Sewage Sludge Quality and Management for Circular Economy Opportunities in Lombardy

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

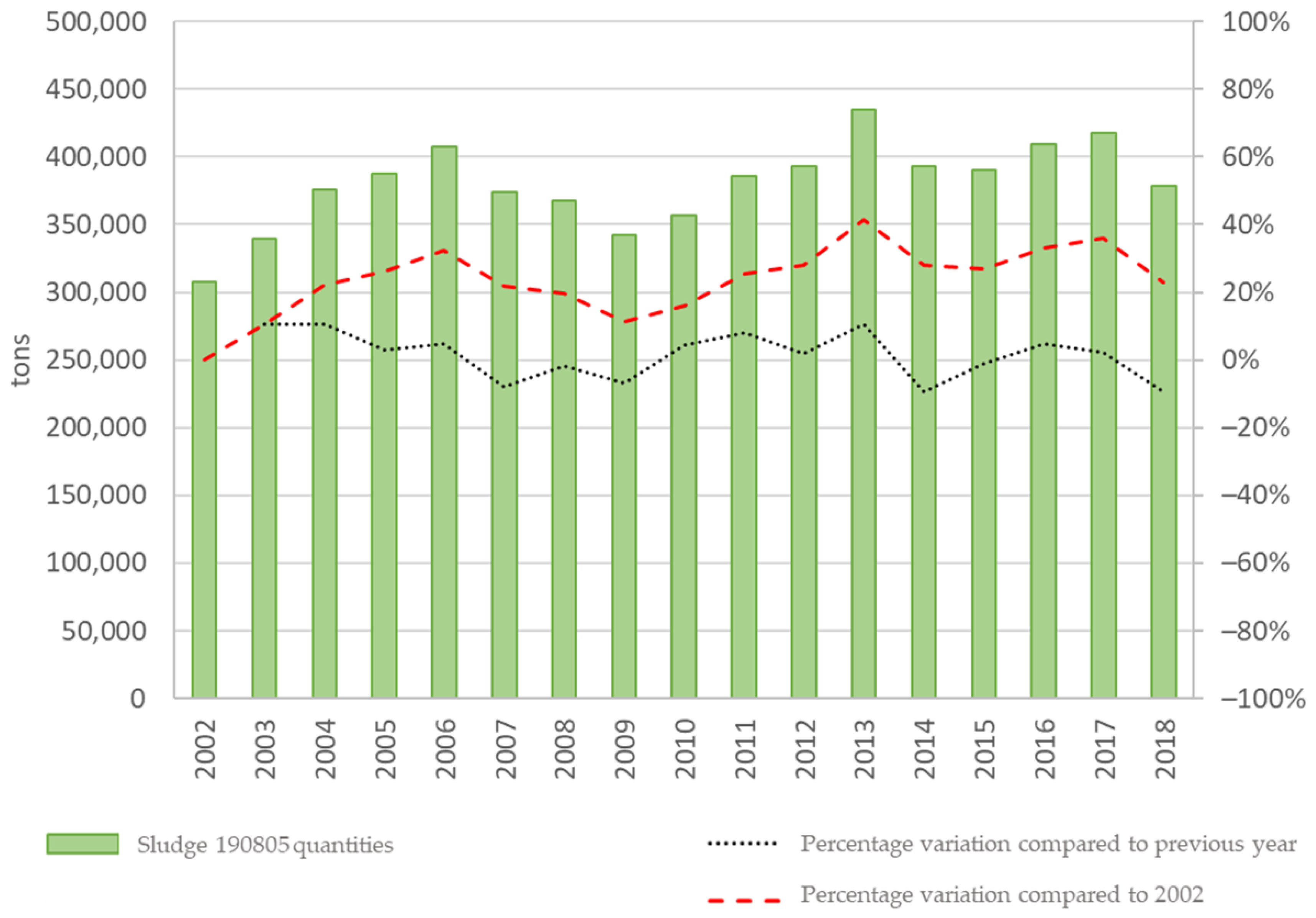

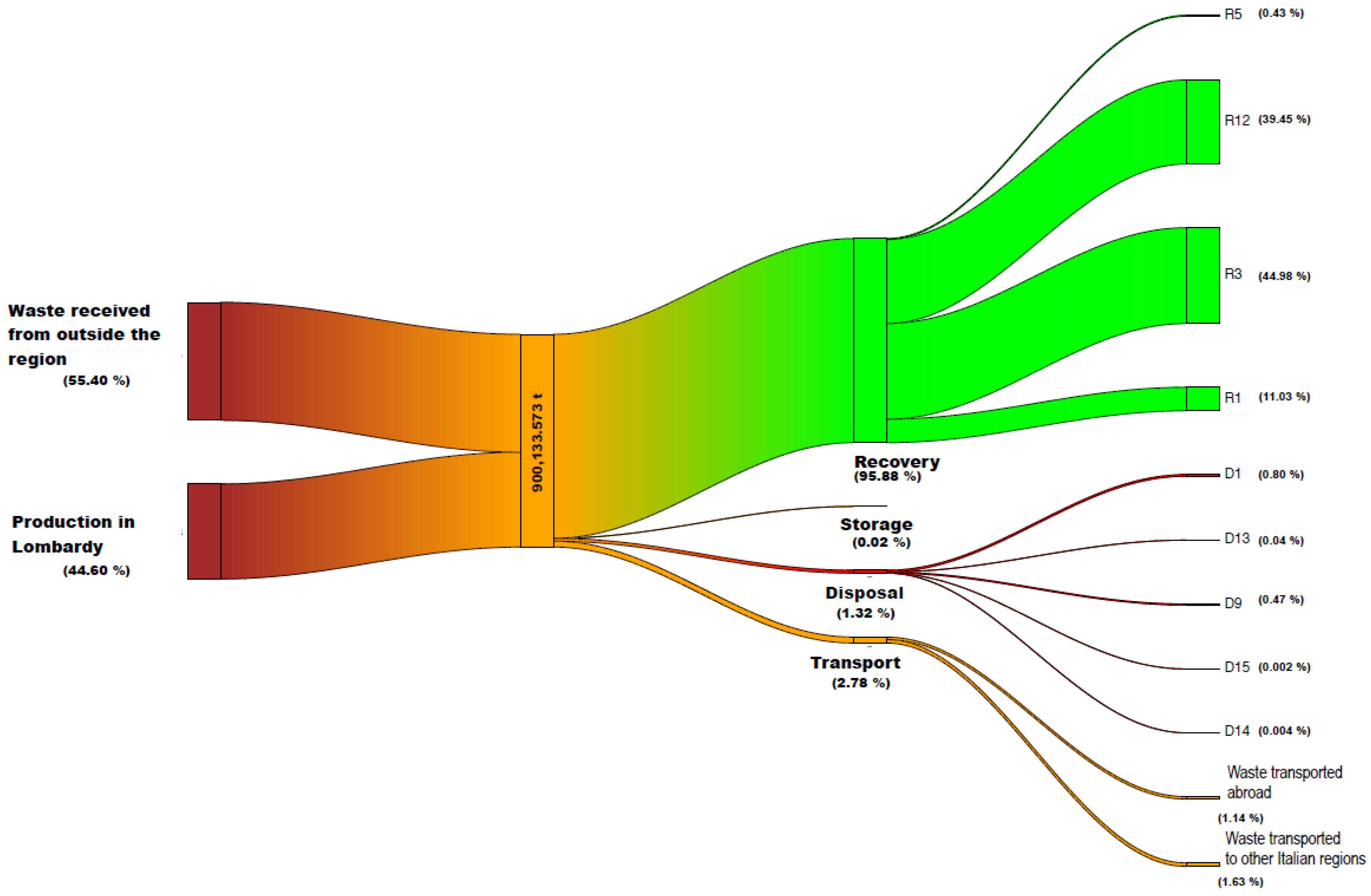

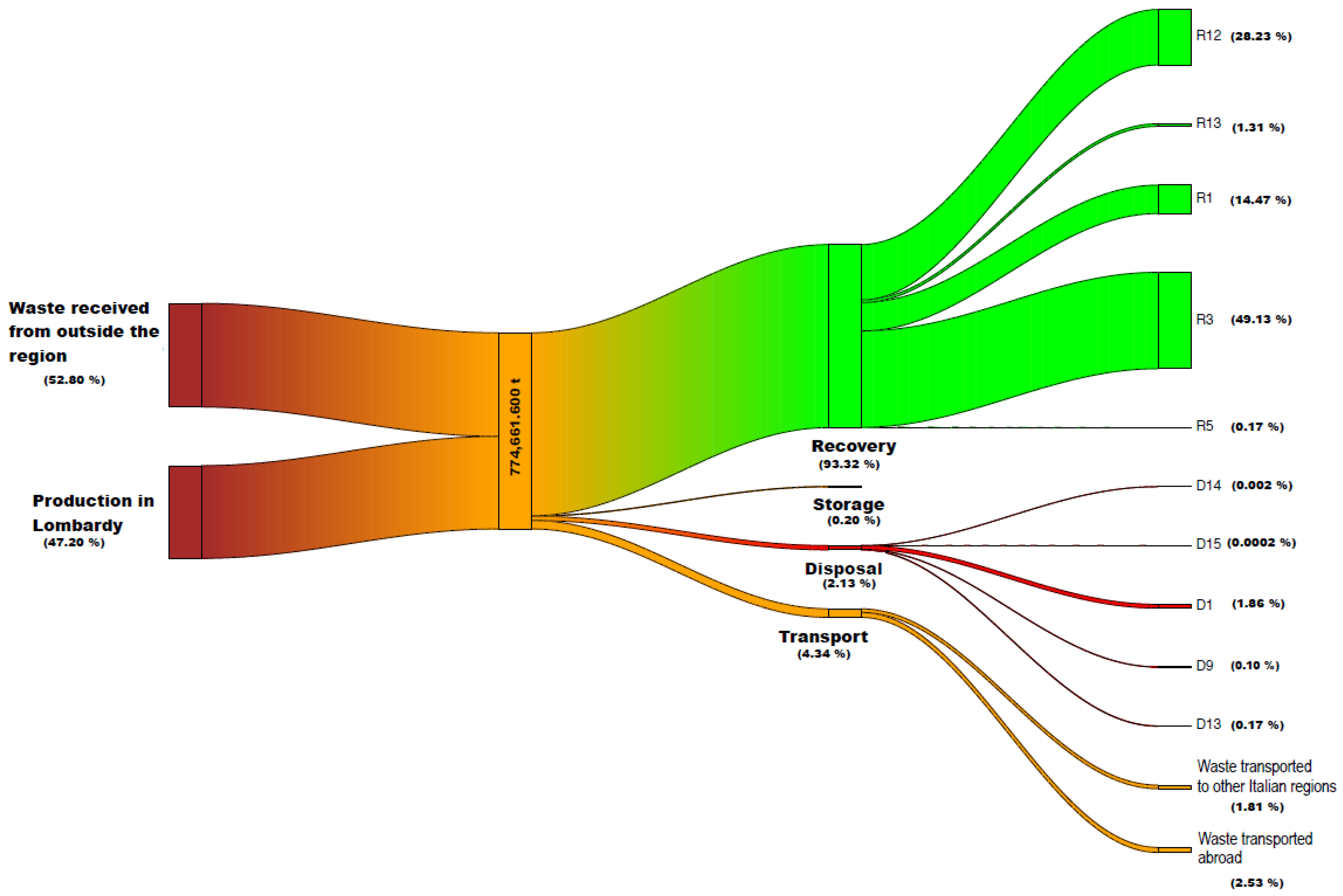

2.1. Sludge Quantities and Management

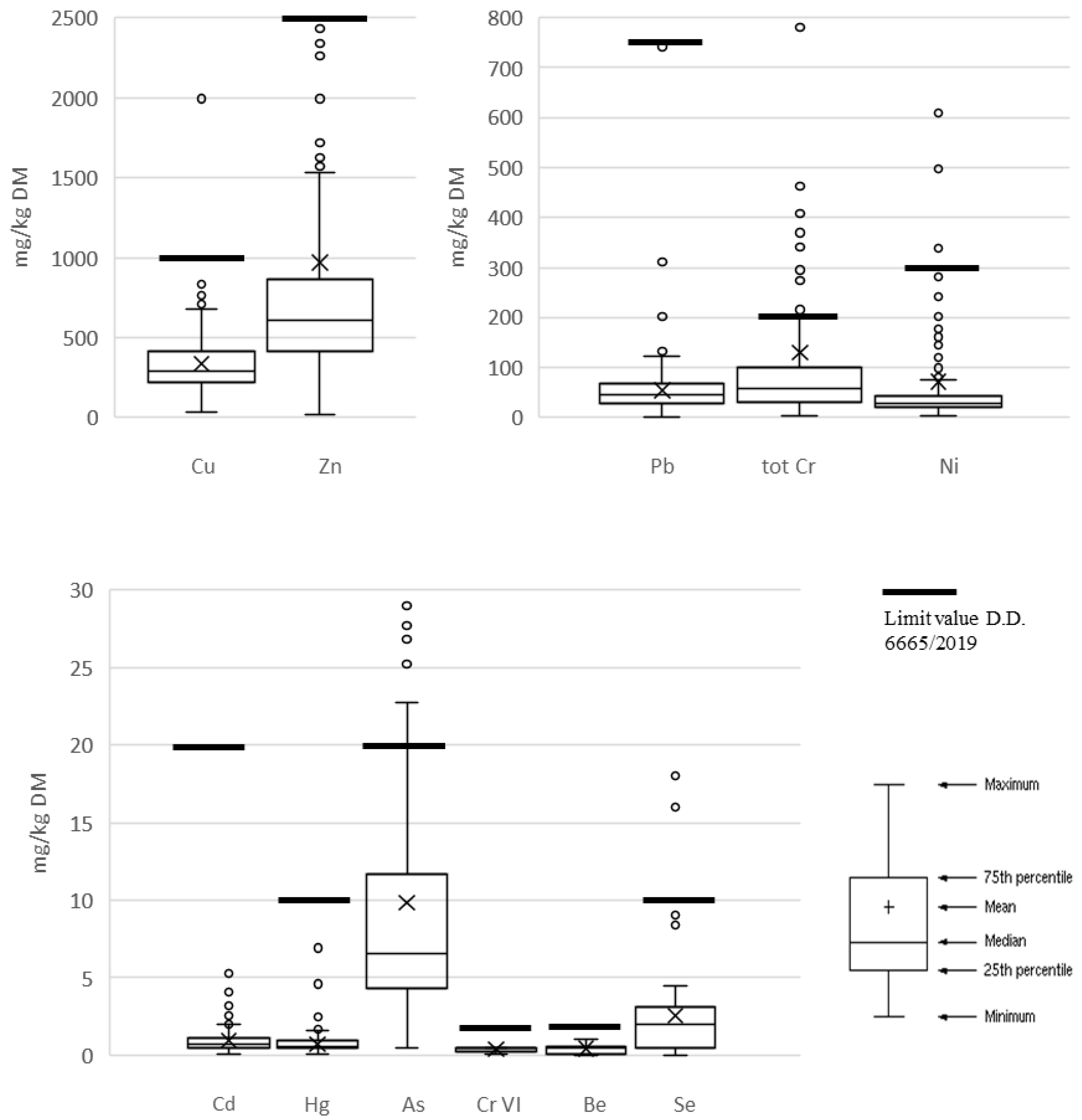

2.2. Sludge Quality

3. Results

3.1. Sludge Quantities and Management

3.2. Sludge Quality

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pikaar, I.; Guest, J.; Ganigué, R.; Jensen, P.; Rabaey, K.; Seviour, T.; Trimmer, J.; Van der Kolk, O.; Vaneeckhaute, C.; Verstraete, W. Resource Recovery from Water: Principles and Applicatio; Pikaar, I., Guest, J., Ganigué, R., Paul, J., Eds.; IWA Publishing: London, UK, 2022. [Google Scholar] [CrossRef]

- Rorat, A.; Courtois, P.; Vandenbulcke, F.; Lemiere, S. Sanitary and environmental aspects of sewage sludge management. In Industrial and Municipal Sludge, 1st ed.; Prasad, M.N.V., de Campos Favas, P.J., Vithanage, M., Mohan, S.V., Eds.; Butterworth-Heinemann: Oxford, UK, 2019; pp. 155–180. [Google Scholar] [CrossRef]

- Fijalkowski, K.; Rorat, A.; Grobelak, A.; Kacprzak, M.J. The presence of contaminations in sewage sludge—The current situation. J. Environ. Manag. 2017, 203, 1126–1136. [Google Scholar] [CrossRef] [PubMed]

- Lamastra, L.; Suciu, N.A.; Trevisan, M. Sewage sludge for sustainable agriculture: Contaminants’ contents and potential use as fertilizer. Chem. Biol. Technol. Agric. 2018, 5, 10. [Google Scholar] [CrossRef] [Green Version]

- Taheran, M.; Naghdi, M.; Brar, S.K.; Verma, M.; Surampalli, R.Y. Emerging contaminants: Here today, there tomorrow! Environ. Nanotechnol. Monit. Manag. 2018, 10, 122–126. [Google Scholar] [CrossRef]

- Escher, B.I.; Stapleton, H.M.; Schymanski, E.L. Tracking complex mixtures of chemicals in our changing environment. Science 2020, 367, 388–392. [Google Scholar] [CrossRef] [PubMed]

- Faragò, M.; Damgaard, A.; Madsen, J.A.; Andersen, J.K.; Thornberg, D.; Andersen, M.H.; Rygaard, M. From wastewater treatment to water resource recovery: Environmental and economic impacts of full-scale implementation. Water Res. 2021, 204, 117554. [Google Scholar] [CrossRef] [PubMed]

- Barros, M.V.; Salvador, R.; de Francisco, A.C.; Piekarski, C.M. Mapping of research lines on circular economy practices in agriculture: From waste to energy. Renew. Sustain. Energy Rev. 2020, 131, 109958. [Google Scholar] [CrossRef]

- Gherghel, A.; Teodosiu, C.; De Gisi, S. A review on wastewater sludge valorisation and its challenges in the context of circular economy. J. Clean. Prod. 2019, 228, 244–263. [Google Scholar] [CrossRef]

- Lipińska, D. The Water-Wastewater-Sludge Sector and the Circular Economy. Comparative Economic Research. Central and Eastern Europe; Lodz University Press: Lodz, Polnad, 2018; Volume 21. [Google Scholar] [CrossRef]

- Correa, R.S.; Silva, D.J. Effectiveness of Five Biosolids as Nitrogen Sources to Produce Single and Cumulative Ryegrass Harvests in Two Australian Soils. Rev. Bras. Ciênc. Sole 2016, 40, e0150216. [Google Scholar] [CrossRef] [Green Version]

- Ofoegbu, S.U. Technological challenges of phosphorus removal in high-phosphorus ores: Sustainability implications and possibilities for greener ore processing. Sustainability 2019, 11, 6787. [Google Scholar] [CrossRef] [Green Version]

- European Sustainable Phosphorous Platform. Available online: https://phosphorusplatform.eu/ (accessed on 6 October 2022).

- Bertanza, G.; Foladori, P.; Guglielm, L. Recupero di Materia ed Energia negli Impianti di Depurazione [The Recovery of Materials and Energy in Wastewater Treatment Plants]; Maggioli: Santarcangelo di Romagna (RN), Italy, 2018. [Google Scholar]

- Dhaliwal, S.S.; Naresh, R.K.; Mandal, A.; Singh, R.; Dhaliwal, M.K. Dynamics and transformations of micronutrients in agricultural soils as influenced by organic matter build-up: A review. Environ. Sustain. Indic. 2019, 1, 100007. [Google Scholar] [CrossRef]

- Sharma, B.; Sarkar, A.; Singh, P.; Singh, R.P. Agricultural utilization of biosolids: A review on potential effects on soil and plant grown. Waste Manag. 2017, 64, 117–132. [Google Scholar] [CrossRef] [PubMed]

- Tervahauta, T.; Rani, S.; Leal, L.H.; Buisman, C.J.N.; Zeeman, G. Black water sludge reuse in agriculture: Are heavy metals a problem? J. Hazard. Mater. 2014, 274, 229–236. [Google Scholar] [CrossRef] [PubMed]

- Raheem, A.; Sikarwar, V.S.; He, J.; Dastyar, W.; Dionysiou, D.D.; Wang, W.; Zhao, M. Opportunities and challenges in sustainable treatment and resource reuse of sewage sludge: A review. Chem. Eng. J. 2018, 337, 616–641. [Google Scholar] [CrossRef]

- Kumar, V.; Srivastava, S.; Thakur, I.S. Enhanced recovery of polyhydroxyalkanoates from secondary wastewater sludge of sewage treatment plant: Analysis and process parameters optimization. Bioresour. Technol. Rep. 2021, 15, 100783. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, C.C.; Champagne, P.; Mabee, W. Overview of current biological and thermo-chemical treatment technologies for sustainable sludge management. Waste Manag. Res. 2014, 32, 586–600. [Google Scholar] [CrossRef] [PubMed]

- Đurđević, D.; Blecich, P.; Jurić, Z. Energy recovery from sewage sludge: The case study of Croatia. Energies 2019, 12, 1927. [Google Scholar] [CrossRef] [Green Version]

- Manara, P.; Zabaniotou, A. Towards sewage sludge based biofuels via thermochemical conversion—A review. Renew. Sustain. Energy Rev. 2012, 16, 2566–2582. [Google Scholar] [CrossRef]

- Oladejo, J.; Shi, K.; Luo, X.; Yang, G.; Wu, T. A Review of Sludge-to-Energy Recovery Methods. Energies 2019, 12, 60. [Google Scholar] [CrossRef] [Green Version]

- Nazari, L.; Sarathy, S.; Santoro, D.; Ho, D.; Ray, M.B.; Xu, C.C. Recent advances in energy recovery from wastewater sludge. In Direct Thermochemical Liquefaction for Energy Applications; Woodhead Publishing Elsevier Ldt.: Amsterdam, The Netherlands, 2018; pp. 67–100. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Abbà, A.; Carnevale Miino, M.; Torretta, V. What advanced treatments can be used to minimize the production of sewage sludge in WWTPs? Appl. Sci. 2019, 9, 2650. [Google Scholar] [CrossRef] [Green Version]

- Council of the European Union. Council Directive of 12 June 1986 on the Protection of the Environment, and in Particular of the Soil, When Sewage Sludge is Used in Agriculture (86/278/EEC). Off. J. Eur. Communities 1986, 181, 6–12. [Google Scholar]

- Sewage Sludge. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/sewage-sludge_en (accessed on 12 September 2022).

- CORDIS. Available online: https://cordis.europa.eu/en (accessed on 4 September 2022).

- Bianchini, A.; Bonfiglioli, L.; Pellegrini, M.; Saccani, C. Sewage sludge management in Europe: A critical analysis of data quality. Int. J. Environ. Waste Manag. 2016, 18, 226. [Google Scholar] [CrossRef]

- EurEau. Europe’s Water in Figures: An Overview of the European Drinking water and Waste Water Sectors. Brussels, Belgium. 2021. Available online: https://www.eureau.org/resources/publications/eureau-publications/5824-europe-s-water-in-figures-2021/file (accessed on 2 September 2021).

- Eurostat. Water Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Water_statistics#Wastewater_treatment_and_disposal (accessed on 2 September 2022).

- Collivignarelli, M.C.; Abbà, A.; Benigna, I. The reuse of biosolids on agricultural land: Critical issues and perspective. Water Environ. Res. 2020, 92, 11–25. [Google Scholar] [CrossRef]

- ISPRA. Rapporto Rifiuti Speciali—Edizione 2022 [Report on Special Waste—Edition 2022]; ISPRA Report n. 367/2022; ISPRA: Rome, Italy, 2022; ISBN 978-88-448-1116-7. [Google Scholar]

- Italian Parliament. Decreto Legislativo 27 Gennaio 1992, n. 99—Attuazione della Direttiva 86/278/CEE Concernente la Protezione Dell’Ambiente, in Particolare del Suolo, Nell’Utilizzazione dei Fanghi di Depurazione in Agricoltura [Legislative Decree January 27, 1992, n. 99 Implementation of the European Directive n. 86/278/CEE on the Protection of the Environment, in Particular of the Soil, for the Use of Sewage Sludge in Agriculture]. Italian Official Gazette, February 15, 1992, n. 38, Ordinary Supplement n. 28. Available online: https://www.gazzettaufficiale.it/eli/id/1992/02/15/092G0139/sg (accessed on 10 October 2022).

- Italian Parliament. Decreto Legge 28 Settembre 2018—Disposizioni Urgenti Per la Città di Genova, La Sicurezza Della Rete Nazionale Delle Infrastrutture e dei Trasporti, gli Eventi Sismici del 2016 e 2017, il Lavoro e le Altre Emergenze [Law 28 September 2018—Urgent Provisions for the City of Genova, the Safety of the National Infrastructure and Transport Network, the Seismic Events of 2016 and 2017, the Work and the Other Emergencies]. Italian Official Gazette, September 28, 2018, n. 226, Ordinary Supplement n. 25. Available online: https://www.gazzettaufficiale.it/eli/id/2018/09/28/18G00137/sg (accessed on 10 October 2022).

- Lombardy Region. Deliberazione del Consiglio Regionale X/2031, 1 Luglio 2014—Disposizioni Regionali per il Trattamento e L’Utilizzo, a Beneficio Dell’Agricoltura, dei Fanghi di Depurazione Delle Acque Reflue Di Impianti Civili ed Industriali in Attuazione dell’Art. 8, Comma 8, Della Legge Regionale 12 Luglio 2007, n. 12. Conseguente Integrazione del Punto 7.4.2, Comma 6, n. 2) della D.G.R. 18 Aprile 2012, n. IX/3298, Riguardante le Linee Guida Regionali per L’Autorizzazione Degli Impianti per la Produzione di Energia Elettrica da Fonti Energetiche Rinnovabili, 2014 [Deliberation of Regional Council X/2031 July 1, 2014 Containing Regional Dispositions for Treatment and Use, for the Benefit of Agriculture, of Sewage Sludge from Urban and Industrial Wastewater Treatment Plants in Implementation of Art. 8, Paragraph 8 of Regional Law July 12, 2007, n. 12. Consequent Integration of Point 7.4.2, Paragraph 6, n. 2 of D.G.R. April 18, 2012, n. IX/3298, Regarding Regional Guidelines for the Authorization of Plants for the Production of Electricity from Renewable Energy Sources]. Available online: https://www.regione.lombardia.it/wps/wcm/connect/e81d0f54-bedf-4918-886f-ad4db4c04911/D.g.r.+2031_2014.pdf?MOD=AJPERES&CACHEID=ROOTWORKSPACE-e81d0f54-bedf-4918-886f-ad4db4c04911-mH4K-bC (accessed on 10 October 2022).

- Lombardy Region. Deliberazione del Consiglio Regionale X/7076, 11 Settembre 2017—Disposizioni Integrative, in Materia di Parametri e Valori Limite da Considerare Per i Fanghi Idonei All’utilizzo in Agricoltura, alla D.G.R. 2031/2014 Recante Disposizioni Regionali per il Trattamento e L’Utilizzo, a Beneficio Dell’Agricoltura, dei Fanghi di Depurazione Delle Acque Reflue di Impianti Civili ed Industriali in Attuazione dell’Art. 8, Comma 8, della Legge Regionale 12 Luglio 2007, n. 12. 2017 [Deliberation of Regional Council X/7076 September 11, 2017 Containing Supplementary Dispositions on the Parameters and Limit Values to be Considered for Sludge Suitable for Use in Agriculture, to the D.G.R. 2031/2014 Laying Down Regional Disposition for the Treatment and Use, for the Benefit of Agriculture, of Sewage Sludge from Urban and Industrial Wastewater Treatment Plants in Implementation of Art. 8, Paragraph 8, of the Regional Law July 12, 2007, n. 12]. Available online: https://www.regione.lombardia.it/wps/wcm/connect/75f88ec2-3c37-4374-a8a9-20a6d36a4a4f/dgr_7076_2017.pdf?MOD=AJPERES&CACHEID=75f88ec2-3c37-4374-a8a9-20a6d36a4a4f (accessed on 10 October 2022).

- Lombardy Region. Decreto Dirigenziale 6665, 14 Maggio—Ricognizione dei Limiti di Concentrazione Caratterizzanti i Fanghi di Depurazione Idonei per L’Utilizzo in Agricoltura, a Seguito Delle Nuove Disposizioni Normative Nazionali di Cui Alla Legge 16 Novembre 2018, n. 130. 2019 [Decree 6665, May 14—Recognition of the Concentration Limits Characterizing Sewage Sludge Suitable for Use in Agriculture, Following the New National Norms Cetermioned by the to Law no. 130 of November 16 2018]. Available online: https://www.regione.lombardia.it/wps/wcm/connect/19df87f4-0ac9-4fac-b171-084e37a5bc51/D.d.u.o.+6665_2019.pdf?MOD=AJPERES&CACHEID=ROOTWORKSPACE-19df87f4-0ac9-4fac-b171-084e37a5bc51-mH4MG8K (accessed on 10 October 2022).

- GSE. Rapporto Statistico—Energia da Fonti Rinnovabili in Italia. Anno 2016 [Statistical Report. Energy from Renewable Sources in Italy. Year 2016]. Gestore dei Servizi Energetici S.p.A. 2018. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Rapporto%20statistico%20GSE%20-%202016.pdf (accessed on 24 February 2021).

- Scientific Data. Better Science through Better Data 2019 (#SciData19). Figshare Collect. 2019. [Google Scholar] [CrossRef]

- Ruiz-Puente, C.; Jato-Espino, D. Systemic analysis of the contributions of co-located industrial symbiosis to achieve sustainable development in an industrial park in Northern Spain. Sustainability 2020, 12, 5802. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2020; Available online: http://www.r-project.org/index.html (accessed on 1 September 2021).

- Vahidzadeh, R.; Liaghati, E.; Bertanza, G.; Sbaffoni, S.; Vaccari, M. Exploring the potentials of applying the circular economy for waste minimization at a regional scale based on Big Data Analysis. Environ. Eng. Manag. J. 2021, 20, 1683–1692. [Google Scholar] [CrossRef]

- Chopra, S.S.; Khanna, V. Toward a network perspective for understanding resilience and sustainability in industrial symbiotic networks. In Proceedings of the 2012 IEEE International Symposium on Sustainable Systems and Technology, Boston, MA, USA, 16–18 May 2012. Article no. 6227987. [Google Scholar] [CrossRef]

- CRAN. Package Sankey, CRAN, The Comprehensive R Archive Network. 2017. Available online: https://cran.r-project.org/web/packages/sankey/sankey.pdf (accessed on 24 February 2022).

- Tyagi, V.K.; Lo, S.L. Sludge: A waste or renewable source for energy and resources recovery? Renew. Sust. Energ. Rev. 2013, 25, 708–728. [Google Scholar] [CrossRef]

- Tartari, G.; Bergna, G.; Lietti, M.; Rizzo, A.; Lazzari, F.; Brioschi, C. GdL-MIE Inquinanti Emergenti [Emerging Pollutants]; Lombardy Energy Cleantech Cluster: Milan, Italy, 2020; ISBN 9788894555707. [Google Scholar]

- Regione Lombardia. Delibera di Giunta regionale n° 6408 del 23/05/2022. Aggiornamento del Programma Regionale di Gestione (PRGR) dei Rifiuti, Comprensivo del Programma delle Aree Inquinate (PRB) [Council Resolution n. 6408 of 05/23/2022. Update of the Regional Waste Management Program, Including the Polluted Areas Program]. 2022. Available online: https://www.regione.lombardia.it/wps/portal/istituzionale/HP/DettaglioRedazionale/servizi-e-informazioni/Enti-e-Operatori/ambiente-ed-energia/Rifiuti/aggiornamento-piano-rifiuti-e-bonifiche-regionale/aggiornamento-piano-rifiuti-e-bonifiche-regionale (accessed on 10 October 2022).

- Pedrazzani, R.; Bertanza, G.; Brnardić, I.; Cetecioglu, Z.; Dries, J.; Dvarionienė, J.; García-Fernández, A.J.; Langenhoff, A.; Libralato, G.; Lofrano, G.; et al. Opinion paper about organic trace pollutants in wastewater: Toxicity assessment in a European perspective. Sci. Total Environ. 2019, 651, 3202–3221. [Google Scholar] [CrossRef]

- Segrè Cohen, A.; Love, N.G.; Nace, K.K.; Árvai, J. Consumers’ acceptance of agricultural fertilizers derived from diverted and recycled human urine. Environ. Sci. Technol. 2020, 54, 5297–5305. [Google Scholar] [CrossRef] [PubMed]

- Bertanza, G.; Canato, M.; Laera, G. Towards energy self-sufficiency and integral material recovery in wastewater treatment plants: Assessment of upgrading options. J. Clean. Prod. 2018, 170, 1206–1218. [Google Scholar] [CrossRef]

| Parameter | n. of Data | MIN | 1st Quartile | Average | Median | 3rd Quartile | MAX | D.D. 6665/2019 * and D.G.R X/2031/2014 Limit Values | n. Analysis Complying with Limits | % Analysis Complying with Limits |

|---|---|---|---|---|---|---|---|---|---|---|

| Heavy metals (mg/kg DM) | ||||||||||

| Copper | 203 | 31.2 | 224.5 | 335.2 | 289.0 | 405.0 | 1994 | ≤1000 (≤400) ≤1200 | 202 (152) 202 | 99.5 (75) 99.5 |

| Zinc | 203 | 18.0 | 414.0 | 967.6 | 610.0 | 861.5 | 32,800 | ≤2500 (≤600) ≤3000 | 197 (101) 197 | 97 (50) 97 |

| Lead | 204 | 1.0 | 29.0 | 54.9 | 46.0 | 68.0 | 742 | ≤750 (≤250) ≤900 | 204 (202) 204 | 100 (99) 100 |

| Tot chromium | 203 | 2.5 | 31.3 | 129.9 | 58.9 | 100.0 | 2400 | <200 (≤150) ≤900 | 182 (176) 198 | 90 (87) 97.5 |

| Nickel | 203 | 2.7 | 20.1 | 71.4 | 29.0 | 42.8 | 1690 | ≤300 (≤50) ≤330 | 197 (159) 197 | 97 (78) 97 |

| Cadmium | 202 | 0.05 | 0.5 | 1.0 | 0.7 | 1.1 | 5.4 | ≤20 (≤5) ≤22 | 202 (200) 202 | 100 (99) 100 |

| Mercury | 177 | 0.05 | 0.5 | 0.7 | 0.5 | 1.0 | 6.92 | ≤10 (≤5) ≤11 | 177 (176) 177 | 100 (99) 100 |

| Arsenic | 183 | 0.5 | 4.4 | 9.8 | 6.6 | 11.6 | 57.5 | ≤20 (≤10) | 164 (127) | 90 (69) |

| Chromium IV | 96 | 0.1 | 0.3 | 0.4 | 0.5 | 0.5 | 0.5 | <2 | 96 | 100 |

| Beryllium | 48 | 0.1 | 0.2 | 0.5 | 0.5 | 0.6 | 1.0 | ≤2 | 44 | 91.7 |

| Selenium | 55 | 0.0 | 0.6 | 2.5 | 2.0 | 2.8 | 18.0 | ≤10 | 53 | 96.4 |

| Agronomic parameters (%DM) | ||||||||||

| Corg | 190 | 14.9 | 29.1 | 33.3 | 34.2 | 38.5 | 45.0 | >20 >10 | 183 190 | 96.3 100 |

| Total N | 180 | 1.9 | 3.9 | 5.0 | 4.8 | 6.0 | 9.8 | >1.5 >1 | 180 180 | 100 100 |

| Total P | 187 | 0.5 | 1.6 | 2.2 | 2.1 | 2.8 | 4.0 | >0.4 | 187 | 100 |

| pH | 246 | 5.8 | 7 | 7.4 | 7.34 | 7.8 | 12.2 | 5.5 < pH ≤ 11 | 244 | 99.2 |

| Germination index | 96 | 2 | 19.9 | 50.0 | 49.9 | 80 | 99.6 | >60 | 41 | 42.7 |

| Microbiological parameters (MPN/gDM) | ||||||||||

| Fecal coliforms | 154 | 1.5 | 8200 | 11.1 × 106 | 0.05 × 106 | 0.1 × 106 | 640 × 106 | <10,000 | 45 | 29.2 |

| Salmonella sp. | 176 | 0 | 0 | 114.1 | 1.5 | 50 | 2700 | <100 | 146 | 83 |

| Organic micropollutants (mg/kgDM) | ||||||||||

| PCB | 205 | 0.001 | 0.005 | 0.1 | 0.05 | 0.1 | 0.847 | Σ < 0.8 | 204 | 99.5 |

| PAH | 205 | 0.005 | 0.005 | 0.4 | 0.05 | 0.5 | 4.577 | Σ < 6 | 205 | 100 |

| PCDD/F + Dioxin-like PCB (ng TEQ/kgDM) | 31 | 0.01 | 0.6 | 3.3 | 1.28 | 5 | 22.57 | Σ ≤ 25 | 31 | 100 |

| Nonylphenols | 72 | 0.0025 | 2.5 | 2.9 | 2.5 | 2.5 | 31 | Σ < 50 | 72 | 100 |

| DEHP | 71 | 0.05 | 0.5 | 5.8 | 2.65 | 5 | 58.7 | Σ < 100 | 71 | 100 |

| Heavy hydrocarbons | 197 | 9 | 410 | 2309.1 | 1718 | 3218 | 9544 | Σ ≤ 10,000 | 197 | 100 |

| AOX | 86 | 0.0025 | 0.5 | 9.81 | 3.75 | 17.5 | 75.7 | Σ ≤ 500 | 86 | 100 |

| Toluene | 95 | 0.01 | 0.12 | 16.4 | 2.38 | 5 | 385 | ≤100 | 91 | 95.8 |

| Degree of stabilization (%) | ||||||||||

| VS/TS | 129 | 30.1 | 63.5 | 68.4 | 70.9 | 75 | 89.1 | <65 (<60) | 38 (21) | 29.5 (16.3) |

| Data | Calculated Values | ||||||||

|---|---|---|---|---|---|---|---|---|---|

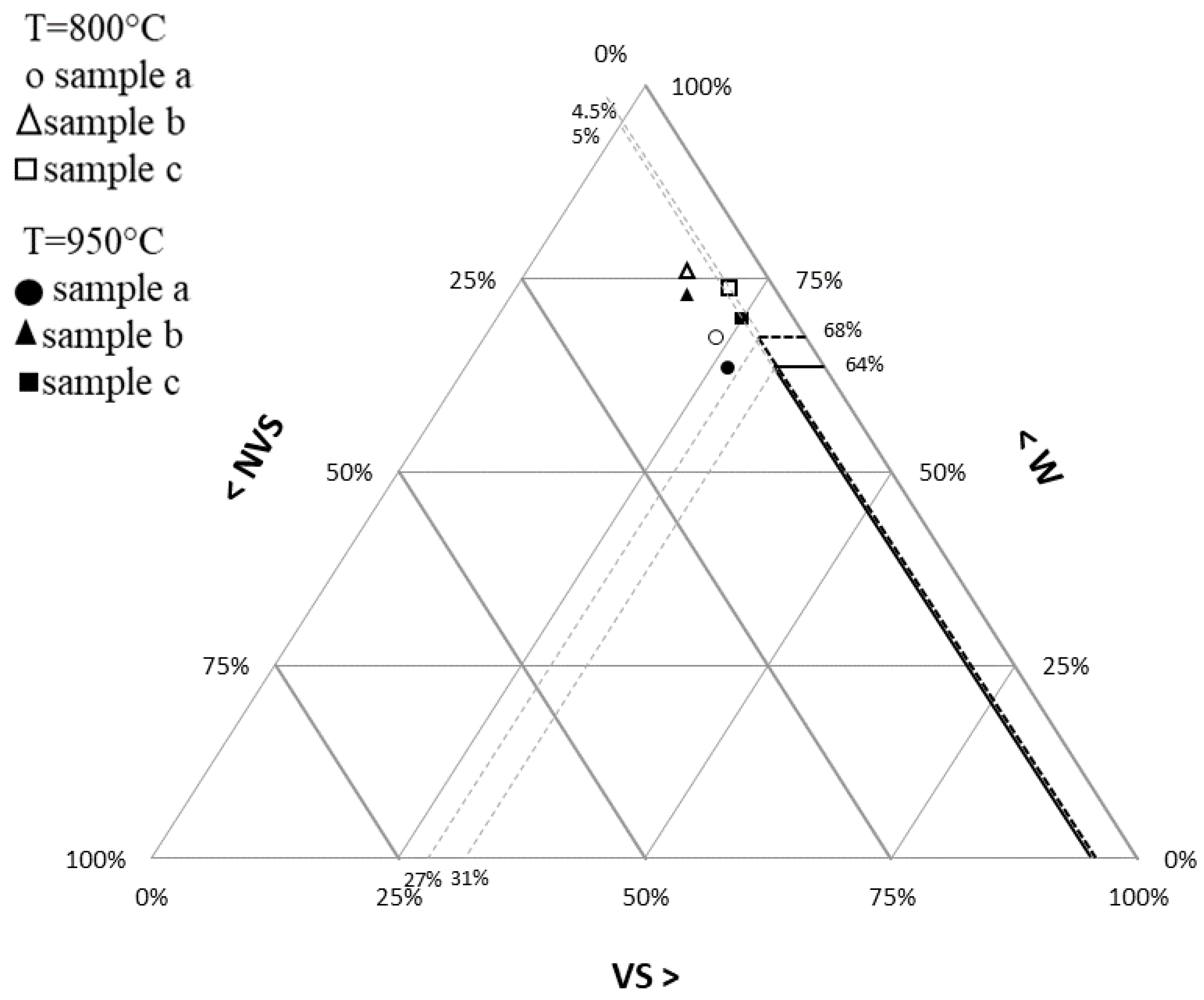

| Sludge Sample | C [%DM] | H [%DM] | N [%DM] | S [%DM] | W [%] | NVS [%] | VS [%] | HHV [kJ/kg DM] | T [°C] |

| a | 34.7 | 5 | 6 | 0.1 | 80.1 | 5.4 | 14.5 | 2811 | 253 |

| b | 39.2 | 6 | 7 | 0.2 | 79.8 | 7.0 | 13.2 | 3965 | 617 |

| c | 41.7 | 6 | 7 | 0.2 | 83.4 | 2.8 | 13.8 | 2939 | 267 |

| Results for T = 800 °C | Results for T = 950 °C | |||||||

|---|---|---|---|---|---|---|---|---|

| Sludge | W [%] | VS [%] | NVS [%] | TS [%] | W [%] | VS [%] | NVS [%] | TS [%] |

| a | 68.1 | 23.2 | 8.7 | 31.9 | 63.6 | 26.5 | 10.0 | 36.5 |

| b | 76.3 | 15.5 | 8.2 | 23.7 | 73.0 | 17.7 | 9.4 | 27.0 |

| c | 73.5 | 22.0 | 4.5 | 26.5 | 69.6 | 25.3 | 5.1 | 30.4 |

| Primary, average | 75.5 | 17.2 | 7.4 | 24.5 | 72.0 | 19.6 | 8.4 | 28.1 |

| Primary, min-max | 72.3–78.1 | 16.6–17.6 | 11.1–4.4 | 27.7–22.0 | 68.4–74.8 | 19.0–20.2 | 12.7–5.0 | 31.7–25.2 |

| Secondary, average | 68.9 | 19.7 | 11.4 | 31.1 | 64.5 | 22.5 | 13.0 | 35.5 |

| Secondary, min–max | 67.1–70.5 | 19.4–20.1 | 13.5–9.4 | 32.9–29.5 | 62.6–66.3 | 22.1–22.9 | 15.4–10.8 | 37.5–33.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Domini, M.; Bertanza, G.; Vahidzadeh, R.; Pedrazzani, R. Sewage Sludge Quality and Management for Circular Economy Opportunities in Lombardy. Appl. Sci. 2022, 12, 10391. https://doi.org/10.3390/app122010391

Domini M, Bertanza G, Vahidzadeh R, Pedrazzani R. Sewage Sludge Quality and Management for Circular Economy Opportunities in Lombardy. Applied Sciences. 2022; 12(20):10391. https://doi.org/10.3390/app122010391

Chicago/Turabian StyleDomini, Marta, Giorgio Bertanza, Reza Vahidzadeh, and Roberta Pedrazzani. 2022. "Sewage Sludge Quality and Management for Circular Economy Opportunities in Lombardy" Applied Sciences 12, no. 20: 10391. https://doi.org/10.3390/app122010391

APA StyleDomini, M., Bertanza, G., Vahidzadeh, R., & Pedrazzani, R. (2022). Sewage Sludge Quality and Management for Circular Economy Opportunities in Lombardy. Applied Sciences, 12(20), 10391. https://doi.org/10.3390/app122010391