Calibration of Rotary Encoders Using a Shift-Angle Method

Abstract

:1. Introduction

2. Theory and Configuration

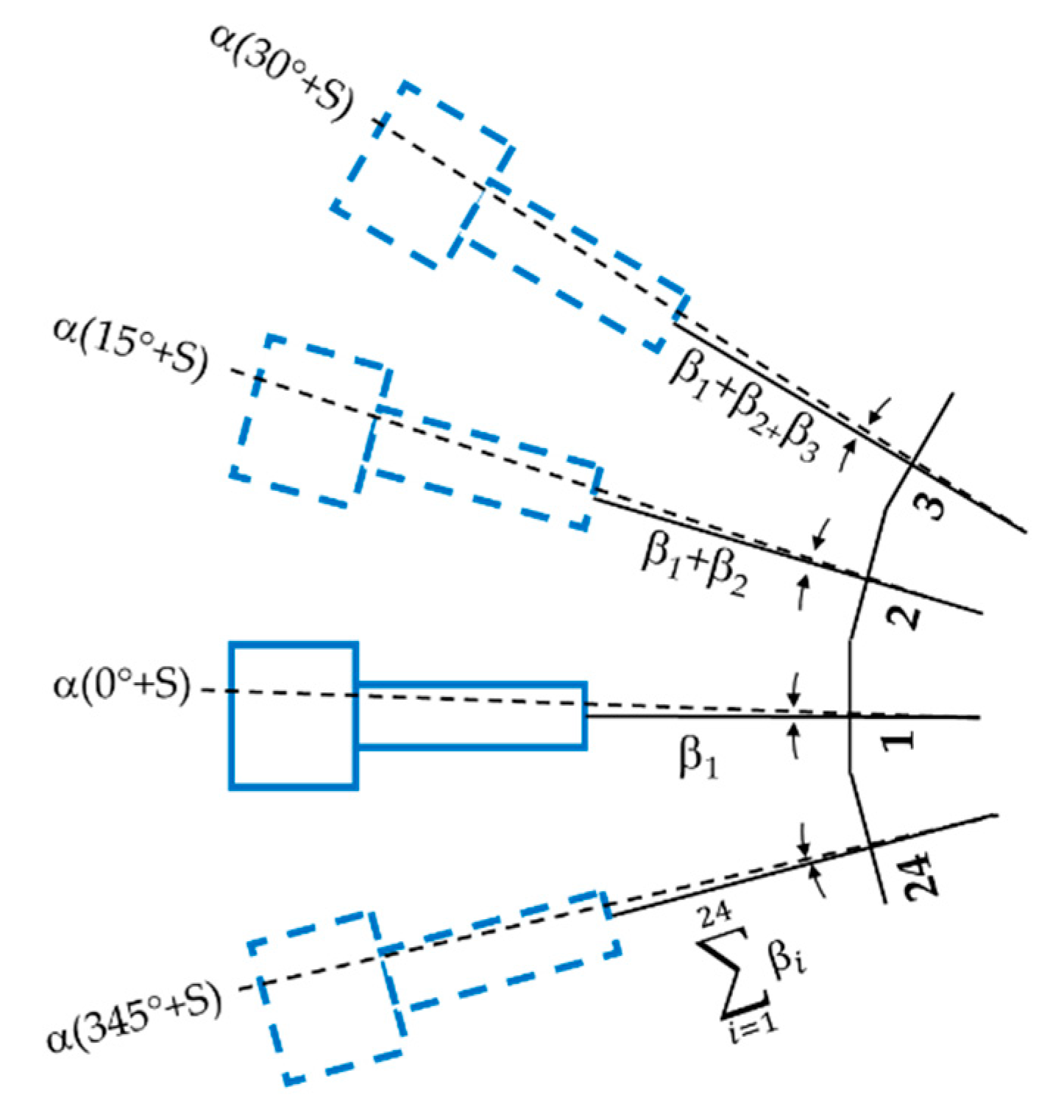

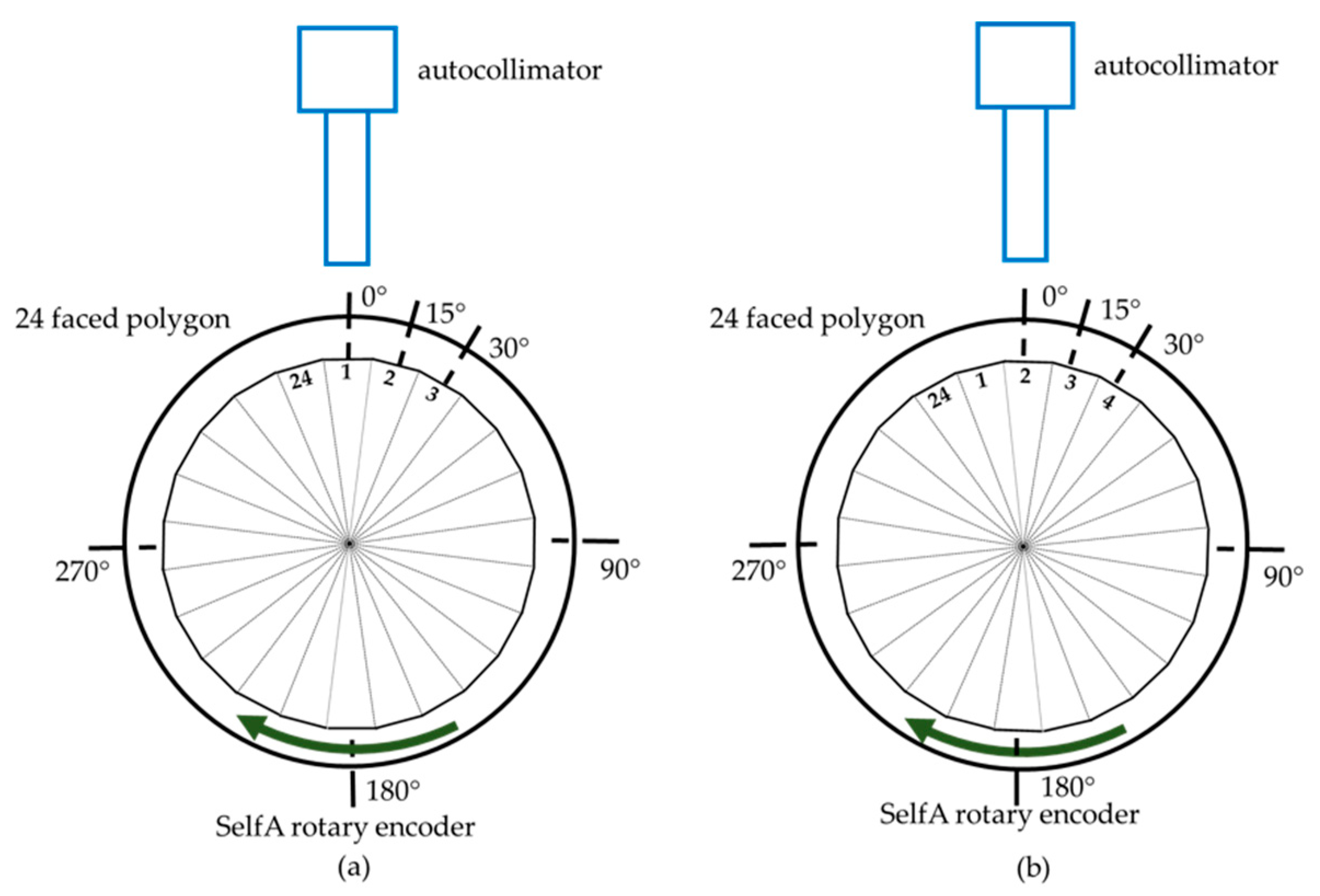

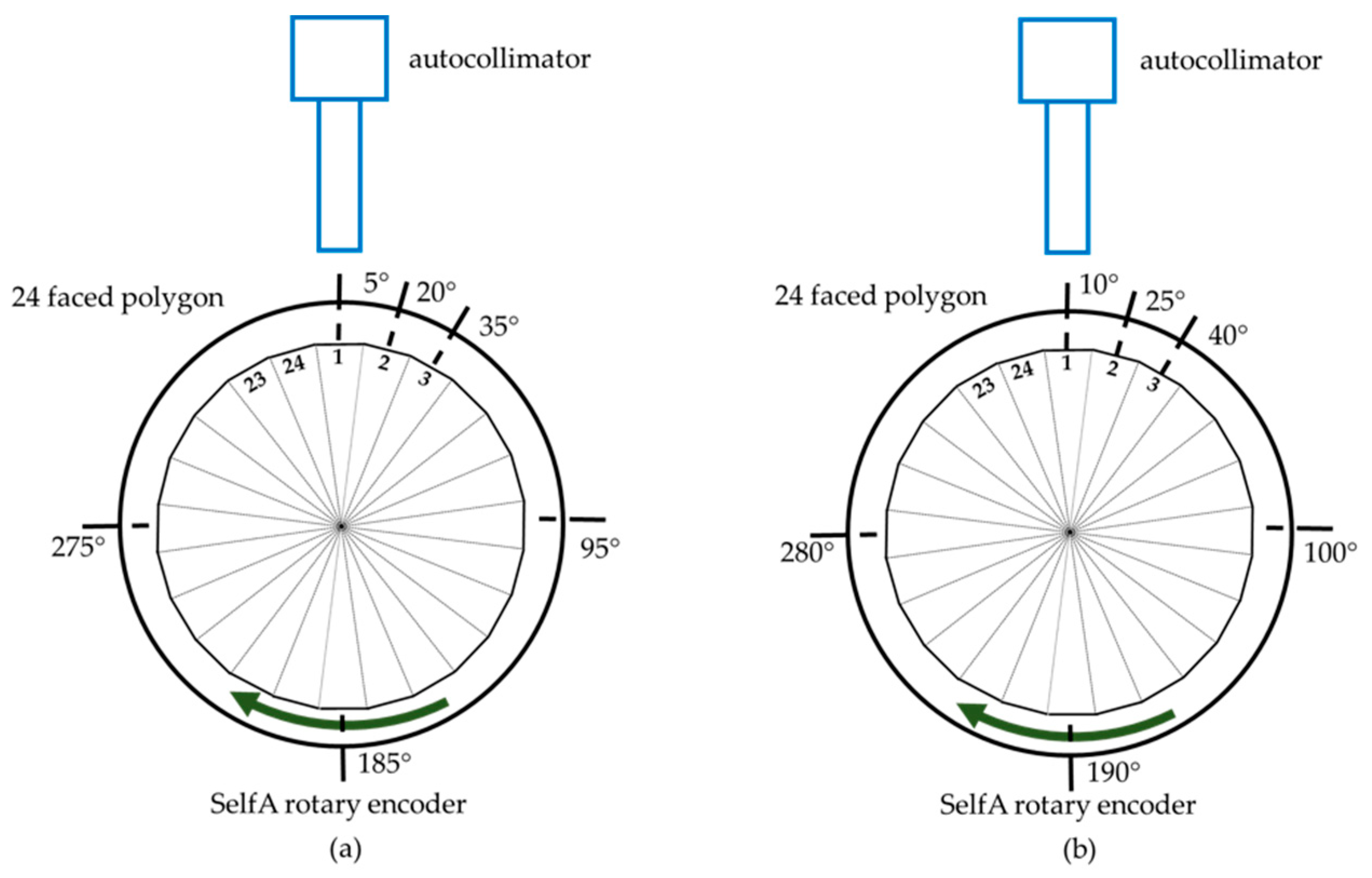

2.1. Shift-Angle Method for Polygon

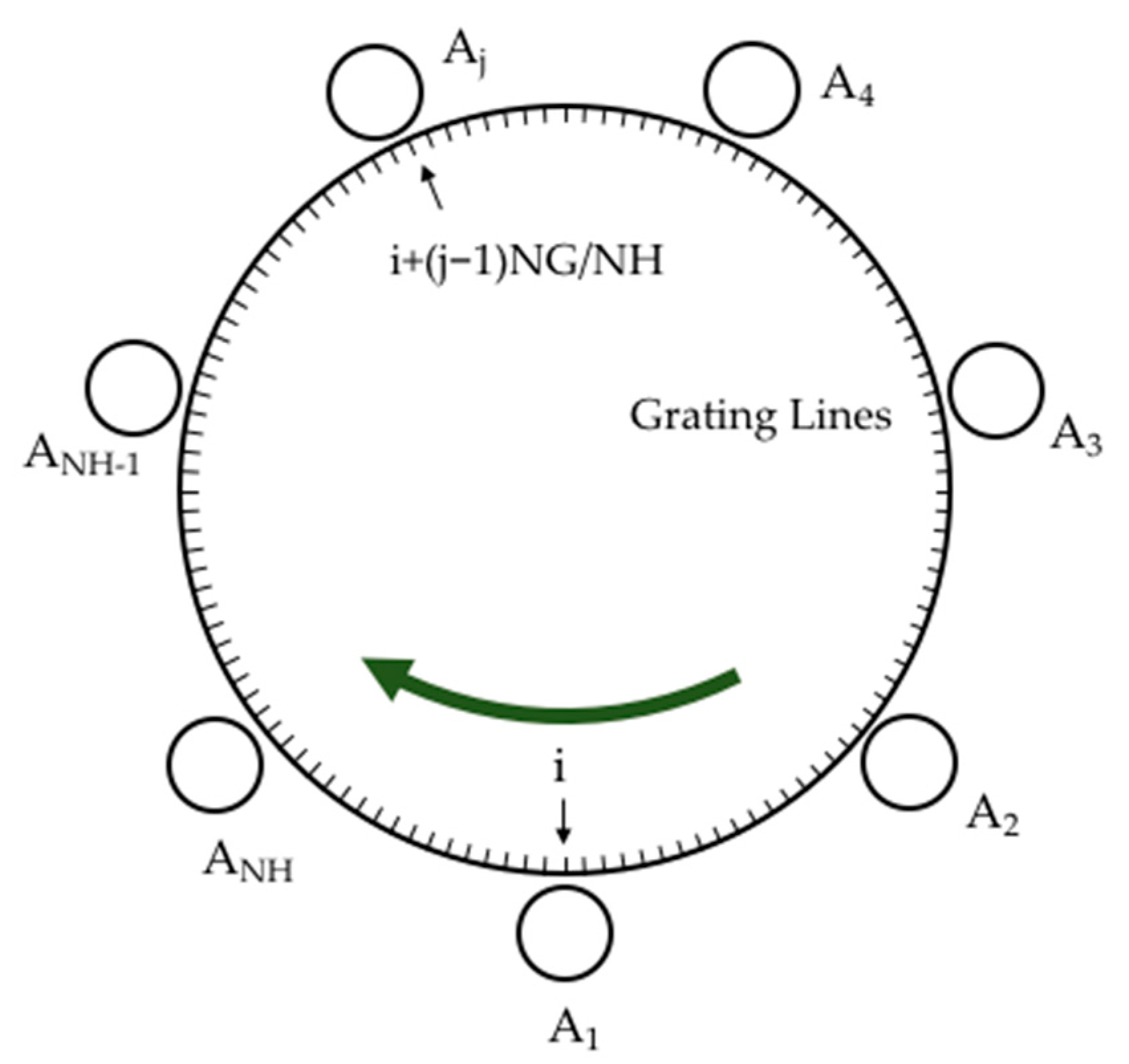

2.2. Shift-Angle Method for Rotary Encoders

2.3. Self-Calibration

3. Experiments

3.1. Shift-Angle Method

3.2. Comparison of Calibration Results Obtained Using the Shift-Angle Method and Self-Calibration

3.3. Uncertainty Evaluation

- (1)

- Repeatability of angle error measurement.

- (2)

- Resolution of the autocollimator.

- (3)

- Traceability of the autocollimator.

- (4)

- Angle error of the autocollimator.

- (5)

- Resolution of SelfA rotary encoder.

- (6)

- Residual setup error calculation.

- (7)

- Repeatability of the pitch angle deviation measurement, β.

- (8)

- Setup error of the polygon, U.

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Lu, X.D.; Trumper, D.L. Self-calibration of on-axis rotary encoders. CIRP Ann. 2007, 56, 499–504. [Google Scholar] [CrossRef]

- Masuda, T.; Kajitani, M. An Automatic Calibration System for Angular Encoders. Precis. Eng. 1989, 11, 95–100. [Google Scholar] [CrossRef]

- Probst, R.; Wittekopf, R.; Krause, M.; Dangschat, H.; Ernst, A. The new PTB angle comparator. Meas. Sci. Technol. 1998, 9, 1059–1066. [Google Scholar] [CrossRef]

- Probst, R. Self-calibration of divided circles on the basis of a prime factor algorithm. Meas. Sci. Technol. 2008, 19, 015101. [Google Scholar] [CrossRef]

- Geckeler, R.D.; Link, A.; Krause, M.; Elster, C. Capabilities and limitations of the self-calibration of angle encoders. Meas. Sci. Technol. 2014, 25, 055003. [Google Scholar] [CrossRef] [Green Version]

- Jiao, Y.; Dong, Z.G.; Ding, Y.; Liu, P.K. Optimal arrangements of scanning heads for self-calibration of angle encoders. Meas. Sci. Technol. 2017, 28, 105013. [Google Scholar] [CrossRef] [Green Version]

- Jiao, Y.; Ding, Y.; Dong, Z.G.; Huang, M.; Liu, P.K. Optimal-arrangement-based four-scanning-heads error separation technique for self-calibration of angle encoders. Meas. Sci. Technol. 2018, 29, 085005. [Google Scholar] [CrossRef]

- Watanabe, T.; Fujimoto, H.; Masuda, T. Self-calibratable rotary encoder. J. Phys. Conf. Ser. 2005, 13, 240. [Google Scholar] [CrossRef]

- Watanabe, T.; Hiroyuki, F. Application of a self-calibratable rotary encoder. Proc. ISMTII 2009, 3, 54–58. [Google Scholar]

- Watanabe, T.; Kon, M.; Nebeshima, N.; Taniguchi, K. An angle encoder for super-high resolution and super-high accuracy using SelfA. Meas. Sci. Technol. 2014, 25, 065002. [Google Scholar] [CrossRef]

- Ueyama, Y.; Furutani, R.; Watanabe, T. A super-high-accuracy angular index table. Meas. Sci. Technol. 2020, 31, 094006. [Google Scholar] [CrossRef]

- Pavlov, P.A. Aspects of the Cross-Calibration Method in Laser Gonimetry. Meas. Tech. 2015, 58, 970–974. [Google Scholar] [CrossRef]

- Pavlov, P.A. A Method for investigating the error of a laser dynamic goniometry. Meas. Tech. 2020, 63, 106–110. [Google Scholar] [CrossRef]

- Akgoz, S.-A.; Yangdayan, T. High precision calibration of polygons for emerging demands. IOP Conf. Ser. J. Phys. Conf. Ser. 2018, 1065, 142005. [Google Scholar] [CrossRef]

- Jia, H.K.; Yu, L.D.; Zhao, H.N.; Jiang, Y.-Z. A new method of angle measurement error analysis of rotary encoders. Appl. Sci. 2019, 9, 3415. [Google Scholar] [CrossRef] [Green Version]

- Reeve, P.C. The calibration of indexing tables by subdivision. NBS Int. Rep. 1975, 1–37, 75–750. [Google Scholar]

- Estler, W.T.; Queen, Y.H.; Bryan, J. An advanced angle metrology system. CIRP Ann. 1993, 42, 573–576. [Google Scholar] [CrossRef]

- Kim, J.A.; Kim, J.W.; Kang, C.S.; Jin, J.H.; Eom, T.-B. Calibration of angle artifacts and instruments using a high precision angle generator. Int. J. Precis. Eng. Manuf. 2012, 14, 367–371. [Google Scholar] [CrossRef]

- Huang, Y.; Xue, Z.; Huang, M.; Qiao, D. The NIM continuous full circle angel standard. Meas. Sci. Technol. 2018, 29, 074013. [Google Scholar] [CrossRef]

- Pisani, M.; Astrua, M. The new INRIM rotating encoder angle comparator (REAC). Meas. Sci. Technol. 2017, 28, 045008. [Google Scholar] [CrossRef]

- ISO/IEC Guide 98-3:2008. Uncertainty of Measurement—Part 3: Guide to the Expression of Uncertainty in Measurement; ISO: Geneva, Switzerland, 2008. [Google Scholar]

- Estler, W.T. Uncertainty analysis for angle calibrations using circle closure. J. Res. NIST 1998, 103, 141–151. [Google Scholar] [CrossRef] [PubMed]

| i | 1 | 2 | … | 23 | 24 |

|---|---|---|---|---|---|

| j | |||||

| 1 | … | ||||

| 2 | … | ||||

| … | … | … | … | … | … |

| 23 | … | ||||

| 24 | … | ||||

| l,m n | 2,1 | l,m n | 3,2 | … | l,m n | 24,23 | l,m n | 25,24 | The Average of the Row |

|---|---|---|---|---|---|---|---|---|---|

| 24 | 23 | … | 2 | 1 | |||||

| 1 | 24 | … | 3 | 2 | |||||

| … | … | … | … | … | … | … | … | … | … |

| 22 | 21 | … | 24 | 23 | |||||

| 23 | 22 | … | 1 | 24 | |||||

| Standard Uncertainty | u | Degree of Freedom | ||

|---|---|---|---|---|

| measured value uncertainty, ε | 0.0676″ | 1 | 0.0676″ | 12 |

| Repeatability of angle error measurement | 0.0531″ | 1 | 0.0531″ | 5 |

| Resolution of the autocollimator | 0.0003″ | 1 | 0.0003″ | 50 |

| Traceability of the autocollimator | 0.0050″ | 1 | 0.0050″ | 50 |

| Angle error of autocollimator | 0.0404″ | 1 | 0.0404″ | 50 |

| Resolution of the rotary encoder | 0.0101″ | 1 | 0.0101″ | 50 |

| Residual setup error calculation | 0.0001″ | 1 | 0.0001″ | 50 |

| Repeatability of the pitch angle deviation measurement | 0.0490″ | 0.0401 | 0.0020″ | 5 |

| setup error uncertainty | 0.0144″ | 1 | 0.0144″ | 50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsieh, T.-H.; Watanabe, T.; Hsu, P.-E. Calibration of Rotary Encoders Using a Shift-Angle Method. Appl. Sci. 2022, 12, 5008. https://doi.org/10.3390/app12105008

Hsieh T-H, Watanabe T, Hsu P-E. Calibration of Rotary Encoders Using a Shift-Angle Method. Applied Sciences. 2022; 12(10):5008. https://doi.org/10.3390/app12105008

Chicago/Turabian StyleHsieh, Tsung-Han, Tsukasa Watanabe, and Po-Er Hsu. 2022. "Calibration of Rotary Encoders Using a Shift-Angle Method" Applied Sciences 12, no. 10: 5008. https://doi.org/10.3390/app12105008

APA StyleHsieh, T.-H., Watanabe, T., & Hsu, P.-E. (2022). Calibration of Rotary Encoders Using a Shift-Angle Method. Applied Sciences, 12(10), 5008. https://doi.org/10.3390/app12105008