A New Method for Evaluating the Homogeneity and Structure of Remolded Loess Samples with the Air Permeability Coefficient

Abstract

:1. Introduction

2. Test Principle and Scheme

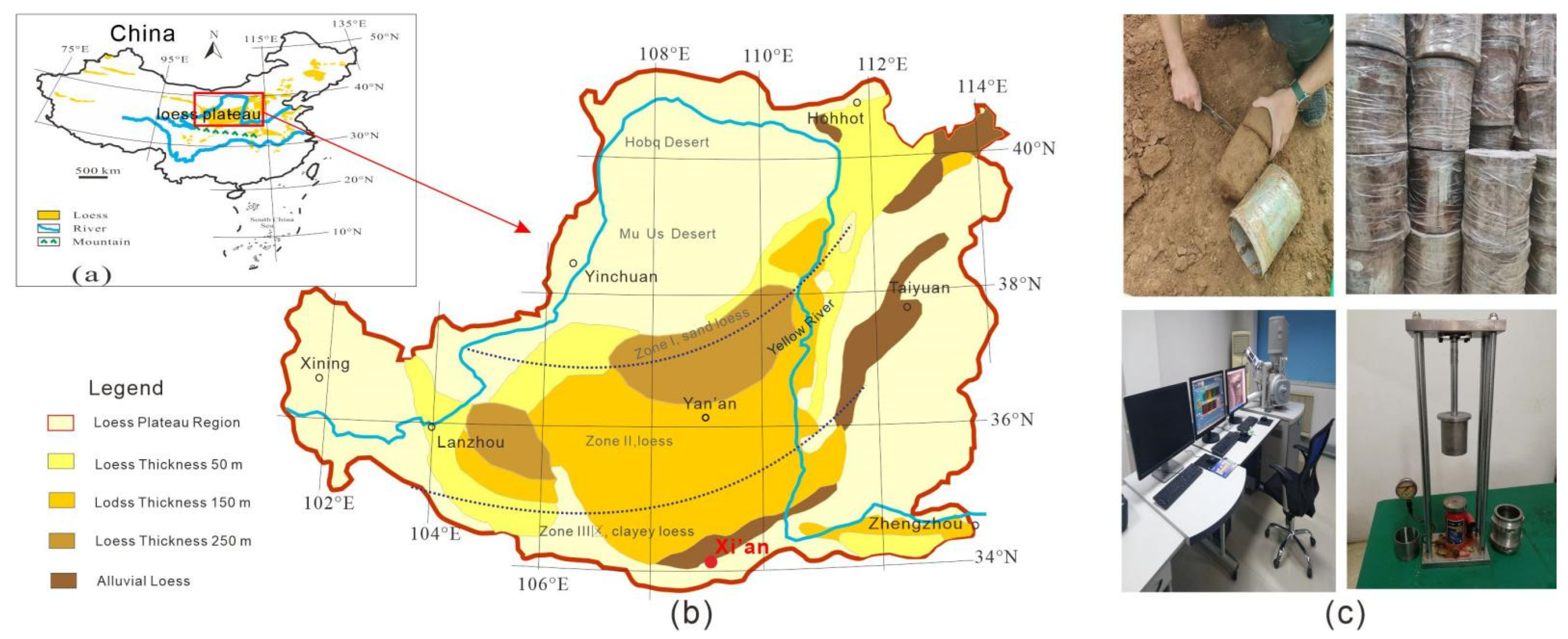

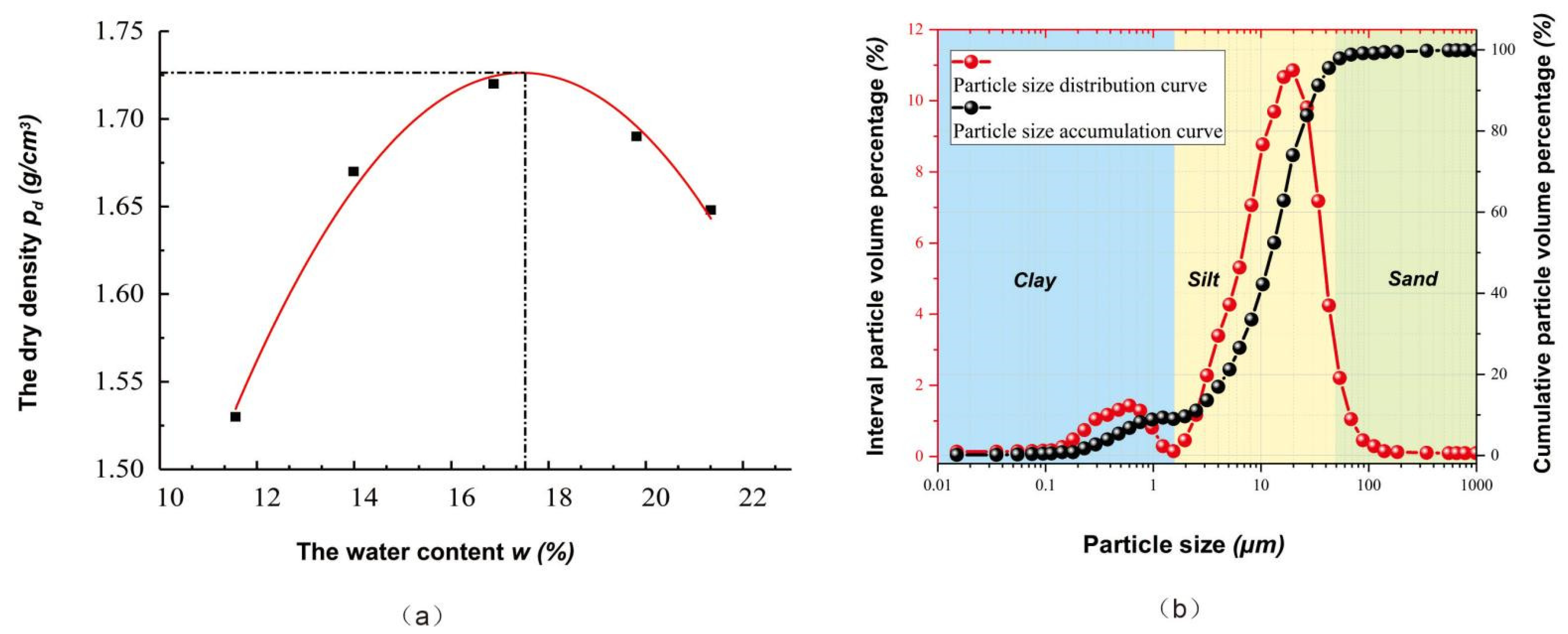

2.1. Test Materials

2.2. Test Scheme

2.3. Calculation Formula of the Air Permeability Coefficient

3. Results and Mechanism Analysis

3.1. Uniformity Analysis of Remolded Specimens

3.1.1. Influence of the Sample Height on Uniformity

3.1.2. Stress Distribution Analysis of Sample Uniformity

3.1.3. Analysis of Sample Uniformity via the Range Method

3.1.4. Analysis of Sample Uniformity via the Discrete Element Method

3.2. Analysis of the Air Permeability of In Situ, Undisturbed, and Remolded Loess Samples

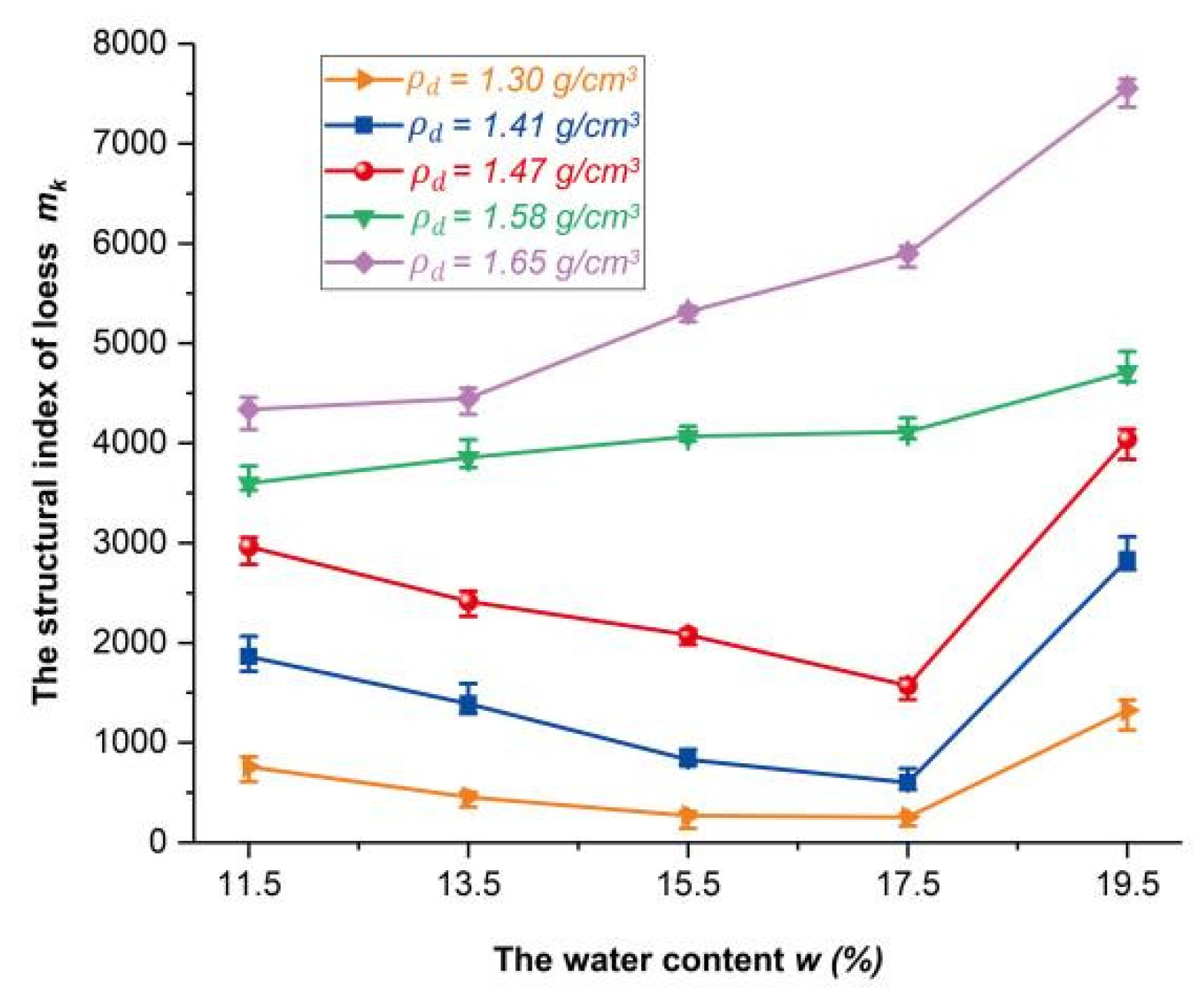

3.3. Quantitative Index of Loess Structure Based on Air Permeability

3.4. Structural Differences between Undisturbed and Remolded Loess Based on SEM Images

3.5. The Geological Origin of the Structural Differences between Undisturbed and Remolded Loess

4. Conclusions

- 1.

- When the moisture content is fixed, the delamination dry density of remolded samples changes with the designed dry density and the overall height of the sample.

- 2.

- With the increase in sample height, the air permeability coefficient of the sample gradually increases, which indicates that the sample tends to be more uniform with the increase in the overall sample height. The more uniform the soil sample, the greater the air permeability coefficient of the remolded sample.

- 3.

- When the dry density was < 1.58 g/, the air permeability and structural texture index mk of remolded loess were found to first decrease and then increase with the increase in moisture content; when ≥ 1.58 g/, was found to increase with the increase in the moisture content of remolded loess, and the range of the increase in was found to vary with dry density.

- 4.

- Combined with the microscopic scanning electron microscope images, it was revealed that the redistribution of clay, colloidal particles, and soluble salt ions in undisturbed loess during countless drying/wetting cycles endows the loess with a strong structure. However, remolded loess is characterized by the greatly reduced effectiveness of cementation between skeleton particles, which causes its structure to be weaker than that of undisturbed loess.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ding, H.; Li, Y.; Yang, Y.; Jia, X. Origin and evolution of modern loess science-1824 to 1964. J. Asian Earth Sci. 2019, 170, 45–55. [Google Scholar] [CrossRef]

- Sun, J.; Ding, Z.L. Spatial and temporal changes of dry and wet climate during the last 130, 000 years in the Loess Plateau. Quat. Sci. 1997, 2, 168–175. [Google Scholar]

- Shao, S.J.; Zhou, F.F.; Long, J.Y. Structural properties of loess and its quantitative parameter. Chin. J. Geotech. Eng. 2004, 4, 531–536. [Google Scholar]

- Zhang, Y.; Qian, H.; Hou, K.; Qu, W. Investigating and predicting the temperature effects of permeability for loess. Eng. Geol. 2021, 285, 106050. [Google Scholar] [CrossRef]

- Wang, H.; Sun, P.; Liu, E.; Li, R. Dynamic properties of Tianshui saturated remolded loess: A laboratory study. Eng. Geol. 2020, 272, 105570. [Google Scholar] [CrossRef]

- Benahmed, N.; Canou, J.; Dupla, J.C. Structure initiale et propriétés de liquéfaction statique d’un sable. Comptes Rendus Mec. 2004, 332, 887–894. [Google Scholar] [CrossRef]

- Bradshaw, A.S.; Baxter, C. Sample Preparation of Silts for Liquefaction Testing. Geotech. Test. J. 2007, 30, 1–9. [Google Scholar] [CrossRef]

- Karathanasis, A.D.; Macneal, B.R. Evaluation of parent material uniformity criteria in loess-influenced soils of west-central Kentucky. Geoderma 1994, 64, 73–92. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, F.; Dupla, J.-C.; Canou, J.; Foerster, E.; Peng, Q. Assessment of tamping-based specimen preparation methods on static liquefaction of loose silty sand. Soil Dyn. Earthq. Eng. 2021, 143, 106592. [Google Scholar] [CrossRef]

- Mehlich, A. Uniformity of soil test results as influenced by volume weight. Commun. Soil Sci. Plant Anal. 1973, 4, 475–486. [Google Scholar] [CrossRef]

- Kuerbis, R.; Vaid, Y.P. Sand sample preparation-the slurry deposition method. Proc. Soil Eng. Soc. 1988, 28, 107–118. [Google Scholar] [CrossRef]

- Wen, Y.; Li, X. Method for measurement and evaluation of soil homogeneity. Corros. Sci. Prot. Technol. 1997, 9, 53–57. [Google Scholar]

- Jiang, M.; Konrad, J.-M.; Leroueil, S. An efficient technique to generate homogeneous specimens for DEM studies. Comput. Geotech. 2003, 30, 579–597. [Google Scholar] [CrossRef]

- Zheng, J.; Zhao, S.; Ma, W. Application of CT testing technology in evaluating the uniformity of soil samples. J. Lanzhou Univ. (Nat. Sci.) 2009, 45, 20–25. [Google Scholar] [CrossRef]

- Meng, J.; Li, X.a. Uniformity analysis of remolded loess samples based on high precision μCT scan. J. Chang. Sci. Res. Inst. 2019, 036, 125–130. [Google Scholar] [CrossRef]

- Chou, Y.L.; Jia, S.S.; Zhang, Q.H.; Cao, W.; Sehng, Y. The influence of freeze-thaw action on loess collapsibility coefficient considering soil structure. Yantu Lixue/Rock Soil Mech. 2018, 39, 2715–2722 and 2731. [Google Scholar] [CrossRef]

- Haeri, S.M.; Zamani, A.; Garakani, A.A. Collapse Potential and Permeability of Undisturbed and Remolded Loessial Soil Samples; Springer: Berlin, Germany, 2012; pp. 301–308. [Google Scholar] [CrossRef]

- Wang, H.; Yue, Z.; Ye, C. Experimental study on permeability of undisturbed loess and remolded loess. J. Shijiazhuang Tiedao Univ. (Nat. Sci. Ed.) 2009, 22, 20–22. [Google Scholar] [CrossRef]

- Chen, H.; Liu, M.; Song, Z. Study on structural parameters of remolded and undisturbed saturated loess. J. Undergr. Space Eng. 2010, 6, 487–491+497. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, S.; Chen, D.; Zhao, D.; Zhang, D. An experimental study of the influence of structural parameters on dynamic characteristics of loess. Soil Dyn. Earthq. Eng. 2020, 132, 106067. [Google Scholar] [CrossRef]

- Zhang, Y.; Song, Z.; Wen, X. Soil and water characteristics of Q3 undisturbed loess and remolded loess. J. Water Resour. Water Eng. 2019, 30, 224–229. [Google Scholar] [CrossRef]

- Ding, P. Study of ZC-5 type gas permeation meter and gas permeation test method. J. Xi’an Univ. Technol. 1986, 40–55. [Google Scholar]

- Li, X.A.; Liu, J. Study on the relationship between pore structure parameters and permeability of Malan loess. Eng. Geol. 2018, 26, 10–18. [Google Scholar]

- Liu, J.; Li, X.A. Study on the relationship between gas permeability and saturated permeability coefficient in Malan loess. Hydrogeol. Eng. Geol. 2017, 44, 154–162. [Google Scholar] [CrossRef]

- Iversen, B.; Schjønning, P.; Poulsen, T.; Moldrup, P. In Situ, on-Site and Laboratory Measurements of Soil Air Permeability: Boundary Conditions and Measurement Scale. Soil Sci. 2001, 166, 97–106. [Google Scholar] [CrossRef]

- Klinkenberg, L.J. The permeability of porous media to liquids and gases. Am. Pet. Inst. Drill. Prod. Pract. 2012, 2, 57–73. [Google Scholar] [CrossRef]

- Zhou, W. Study on homogeneity of remolded loess samples. Sci. Technol. Eng. 2015, 15, 266–269. [Google Scholar] [CrossRef]

- Waal, W.W.; Mikes, D.; Bruining, H. Inertia factor measurements from pressure-decay curves obtained with probe-permeameters. Situ 1998, 22, 339–371. [Google Scholar]

- Li, G. Advanced Soil Mechanics; Tsinghua University Press: Beijing, China, 2004. [Google Scholar]

- Liu, J.; Li, X.; Xue, Q.; Guo, Z. Experimental study on air permeability and microscopic mechanism of intact and remolded Malan loess, Loess Plateau, China. Bull. Eng. Geol. Environ. 2020, 79, 3909–3919. [Google Scholar] [CrossRef]

- Hong, B.; Li, X.; Pang, T.; Wang, L.; Li, L.; Guo, Z.; Liu, J.; Lei, H. Application of vacuum decay tester in measuring air permeability of loess in the Chinese Loess Plateau, northwest China. Hum. Ecol. Risk Assessment: Int. J. 2020, 26, 2520–2540. [Google Scholar] [CrossRef]

- Barden, L.; Pavlakis, G. Air and water permeability of compacted unsaturated cohesive soil. J. Soil Sci. 2006, 22, 302–318. [Google Scholar] [CrossRef]

- Wang, L.; Bai, X. Discussion on shearing strength influencing factors of compacted loess-like backfill. Chin. J. Geotech. Eng. 2010, 32, 132–135. [Google Scholar]

- Li, X.A.; Xue, Q. Study on gas permeability rate of loess latent erosion formation based on in situ gas permeability test. J. Eng. Geol. 2019, 27, 8. [Google Scholar] [CrossRef]

- Dixon, D.A.; Graham, J.; Gray, M.N. Hydraulic conductivity of clays in confined tests under low hydraulic gradients. Can. Geotech. J. 2011, 36, 815–825. [Google Scholar] [CrossRef]

- Wang, Y.; Xie, D.; Guo, Q. Motion characteristics of gas in unsaturated soil and determination of gas permeability coefficient. Northwest Hydroelectr. 1993, 1, 46–49. [Google Scholar]

- Liu, F.; Zhang, Z.; Zhou, D. Gas and water permeability function of unsaturated loess with double change of humidity and density. Chin. J. Rock Mech. Eng. 2010, 29, 1907–1914. [Google Scholar]

- Luo, Y.; Xie, D.; Shao, S. Structural parameter of soil under complex stress conditions. Chin. J. Rock Mech. Eng. 2004, 23, 4248–4251. [Google Scholar] [CrossRef]

- Shao, S.; Zheng, W.; Wang, Z.; Wang, S. Structure index of loess and its experimental determination method. Rock Soil Mech. 2010, 31, 15–19. [Google Scholar] [CrossRef]

- Xie, D.; Qi, J. A new approach to the study of soil structure and its quantitative parameters. Chin. J. Geotech. Eng. 1999, 21, 651–656. [Google Scholar]

- Xie, D. Some new trends in the study of loess mechanics in China. Chin. J. Geotech. Eng. 2001, 1, 3–13. [Google Scholar] [CrossRef]

- Jiang, M.; Zhang, F.; Hu, H.; Cui, Y.; Peng, J. Structural characterization of natural loess and remolded loess under triaxial tests. Eng. Geol. 2014, 181, 249–260. [Google Scholar] [CrossRef]

- Shao, X.; Zhang, H.; Tan, Y. Collapse behavior and microstructural alteration of remolded loess under graded wetting tests. Eng. Geol. 2017, 233, 11–22. [Google Scholar] [CrossRef]

- Wen, B.; Yan, Y. Influence of structure on shear characteristics of the unsaturated loess in Lanzhou, China. Eng. Geol. 2014, 168, 46–58. [Google Scholar] [CrossRef]

- Wang, X. Study on the Influence of Dry Wet Cycle on Shear Strength, Structure and Slope Stability of Loess. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2017. [Google Scholar] [CrossRef]

- Iversen, B.; Moldrup, P.; Schjønning, P.; Loll, P. Air and Water Permeability in Differently Textured Soils At Two Measurement Scales. Soil Sci. 2001, 166, 643–659. [Google Scholar] [CrossRef]

- Nazaroff, W. Radon transport from soil to air. Rev. Geophys. Rev. Geophys 1992, 30, 137–160. [Google Scholar] [CrossRef]

- Zhu, M.; Zhang, Z.; Pan, Y.; Guo, D. Experimental study on the effect of soil texture, bulk density and moisture content on air conductivity. Agric. Res. Arid Areas 2013, 31, 116–121. [Google Scholar]

- Gupta, S.; Sharma, P.; DeFranchi, S. Compaction Effects on Soil Structure. Adv. Agronomy 1989, 42, 311–338. [Google Scholar]

- Bi, M. Research on Collapsible Mechanism of Loess Based on Grain Scale. Master’s Thesis, Changan University, Xi’an, China, 2020. [Google Scholar] [CrossRef]

- Xu, J.; Wang, Z.; Ren, J.; Yuan, J. Experimental study on permeability characteristics of undisturbed and remolded loess during freeze-thaw process. J. Eng. Geol. 2017, 25, 292–299. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Su, Z.; Chai, Z. Study on permeability and influencing factors of remolded loess. J. Lanzhou Railw. Inst. 2003, 04, 95–97. [Google Scholar] [CrossRef]

- Blackwell, P.S.; Ringrose-Voase, A.J.; Jayawardane, N.S.; Olsson, K.A.; Mckenzie, D.C.; Mason, W.K. The use of air-filled porosity and intrinsic permeability to air to characterize structure of macropore space and saturated hydraulic conductivity of clay soils. J. Soil Sci. 1990, 41, 215–228. [Google Scholar] [CrossRef]

- Yao, Z.; Chen, Z. Experimental study on air permeability characteristics of unsaturated Q3 loess. Chin. J. Rock Mech. Eng. 2012, 34, 1020–1027. [Google Scholar] [CrossRef]

| Depth (m) | Gs | W (%) | Wl (%) | Wp (%) | ρd (g/cm3) | Particle Size Composition (%) | ||

|---|---|---|---|---|---|---|---|---|

| >0.075 mm | 0.075–0.005 mm | <0.005 mm | ||||||

| 2 | 2.47 | 14.80 | 27.30 | 16.10 | 1.30 | 4.47 | 77.09 | 18.44 |

| 4 | 2.70 | 16.92 | 29.12 | 17.50 | 1.41 | 2.78 | 73.06 | 24.16 |

| 6 | 2.58 | 17.10 | 26.90 | 17.30 | 1.47 | 2.94 | 79.34 | 17.72 |

| 8 | 3.24 | 17.50 | 28.70 | 17.80 | 1.58 | 2.65 | 76.52 | 20.83 |

| 10 | 3.72 | 17.70 | 30.40 | 18.20 | 1.65 | 2.24 | 72.47 | 25.29 |

| Designed Dry Density of the Sample ρd (g/cm3) | Overall Height h of the Prepared Sample (cm) | ||||

|---|---|---|---|---|---|

| 8 | 10 | 12 | 14 | 16 | |

| 1.5 | 0.134450 | 0.110383 | 0.087022 | 0.059050 | 0.032733 |

| 1.4 | 0.107363 | 0.097991 | 0.053462 | 0.039350 | 0.028700 |

| 1.3 | 0.080375 | 0.073550 | 0.036197 | 0.029375 | 0.018952 |

| Designed Dry Density of the Sample ρd (g/cm3) | Overall Height h of the Prepared Sample (cm) | ||||

|---|---|---|---|---|---|

| 8 | 10 | 12 | 14 | 16 | |

| 1.5 | 2.83 × 10−3 | 2.60 × 10−3 | 2.21 × 10−3 | 1.82 × 10−3 | 1.31 × 10−3 |

| 1.4 | 2.17 × 10−3 | 1.91 × 10−3 | 1.64 × 10−3 | 1.56 × 10−3 | 1.25 × 10−3 |

| 1.3 | 1.94 × 10−3 | 1.63 × 10−3 | 1.59 × 10−3 | 1.50 × 10−3 | 1.11 × 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, Z.; Li, X.; Gao, R.; An, M.; Zhang, J.; Wen, F.; Zhou, B.; Xue, Q. A New Method for Evaluating the Homogeneity and Structure of Remolded Loess Samples with the Air Permeability Coefficient. Appl. Sci. 2022, 12, 9412. https://doi.org/10.3390/app12199412

Hao Z, Li X, Gao R, An M, Zhang J, Wen F, Zhou B, Xue Q. A New Method for Evaluating the Homogeneity and Structure of Remolded Loess Samples with the Air Permeability Coefficient. Applied Sciences. 2022; 12(19):9412. https://doi.org/10.3390/app12199412

Chicago/Turabian StyleHao, Zhitao, Xi’an Li, Rongrong Gao, Mingxiao An, Jing Zhang, Feng Wen, Bingquan Zhou, and Quan Xue. 2022. "A New Method for Evaluating the Homogeneity and Structure of Remolded Loess Samples with the Air Permeability Coefficient" Applied Sciences 12, no. 19: 9412. https://doi.org/10.3390/app12199412