LCA Practices of Plastics and Their Recycling: A Critical Review

Abstract

:1. Introduction

2. The Methodological Foundations and Advances in Life Cycle Assessment

2.1. The Four Phases According to ISO 14040/14044

2.1.1. Goal and Scope Definition

2.1.2. Inventory Analysis (LCI)

2.1.3. Impact Assessment (LCIA)

2.1.4. Interpretation

- identifying significant issues based on the preceding inventory and impact assessment phases;

- a thorough evaluation to check whether the work is complete and consistent, as well as sensitivity and or scenario analyses;

- a set of recommendations, conclusions and limitations.

2.2. Types of LCA

2.2.1. Attributional vs. Consequential LCA

2.2.2. Allocation Methods: Accounting for the Environmental Impacts

- (a)

- In the system expansion method, the co-functions that arise due to the new life cycle that consumes the recycled product are incorporated in the functional unit [29]. This method ensures proper accounting of the burdens and credits. In the consequential approach it leads to substitution as conventional products and their impacts are avoided.

- (b)

- In the partitioning method, inputs and outputs of the system are allocated to functions according to a set of criteria, thereby distributing the burden and impact among the primary and recycled/co-products.

- (c)

- The cut-off approach refers to a situation in which the modeler or analyst excludes the second function of the recycled product and only includes the products and processes that are directly related to the functional unit. This means that waste management and recycling functions are attributed to the second life cycle of the product [30,31].

- (d)

- The waste mining method imposes the burdens associated with recycling on the recycled material input of the system and no benefits are attributed to the production of recycled material.

- (e)

- The 50/50 method equally distributes credits and burdens between the different life cycles as a sort of compromise and could be seen as a quick and dirty method in that respect, although it is recommended by some [32].

- (f)

- The end-of-life recycling method assigns benefits to the production of recycled materials since it mitigates the production of primary material. A quality correction factor is used to account for the displacement of primary material as a result of the recycled material use.

2.2.3. Dynamic LCA

- dynamic process inventory: Potential future developments are accounted for in unit-processes;

- dynamic systems inventory: Potential future changes in components of the system under study are modelled by switching between unit processes or behaviors;

- dynamic characterization: adjusting factors to account for temporality in emissions of for example, CO2 equivalency (future versus present day).

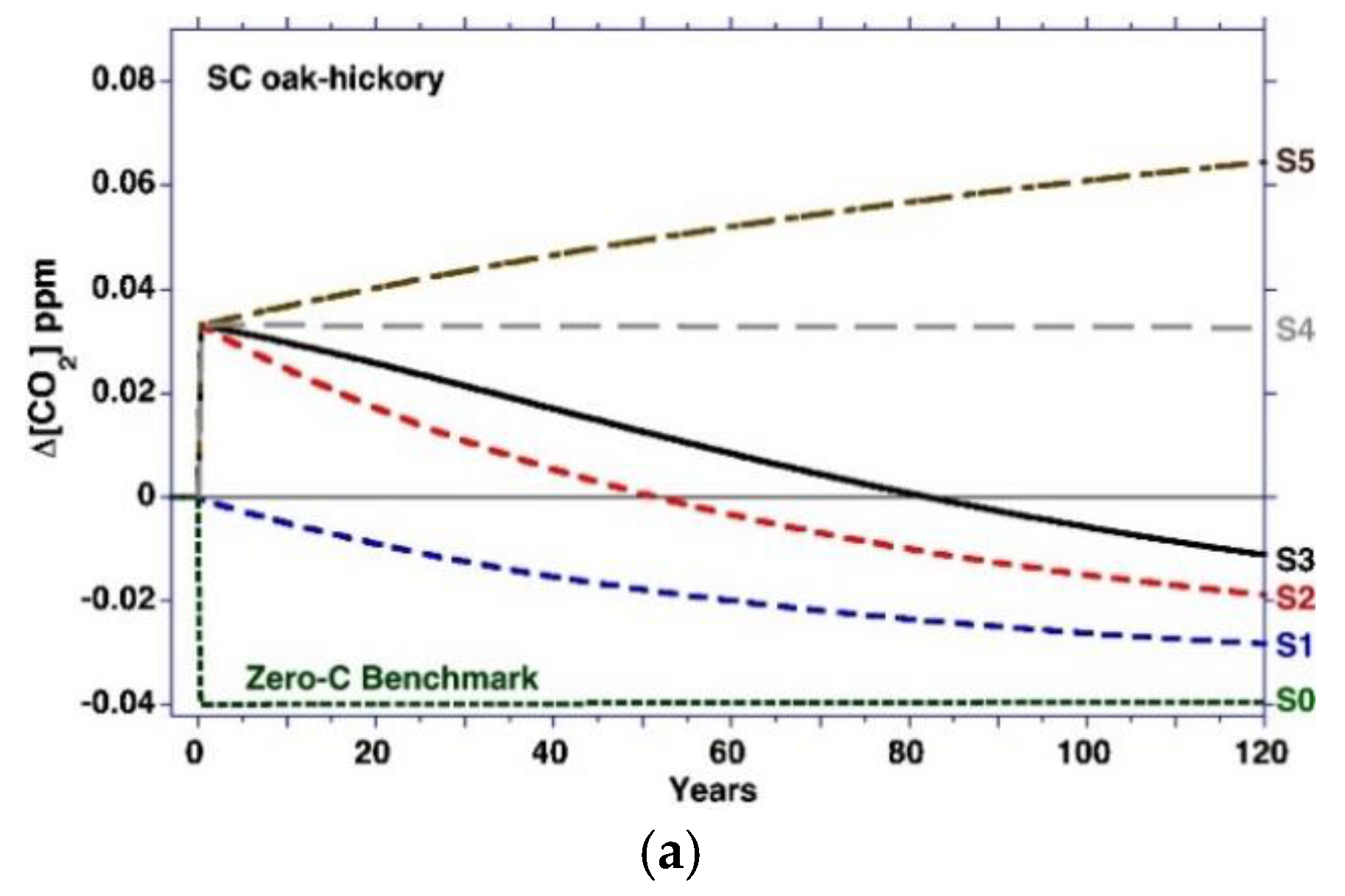

- (a)

- Scenario 1: Burning wood pellets has the same combustion, processing, and supply chain efficiency as coal. Interestingly, 25% of biomass harvested from the land occurred through thinning;

- (b)

- Scenario 2: Same as Scenario 1 but now with the actual efficiencies and supply chain emissions for wood;

- (c)

- Scenario 3: Scenario 2 but with 95% of biomass harvested (clear cut);

- (d)

- Scenario 4: Clear cut, no regrowth of harvested wood, and no carbon emissions from soil stocks;

- (e)

- Scenario 5: Scenario 4 but with carbon emissions from soil stocks.

2.2.4. Ex-ante LCA and Multi Method Approaches

3. An Overview of Recent Plastics and Recycling LCA Studies

4. Results

5. Discussion

Bridging the Gap?

- Mix methods by including dynamic modelling practices such as for example DES, SD, and/or ABM to allow for the inclusion of temporal and spatial dynamics;

- Use the aforementioned or other methods to model the dynamics between fore and background systems and the wider context in order to facilitate policy analysis;

- Use more rigorous sampling methods to investigate model behavior and consider using tools and techniques pertaining to deep uncertainty to assess policy options for their robustness, so that potential real world effects can be investigated and policymakers can be supported in long term planning.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dhanumalayan, E.; Joshi, G. Performance properties and applications of polytetrafluoroethylene (PTFE)—A review. Adv. Compos. Hybrid Mater. 2018, 1. [Google Scholar] [CrossRef]

- McKeen, L.W. 6-Polyester Plastics. In Permeability Properties of Plastics and Elastomers, 4th Ed.; McKeen, L.W., Ed.; Plastics Design Library; William Andrew Publishing: Norwich, NY, USA, 2017; pp. 95–114. [Google Scholar] [CrossRef]

- McKinsey Center. Ocean Conservancy. Stemming the Tide: Land-Based Strategies for a Plastic-Free Ocean; Ocean Conservancy: Washington, DC, USA; McKinsey Center for Business and Environment: Chicago, IL, USA, 2015; p. 47. [Google Scholar]

- Sala, S.; Reale, F.; Cristóbal-García, J.; Marelli, L.; Rana, P. Life Cycle Assessment for the Impact Assessment of Policies. Life Thinking and Assessment in the European Policies and for Evaluating Policy Options; European Commission: Ispra, Italy, 2016; Volume 28380. [Google Scholar] [CrossRef]

- Kloepffer, W. Life cycle sustainability assessment of products. Int. J. Life Cycle Assess. 2008, 13, 89. [Google Scholar] [CrossRef]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life Cycle Assessment: Past, Present, and Future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef] [PubMed]

- Sohn, J.; Kalbar, P.; Goldstein, B.; Birkved, M. Defining Temporally Dynamic Life Cycle Assessment: A Review. Integr. Environ. Assess. Manag. 2020, 16, 314–323. [Google Scholar] [CrossRef] [PubMed]

- Hunt, R.G.; Franklin, W.E. LCA—How it Came About. Int. J. LCA 1996, 1, 4–7. [Google Scholar] [CrossRef]

- Klöpffer, W. The role of SETAC in the development of LCA. Int. J. Life Cycle Assess. 2006, 11, 116–122. [Google Scholar] [CrossRef]

- ISO14040. Environmental management—Life Cycle Assessment—Part 1: Principles and Framework; ISO: Geneva, Switzerland, 1997. [Google Scholar]

- ISO. ISO/IEC 14044:2006 Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Klopffer, W.; Grahl, B. Life Cycle Assessment (LCA): A Guide to Best Practice; Wiley-VCH: Weinheim, Germany, 2014. [Google Scholar]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life cycle assessment Part 1: Framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef]

- Guinée, J.B. Selection of Impact Categories and Classification of LCI Results to Impact Categories. In Life Cycle Impact Assessment; Springer Science & Business Media: Dordrecht, The Netherlands, 2015; pp. 17–37. [Google Scholar]

- Heijungs, R.; Suh, S. The Computational Structure of Life Cycle Assessment; Kluwer: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Brander, M. Conceptualising attributional LCA is necessary for resolving methodological issues such as the appropriate form of land use baseline. Int. J. Life Cycle Assess. 2016, 21, 1816–1821. [Google Scholar] [CrossRef] [Green Version]

- Sonnemann, G.; Vigon, B. Global Guidance Principles for Life Cycle Assessment Databases: A Basis for Greener Processes and Products; UNEP: Paris, France, 2011. [Google Scholar]

- Soimakallio, S.; Cowie, A.; Brandão, M.; Finnveden, G.; Ekvall, T.; Erlandsson, M.; Koponen, K.; Karlsson, P.E. Attributional life cycle assessment: Is a land-use baseline necessary? Int. J. Life Cycle Assess. 2015, 20, 1364–1375. [Google Scholar] [CrossRef]

- Curran, M.A.; Mann, M.; Norris, G. The international workshop on electricity data for life cycle inventories. J. Clean. Prod. 2005, 13, 853–862. [Google Scholar] [CrossRef]

- Ekvall, T.; Weidema, B.P. System boundaries and input data in consequential life cycle inventory analysis. Int. J. Life Cycle Assess. 2004, 9, 161–171. [Google Scholar] [CrossRef]

- Martin, E.W.; Chester, M.V.; Vergara, S.E. Attributional and Consequential Life-cycle Assessment in Biofuels: A Review of Recent Literature in the Context of System Boundaries. Curr. Sustain. Energy Rep. 2015, 2, 82–89. [Google Scholar] [CrossRef] [Green Version]

- McManus, M.C.; Taylor, C.M. The changing nature of life cycle assessment. Biomass Bioenergy 2015, 82, 13–26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ekvall, T.; Tillman, A.M.; Molander, S. Normative ethics and methodology for life cycle assessment. J. Clean. Prod. 2005, 13, 1225–1234. [Google Scholar] [CrossRef] [Green Version]

- Thonemann, N.; Schulte, A.; Maga, D. How to conduct prospective life cycle assessment for emerging technologies? A systematic review and methodological guidance. Sustainability 2020, 12, 1192. [Google Scholar] [CrossRef] [Green Version]

- ISO 14041 Environmental management—Life Cycle Assessment—Goal and Scope Definition and Inventory Analysis; ISO: Geneva, Switzerland, 1998.

- Jones, C.; Gilbert, P.; Raugei, M.; Mander, S.; Leccisi, E. An approach to prospective consequential life cycle assessment and net energy analysis of distributed electricity generation. Energy Policy 2017, 100, 350–358. [Google Scholar] [CrossRef]

- Reap, J.; Roman, F.; Duncan, S.; Bras, B. A survey of unresolved problems in life cycle assessment. Part 1: Goal and scope and inventory analysis. Int. J. Life Cycle Assess. 2008, 13, 290–300. [Google Scholar] [CrossRef]

- Schrijvers, D.L.; Loubet, P.; Sonnemann, G. Developing a systematic framework for consistent allocation in LCA. Int. J. Life Cycle Assess. 2016, 21, 976–993. [Google Scholar] [CrossRef]

- Heijungs, R. Ten easy lessons for good communication of LCA. Int. J. Life Cycle Assess. 2014, 19, 473–476. [Google Scholar] [CrossRef] [Green Version]

- Ekvall, T.; Tillman, A.M. Open-loop recycling: Criteria for allocation procedures. Int. J. Life Cycle Assess. 1997, 2, 155–162. [Google Scholar] [CrossRef] [Green Version]

- Frischknecht, R. LCI modelling approaches applied on recycling of materials in view of environmental sustainability, risk perception and eco-efficiency. Int. J. Life Cycle Assess. 2010, 15, 666–671. [Google Scholar] [CrossRef] [Green Version]

- European Union. Commission Recommendation of 9 April 2013 on the Use of Common Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organisations; European Union: Brussels, Belgium, 2013; Volume 56. [Google Scholar]

- Wardenaar, T.; Van Ruijven, T.; Beltran, A.M.; Vad, K.; Guinée, J.; Heijungs, R. Differences between LCA for analysis and LCA for policy: A case study on the consequences of allocation choices in bio-energy policies. Int. J. Life Cycle Assess. 2012, 17, 1059–1067. [Google Scholar] [CrossRef] [Green Version]

- Cherubini, E.; Franco, D.; Zanghelini, G.M.; Soares, S.R. Uncertainty in LCA case study due to allocation approaches and life cycle impact assessment methods. Int. J. Life Cycle Assess. 2018, 23, 2055–2070. [Google Scholar] [CrossRef]

- Blass, V.; Corbett, C.J. Same Supply Chain, Different Models: Integrating Perspectives from Life Cycle Assessment and Supply Chain Management. J. Ind. Ecol. 2018, 22, 18–30. [Google Scholar] [CrossRef] [Green Version]

- Shimako, A. Contribution to the Development of a Dynamic Life Cycle Assessment Method. Ph.D. Thesis, INSA de Toulouse, Toulouse, France, November 2017. [Google Scholar]

- Shimako, A.H.; Tiruta-Barna, L.; Bisinella de Faria, A.B.; Ahmadi, A.; Spérandio, M. Sensitivity analysis of temporal parameters in a dynamic LCA framework. Sci. Total Environ. 2018, 624, 1250–1262. [Google Scholar] [CrossRef] [PubMed]

- Pigné, Y.; Gutiérrez, T.N.; Gibon, T.; Schaubroeck, T.; Popovici, E.; Shimako, A.H.; Benetto, E.; Tiruta-Barna, L. A tool to operationalize dynamic LCA, including time differentiation on the complete background database. Int. J. Life Cycle Assess. 2020, 25, 267–279. [Google Scholar] [CrossRef] [Green Version]

- Su, S.; Li, X.; Zhu, Y.; Lin, B. Dynamic LCA framework for environmental impact assessment of buildings. Energy Build. 2017, 149, 310–320. [Google Scholar] [CrossRef]

- Pehnt, M. Dynamic life cycle assessment (LCA) of renewable energy technologies. Renew. Energy 2006, 31, 55–71. [Google Scholar] [CrossRef]

- Aktar, W.; Sengupta, D.; Chowdhury, A. Impact of pesticides use in agriculture: Their benefits and hazards. Interdiscip. Toxicol. 2009, 2, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Lan, K.; Yao, Y. Integrating Life Cycle Assessment and Agent-Based Modeling: A Dynamic Modeling Framework for Sustainable Agricultural Systems. J. Clean. Prod. 2019, 238, 117853. [Google Scholar] [CrossRef]

- Tillman, A.M. Significance of decision-making for LCA methodology. Environ. Impact Assess. Rev. 2000, 20, 113–123. [Google Scholar] [CrossRef] [Green Version]

- Sterman, J.D.; Siegel, L.; Rooney-Varga, J.N. Does replacing coal with wood lower CO2 emissions? Dynamic lifecycle analysis of wood bioenergy. Environ. Res. Lett. 2018, 13, 015007. [Google Scholar] [CrossRef]

- Madsen, K.; Bentsen, N.S. Carbon debt payback time for a biomass fired CHP plant—A case study from northern Europe. Energies 2018, 11, 807. [Google Scholar] [CrossRef] [Green Version]

- Levasseur, A.; Lesage, P.; Margni, M.; Deschěnes, L.; Samson, R. Considering time in LCA: Dynamic LCA and its application to global warming impact assessments. Environ. Sci. Technol. 2010, 44, 3169–3174. [Google Scholar] [CrossRef]

- Pinsonnault, A.; Lesage, P.; Levasseur, A.; Samson, R. Temporal differentiation of background systems in LCA: Relevance of adding temporal information in LCI databases. Int. J. Life Cycle Assess. 2014, 19, 1843–1853. [Google Scholar] [CrossRef]

- Cucurachi, S.; Van Der Giesen, C.; Guinée, J. Ex-ante LCA of Emerging Technologies. Procedia CIRP 2018, 69, 463–468. [Google Scholar] [CrossRef]

- Fernandez-Dacosta, C.; Wassenaar, P.N.H.; Dencic, I.; Zijp, M.C.; Morao, A.; Heugens, E.H.W.; Shen, L. Can we assess innovative bio-based chemicals in their early development stage? A comparison between early-stage and life cycle assessments. J. Clean. Prod. 2019, 230, 137–149. [Google Scholar] [CrossRef]

- Buyle, M.; Audenaert, A.; Billen, P.; Boonen, K.; Van Passel, S. The future of ex-ante LCA? Lessons learned and practical recommendations. Sustainability 2019, 11, 5456. [Google Scholar] [CrossRef] [Green Version]

- Moni, S.M.; Mahmud, R.; High, K.; Carbajales-Dale, M. Life cycle assessment of emerging technologies: A review. J. Ind. Ecol. 2020, 24, 52–63. [Google Scholar] [CrossRef]

- Budzinski, M.; Sisca, M.; Thrän, D. Consequential LCA and LCC using linear programming: An illustrative example of biorefineries. Int. J. Life Cycle Assess. 2019, 24, 2191–2205. [Google Scholar] [CrossRef] [Green Version]

- Guinée, J. Life cycle sustainability assessment: What is it and what are its challenges? In Taking Stock of Industrial Ecology; Springer: Cham, Switzerland, 2015; pp. 45–68. [Google Scholar] [CrossRef] [Green Version]

- Kucukvar, M. Life Cycle Sustainability Assessment Framework for the U.S. Built Environment. Ph.D. Thesis, University of Central Florida, Orlando, FL, USA, December 2014. [Google Scholar]

- Onat, N.C.; Kucukvar, M.; Halog, A.; Cloutier, S. Systems thinking for life cycle sustainability assessment: A review of recent developments, applications, and future perspectives. Sustainability 2017, 9, 706. [Google Scholar] [CrossRef] [Green Version]

- Nunes, A.O.; Viana, L.R.; Guineheuc, P.M.; da Silva Moris, V.A.; de Paiva, J.M.F.; Barna, R.; Soudais, Y. Life cycle assessment of a steam thermolysis process to recover carbon fibers from carbon fiber-reinforced polymer waste. Int. J. Life Cycle Assess. 2018, 23, 1825–1838. [Google Scholar] [CrossRef] [Green Version]

- Bertolini, M.; Bottani, E.; Vignali, G.; Volpi, A. Comparative Life Cycle Assessment of Packaging Systems for Extended Shelf Life Milk. Packag. Technol. Sci. 2016, 29, 525–546. [Google Scholar] [CrossRef]

- Aryan, V.; Font-Brucart, M.; Maga, D. A comparative life cycle assessment of end-of-life treatment pathways for photovoltaic backsheets. Prog. Photovolt. Res. Appl. 2018, 26, 443–459. [Google Scholar] [CrossRef]

- Haylock, R.; Rosentrater, K.A. Cradle-to-Grave Life Cycle Assessment and Techno-Economic Analysis of Polylactic Acid Composites with Traditional and Bio-Based Fillers. J. Polym. Environ. 2018, 26, 1484–1503. [Google Scholar] [CrossRef]

- Oliveira, M.C.; Magrini, A. Life cycle assessment of lubricant oil plastic containers in Brazil. Sustainability 2017, 9, 576. [Google Scholar] [CrossRef] [Green Version]

- Mendes Campolina, J.; São Leandro Sigrist, C.; Faulstich de Paiva, J.M.; Oliveira Nunes, A.; da Silva Moris, V.A. A study on the environmental aspects of WEEE plastic recycling in a Brazilian company. Int. J. Life Cycle Assess. 2017, 22, 1957–1968. [Google Scholar] [CrossRef]

- De Meester, S.; Nachtergaele, P.; Debaveye, S.; Vos, P.; Dewulf, J. Using material flow analysis and life cycle assessment in decision support: A case study on WEEE valorization in Belgium. Resour. Conserv. Recycl. 2019, 142, 1–9. [Google Scholar] [CrossRef]

- Sommerhuber, P.F.; Wenker, J.L.; Rüter, S.; Krause, A. Life cycle assessment of wood-plastic composites: Analysing alternative materials and identifying an environmental sound end-of-life option. Resour. Conserv. Recycl. 2017, 117, 235–248. [Google Scholar] [CrossRef]

- Sun, X.; Liu, J.; Lu, B.; Zhang, P.; Zhao, M. Life cycle assessment-based selection of a sustainable lightweight automotive engine hood design. Int. J. Life Cycle Assess. 2017, 22, 1373–1383. [Google Scholar] [CrossRef]

- Ferreira, S.; Cabral, M.; De Jaeger, S.; Da Cruz, N.F.; Simões, P.; Marques, R.C. Life cycle assessment and valuation of the packaging waste recycling system in Belgium. J. Mater. Cycles Waste Manag. 2017, 19, 144–154. [Google Scholar] [CrossRef]

- Gu, F.; Guo, J.; Zhang, W.; Summers, P.A.; Hall, P. From waste plastics to industrial raw materials: A life cycle assessment of mechanical plastic recycling practice based on a real-world case study. Sci. Total Environ. 2017, 601–602, 1192–1207. [Google Scholar] [CrossRef]

- Toniolo, S.; Mazzi, A.; Pieretto, C.; Scipioni, A. Allocation strategies in comparative life cycle assessment for recycling: Considerations from case studies. Resour. Conserv. Recycl. 2017, 117, 249–261. [Google Scholar] [CrossRef]

- Faraca, G.; Martinez-Sanchez, V.; Astrup, T.F. Environmental life cycle cost assessment: Recycling of hard plastic waste collected at Danish recycling centres. Resour. Conserv. Recycl. 2019, 143, 299–309. [Google Scholar] [CrossRef]

- Vidal, R.; Moliner, E.; Martin, P.P.; Fita, S.; Wonneberger, M.; Verdejo, E.; Vanfleteren, F.; Lapeña, N.; González, A. Life Cycle Assessment of Novel Aircraft Interior Panels Made from Renewable or Recyclable Polymers with Natural Fiber Reinforcements and Non-Halogenated Flame Retardants. J. Ind. Ecol. 2018, 22, 132–144. [Google Scholar] [CrossRef] [Green Version]

- Bataineh, K.M. Life-Cycle Assessment of Recycling Postconsumer High-Density Polyethylene and Polyethylene Terephthalate. Adv. Civ. Eng. 2020, 2020. [Google Scholar] [CrossRef] [Green Version]

- Cosate de Andrade, M.F.; Souza, P.M.S.; Cavalett, O.; Morales, A.R. Life Cycle Assessment of Poly(Lactic Acid) (PLA): Comparison Between Chemical Recycling, Mechanical Recycling and Composting. J. Polym. Environ. 2016, 24, 372–384. [Google Scholar] [CrossRef]

- Simon, B.; Amor, M.B.; Földényi, R. Life cycle impact assessment of beverage packaging systems: Focus on the collection of post-consumer bottles. J. Clean. Prod. 2016, 112, 238–248. [Google Scholar] [CrossRef]

- Beigbeder, J.; Soccalingame, L.; Perrin, D.; Bénézet, J.C.; Bergeret, A. How to manage biocomposites wastes end of life? A life cycle assessment approach (LCA) focused on polypropylene (PP)/wood flour and polylactic acid (PLA)/flax fibres biocomposites. Waste Manag. 2019, 83, 184–193. [Google Scholar] [CrossRef] [Green Version]

- Gear, M.; Sadhukhan, J.; Thorpe, R.; Clift, R.; Seville, J.; Keast, M. A life cycle assessment data analysis toolkit for the design of novel processes—A case study for a thermal cracking process for mixed plastic waste. J. Clean. Prod. 2018, 180, 735–747. [Google Scholar] [CrossRef]

- Isola, C.; Sieverding, H.L.; Raghunathan, R.; Sibi, M.P.; Webster, D.C.; Sivaguru, J.; Stone, J.J. Life cycle assessment of photodegradable polymeric material derived from renewable bioresources. J. Clean. Prod. 2017, 142, 2935–2944. [Google Scholar] [CrossRef] [Green Version]

- Hou, P.; Xu, Y.; Taiebat, M.; Lastoskie, C.; Miller, S.A.; Xu, M. Life cycle assessment of end-of-life treatments for plastic film waste. J. Clean. Prod. 2018, 201, 1052–1060. [Google Scholar] [CrossRef]

- Demetrious, A.; Crossin, E. Life cycle assessment of paper and plastic packaging waste in landfill, incineration, and gasification-pyrolysis. J. Mater. Cycles Waste Manag. 2019, 21, 850–860. [Google Scholar] [CrossRef]

- Santos, A.; Barbosa-Póvoa, A.; Carvalho, A. Life cycle assessment in chemical industry—A review. Curr. Opin. Chem. Eng. 2019, 26, 139–147. [Google Scholar] [CrossRef]

- Plevin, R.J.; Delucchi, M.A.; Creutzig, F. Using Attributional Life Cycle Assessment to Estimate Climate-Change Mitigation Benefits Misleads Policy Makers. J. Ind. Ecol. 2014, 18, 73–83. [Google Scholar] [CrossRef]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef] [PubMed]

- Ghorbani, A.; Dechesne, F.; Dignum, V.; Jonker, C. Enhancing ABM into an Inevitable Tool for Policy Analysis. J. Policy Complex Syst. 2014, 1, 61–76. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Tatari, O.; Egilmez, G. Integration of system dynamics approach toward deepening and broadening the life cycle sustainability assessment framework: A case for electric vehicles. Int. J. Life Cycle Assess. 2016, 21, 1009–1034. [Google Scholar] [CrossRef]

- Pinto, J.T.M.; Sverdrup, H.U.; Diemer, A. Integrating life cycle analysis into system dynamics: The case of steel in Europe. Environ. Syst. Res. 2019, 8. [Google Scholar] [CrossRef]

- Wu, S.R.; Li, X.; Apul, D.; Breeze, V.; Tang, Y.; Fan, Y.; Chen, J. Agent-Based Modeling of Temporal and Spatial Dynamics in Life Cycle Sustainability Assessment. J. Ind. Ecol. 2017, 21, 1507–1521. [Google Scholar] [CrossRef] [Green Version]

- Kwakkel, J.H. The Exploratory Modeling Workbench: An open source toolkit for exploratory modeling, scenario discovery, and (multi-objective) robust decision-making. Environ. Model. Softw. 2017, 96, 239–250. [Google Scholar] [CrossRef]

- Zamagni, A. Life cycle sustainability assessment. Int. J. Life Cycle Assess. 2012, 17, 373–376. [Google Scholar] [CrossRef] [Green Version]

| Accounting Method | Attributional LCA | Consequential LCA |

|---|---|---|

| System Expansion | X | X * |

| Partitioning | X | |

| Cut-off Approach | X | |

| Waste Mining | X | |

| 50/50 | X | |

| End-of-Life Recycling | X |

| Authors | LCA Type | Functional Unit | System Boundaries | Dynamism | Accounting Method | Feedback Effects | Multi-Method | Model Uncertainty |

|---|---|---|---|---|---|---|---|---|

| [56] | aLCA | Mass | Gate-to-grave/Gate-to-cradle | No | A form of partitioning * | No | No | No |

| [57] | aLCA | Volume + Time | Cradle-to-cradle | No | N/A * | No | No | Sensitivity Analysis |

| [58] | aLCA | Area | Gate-to-grave | No | Cut-off | No | No | No |

| [59] | aLCA | Mass | Cradle-to-grave | No | N/A * | No | Yes | No |

| [60] | aLCA | Mass | Gate-to-cradle | No | Cut-off | No | No | Sensitivity Analysis |

| [61] | aLCA | Mass | Gate-to-Gate | No | Partitioning | No | No | No |

| [62] | cLCA | Mass | Cradle-to-Gate | No | End-of-Life Recycling | No | Yes | Sensitivity Analysis |

| [63] | Ex-ante LCA | Mass | Cradle-to-Gate | No | System Expansion | No | No | No |

| [64] | cLCA | Mass + Distance | Gate-to-Grave/Cradle | No | End-of-Life Recycling | No | No | Sensitivity Analysis |

| [65] | cLCA | Mass | Gate-to-Grave/Cradle | No | System Expansion | No | No | No |

| [66] | aLCA | Mass | Gate-to-Cradle | No | Partitioning | No | No | Sensitivity Analysis |

| [67] | aLCA* | Volume/Mass | Gate-to-Grave/Cradle | No | Cut-off and System Expansion (they call it substitution) | No | No | No |

| [68] | cLCA | Mass | Gate-to-Cradle | No | System Expansion | No | Yes | Sensitivity Analysis |

| [69] | aLCA | Area | Cradle-to-Grave/Cradle | No | N/A * | No | Yes | No |

| [70] | aLCA | Mass | Gate-to-Cradle | No | Cut-off and System Expansion | No | No | No |

| [71] | cLCA | Mass | Gate-to-Cradle | No | End-of-Life Recycling * | No | No* | Sensitivity Analysis |

| [72] | cLCA | Mass/Volume | Cradle-to-Grave/Cradle | No | End-of-Life Recycling * | No | No | Sensitivity Analysis |

| [73] | cLCA | Mass | Gate-to-Cradle/Grave | No | System Expansion | No | No | Sensitivity Analysis |

| [74] | cLCA | Mass | Gate-to-Gate | No | System Expansion | No | Yes | No |

| [75] | cLCA | Mass | Cradle-to-Gate* | No | N/A * | No | No | Monte Carlo + Sensitivity Analysis |

| [76] | cLCA | Mass | Gate-to-Cradle | No | End-of-Life Recycling | No | No | Sensitivity Analysis |

| [77] | aLCA | Mass | Gate-to-Cradle/Grave | No | Partitioning * | No | No | Monte Carlo |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kousemaker, T.M.; Jonker, G.H.; Vakis, A.I. LCA Practices of Plastics and Their Recycling: A Critical Review. Appl. Sci. 2021, 11, 3305. https://doi.org/10.3390/app11083305

Kousemaker TM, Jonker GH, Vakis AI. LCA Practices of Plastics and Their Recycling: A Critical Review. Applied Sciences. 2021; 11(8):3305. https://doi.org/10.3390/app11083305

Chicago/Turabian StyleKousemaker, Timothy M., Gerald H. Jonker, and Antonis I. Vakis. 2021. "LCA Practices of Plastics and Their Recycling: A Critical Review" Applied Sciences 11, no. 8: 3305. https://doi.org/10.3390/app11083305

APA StyleKousemaker, T. M., Jonker, G. H., & Vakis, A. I. (2021). LCA Practices of Plastics and Their Recycling: A Critical Review. Applied Sciences, 11(8), 3305. https://doi.org/10.3390/app11083305