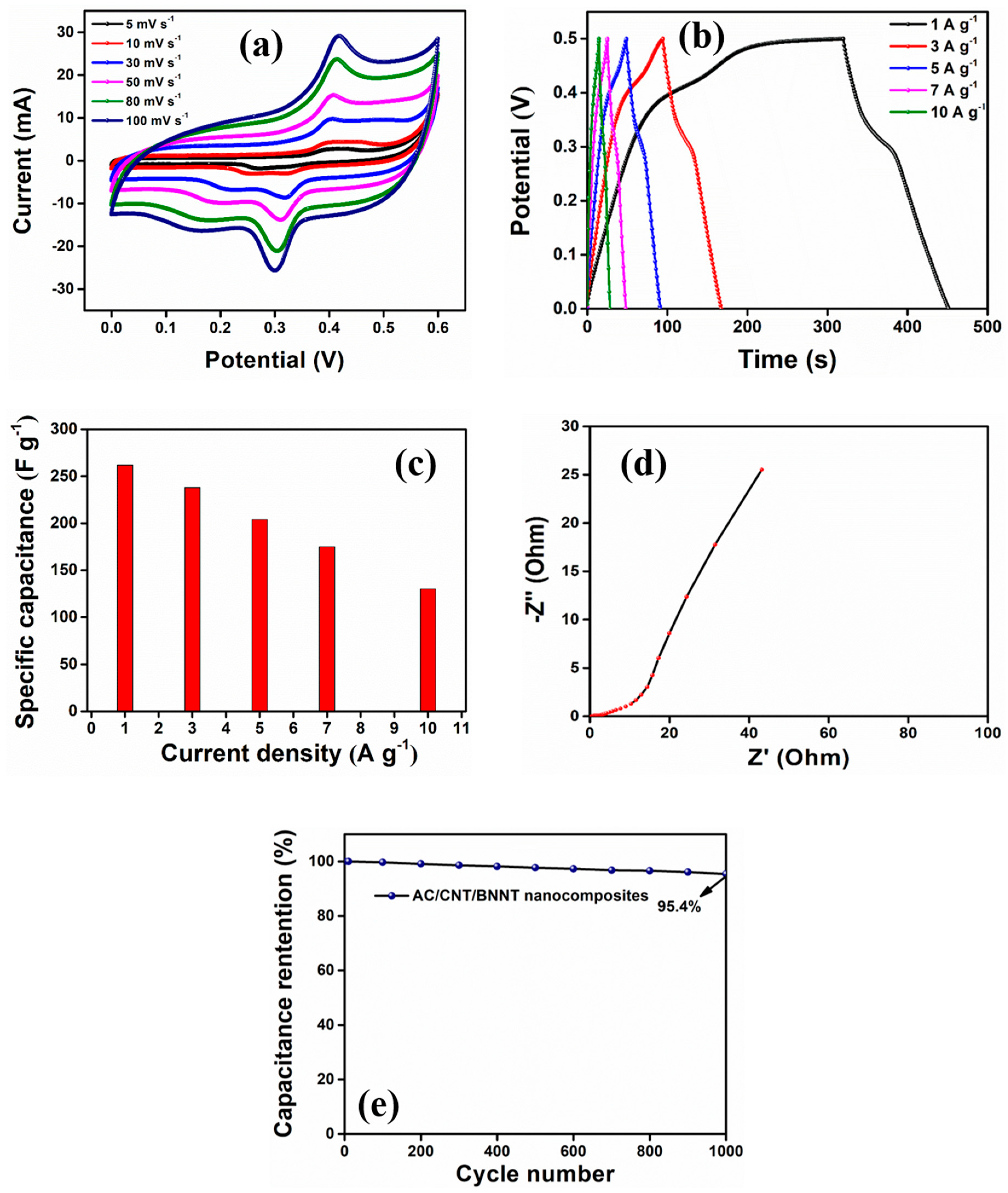

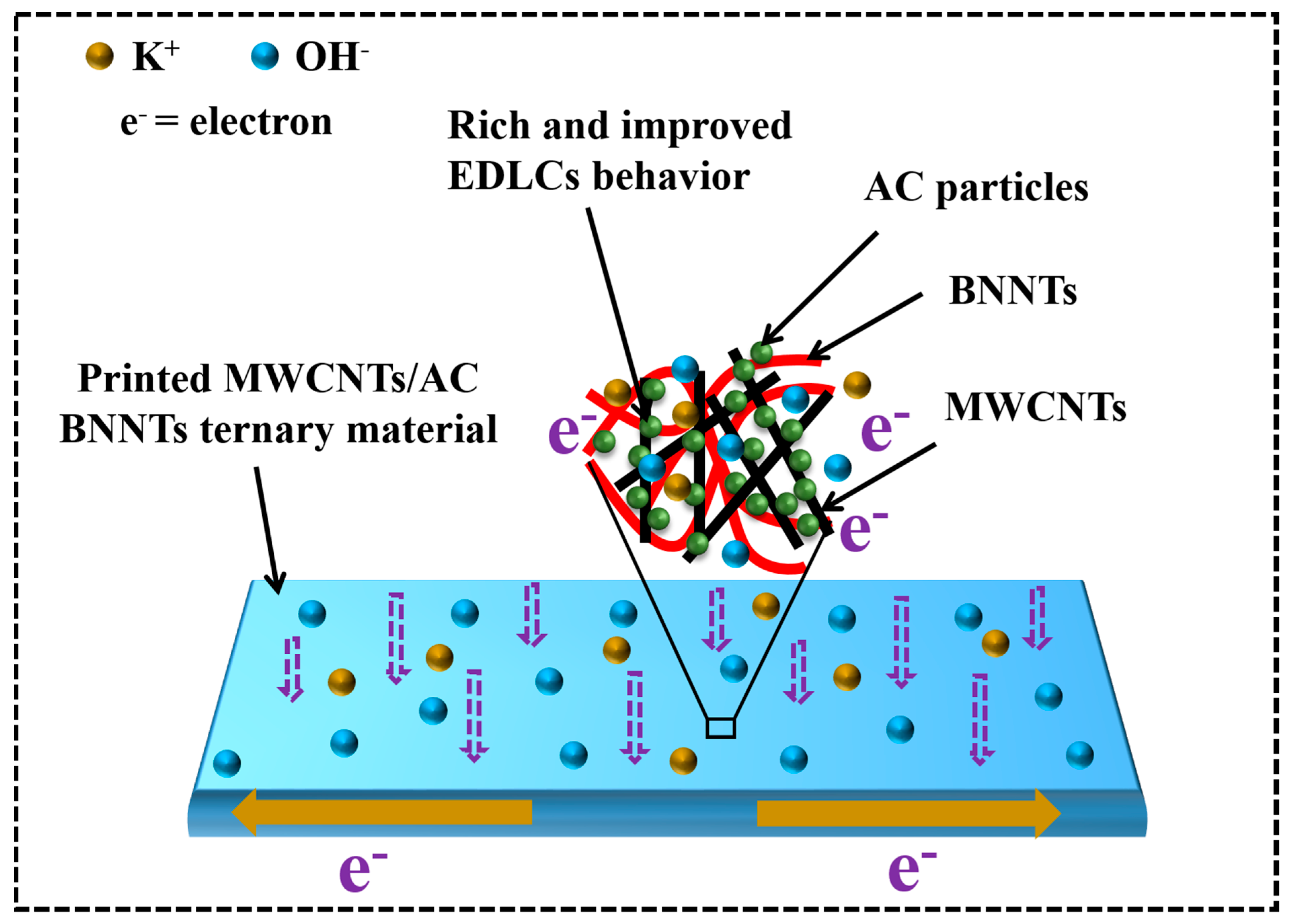

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alam, A.; Saeed, G.; Lim, S. One-step synthesis of 2D–2D Co(OH)2–MoSe2 hybrid nanosheets as an-efficient electrode material for high-performance. J. Electroanal. Chem. 2020, 879, 114775. [Google Scholar] [CrossRef]

- Yao, B. TiN paper for ultrafast-charging supercapacitors. Nano Micro Lett. 2020, 12, 3. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.; Yu, J. A conductive and highly deformable all-pseudocapacitive composite paper as supercapacitor electrode with improved areal and volumetric capacitance. Small 2018, 14, 1803786. [Google Scholar] [CrossRef] [PubMed]

- Saeed, G.; Alam, A.; Bandyopadhyay, P.; Lim, S.; Kim, N.H.; Lee, J.H. Development of hierarchically structured nanosheet arrays of CuMnO2-MnxOy@graphene foam as a nanohybrid electrode material for high-performance asymmetric supercapacitor. J. Alloys Comp. 2021, 858, 158343. [Google Scholar] [CrossRef]

- Chen, T.; Dai, L. Carbon nanomaterials for high-performance supercapacitors. Mater. Today 2013, 16, 272–280. [Google Scholar] [CrossRef]

- Pan, H.; Li, J.; Feng, Y.P. Carbon nanotubes for supercapacitor. Nanoscale Res. Lett. 2010, 5, 654–668. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aval, L.F.; Ghoranneviss, M.; Pour, G.B. High-performance supercapacitors based on the carbon nanotubes, graphene and graphite nanoparticles electrodes. Heliyon 2018, 4, 00862. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Tian, J.; Yin, Z.; Cui, C.; Qian, W.; Wei, F. Carbon nanotube and graphene-based nanomaterials and applications in high-voltage supercapacitor: A review. Carbon 2019, 141, 467–480. [Google Scholar] [CrossRef]

- Alam, A.; Saeed, G.; Lim, S. Screen-printed activated carbon/silver nanocomposite electrode material for a high performance supercapacitor. Mater. Lett. 2020, 273, 127933. [Google Scholar] [CrossRef]

- Dong, Q. Ultrasound-assisted preparation of electrospun carbon nano fiber/graphene composite electrode for supercapacitors. J. Power Sources 2013, 243, 350–353. [Google Scholar] [CrossRef]

- Chen, X.; Zhu, X.; Xiao, Y.; Yang, X. PEDOT/g-C3N4 binary electrode material for supercapacitors. J. Electroanal. Chem. 2015, 743, 99–104. [Google Scholar] [CrossRef]

- Yu, D.; Dai, L. Self-assembled graphene/carbon nanotube hybrid films for supercapacitors. J. Phys. Chem. Lett. 2010, 1, 467–470. [Google Scholar] [CrossRef]

- You, B. Three dimensional N-doped graphene–CNT networks for supercapacitor. Chem. Comm. 2013, 1, 5016–5018. [Google Scholar] [CrossRef] [PubMed]

- Abbas, W.A. Recent advances in the use of TiO2 nanotube powder in biological, environmental, and energy applications. Nanoscale Adv. 2019, 1, 2801–2816. [Google Scholar] [CrossRef] [Green Version]

- Gilshteyn, E.P.; Amanbayev, D.; Anisimov, A.S.; Kallio, T.; Nasibulin, A.G. All-nanotube stretchable supercapacitor with low equivalent series resistance. Sci. Rep. 2017, 7, 1–9. [Google Scholar]

- Orangi, J.; Hamade, F.; Davis, V.A.; Beidaghi, M. 3D Printing of additive-free 2D Ti3C2Tx (mxene) ink for fabrication of micro-supercapacitors with ultra-high energy densities. ACS Nano 2020, 14, 640–650. [Google Scholar] [CrossRef]

- Fan, Z.; Yu, C.W.L.; Xia, Z.; Cai, J. 3D Printing of porous nitrogen-doped Ti3C2 MXene Scaffolds for high-performance sodium-ion hybrid capacitors. ACS Nano 2020, 14, 867–876. [Google Scholar] [CrossRef]

- Kim, K.S.; Kingston, C.T.; Hrdina, A.; Jakubinek, M.B.; Guan, J.; Plunkett, M.; Simard, B. Hydrogen-catalyzed, pilot-scale production of small-diameter boron nitride nanotubes and their macroscopic assemblies. ACS Nano 2014, 8, 6211–6220. [Google Scholar] [CrossRef] [PubMed]

- Romanitan, C. High-performance solid state supercapacitors assembling graphene interconnected networks in porous silicon electrode by electrochemical methods using. Sci. Rep. 2018, 8, 1–14. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saeed, G.; Kumar, S.; Bandyopadhyay, P.; Kim, N.H.; Lee, J.H. Hierarchical design of Cu-Ni(OH)2/Cu-MnxOy core/shell nanosheet arrays for ultra-high performance of asymmetric supercapacitor. Chem. Eng. J. 2019, 369, 705–715. [Google Scholar] [CrossRef]

- Sun, B. New complete assignment of X-ray powder diffraction patterns in graphitic carbon nitride using discrete Fourier transform and direct experimental evidence. Phys. Chem. Chem. Phys. 2017, 87, 26072–26084. [Google Scholar] [CrossRef]

- Saeed, G.; Kumar, S.; Kim, N.H.; Lee, J.H. Fabrication of 3D graphene-CNTs/α-MoO3 hybrid film as an advance electrode material for asymmetric supercapacitor with excellent energy density and cycling life. Chem. Eng. J. 2018, 352, 268–276. [Google Scholar] [CrossRef]

- Hua, S.; Luo, J.; Ji, W.; Lin, J. Synthesis of boron nitride nanotubes and its hydrogen uptake. Catal. Today 2007, 120, 346–350. [Google Scholar]

- Wang, Z.; Liu, J.; Cheng, Y.; Chen, S. Alignment of boron nitride nanofibers in epoxy composite films for thermal conductivity and dielectric breakdown strength improvement. Nanomaterials 2018, 8, 242. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Sample | BET Surface Area (m2 g−1) | Size of Pore (Å) | Pore Volume (cm3 g) |

|---|---|---|---|

| Multiwalled carbon nanotubes | 62.0763 | 201.7726 | 0.313132 |

| Activated carbon | 271.7288 | 365.4881 | 2.482841 |

| Boron nitride nanotubes | 54.6504 | 202.8095 | 0.277091 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alam, A.; Saeed, G.; Hong, S.M.; Lim, S. Development of 3D-Printed MWCNTs/AC/BNNTs Ternary Composite Electrode Material with High-Capacitance Performance. Appl. Sci. 2021, 11, 2636. https://doi.org/10.3390/app11062636

Alam A, Saeed G, Hong SM, Lim S. Development of 3D-Printed MWCNTs/AC/BNNTs Ternary Composite Electrode Material with High-Capacitance Performance. Applied Sciences. 2021; 11(6):2636. https://doi.org/10.3390/app11062636

Chicago/Turabian StyleAlam, Asrar, Ghuzanfar Saeed, Seong Min Hong, and Sooman Lim. 2021. "Development of 3D-Printed MWCNTs/AC/BNNTs Ternary Composite Electrode Material with High-Capacitance Performance" Applied Sciences 11, no. 6: 2636. https://doi.org/10.3390/app11062636