A Systematic Framework for Evaluating the Effectiveness of Dynamic Compaction (DC) Technology for Soil Improvement Projects Using Cone Penetration Test Data

Abstract

:1. Introduction

- D = compaction depth in meters

- W = mass of drop weight in tons

- H = drop height in meters

- n = empirical coefficient (0.3 < n < 0.8; n = 0.5 typical)

- N = number of drops

- P = number of passes

- W = mass of the tamper

- H = drop height

- qt = CPT corrected total cone resistance

- fs = CPT sleeve friction

- σvo = pre-insertion in-situ total vertical stress

- σ′vo = pre-insertion in-situ effective vertical stress

- (qt–σvo)/pa = dimensionless net cone resistance, and,

- (pa/σ′vo)n = stress normalization factor

- n = stress exponent that varies with SBT

- pa = atmospheric pressure in same units as qt, v and v

- Qtn = Normalized cone resistance

- Fr = Normalized friction ratio

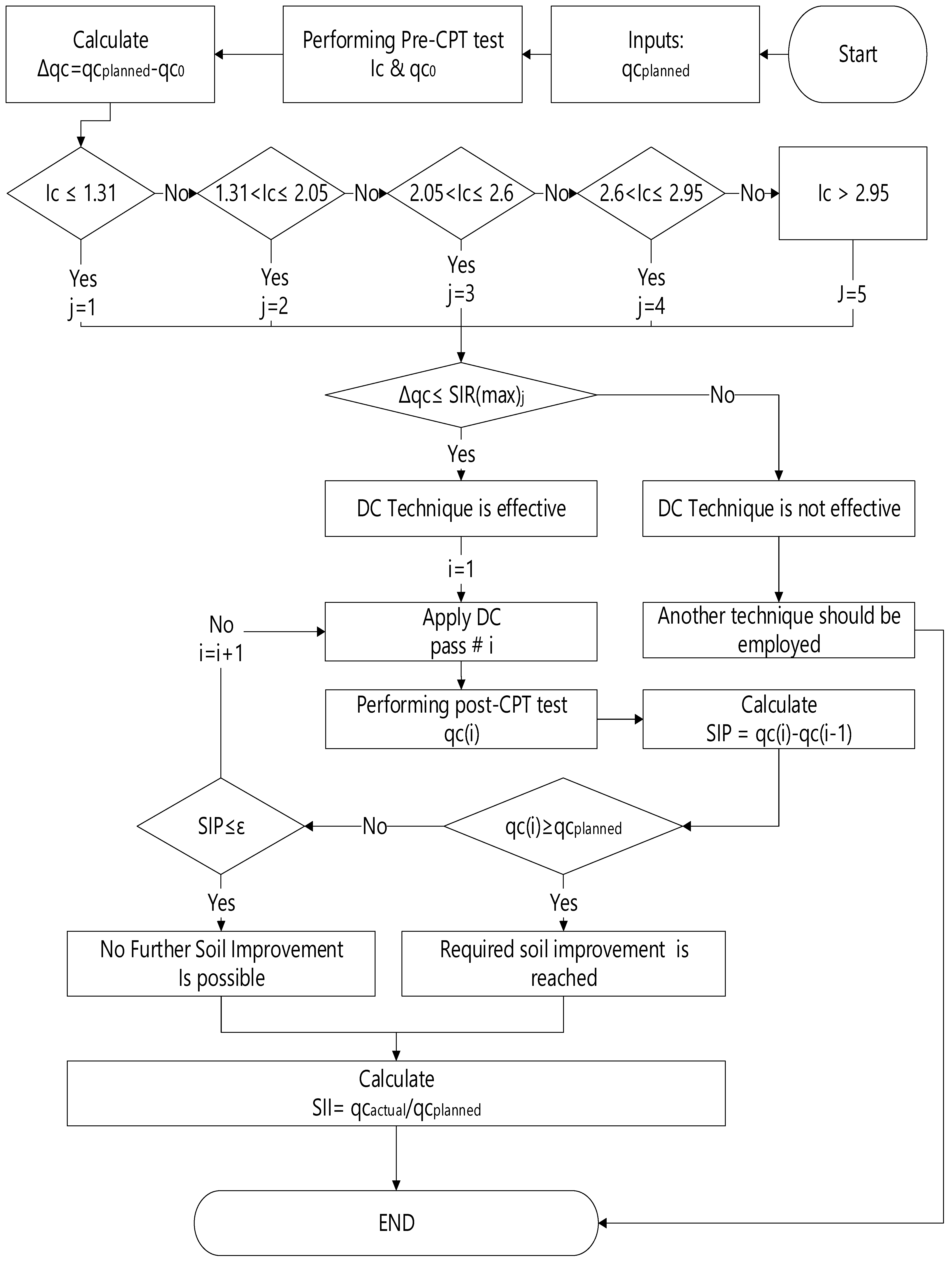

2. Proposed Methodology

3. Pre-Implementation Phase

- Input data: In this phase, there are three types of input data that can be collected: (i) CPT data before the application of the soil improvement technique, which is called Pre-implementation CPT data, (ii) the planned bearing capacity of soil (i.e., 35 MPa) after the implementation of the DC technique, referred to as qcplanned, and (iii) the DC effectiveness threshold (ETDC) for the project stakeholders. The effectiveness threshold represents the percentage of DC effectiveness (e.g., ≥90%) to be considered as acceptable.

- Data analysis: In this phase, the pre-implementation CPT data is analyzed to collect the Ic values of each layer in the soil profile to identify the soil category (from 1 to 5) of each layer, which indicates the category soil improvement range values called SIRj = [minj, maxj] where j = 1,..,5 and represents the number of the soil category, as shown in Table 2. Furthermore, the initial bearing capacity of soil before the implementation of the DC technique is calculated, and is called qc0.

- 3.

- DC effectiveness evaluation: The effectiveness of dynamic compaction depends on the combination of weight, rammer geometry, drop height, distance, number of drops, and total compaction energy applied. On-site experiments were conducted, and CPT tests were performed before and after compaction to determine the effectiveness of the DC technique. The effectiveness of DC is evaluated before the implementation of DC using the following equations:

- qcplanned represents the planned bearing capacity after DC implementation.

- qc0 represents the initial bearing capacity before DC implementation.

- SIR(max)j represents the left value of soil improvement range of soil category j.

- N(j) is the total number of data points under soil category (j)

4. Implementation Phase

- Monitoring data: In this phase, DC will be implemented using the weight, height, and grid required for improvement as presented in Equation (2). After each pass, post-implementation CPT data is collected and the improved bearing capacity of pass “i” is calculated, which is referred to as qci.

- Performance evaluation: In this phase, the performance of DC will be evaluated using the following function:

- ε is a small number (e.g., 0.001)

- qci is the bearing capacity improvement in current pass “i”.

- qci−1 is the bearing capacity improvement in previous pass “i − 1”.

- SIPj is the potential in improvement for a soil category.

- j is the number of soil category j = 1…5 (refer to Table 1).

- qcreq is the planned post-implementation bearing capacity.

5. Post-Implementation Phase

- qcactual represents the actual bearing capacity after improvement.

- qcplanned represents the planned bearing capacity after improvement.

6. Evaluation of Performance Indicators

- N(j) is the total number of data points in soil category j.

- NP[SIR(j)] represents the number of predictions that fall within the soil improvement range (SIRj) of Category (j) after the implementation of DC.

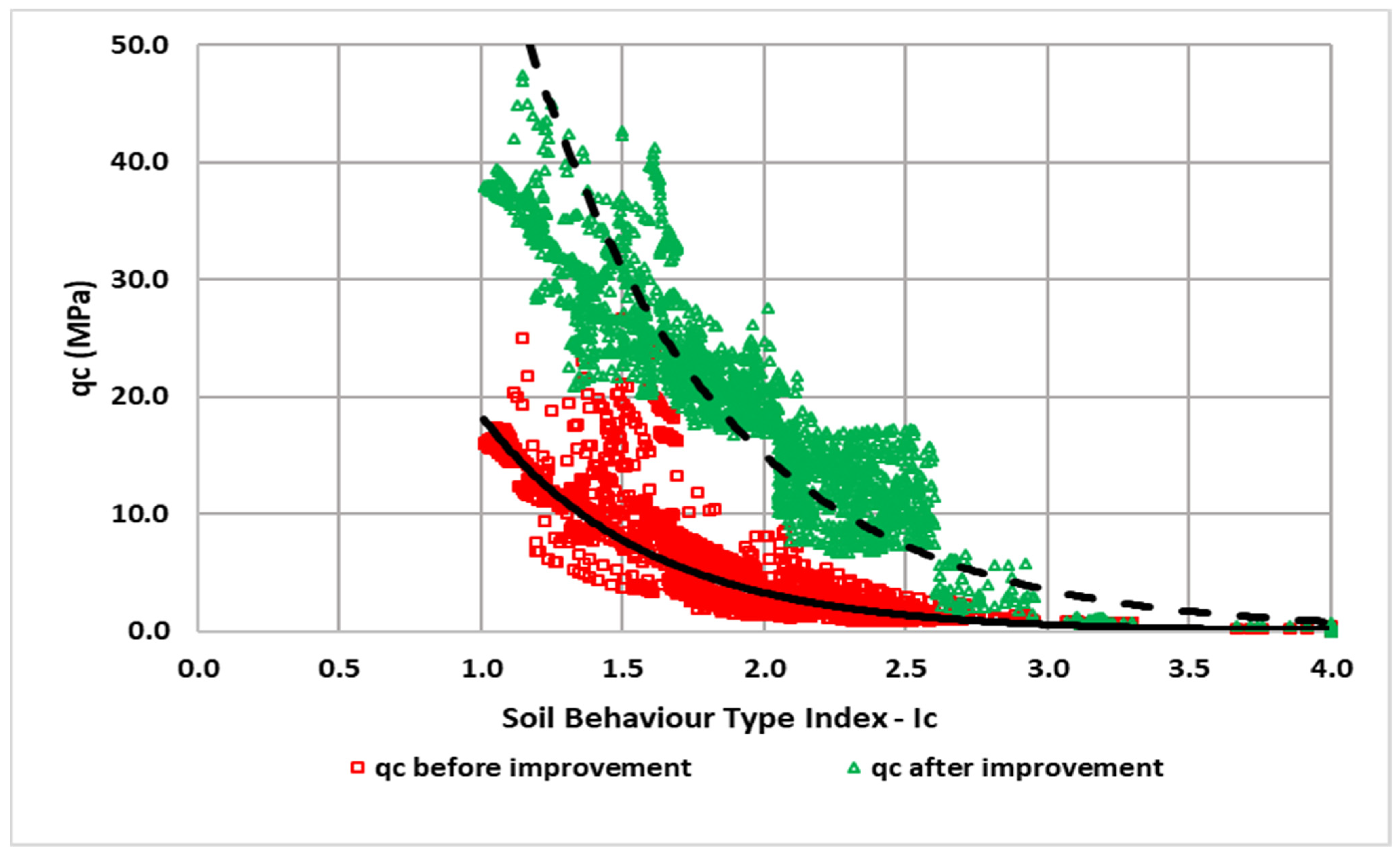

7. Method Implementation and Discussion

7.1. Pre-Implementation Phase

7.2. Implementation Phase

7.3. Post-Implementation Phase

8. Discussion and Analysis

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiang, N.J.; Wang, Y.J.; Chu, J.; Kawasaki, S.; Tang, C.S.; Cheng, L.; Du, Y.J.; Shashank, B.S.; Singh, D.N.; Han, X.L.; et al. Bio-mediated soil improvement: An introspection into processes, materials, characterization and applications. Soil Use Manag. 2022, 38, 68–93. [Google Scholar] [CrossRef]

- Das, B. Principles of Foundation Engineering, 9th ed.; Cengage Learning: Boston, MA, USA, 2016; Volume 1. [Google Scholar]

- Abdel-Rahman, M.M. Review of Soil Improvement Techniques. In Advances in Geotechnical Engineering; Springer: Cham, Switzerland, 2021; pp. 175–199. [Google Scholar] [CrossRef]

- Bilal, M.; Talib, A. A study on advances in ground improvement techniques. Adv. Geotech. Eng. 2016, 322–330. [Google Scholar] [CrossRef]

- Yao, Z.; Zhou, C.; Lin, Q.; Yao, K.; Satchithananthan, U.; Lee, F.H.; Tang, A.M.; Jiang, H.; Pan, Y.; Wang, S. Effect of dynamic compaction by multi-point tamping on the densification of sandy soil. Comput. Geotech. 2022, 151, 104949. [Google Scholar] [CrossRef]

- Li, X.; Zhang, K.; Ma, X.; Teng, J.; Zhang, S. New Method to Evaluate Strengthen Efficiency by Dynamic Compaction. Int. J. Geomech. 2020, 20, 4. [Google Scholar] [CrossRef]

- Ghassemi, A.; Pak, A.; Shahir, H. Numerical study of the coupled hydro-mechanical effects in dynamic compaction of saturated granular soils. Comput. Geotech. 2010, 37, 10–24. [Google Scholar] [CrossRef]

- Bo, M.W.; Na, Y.M.; Arulrajah, A.; Chang, M.F. Densification of granular soil by dynamic compaction. In Institution of Civil Engineers: Ground Improvement; Thomas Telford Ltd.: London, UK, 2009; Volume 162, pp. 121–132. [Google Scholar]

- Ghorbani, J.; Nazem, M.; Carter, J.P. Dynamic Compaction of Clays: Numerical Study Based on the Mechanics of Unsaturated Soils. Int. J. Geomech. 2020, 20, 04020195. [Google Scholar] [CrossRef]

- Brik, A.; Robertson, P.K. Use of CPTu for Design. In Cone Penetration Testing, Proceedings of the Monitoring and Quality Assurance of DC/DR Ground Improvement Projects—Proceedings of the 4th International Symposium on Cone Penetration Testing (CPT’18), Delft, The Netherlands, 21–22 June 2018; CRC Press: Boca Raton, FL, USA, 2018; pp. 21–22. [Google Scholar]

- Maurer, B.W.; Green, R.A.; van Ballegooy, S.; Wotherspoon, L. Development of region-specific soil behavior type index correlations for evaluating liquefaction hazard in Christchurch, New Zealand. Soil Dyn. Earthq. Eng. 2019, 117, 96–105. [Google Scholar] [CrossRef]

- Teng, J.; Zhang, X.; Zhang, S.; Zhao, C.; Sheng, D. An analytical model for evaporation from unsaturated soil. Comput. Geotech. 2019, 108, 107–116. [Google Scholar] [CrossRef]

- Lukas, R.G. Geotechnical Engineering Circular No. 1, Dynamic Compaction; Fhwa-Sa-95-037; U.S. Federal Highway Administration: Washington, DC, USA, 1995. [Google Scholar] [CrossRef]

- Moinfar, A.; Shahgholi, G.; Abbaspour-Gilandeh, Y.; Herrera-Miranda, I.; Hernández-Hernández, J.L.; Herrera-Miranda, M.A. Investigating the effect of the tractor drive system type on soil behavior under tractor tires. Agronomy 2021, 11, 4. [Google Scholar] [CrossRef]

- Robertson, P.K. Evaluation of flow liquefaction and liquefied strength using the cone penetration test: An update. Can. Geotech. J. 2022, 59, 620–624. [Google Scholar] [CrossRef]

- Rainer Massarsch, K.; Fellenius, B.H. Chapter 19 Deep vibratory compaction of granular soils. Elsevier Geo-Eng. B Ser. 2005, 3, 539–561. [Google Scholar] [CrossRef]

- Chen, L.; Qiao, L.; Li, Q. Study on dynamic compaction characteristics of gravelly soils with crushing effect. Soil Dyn. Earthq. Eng. 2019, 120, 158–169. [Google Scholar] [CrossRef]

- Zhou, C.; Jiang, H.; Yao, Z.; Li, H.; Yang, C. Computers and Geotechnics Evaluation of dynamic compaction to improve saturated foundation based on the fl uid-solid coupled method with soil cap model. Comput. Geotech. 2020, 125, 103686. [Google Scholar] [CrossRef]

- Wersa, C.; Massarsch, K.R.; Spross, J. ScienceDirect Heavy vibratory plate compaction of silty sand: A field study. Soils Found. 2022, 62, 101208. [Google Scholar] [CrossRef]

- Wu, S.; Wei, Y.; Zhang, Y.; Cai, H.; Du, J.; Wang, D.; Yan, J. Dynamic compaction of a thick soil-stone fill: Dynamic response and strengthening mechanisms. Soil Dyn. Earthq. Eng. 2020, 129, 105944. [Google Scholar] [CrossRef]

- Khosravi, A.; Martinez, A.; DeJong, J.T. Discrete element model (DEM) simulations of cone penetration test (CPT) measurements and soil classification. Can. Geotech. J. 2020, 57, 1369–1387. [Google Scholar] [CrossRef]

- Eslami, A.; Gholami, M. Bearing Capacity Analysis of Shallow Foundations from CPT Data. In Proceedings of the 16th International Conference on Soil Mechanics and Geotechnical Engineering, Osaka, Japan, 12–16 September 2005; pp. 1463–1466. [Google Scholar]

- Xu, D.S.; Liu, Z.W.; Chen, B.; Xu, X.Y. Bearing capacity analysis of offshore pipe piles with CPTs by considering uncertainly. Comput. Geotech. 2020, 126, 103731. [Google Scholar] [CrossRef]

- Alyami, S.H.; Almutlaqa, A.A.; Alqahtany, A.M.; Ashraf, N. Likelihood of Reaching Zero Energy Building Design in Hot Dry Climate: Saudi Arabia. IEEE Access 2021, 9, 167054–167066. [Google Scholar] [CrossRef]

| Zone | Soil Behavior Type | Ic |

|---|---|---|

| 1 | Sensitive, fine grained | N/A |

| 2 | Organic soils—clay | >3.6 |

| 3 | Clays—silty clay to clay | 2.95–3.6 |

| 4 | Slit mixtures—clayey slit to slit clay | 2.60–2.95 |

| 5 | Sand mixtures—silty sand to sandy slit | 2.05–2.6 |

| 6 | Sands—clean sand to silty sand | 1.31–2.05 |

| 7 | Gravelly sand to dense sand | <1.31 |

| 8 | Very stiff sand to clayey sand | N/A |

| 9 | Very stiff, fine grained | N/A |

| Proposed Soil Category (j) | Zone | Ic | Fine Content % Robertson and Wride, 1998) | Proposed SIRj [minj, maxj] (Adopted) |

|---|---|---|---|---|

| 1 | 7–9 | ≤ 1.31 | Fine content is less than 0.5% | [20, +∞] MPa |

| 2 | 6 | 1.31 < ≤ 2.05 | Fine content is between 0.5% and 14% | [15–20] MPa |

| 3 | 5 | 2.05 < ≤ 2.6 | Fine content is between 14% and 35% | [5–15] MPa |

| 4 | 4 | 2.6 < ≤ 2.95 | Fine content is between 35% and 55% | [1–5] MPa |

| 5 | 1,2 & 3 | 2.95 < | Fine content is between 55% and 100% | [0–1] MPa |

| Soil Category (j) | N | SIR | Ic | qc0 | Δqc | Effj (Ic) | EffDC (j) | EffDC |

|---|---|---|---|---|---|---|---|---|

| (MPa) | (k) | |||||||

| 1 | 172 | [20, +∞] | Ic ≤ 1.31 | 25.05 | 0.00 | 1.00 | 1.00 | 0.939 |

| 11.44 | 0.00 | 1.00 | ||||||

| 11.95 | 0.00 | 1.00 | ||||||

| 12.27 | 0.00 | 1.00 | ||||||

| 12.68 | 0.00 | 1.00 | ||||||

| 12.15 | 0.00 | 1.00 | ||||||

| 7.92 | 0.09 | 1.00 | ||||||

| 7.53 | 0.47 | 1.00 | ||||||

| 7.53 | 0.47 | 1.00 | ||||||

| 6.80 | 1.20 | 1.00 | ||||||

| 2 | 1165 | [15–20] | 1.31 < Ic ≤ 2.05 | 18.15 | 0.00 | 1.00 | 1.00 | |

| 18.45 | 0.00 | 1.00 | ||||||

| 7.33 | 0.67 | 1.00 | ||||||

| 13.00 | 0.00 | 1.00 | ||||||

| 15.56 | 0.00 | 1.00 | ||||||

| 15.15 | 0.00 | 1.00 | ||||||

| 3.50 | 4.50 | 1.00 | ||||||

| 3.53 | 4.47 | 1.00 | ||||||

| 6.15 | 1.85 | 1.00 | ||||||

| 6.61 | 1.39 | 1.00 | ||||||

| 3 | 799 | [5–15] | 2.05 < Ic ≤ 2.6 | 4.81 | 3.19 | 1.00 | 1.00 | |

| 6.74 | 1.26 | 1.00 | ||||||

| 5.55 | 2.45 | 1.00 | ||||||

| 5.21 | 2.79 | 1.00 | ||||||

| 4.88 | 3.12 | 1.00 | ||||||

| 2.92 | 5.08 | 1.00 | ||||||

| 2.92 | 5.08 | 1.00 | ||||||

| 2.21 | 5.79 | 1.00 | ||||||

| 2.06 | 5.94 | 1.00 | ||||||

| 1.73 | 6.27 | 1.00 | ||||||

| 4 | 66 | [1–5] | 2.6 < Ic ≤ 2.95 | 1.10 | 6.90 | 0.00 | 0.00 | |

| 1.06 | 6.94 | 0.00 | ||||||

| 1.04 | 6.96 | 0.00 | ||||||

| 1.03 | 6.97 | 0.00 | ||||||

| 1.32 | 6.68 | 0.00 | ||||||

| 1.22 | 6.78 | 0.00 | ||||||

| 1.46 | 6.54 | 0.00 | ||||||

| 1.02 | 6.98 | 0.00 | ||||||

| 1.00 | 7.00 | 0.00 | ||||||

| 0.95 | 7.05 | 0.00 | ||||||

| 5 | 73 | [0–1] | Ic > 2.95 | 0.92 | 7.08 | 0.00 | 0.00 | |

| 0.72 | 7.28 | 0.00 | ||||||

| 0.69 | 7.31 | 0.00 | ||||||

| 0.69 | 7.31 | 0.00 | ||||||

| 0.69 | 7.31 | 0.00 | ||||||

| 0.69 | 7.31 | 0.00 | ||||||

| 0.75 | 7.25 | 0.00 | ||||||

| 0.81 | 7.19 | 0.00 | ||||||

| 0.80 | 7.20 | 0.00 | ||||||

| 0.80 | 7.20 | 0.00 |

| Parameter | Value |

|---|---|

| Height (m) | 20 |

| Blows | 15 |

| Weight (Ton) | 26 |

| Primary Grid Patterns (m) | 8.5 |

| Depth of Improvement (m) | 8 |

| ID | Ic Value | qcplanned-MPa | qci−1-MPa | qci-MPa | SIP(Ic)i | Is There Any Improvement Potential for This Ic Value? | Soil Improvement Index (SII) |

|---|---|---|---|---|---|---|---|

| 1 | 2.85 | 8 | 1.10 | 2.44 | 1.34 | Yes | 0.30 |

| 2 | 2.85 | 1.06 | 2.92 | 1.87 | Yes | 0.37 | |

| 3 | 2.87 | 1.04 | 2.92 | 1.89 | Yes | 0.37 | |

| 4 | 2.87 | 1.03 | 3.64 | 2.61 | Yes | 0.45 | |

| 5 | 2.79 | 1.32 | 4.02 | 2.70 | Yes | 0.50 | |

| 6 | 2.93 | 1.22 | 3.02 | 1.80 | Yes | 0.38 | |

| 7 | 2.92 | 1.46 | 2.82 | 1.37 | Yes | 0.35 | |

| 8 | 2.64 | 1.02 | 3.00 | 1.97 | Yes | 0.37 | |

| 9 | 3.19 | 0.74 | 0.93 | 0.19 | No | 0.12 | |

| 10 | 3.18 | 0.75 | 0.93 | 0.19 | No | 0.12 | |

| 11 | 3.16 | 0.77 | 0.96 | 0.20 | No | 0.12 | |

| 12 | 3.15 | 0.78 | 0.87 | 0.09 | No | 0.11 | |

| 13 | 3.07 | 0.87 | 0.88 | 0.01 | No | 0.11 | |

| 14 | 3.10 | 0.85 | 0.97 | 0.12 | No | 0.12 | |

| 15 | 3.20 | 0.65 | 0.91 | 0.26 | No | 0.11 | |

| 16 | 3.20 | 0.65 | 1.04 | 0.39 | No | 0.13 | |

| 17 | 3.20 | 0.65 | 1.11 | 0.46 | No | 0.14 | |

| 18 | 3.20 | 0.65 | 1.14 | 0.49 | No | 0.14 | |

| 19 | 3.18 | 0.65 | 1.13 | 0.48 | No | 0.14 | |

| 20 | 3.19 | 0.65 | 1.11 | 0.46 | No | 0.14 | |

| 21 | 3.19 | 0.64 | 1.09 | 0.45 | No | 0.14 | |

| 22 | 3.17 | 0.65 | 1.08 | 0.43 | No | 0.14 | |

| 23 | 3.19 | 0.64 | 1.08 | 0.43 | No | 0.13 | |

| 24 | 3.19 | 0.64 | 1.13 | 0.49 | No | 0.14 | |

| 25 | 2.09 | 2.88 | 12.83 | 9.96 | Yes | 1.60 | |

| 26 | 2.11 | 2.82 | 12.11 | 9.30 | Yes | 1.51 | |

| 27 | 2.11 | 2.80 | 11.43 | 8.63 | Yes | 1.43 | |

| 28 | 2.10 | 2.80 | 10.49 | 7.70 | Yes | 1.31 | |

| 29 | 2.07 | 2.94 | 10.21 | 7.27 | Yes | 1.28 | |

| 30 | 2.06 | 2.95 | 10.65 | 7.70 | Yes | 1.33 | |

| 31 | 2.06 | 2.95 | 10.75 | 7.79 | Yes | 1.34 | |

| 32 | 2.06 | 2.97 | 10.84 | 7.87 | Yes | 1.36 | |

| 33 | 2.05 | 3.01 | 10.96 | 7.94 | Yes | 1.37 | |

| 34 | 2.09 | 2.88 | 12.83 | 9.96 | Yes | 1.60 | |

| 35 | 2.11 | 2.82 | 12.11 | 9.30 | Yes | 1.51 | |

| 36 | 2.11 | 2.80 | 11.43 | 8.63 | Yes | 1.43 | |

| 37 | 2.10 | 2.80 | 10.49 | 7.70 | Yes | 1.31 | |

| 38 | 2.07 | 2.94 | 10.21 | 7.27 | Yes | 1.28 | |

| 39 | 1.66 | 7.70 | 23.53 | 15.82 | Yes | 2.94 | |

| 40 | 1.54 | 8.86 | 24.49 | 15.64 | Yes | 3.06 | |

| 41 | 1.54 | 8.94 | 24.49 | 15.55 | Yes | 3.06 | |

| 42 | 1.82 | 10.44 | 26.04 | 15.59 | Yes | 3.25 | |

| 43 | 1.65 | 8.98 | 24.73 | 15.75 | Yes | 3.09 | |

| 44 | 1.69 | 8.42 | 24.07 | 15.64 | Yes | 3.01 | |

| 45 | 1.70 | 8.33 | 23.73 | 15.39 | Yes | 2.97 | |

| 46 | 1.71 | 8.19 | 23.37 | 15.18 | Yes | 2.92 | |

| 47 | 1.70 | 8.19 | 23.35 | 15.16 | Yes | 2.92 | |

| 48 | 1.70 | 8.04 | 23.34 | 15.30 | Yes | 2.92 | |

| 49 | 1.13 | 12.32 | 36.49 | 24.17 | Yes | 4.56 | |

| 50 | 1.14 | 12.30 | 36.54 | 24.24 | Yes | 4.57 | |

| 51 | 1.16 | 12.25 | 36.68 | 24.43 | Yes | 4.58 | |

| 52 | 1.16 | 12.19 | 36.48 | 24.30 | Yes | 4.56 | |

| 53 | 1.17 | 12.11 | 36.40 | 24.28 | Yes | 4.55 | |

| 54 | 1.19 | 12.11 | 36.39 | 24.28 | Yes | 4.55 | |

| 55 | 1.19 | 12.11 | 35.31 | 23.20 | Yes | 4.41 | |

| 56 | 1.20 | 12.09 | 33.52 | 21.43 | Yes | 4.19 | |

| 57 | 1.21 | 12.00 | 32.18 | 20.18 | Yes | 4.02 | |

| 58 | 1.22 | 11.07 | 37.22 | 26.14 | Yes | 4.65 | |

| 59 | 1.20 | 11.13 | 38.25 | 27.12 | Yes | 4.78 | |

| 60 | 1.18 | 11.39 | 38.23 | 26.84 | Yes | 4.78 |

| Soil Category (j) | Ic Range | SIR | N(j) | NP[SIR(j)] | PA | OPA | PPI |

|---|---|---|---|---|---|---|---|

| 1 | Ic ≤ 1.31 | [20, +∞] MPa | 2275 | 172 | 1.00 | 0.99 | 1.06 |

| 2 | 1.31 < Ic ≤ 2.05 | [10–20] MPa | 1165 | 1.00 | |||

| 3 | 2.05 < Ic ≤ 2.6 | [5–10] MPa | 799 | 0.99 | |||

| 4 | 2.6 < Ic ≤ 2.95 | [1–5] MPa | 66 | 0.79 | |||

| 5 | Ic > 2.95 | [0–1] MPa | 73 | 0.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alnaim, A.; AlQahtany, A.M.; Alshammari, M.S.; Al-Gehlani, W.A.G.; Alyami, S.H.; Aldossary, N.A.; Naseer, M.N. A Systematic Framework for Evaluating the Effectiveness of Dynamic Compaction (DC) Technology for Soil Improvement Projects Using Cone Penetration Test Data. Appl. Sci. 2022, 12, 9686. https://doi.org/10.3390/app12199686

Alnaim A, AlQahtany AM, Alshammari MS, Al-Gehlani WAG, Alyami SH, Aldossary NA, Naseer MN. A Systematic Framework for Evaluating the Effectiveness of Dynamic Compaction (DC) Technology for Soil Improvement Projects Using Cone Penetration Test Data. Applied Sciences. 2022; 12(19):9686. https://doi.org/10.3390/app12199686

Chicago/Turabian StyleAlnaim, Abdulrahman, Ali M. AlQahtany, Maher S. Alshammari, Wadee Ahmed Ghanem Al-Gehlani, Saleh H. Alyami, Naief A. Aldossary, and Muhammad Nihal Naseer. 2022. "A Systematic Framework for Evaluating the Effectiveness of Dynamic Compaction (DC) Technology for Soil Improvement Projects Using Cone Penetration Test Data" Applied Sciences 12, no. 19: 9686. https://doi.org/10.3390/app12199686