High-Temperature Annealing Effects on Atomically Thin Tungsten Diselenide Field-Effect Transistor

Abstract

:1. Introduction

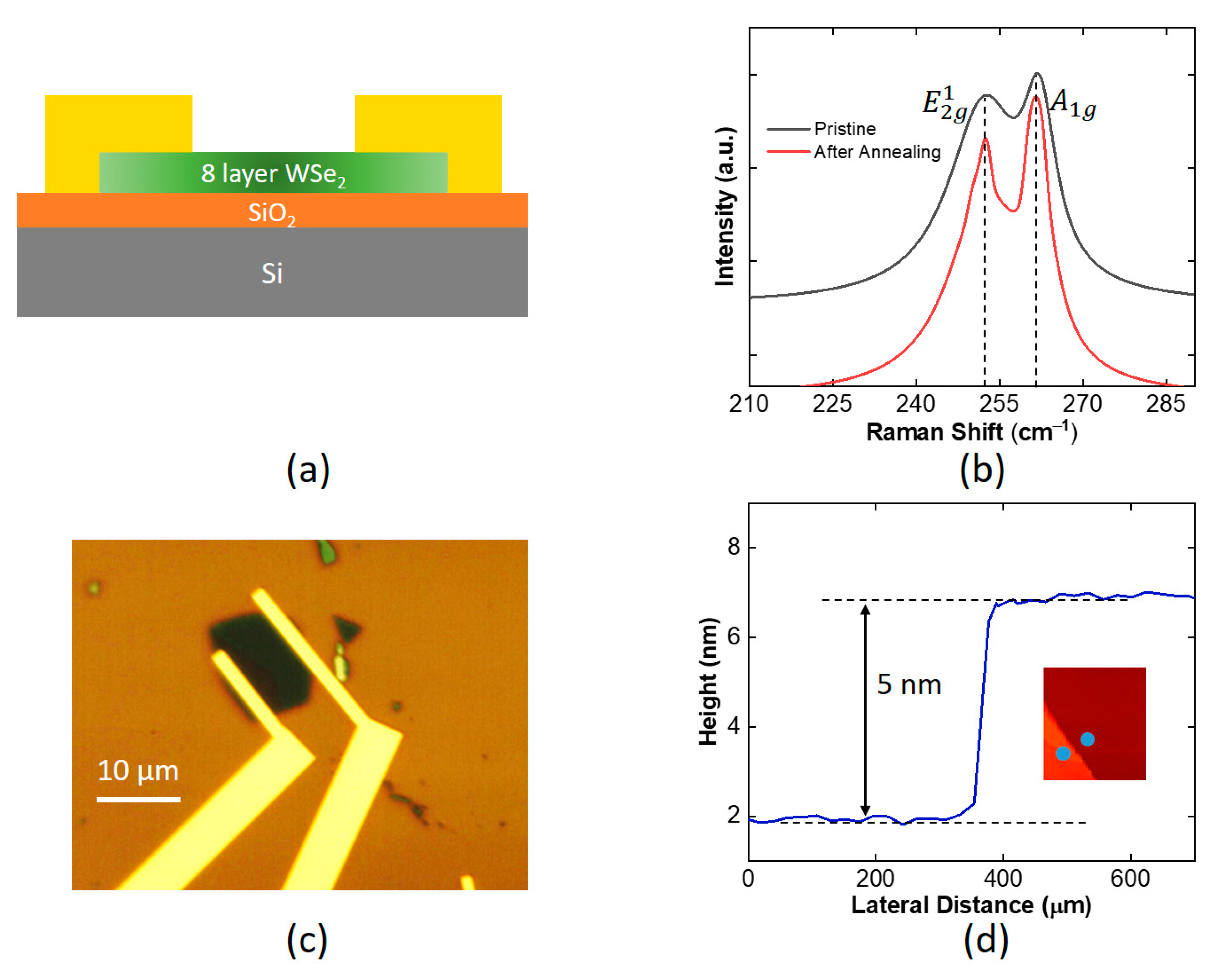

2. Materials and Methods

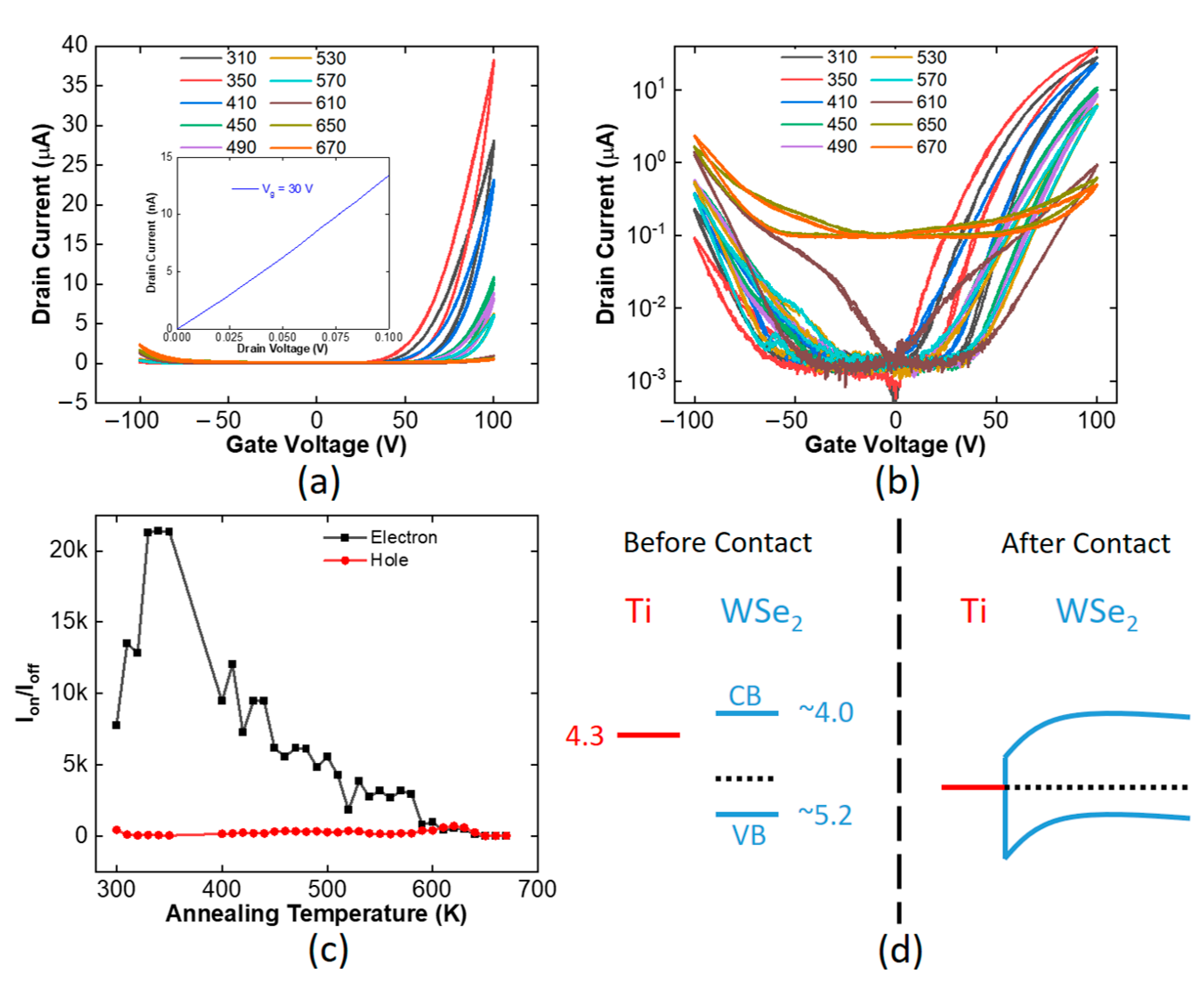

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Massoud, Y.; White, J. Managing On-Chip Inductive Effects. IEEE Trans. Very Large Scale Integr. (VLSI) Syst. 2002, 10, 789–798. [Google Scholar] [CrossRef]

- Hosseini, A.; Ragheb, T.; Massoud, Y. A Fault-Aware Dynamic Routing Algorithm for On-Chip Networks. In Proceedings of the 2008 International Symposium on Circuits and Systems, Seattle, WA, USA, 18–21 May 2008; pp. 2653–2656. [Google Scholar]

- Massoud, Y.; White, J. Simulation and Modeling of the Effect Substrate Conductivity on Coupling Inductance and Circuit Crosstalk. IEEE Trans. Very Large Scale Integr. (VLSI) Syst. 2002, 10, 286–291. [Google Scholar] [CrossRef]

- Massoud, Y.; Ismail, Y. Grasping the Impact of On-Chip Inductance in High Speed ICs. IEEE Circuits Devices Mag. 2001, 17, 14–21. [Google Scholar] [CrossRef]

- Hosseini, A.; Nejati, H.; Massoud, Y. Triangular lattice plasmonic photonic band gaps in subwavelength metal-insulator-metal waveguide structures. Appl. Phys. Lett. 2008, 92, 013116. [Google Scholar] [CrossRef]

- Ijaz, S.; Rana, A.S.; Ahmad, Z.; Zubair, M.; Massoud, Y.; Mehmood, M.Q. The Dawn of Meta-devices: From Contemporary Designs to Exotic Applications. Adv. Devices Instrum. 2022, 2022, 9861078. [Google Scholar] [CrossRef]

- Naveed, M.A.; Kim, J.; Javed, I.; Ansari, M.A.; Seong, J.; Massoud, Y.M.; Badloe, T.; Kim, I.; Riaz, K.; Zubair, M.; et al. Novel Spin-Decoupling Strategy in Liquid Crystal-Integrated Metasurfaces for Interactive Meta-Displays. Adv. Opt. Mater. 2022, 10, 2200196. [Google Scholar] [CrossRef]

- Hosseini, A.; Massoud, Y. Nanoscale surface plasmon based resonator using rectangular geometry. Appl. Phys. Lett. 2007, 90, 181102. [Google Scholar] [CrossRef]

- Macilwain, C. Silicon down to the win. Nature 2005, 436, 22. [Google Scholar]

- Alam, A.; Massoud, Y. RLC ladder model for scattering in single metallic nanoparticles. IEEE Trans. Nanotechnol. 2006, 5, 491–498. [Google Scholar] [CrossRef]

- Massoud, Y.; White, J. Improving the Generality of the Fictitious Magnetic Charge Approach to Computing Inductances in the Presence of Permeable Materials. In Proceedings of the IEEE/ACM Design Automation Conference, New Orleads, LA, USA, 10–14 June 2002; pp. 552–555. [Google Scholar]

- Peng, L.; Zhang, Z.; Whang, S. Carbon nanotube electronics: Recent advances. Mater. Today 2014, 17, 433–442. [Google Scholar] [CrossRef]

- Nieuwoudt, A.; Massoud, Y. Understanding the Impact of Inductance in Carbon Nanotube Bundles for VLSI Interconnect using Scalable Modeling Techniques. IEEE Trans. Nanotechnol. 2006, 5, 758–765. [Google Scholar] [CrossRef]

- Massoud, Y.; Nieuwoudt, A. Modeling and Design Challenges and Solutions for Carbon Nanotube-Based Interconnect in Future High-Performanc Integrated Circuits. ACM J. Emerg. Technol. Comput. Syst. 2006, 2, 155–196. [Google Scholar] [CrossRef]

- Nieuwoudt, A.; Massoud, Y. On the Optimal Design, Performance, and Reliability of Future Carbon Nanotube-Based Interconnect Solutions. IEEE Trans. Electron Devices 2008, 55, 2097–2110. [Google Scholar] [CrossRef]

- Nieuwoudt, A.; Massoud, Y. On the Impact of Process Variations for Carbon Nanotube Bundles for VLSI Interconnect. IEEE Trans. Electron. Devices 2007, 54, 446–455. [Google Scholar] [CrossRef]

- Singh, V.; Joung, D.; Zhai, L.; Das, S.; Khondaker, S.I.; Seal, S. Graphene-based materials: Past, present and future. Prog. Mater. Sci. 2011, 56, 1178–1271. [Google Scholar] [CrossRef]

- Li, X.; Zhu, H. Two-dimensional MoS2: Properties, preparation, and applications. J. Materiomics 2015, 1, 33–44. [Google Scholar] [CrossRef]

- Hosseini, A.; Nieuwoudt, A.; Massoud, Y. Optimizing Dielectric Strips Over a Metallic Substrate for Subwavelength Light Confinement. IEEE Photonics Lett. 2007, 19, 522–524. [Google Scholar] [CrossRef]

- Massoud, Y.; Majors, S.; Bustami, T.; White, J. Layout Techniques for Minimizing On-Chip Interconnect Self Inductance. In Proceedings of the IEEE/ACM Design Automation Conference, San Francisco, CA, USA, 15–19 June 1998; pp. 566–571. [Google Scholar]

- Geim, K.; Grigorieva, I.V. Van der Waals heterostructures. Nature 2013, 499, 419–425. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Mishchenkoa, A.; Carvalhoand, A.; Neto, A.H.C. 2D materials and van der Waals heterostructures. Science 2016, 353, 6298. [Google Scholar] [CrossRef]

- Alam, M.; Massoud, Y. A closed-form analytical model for single nanoshells. IEEE Trans. Nanotechnol. 2006, 5, 265–272. [Google Scholar] [CrossRef]

- Hosseini, A.; Massoud, Y. A low-loss metal-insulator-metal plasmonic bragg reflector. Opt. Express 2006, 14, 11318–11323. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; Chin, M.L.; Najmaei, S.; Guo, Q.; Xia, F.; Wang, H.; Dubey, M. Optoelectronic devices based on two-dimensional transition metal dichalcogenides. Nano Res. 2016, 9, 1543–1560. [Google Scholar] [CrossRef]

- Wu, H.; Yan, Z.; Xie, Z.; Zhu, S. WSe2/Pd Schottky diode combining van der Waals integrated and evaporated metal contacts. Appl. Phys. Lett. 2021, 119, 213102. [Google Scholar] [CrossRef]

- Ross, J.S.; Klement, P.; Jones, A.M.; Ghimire, N.J.; Yan, J.; Mandrus, D.G.; Taniguchi, T.; Watanabe, K.; Kitamura, K.; Yao, W.; et al. Electrically tunable excitonic light-emitting diodes based on monolayer WSe2 p–n junctions. Nat. Nanotechnol. 2014, 9, 268–272. [Google Scholar] [CrossRef]

- Schultz, J.F.; Jiang, N. Characterizations of two-dimensional materials with cryogenic ultrahigh vacuum near-field optical microscopy in the visible range. J. Vac. Sci. Technol. 2022, 40, 040801. [Google Scholar] [CrossRef]

- Abbas, M.A.; Kim, J.; Rana, A.S.; Kim, I.; Rehman, B.; Ahmad, Z.; Massoud, Y.; Seong, J.; Badloe, T.; Park, K.; et al. Nanostructured Chromium-based Broadband Absorber and Emitter to Realize Thermally Stable Solar Thermophotovoltaic Systems. Nanoscale 2022, 14, 6425–6436. [Google Scholar] [CrossRef]

- Hosseini, A.; Nieuwoudt, A.; Massoud, Y. Efficient simulation of subwavelength plasmonic waveguides using implicitly restarted Arnoldi. Opt. Express 2006, 14, 7291–7298. [Google Scholar] [CrossRef]

- Hosseini, A.; Nejati, H.; Massoud, Y. Design of a maximally flat optical low pass filter using plasmonic nanostrip waveguides. Opt. Express 2007, 15, 15280–15286. [Google Scholar] [CrossRef]

- Gu, X.; Yang, R. Phonon transport and thermal conductivity in two-dimensional materials. Annu. Rev. Heat Transf. 2016, 19, 1. [Google Scholar] [CrossRef]

- Massoud, Y.; White, J. FastMag: A 3-D Fast Inductance Extraction Program for Structures with Permeable materials. In Proceedings of the IEEE/ACM International Conference on Computer Aided Design, San Jose, CA, USA, 10–14 November 2002; pp. 478–484. [Google Scholar]

- Amir, H.; Massoud, Y. Optical range microcavities and filters using multiple dielectric layers in metal-insulator-metal structures. J. Opt. Soc. Am. A 2007, 24, 221–224. [Google Scholar]

- Massoud, Y.; Kawa, J.; MacMillen, D.; White, J. Modeling and Analysis of Differential Signaling for Minimizing Inductive Cross-Talk. In Proceedings of the IEEE/ACM Design Automation Conference, Las Vegas, NV, USA, 22 June 2001; pp. 804–809. [Google Scholar]

- Hosseini, A.; Nejati, H.; Massoud, Y. Modeling and design methodology for metal-insulator-metal plasmonic Bragg reflectors. Opt. Express 2008, 16, 1475–1480. [Google Scholar] [CrossRef] [PubMed]

- Corro, E.; Terrones, H.; Elias, A.; Fantini, C.; Feng, S.; Nguyen, M.A.; Mallouk, T.E.; Terrones, M.; Pimenta, M.A. Excited excitonic states in 1L, 2L, 3L, and bulk WSe2 observed by resonant Raman spectroscopy. ACS Nano 2014, 8, 9629–9635. [Google Scholar] [CrossRef] [PubMed]

- Sahin, H.; Tongay, S.; Horzum, S.; Fan, W.; Zhou, J.; Li, J.; Wu, J.; Peeters, F.M. Anomalous Raman spectra and thickness-dependent electronic properties of WSe. Mater. Today 2013, 87, 165409. [Google Scholar]

- Kim, K.; Larentis, S.; Fallahazad, B.; Lee, K.; Xue, J.; Dillen, D.C.; Corbet, C.M.; Tutuc, E. Band alignment in WSe2–graphene heterostructures. ACS Nano 2015, 9, 4527–4532. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, C.; Shaw, J.C.; Cheng, R.; Chen, Y.; Huang, X.; Liu, Y.; Weiss, N.O.; Lin, Z.; Huang, Y.; et al. Large Area Growth and Electrical Properties of p-Type WSe2 Atomic Layers. Nano Lett. 2015, 15, 709–713. [Google Scholar] [CrossRef]

- Namgung, S.D.; Yang, S.; Park, K.; Cho, A.-J.; Kim, H.; Kwon, J.-Y. Influence of post-annealing on the off current of MoS2 field-effect transistors. Nanoscale Res. Lett. 2015, 10, 62. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Tan, C.; Chou, H.; Nayak, A.; Wu, D.; Ghosh, R.; Chang, H.-Y.; Hao, Y.; Wang, X.; Kim, J.-S.; et al. Thermal oxidation of WSe2 nanosheets adhered on SiO2/Si substrates. Nano Lett. 2015, 15, 4979–4984. [Google Scholar] [CrossRef]

- Wang, B.; Eichfield, S.M.; Wang, D.; Haque, M.A. In situ degradation studies of two-dimensional WSe2–graphene heterostructures. Nanoscale 2015, 7, 14489–14495. [Google Scholar] [CrossRef]

- Kang, M.; Yang, H.I.; Choi, W. Oxidation of WS2 and WSe2 monolayers by ultraviolet-ozone treatment. J. Phys. D Appl. Phys. 2019, 52, 505105. [Google Scholar] [CrossRef]

- Tan, C.; Liu, Y.; Chou, H.; Kim, J.-S.; Wu, D.; Akinwande, D.; Lai, K. Laser-assisted oxidation of multi-layer tungsten diselenide nanosheets. Appl. Phys. Lett. 2016, 108, 083112. [Google Scholar] [CrossRef]

- Li, Z.; Yang, S.; Dhall, R.; Kosmowska, E.; Shi, H.; Chatzakis, I.; Cronin, S.B. Layer control of WSe2 via selective surface layer oxidation. ACS Nano 2016, 10, 6836–6842. [Google Scholar] [CrossRef] [PubMed]

- Gammelgaard, L.; Whelan, P.R.; Booth, T.J.; Bøggild, P. Long-term stability and tree-ring oxidation of WSe 2 using phase-contrast AFM. Nanoscale 2021, 13, 19238–19246. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, M.; Dutta, S.; Aikawa, S.; Nakaharai, S.; Wakabayashi, K.; Fuhrer, M.S.; Ueno, K.; Tsukagoshi, K. Self-limiting layer-by-layer oxidation of atomically thin WSe2. Nano Lett. 2015, 15, 2067–2073. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, M.A.; Mehmood, M.Q.; Massoud, Y. High-Temperature Annealing Effects on Atomically Thin Tungsten Diselenide Field-Effect Transistor. Appl. Sci. 2022, 12, 8119. https://doi.org/10.3390/app12168119

Khan MA, Mehmood MQ, Massoud Y. High-Temperature Annealing Effects on Atomically Thin Tungsten Diselenide Field-Effect Transistor. Applied Sciences. 2022; 12(16):8119. https://doi.org/10.3390/app12168119

Chicago/Turabian StyleKhan, Muhammad Atif, Muhammad Qasim Mehmood, and Yehia Massoud. 2022. "High-Temperature Annealing Effects on Atomically Thin Tungsten Diselenide Field-Effect Transistor" Applied Sciences 12, no. 16: 8119. https://doi.org/10.3390/app12168119

APA StyleKhan, M. A., Mehmood, M. Q., & Massoud, Y. (2022). High-Temperature Annealing Effects on Atomically Thin Tungsten Diselenide Field-Effect Transistor. Applied Sciences, 12(16), 8119. https://doi.org/10.3390/app12168119