A Semi-Automated 3D-Printed Chainmail Design Algorithm with Preprogrammed Directional Functions for Hand Exoskeleton

Abstract

:Featured Application

Abstract

1. Introduction

- The size and shape of the elements and the resulting properties;

- The material used (PLA, ABS, and others) and the resulting properties;

- Bending: in all directions, in only one direction, or in selected directions, with a programmed maximum bending angle;

- Tensile properties in both directions (e.g., kinesiotex tapes with properties similar to human skin);

- Degree of softness;

- Other properties (durability, etc.) as needed;

- Opportunities for computerisation of design and optimisation of ownership thanks to artificial intelligence (AI) [18].

2. Materials and Methods

2.1. Materials

2.2. Methods

- 3D printer (2.3.1);

- Additive manufacturing (2.1.2);

- Material extrusion (2.2.3);

- Feedstock (2.5.2);

- Laser sintering (LS).

- Prusa i3 MK3S3 filament printer;

- Prusa SL1S3D SLA printer.

- An algorithm for calculating/setting the repetitive pattern, implemented and tested in Java (Java IDE IntelliJ Idea 2019.3);

- A machine-learning-based tool using traditional artificial neural networks using Matlab R2021b with Neural Networks Toolbox (MathWorks, Natick, MA, USA).

2.3. Statistical Analysis

2.4. Computational Methods

- Homogeneous values;

- Normalisation of input data.

- The programmer’s knowledge;

- ‘Hit and miss’ trials;

- Genetic algorithm.

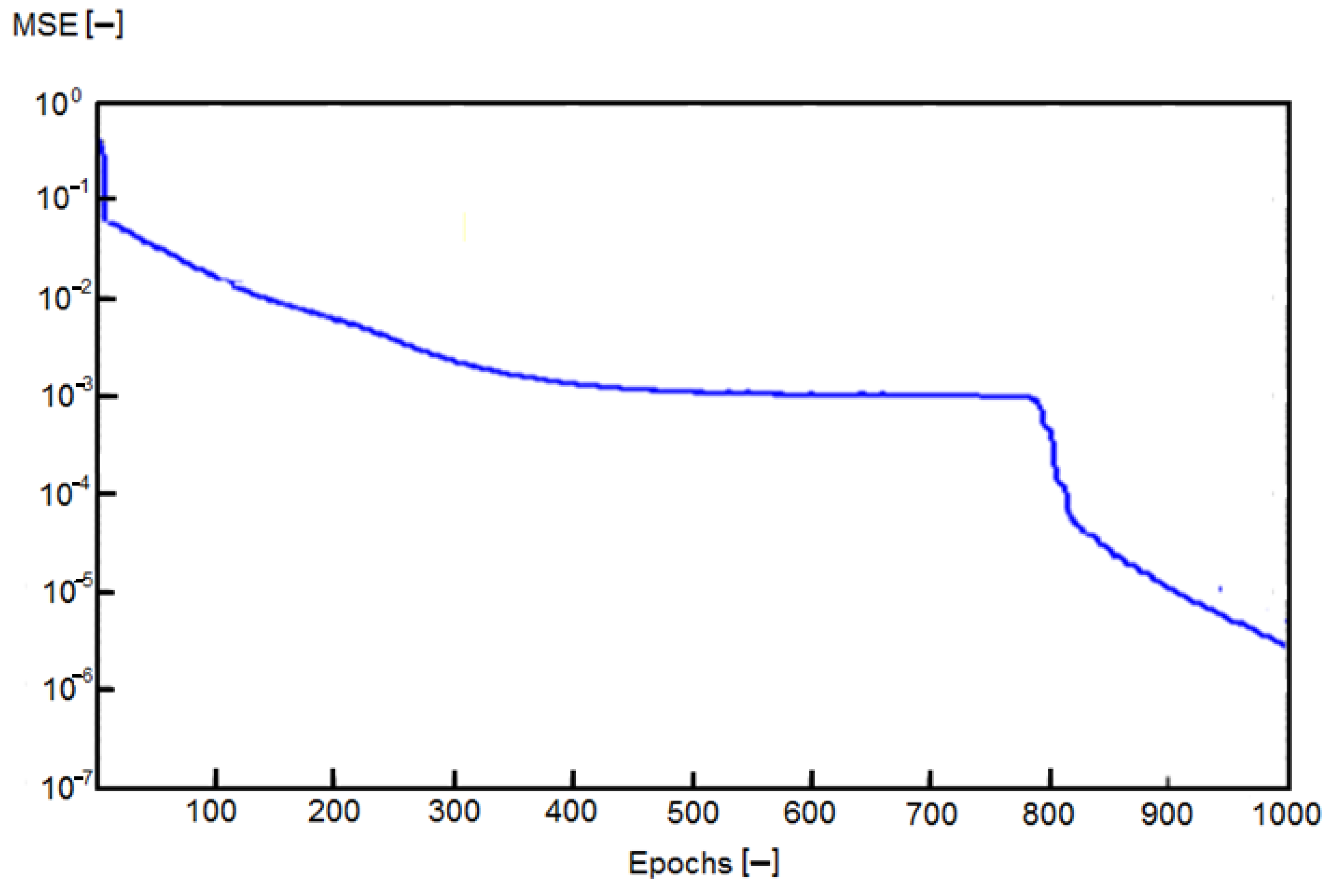

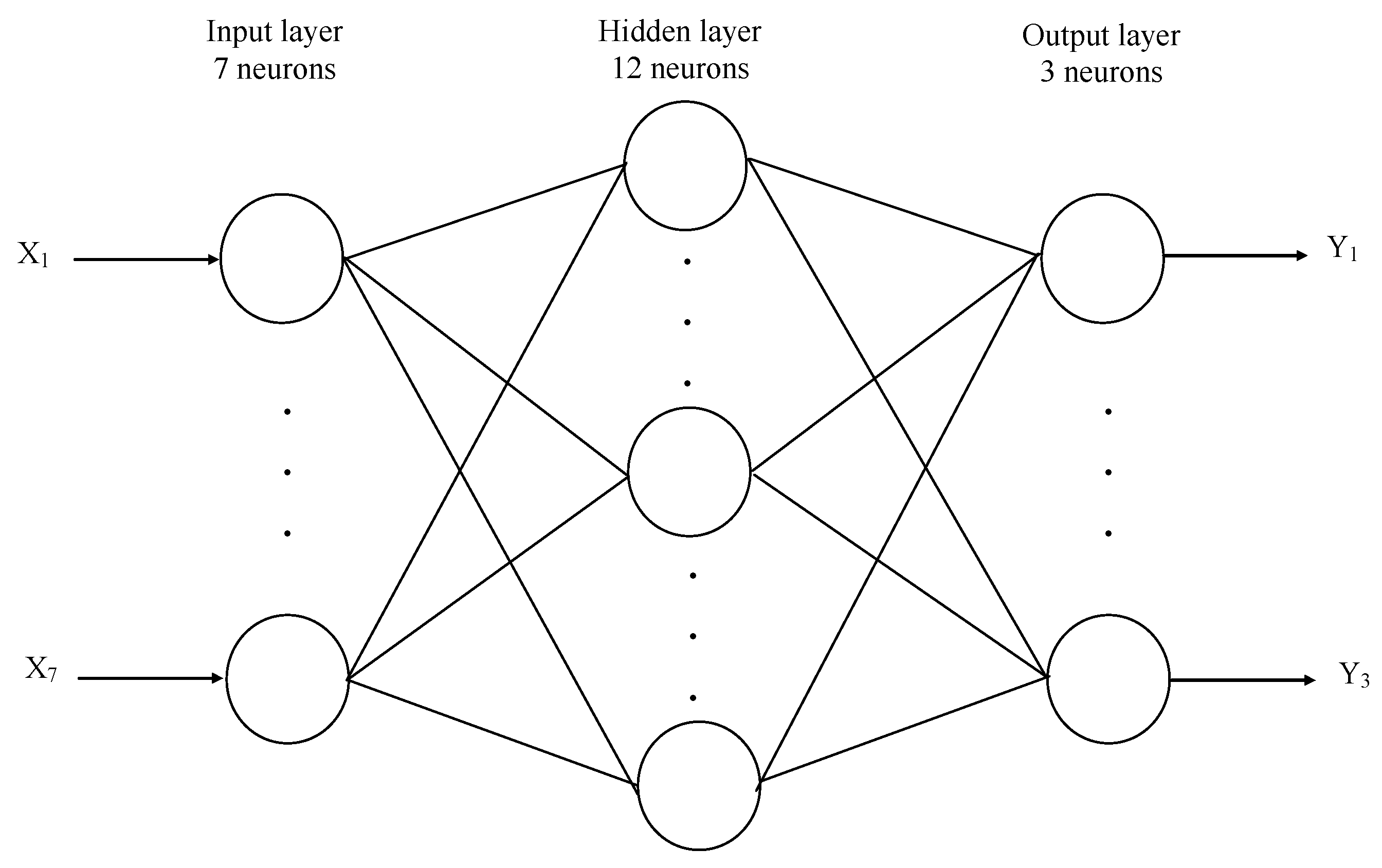

- A three-layer forward neural network (Figure 2);

- Back-propagation (BP) algorithm;

- Perceptron Linkage Optimisation set for minimal multilayer diagnostics focused on setting the mean squared error (MSE);

- naive initialisation techniques over more advanced solutions (e.g., LeCun initialisation).

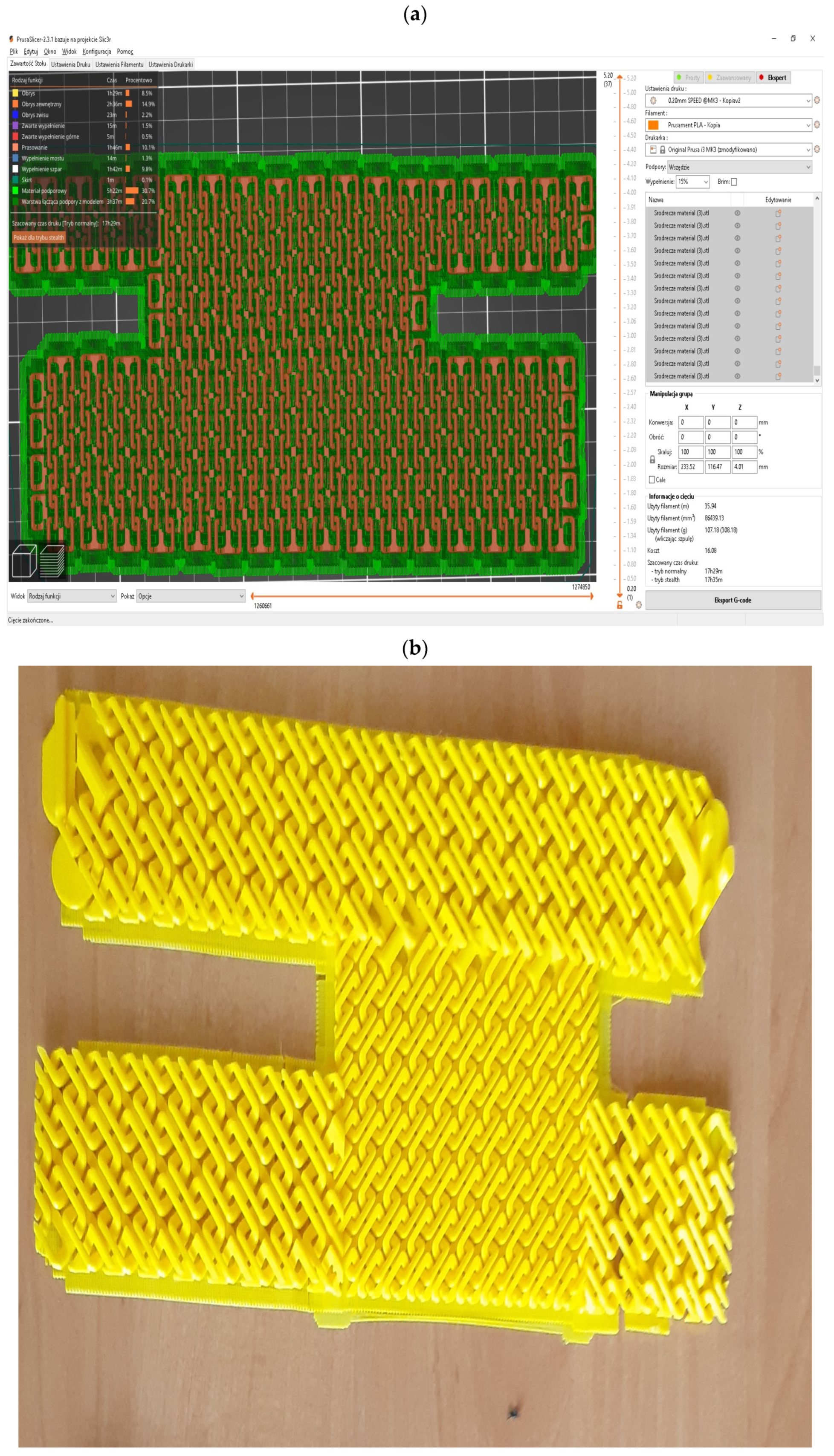

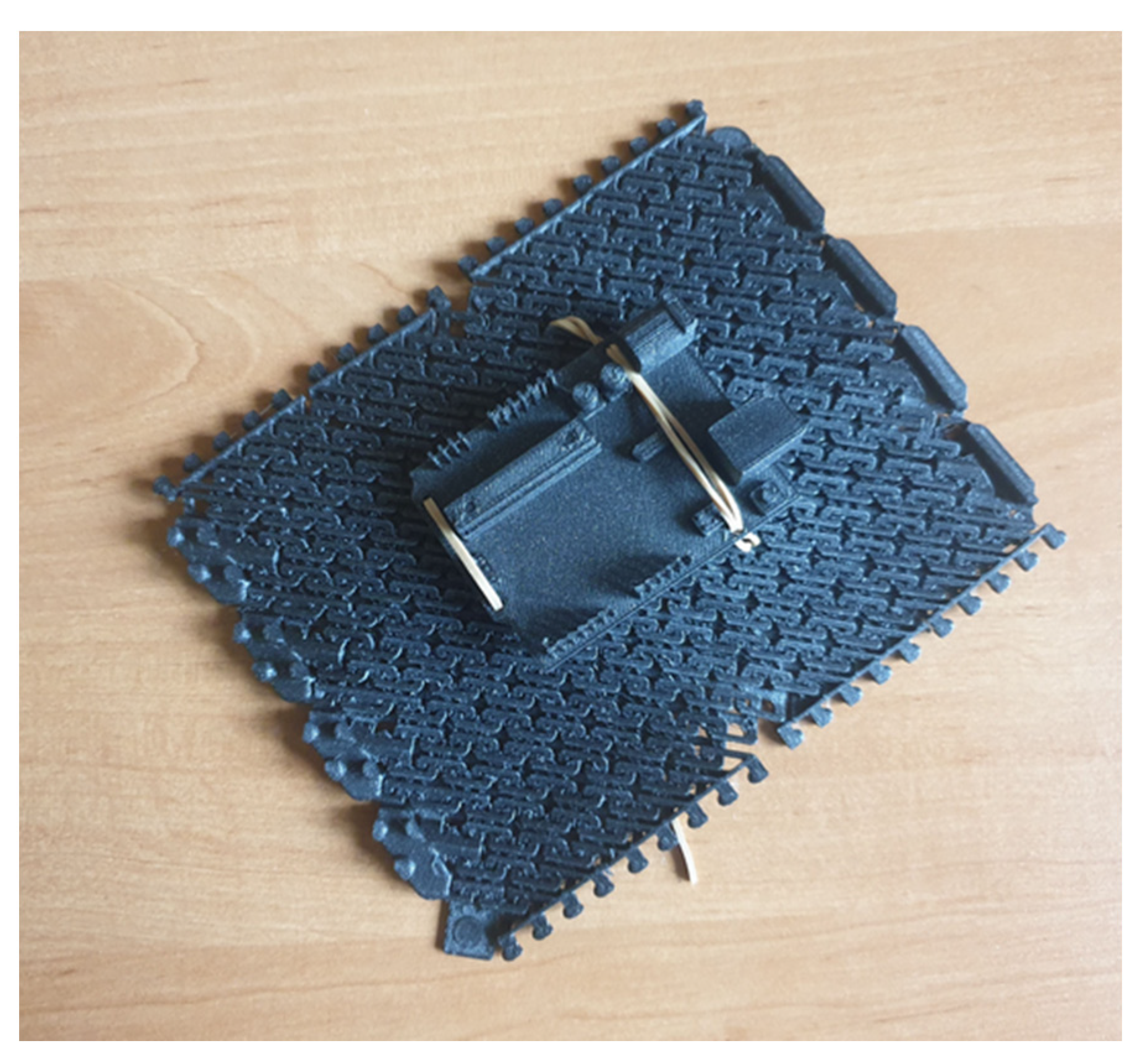

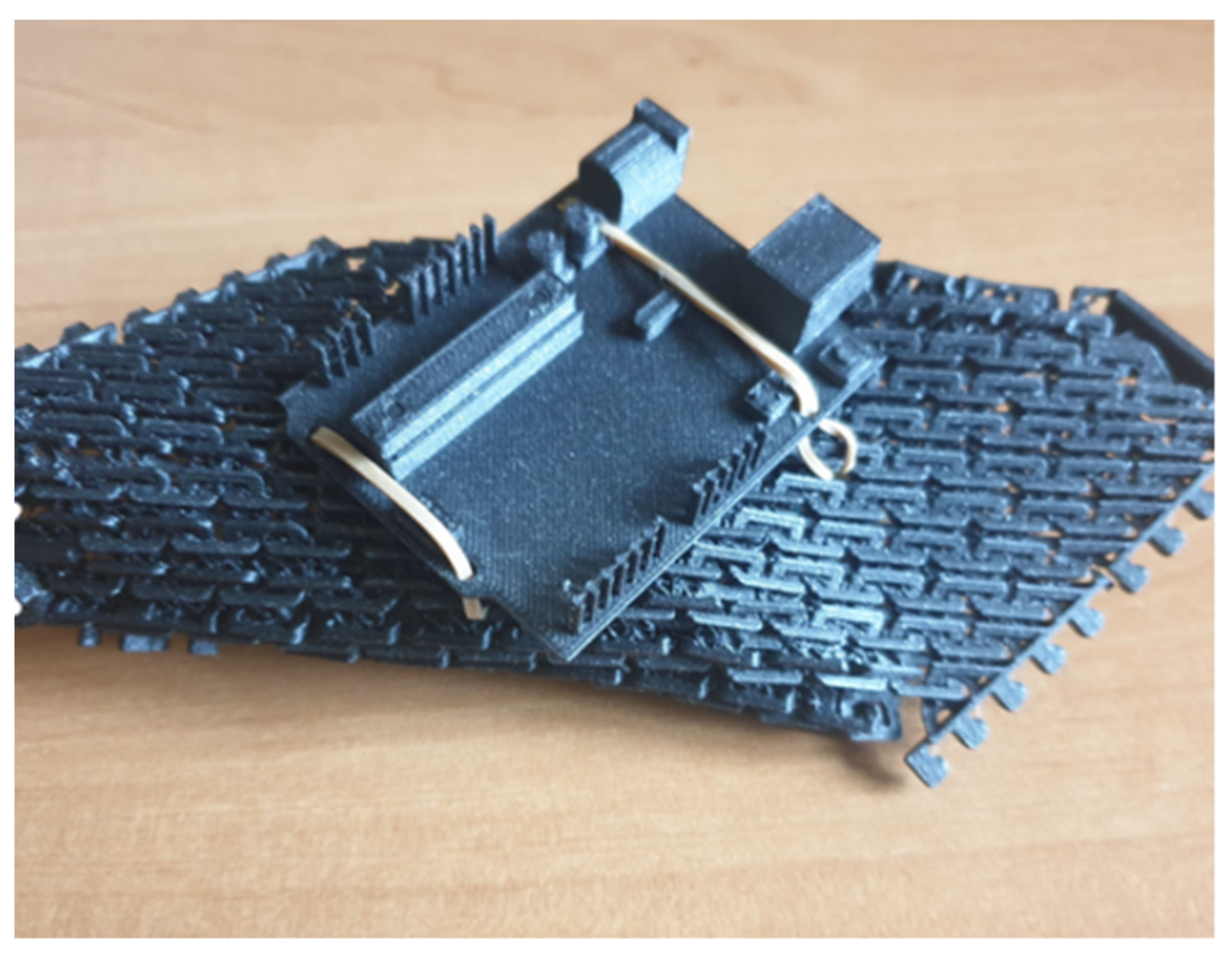

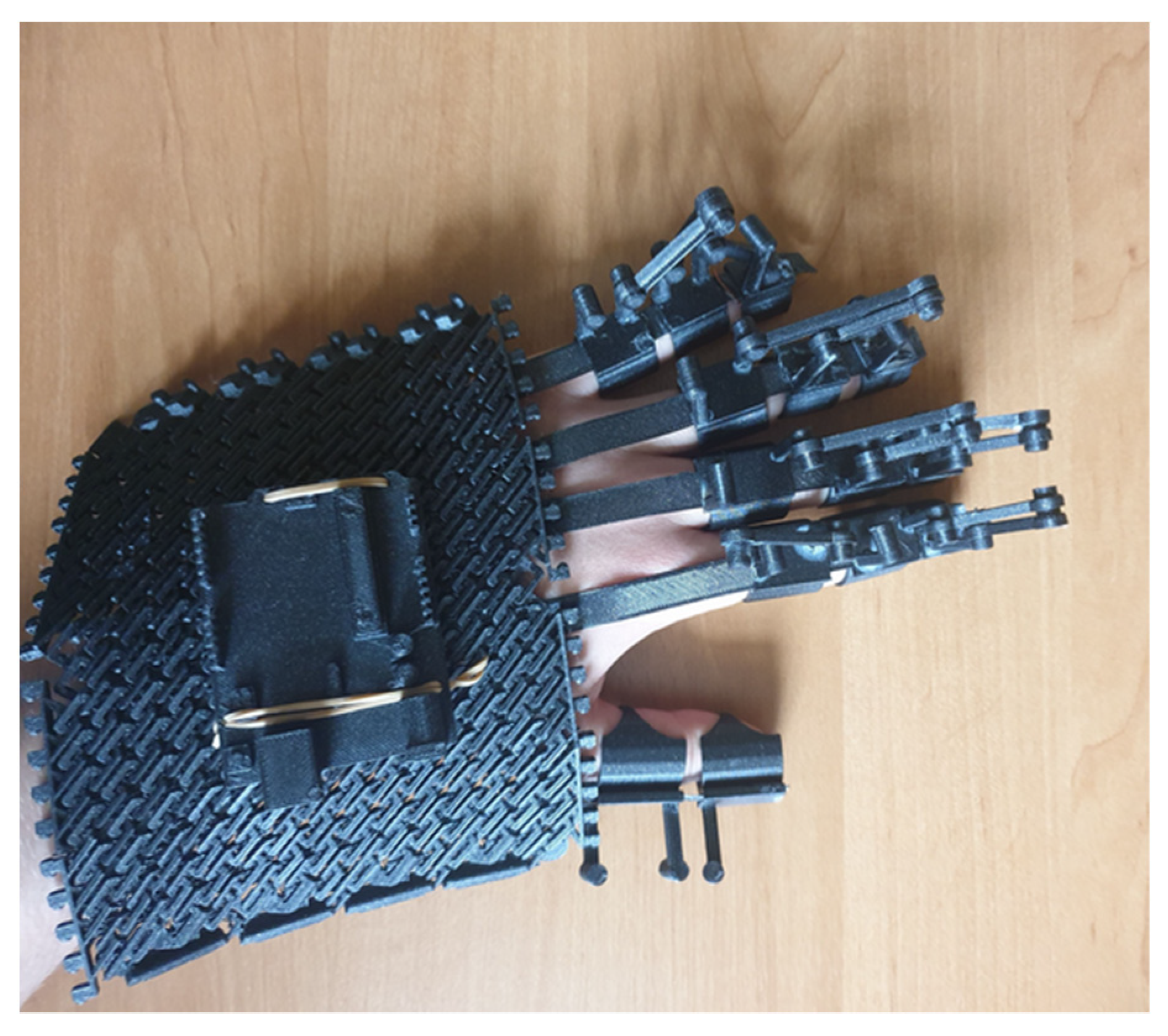

3. Results

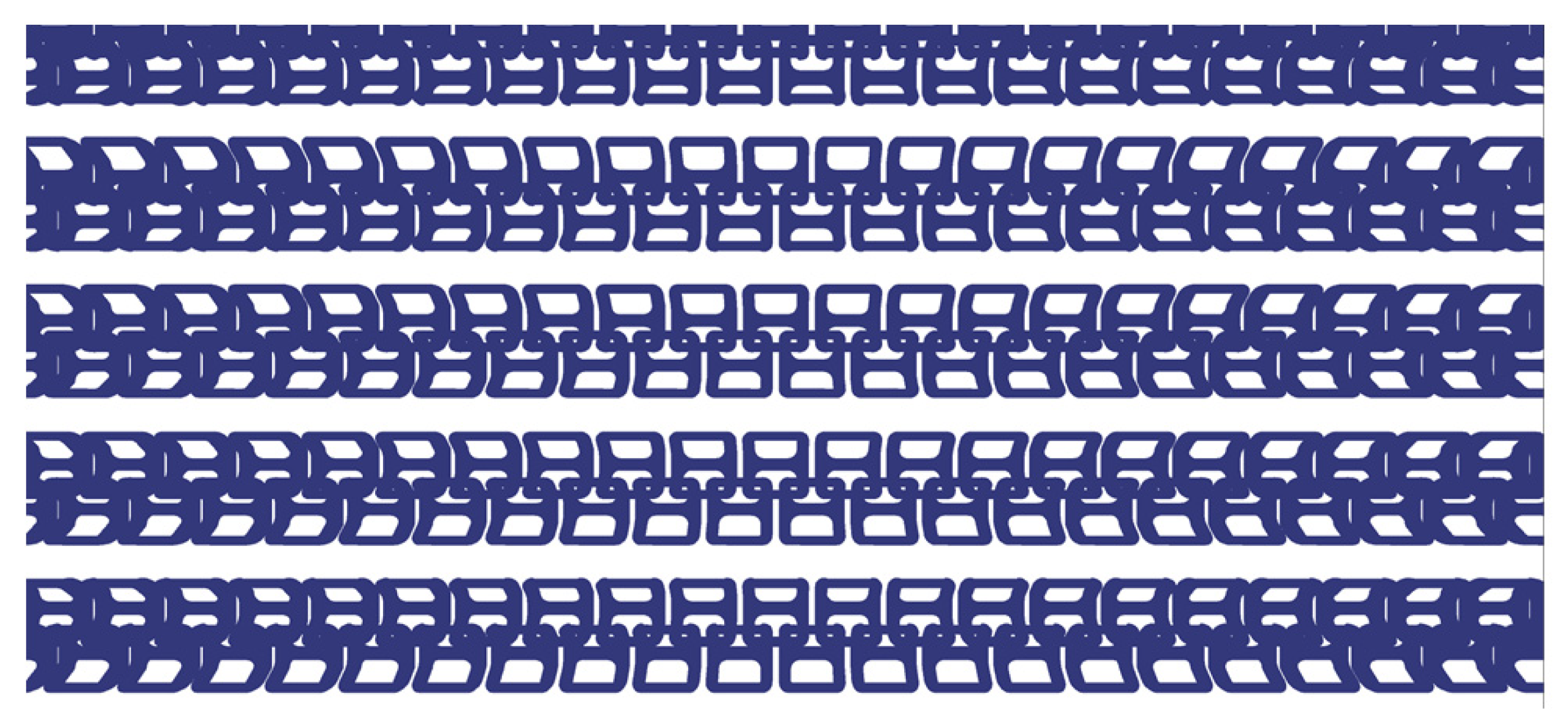

- Base (marked in red)—an element that is placed on the table during 3D printing. This is a necessary part due to the specificity of 3D printing (for printers that do not make supports) without which the material cannot be made;

- Dyelet (marked in blue)—the part that connects the individual elements. This is an example of a 3D material, which was used to create material for the metacarpals.

| Algorithm 1: Algorithm that creates and sets the material of the chainmail |

| int iloscWierszy = 10; // number of lines of material |

| int numberMarches = 10; // number of meshes (elements) in the given row |

| float offset = 0; |

| float LOCATION OFFSETX = −6; # shift in the X axis float |

| LOCATION OFFSETY = 10; # Y axis shift float |

| RozstawElementow = 4.5; # multiplier of single items |

| fileZobiektem = loadOvject (“object.stl.”); # loading the model of the element |

| for (int ix = 0; ix <iloscWowsze; ix ++) |

| { |

| for (int jx = 0; jx <number of mesh; jx ++) |

| { |

| if ((jx% 2) == 0) |

| { |

| // modulo for lines that is for every other line it does. |

| shape (fileObject, (Jx + Shift)) +LinkLiftX, Elemntow * (jx + Shift) +LinkLiftY); |

| // Move every other line to fit in the previous line |

| } |

| else |

| { |

| shape (objectFile, (Elemntow * (ix + offset)) + 0, Elemntow * (jx + offset)); |

| } |

| } |

| } |

- Database completeness;

- Required accuracy.

- For unidirectional folding: by wrapping on a shaft of specified diameter;

- For bidirectional folding: by wrapping on a sphere with a specified radius.

4. Discussion

- Research on new aircraft with properties described by mathematical formulas;

- Research into new materials and technologies better suited to medical applications;

- Research on changes in the properties of materials and 3D prints from them, including the development of both solutions with increased strength and extended durability, and solutions with a programmed useful life after which they can be easily recycled [6]—this is important for the multicriterion determination of the optimal material parameters for nonlinear properties, so that the realism of the modelling better reflects the real changes (e.g., in the user’s movement system);

- In terms of industrial and clinical applications, the scalability of the proposed method is important, i.e., its susceptibility to the mapping of many elements as the number of elements increases without deterioration of the required characteristics (including directional ones).

- Facilitation of the proper hand movements;

- Protection of the human hand from injury (including injuries caused by a range of motion (ROM) that is much too large).

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Majid, M.; Habib, S.; Javed, A.R.; Rizwan, M.; Srivastava, G.; Gadekallu, T.R.; Lin, J.C. Applications of Wireless Sensor Networks and Internet of Things Frameworks in the Industry Revolution 4.0: A Systematic Literature Review. Sensors 2022, 22, 2087. [Google Scholar] [CrossRef] [PubMed]

- Webert, H.; Döß, T.; Kaupp, L.; Simons, S. Fault Handling in Industry 4.0: Definition, Process and Applications. Sensors 2022, 22, 2205. [Google Scholar] [CrossRef] [PubMed]

- Osterrieder, P.; Budde, L.; Friedli, T. The smart factory as a key construct of Industry 4.0: A systematic literature review. Int. J. Prod. Econ. 2020, 221, 107476. [Google Scholar] [CrossRef]

- Awad, A.; Trenfield, S.J.; Pollard, T.D.; Ong, J.J.; Elbadawi, M.; McCoubrey, L.E.; Goyanes, A.; Gaisford, S.; Basit, A.W. Connected healthcare: Improving patient care using digital health technologies. Adv. Drug Deliv. Rev. 2021, 178, 113958. [Google Scholar] [CrossRef] [PubMed]

- Elbadawi, M.; McCoubrey, L.E.; Gavins, F.K.H.; Ong, J.J.; Goyanes, A.; Gaisford, S.; Basit, A.W. Disrupting 3D printing of medicines with machine learning. Trends Pharmacol. Sci. 2021, 42, 745–757. [Google Scholar] [CrossRef] [PubMed]

- Volk, M.J.; Lourentzou, I.; Mishra, S.; Vo, L.T.; Zhai, C.; Zhao, H. Biosystems Design by Machine Learning. ACS Synth. Biol. 2020, 9, 1514–1533. [Google Scholar] [CrossRef]

- Selvaraj, C.; Chandra, I.; Singh, S.K. Artificial intelligence and machine learning approaches for drug design: Challenges and opportunities for the pharmaceutical industries. Mol. Divers. 2021, 1–21. [Google Scholar] [CrossRef]

- Toptas, E. Innovative approach to the design of mechanical parts. J. Mechatron. Artif. Intell. Eng. 2020, 1, 14–20. [Google Scholar] [CrossRef]

- Huang, Q. Application of Artificial Intelligence in Mechanical Engineering. Adv. Comput. Sci. Res. 2017, 74, 855–860. [Google Scholar]

- Jäger, M.; Mayer, C.; Hefter, H.; Siebler, M.; Kecskeméthy, A. Big data and deep learning in preventive and rehabilitation medicine. Orthopade 2018, 47, 826–833. [Google Scholar] [CrossRef]

- Xu, J.; Song, J. High performance shape memory polymer networks based on rygid nanoparticle cores. Proc. Natl. Acad. Sci. USA 2010, 107, 7652–7657. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, J.; Zhong, Y.; Smith, J.; Gu, C. ChainMail based neural dynamics modeling of soft tissue deformation for surgical simulation. Technol. Health Care 2017, 25, 231–239. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, J.; Zhong, Y.; Smith, J.; Gu, C. A new ChainMail approach for real-time soft tissue simulation. Bioengineered 2016, 7, 246–252. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rodríguez, A.; León, A.; Arroyo, G. Parallel deformation of heterogeneous ChainMail models: Application to interactive deformation of large medical volumes. Comput. Biol. Med. 2016, 79, 222–232. [Google Scholar] [CrossRef]

- Memon, A.R.; Li, J.; Egger, J.; Chen, X. A review on patient-specific facial and cranial implant design using Artificial Intelligence (AI) techniques. Expert. Rev. Med. Devices 2021, 18, 985–994. [Google Scholar] [CrossRef]

- Saeidi Pour, R.; Edelhoff, D.; Prandtner, O.; Liebermann, A. Rehabilitation of a patient with amelogenesis imperfecta using porcelain veneers and CAD/CAM polymer restorations: A clinical report. Quintessence Int. 2015, 46, 843–852. [Google Scholar] [CrossRef]

- Ransley, M.; Smitham, P.; Miodownik, M. Active chainmail fabrics for soft robotic applications. Smart Mater. Struct. 2017, 26, 08LT02. [Google Scholar] [CrossRef]

- Cabibihan, J.J.; Alkhatib, F.; Mudassir, M.; Lambert, L.A.; Al-Kwifi, O.S.; Diab, K.; Mahdi, E. Suitability of the Openly Accessible 3D Printed Prosthetic Hands for War-Wounded Children. Front. Robot. AI 2021, 7, 594196. [Google Scholar] [CrossRef]

- Thurzo, A.; Kočiš, F.; Novák, B.; Czako, L.; Varga, I. Three-Dimensional Modeling and 3D Printing of Biocompatible Orthodontic Power-Arm Design with Clinical Application. Appl. Sci. 2021, 11, 9693. [Google Scholar] [CrossRef]

- Thurzo, A.; Urbanová, W.; Novák, B.; Waczulíková, I.; Varga, I. Utilization of a 3D Printed Orthodontic Distalizer for Tooth-Borne Hybrid Treatment in Class II Unilateral Malocclusions. Materials 2022, 15, 1740. [Google Scholar] [CrossRef]

- Hu, F.; Wang, W.; Cheng, J.; Bao, Y. Origami spring–inspired metamaterials and robots: An attempt at fully programmable robotics. Sci. Prog. 2020, 103, 0036850420946162. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Z.; Wu, L.; Jiang, H. Mechanical metamaterials based on origami and kirigami. Appl. Phys. Rev. 2021, 8, 041319. [Google Scholar] [CrossRef]

- Zhu, H.; Li, Z.; Wang, R.; Chen, S.; Zhang, C.; Li, F. Revealing the Dynamic Characteristics of Composite Material-Based Miura-Origami Tube. Materials 2021, 14, 6374. [Google Scholar] [CrossRef] [PubMed]

- Ai, C.; Chen, Y.; Xu, L.; Li, H.; Liu, C.; Shang, F.; Xia, Q.; Zhang, S. Current Development on Origami/Kirigami-Inspired Structure of Creased Patterns toward Robotics. Adv. Eng. Mater. 2021, 23, 2100473. [Google Scholar] [CrossRef]

- Blanco-Ortega, A.; Vázquez-Sánchez, L.; Adam-Medina, M.; Colín-Ocampo, J.; Abúndez-Pliego, A.; Cortés-García, C.; García-Beltrán, C.D. A Robust Controller for Upper Limb Rehabilitation Exoskeleton. Appl. Sci. 2022, 12, 1178. [Google Scholar] [CrossRef]

- Chae, S.; Choi, A.; Jung, H.; Kim, T.H.; Kim, K.; Mun, J.H. Machine Learning Model to Estimate Net Joint Moments during Lifting Task Using Wearable Sensors: A Preliminary Study for Design of Exoskeleton Control System. Appl. Sci. 2021, 11, 11735. [Google Scholar] [CrossRef]

- Meng, Q.; Shen, Z.; Nie, Z.; Meng, Q.; Wu, Z.; Yu, H. Modeling and Evaluation of a Novel Hybrid-Driven Compliant Hand Exoskeleton Based on Human-Machine Coupling Model. Appl. Sci. 2021, 11, 10825. [Google Scholar] [CrossRef]

- Lee, H.-W.; Lee, K.-O.; Chae, Y.-J.; Kim, S.-Y.; Park, Y.-Y. A Time-Scalable Posture Detection Algorithm for Paraplegic Patient Rehabilitation Using Exoskeleton-Type Wearable Robots. Appl. Sci. 2022, 12, 2374. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Dostatni, E.; Macko, M. AI-Optimized Technological Aspects of the Material Used in 3D Printing Processes for Selected Medical Applications. Materials 2020, 13, 5437. [Google Scholar] [CrossRef]

- Hossain, N.; Chowdhury, M.A.; Shuvho, M.B.A.; Kashem, M.A.; Kchaou, M. 3D-Printed Objects for Multipurpose Applications. J. Mater. Eng. Perform. 2021, 30, 4756–4767. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Dostatni, E. Digital Twins in Product Lifecycle for Sustainability in Manufacturing and Maintenance. Appl. Sci. 2021, 11, 31. [Google Scholar] [CrossRef]

- Mahmood, M.A.; Visan, A.I.; Ristoscu, C.; Mihailescu, I.N. Artificial Neural Network Algorithms for 3D Printing. Materials 2020, 14, 163. [Google Scholar] [CrossRef] [PubMed]

- Regulation (Eu) 2017/745 of the European Parliament and of the Council of 5 April 2017 on Medical Devices, Amending Directive 2001/83/EC, Regulation (EC) No 178/2002 and Regulation (EC) No 1223/2009 and Repealing Council Directives 90/385/EEC and 93/42/EEC. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32017R0745 (accessed on 8 March 2022).

- ISO 13485:2016 Medical Devices Quality Management Systems. Available online: https://www.iso.org/obp/ui#iso:std:iso:13485:ed-3:v1:en (accessed on 8 March 2022).

- Płoszajski, A.R.; Jackson, R.; Ransley, M.; Miodownik, M. 4D printing of magnetically functionalized chainmail for exoskeletal biomedical applications. MRS Adv. 2019, 4, 1361–1366. [Google Scholar] [CrossRef]

- Wang, Y.; Li, L.; Hofmann, D.; Andrade, J.E.; Daraio, C. Structured fabrics with tunable mechanical properties. Nature 2021, 596, 238–243. [Google Scholar] [CrossRef]

- YunáHann, S.; GraceáZhang, L.; KumaráMaiti, T. 4D printing in biomedical applications: Emerging trends and technologies. J. Mater. Chem. B 2021, 9, 7608–7632. [Google Scholar]

- Fu, P.; Li, H.; Gong, J.; Fan, Z.; Smith, A.T.; Shen, K.; Khalfalla, T.O.; Huang, H.; Qian, X.; McCutcheon, J.R.; et al. 4D Printing of Polymeric Materials: Techniques, Materials, and Prospects. Prog. Polym. Sci. 2022, 126, 101506. [Google Scholar] [CrossRef]

- Fernandez, S.V.; Cai, F.; Chen, S.; Suh, E.; Tiepelt, J.; McIntosh, R.; Marcus, C.; Acosta, D.; Mejorado, D.; Dagdeviren, C. On-Body Piezoelectric Energy Harvesters through Innovative Designs and Conformable Structures. ACS Biomater. Sci. Eng. 2021, 1–17. [Google Scholar] [CrossRef]

- Kopowski, J.; Mikołajewski, D.; Macko, M.; Rojek, I. Bydgostian hand exoskeleton-own concept and the biomedical factors. Bio-Algorithms Med-Syst. 2019, 15, 20190003. [Google Scholar] [CrossRef]

- Kataria, S.; Ravindran, V. Musculoskeletal care-at the confluence of data science, sensors, engineering, and computation. BMC Musculoskelet Disord. 2022, 23, 169. [Google Scholar] [CrossRef]

- Taylor, J.M.; Luan, H.; Lewis, J.A.; Rogers, J.A.; Nuzzo, R.G.; Braun, P.V. Biomimetic and Biologically Compliant Soft Architectures via 3D and 4D Assembly Methods: A Perspective. Adv. Mater. 2022, 34, 2108391. [Google Scholar] [CrossRef]

- Zhang, J.; Yin, Z.; Ren, L.; Liu, Q.; Ren, L.; Yang, X.; Zhou, X. Advances in 4D Printed Shape Memory Polymers: From 3D Printing, Smart Excitation, and Response to Applications. Adv. Mater. Technol. 2022, 210156. [Google Scholar] [CrossRef]

- Bean, P.; Lopez-Anido, R.A.; Vel, S. Numerical Modeling and Experimental Investigation of Effective Elastic Properties of the 3D Printed Gyroid Infill. Appl. Sci. 2022, 12, 2180. [Google Scholar] [CrossRef]

- Dudley, D.R.; Knarr, B.A.; Siu, K.C.; Peck, J.; Ricks, B.; Zuniga, J.M. Testing of a 3D printed hand exoskeleton for an individual with stroke: A case study. Disabil. Rehabil. Assist. Technol. 2021, 16, 209–213. [Google Scholar] [CrossRef] [PubMed]

- Webster, R.; Haluck, R.; Ravenscroft, R.; Mohler, B.; Crouthamel, E.; Frack, T.; Terlecki, S.; Sheaffer, J. Elastically deformable 3D organs for haptic surgical simulation. Stud. Health Technol. Inform. 2002, 85, 570–572. [Google Scholar] [PubMed]

- Meier, U.; López, O.; Monserrat, C.; Juan, M.C.; Alcañiz, M. Real-time deformable models for surgery simulation: A survey. Comput. Methods Programs Biomed. 2005, 77, 183–197. [Google Scholar] [CrossRef]

- Nadagouda, M.N.; Ginn, M.; Rastogi, V. A review of 3D printing techniques for environmental applications. Curr. Opin. Chem. Eng. 2020, 28, 173–178. [Google Scholar] [CrossRef]

- Thurzo, A.; Kurilová, V.; Varga, I. Artificial Intelligence in Orthodontic Smart Application for Treatment Coaching and Its Impact on Clinical Performance of Patients Monitored with AI-TeleHealth System. Healthcare 2021, 9, 1695. [Google Scholar] [CrossRef]

| ANN Structure. | Activation Function in the Hidden Layer | Activation Function in the Output Layer |

|---|---|---|

| MLP 7-8-3 | Sigmoid | Sigmoid |

| MLP 7-10-3 | Sigmoid | Sigmoid |

| MLP 7-12-3 | Sigmoid | Sigmoid |

| MLP 7-14-3 | Sigmoid | Sigmoid |

| MLP 7-16-3 | Sigmoid | Sigmoid |

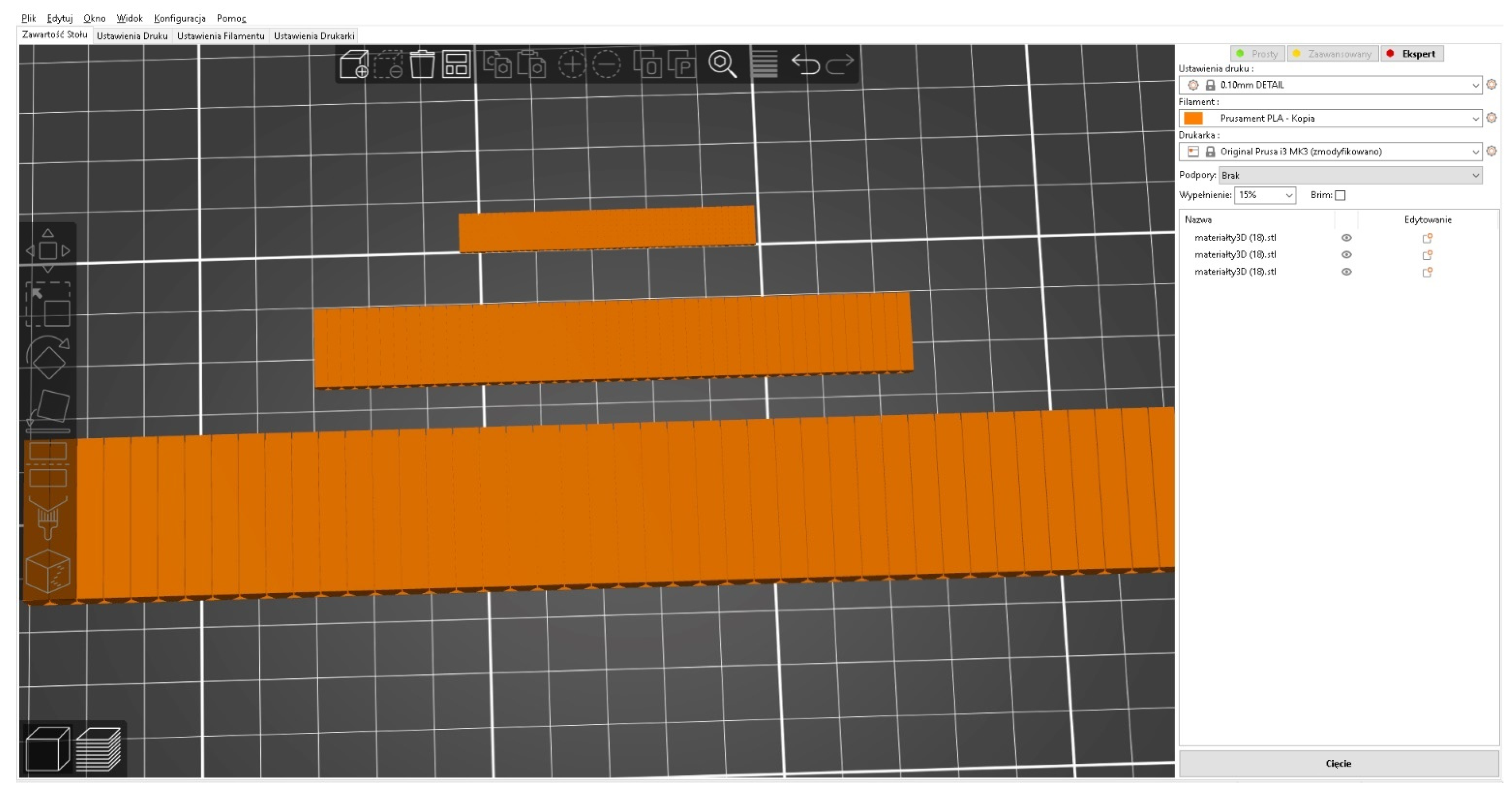

| Parameter | Value |

|---|---|

| Layer height | |

| Layer height | 0.2 mm |

| First layer height | 0.2 mm |

| Vertical shells | |

| Perimeters minimum | 2 |

| Spiral vase | diasbled |

| Horizontal shells | |

| Solid layer | top: 5, bottom: 4 |

| Minimum shell thickness: | top: 0.7 mm, bottom: 0.5 mm |

| Quality settings | |

| Extra perimeter if needed | disabled |

| Ensure vertical shell thickness | enabled |

| Avoid crossing perimeters | disabled |

| Avoid crossing perimeters–max detour length | 0% (disabled) |

| Detect thin walls | disabled |

| Advanced layers setting | |

| Seam position | nearest |

| External perimeters first | disabled |

| Infill | |

| Fill density: 15% | 15% |

| Fill pattern | gyroid |

| Length of infill anchor | 2.5 mm |

| Maximum length of infill anchor | 12 mm |

| Top fill pattern | monotonic |

| Bottom fill pattern | monotonic |

| Ironing | |

| Ironing | disabled all |

| Reducing printing time | |

| Combine infill every | 1 layers |

| Only infill where needed | disabled |

| Advanced infill | |

| Solid infill every | 0 layers |

| Fill angle | 45o |

| Solid infill threshold area | 0 mm2 |

| Bridging angle | 0o |

| Only retract when crossing perimetrs | disabled |

| Infill before perimetrs | disabled |

| Support material | |

| Generate support material | disabled |

| Auto generate support | disabled |

| Raft layer | 0 layers (disabled) |

| Speed for print moves | |

| Perimeters | 45 mm/s |

| Small perimeters | 25 mm/s |

| External perimeters | 25 mm/s |

| Infill | 80 mm/s |

| Solid infill | 80 mm/s |

| Top solid infill | 40 mm/s |

| Gap fill | 30 mm/s |

| Extruders | |

| Extruders | only one |

| Parameter | Value |

|---|---|

| Identification | |

| Trade name | Prusament PLA |

| Chemical name | Polylactic (PLA) |

| Usage | FDM 3D printing |

| Manufacturer | Prusa Polymers, Prague, Czech Republic |

| Recommended print settings | |

| Nozzle temperature [°C] | 210 +/− 10 |

| Heatbed temperature [°C] | 40–60 |

| Print speed [mm/s] | Max 200 |

| Typical material properties | |

| Physical properties | Typical value |

| Peak melt temperature [°C] | 145–160 |

| Glass transition temperature [°C] | 55–60 |

| MFR [g/10 min] | 10.4 |

| MVR [cm3/10 min] | 9.4 |

| Specific gravity [g/cm3] | 1.24 |

| MFR [g/10 min] | 10.4 |

| MVR [cm3/10 min] | 9.4 |

| Specific gravity [g/cm3] | 1.24 |

| Heat deflection temperature (0.45 MPa) [°C] | 57.4 +/− 0.4 |

| MFR [g/10 min] | 10.4 |

| Network Name | Quality (Learning) | Quality (Testing) |

|---|---|---|

| MLP 7-8-3 | 0.8119 | 0.8771 |

| MLP 7-10-3 | 0.8788 | 0.8975 |

| MLP 7-12-3 | 0.9113 | 0.9212 |

| MLP 7-14-3 | 0.8814 | 0.8858 |

| MLP 7-16-3 | 0.8321 | 0.8714 |

| Network Name | (R)MSE |

|---|---|

| MLP 7-8-3 | 0.02 |

| MLP 7-10-3 | 0.01 |

| MLP 7-12-3 | 0.001 |

| MLP 7-14-3 | 0.01 |

| MLP 7-16-3 | 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kopowski, J.; Mikołajewski, D.; Kotlarz, P.; Dostatni, E.; Rojek, I. A Semi-Automated 3D-Printed Chainmail Design Algorithm with Preprogrammed Directional Functions for Hand Exoskeleton. Appl. Sci. 2022, 12, 5007. https://doi.org/10.3390/app12105007

Kopowski J, Mikołajewski D, Kotlarz P, Dostatni E, Rojek I. A Semi-Automated 3D-Printed Chainmail Design Algorithm with Preprogrammed Directional Functions for Hand Exoskeleton. Applied Sciences. 2022; 12(10):5007. https://doi.org/10.3390/app12105007

Chicago/Turabian StyleKopowski, Jakub, Dariusz Mikołajewski, Piotr Kotlarz, Ewa Dostatni, and Izabela Rojek. 2022. "A Semi-Automated 3D-Printed Chainmail Design Algorithm with Preprogrammed Directional Functions for Hand Exoskeleton" Applied Sciences 12, no. 10: 5007. https://doi.org/10.3390/app12105007

APA StyleKopowski, J., Mikołajewski, D., Kotlarz, P., Dostatni, E., & Rojek, I. (2022). A Semi-Automated 3D-Printed Chainmail Design Algorithm with Preprogrammed Directional Functions for Hand Exoskeleton. Applied Sciences, 12(10), 5007. https://doi.org/10.3390/app12105007