The Investigation of Microstructure and Mechanical Behavior and the Fractographic Analysis of the Ti49.1Ni50.9 Alloy in States with Different Activation Deformation Volumes

Abstract

1. Introduction

2. Materials and Methods

3. Results

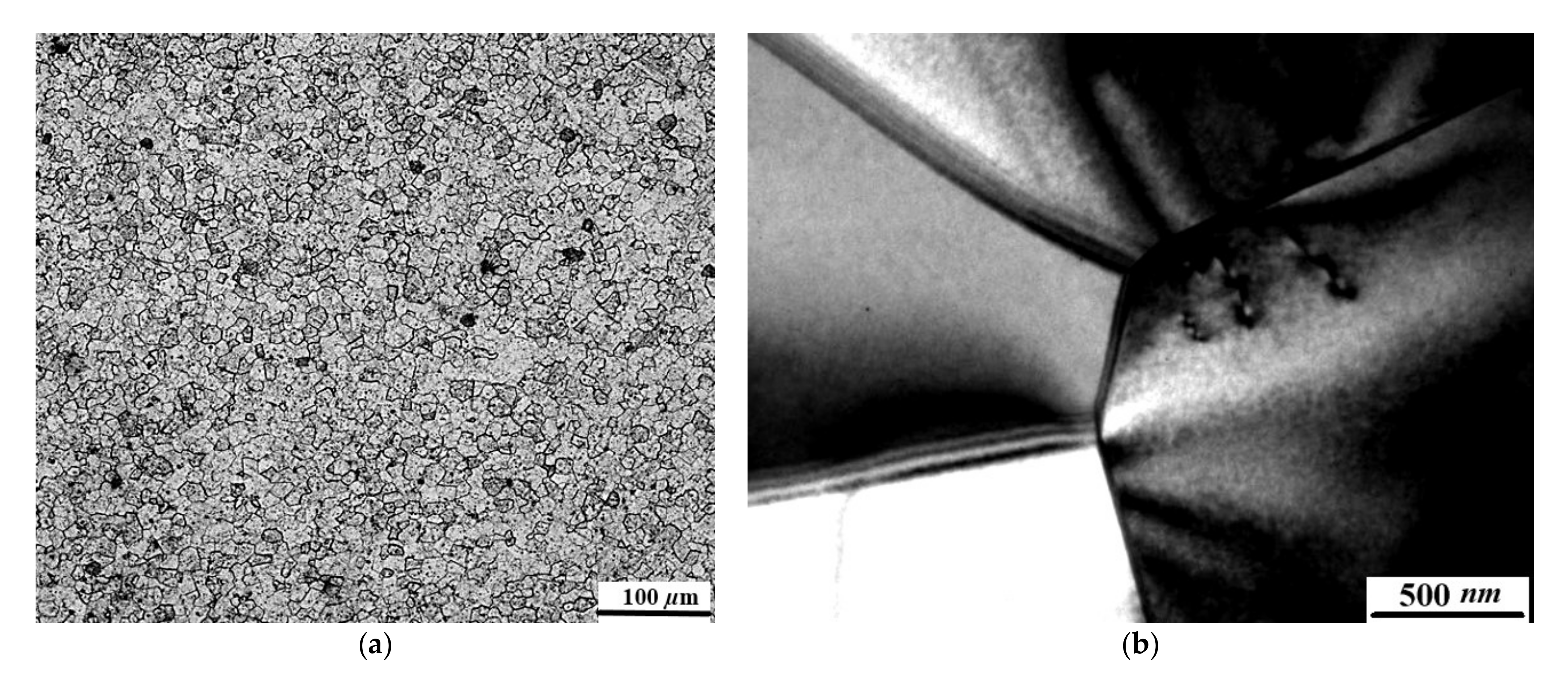

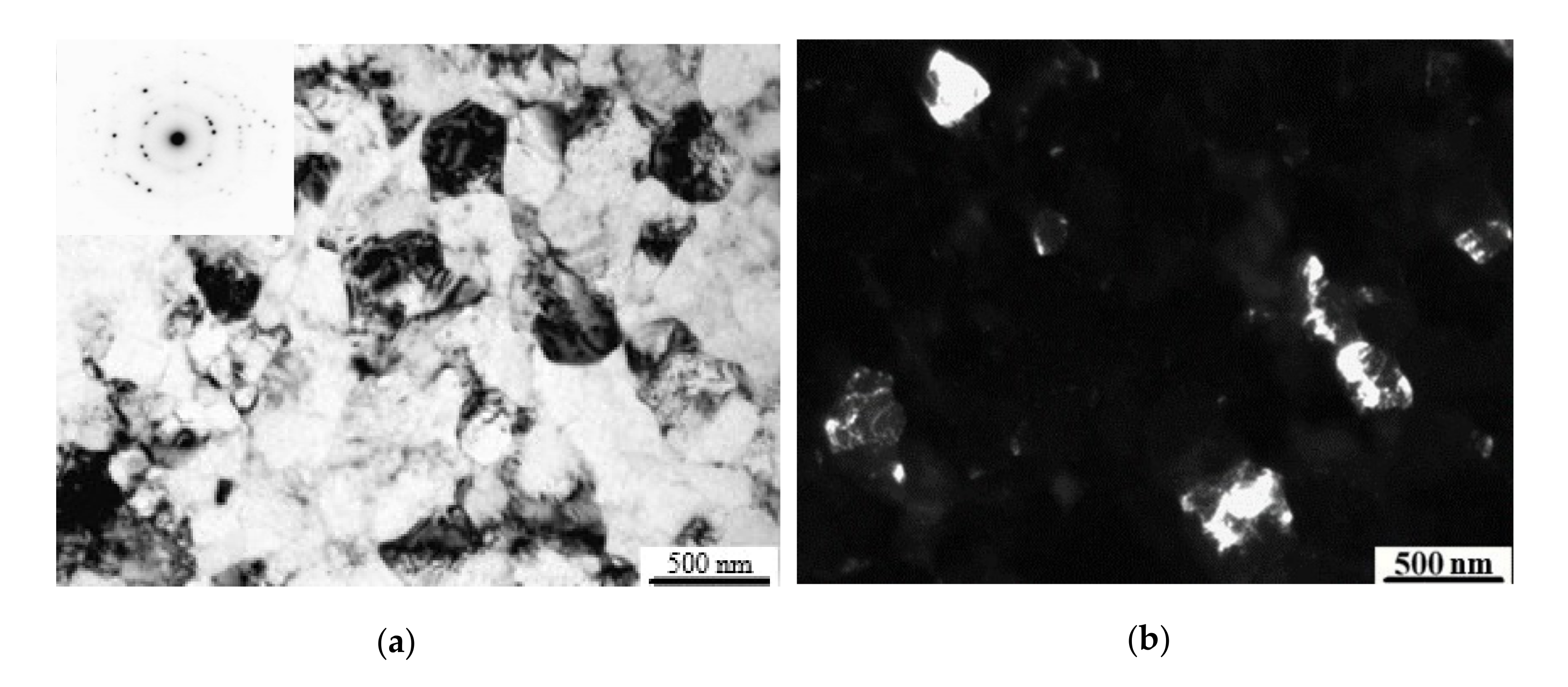

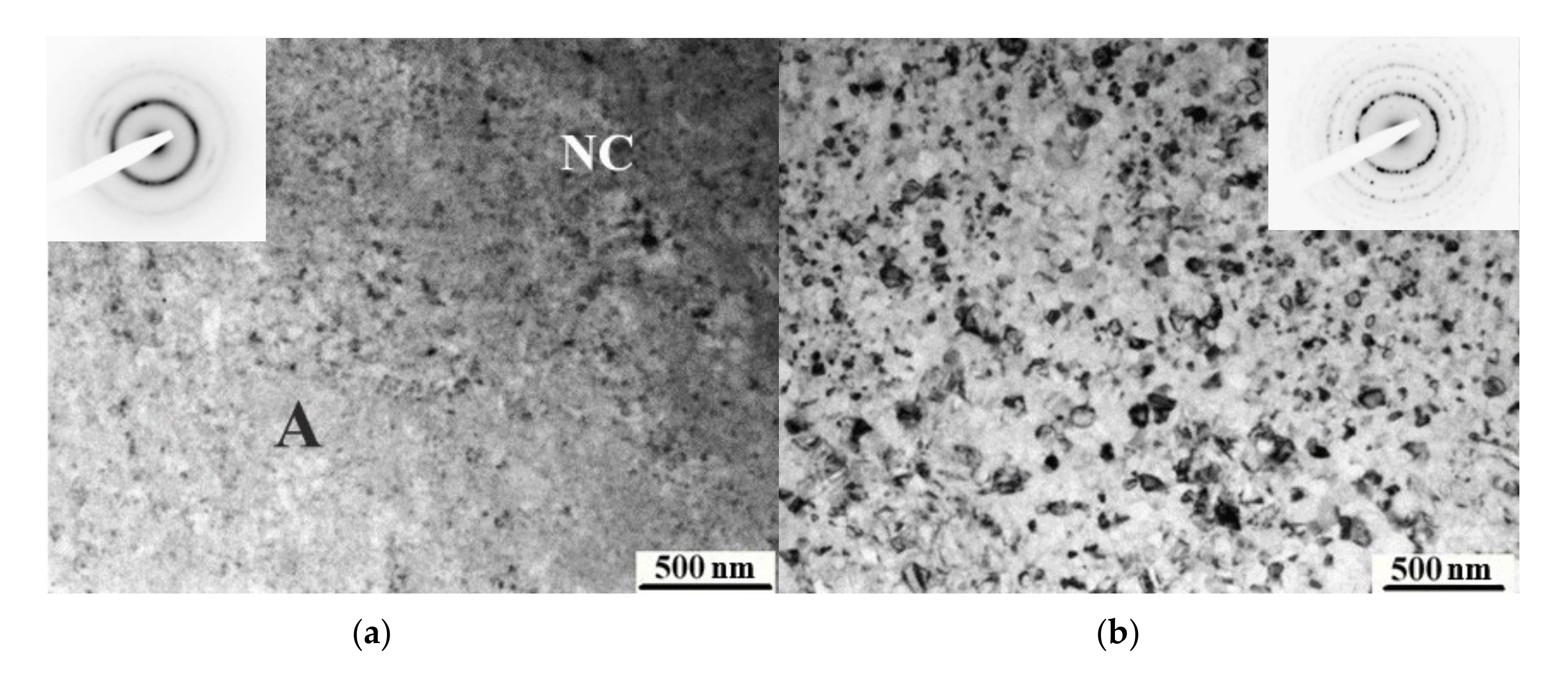

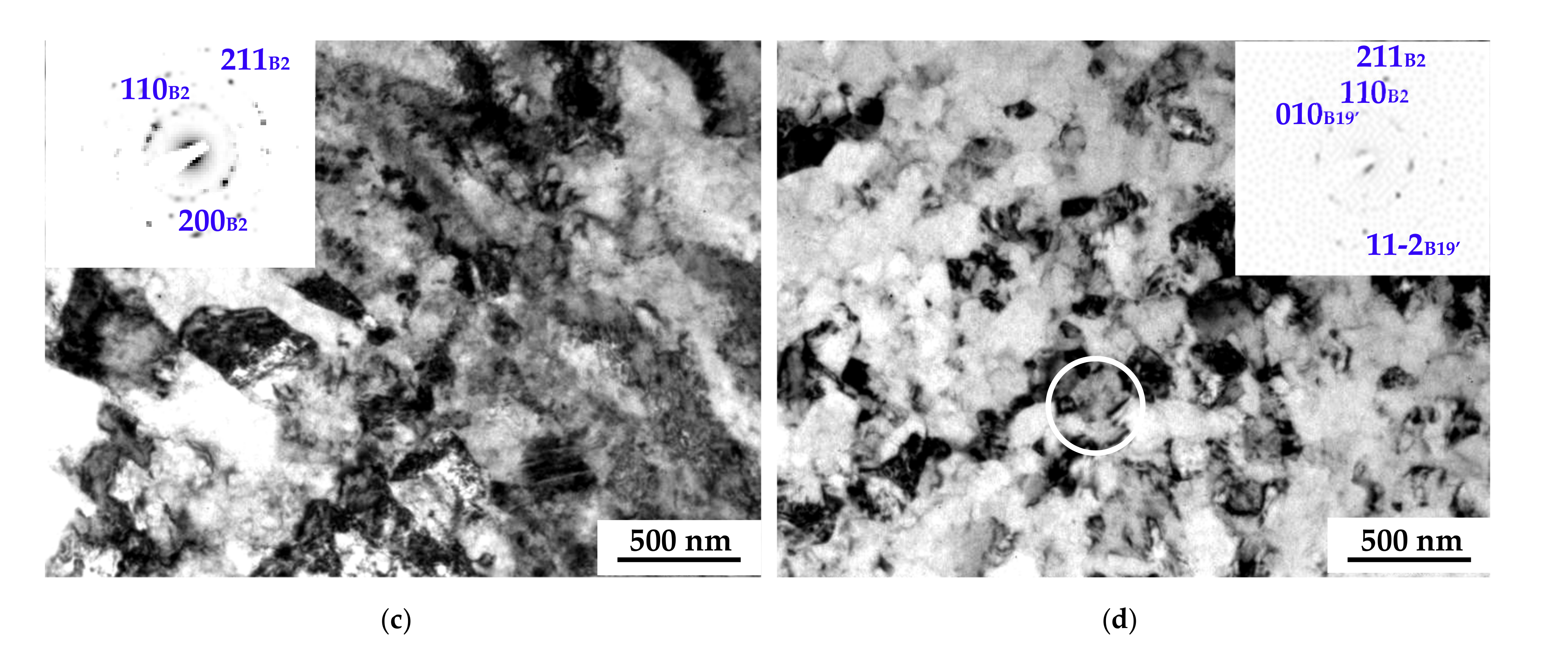

3.1. Microstructural Studies of the Ti49.1Ni50.9 Alloy

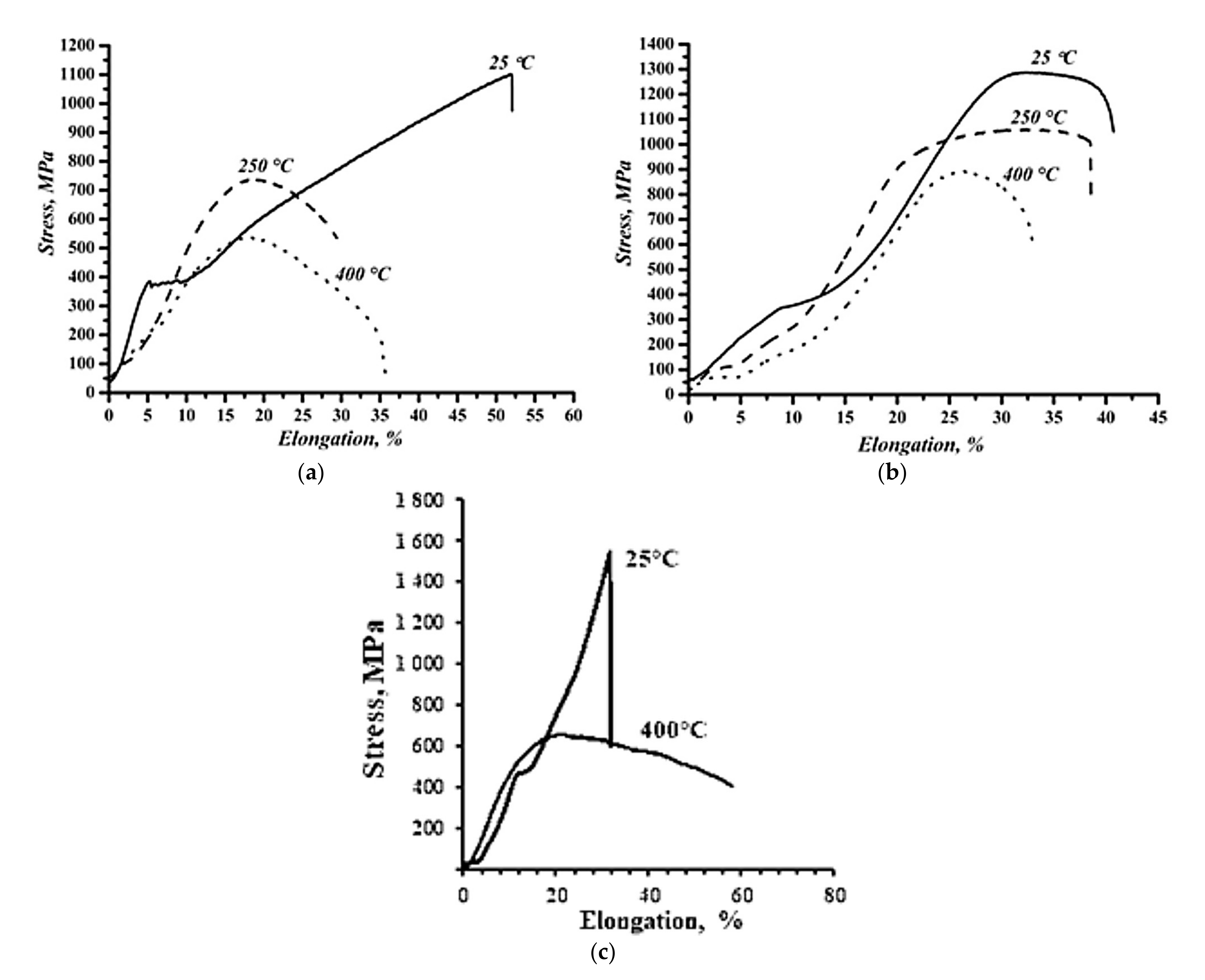

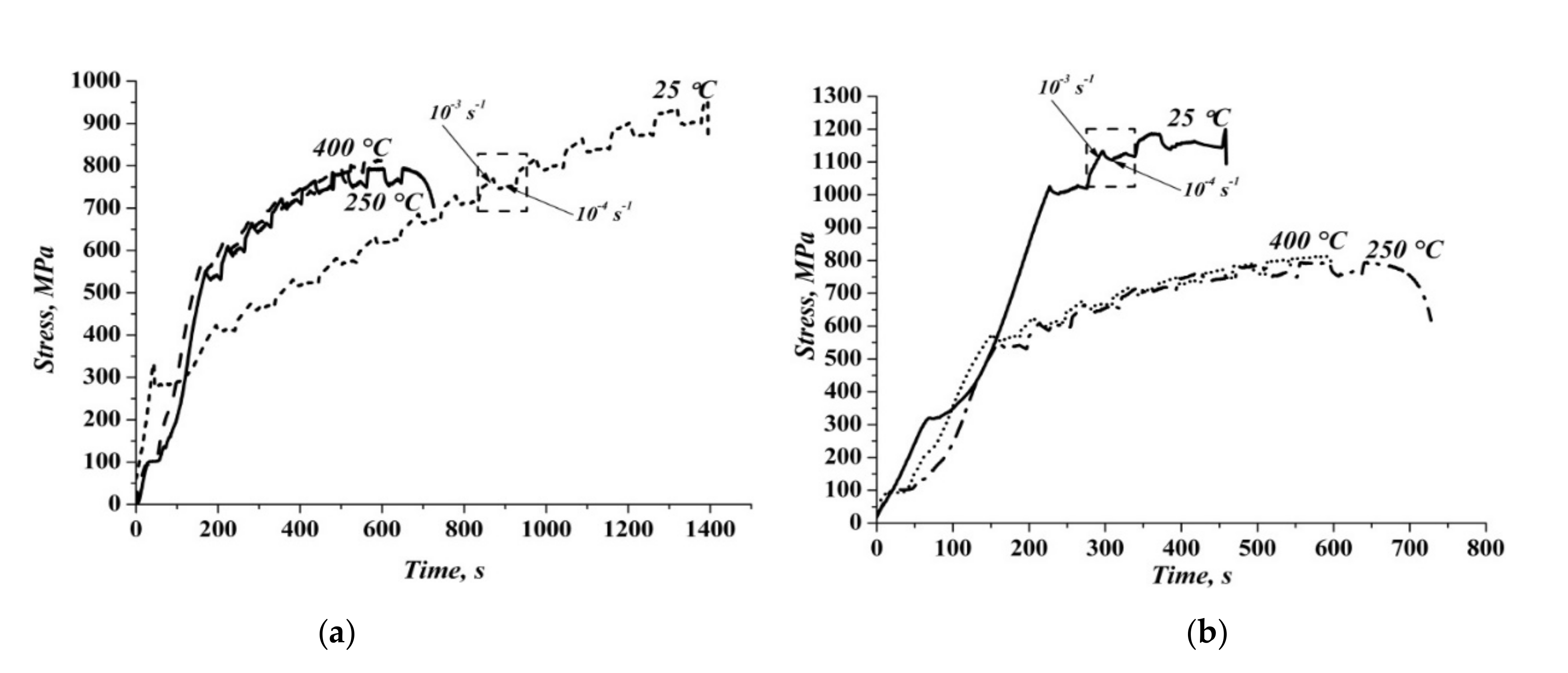

3.2. Mechanical Properties of the Ti49.1Ni50.9 Alloy

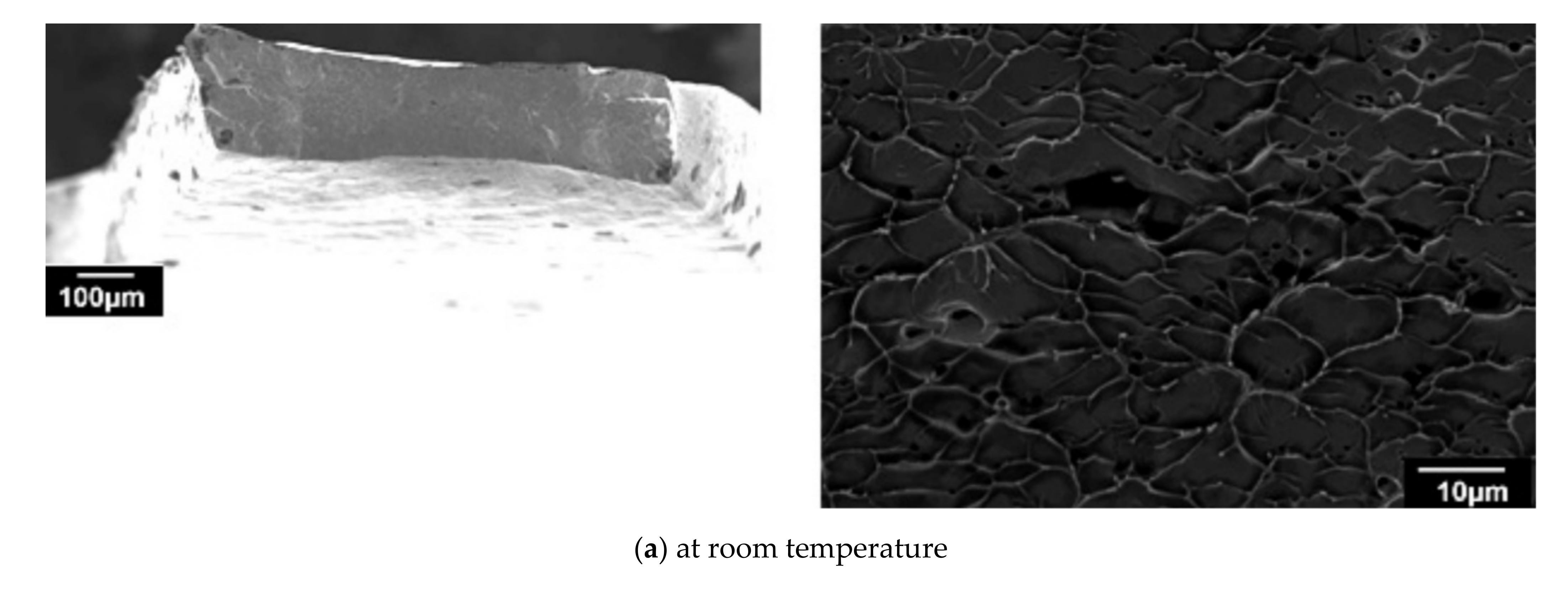

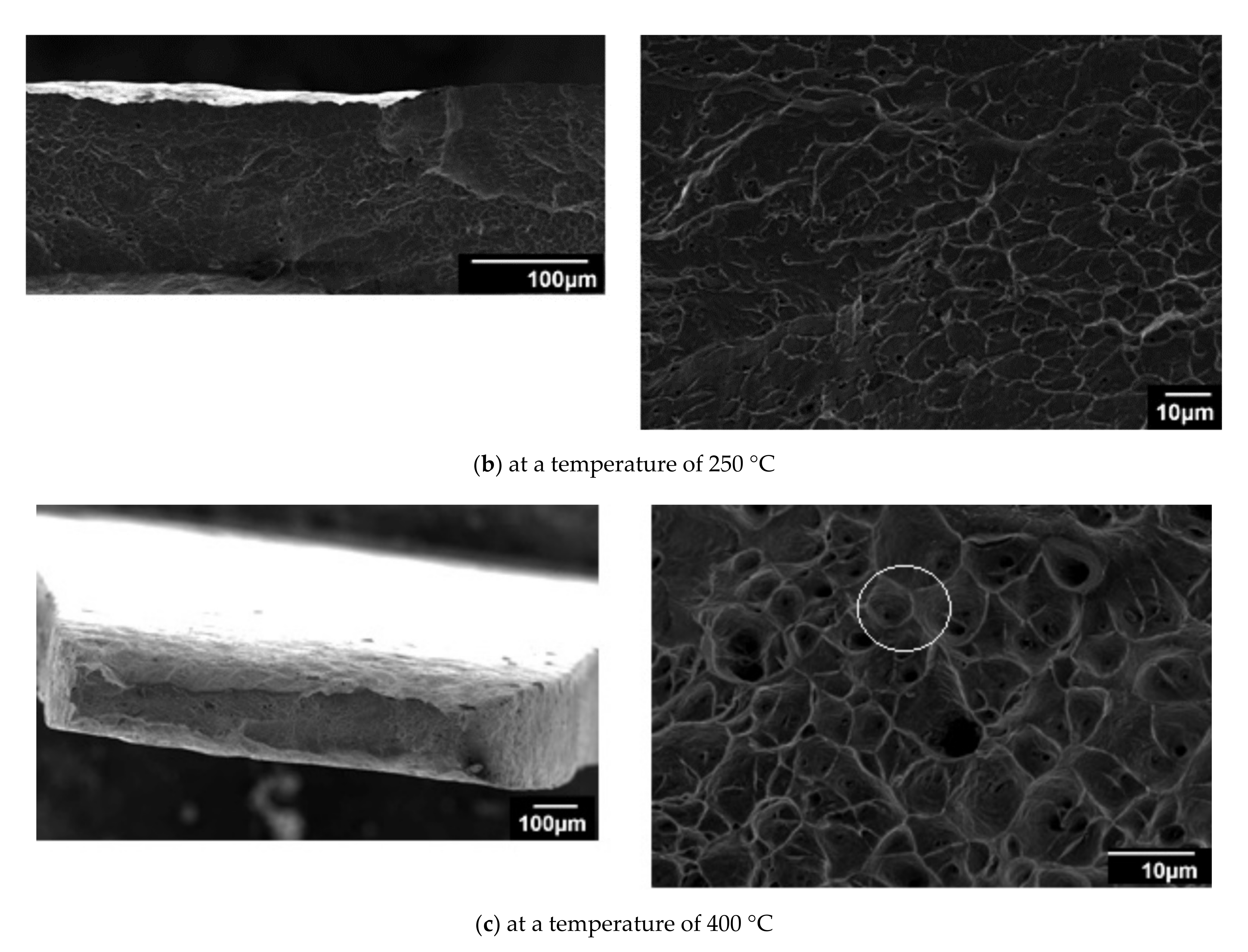

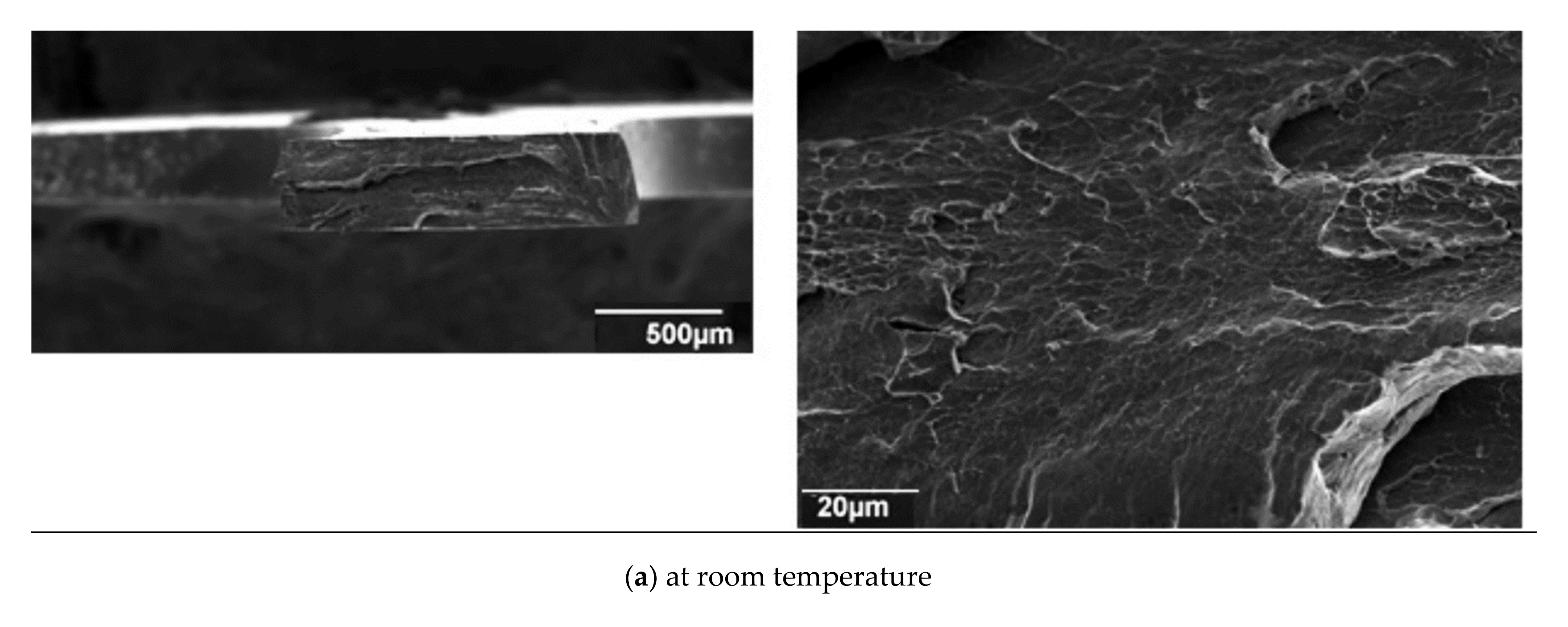

3.3. Fractographic Studies and Microstructure Analysis after Tensile Testing

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Khachin, V.N.; Pushin, V.G.; Kondratiev, V.V. Titanium Nickelide: Structure and Properties, Russia; Nauka: Moscow, Russia, 1992; p. 161. (In Russian) [Google Scholar]

- Brailovski, V.; Prokoshkin, S.; Terriault, P.; Trochu, F. Shape Memory Alloys: Fundamentals, Modeling and Applications, Montreal: Ecole de Technologie Superieure (ETS); Universite du Quebec: Québec, QC, Canada, 2003; p. 851. [Google Scholar]

- Valiev, R.Z. Nanostructuring of metals by severe plastic deformation for advanced properties. Nat. Mater. 2004, 3, 511–516. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Aleksandrov, I.V. Bulk Nanostructured Metallic Materials. Manufacture, Structure and Properties, Russia; Akademkniga: Moscow, Russia, 2007; p. 398. (In Russian) [Google Scholar]

- Pushin, V.G.; Valiev, R.Z.; Zhu, Y.T.; Gunderov, D.V.; Kuntsevich, T.E.; Kourov, N.I.; Uksusnicov, A.N.; Yurchenko, L.I. Effect of Severe Plastic Deformation on the Behavior of Ti–Ni Shape Memory Alloys. Mater. Trans. 2006, 47, 694–697. [Google Scholar] [CrossRef]

- Stolyarov, V.V. Effect of electopulsed treatment on the structure and mechanical properties of nanocrystalline TiNi shape memory alloy. Mater. Lett. 2011, 1, 75–77. [Google Scholar] [CrossRef][Green Version]

- Pushin, V.G.; Stolyarov, V.V.; Gunderov, D.V.; Valiev, R.Z.; Lowe, T.C.; Zhu, Y.T. Nanostructured TiNi-based shape memory alloys processed by severe plastic deformation. Mater. Sci. Eng. A 2005, 410–411, 386–389. [Google Scholar] [CrossRef]

- Gunderov, D.; Lukyanov, A.; Prokofiev, E.; Pushin, V. Mechanical properties of the nanocrystalline Ti49.4Ni50.6 alloy, produced by High Pressure Torsion. Eur. Phys. J. Spec. Top. 2008, 158, 53–58. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Gunderov, D.V.; Lukyanov, A.V.; Pushin, V.G. Mechanical behavior of nanocrystalline TiNi alloy produced by severe plastic deformation. J. Mater. Sci. 2012, 47, 7848–7853. [Google Scholar] [CrossRef]

- Dudarev, E.F.; Valiev, R.Z.; Kolobov, Y.u.R.; Lotkov, A.I.; Pushin, V.G.; Bakach, G.P.; Gunderov, D.V.; Dyupin, A.P.; Kuranova, N.N. On the nature of anomalously high plasticity of high-strength titanium nickelide alloys with shape-memory effects: II. Phys. Metals Metallogr. 2009, 107, 298–311. [Google Scholar] [CrossRef]

- Warlimont, H.; Delaey, L. Martensitic Transformations in Copper, Silver and Gold-Based Alloys; Pergamont Press: Oxford, UK; New York, NY, USA; Toronto, ON, Canada; Sydney, Australia, 1974. [Google Scholar]

- Shape Memory Effects in Alloys; Perkins, J., Ed.; Plenum Press: London, UK, 1975. [Google Scholar]

- Kornilov, I.I.; Belousov, O.K.; Kachur, E.V. Nickel Titanium and Other Alloys with the Shape Memory Effect; Nauka: Moscow, Russia, 1977; p. 179. [Google Scholar]

- Nishiyama, Z. Martensitic Transformations; Academic Press: New York, NY, USA, 1978. [Google Scholar]

- Nakanishi, N. Elastic Constants as they Relate to Lattice Properties and Martensite Formation. Progr. Mater. Sci. 1980, 24, 143–265. [Google Scholar] [CrossRef]

- Khalil Allafi, J. The mechanism of multistage martensitic transformations in aged Ni-rich NiTi shape memory alloys. Acta Mater. 2002, 50, 793–803. [Google Scholar] [CrossRef]

- Vintaykin, E.Z. Martensitic transformations. Results of science and technology. Ser. Metal science and heat treatment. M. VINITI 1983, 17, 3–63. [Google Scholar]

- Pushin, V.G.; Kondratiev, V.V.; Khachin, V.N. Pretransition phenomena and martensitic transformations in alloys based on titanium nickelide. Izvesiya Vuzov. Physics 1985, 5, 5–20. [Google Scholar]

- Pushin, V.G.; Kondratiev, V.V. Premartensitic states in metals, their alloys and compounds: Experimental results, structural models, classification. FMM 1985, 60, 629–650. [Google Scholar]

- Likhachev, V.A.; Kuzmin, S.L.; Kamentseva, Z.P. Shape Memory Effect; LSU: Saint Petersburg, Russia, 1987. [Google Scholar]

- Miyazaki, S.; Otsuka, K. Development of Shape Memory Alloys. ISIJ Intern. 1989, 29, 353–377. [Google Scholar] [CrossRef]

- Otsuka, K.; Shimizu, K.; Suzuki, Y. Shape Memory Alloys; Metallurgy Publ.: Moscow, Russia, 1990; p. 224. [Google Scholar]

- Caillard, D.; Martin, J.L. Thermally Activated Mechanisms in Crystal Plasticity, Pergamon Materials Series; Elsevier: Oxford, UK, 2003. [Google Scholar]

- Rodriguez, P. Grain size dependence of the activation parameters for plastic deformation: Influence of crystal structure, slip system, and rate-controlling dislocation mechanism. Metall. Mater. Trans. A 2004, 35, 2697–2705. [Google Scholar] [CrossRef]

- Mukherjee, A.K.; Mishra, R.S. Superplasticity. Encycl. Mater. Sci. Technol. 2001, 2, 8977–8981. [Google Scholar]

- Mukherjee, A.K. An examination of the constitutive equation for elevated temperature plasticity. Mater. Sci. Eng. A 2002, 322, 1–22. [Google Scholar] [CrossRef]

- Mayo, M.J. High and low temperature superplasticity in nanocrystalline materials. Nanostructuctured Mater. 1997, 9, 717–726. [Google Scholar] [CrossRef]

- Wei, Q. Strain rate effects in the ultrafine grain and nanocrystalline regimes influence on some constitutive responses. J. Mater. Sci. 2007, 42, 1709–1727. [Google Scholar] [CrossRef]

- Wei, Q.; Cheng, S.; Ramesh, K.T. Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: Fcc versus bcc metals. Mater. Sci. Eng. A 2004, 381, 71–79. [Google Scholar] [CrossRef]

- Wang, N.; Wang, Z.; Aust, K.T. Room temperature creep behavior of nanocrystalline nickel produced by an electrodeposition technique. Mater. Sci. Eng. A 1997, A237, 150–158. [Google Scholar] [CrossRef]

- Schwaiger, R.; Moser, B.; Dao, M.; Chollacoop, N.; Suresh, S. Some critical experiments on the strain-rate sensitivity of nanocrystalline nickel. Acta Mater. 2003, 51, 5159–5172. [Google Scholar] [CrossRef]

- Wang, F.; Li, B.; Gao, T.T.; Huang, P.; Xu, K.W.; Lu, T.J. Activation volume and strain rate sensitivity in plastic deformation of nanocrystalline Ti. Surface Coat. Technol. 2013, 228, S254–S256. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, X.; Yang, X. Strain rate sensitivity of ultrafine-grained CP-Ti processed by ECAP at room temperature. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2011; pp. 707–712. [Google Scholar]

- Dorn, J.E. Some fundamental experiments on high temperature creep. J. Mech. Phys. Solids 1955, 3, 85–116. [Google Scholar] [CrossRef]

- Kato, H.; Yamamoto, T.; Hashimoto, S.; Miura, S. High-temperature plasticity of the phase in nearly-equiatomic nickel-titanium alloys. Mater. Trans. 1999, 40, 343–350. [Google Scholar] [CrossRef]

- Eggeler, G.; Khalil-Allafi, J.; Neuking, K.; Dlouhy, A. Creep of binary Ni-rich NiTi shape memory alloys and the influence of pre-creep on martensitic transformations. Z. Met. 2002, 93, 654–660. [Google Scholar] [CrossRef]

- Kobus, E.; Neuking, K.; Eggeler, G.; Wittkamp, I. The creep behaviour of a NiTi-alloy and the effect of creep deformation on it’s shape memory properties. Prakt. Metallogr. 2002, 39, 177–186. [Google Scholar]

- Morakabati, M.; Aboutalebi, M.; Kheirandish, S.; Taheri, A.K.; Abbasi, S.M. High temperature deformation and processing map of a NiTi intermetallic alloy. Intermetallics 2011, 19, 1399–1404. [Google Scholar] [CrossRef]

- Lexcellent, C.; Robinet, P.; Bernardini, J.; Beke, D.L.; Olier, P. High temperature creep measurements in equiatomic Ni-Ti shape memory alloy. Mater. Werkst. 2005, 36, 509–512. [Google Scholar] [CrossRef]

- Oppenheimer, S.M.; Yung, A.R.; Dunand, D.C. Power-law creep in near-equiatomic nickel-titanium alloys. Scr. Mater. 2007, 57, 377–380. [Google Scholar] [CrossRef]

- Duerig, T.; Pelton, A.; Stockel, D. An overview of nitinol medical applications. Mater. Sci. Eng. A 1999, 273–275, 149–160. [Google Scholar] [CrossRef]

| State | Test Temperature | UTS, MPa | YS, MPa | σm, MPa | El.,% |

|---|---|---|---|---|---|

| CG | 25 | 1095 ± 45 | 480 | 370 | 40 ± 7 |

| 250 | 795 ± 30 | 600 | - | 25 ± 4 | |

| 400 | 580 ± 25 | 545 | - | 31 ± 3 | |

| UFG | 25 | 1260 ± 80 | 1120 | 350 | 35 ± 6 |

| 250 | 1100 ± 30 | 950 | - | 32 ± 4 | |

| 400 | 910 ± 30 | 790 | - | 30 ± 2 | |

| NC | 25 | 1600 ± 80 | 1550 | 420 | 15 ± 3 |

| 400 | 680 ± 25 | 600 | - | 45 ± 5 |

| State | Temperature, °C | m | V × 1023 | Mechanism of Deformation |

|---|---|---|---|---|

| CG | 25 | 0.016 | 69 | annihilation of dislocations along the grain boundaries |

| 250 | 0.019 | 121 | deformation is a slip of dislocations and the formation of a forest of dislocations | |

| 400 | 0.024 | 185 | ||

| UFG | 25 | 0.025 | 134 | deformation is a slip of dislocations and the formation of a forest of dislocations |

| 250 | 0.06 | 147 | ||

| 400 | 0.07 | 315 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Churakova, A.; Gunderov, D.; Kayumova, E. The Investigation of Microstructure and Mechanical Behavior and the Fractographic Analysis of the Ti49.1Ni50.9 Alloy in States with Different Activation Deformation Volumes. Appl. Sci. 2021, 11, 3052. https://doi.org/10.3390/app11073052

Churakova A, Gunderov D, Kayumova E. The Investigation of Microstructure and Mechanical Behavior and the Fractographic Analysis of the Ti49.1Ni50.9 Alloy in States with Different Activation Deformation Volumes. Applied Sciences. 2021; 11(7):3052. https://doi.org/10.3390/app11073052

Chicago/Turabian StyleChurakova, Anna, Dmitry Gunderov, and Elina Kayumova. 2021. "The Investigation of Microstructure and Mechanical Behavior and the Fractographic Analysis of the Ti49.1Ni50.9 Alloy in States with Different Activation Deformation Volumes" Applied Sciences 11, no. 7: 3052. https://doi.org/10.3390/app11073052

APA StyleChurakova, A., Gunderov, D., & Kayumova, E. (2021). The Investigation of Microstructure and Mechanical Behavior and the Fractographic Analysis of the Ti49.1Ni50.9 Alloy in States with Different Activation Deformation Volumes. Applied Sciences, 11(7), 3052. https://doi.org/10.3390/app11073052