Rolling Bearing Fault Diagnosis Based on Depth-Wise Separable Convolutions with Multi-Sensor Data Weighted Fusion

Abstract

:1. Introduction

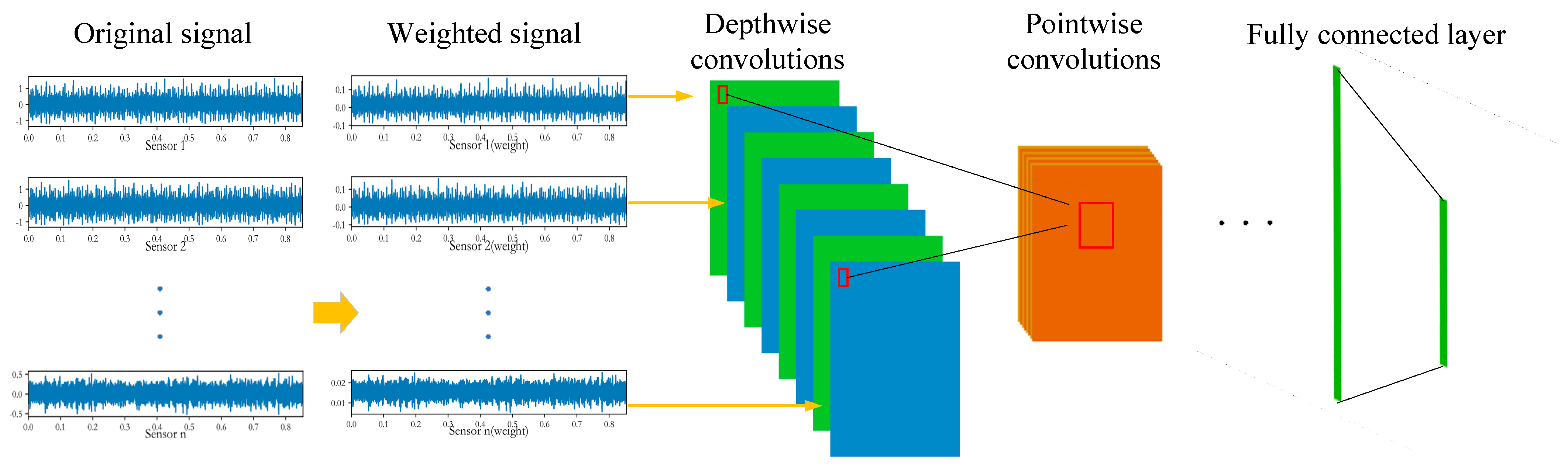

2. Basic Method

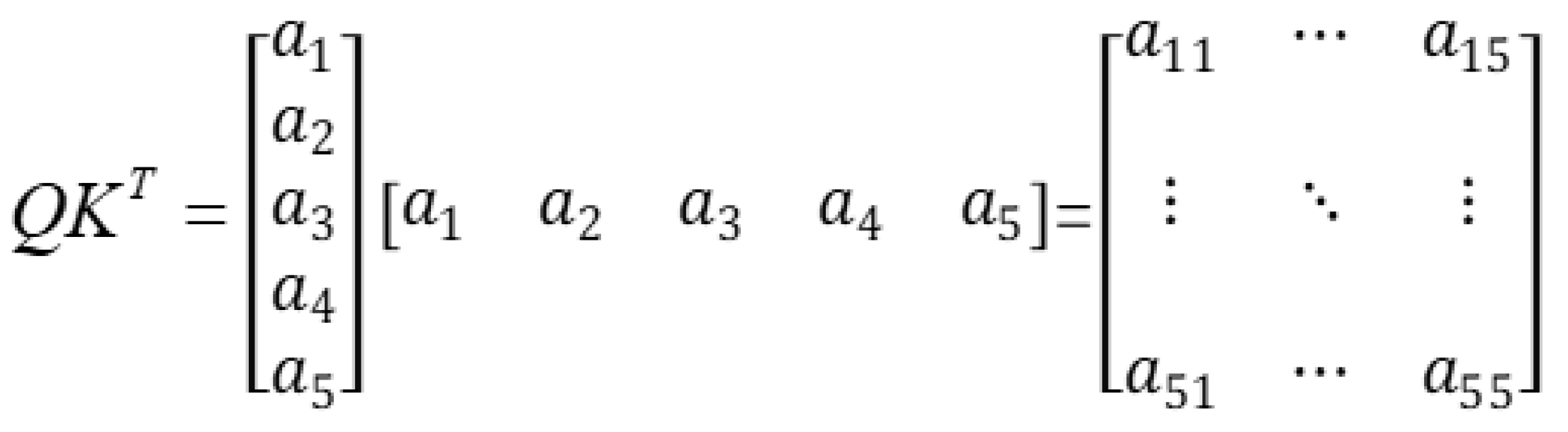

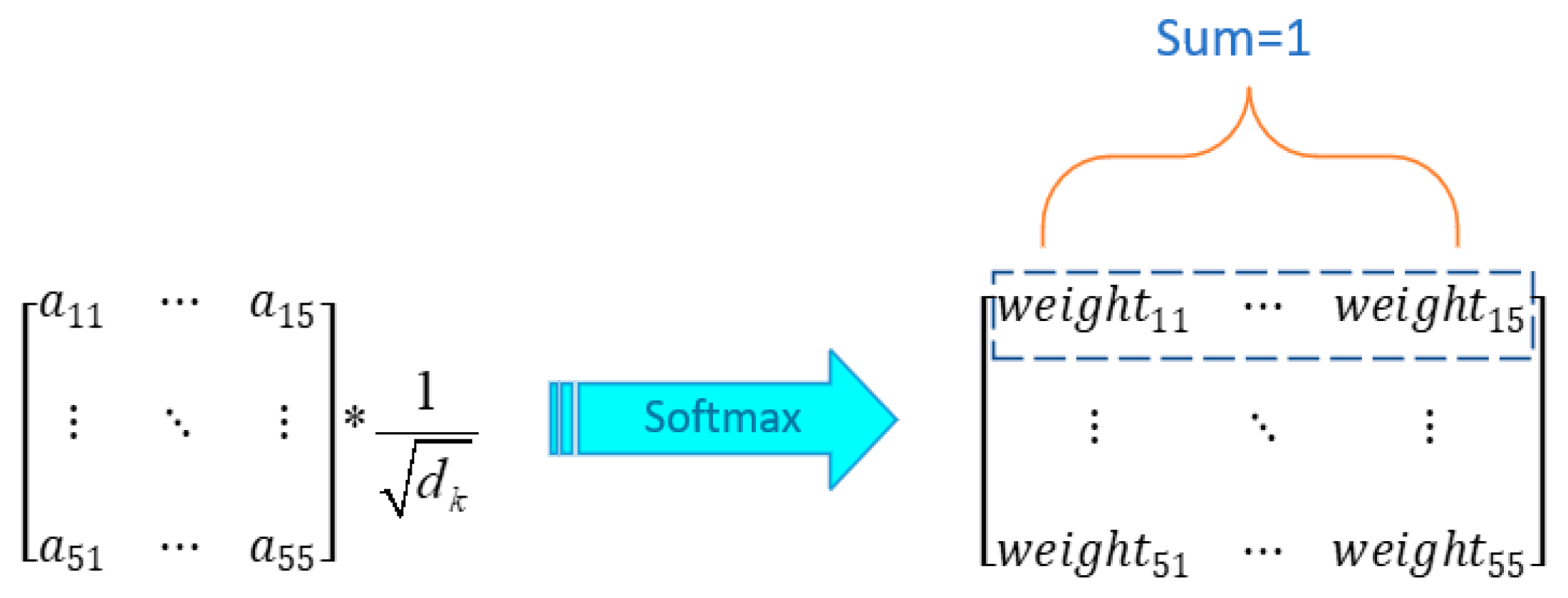

2.1. SAM

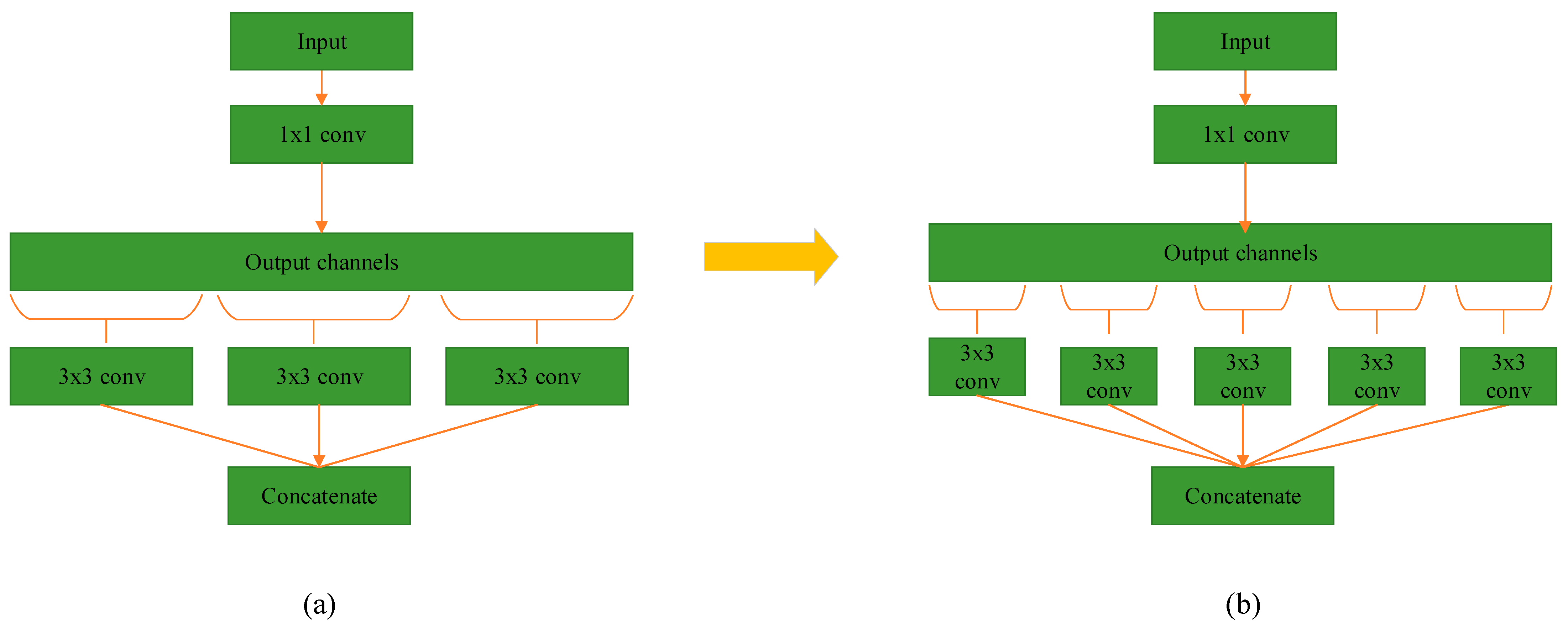

2.2. Depth-Wise Separable Convolutions

3. Proposed Method Based on MSDWF and DWSC

4. Experiment Validation

4.1. Case 1: Bearing Fault Diagnosis Based on CWRU Bearing Datasets

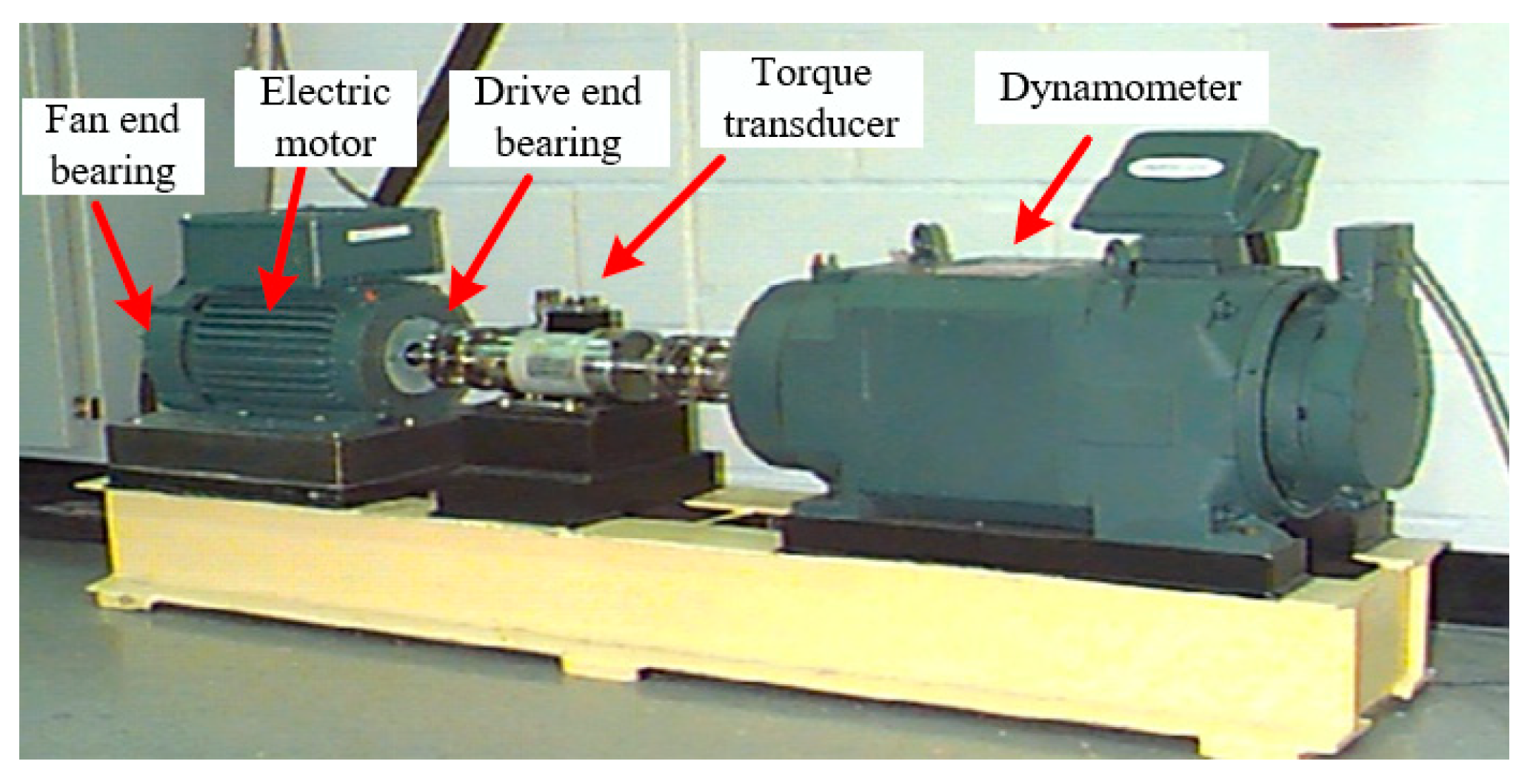

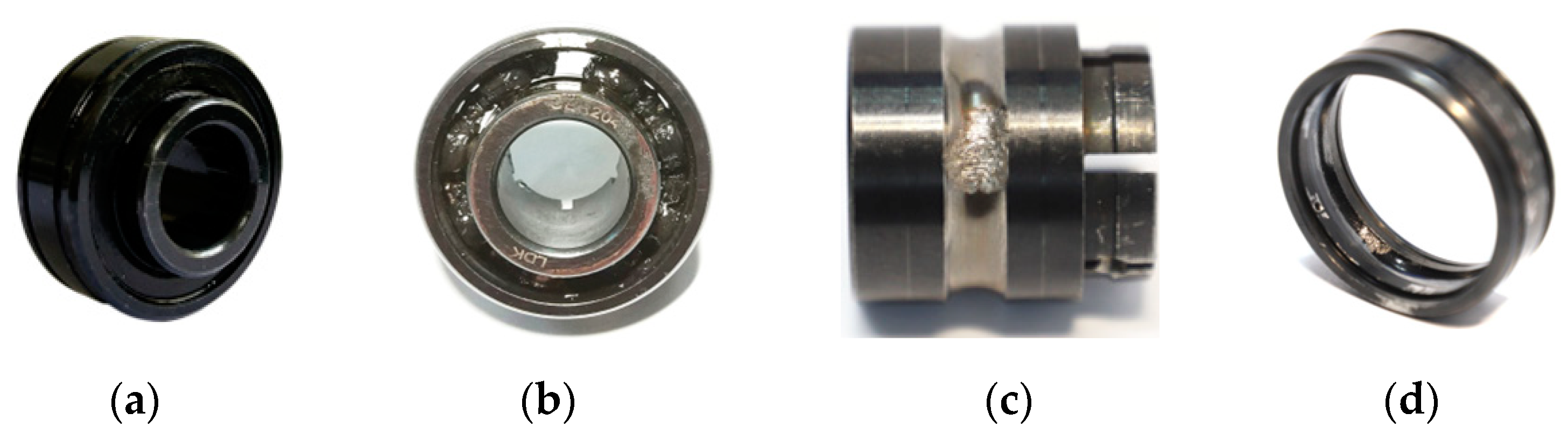

4.1.1. Experiment Setup and Data Description

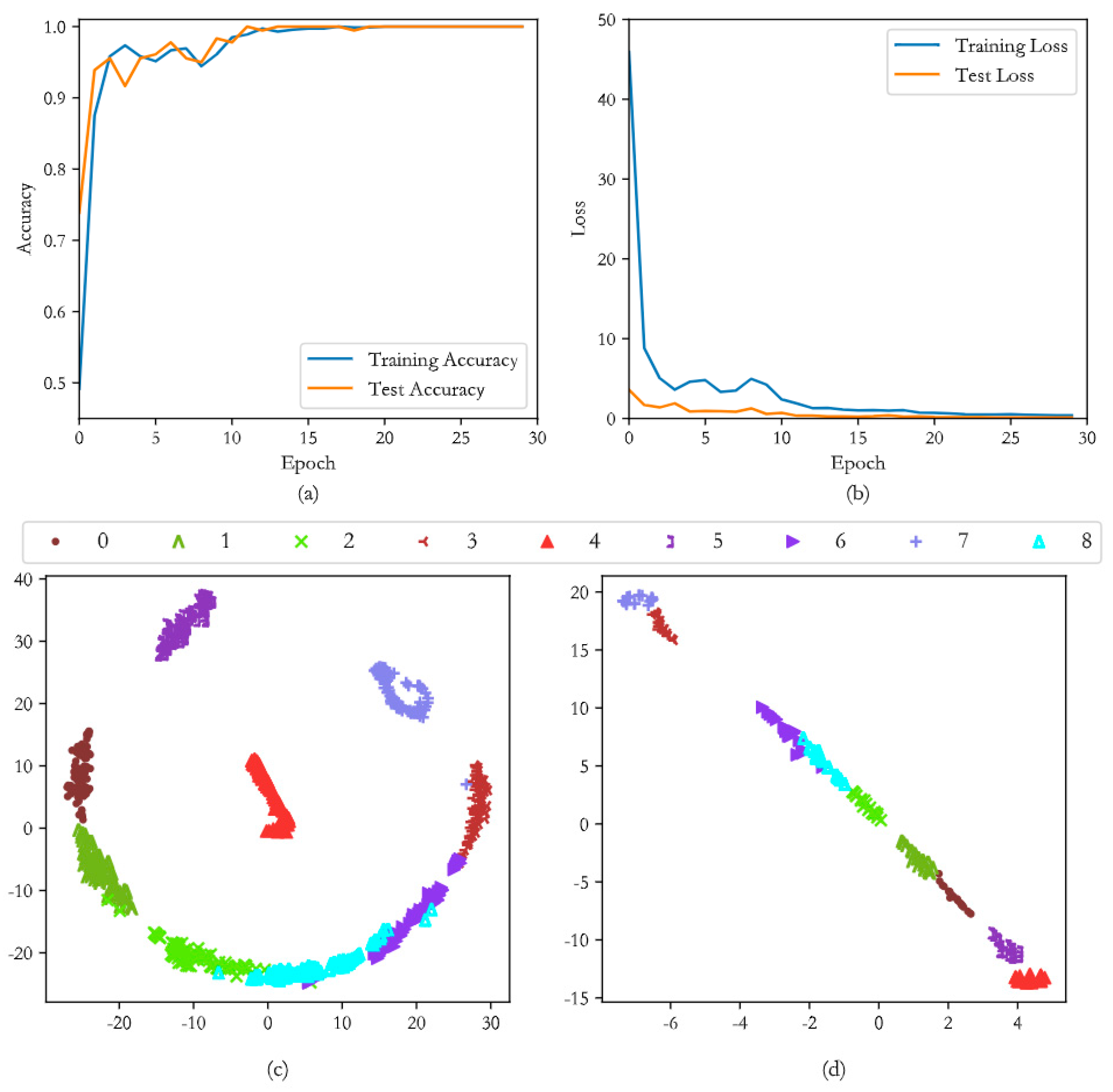

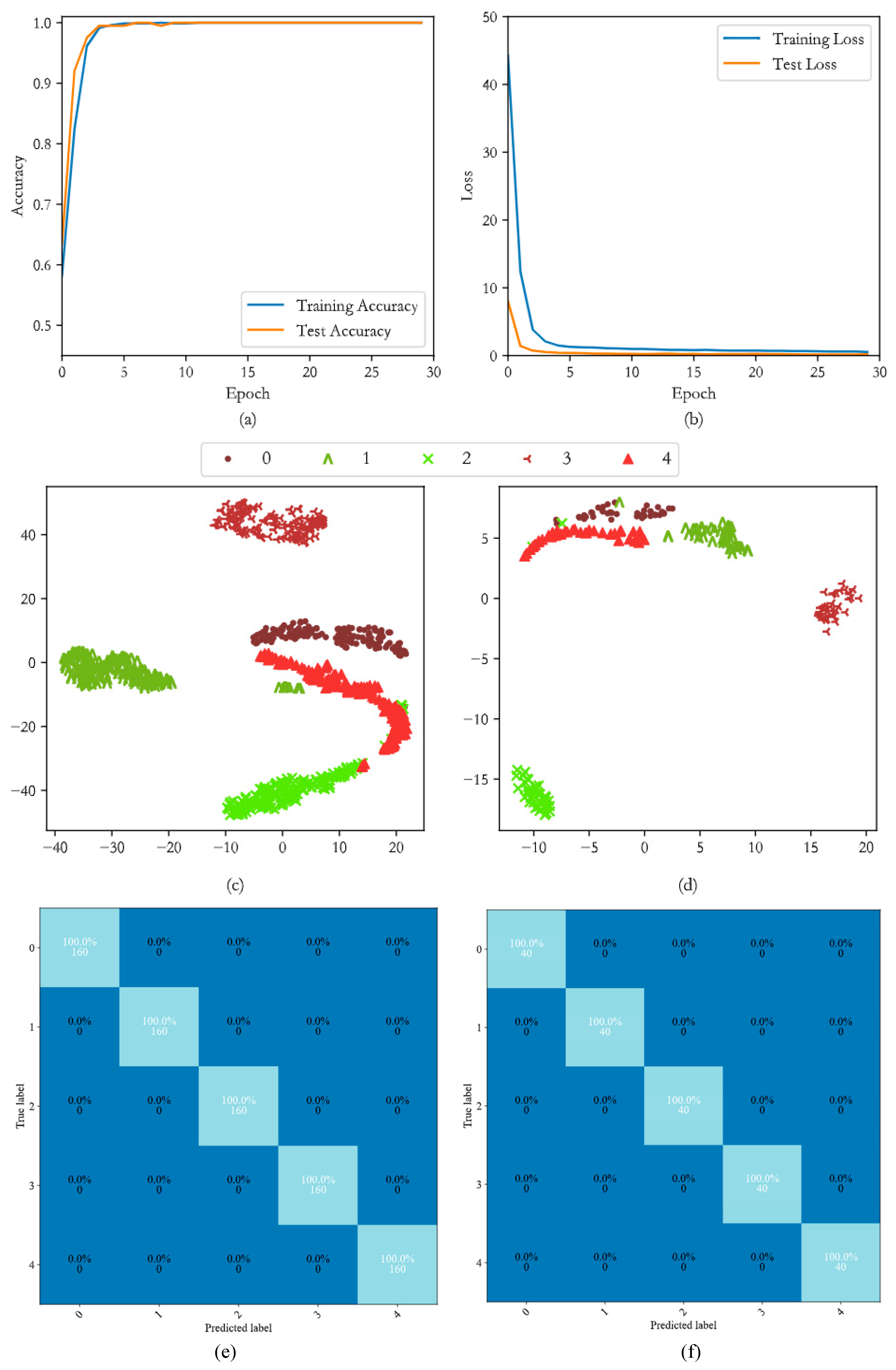

4.1.2. Model Parameters and Results Analysis

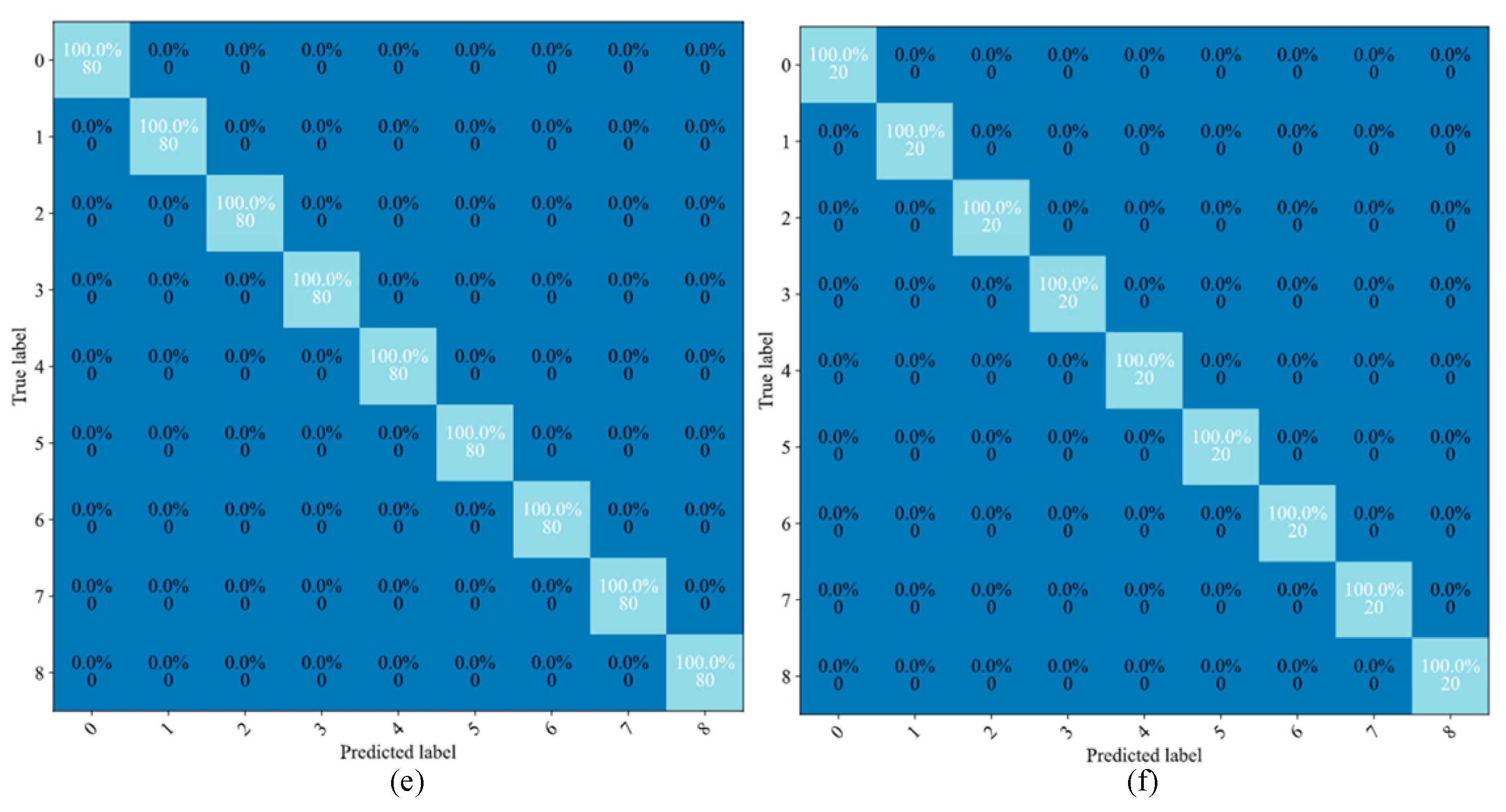

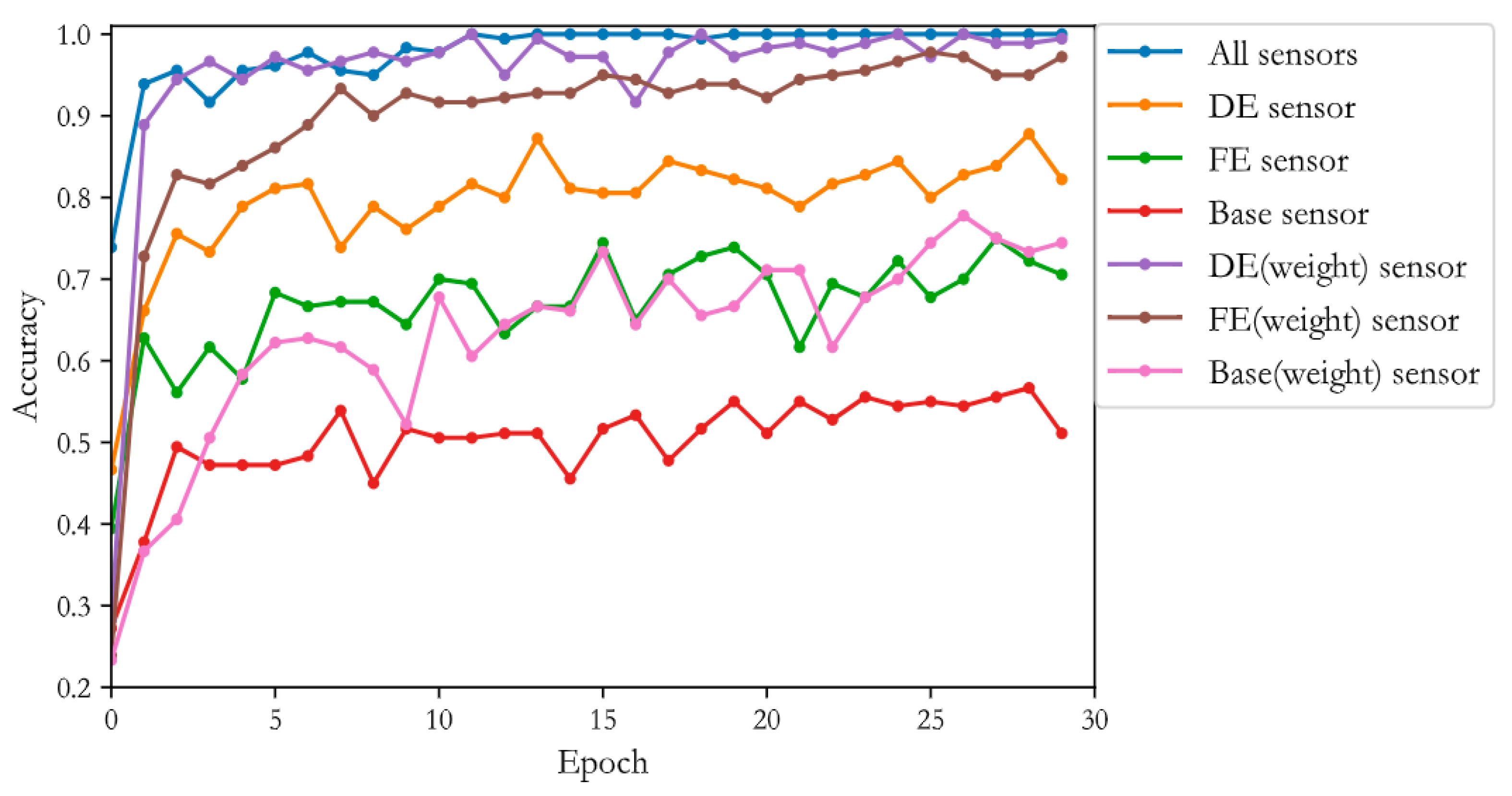

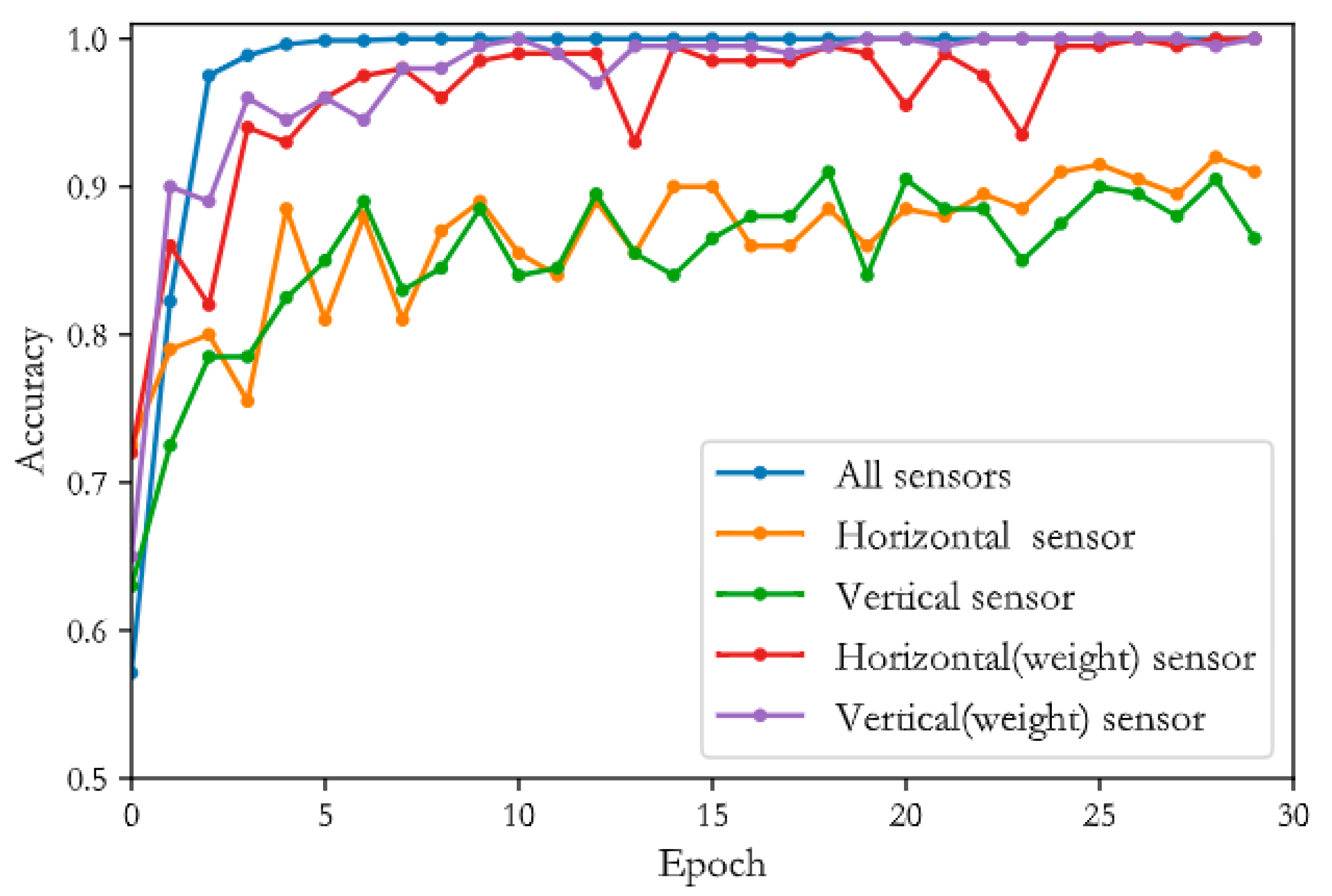

4.1.3. Comparison between Different Number of Sensors

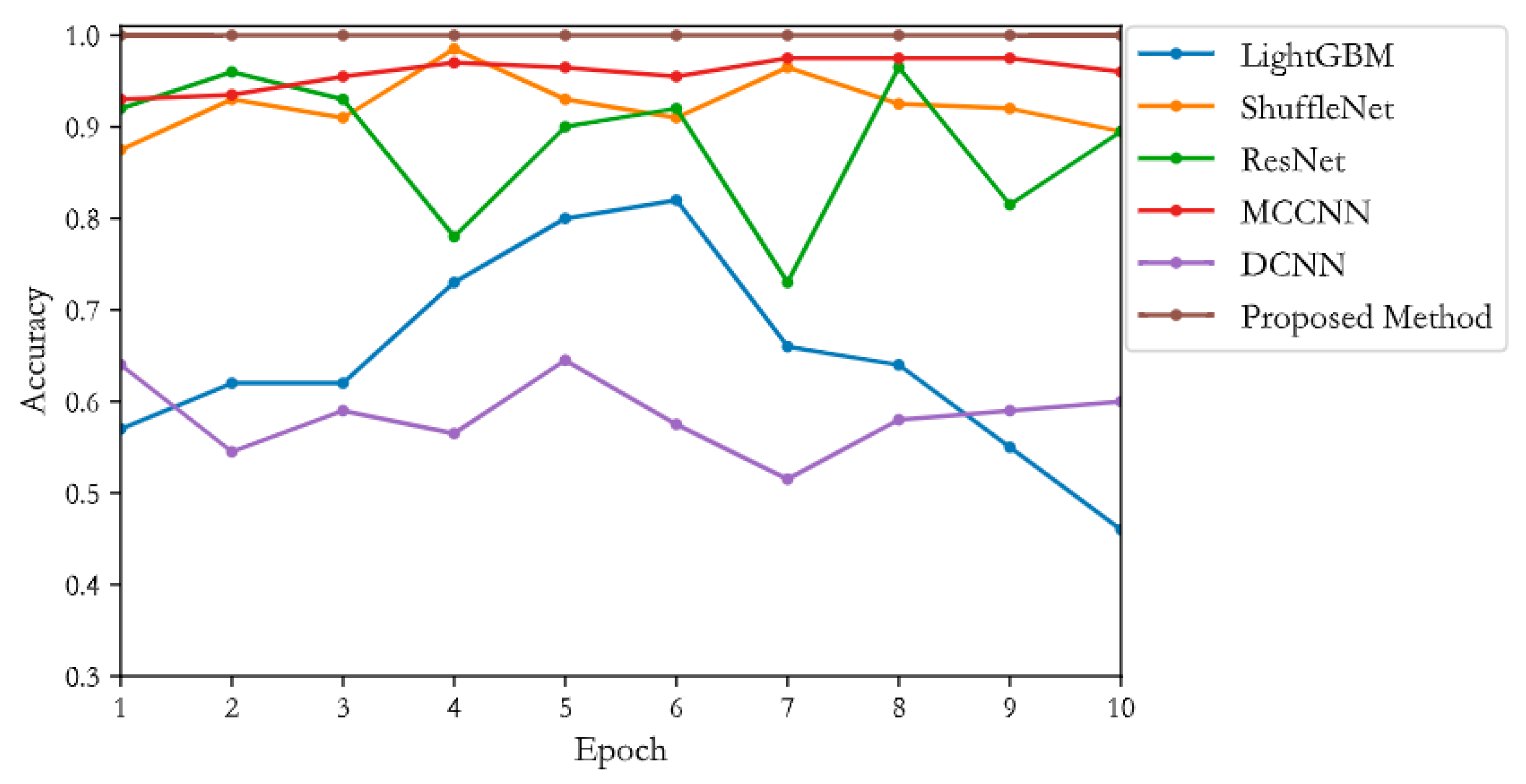

4.1.4. Comparison between Different Methods

4.2. Case 2: Bearing Fault Diagnosis Based on XJTU Bearing Datasets

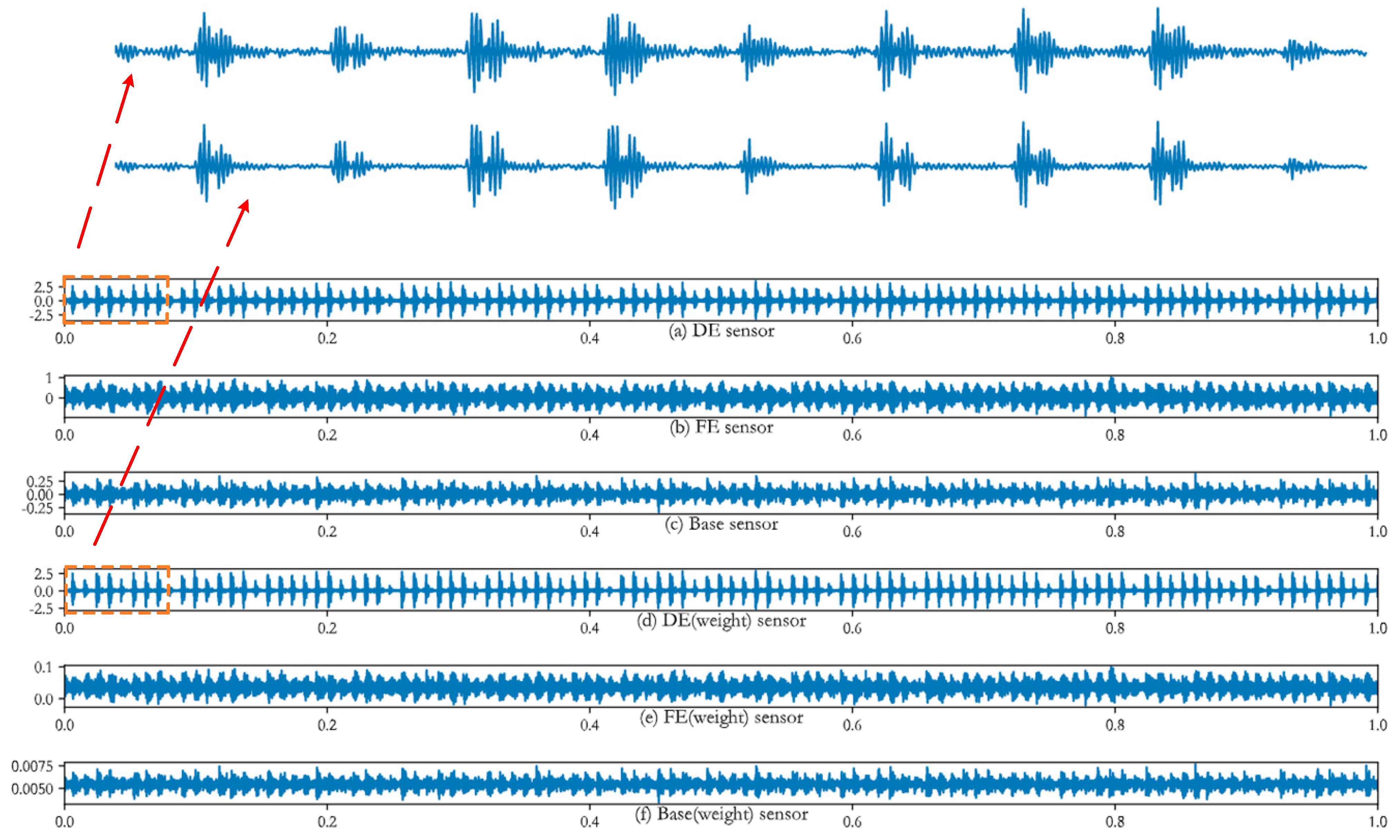

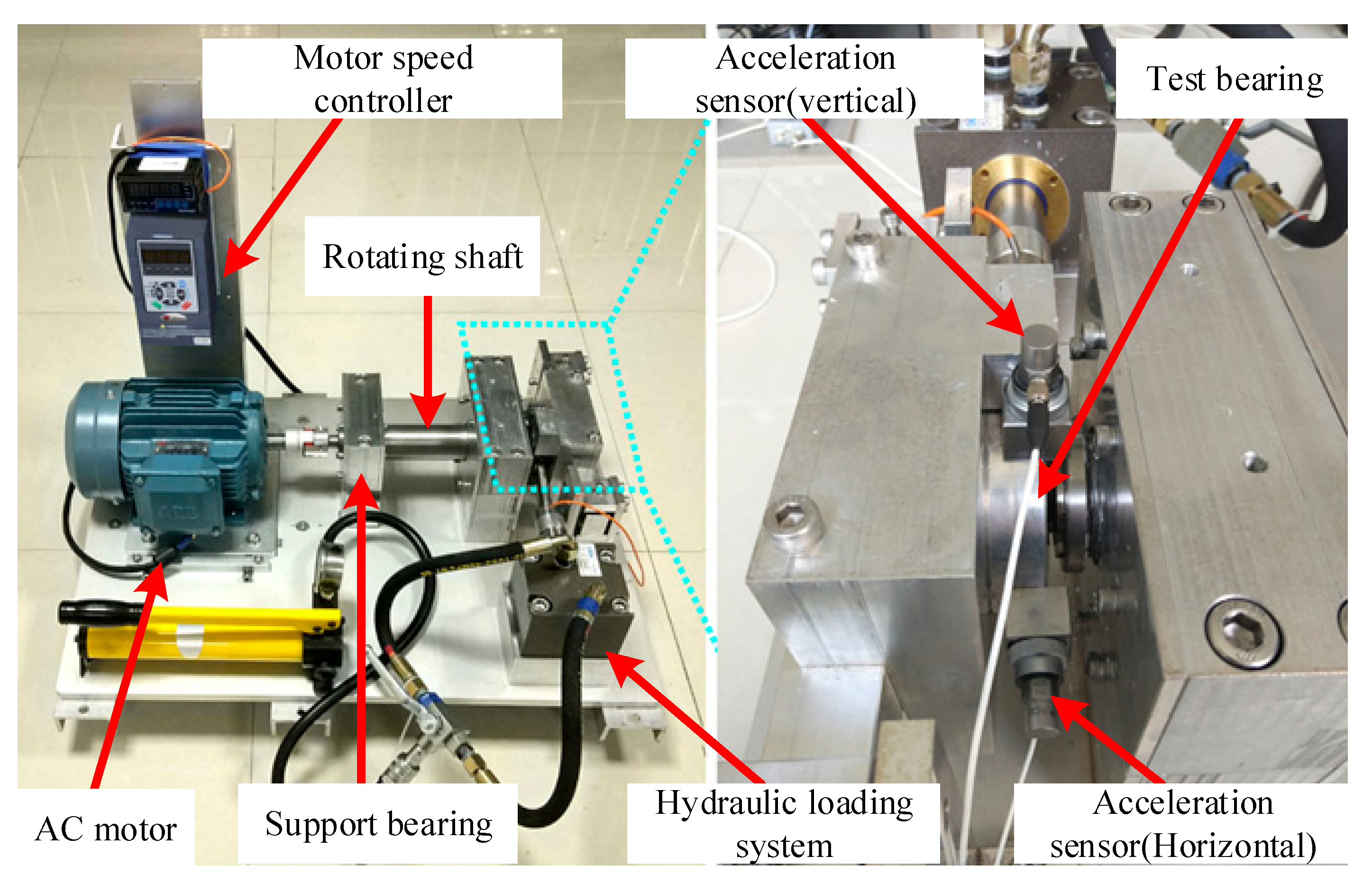

4.2.1. Experiment Setup and Data Description

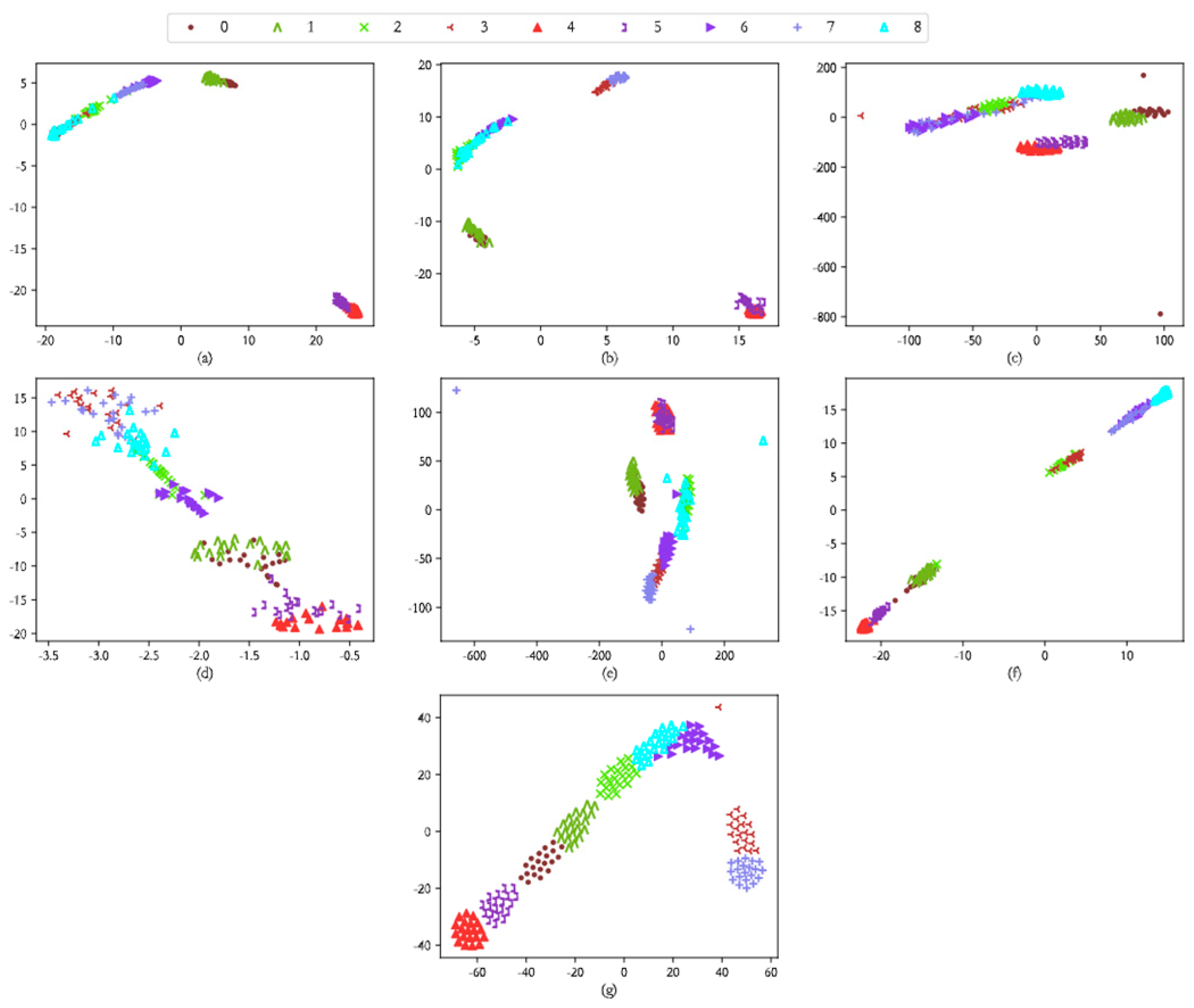

4.2.2. Diagnostic Results and Analysis

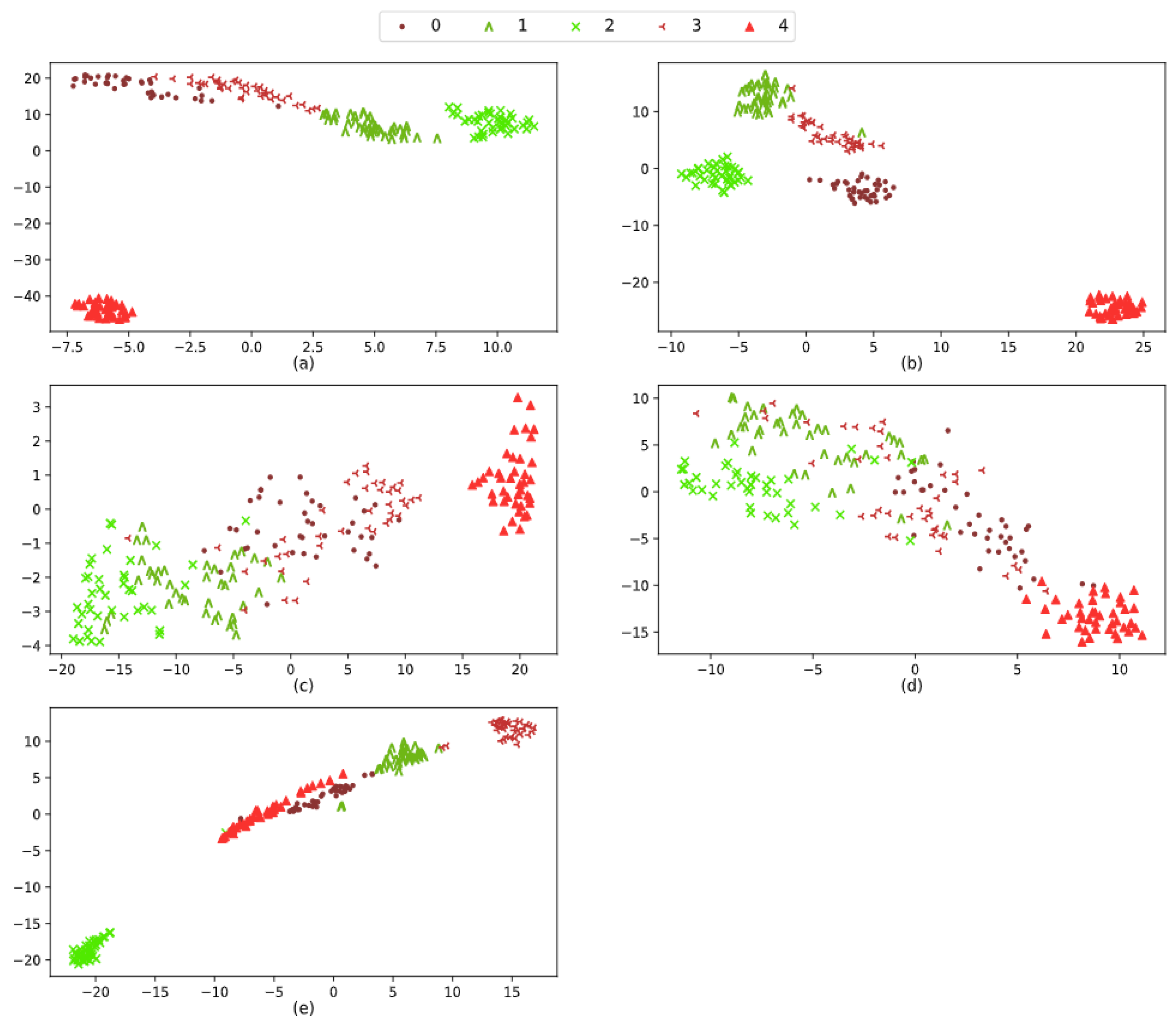

4.2.3. Diagnostic Results and Analysis

4.2.4. Comparison between Different Methods

5. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

Nomenclatures

| MSDWF | Multi-sensor data weighted fusion |

| DWSC | Depth-wise separable convolutions |

| MCCNN | Multi-channel convolutional neural networks |

| BPFI | Ball pass frequency on inner race |

| BPFO | Ball pass frequency on outer race |

| BSF | Ball spin frequency |

| SAM | Self-attention method |

| PWC | Point-wise convolutions |

| DWC | Depth-wise convolutions |

| FCL | Fully connection layer |

| AM | Attention mechanism |

| CNN | Convolutional neural networks |

| MCCNN | Multi-channel convolutional neural networks |

| LightGBM | Light Gradient Bosting Machine |

| BN | Normalization batch |

| DL | Deep learning |

| NN | Neural networks |

| RMS | Root means square |

| SD | Standard deviation |

| t-SNE | t-distributed Stochastic Neighbor Embedding |

| KNNC | K-nearest neighbor classifier |

| PE | Permutation entropy |

| MPE | Multiscale permutation entropy |

| NLP | Natural language processing |

| DE | Drive end |

| FE | Fan end |

References

- Yan, X.; Jia, M. A novel optimized SVM classification algorithm with multi-domain feature and its application to fault diagnosis of rolling bearing. Neurocomputing 2018, 313, 47–64. [Google Scholar] [CrossRef]

- Heras, I.; Aguirrebeitia, J.; Abasolo, M.; Coria, I.; Escanciano, I. Load distribution and friction torque in four-point contact slewing bearings considering manufacturing errors and ring flexibility. Mech. Mach. Theory 2019, 137, 23–36. [Google Scholar] [CrossRef]

- Gao, S.; Chatterton, S.; Pennacchi, P.; Han, Q.; Chu, F. Skidding and cage whirling of angular contact ball bearings: Kinematic-hertzian contact-thermal-elasto-hydrodynamic model with thermal expansion and experimental validation. Mech. Syst. Signal Process. 2022, 166, 108427. [Google Scholar] [CrossRef]

- Ambrożkiewicz, B.; Syta, A.; Meier, N.; Litak, G.; Georgiadis, A. Radial internal clearance analysis in ball bearings. Eksploat. i Niezawodn. Maint. Reliab. 2021, 23, 42–54. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, S.; Chen, B.; Mei, G.; Zhang, W.; Peng, H.; Tian, G. An improved envelope spectrum via candidate fault frequency optimization-gram for bearing fault diagnosis. J. Sound Vib. 2022, 523, 116746. [Google Scholar] [CrossRef]

- Wang, Z.; Du, W.; Wang, J.; Zhou, J.; Han, X.; Zhang, Z.; Huang, L. Research and application of improved adaptive MOMEDA fault diagnosis method. Measurement 2019, 140, 63–75. [Google Scholar] [CrossRef]

- Guo, T.; Deng, Z. An improved EMD method based on the multi-objective optimization and its application to fault feature extraction of rolling bearing. Appl. Acoust. 2017, 127, 46–62. [Google Scholar] [CrossRef]

- Poongodi, C.; Hari, B.; Arunkumar, S. Vibration analysis of nylon gear box utilizing statistical method. Mater. Today Proc. 2020, 33, 3525–3531. [Google Scholar] [CrossRef]

- Wang, W.; Deng, L.; Zhao, R.; Wu, Y. Fault Feature Extraction Method of Rolling Bearing Based on Integrating KPCA and t-SNE. J. Vib. Eng. 2021, 34, 431–440. [Google Scholar]

- Wang, Z.; Zheng, L.; Du, W.; Cai, W.; Zhou, J.; Wang, J.; Han, X.; He, G. A Novel Method for Intelligent Fault Diagnosis of Bearing Based on Capsule Neural Network. Complexity 2019, 2019, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Zhao, B.; Zhang, X.; Zhan, Z.; Wu, Q. Deep multi-scale adversarial network with attention: A novel domain adaptation method for intelligent fault diagnosis. J. Manuf. Syst. 2021, 59, 565–576. [Google Scholar] [CrossRef]

- Jiang, G.; He, H.; Yan, J.; Xie, P. Multiscale Convolutional Neural Networks for Fault Diagnosis of Wind Turbine Gearbox. IEEE Trans. Ind. Electron. 2019, 66, 3196–3207. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, X.; Li, H.; Yang, Z. Intelligent fault diagnosis of rolling bearings based on normalized CNN considering data imbalance and variable working conditions. Knowl. Based Syst. 2020, 199, 105971. [Google Scholar] [CrossRef]

- Zhao, M.; Zhong, S.; Fu, X.; Tang, B.; Pecht, M. Deep Residual Shrinkage Networks for Fault Diagnosis. IEEE Trans. Ind. Informatics 2020, 16, 4681–4690. [Google Scholar] [CrossRef]

- Liang, H.; Zhao, X. Rolling Bearing Fault Diagnosis Based on One-Dimensional Dilated Convolution Network with Residual Connection. IEEE Access 2021, 9, 31078–31091. [Google Scholar] [CrossRef]

- Hu, J.; Chen, Z.; Yang, M.; Zhang, R.; Cui, Y. A Multiscale Fusion Convolutional Neural Network for Plant Leaf Recognition. IEEE Signal Process. Lett. 2018, 25, 853–857. [Google Scholar] [CrossRef]

- Li, H.; Huang, J.; Ji, S. Bearing Fault Diagnosis with a Feature Fusion Method Based on an Ensemble Convolutional Neural Network and Deep Neural Network. Sensors 2019, 19, 2034. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Li, C.; Sanchez, R.-V. Gearbox Fault Identification and Classification with Convolutional Neural Networks. Shock Vib. 2015, 2015, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Mao, W.; Ding, L.; Tian, S.; Liang, X. Online detection for bearing incipient fault based on deep transfer learning. Measurement 2020, 152, 107278. [Google Scholar] [CrossRef]

- Li, H.; Huang, J.; Yang, X.; Luo, J.; Zhang, L.; Pang, Y. Fault Diagnosis for Rotating Machinery Using Multiscale Permutation Entropy and Convolutional Neural Networks. Entropy 2020, 22, 851. [Google Scholar] [CrossRef]

- Jing, L.; Wang, T.; Zhao, M.; Wang, P. An Adaptive Multi-Sensor Data Fusion Method Based on Deep Convolutional Neural Networks for Fault Diagnosis of Planetary Gearbox. Sensors 2017, 17, 414. [Google Scholar] [CrossRef] [Green Version]

- Xia, M.; Li, T.; Xu, L.; Liu, L.; de Silva, C.W. Fault Diagnosis for Rotating Machinery Using Multiple Sensors and Convolutional Neural Networks. IEEE/ASME Trans. Mechatron. 2018, 23, 101–110. [Google Scholar] [CrossRef]

- Chen, Q.; Chen, Y.; Li, W.; Jia, Y. Multi-scale SE-Xception Clothing Image Classification. J. Zhejiang Univ. 2020, 54, 1727–1735. [Google Scholar]

- Luo, X.; Xia, X.; An, Y.; Chen, X. Chinese Clinical Entity Recognition Combined with Multi-head Self-Attention Mechanism and BiLSTM-CRF. J. Hunan Univ. 2021, 48, 45–55. [Google Scholar]

- Chollet, F. Xception: Deep learning with depthwise separable convolutions. In Proceedings of the 2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017. [Google Scholar]

| Location | Inner Race | Ball | Outer Race@6 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Diameter (mil) | 7 | 14 | 14 | 7 | 14 | 14 | 7 | 14 | 14 |

| Label | 0 | 1 | 6 | 2 | 3 | 7 | 4 | 5 | 8 |

| Motor Load (hp) | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 |

| Train | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 |

| Test | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Layer | Structure | Parameters | Title 4 |

|---|---|---|---|

| 1 | Depth-wise separable convolutions | Channel = (3, 3) | Batch size = 32 Initial learning rate = 0.01 MaxPool = (1, 2) Dropout = 0.5 Ceil mode = True Optimizer = Adam Test sample rate = 20% |

| Kernel size = (1, 3) | |||

| 2 | Point-wise separable convolutions | Channel = (3, 16) | |

| Kernel size = (1, 1) | |||

| 3 | Conv1 + BN1 | Channel = (16, 32) | |

| Kernel size = (1, 3) | |||

| 4 | Conv2_1 + Conv2_2 + BN2 | Channel = (32, 64), (64, 128) | |

| Kernel size = (1, 3), (1, 5) | |||

| 5 | Conv3 + BN3 | Channel = (128, 128) | |

| Kernel size = (1, 3) | |||

| 6 | Conv4 + BN4 | Channel = (128, 32) | |

| Kernel size = (1, 5) | |||

| 7 | Conv5 + BN5 | Channel = (32, 1) | |

| Kernel size = (1, 1) | |||

| 8 | Linear | Input = 128 | |

| Output = 9 |

| Method | Average (%) | Standard Deviation |

|---|---|---|

| LightGBM | 68.78 | 0.046 |

| ShuffleNet | 87.89 | 0.055 |

| ResNet | 84.33 | 0.062 |

| MCCNN | 98.17 | 0.015 |

| DCNN | 71.11 | 0.033 |

| Proposed Method | 100 | — |

| Parameter Names | Value | Parameter Names | Value |

|---|---|---|---|

| Diameter of inner ring raceway/mm | 29.30 | ball diameter/mm | 7.92 |

| Diameter of outer ring raceway/mm | 39.80 | Number of balls | 8 |

| Basic static load rating/KN | 6.65 | Contact angle/(°) | 0 |

| Basic Dynamic Load Rating/KN | 12.82 | Pitch diameter/mm | 34.55 |

| Label | Fault Type | Radical Force (KN) | RPM | Train | Test |

|---|---|---|---|---|---|

| 0 | CFICR | 12 | 2100 | 160 | 40 |

| 1 | Inner race | 11 | 2250 | 160 | 40 |

| 2 | Outer race | 11 | 2250 | 160 | 40 |

| 3 | Cage | 11 | 2250 | 160 | 40 |

| 4 | CFIO | 10 | 2400 | 160 | 40 |

| Method | Average (%) | Standard Deviation |

|---|---|---|

| LightGBM | 64.70 | 0.106 |

| ShuffleNet | 92.45 | 0.030 |

| ResNet | 88.15 | 0.075 |

| MCCNN | 95.95 | 0.015 |

| DCNN | 58.45 | 0.037 |

| Proposed Method | 100 | — |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Xu, X.; Pan, H.; Chang, X.; Yuan, T.; Zhang, X.; Xu, H. Rolling Bearing Fault Diagnosis Based on Depth-Wise Separable Convolutions with Multi-Sensor Data Weighted Fusion. Appl. Sci. 2022, 12, 7640. https://doi.org/10.3390/app12157640

Wang T, Xu X, Pan H, Chang X, Yuan T, Zhang X, Xu H. Rolling Bearing Fault Diagnosis Based on Depth-Wise Separable Convolutions with Multi-Sensor Data Weighted Fusion. Applied Sciences. 2022; 12(15):7640. https://doi.org/10.3390/app12157640

Chicago/Turabian StyleWang, Tong, Xin Xu, Hongxia Pan, Xuefang Chang, Taotao Yuan, Xu Zhang, and Hongzhao Xu. 2022. "Rolling Bearing Fault Diagnosis Based on Depth-Wise Separable Convolutions with Multi-Sensor Data Weighted Fusion" Applied Sciences 12, no. 15: 7640. https://doi.org/10.3390/app12157640

APA StyleWang, T., Xu, X., Pan, H., Chang, X., Yuan, T., Zhang, X., & Xu, H. (2022). Rolling Bearing Fault Diagnosis Based on Depth-Wise Separable Convolutions with Multi-Sensor Data Weighted Fusion. Applied Sciences, 12(15), 7640. https://doi.org/10.3390/app12157640