Abstract

This paper presents a novel biomechatronic device that resolves the necessities of mobility for people with spinal cord trauma (SCI) and disability. The proposed device features a safe and reliable mobility mechanism that withstands daily use without premature mechanical wear, facilitating the activities of daily living (ADL) for people affected by SCI, integrating them to a social and workforce environment that allows them, on one hand, to move in a standing upright position in complex situations of the urban architecture, and on the other hand, provides them a mechatronic system to assist them to stand up and sit down.

1. Introduction

The physiological functions and internal organs of a human being are adapted to the standing upright position and biped locomotion. Accidents and diseases such as cerebral palsy, embolism, spinal cord injury (SCI), muscular dystrophy, and post-polio syndrome generate adverse conditions such as muscular stiffness, tendon deformations, bone density loss, urinary infections, and intestinal constipation [1].

SCIs present different grades of affectations in the body (partial and total paralysis in human limbs) and are classified with respect to the level of location according to the American Spinal Injury Association (ASIA) using the International Standards for Neurological and Functional Classification of Spinal Cord Injury [2].

The mobility options for people affected by SCI are limited [1] and in the case of motor disability the option of mobility that is widely used is the wheelchair of manual impulse [3]. However, the wheelchair produces secondary problems generated by long periods of time when the users remain seated, producing physical and social problems called secondaries such as blisters, osteoporosis, gastric problems, urinary tract infections, tendon deformation, muscle atrophy, mental stress and low self-esteem. The low self-esteem is presented by the condition of looking from a low position, but can be decreased if the patient stands up, remains standing and moves in a standing upright position. Exoskeletons are an option for substituting wheelchairs, and those high-technology devices allow them to accomplish Activities of Daily Living (ADL) such as those listed in Table 1. It is worth mentioning that both devices have their own problems with working effectively in an urban environment designed for healthy people. The trend in exoskeletons is to add everyday high technology sensors, actuators, and electronic control devices [4] that, in short, are genuine contributions to science and technological development but, due to their level of complexity, are susceptible to failure and, therefore, have low reliability and high costs that do not allow their massive application. Exoskeletons have the following drawback: biological joints do not have a fixed rotation center; therefore, a slight misalignment with the user’s kinematics will produce forces and torques against the movement, increasing the required effort [5,6,7]. The reduction of degrees of freedom (DOF) reduces the complexity of Exoskeletons resulting in the reduction of the system weight, robustness, and reliability of the systems and, therefore, a lower cost for end-users [8]. A heavy exoskeleton requires high electromechanical power, therefore demanding a higher battery capability and weight.

Table 1.

Considerations included in Activities of Daily Living.

Today, the control algorithms that rule robots have not reached a behavior to be compared with the methods of strength, control of force, and natural sensors developed in the human body [5,9]. From seated to standing is the first step of the transition to help SCI users move to their wheelchairs and progress towards their mobility. The structure of exoskeletons equipment is very complex and uncomfortable, turning into fixing and maintenance issues. The new Soft-EXO rehabilitation devices greatly simplify the structure and weight, but the applied force is reduced. The most important achievement of the exoskeletons is to enable patients with total paraplegia to stand up and walk [10]. On the other hand, passive exoskeletons have features such as a lower level of complexity, structural simplicity, and operational ease. Moreover, their designs avoid energy problems, actuation systems, and control [11]. Objects and the urban architecture are designed for healthy people capable of walking and remaining in a biped posture [10]. Although there is a great effort to adapt urban architecture for people in wheelchairs, it is common to find different problems such as curbs, ramps, obstacles, and slopes on the streets, generating a complex environment in which to drive a wheelchair. Currently, the exoskeletons are applied principally in the field of physical rehabilitation and are used in the same way as ambulatory devices [12]. These devices clearly represent one of the most important developments in SCI rehabilitation, although there is no true progress in the field of mobility [13].

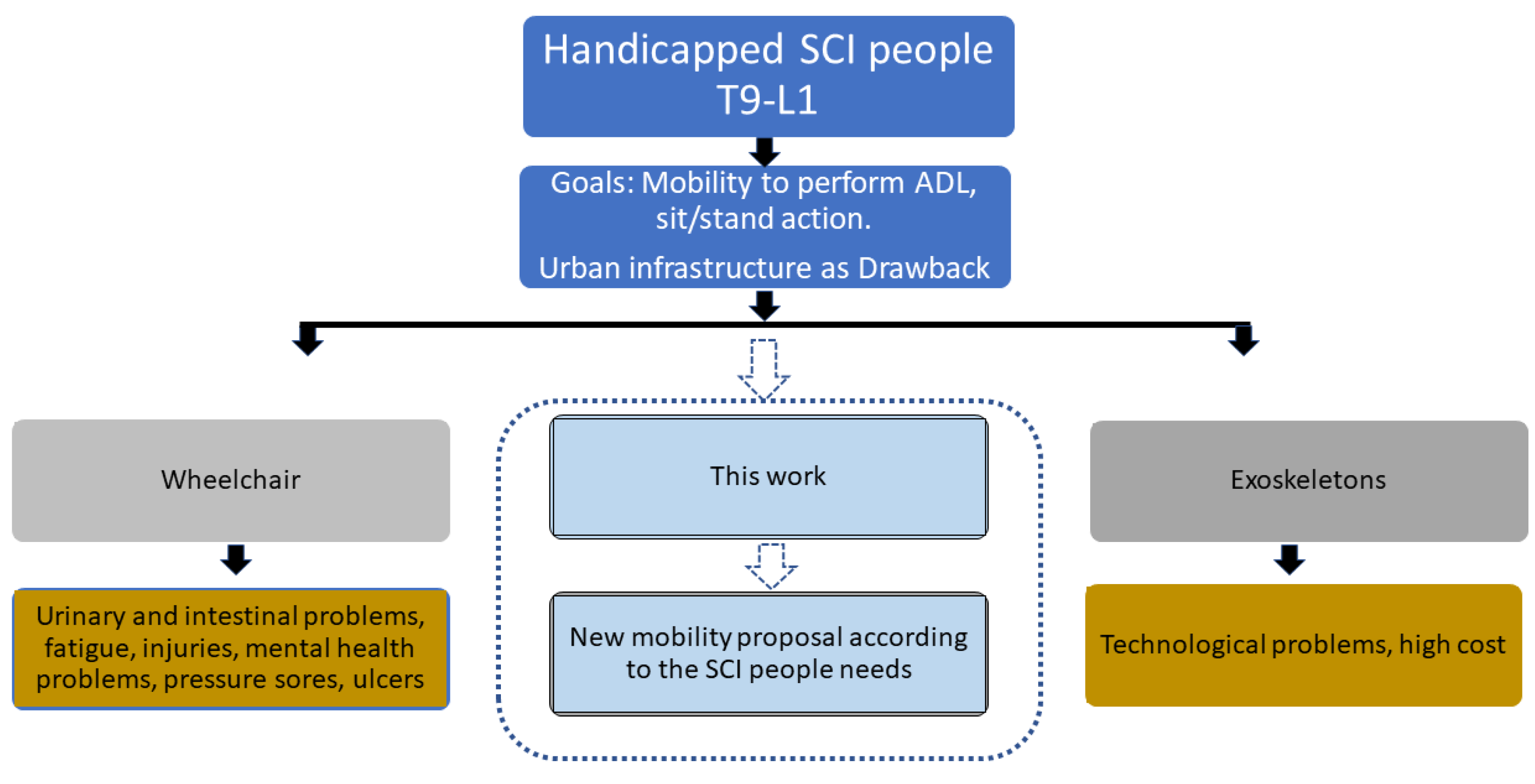

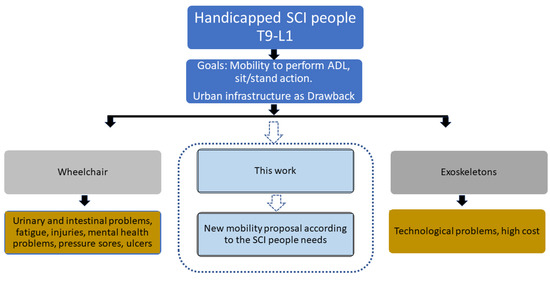

Figure 1 presents a block diagram of this problem derived from the state-of-the-art, whereas the entrance is the need of SCI disabled people and as the outlet, the result concerns a necessary change of direction to meet this need through a disruptive innovation, consisting of the design and development of an exoskeleton system for upright mobility in an urban environment.

Figure 1.

Block diagram problem derived from the state-of-the-art.

The priority needs of people with SCI disabilities can be summarized as Mobility for ADL, where today, the options to achieve their goal are limited to the use of the wheelchair and the high technology devices called Active Exoskeletons. Each of the solutions proposed for mobility, even wheelchairs or exoskeletons, have their own advantages and disadvantages, which is why they do not offer a complete solution to the different circumstances presented by the urban environment. Therefore, in this work, an intermediate solution (Figure 1) is proposed to face the different difficulties that the urban environment presents for people with reduced mobility. This biomechatronic device is focused on Paraplegia with specific T9 to T11 injury, which represents a lower limb motor disability that could involve a partial or total and loss of sensation. It corresponds to people without any possibility of motor rehabilitation through a therapeutic process [13].

This work considers generating a new biomechatronic device that manages to attend to and solve the needs of people with SCI as the priority factor to solve, and in this case, a safe and reliable mobility device that supports daily use without premature wear, without involving a strenuous physical effort when performing the activities of daily living, integrating them into a social and work environment, which on the one hand allows them to move in an upright position at the average speed of healthy people who accompany them, and on the other hand, provides a system for incorporating them standing and sitting.

The article is structured as follows: first, the user, security, and operative requirements are presented; then, using those requirements, the system design is introduced where sitting-standing, sagittal stability, and coronal stability mechanism are detailed and described; finally, the mathematical modeling, the drive system design. The results of the DC motor characterization and finite element analysis are presented. Finally a comparison of the advantages of this device respect to the prior state-of-the-art is included in this section.

2. Materials and Methods

The integration of the scientific method to Industrial Design methodology is proposed to conceive an innovation that allows to generate a scientific contribution. The mechanism was designed considering the state-of-the-art’ challenges and opportunities to establish the design requirements; the anthropometric dimensions, ISO standards, and standard materials dimensions lead to the mechanism CAD modeling. The mechanism kinetics and dynamics were obtained using mathematical modeling and simulation, and CNC machines performed manufacturing.

2.1. Design Requirements

The following list of Design Requirements has been developed to generate a proposal of new techniques that integrate the design, which are translated as characteristics of the mobility exoskeleton device. The design has been subdivided into three tables of requirements: the user (Table 2), the operative (Table 3) and the Security (Table 4). The user requirements of people affected by SCI are the most important factor.

Table 2.

User Requirements.

Table 3.

Operative Requirements.

Table 4.

Security Requirements.

2.2. Anthropometry

Derived from the Anthropometry considerations in [14], the dimensions referring to the 50 percentile for men and women have been selected. Covering and applying the height range of 1.60 m to 1.75 m and their associated dimensions for the human body proposed for this project.

3. System Design

3.1. Design of the Mechatronic System

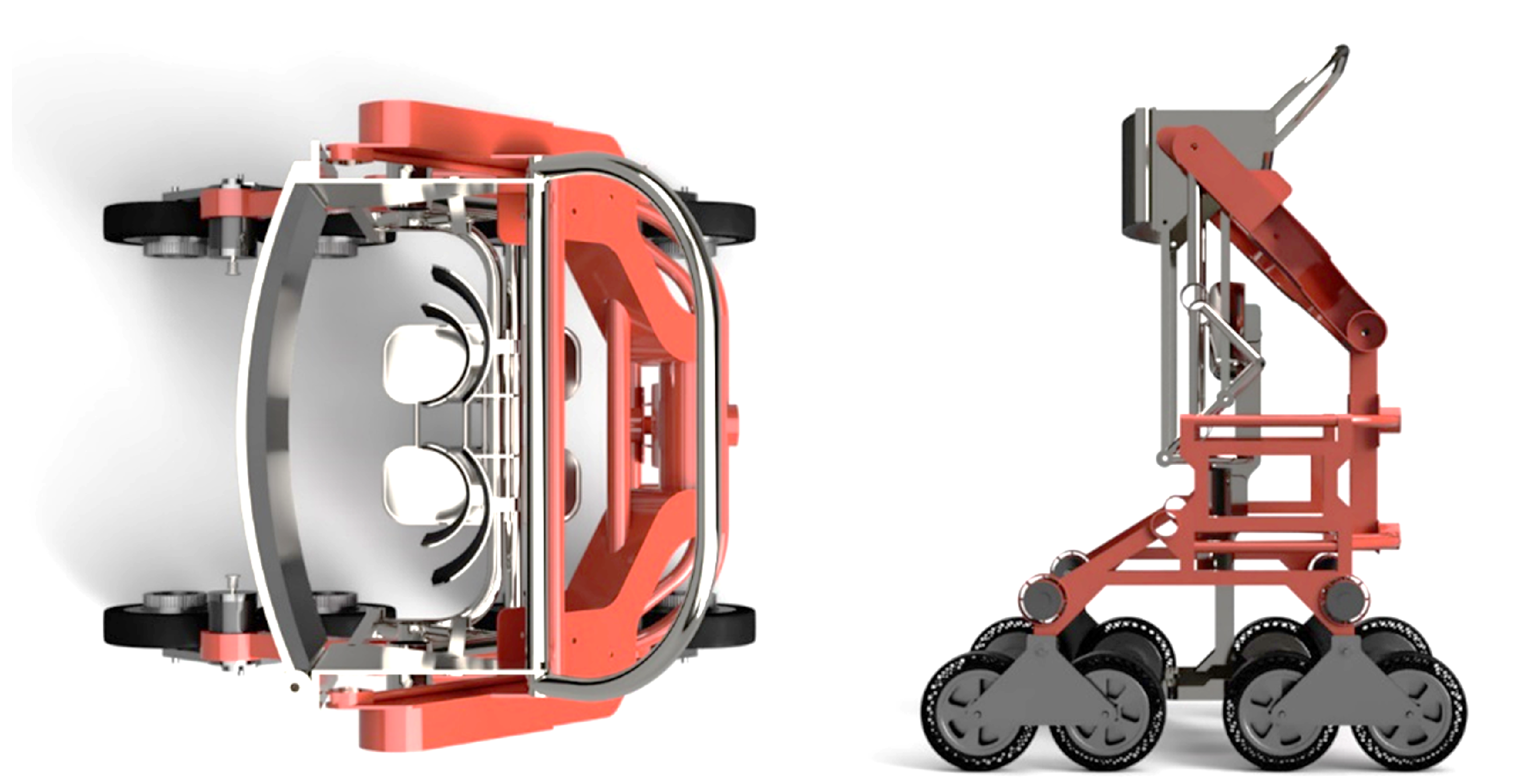

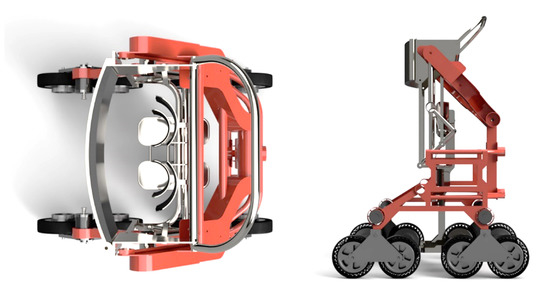

The design of the biomechatronic device generates a solution to sagittal and coronal stability problems that the urban environment implies in the ascent and descent of lateral and frontal ramps, curbs, and irregular surfaces, which make the displacement impossible to use with traditional or electric mobile systems. Applying the design requirements, based on anthropometric studies [14] and the adjustment and tolerance standard, a novel design is generated that successfully integrates the main components without any interference between them. Figure 2 and Figure 3 show the mechatronic device rendered in different views.

Figure 2.

(Left) Top View of the mechatronic device. (Right) Lateral View of the mechatronic device.

Figure 3.

(Left) Frontal View of the mechatronic device, (Right) Rear View of the mechatronic device.

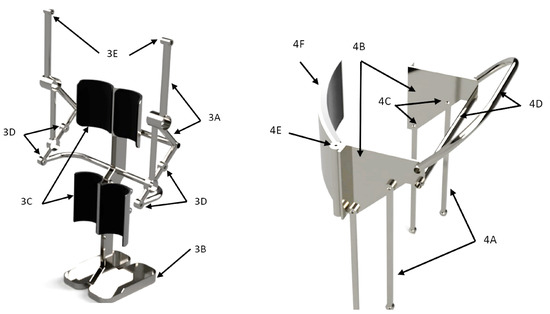

Figure 4-(Left) shows the mechanism sitting-standing-sitting turned 90° sagittally, with the backrest folded down to allow access to the user who is seated in a chair, bed or toilet. Subsequently, in Figure 4-(Right) this parallelogram mechanism incorporates the user to a standing position, keeping the backrest in an upright position at all moment during incorporation or sagittal rotation.

Figure 4.

Seated-standing Mechanism. (Left) Seated Position, (Right) Standing Position.

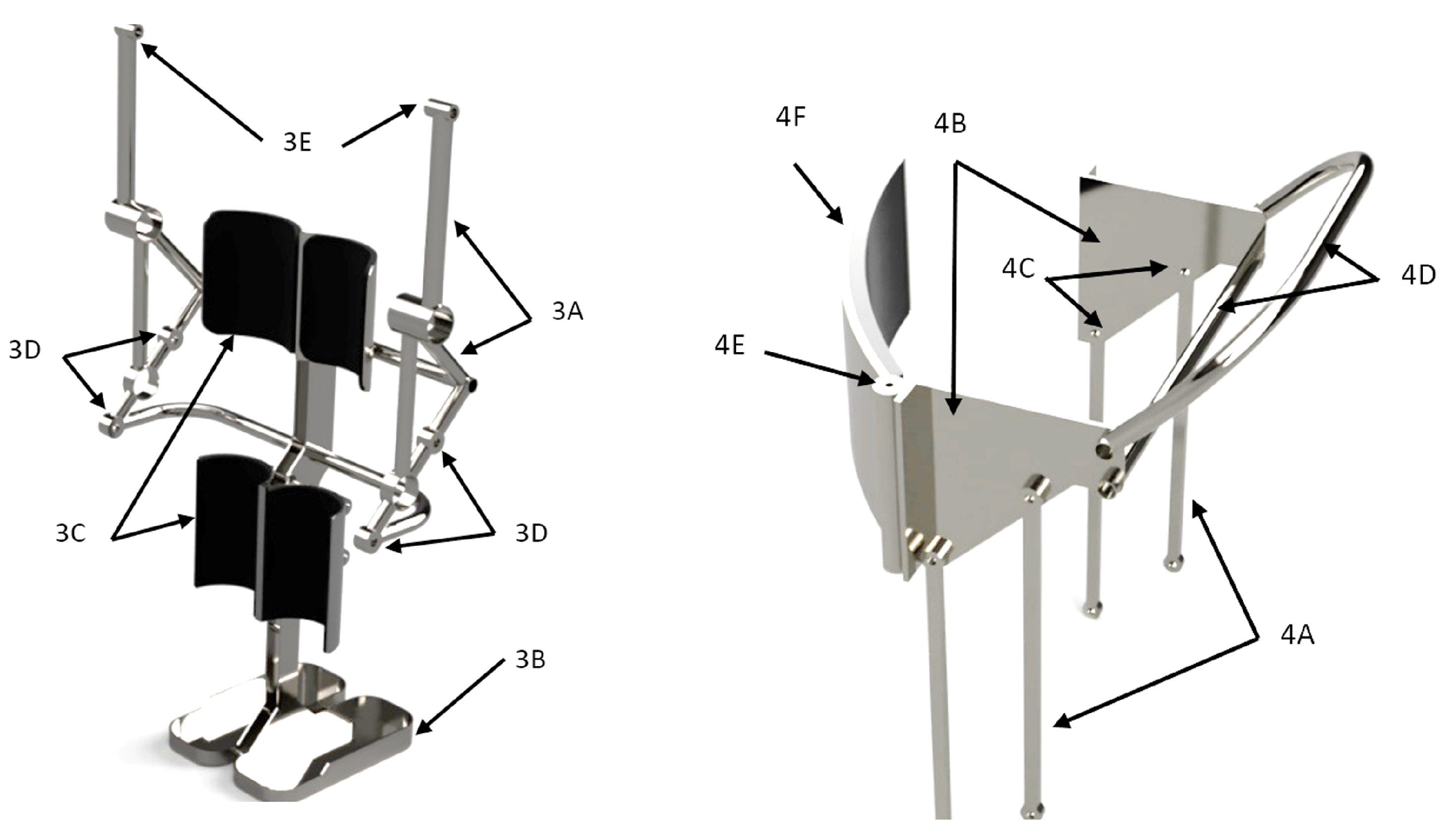

Figure 5 shows illustrations (Left) and (Right), which contain two main components; exoskeleton with pendulum movement and motor structure. The exoskeleton is the carrier in the seated phase and standing of the user, who keeps himself upright, resting his weight on the footrests of the device. The motor structure contains the skates with wheels assembled to the transverse parallelograms symmetrically to the central pedestal, this serves as a support to the clevis that work as the support spot of the exoskeleton.

Figure 5.

Seated-standing Mechanism. (Left) Exoskeleton, (Right) Mobility structure.

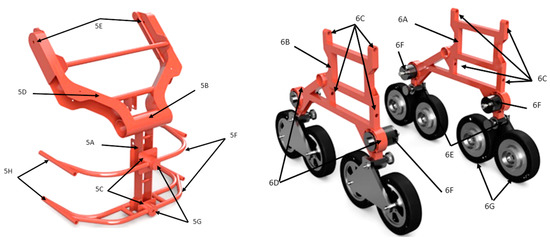

Figure 6 exhibits stability movements of the device according to the kinematics applied to the coronal and sagittal ramp, the systems observed; sagittal tilting and transverse parallelogram with coronal actuator. It stands out here, the narrow skates to accommodate the user with enough space to interact freely with the mechanical components safely.

Figure 6.

Model of the stabilizing mechanism. (Left) Coronal, (Right) Sagittal.

Figure 7 presents the front and rear isometric views of the mechanical device of mobility in an upright position with exoskeleton with pendulum movement to stabilize in an urban environment for paraplegic people.

Figure 7.

Model of the stabilizing mechanism. (Left) Coronal, (Right) Sagittal.

3.2. Seated-Standing Mechanism

As indicated in Figure 8 when the user is in a sitting position in a bed or chair, the parallelogram subsystem for seated-standing action it retracts 90° by action of a wired remote control and the DC motor and Bowden cable assembly, which rotates counterclockwise (CCW) until it reaches the horizontal position, observing in all moments the lumbar support (4F) and lateral plates (4B) keeping an upright position, by effect of the four cylindrical bars of which are articulated at the top to the four horizontal augers of and on its lower part to the four horizontal brackets of (3D), so the lumbar support can be manually lowered by the user (4F) articulated with hinge (4E) respect to the right lateral plate (4B), and is moved backwards in slow motion, through the wired remote control, until the user touches with the belly the bar of the tubular handlebars of the (4D), so now, the lumbar support can close (4F) until it locks with the left side plate (4B), at this point the user puts his feet on the footrest (3B) with the help of his hands. Through the wired remote control, the DC motors that rotate clockwise (CW) are activated, winding the Bowden cable.

Figure 8.

Model of the stabilizing mechanism. (Left) Coronal, (Right) Sagittal.

In Figure 9, the user is incorporated to reach the upright position. Through all this process of sitting-standing transition, the pendulum articulation consisting of the two horizontal transverse supports made of (3E) and threaded cross holes of (5E) is locked by the action of an automatic mechanical brake.

Figure 9.

Seated-standing Mechanism.

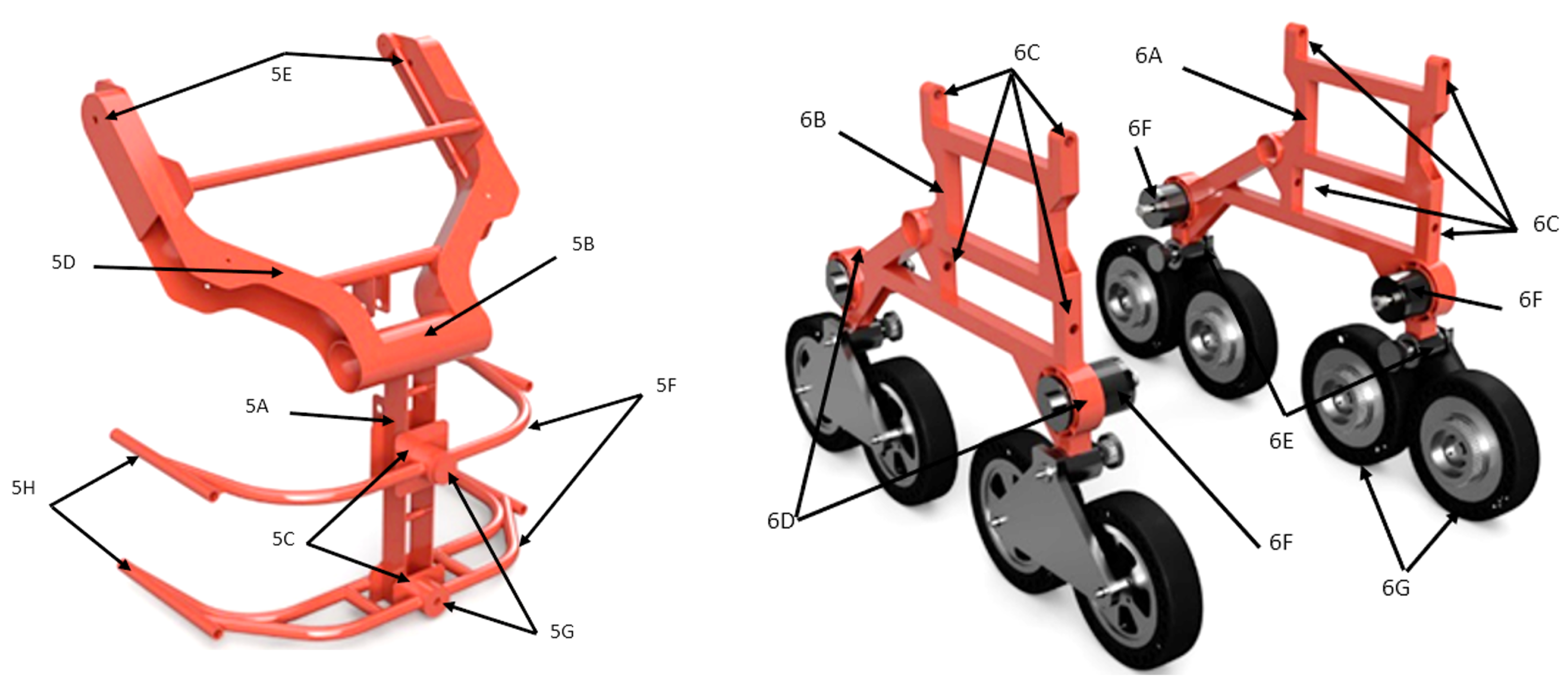

3.3. Mobility Motor System

Figure 10 displays the isometric view of the subsystems, that is composed by the parallelogram subsystem with coronal stability (see Figure 10-Left), and the skates with drive wheels subsystem (see Figure 10-Right). The parallelogram subsystem with coronal stability (Figure 10-Left), is constituted by a central vertical pedestal (5A) in 1 carbon steel, an upper horizontal transverse support (5B) in 1 tubular carbon steel, and two longitudinal support (5C). The upper horizontal transversal support (5B) is articulated with the clevis support of the tilting exoskeleton (5D) in carbon steel cal. 16, which supports the exoskeleton with pendulum movement system for sagittal stability with mechanism for sitting-standing action, by means of threaded transversal holes (5E). The longitudinal supports (5C), articulate with the upper and lower transverse parallelogram (5F), which integrates components such as the longitudinal boring supports (5G), and the longitudinal tubular supports (5H) in each extreme. The skates subsystem, with driving wheels (Figure 10-Right), is constituted by a left (6A) and a right (6B) vertical skate of PTR. Each vertical skate left and right (6A and 6B), has the longitudinal augers (6C) in their upper and medium parts, the 1 transverse tubulars (6D) in their medium part, and the transverse tubulars (6E) in its lower part. The longitudinal augers (6C) are articulated with the longitudinal tubular supports (5H) of the upper and down transverse parallelogram (5F). The 1 transverse tubulars (6D) support the DC gear motors (6F) of 150 Watts. The transverse tubulars (6E) articulate with the driving pairs of pendulum wheels (6G).

Figure 10.

Seated-standing mechanism. (Left) Coronal, (Right) Sagittal.

3.4. Mobility in an Urban Environment

When the user is incorporated in an upright position, the device is capable of transporting the user in an adverse urban environment that is characterized by frontal and sagittal ramps, curbs, sidewalks with irregular surface, puddles of water, grass, gravel, etc., characteristics that must be overcome by means of sagittal and coronal stability systems control and maintain upright position of the user, as is described below.

3.4.1. Horizontal Floor

The user uses a manual activation joystick to perform forward, reverse, left and right movements, using an electronic speed control system for DC gear motors of 150 watt (6F), which is coupled to each pair of pendulous wheels (6G), using a belt and synchronous pulleys. The biomechatronic system has a rechargeable battery bank that is mounted on the right and left vertical skates (6A and 6B). The pendulous wheels (6G) are air free with transverse perforations from face to face, to facilitate their slight deformation when ascending and descending curbs.

3.4.2. Sagittal Ramp

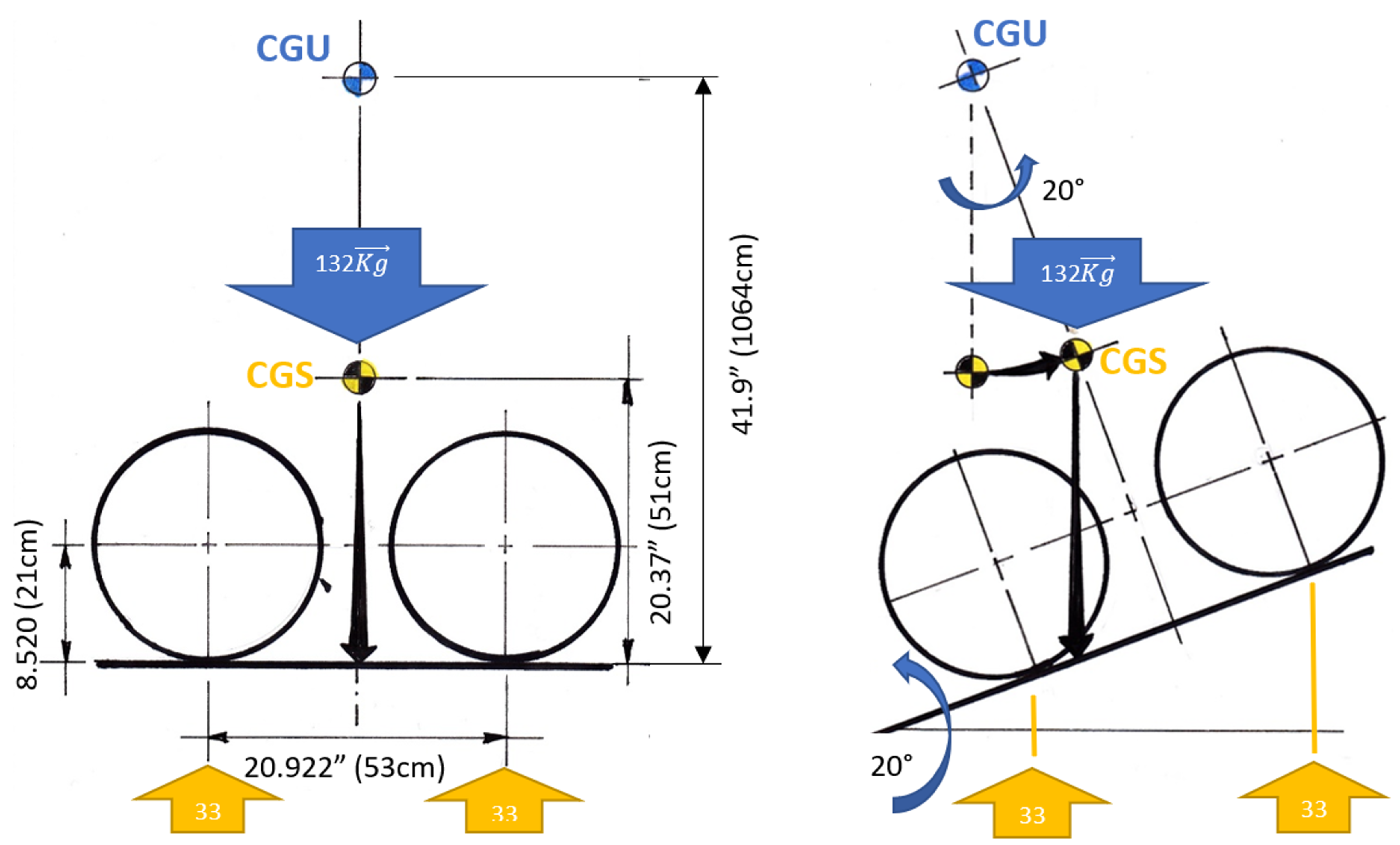

Figure 11 shows an ascending action on a sagittal ramp. Where the pendulous exoskeleton system for sagittal stability maintain position by force action of gravity throughout the joint by the two horizontal supports of the exoskeleton (3E) with respect to the threaded transversal holes (5E) of the mobility motor system with coronal stability. During this process, an IMU sensor is located on the left side plate and detects a leaned position and the control automatically releases the mechanical brake blocker that is inside the pendulous exoskeleton support (5D) to achieve the pendulum movement in the range of ±15°.

Figure 11.

Simplified model of the sagittal stability system (Left) Coronal, (Right) Sagittal.

3.5. Mathematical Model

The mathematical model provides information regarding the behavior of the mobility device in an upright position over time, especially the location of the center of gravity of the human-machine interaction, and the joints of the device, through which the stability of the interaction in sagittal and/or coronal position is demonstrated.

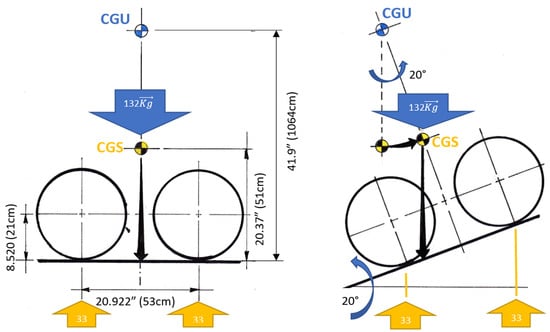

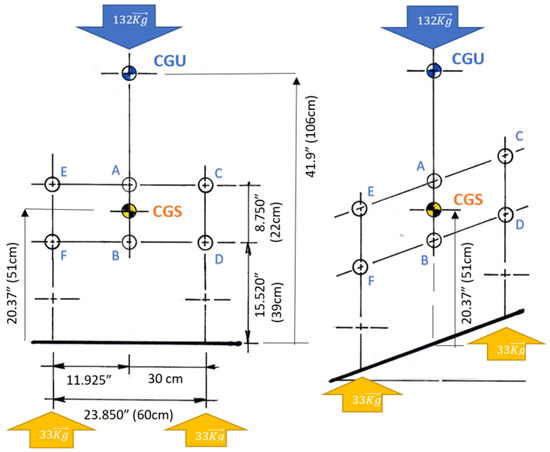

3.5.1. Sagittal Stability System

- 1.

- Integrated by the exoskeleton with pendulum movement which is composed of two components: a user of 80 kg and an Exoskeleton of 10 kg.

- 2.

- The center of gravity of the user CGU corresponds to a healthy user according to 50 percentile (average height of Mexican man), with an elevation to of the plant of its feet placed in the footrest of the exoskeleton of elevation to the floor, therefore, the CGU is located to with respect to the ground. The exoskeleton is articulated as a pendulum, coinciding with the location of the CGU. This exoskeleton supports the user in an upright position and covers or dresses him from the CGU to the soles of his feet, perched on the footrest, thus constituting the pendulum elements of the sagittal stability system;

- 3.

- The sagittal and coronal stability systems are designed by requirement protocol and internal validation, to operate in an urban environment, with a maximum inclination of 15°. However, considering the issue of abuse of use by the user identified by FDA, in which the Exoskeleton devices are taken, to operate beyond the capacity for which they were designed, it is decided, to perform the mathematical model for an extreme case of ramp at 20°, as an application of safety factor;

- 4.

- The simplified version mobility device considers only four wheels of r = , supporting 33 kg each one of them;

- 5.

- The Sagittal stability system considers only one degree of freedom or pendulum joint, located in coincidence with the point called CGU;

- 6.

- The Mathematical Model of the sagittal stability system considers, for special attention, the position of the Center of Gravity of the System (CGS) through time. The sagittal stability system considers a weight of the mobility device is equal to 42 kg in bilateral symmetry, with a center of gravity collinear to the CGU and CGS, not represented in Figure 11, but included in the CGS resultant.

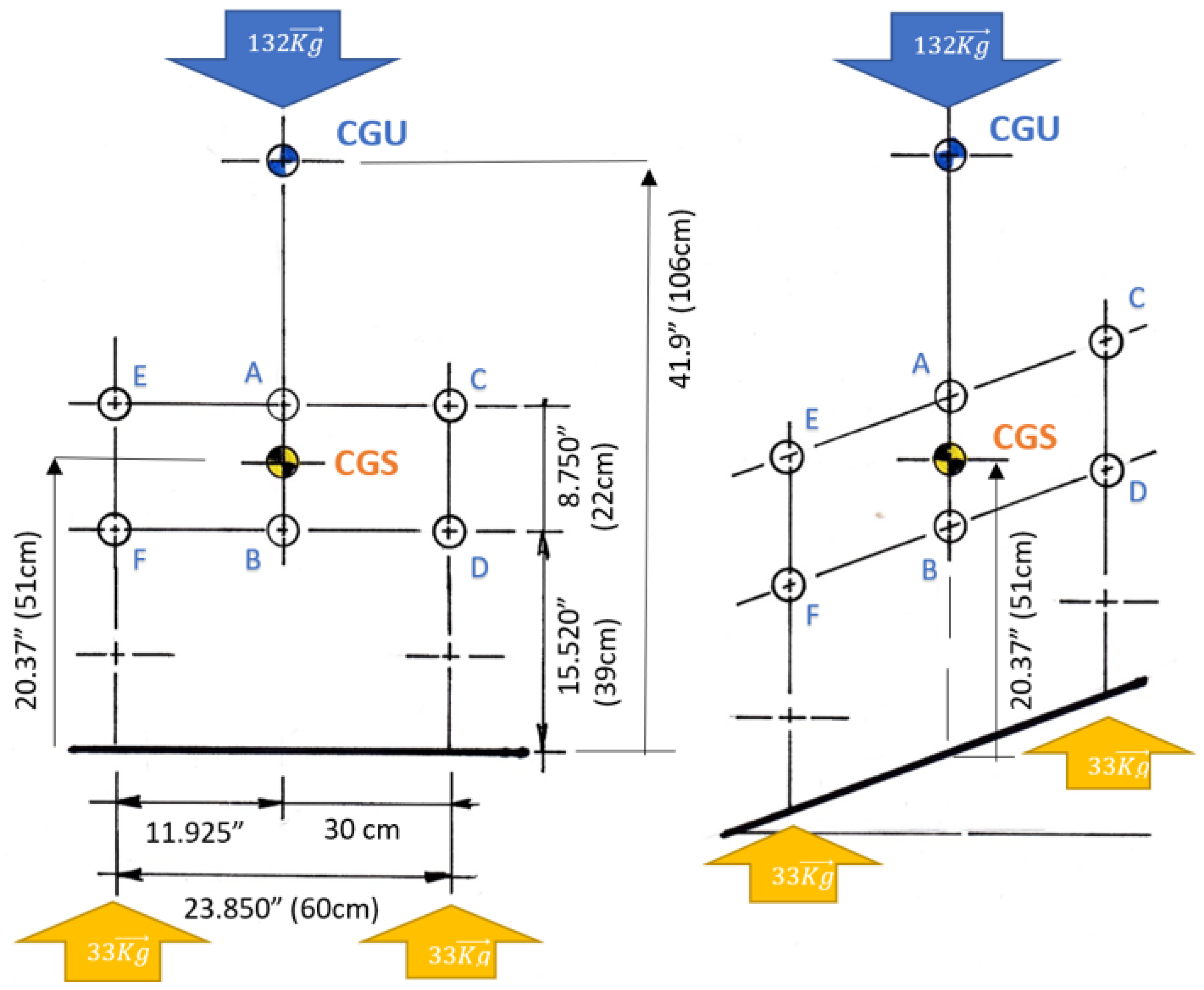

3.5.2. Coronal Stability System

- 1.

- Integrated by a parallelogram system constituted by two horizontal bars, articulated at their central point with a vertical pedestal (A, B), on their sides to a left vertical skate (C, D) and a right vertical skate (E, F), for a total of six joints or degrees of freedom. Weight of the system = 42 kg. The joint with the pedestal allows both horizontal bars to turn to the left (CCW) or right (CW) a maximum of 15°, nevertheless, Figure 12 represents the extreme case of 20° as an additional safety factor;

Figure 12. Simplified model of the coronal stability system. (Left) Coronal, (Right) Sagittal.

Figure 12. Simplified model of the coronal stability system. (Left) Coronal, (Right) Sagittal. - 2.

- In the complete version of the coronal stability system, each skate has two pairs of line wheels, and each pair of lined wheels is articulated to the skate through a transverse tubular (bearing shaft) mentioned in Figure 12 and Figure 13. The 6E component, which allows swinging every pair of lined wheels a maximum of 45° to the left and right, is a feature that allows traction around the curb of the sidewalk in its up/down movement. As a simplified model, every transverse tubular is considered (bearing axle) as an axle for a single wheel of diameter (r = ); therefore, the mobility device in its simplified scheme has only four wheels without the possibility of a pendulum and—where it stands out—the location of the CGU and CGS remain unchanged. In this simplified model, every wheel supports 33 kg.

Figure 13. Free Body Kinematics.

Figure 13. Free Body Kinematics. - 3.

- Two packs of batteries are considered to be applied to energize the mobility device, located on the back side of each skate (left and right), inside an exclusive container, independent and isolated. Its weight is already considered in the weight of the system (12 kg).

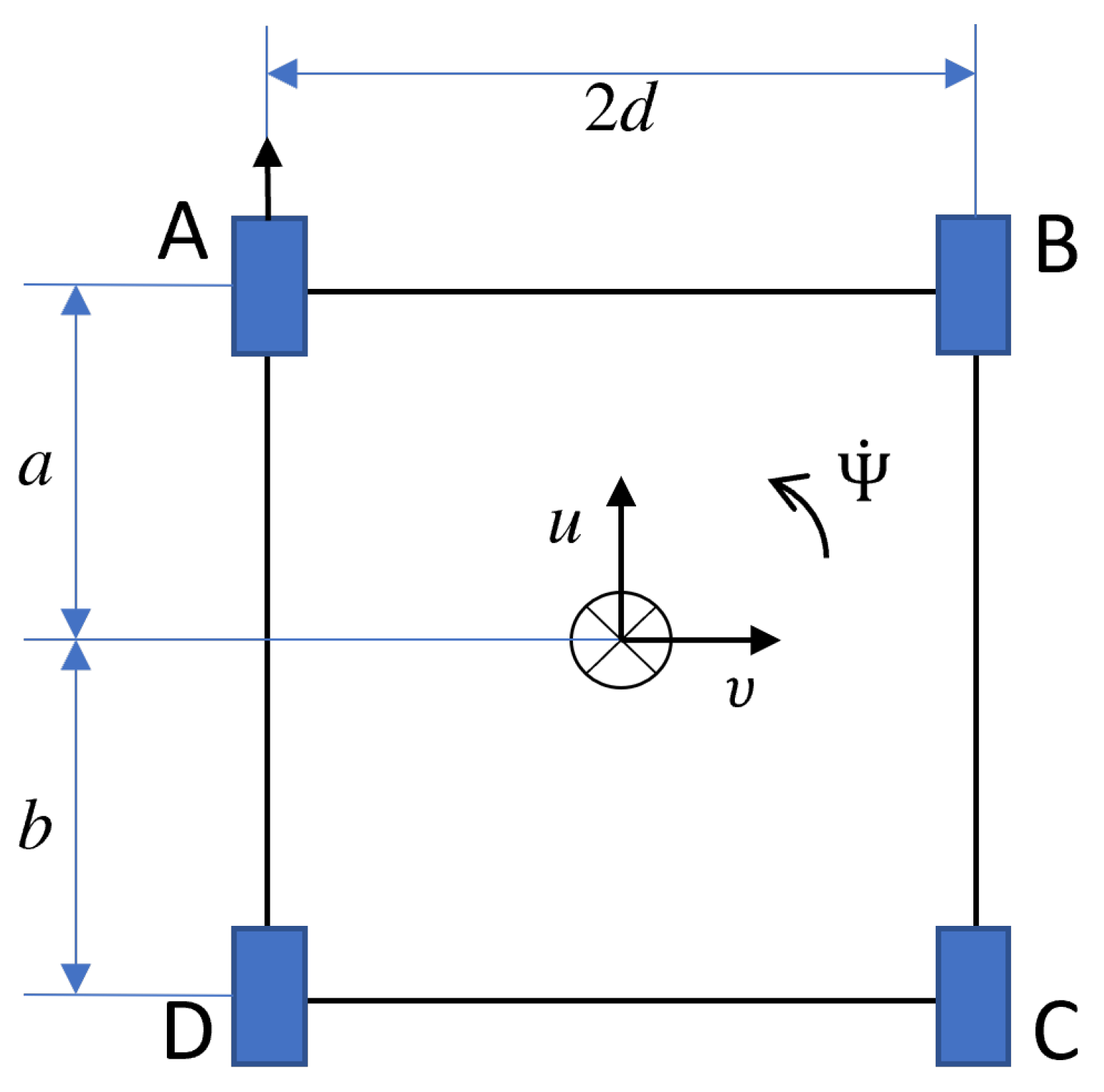

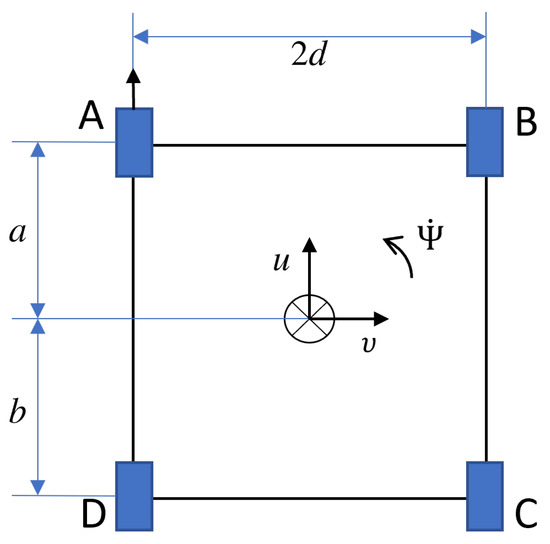

3.5.3. Kinematics

For the kinematics model the inline wheels were considered as a single diameter wheel therefore, a four wheels simplified scheme was obtained. By doing so, the location of the CGU and CGS remain unaltered during the analysis. In the following, the expressions where this is represented according to Figure 13 are presented:

Description:

- A—Left front wheel

- B—Right front wheel

- C—Right rear wheel

- D—Left rear wheel

- a—Distance between robot center and front wheels

- b—Distance between robot center and rear wheels

- u—Longitudinal velocity

- v—lateral velocity

- — Yaw Angle

From Equations (1)–(4) the wheel center velocities of the four wheels are obtained from the longitudinal, lateral and angular velocities.

The longitudinal and lateral velocities of each one of the four wheels are obtained through Equation (5):

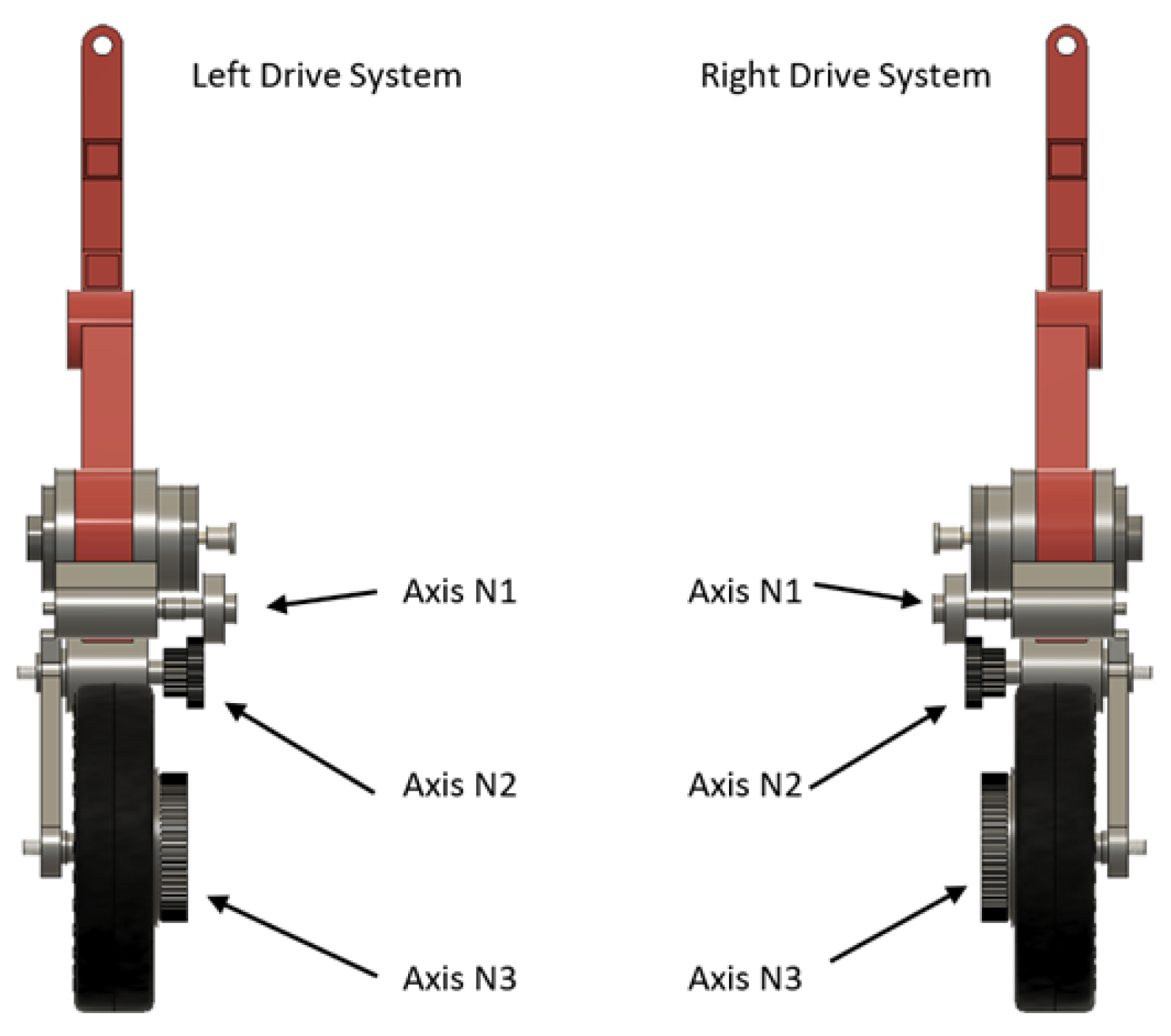

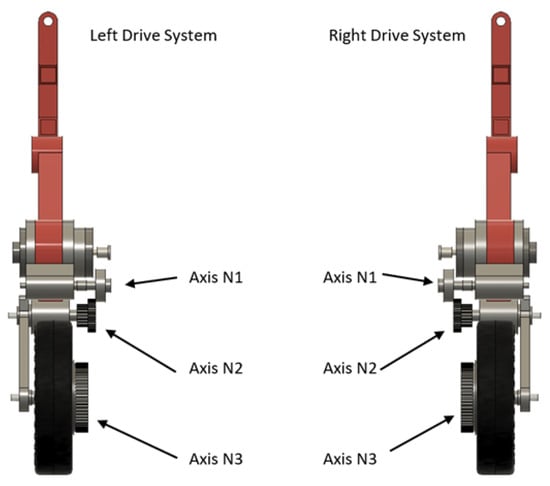

3.6. Drive System Design

The maximum walking speed for a healthy person is 5 kph, therefore, taking into account that 3530 rpm is the speed with the best efficiency of the DC motor, it is considered that at this speed the device operates at a speed of 5 kph. To achieve this, the transmission is calculated and designed as shown below:

3.6.1. Ratio of DC Electric Motor and Wheel Tire

It has been determined to apply eight rubber tires (open honeycomb type design), air free, weighing 580 g each, diameter of with the idea of not suffering punctures during the user’s mobility; likewise, to absorb road irregularities and simplify the ascent/descent of curbs due to its capacity of slight deformation. Four tires are applied on the left section and four on the right section, to maintain a continuous user-ground clearance of 10 cm on all types of surfaces and circumstances.

The reduction factor is calculated from the angular velocity of the motor at its maximum efficiency which is 3530 rpm (369.66 rad/s) between the maximum angular velocity of displacement of a person (12.8721 rad/s) whose tangential displacement is 5 kph (1.3880 mts/s) with a tire radius of 0.1079 mts. This results in a ratio of 28.71, with which it can be guaranteed that the device moves at 5 kph using the motor at an angular velocity of 3530 rpm where its maximum efficiency is located.

3.6.2. Transmission

The system of reduction and transmission of motion from the motor to the wheel uses a synchronous toothed belt or belt with toothed pulleys made of aluminum and ABS due to its low weight and low noise emission (55 dB) approximately, with respect to its counterparts sprockets and steel chains (65 dB). Due to the availability of commercial line components, a reduction of 27:1 is used, instead of the calculated 28.74:1 in (4), by means of three reduction stages, each one with a 3:1 ratio, as follows: For the first reduction (3530 rpm to 1176.66 rpm) and second reduction (1176.66 rpm to 392.22 rpm) is used: a driven pulley Ø = (14.5 mm), 16 teeth, GT3, 3mm Pitch, 9 mm width. The driven pulley Ø = 1.771 (45 mm), 48 teeth, GT3, 3 mm pitch, 9 mm wide. The elements are connected using a Toothed belt GT3, 9 mm wide, 075 teeth, (225 mm) with neoprene-nylon cover. For the third reduction (292.22 rpm to 130.7 rpm) the following components are used: one driven pulley Ø = (30.68 mm), 20 teeth, GT3, 5 mm pitch, 15 mm wide. One driven pulley Ø = (94.36 mm), 60 teeth, GT3, 5 mm Pitch, 15 mm width.

3.6.3. Weight

According to the User-Design and Operational requirements, derived from the anthropometric study of 50 percentile (male and female), the user’s weight is 176.37 lb (80 kg), and the weight of the device with the mechanical components, electronics and batteries is 114.64 lb (52 kg) giving a total weight of 319.67 lb (132 kg).

3.6.4. Bearings

(a) Loads: Considering specifically the drive shafts N1, N2 and N3 Figure 14, which rotate by means of pulleys and synchronous belts, they are subjected to loads of different magnitudes and directions as described below. Axial load is not present in rotating shafts N1 and N2. There is a momentary and reduced axial load on N3 axis when is performed the mobility of the device. Radial load is fixed and permanent type by traction of synchronous belts on rotary axes N1, N2 and N3. The N3 rotating shaft must also support a permanent type load, corresponding to the carrying of a User of 784 N, and including the mobility device of 509.95 N = 1294 N (132 kg).

Figure 14.

Left and Drive Systems.

For N1 and N2 shafts, a single row deep groove ball bearing with sliding sealing plates is used. d = 8, D = 22 and B = 7, with a dynamic load capacity of 3450 N, static of 1370 N, fatigue limit load 57 N and a nominal speed with lithium grease lubrication of 75,000 r/min. For shaft N3, a single row deep groove ball bearing with sliding sealing plates is used. d = 10, D = 26 and B = 8, it has a dynamic load capacity of 4750 N, a static load capacity of 1960 N, a fatigue limit load of 83 N and a nominal speed with lithium grease lubrication of 67,000 r/min.

4. Results

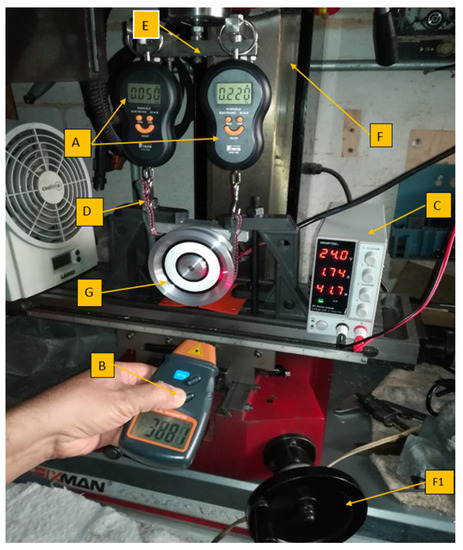

4.1. Motor Characterization

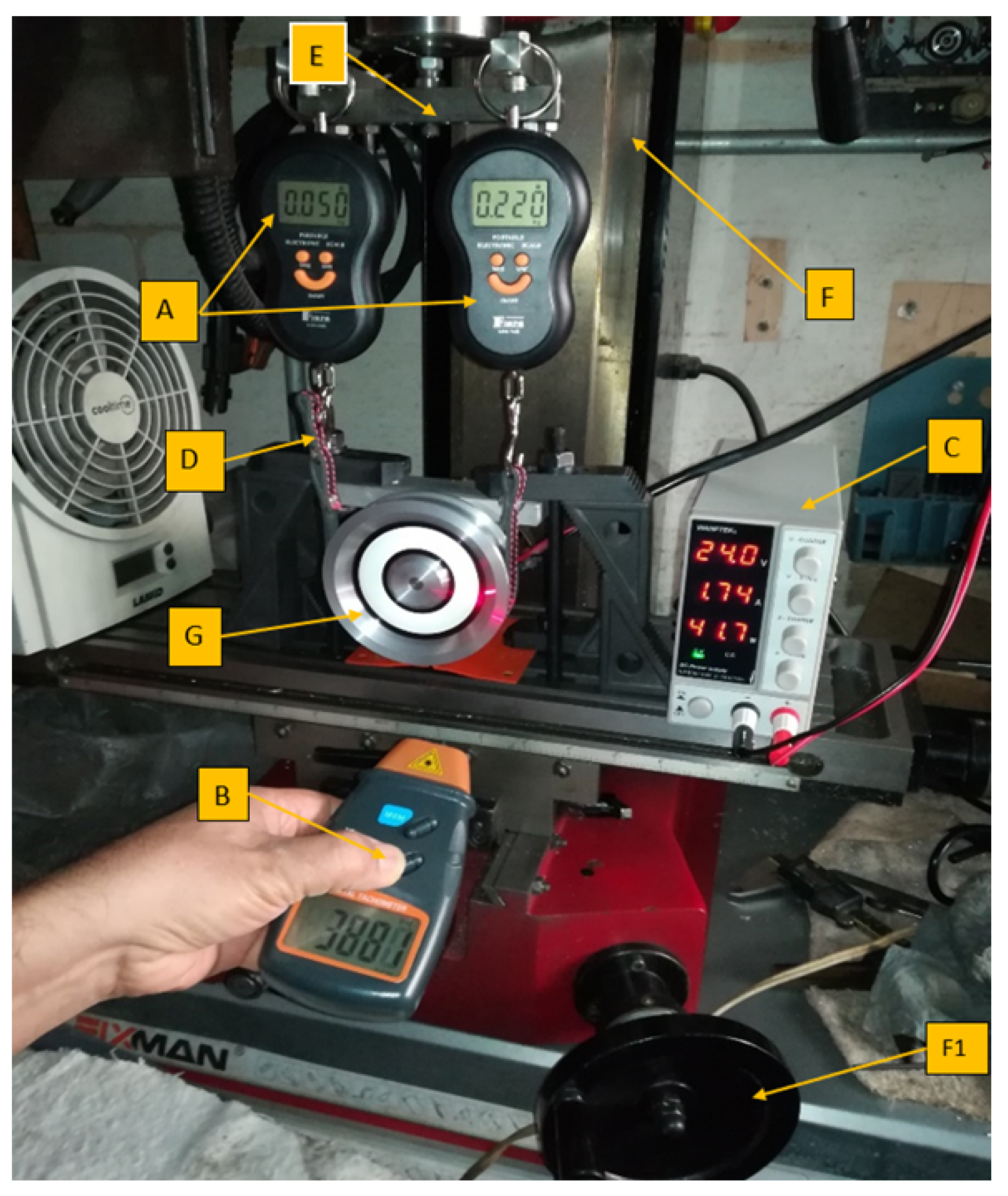

The motors were characterized using a Prony Break absorption type dynamometer, it was used with a reversible DC electric motor with brushes, Yaegoo brand, model JK-0228 of 24 volts and with a power of 150 W at 3800 rpm, with a weight of 3 lb and ball bearings, shown in Figure 15 where (A) dynamometers, (B) digital laser tachometer, (C) power supply, (D) leather belt wide and thick, (E) stainless steel cross support with longitudinal holes, (F) milling machine with manual operation, (G) CD motor with aluminum pulley.

Figure 15.

Motor characterization Components and set-up, (A) Dynamometers, (B) Digital laser tachometer, (C) Power supply, (D) Leather belt wide and thick, (E) Stainless steel cross support with longitudinal holes, (F) Milling machine with manual operation, (F1) Flywheel for vertical axis movement, (G) CD motor with aluminum pulley.

Seventeen tests were performed varying the force exerted from 0.2 lb to 2.74 lb on the pulley (moving the z axis of the milling machine (F) where the two dynamometers and the leather belt are connected). The results are shown in Table 5, obtaining a maximum efficiency in 79.5% at 3530 rpm and with a power of 106.5 W.

Table 5.

Results of Motor Characterization.

4.2. Finite Element Analysis

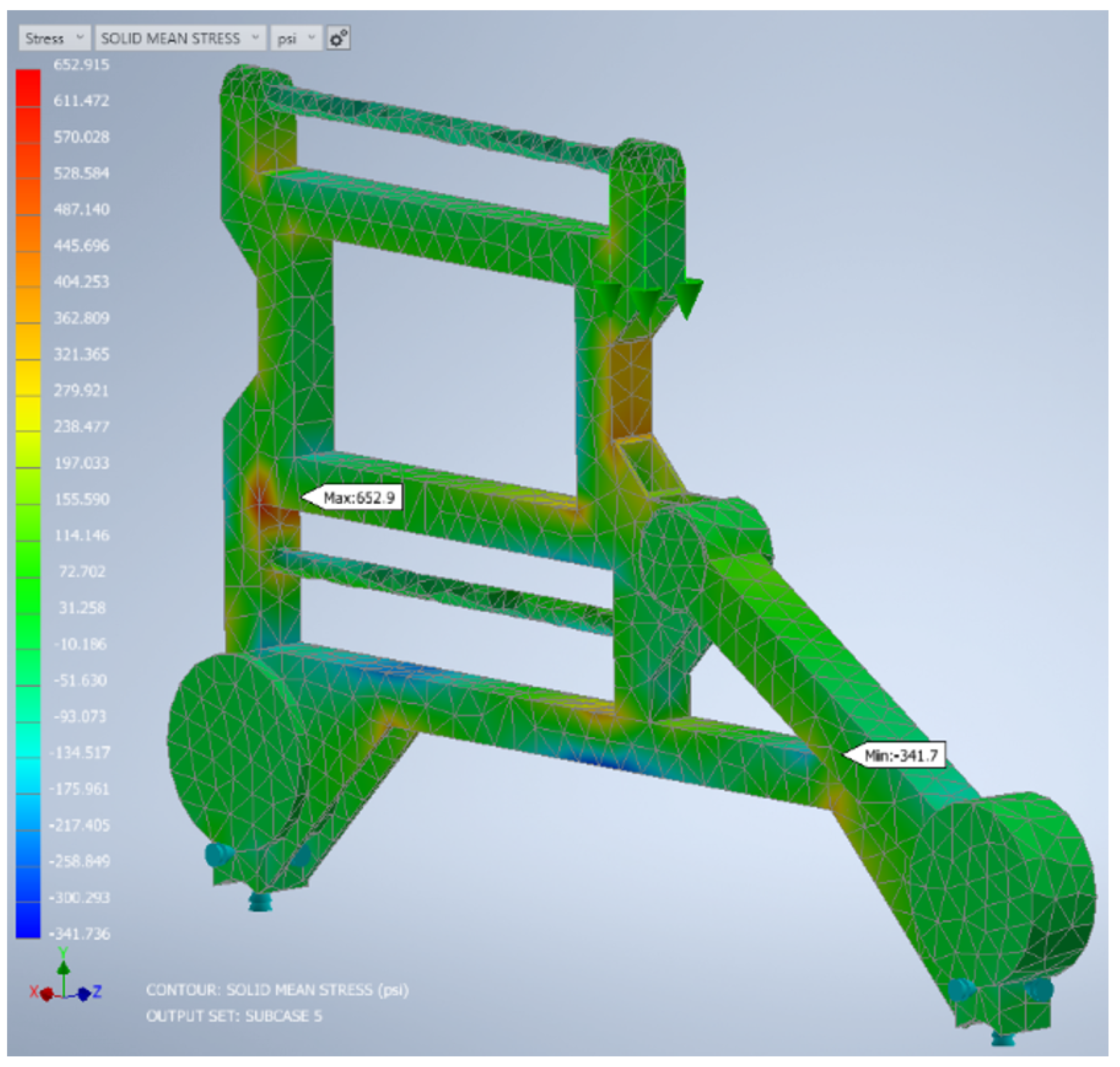

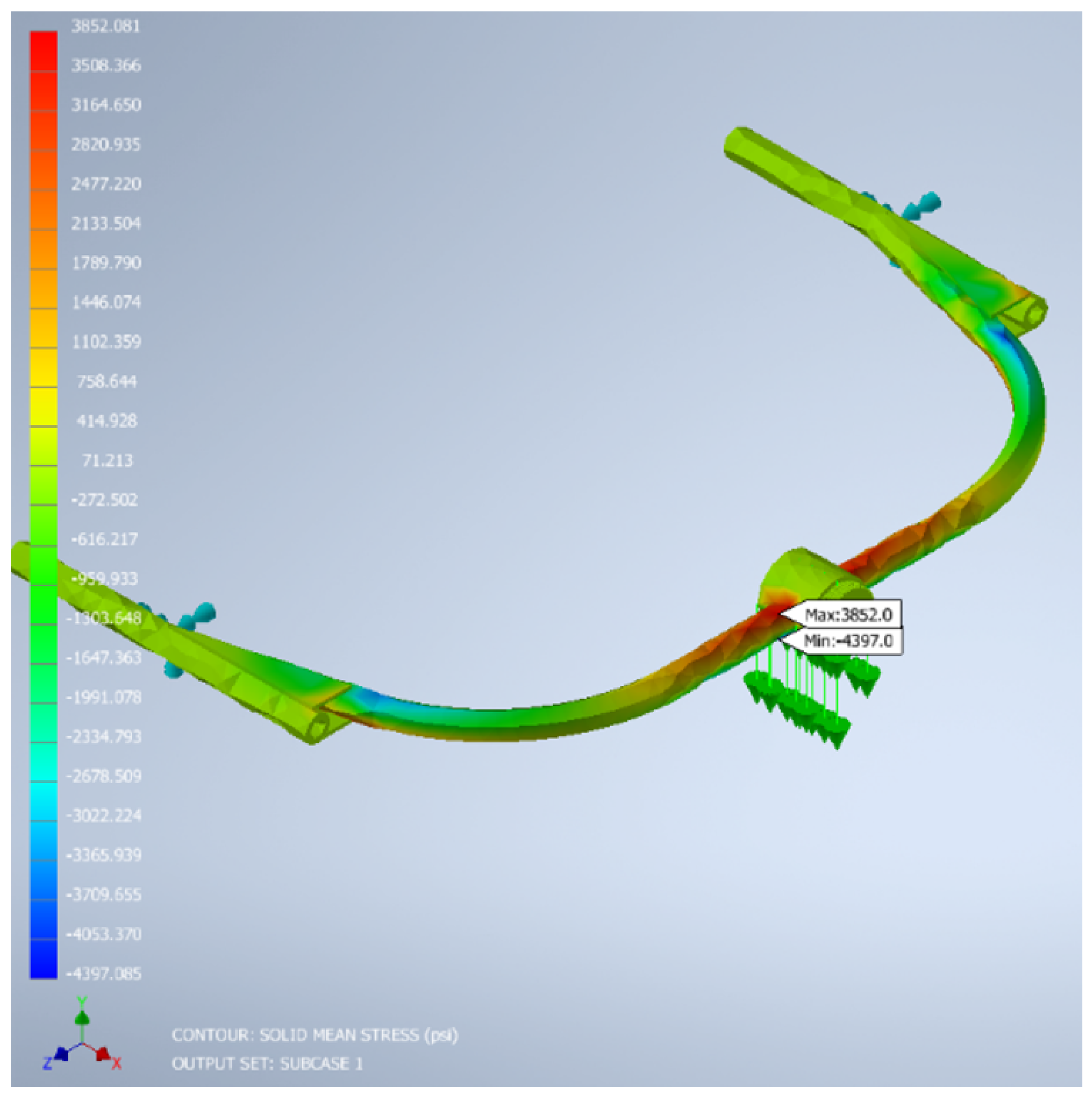

A finite element study was performed to calculate the stresses and strains of two parts considered critical in the device. The analysis were carried out using Nastran software in Autodesk Inventor.

A static analysis was performed using the finite element model of the Figure 16 and Figure 17. The model consists of a total of 16,660 nodes and 8545 elements. An isotropic material carbon steel was used and a PSS linear solver was used.

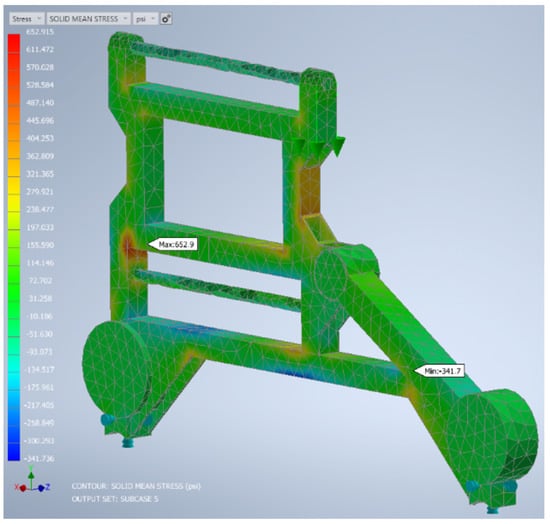

Figure 16.

FEM Analysis of the mechanical structure part Drive System (left side).

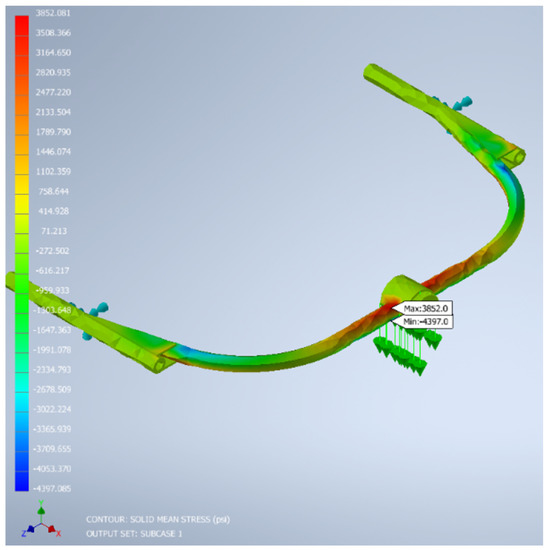

Figure 17.

FEM Analysis of the mechanical parallel support part.

The first finite element analysis was performed on the left section part of the drive system structure. A motion constraint was placed on the lower ends of the part. A load of −185 lbf was applied to each of the two shafts supporting the two parallel bars that support the entire weight of the exoskeleton and the person. It can be seen in Figure 16 that the maximum stress obtained is 652 psi which indicates that it is below the maximum allowable stress of carbon steel. The maximum displacement obtained was 0.008.

The second analysis was performed on the parallel support part which is responsible for carrying the weight of the exoskeleton and the user. A motion constraint was placed on each of the lateral ends. Due to the fact that there are two parallel bars in the design, only a load of −185 lbf (corresponding to half the weight of the exoskeleton and the user) was applied. It can be seen in Figure 17 that the maximum stress obtained is 3508 psi. The maximum displacement is 0.037 in. This indicates that the part will be operating in the elastic zone of the material and will support the load provided.

5. Discussion

This research has achieved a technological development based on a thorough study of the real and important mobility needs of people with SCI. Simplicity in the design was one of the great challenges and goals of the project. The generation of a simple mechanical model makes it possible to develop technology that is within the reach of most people, making the system easier to manufacture and replicate. Upright mobility presents several difficulties when the device is used on the streets, where slopes, edges, potholes and other obstacles can generate a stability problem. Therefore, a mechanism was designed in which the user can always maintain an upright position, without tilting, making the rest of the mechanism adapt to maintain the user’s posture. Table 6 presents a comparison of the main contributions of some exoskeletons available in the state-of-the-art of different research where technological developments related to the issue of upright mobility in people with lower limb disabilities have been carried out.

Table 6.

Literature comparison with exoskeletons in the state-of-the-art.

Limitations of this study. At this time, the main components have been tested separately, and the tests have been limited to stress analysis and spatial stability; however, users have not tested the system, nor has the scalability in the manufacturing processes been verified. The feasibility of manufacturing the proposed system must be verified according to the industrial design. The duration and wear of the parts susceptible to wear must be checked. Users should test the system in a suitable environment close to activities of daily living.

6. Conclusions

The integration of the methodology of industrial design into the scientific method has generated a wide number of possible designs to solve the problem. The design shows that the proposed movement to solve the kinematics of the movements for sagittal and coronal stabilization are correct and are resolved according to the objective on a robust mechanism to propose a simplified electronics.

The proposed pendulum system fulfills all the design-established requirements proposed in Table 2, Table 3 and Table 4, taking into consideration the 50 percentile of the Dreyfus considerations. The proposed mechatronic device allows the user to deal with curbs, ramps, and other obstacles presented in the activities of daily living. At the same time, it restores the user’s self-esteem because it can bring the user to an upright position.

For future work, we consider evaluating the system under an experimental protocol with people who have SCI, endorsed by a bioethics committee and medical specialists, which will allow us to obtain relevant information about the performance of the device.

Author Contributions

Conceptualization, M.A.H.-R. and O.O.S.-G.; methodology, M.A.H.-R., J.d.J.A.F.-C. and A.F.; validation, J.d.J.A.F.-C., O.L.-E. and O.O.S.-G.; formal analysis, A.F. and O.O.S.-G.; investigation, M.A.H.-R. and J.M.J.-V.; writing—original draft preparation, J.d.J.A.F.-C., M.A.H.-R. and O.O.S.-G.; writing—review and editing, J.d.J.A.F.-C., M.A.H.-R., A.F., J.P.R.-J., J.M.J.-V. and O.O.S.-G.; visualization, M.A.H.-R. and J.M.J.-V.; supervision, O.O.S.-G. and O.L.-E. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Tecnológico Nacional de México, grant number 10099.21-P.

Informed Consent Statement

This work does not contain any studies with human participants performed by any of the authors.

Acknowledgments

We are grateful to CONACYT for the scholarships granted to the students for this project.

Conflicts of Interest

The authors declare no conflict of interest.The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| SCI | Spinal Cord Injury |

| ASIA | American Spinal Injury Association |

| ADL | Activities of Daily Living |

| DOF | Degree of Freedom |

| CG | Center of gravity |

| DC | Direct Current |

| CCW | Counterclockwise |

| CW | Clockwise |

| CGS | Center of Gravity of the System |

| CNC | Computer Numerical Control |

References

- Karimi, M.T. Evidence-based evaluation of physiological effects of standing and walking in individuals with spinal cord injury. Iran. J. Med. Sci. 2011, 36, 242–253. [Google Scholar] [PubMed]

- Kirshblum, S.C.; Burns, S.P.; Biering-Sorensen, F.; Donovan, W.; Graves, D.E.; Jha, A.; Johansen, M.; Jones, L.; Krassioukov, A.; Mulcahey, M.J.; et al. International standards for neurological classification of spinal cord injury (revised 2011). J. Spinal Cord. Med. 2011, 34, 535–546. [Google Scholar] [CrossRef] [PubMed]

- Ma, Q.; Ji, L.; Wang, R. The Development and Preliminary Test of a Powered Alternately Walking Exoskeleton With the Wheeled Foot for Paraplegic Patients. IEEE Trans. Neural Syst. Rehabil. Eng. Publ. IEEE Eng. Med. Biol. Soc. 2018, 26, 451–459. [Google Scholar] [CrossRef] [PubMed]

- Tiboni, M.; Borboni, A.; Vérité, F.; Bregoli, C.; Amici, C. Sensors and Actuation Technologies in Exoskeletons: A Review. Sensors 2022, 22, 884. [Google Scholar] [CrossRef] [PubMed]

- Lee, L.W.; Li, I.H.; Lu, L.Y.; Hsu, Y.B.; Chiou, S.J.; Su, T.J. Hardware Development and Safety Control Strategy Design for a Mobile Rehabilitation Robot. Appl. Sci. 2022, 12, 5979. [Google Scholar] [CrossRef]

- Tang, X.; Wang, X.; Ji, X.; Zhou, Y.; Yang, J.; Wei, Y.; Zhang, W. A Wearable Lower Limb Exoskeleton: Reducing the Energy Cost of Human Movement. Micromachines 2022, 13, 900. [Google Scholar] [CrossRef] [PubMed]

- Veneman, J.F.; Kruidhof, R.; Hekman, E.E.G.; Ekkelenkamp, R.; Van Asseldonk, E.H.F.; van der Kooij, H. Design and evaluation of the LOPES exoskeleton robot for interactive gait rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. Publ. IEEE Eng. Med. Biol. Soc. 2007, 15, 379–386. [Google Scholar] [CrossRef] [PubMed]

- Fattah, A.; Agrawal, S.K.; Catlin, G.; Hamnett, J. Design of a Passive Gravity-Balanced Assistive Device for Sit-to-Stand Tasks. J. Mech. Des. 2005, 128, 1122–1129. [Google Scholar] [CrossRef]

- Low, K.H.; Liu, X.; Goh, C.H.; Yu, H. Locomotive Control of a Wearable Lower Exoskeleton for Walking Enhancement. J. Vib. Control 2006, 12, 1311–1336. [Google Scholar] [CrossRef]

- Onose, G.; Cârdei, V.; Craciunoiu, S.T.; Avramescu, V.; Opris, I.; Lebedev, M.A.; Constantinescu, M.V. Mechatronic Wearable Exoskeletons for Bionic Bipedal Standing and Walking: A New Synthetic Approach. Front. Neurosci. 2016, 10, 343. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Xie, H.; Li, W.; Yao, Z. Proceeding of human exoskeleton technology and discussions on future research. Chin. J. Mech. Eng. 2014, 27, 437–447. [Google Scholar] [CrossRef]

- Yepes, J.C.; Rúa, S.; Osorio, M.; Pérez, V.Z.; Moreno, J.A.; Al-Jumaily, A.; Betancur, M.J. Human-Robot Interaction Torque Estimation Methods for a Lower Limb Rehabilitation Robotic System with Uncertainties. Appl. Sci. 2022, 12, 5529. [Google Scholar] [CrossRef]

- Hammell, K.R.W. Spinal cord injury rehabilitation research: Patient priorities, current deficiencies and potential directions. Disabil. Rehabil. 2010, 32, 1209–1218. [Google Scholar] [CrossRef] [PubMed]

- Tilley, A.; Dreyfuss, H.; Associates, H.D. The Measure of Man and Woman: Human Factors in Design; Whitney Library of Design: New York, NY, USA, 1993. [Google Scholar]

- Walsh, C.J.; Paluska, D.; Pasch, K.A.; Grand, W.; Valiente, A.; Herr, H.M. Development of a lightweight, underactuated exoskeleton for load-carrying augmentation. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation, ICRA 2006, Orlando, FL, USA, 15–19 May 2006; pp. 3485–3491. [Google Scholar]

- Ferris, D.P.; Sawicki, G.S.; Domingo, A. Powered lower limb orthoses for gait rehabilitation. Top. Spinal Cord. Inj. Rehabil. 2005, 11, 34–49. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, K.; Mito, G.; Kawamoto, H.; Hasegawa, Y.; Sankai, Y. Intention-based walking support for paraplegia patients with Robot Suit HAL. Adv. Robot. 2007, 21, 1441–1469. [Google Scholar] [CrossRef]

- Costa, N.; Caldwell, D.G. Control of a Biomimetic “Soft-actuated” 10DoF Lower Body Exoskeleton. In Proceedings of the First IEEE/RAS-EMBS International Conference on Biomedical Robotics and Biomechatronics, BioRob 2006, Pisa, Italy, 20–22 February 2006; pp. 495–501. [Google Scholar] [CrossRef]

- Banala, S.K.; Agrawal, S.K.; Scholz, J.P. Active Leg Exoskeleton (ALEX) for Gait Rehabilitation of Motor-Impaired Patients. In Proceedings of the 2007 IEEE 10th International Conference on Rehabilitation Robotics, Noordwijk, The Netherlands, 13–15 June 2007; pp. 401–407. [Google Scholar] [CrossRef]

- Marcheschi, S.; Salsedo, F.; Fontana, M.; Bergamasco, M. Body Extender: Whole body exoskeleton for human power augmentation. In Proceedings of the IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 611–616. [Google Scholar] [CrossRef]

- Tsukahara, A.; Kawanishi, R.; Hasegawa, Y.; Sankai, Y. Sit-to-Stand and Stand-to-Sit Transfer Support for Complete Paraplegic Patients with Robot Suit HAL. Adv. Robot. 2010, 24, 1615–1638. [Google Scholar] [CrossRef]

- Tanabe, S.; Hirano, S.; Saitoh, E. Wearable Power-Assist Locomotor (WPAL) for supporting upright walking in persons with paraplegia. NeuroRehabilitation 2013, 33, 99–106. [Google Scholar] [CrossRef] [PubMed]

- Contreras-Vidal, J.L.; Grossman, R.G. NeuroRex: A clinical neural interface roadmap for EEG-based brain machine interfaces to a lower body robotic exoskeleton. In Proceedings of the 2013 35th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Osaka, Japan, 3–7 July 2013; Volume 2013, pp. 1579–1582. [Google Scholar] [CrossRef]

- Sylos-Labini, F.; La Scaleia, V.; D’Avella, A.; Pisotta, I.; Tamburella, F.; Scivoletto, G.; Molinari, M.; Wang, S.; Wang, L.; van Asseldonk, E.; et al. EMG patterns during assisted walking in the exoskeleton. Front. Hum. Neurosci. 2014, 8, 423. [Google Scholar] [CrossRef] [PubMed]

- Junius, K.; Brackx, B.; Grosu, V.; Cuypers, H.; Geeroms, J.; Moltedo, M.; Vanderborght, B.; Lefeber, D. Mechatronic design of a sit-to-stance exoskeleton. In Proceedings of the 5th IEEE RAS/EMBS International Conference on Biomedical Robotics and Biomechatronics, Sao Paulo, Brazil, 12–15 August 2014; pp. 945–950. [Google Scholar] [CrossRef]

- Collins, S.H.; Wiggin, M.B.; Sawicki, G.S. Reducing the energy cost of human walking using an unpowered exoskeleton. Nature 2015, 522, 212–215. [Google Scholar] [CrossRef] [PubMed]

- Asbeck, A.T.; Dyer, R.J.; Larusson, A.F.; Walsh, C.J. Biologically-inspired soft exosuit. IEEE Int. Conf. Rehabil. Robot. 2013, 2013, 6650455. [Google Scholar] [CrossRef] [PubMed]

- Tarun, D.; Srikanth, V.; Kumar, R.; Anudeep, I.M.; Srikanth, S. Stress Analysis on a Chairless Chair; Research India Publications: Delhi, India, 2017. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).