Unsteady Aerodynamic Characteristics of a High-Speed Train Induced by the Sudden Change of Windbreak Wall Structure: A Case Study of the Xinjiang Railway

Abstract

:1. Introduction

2. Materials and Methods

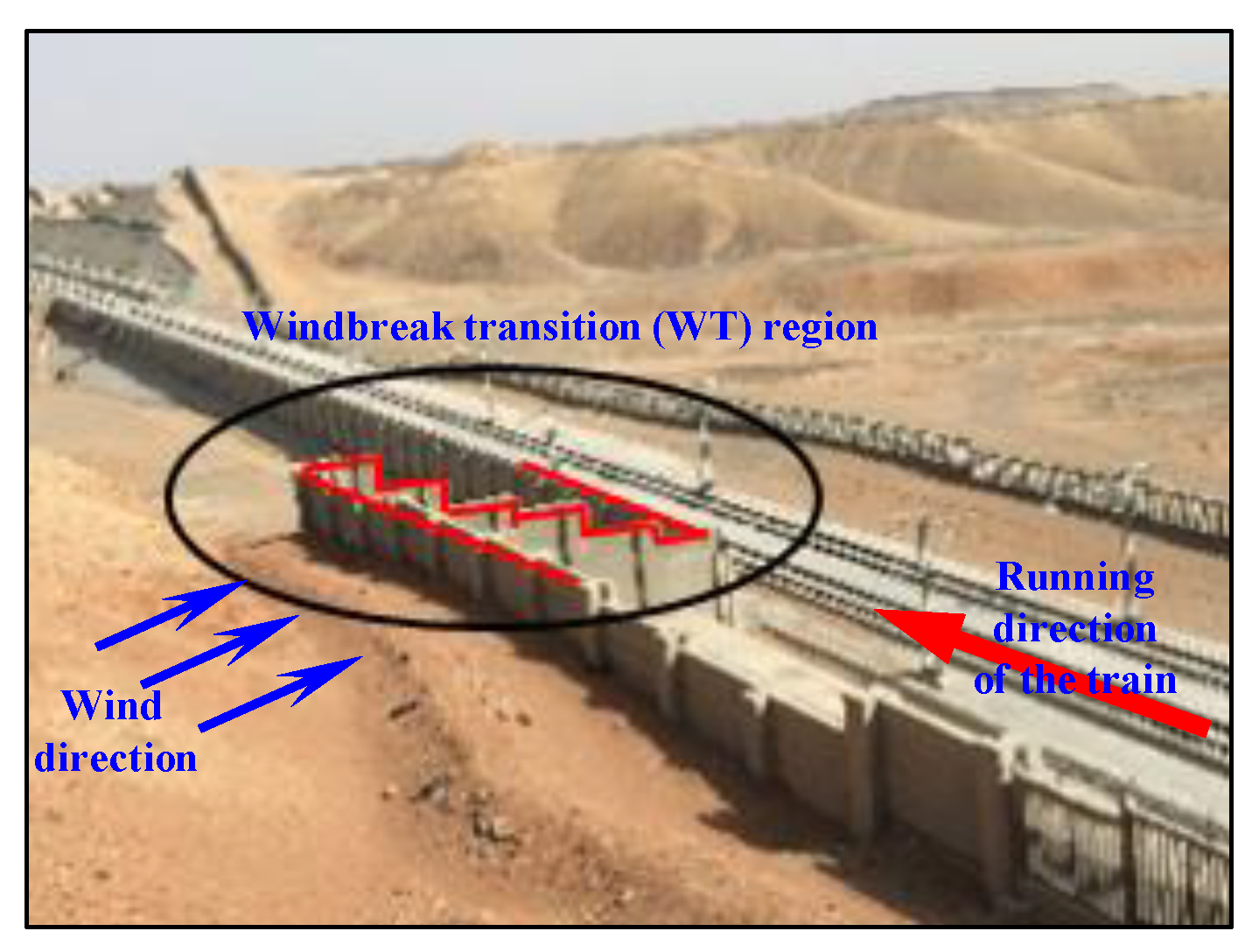

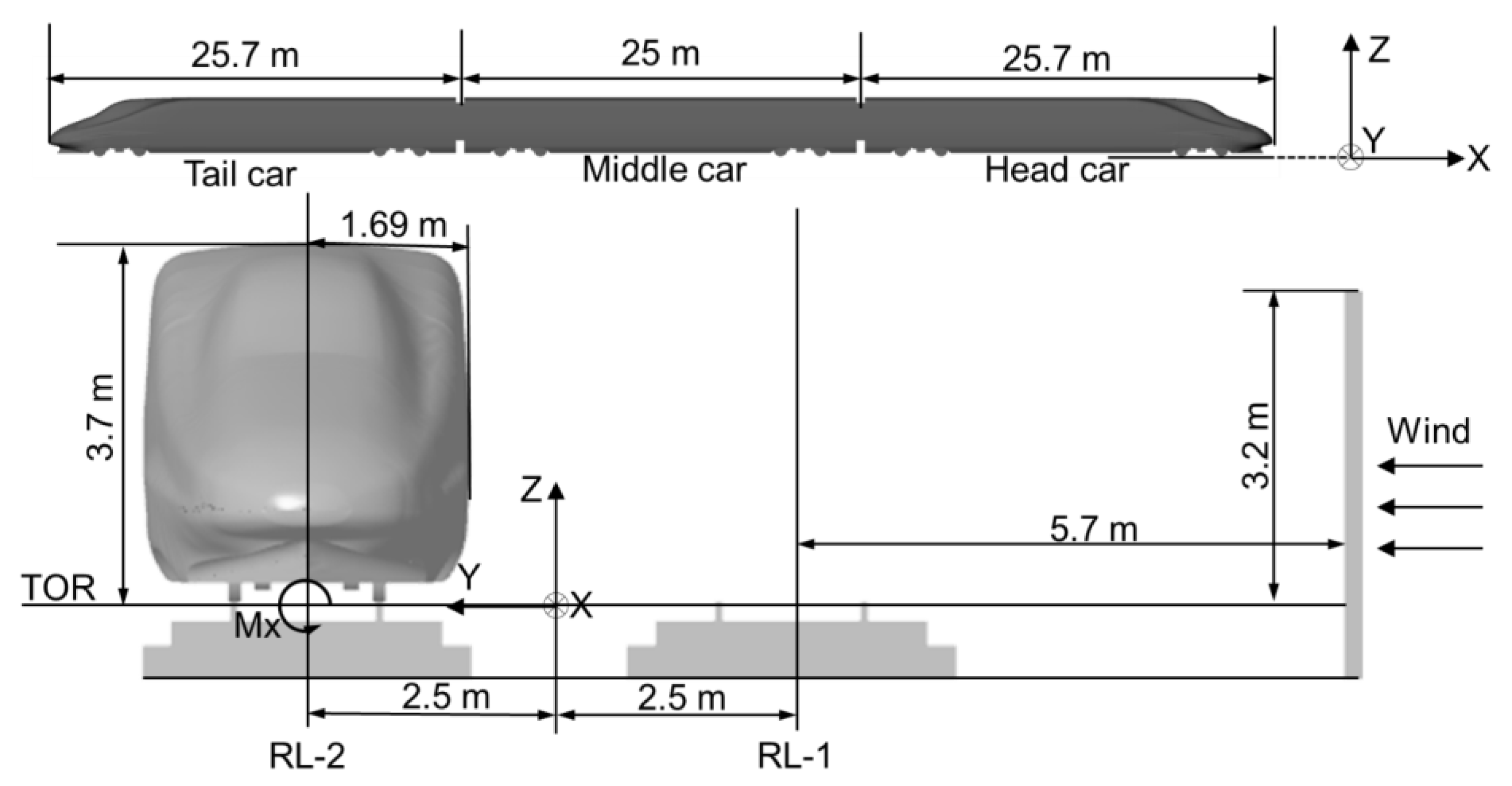

2.1. Objective Geometry

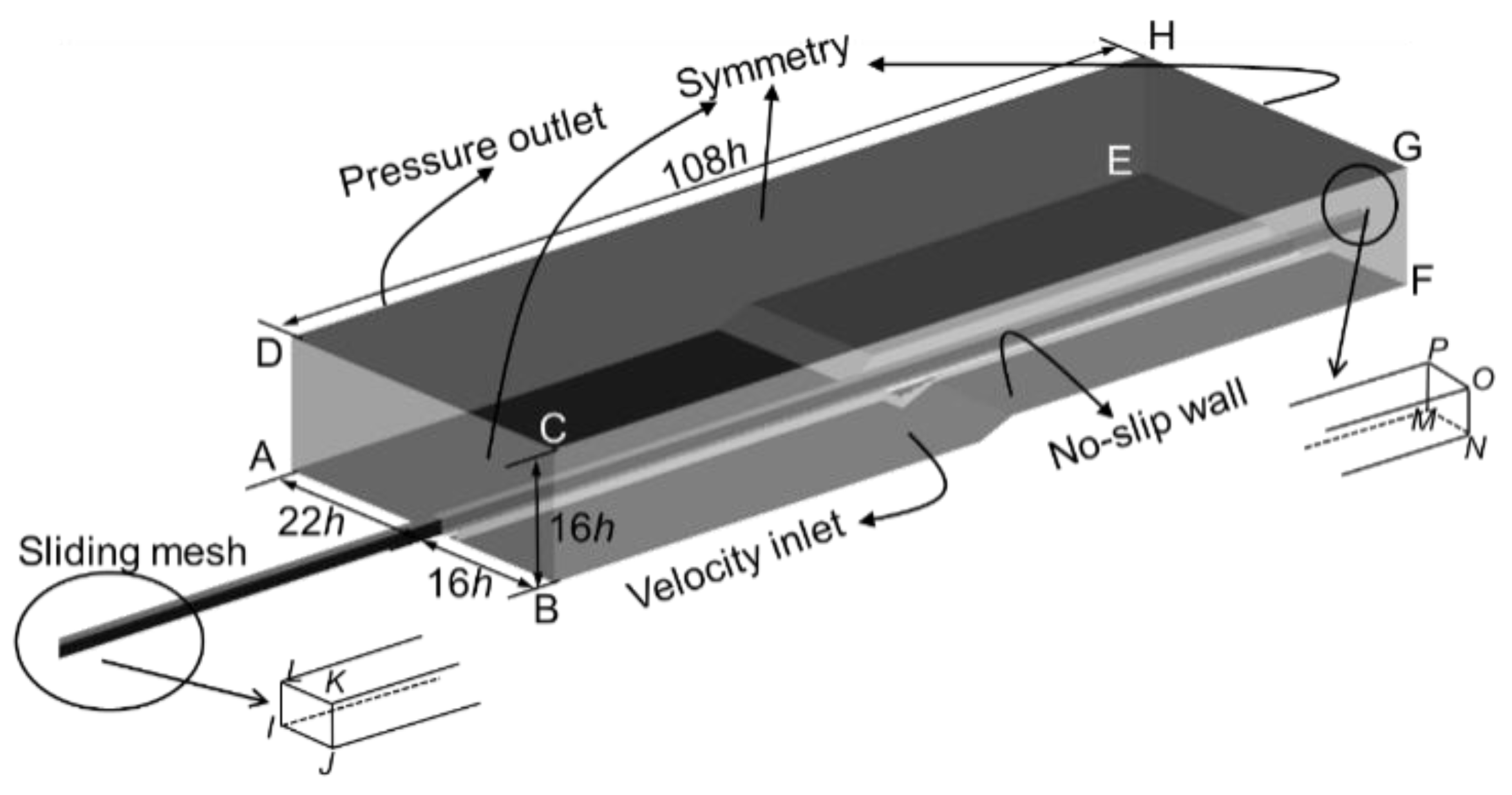

2.2. Research Method

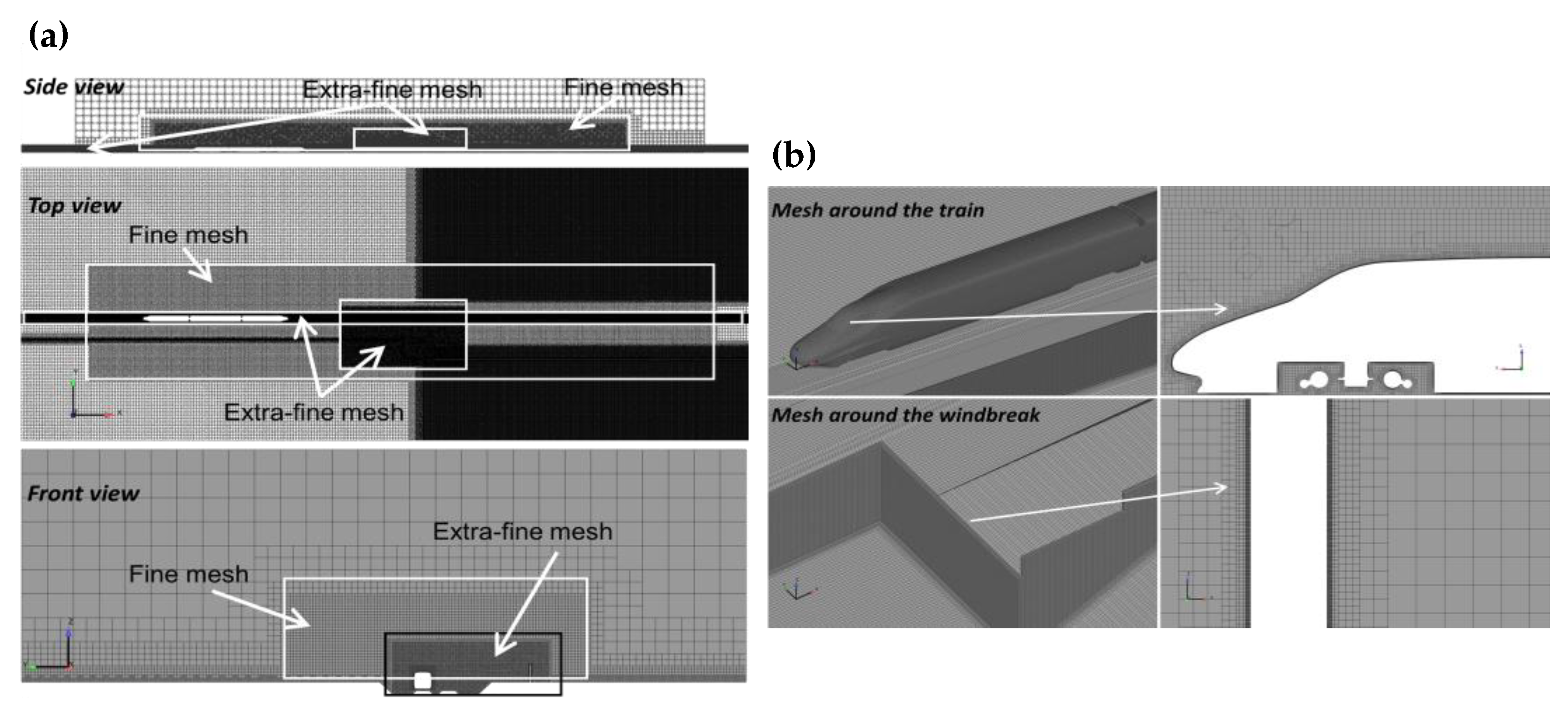

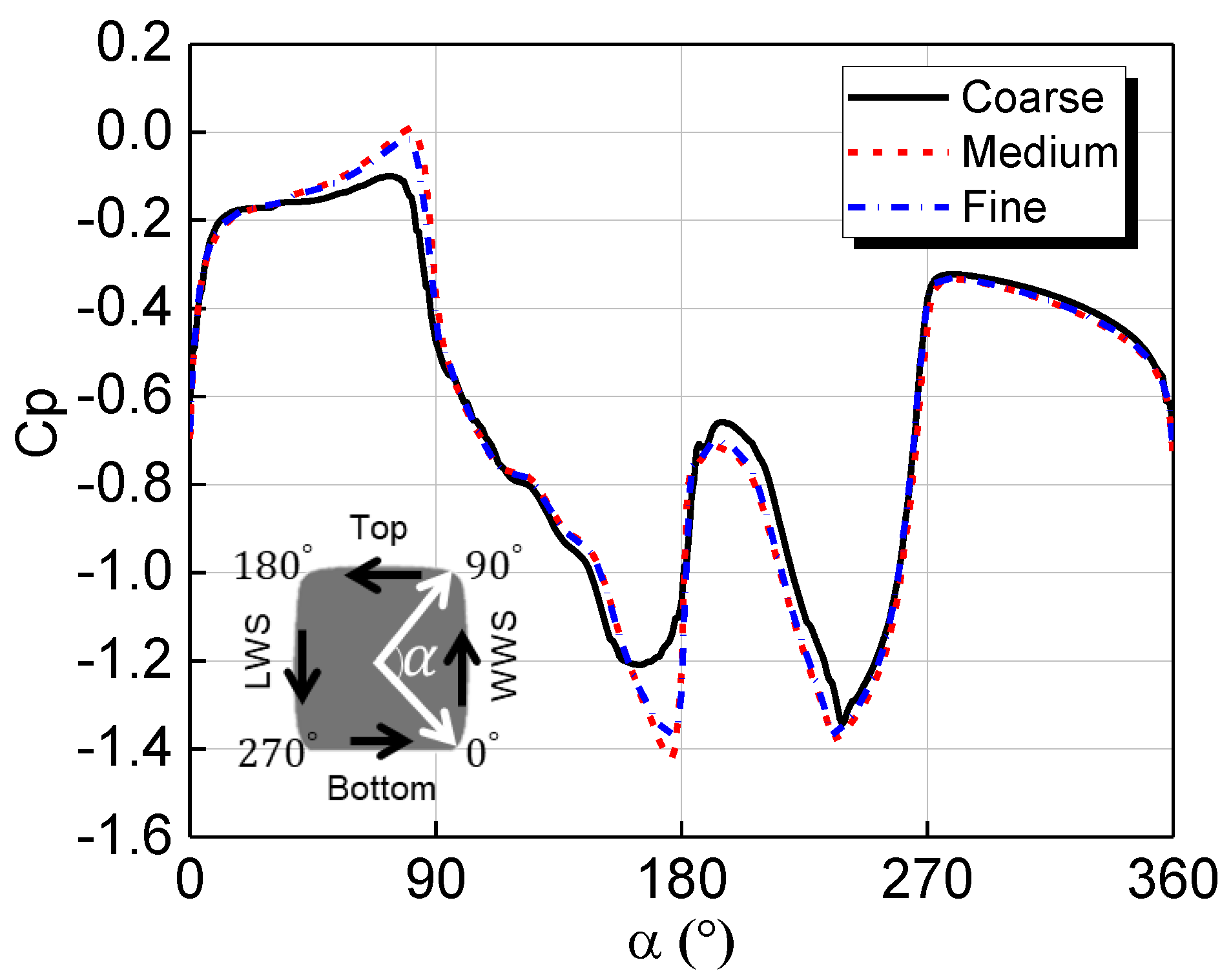

2.3. Computational Mesh

2.4. Data Processing

2.5. Results Validation

3. Results, Analysis, and Discussion

3.1. Transient Aerodynamic Forces

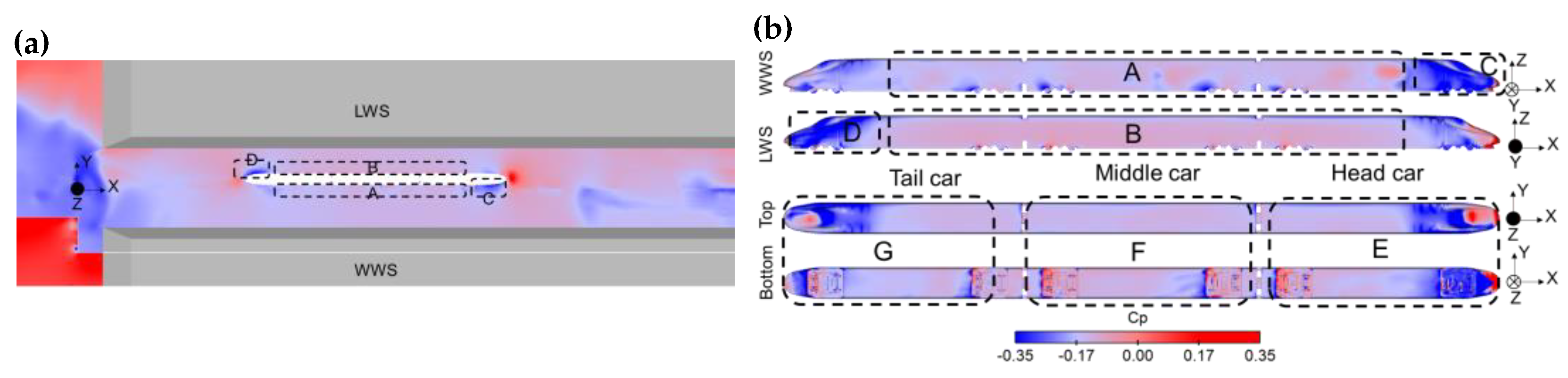

3.2. Transient Flow Structures

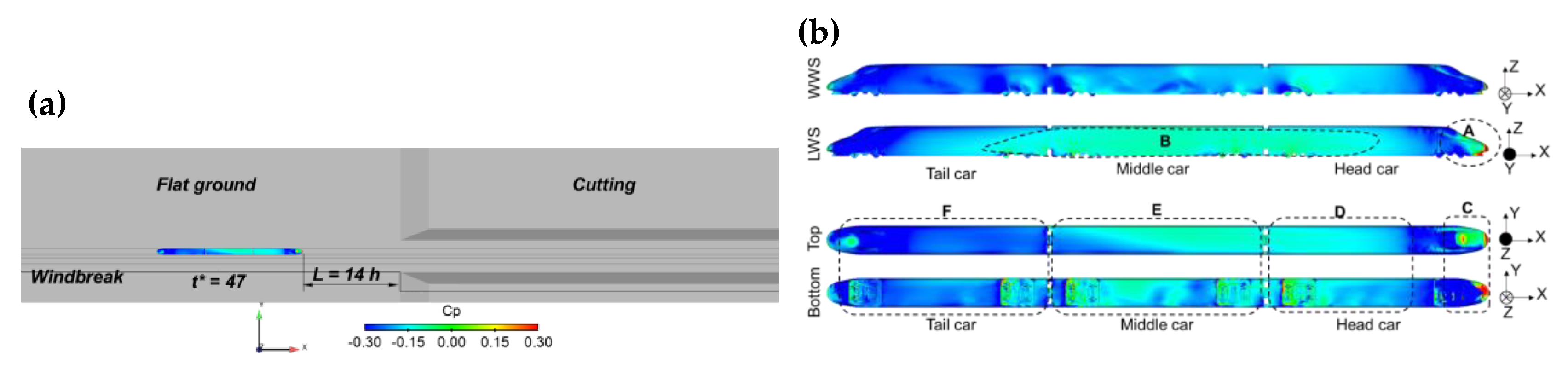

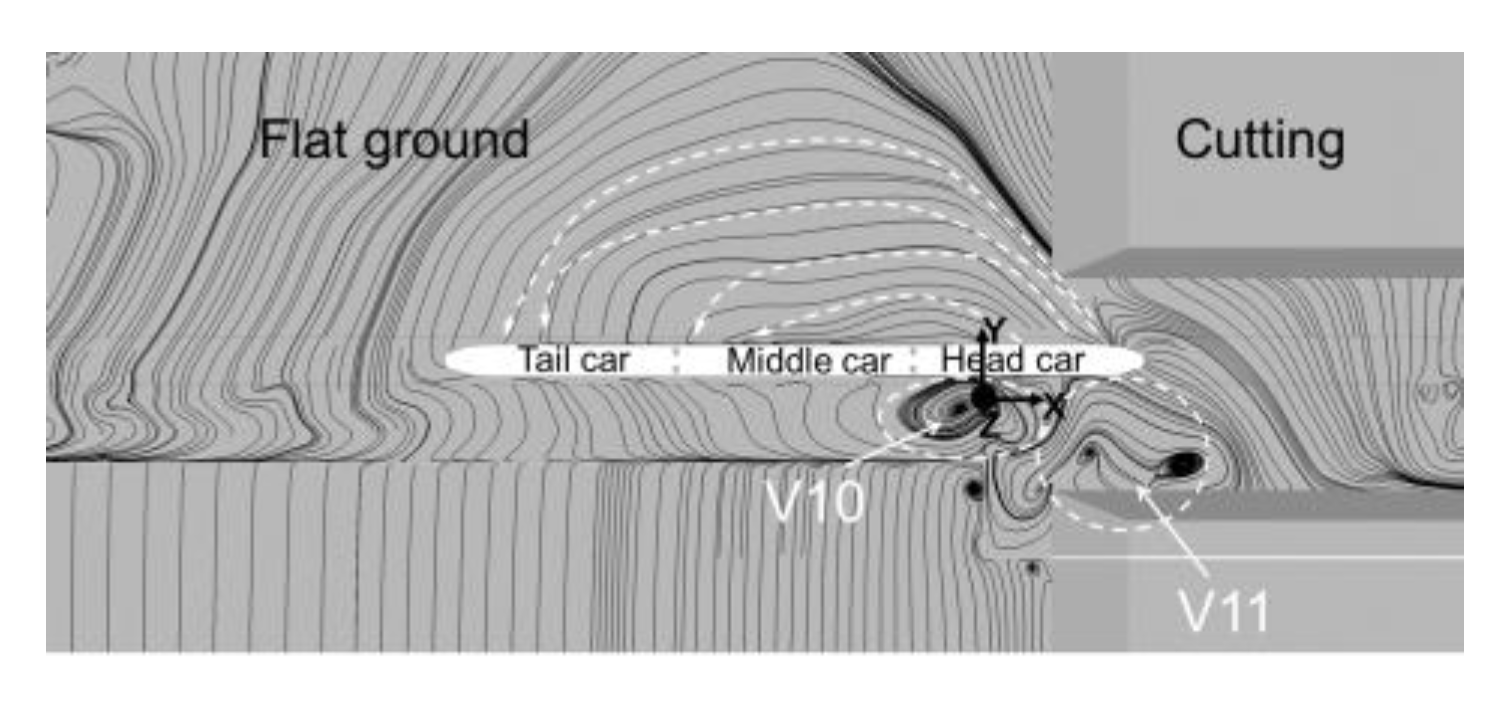

3.2.1. Flow Structures on Flat Ground: t* = 47

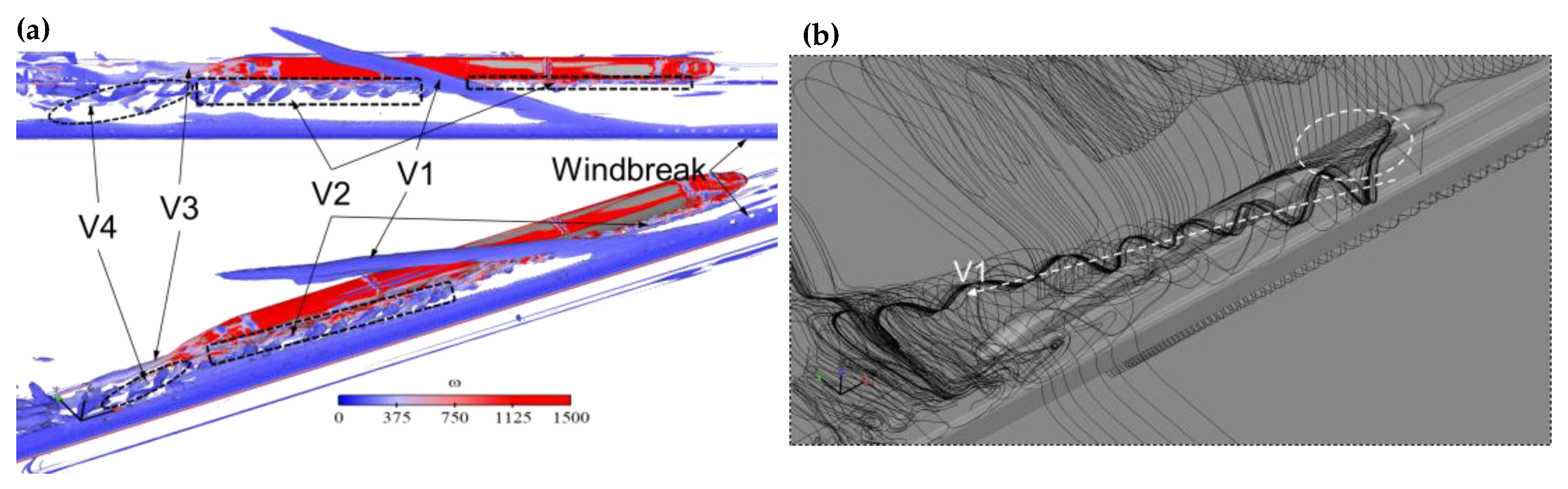

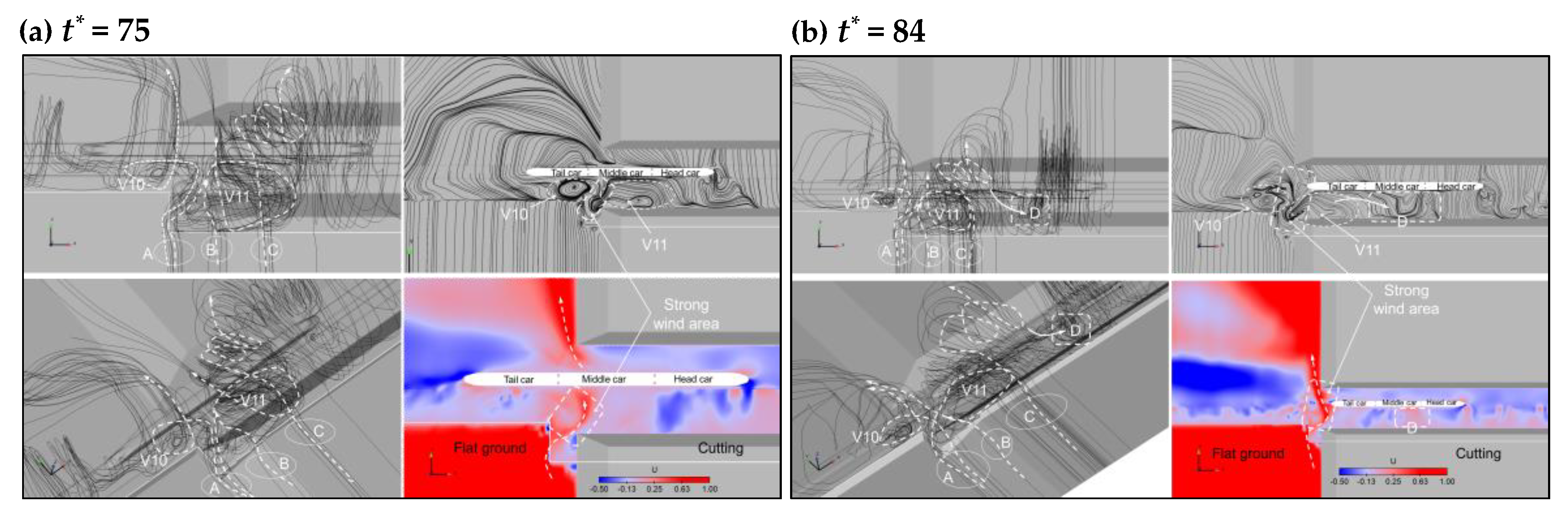

3.2.2. Flow Structures in the WT Region: t* = 65–48

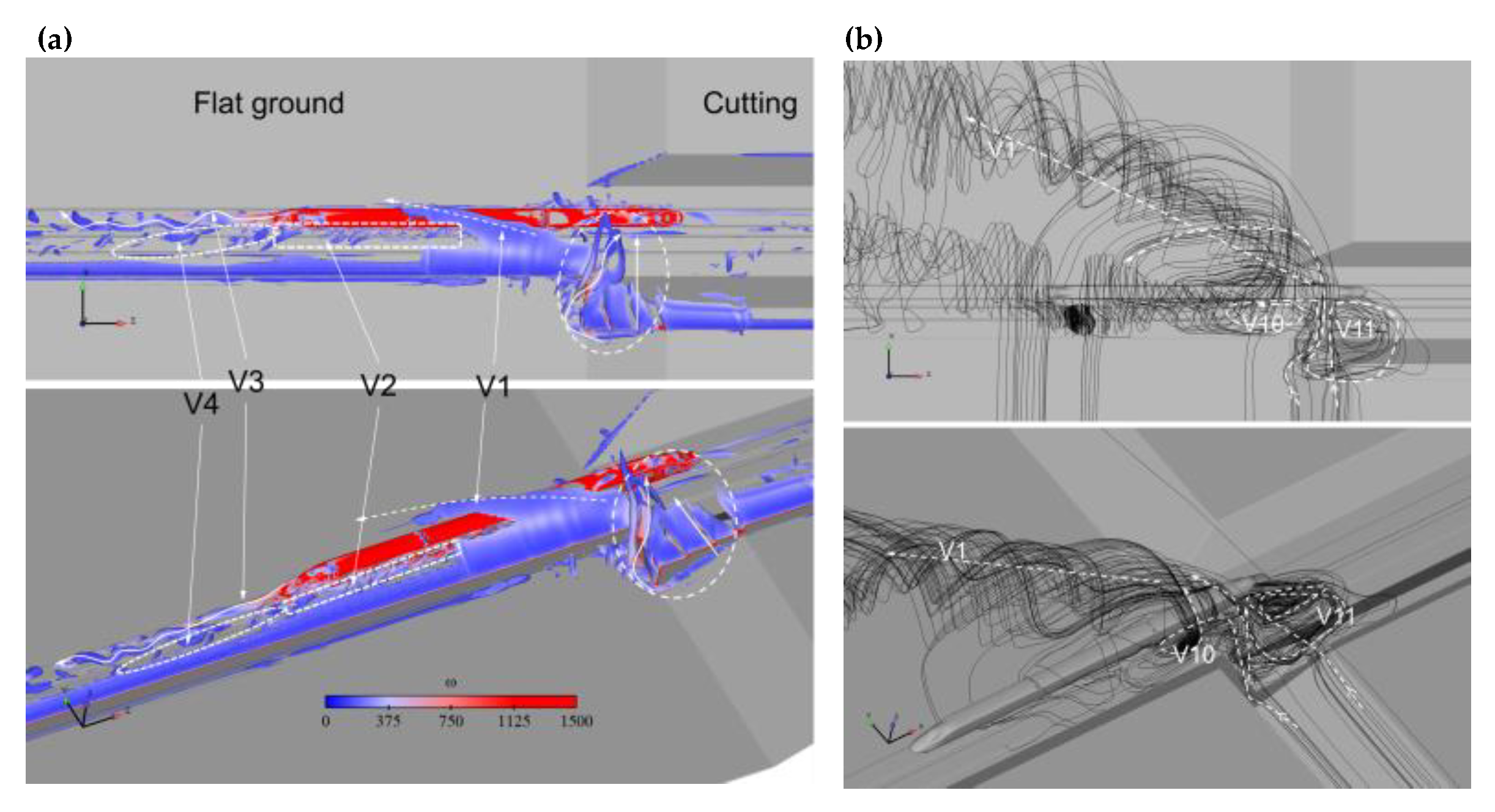

3.2.3. Flow Structures in Cutting Position: t* = 94

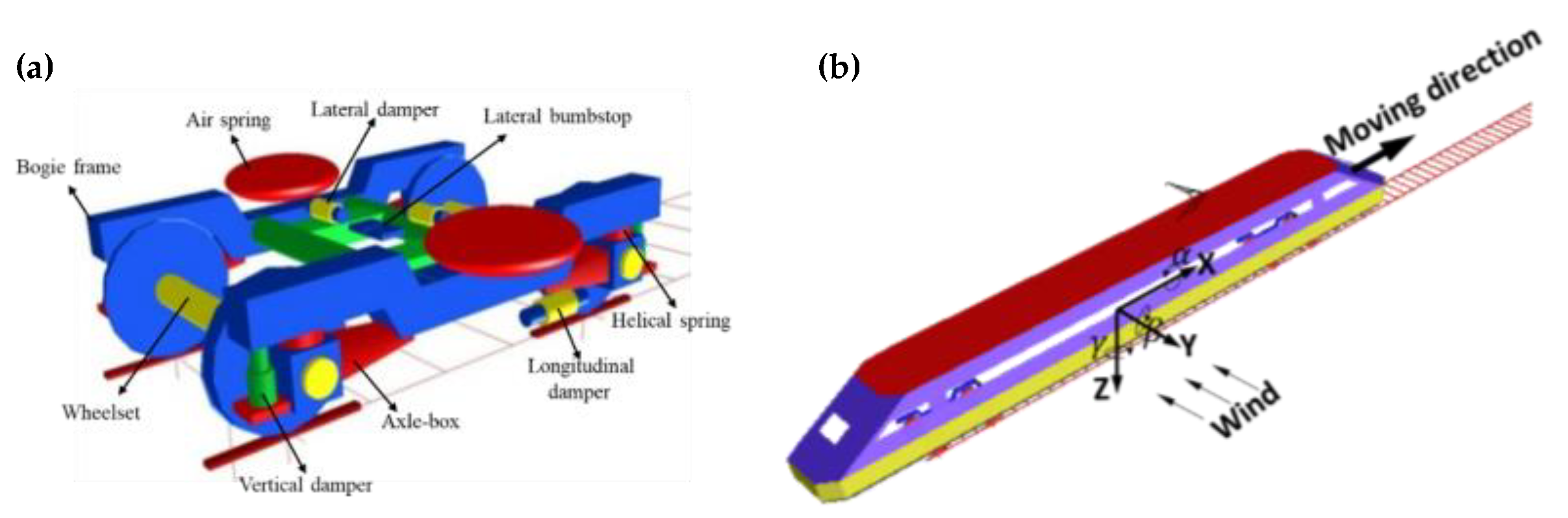

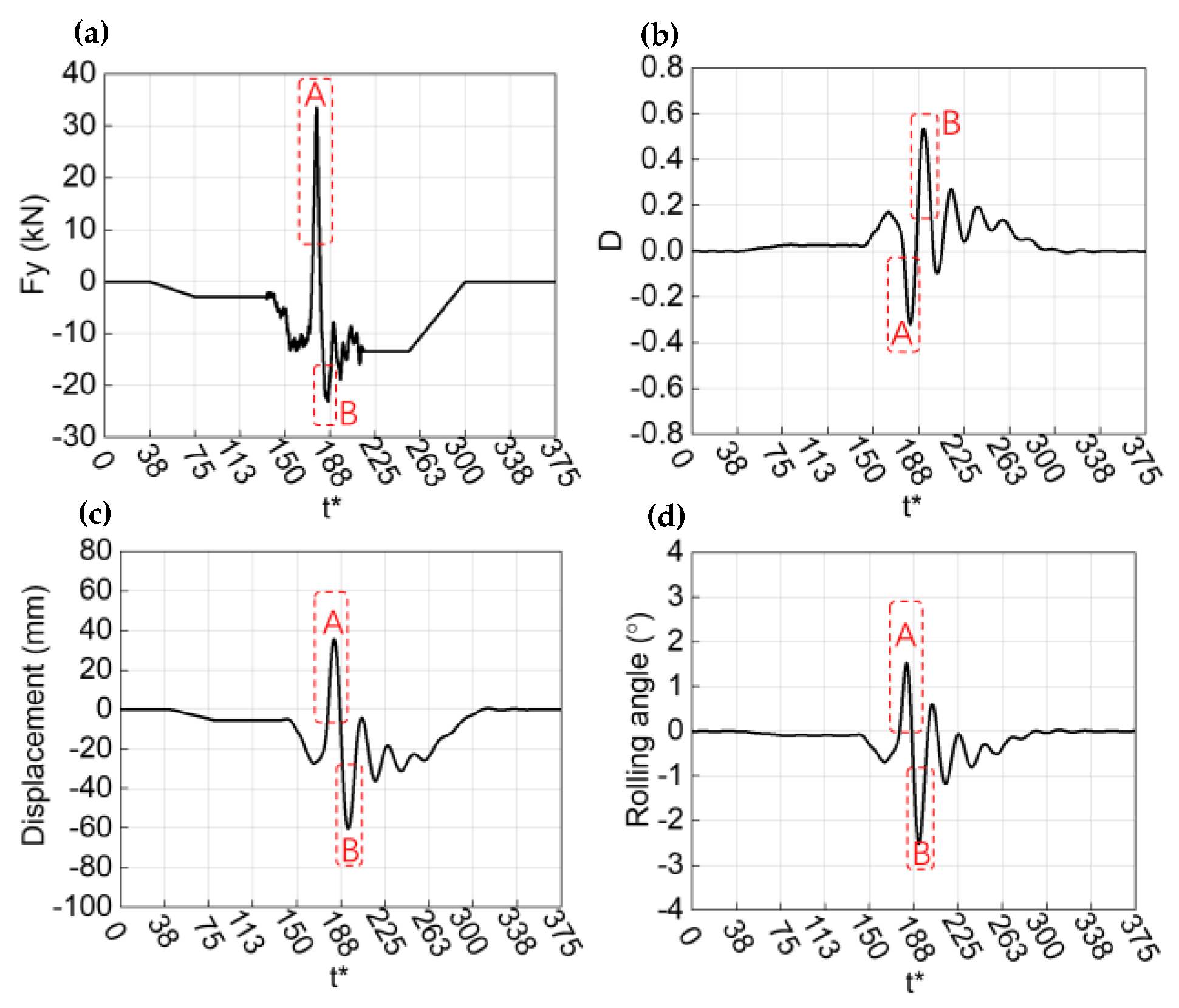

3.3. Analysis of Vehicle System Dynamic (VSD) Responses

4. Conclusions and Further Work

- The impact of the WT was the largest on the head car, and the continuous impact time of the WT was approximately Δt* = 47, Δt* = 50, and Δt* = 50 for the head car, middle car, and tail car, respectively. The sudden wind loads induced by the WT resulted from the position of the right-angle structure and an insufficient height region.

- The action mechanisms of the WT were the airflow rushed into the railway from the right-angle windbreak region and the slope region, with the airflow directly impacting the train. In particular, two main vortices generated by the WT, V10 and V11, played a key role.

- The WT region resulted in sudden and continuous dynamic impacts on the train, and the dynamic responses when the train recovered to the original state were also drastically. Under current running conditions, the dynamic overturning coefficients reached to 0.53, the lateral displacement was 60 mm, and the rolling angle was 2.5°.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Z.; Liu, T.; Jiang, Z.; Guo, Z.; Zhang, J. Comparative analysis of the effect of different nose lengths on train aerodynamic performance under crosswind. J. Fluids Struct. 2018, 78, 69–85. [Google Scholar] [CrossRef]

- Hemida, H.; Krajnović, S. LES study of the influence of the nose shape and yaw angles on flow structures around trains. J. Wind Eng. Ind. Aerodyn. 2010, 98, 34–46. [Google Scholar] [CrossRef]

- Chen, Z.; Ni, Y.; Wang, Y.; Wang, S.; Liu, T. Mitigating crosswind effect on high-speed trains by active blowing method: A comparative study. Eng. Appl. Comput. Fluid Mech. 2022, 16, 1064–1081. [Google Scholar] [CrossRef]

- Dong, X.; Liu, T.; Xia, Y.; Yang, F.; Chen, Z.; Guo, Z. Comparative analysis of the aerodynamic performance of trains and dynamic responses of catenaries for windbreak walls with different heights under crosswind. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2022, 78, 69–85. [Google Scholar] [CrossRef]

- Montenegro, P.; Barbosa, D.; Carvalho, H.; Calçada, R. Dynamic effects on a train-bridge system caused by stochastically generated turbulent wind fields. Eng. Struct. 2020, 211, 110430. [Google Scholar] [CrossRef]

- Liu, T.; Wang, L.; Gao, H.; Xia, Y.; Guo, Z.; Li, W.; Liu, H. Research progress on train operation safety in Xinjiang railway under wind environment. Transp. Saf. Environ. 2022, 4, tdac005. [Google Scholar] [CrossRef]

- Liu, T.-H.; Wang, L.; Chen, Z.-W.; Gao, H.-R.; Li, W.-H.; Guo, Z.-J.; Xia, Y.-T.; Huo, X.-S.; Wang, Y.-W. Study on the pressure pipe length in train aerodynamic tests and its applications in crosswinds. J. Wind. Eng. Ind. Aerodyn. 2022, 220, 104880. [Google Scholar] [CrossRef]

- Gallagher, M.; Morden, J.; Baker, C.; Soper, D.; Quinn, A.; Hemida, H.; Sterling, M. Trains in crosswinds–comparison of full-scale on-train measurements, physical model tests and CFD calculations. J. Wind. Eng. Ind. Aerodyn. 2018, 175, 428–444. [Google Scholar] [CrossRef] [Green Version]

- He, X.-h.; Zuo, T.-h.; Zou, Y.-f.; Yan, L.; Tang, L.-b. Experimental study on aerodynamic characteristics of a high-speed train on viaducts in turbulent crosswinds. J. Cent. South Univ. 2020, 27, 2465–2478. [Google Scholar] [CrossRef]

- Li, W.; Liu, T.; Martinez-Vazquez, P.; Guo, Z.; Huo, X.; Xia, Y.; Chen, Z. Effects of embankment layouts on train aerodynamics in a wind tunnel configuration. J. Wind. Eng. Ind. Aerodyn. 2022, 220, 104830. [Google Scholar] [CrossRef]

- Cheli, F.; Ripamonti, F.; Rocchi, D.; Tomasini, G. Aerodynamic behaviour investigation of the new EMUV250 train to cross wind. J. Wind. Eng. Ind. Aerodyn. 2010, 98, 189–201. [Google Scholar] [CrossRef]

- Sicot, C.; Deliancourt, F.; Boree, J.; Aguinaga, S.; Bouchet, J. Representativeness of geometrical details during wind tunnel tests. Application to train aerodynamics in crosswind conditions. J. Wind Eng. Ind. Aerodyn. 2018, 177, 186–196. [Google Scholar] [CrossRef]

- Xiang, H.; Li, Y.; Chen, S.; Li, C. A wind tunnel test method on aerodynamic characteristics of moving vehicles under crosswinds. J. Wind Eng. Ind. Aerodyn. 2017, 163, 15–23. [Google Scholar] [CrossRef]

- Liu, T.; Chen, Z.; Guo, Z.; Krajnović, S. Reasonable pressure tap layout to measure the aerodynamic forces of a train at different yaw angles. Measurement 2020, 166, 108255. [Google Scholar] [CrossRef]

- Dorigatti, F.; Sterling, M.; Baker, C.; Quinn, A. Crosswind effects on the stability of a model passenger train—A comparison of static and moving experiments. J. Wind Eng. Ind. Aerodyn. 2015, 138, 36–51. [Google Scholar] [CrossRef]

- Chen, Z.; Ni, Y. Sudden flow induced by mountain ridges beside windbreaks in a railway and its mitigation measures. Transp. Saf. Environ. 2022, 4, tdac004. [Google Scholar] [CrossRef]

- Chen, Z.-W.; Liu, T.-H.; Yan, C.-G.; Yu, M.; Guo, Z.-J.; Wang, T.-T. Numerical simulation and comparison of the slipstreams of trains with different nose lengths under crosswind. J. Wind. Eng. Ind. Aerodyn. 2019, 190, 256–272. [Google Scholar] [CrossRef]

- Flynn, D.; Hemida, H.; Baker, C. On the effect of crosswinds on the slipstream of a freight train and associated effects. J. Wind Eng. Ind. Aerodyn. 2016, 156, 14–28. [Google Scholar] [CrossRef] [Green Version]

- Guo, Z.; Liu, T.; Chen, Z.; Liu, Z.; Monzer, A.; Sheridan, J. Study of the flow around railway embankment of different heights with and without trains. J. Wind. Eng. Ind. Aerodyn. 2020, 202, 104203. [Google Scholar] [CrossRef]

- Dong, X.; Liu, T.; Shi, Z.; Xia, Y.; Yang, F.; Chen, Z. Influence of porosity of reformed earth embankment windbreak wall on flow field and displacement of catenary under crosswinds. J. Wind. Eng. Ind. Aerodyn. 2021, 214, 104652. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, M.; Li, Y.; Fang, C. Aerodynamic effects of subgrade-tunnel transition on high-speed railway by wind tunnel tests. Wind. Struct. 2019, 28, 203–213. [Google Scholar] [CrossRef]

- Li, Y.; Hu, P.; Cai, C.; Zhang, M.; Qiang, S. Wind tunnel study of a sudden change of train wind loads due to the wind shielding effects of bridge towers and passing trains. J. Eng. Mech. 2013, 139, 1249–1259. [Google Scholar] [CrossRef]

- Wu, M.; Li, Y.; Chen, N. The impact of artificial discrete simulation of wind field on vehicle running performance. Wind. Struct. 2015, 20, 169–189. [Google Scholar] [CrossRef]

- Lou, P.; Tao, W.; Cai, C.; He, X.; Zou, Y.; Ai, Y. Influence of Wind Barriers with Different Curvatures on Crosswind Aerodynamic Characteristics of a Train-Bridge System. Appl. Sci. 2022, 12, 1747. [Google Scholar] [CrossRef]

- Niu, J.; Zhang, Y.; Li, R.; Chen, Z.; Yao, H.; Wang, Y. Aerodynamic simulation of effects of one-and two-side windbreak walls on a moving train running on a double track railway line subjected to strong crosswind. J. Wind. Eng. Ind. Aerodyn. 2022, 221, 104912. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, T.; Li, M.; Yu, M.; Lu, Z.; Liu, D. Dynamic response of railway vehicles under unsteady aerodynamic forces caused by local landforms. Wind. Struct. 2019, 29, 149–161. [Google Scholar] [CrossRef]

- Huo, X.; Liu, T.; Chen, Z.; Li, W.; Gao, H.; Wang, S. Comparative analysis of the aerodynamic characteristics on double-unit trains formed by different types of high-speed train. J. Wind. Eng. Ind. Aerodyn. 2021, 217, 104757. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, T.; Yu, M.; Chen, G.; Chen, M.; Guo, Z. Experimental and numerical research on wind characteristics affected by actual mountain ridges and windbreaks: A case study of the Lanzhou-Xinjiang high-speed railway. Eng. Appl. Comput. Fluid Mech. 2020, 14, 1385–1403. [Google Scholar] [CrossRef]

- Niu, J.; Zhou, D.; Liang, X. Numerical investigation of the aerodynamic characteristics of high-speed trains of different lengths under crosswind with or without windbreaks. Eng. Appl. Comput. Fluid Mech. 2018, 12, 195–215. [Google Scholar] [CrossRef]

- Sun, Z.; Hashmi, S.A.; Dai, H.; Cheng, X.; Zhang, T.; Chen, Z. Safety comparisons of a high-speed train’s head and tail passing by a windbreak breach. Veh. Syst. Dyn. 2021, 59, 823–840. [Google Scholar] [CrossRef]

- Hashmi, S.A.; Hemida, H.; Soper, D. Wind tunnel testing on a train model subjected to crosswinds with different windbreak walls. J. Wind. Eng. Ind. Aerodyn. 2019, 195, 104013. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, T.; Zhou, X.; Niu, J. Impact of ambient wind on aerodynamic performance when two trains intersect inside a tunnel. J. Wind. Eng. Ind. Aerodyn. 2017, 169, 139–155. [Google Scholar] [CrossRef]

- Mamouri, A.R.; Lakzian, E.; Khoshnevis, A.B. Entropy analysis of pitching airfoil for offshore wind turbines in the dynamic stall condition. Ocean. Eng. 2019, 187, 106229. [Google Scholar] [CrossRef]

- Liu, T.; Chen, Z.; Zhou, X.; Zhang, J. A CFD analysis of the aerodynamics of a high-speed train passing through a windbreak transition under crosswind. Eng. Appl. Comput. Fluid Mech. 2018, 12, 137–151. [Google Scholar] [CrossRef] [Green Version]

- Deng, E.; Yang, W.; Lei, M.; Zhu, Z.; Zhang, P. Aerodynamic loads and traffic safety of high-speed trains when passing through two windproof facilities under crosswind: A comparative study. Eng. Struct. 2019, 188, 320–339. [Google Scholar] [CrossRef]

- Morden, J.A.; Hemida, H.; Baker, C. Comparison of RANS and detached eddy simulation results to wind-tunnel data for the surface pressures upon a class 43 high-speed train. J. Fluids Eng. 2015, 137. [Google Scholar] [CrossRef]

- Yao, S.-B.; Sun, Z.-X.; Guo, D.-L.; Chen, D.-W.; Yang, G.-W. Numerical study on wake characteristics of high-speed trains. Acta Mech. Sin. 2013, 29, 811–822. [Google Scholar] [CrossRef] [Green Version]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef] [Green Version]

- ANSYS, F. ANSYS Fluent Theory Guide 18.1; ANSYS, Inc.: Canonsburg, PA, USA, 2017; Available online: http://www.ansys.com (accessed on 1 June 2022).

- Zhang, L.; Yang, M.-z.; Liang, X.-f. Experimental study on the effect of wind angles on pressure distribution of train streamlined zone and train aerodynamic forces. J. Wind. Eng. Ind. Aerodyn. 2018, 174, 330–343. [Google Scholar] [CrossRef]

- Chen, G.; Li, X.-B.; Liu, Z.; Zhou, D.; Wang, Z.; Liang, X.-F.; Krajnovic, S. Dynamic analysis of the effect of nose length on train aerodynamic performance. J. Wind Eng. Ind. Aerodyn. 2019, 184, 198–208. [Google Scholar] [CrossRef]

- Wang, J.; Minelli, G.; Dong, T.; Chen, G.; Krajnović, S. The effect of bogie fairings on the slipstream and wake flow of a high-speed train. An IDDES study. J. Wind. Eng. Ind. Aerodyn. 2019, 191, 183–202. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, T.; Li, W.; Guo, Z.; Xia, Y. Aerodynamic performance and dynamic behaviors of a train passing through an elongated hillock region beside a windbreak under crosswinds and corresponding flow mitigation measures. J. Wind Eng. Ind. Aerodyn. 2021, 208, 104434. [Google Scholar] [CrossRef]

- Ershkov, S.V. Non-stationary Riccati-type flows for incompressible 3D Navier–Stokes equations. Comput. Math. Appl. 2016, 71, 1392–1404. [Google Scholar] [CrossRef]

- Miloh, T.; Landweber, L. Generalization of the Kelvin–Kirchhoff equations for the motion of a body through a fluid. Phys. Fluids 1981, 24, 6–9. [Google Scholar] [CrossRef]

| Item | Coarse | Medium | Fine |

|---|---|---|---|

| Number of volume meshes/million | 22 | 41 | 64 |

| Size of the smallest mesh on train surface/mm | 3.1 | 1–1.6 | 0.96 |

| Number of prism layers | 10 | 10 | 10 |

| First boundary layer/mm | 0.31 | 0.1–0.16 | 0.096 |

| CFy | CFz | |||||

|---|---|---|---|---|---|---|

| Head Car | Middle Car | Tail Car | Head Car | Middle Car | Tail Car | |

| Test | 1.932 | 0.942 | 0.302 | 1.999 | 1.464 | 1.198 |

| Numerical | 2.010 | 0.957 | 0.312 | 2.012 | 1.480 | 1.253 |

| Error | 4.04% | 1.59% | 3.31% | 0.65% | 1.09% | 4.59% |

| Flat Ground | Transition Region: Maximum Sudden Peak Value | Cutting | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Head Car | Middle Car | Tail Car | Head Car | Middle Car | Tail Car | Head Car | Middle Car | Tail Car | |

| CFy | −0.20 | −0.50 | −0.10 | 1.00 | 0.30 | 0.48 | −0.40 | −0.22 | 0.00 |

| CFz | −0.14 | −0.02 | 0.38 | 0.21 | 0.36 | 0.40 | 0.02 | 0.10 | 0.20 |

| CMx | 0.03 | 0.28 | 0.10 | −0.56 | −0.20 | −0.28 | 0.18 | 0.10 | 0.00 |

| D | Lateral Displacement (mm) | Rolling Angle (°) | |

|---|---|---|---|

| Maximum positive value | 0.53 | 35 | 1.55 |

| Maximum negative value | −0.32 | −60 | −2.5 |

| Peak-to-peak value | 0.85 | 95 | 4.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.-W.; Rui, E.-Z.; Liu, T.-H.; Ni, Y.-Q.; Huo, X.-S.; Xia, Y.-T.; Li, W.-H.; Guo, Z.-J.; Zhou, L. Unsteady Aerodynamic Characteristics of a High-Speed Train Induced by the Sudden Change of Windbreak Wall Structure: A Case Study of the Xinjiang Railway. Appl. Sci. 2022, 12, 7217. https://doi.org/10.3390/app12147217

Chen Z-W, Rui E-Z, Liu T-H, Ni Y-Q, Huo X-S, Xia Y-T, Li W-H, Guo Z-J, Zhou L. Unsteady Aerodynamic Characteristics of a High-Speed Train Induced by the Sudden Change of Windbreak Wall Structure: A Case Study of the Xinjiang Railway. Applied Sciences. 2022; 12(14):7217. https://doi.org/10.3390/app12147217

Chicago/Turabian StyleChen, Zheng-Wei, En-Ze Rui, Tang-Hong Liu, Yi-Qing Ni, Xiao-Shuai Huo, Yu-Tao Xia, Wen-Hui Li, Zi-Jian Guo, and Lei Zhou. 2022. "Unsteady Aerodynamic Characteristics of a High-Speed Train Induced by the Sudden Change of Windbreak Wall Structure: A Case Study of the Xinjiang Railway" Applied Sciences 12, no. 14: 7217. https://doi.org/10.3390/app12147217

APA StyleChen, Z.-W., Rui, E.-Z., Liu, T.-H., Ni, Y.-Q., Huo, X.-S., Xia, Y.-T., Li, W.-H., Guo, Z.-J., & Zhou, L. (2022). Unsteady Aerodynamic Characteristics of a High-Speed Train Induced by the Sudden Change of Windbreak Wall Structure: A Case Study of the Xinjiang Railway. Applied Sciences, 12(14), 7217. https://doi.org/10.3390/app12147217