Marinating and Grilling as Methods of Sensory Enhancement of Sous Vide Beef from Holstein-Friesian Bulls

Abstract

:1. Introduction

2. Materials and Methods

2.1. Beef and Sample Preparation

2.2. Cooking Treatments

2.3. Determination of the Chemical Composition and pH of Raw Beef

2.4. Colour Parameters

2.5. Warner–Bratzler Shear Force (WBSF)

2.6. Sensory Evaluation

2.7. Statistical Analysis

3. Results

3.1. Chemical Composition and pH of Raw Beef

3.2. Colour Parameters

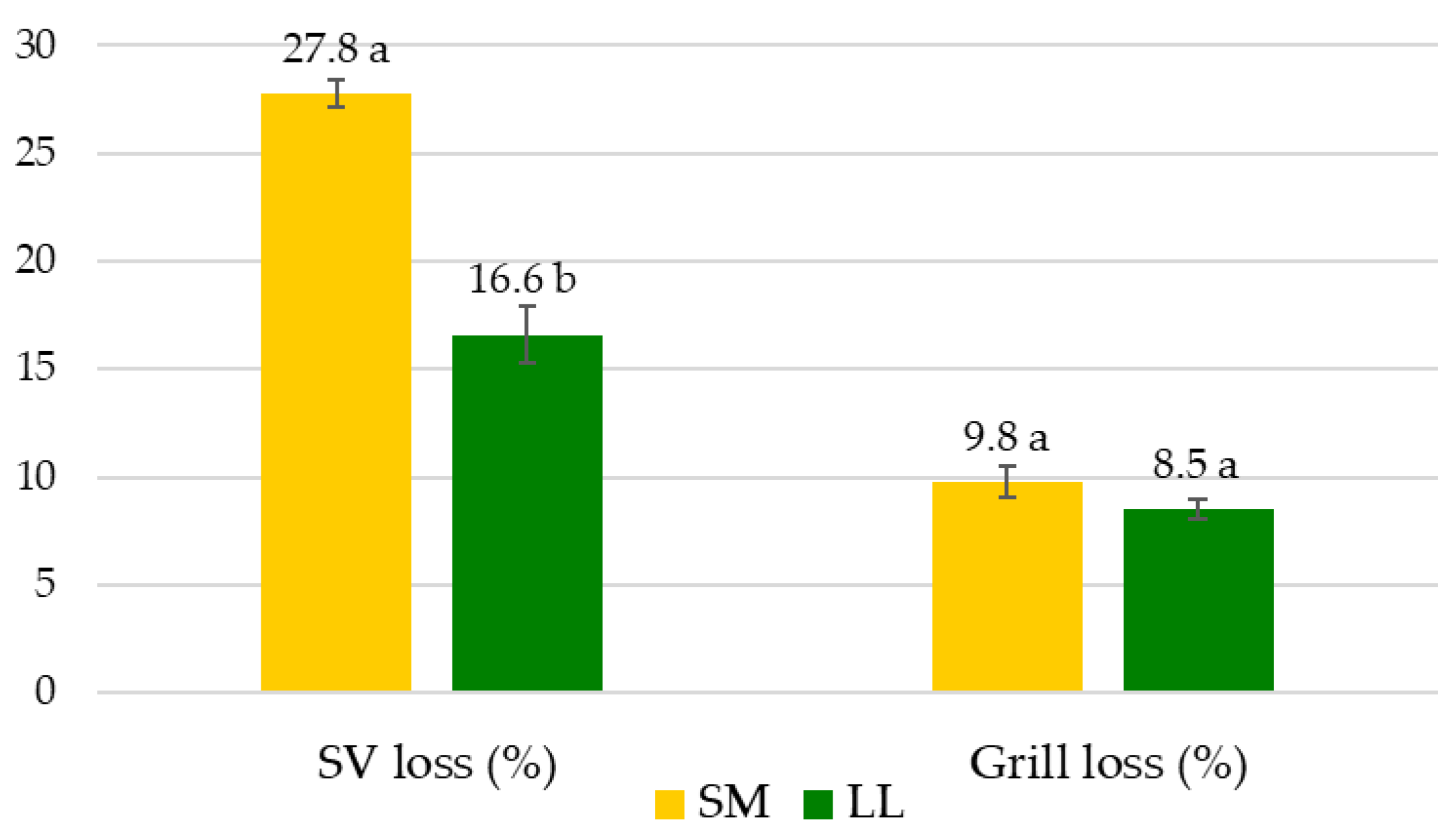

3.3. Yield, Warner–Bratzler Shear Force (WBSF), and Sensory Quality

4. Discussion

4.1. Chemical Composition and pH of Raw Beef

4.2. Colour Parameters

4.3. Yield, Warner–Bratzler Shear Force (WBSF), and Sensory Quality

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Wang, R.; Wen, Q.-H.; Rahaman, A.; Zeng, X.-A. Effects of pulsed electric field pretreatment on mass transfer and quality of beef during marination process. Innov. Food Sci. Emerg. Technol. 2022, 80, 103061. [Google Scholar] [CrossRef]

- Żakowska-Biemans, S.; Pieniak, Z.; Gutkowska, K.; Wierzbicki, J.; Cieszyńska, K.; Sajdakowska, M.; Kosicka-Gębska, M. Beef consumer segment profiles based on information source usage in Poland. Meat Sci. 2017, 124, 105–113. [Google Scholar] [CrossRef] [PubMed]

- Bassam, S.M.; Noleto-Dias, C.; Farag, M.A. Dissecting grilled red and white meat flavor: Its characteristics, production mechanisms, influencing factors and chemical hazards. Food Chem. 2022, 371, 131139. [Google Scholar] [CrossRef]

- Fořtová, J.; Del Mar Campo, M.; Valenta, J.; Needham, T.; Řehák, D.; Lebedová, N.; Bartoň, L.; Klouček, P.; Bureš, D. Preferences and acceptance of Czech and Spanish consumers regarding beef with varying intramuscular fat content. Meat Sci. 2022, 192, 108912. [Google Scholar] [CrossRef]

- Pushkarev, N. Meat Production & Consumption (in Europe) and Public Health. An Exploration. 2021, European Public Health Alliance (EPHA). Available online: https://epha.org/wp-content/uploads/2021/10/meat-production-consumption-in-europe-and-public-health-an-exploration-final.pdf (accessed on 20 July 2022).

- Bhat, Z.F.; Morton, J.D.; Zhang, X.; Mason, S.L.; Bekhit, A.E.-D.A. Sous-vide cooking improves the quality and in-vitro digestibility of Semitendinosus from culled dairy cows. Food Res. Int. 2020, 127, 108708. [Google Scholar] [CrossRef] [PubMed]

- Joo, S.T.; Kim, G.D.; Hwang, Y.H.; Ryu, Y.C. Control of fresh meat quality through manipulation of muscle fiber characteristics. Meat Sci. 2013, 95, 828–836. [Google Scholar] [CrossRef] [PubMed]

- Hawley, A.L.; Liang, X.; Borsheim, E.; Wolfe, R.R.; Salisbury, L.; Hendy, E.; Wu, H.; Walker, S.; Tacinelli, A.M.; Baum, J.I. The potential role of beef and nutrients found in beef on outcomes of wellbeing in healthy adults 50 years of age and older: A systematic review of randomized controlled trials. Meat Sci. 2022, 189, 108830. [Google Scholar] [CrossRef]

- Nogalski, Z.; Wielgosz-Groth, Z.; Purwin, C.; Nogalska, A.; Sobczuk-Szul, M.; Winarski, R.; Pogorzelska, P. The effect of slaughter weight and fattening intensity on changes in carcass fatness in young Holstein-Fresian bulls. Ital. J. Anim. Sci. 2014, 13, 66–72. [Google Scholar] [CrossRef] [Green Version]

- Pogorzelski, G.; Pogorzelska-Nowicka, E.; Pogorzelski, P.; Półtorak, A.; Hocquette, J.-F.; Wierzbicka, A. Towards an integration of pre-and post-slaughter factors affecting the eating quality of beef. Livest. Sci. 2022, 255, 104795. [Google Scholar] [CrossRef]

- Warner, R.D. Review: Analysis of the process and drivers for cellular meat production. Animal 2019, 13, 3041–3058. [Google Scholar] [CrossRef] [PubMed]

- Waughray, D. Meat: The Future. Time for a Protein Portfolio to Meet Tomorrows Demand–A White Paper. 2018. Available online: https://www3.weforum.org/docs/White_Paper_Meat_the_Future_Time_Protein_Portfolio_Meet_Tomorrow_Demand_report_2018.pdf (accessed on 18 May 2022).

- Mann, N.J. A brief history of meat in the human diet and current health implications. Meat Sci. 2018, 144, 169–179. [Google Scholar] [CrossRef]

- Needham, T.; Kotrba, R.; Hoffman, L.C.; Bureš, D. Ante- and post-mortem strategies to improve the meat quality of high-value muscles harvested from farmed male common eland (Taurotragus oryx). Meat Sci. 2020, 168, 108183. [Google Scholar] [CrossRef] [PubMed]

- Pogorzelski, G.; Woźniak, K.; Polkinghorne, R.; Półtorak, A.; Wierzbicka, A. Polish consumer categorisation of grilled beef at 6 mm and 25 mm thickness into quality grades, based on meat standards Australia methodology. Meat Sci. 2020, 161, 107953. [Google Scholar] [CrossRef]

- Realini, C.E.; Pavan, E.; Johnson, P.L.; Font-i-Furnols, M.; Jacob, N.; Agnew, M.; Craigie , C.R.; Moon , C.D. Consumer liking of M. longissimus lumborum of New Zealand pasture finished lamb is influenced by intramuscular fat. Meat Sci. 2021, 173, 108380. [Google Scholar] [CrossRef] [PubMed]

- Naqvi, Z.B.; Thomson, P.C.; Ha, M.; Campbell, M.A.; McGill, D.M.; Friend, M.A.; Warner, R.D. Effect of sous vide cooking and ageing on tenderness and water-holding capacity of low-value beef muscles from young and older animals. Meat Sci. 2021, 175, 108435. [Google Scholar] [CrossRef]

- Bown, M.D.; Muir, P.D.; Thomson, B.C. Dairy and beef breed effects on beef yield, beef quality and profitability. N. Z. J. Agric. Res. 2016, 59, 174–184. [Google Scholar] [CrossRef]

- Martín, N.P.; Schreurs, N.M.; Morris, S.T.; López-Villalobos, N.; McDade, J.H.; Rebecca, E. Meat quality of beef-cross-dairy cattle from Angus or Hereford sires: A case study in a pasture-based system in New Zealand. Meat Sci. 2022, 190, 108840. [Google Scholar] [CrossRef]

- Nogalski, Z.; Pogorzelska-Przybyłek, P.; Sobczuk-Szul, M.; Nogalska, A.; Modzelewska-Kapituła, M.; Purwin, C. Carcass characteristics and meat quality of bulls and steers slaughtered at two different ages. Ital. J. Anim. Sci. 2018, 17, 279–288. [Google Scholar] [CrossRef] [Green Version]

- Tkacz, K.; Modzelewska-Kapituła, M.; Więk, A.; Nogalski, Z. The applicability of total color difference ΔE for determining the blooming time in longissimus lumborum and semimembranosus muscles from Holstein-Friesian bulls at different ageing times. Appl. Sci. 2020, 10, 8215. [Google Scholar] [CrossRef]

- Frank, D.; Ball, A.; Hughes, J.; Krishnamurthy, R.; Piyasiri, U.; Stark, J.; Watkins, P.; Warner, R. Sensory and Flavor Chemistry Characteristics of Australian Beef: Influence of Intramuscular Fat, Feed, and Breed. J. Agric. Food Chem. 2016, 64, 4299–4311. [Google Scholar] [CrossRef]

- Belew, J.B.; Brooks, J.C.; McKenna, D.R.; Savell, J.W. Warner-Bratzler shear evaluations of 40 bovine muscles. Meat Sci. 2004, 64, 507–512. [Google Scholar] [CrossRef]

- Sammel, L.M.; Hunt, M.C.; Kropf, D.H.; Hachmeister, K.A.; Johnson, D.E. Comparison of Assays for Metmyoglobin Reducing Ability in Beef Inside and Outside Semimembranosus Muscle. J. Food Sci. 2002, 67, 978–984. [Google Scholar] [CrossRef]

- Gajaweera, C.; Chung, K.Y.; Lee, S.H.; Wijayananda, H.I.; Kwon, E.G.; Kim, H.J.; Cho, S.H.; Lee, S.H. Assessment of carcass and meat quality of longissimus thoracis and semimembranosus muscles of Hanwoo with Korean beef grading standards. Meat Sci. 2020, 160, 107944. [Google Scholar] [CrossRef] [PubMed]

- Wyrwisz, J.; Moczkowska, M.; Kurek, M.; Stelmasiak, A.; Półtorak, A.; Wierzbicka, A. Influence of 21 days of vacuum-aging on color, bloom development, and WBSF of beef semimembranosus. Meat Sci. 2016, 122, 48–54. [Google Scholar] [CrossRef]

- Modzelewska-Kapituła, M.; Pietrzak-Fiećko, R.; Tkacz, K.; Draszanowska, A.; Więk, A. Influence of sous vide and steam cooking on mineral contents, fatty acid composition and tenderness of semimembranosus muscle from Holstein-Friesian bulls. Meat Sci. 2019, 157, 107877. [Google Scholar] [CrossRef]

- Tkacz, K.; Modzelewska-Kapituła, M.; Petracci, M.; Zduńczyk, W. Improving the quality of sous-vide beef from Holstein-Friesian bulls by different marinades. Meat Sci. 2021, 182, 108639. [Google Scholar] [CrossRef]

- N’Gatta, K.C.A.; Kondjoyan, A.; Favier, R.; Sicard, J.; Rouel, J.; Gruffat, D.; Mirade, P.-S. Impact of Combining Tumbling and Sous-Vide Cooking Processes on the Tenderness, Cooking Losses and Colour of Bovine Meat. Processes 2022, 10, 1229. [Google Scholar] [CrossRef]

- Baldwin, D.E. Sous vide cooking: A review. Int. J. Gastron. Food Sci. 2012, 1, 15–30. [Google Scholar] [CrossRef] [Green Version]

- Karki, R.; Bremer, P.; Silcock, P.; Oey, I. Effect of Sous vide Processing on Quality Parameters of Beef Short Ribs and Optimisation of Sous vide Time and Temperature Using Third-Order Multiple Regression. Food Bioprocess Technol. 2022, 15, 1629–1646. [Google Scholar] [CrossRef]

- Kathuria, D.; Dhiman, A.K.; Attri, S. Sous vide, a culinary technique for improving quality of food products: A review. Trends Food Sci. Technol. 2022, 119, 57–68. [Google Scholar] [CrossRef]

- Dominguez-Hernandez, E.; Salaseviciene, A.; Ertbjerg, P. Low-temperature long-time cooking of meat: Eating quality and underlying mechanisms. Meat Sci. 2018, 143, 104–113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ayub, H.; Ahmad, A. Physiochemical Changes in Sous-Vide and Conventionally Cooked Meat. Int. J. Gastron. Food Sci. 2019, 17, 100145. [Google Scholar] [CrossRef]

- Modzelewska-Kapituła, M.; Tkacz, K.; Więk, A.; Rybaczek, S.; Nogalski, Z. Sida silage in cattle nutrition–effects on the fattening performance of Holstein-Friesian bulls and beef quality. Livest. Sci. 2021, 243, 104383. [Google Scholar] [CrossRef]

- Sengun, I.Y.; Turp, G.Y.; Cicek, S.N.; Avci, T.; Ozturk, B.; Kilic, G. Assessment of the effect of marination with organic fruit vinegars on safety and quality of beef. Int. J. Food Microbiol. 2021, 336, 108904. [Google Scholar] [CrossRef] [PubMed]

- Cordeiro, T.; Viegas, O.; Silva, M.; Martins, Z.E.; Fernandes, I.; Ferreira, I.M.L.P.V.O.; Pinho, O.; Mateus, N.; Calhau, C. Inhibitory effect of vinegars on the formation of polycyclic aromatic hydrocarbons in charcoal-grilled pork. Meat Sci. 2020, 167, 108083. [Google Scholar] [CrossRef]

- Modzelewska-Kapituła, M.; Tkacz, K.; Nogalski, Z. The influence of muscle, ageing and thermal treatment method on the quality of cooked beef. J. Food Sci. Technol. 2021, 59, 123–132. [Google Scholar] [CrossRef] [PubMed]

- PN-ISO1442; Meat and Meat Products. Determination of Water Content (Reference Method). Polish Committee for Standardization: Warsaw, Poland, 2000.

- Association of Analytical Communities. Official Methods of Analysis Method 992.15. Proximate Analysis and Calculations Crude Protein Meat and Meat Products Including Pet Foods, 17th ed.; Association of Analytical Communities: Gaithersburg, MD, USA, 2006. [Google Scholar]

- Association of Analytical Communities. Official Method of Analysis Method 991.36. Fat (Crude) in Meat and Meat Products, 18th ed.; Association of Analytical Communities: Gaithersburg, MD, USA, 2006. [Google Scholar]

- PN-ISO 936; Meat and Meat Products–Determination of Total Ash. Polish Committee for Standardization: Warsaw, Poland, 2000.

- Hamm, R. Functional properties of the myofibrillar system and their measurements. In Muscle as Food; Bechtel, P.J., Ed.; Academic Press, Inc.: New York, NY, USA, 1986; pp. 135–199. [Google Scholar]

- Modzelewska-Kapituła, M.; Tkacz, K.; Nogalski, Z.; Karpińska-Tymoszczyk, M.; Draszanowska, A.; Pietrzak-Fiećko, R.; Purwin, C.; Lipiński, K. Addition of herbal extracts to the Holstein-Friesian bulls’ diet changes the quality of beef. Meat Sci. 2018, 145, 163–170. [Google Scholar] [CrossRef]

- AMSA. Meat Color Measurement Guidelines; American Meat Science Association: Champaign, IL, USA, 2012. [Google Scholar]

- Jeong, K.O.H.; Shin, S.Y.; Kim, Y.S. Effects of different marination conditions on quality, microbiological properties, and sensory characteristics of pork ham cooked by the sous-vide method. Korean J. Food Sci. Anim. Resour. 2018, 38, 506–514. [Google Scholar] [CrossRef]

- PN ISO 4121; Sensory Analysis Methodology–Evaluation of Food Products by Methods using Scales. Polish Committee for Standardization: Warsaw, Poland, 1998.

- Lebedová, N.; Bureš, D.; Needham, T.; Fořtová, J.; Řehák, D.; Bartoň, L. Histological composition, physiochemical parameters, and organoleptic properties of three muscles from Fleckvieh bulls and heifers. Meat Sci. 2022, 188, 108807. [Google Scholar] [CrossRef]

- Hwang, Y.H.; Kim, G.D.; Jeong, J.Y.; Hur, S.J.; Joo, S.T. The relationship between muscle fiber characteristics and meat quality traits of highly marbled Hanwoo (Korean native cattle) steers. Meat Sci. 2010, 86, 456–461. [Google Scholar] [CrossRef]

- Lizaso, G.; Beriain, M.J.; Horcada, A.; Chasco, J.; Purroy, A. Effect of intended purpose (dairy/beef production) on beef quality. Can. J. Anim. Sci. 2011, 91, 97–102. [Google Scholar] [CrossRef] [Green Version]

- Listrat, A.; Lebret, B.; Louveau, I.; Astruc, T.; Bonnet, M.; Lefaucheur, L.; Picard, B.; Bugeon, J. How muscle structure and composition influence meat and flesh quality. Sci. World J. 2016, 28, 125–136. [Google Scholar] [CrossRef] [Green Version]

- Reardon, W.; Mullen, A.M.; Sweeney, T.; Hamill, R.M. Association of polymorphisms in candidate genes with colour, water-holding capacity, and composition traits in bovine M. longissimus and M. semimembranosus. Meat Sci. 2010, 86, 270–275. [Google Scholar] [CrossRef]

- Kaliniak-Dziura, A.; Domaradzki, P.; Kowalczyk, M.; Florek, M.; Skałecki, P.; Kędzierska-Matysek, M.; Stanek, P.; Dmoch, M.; Grenda, T.; Kowalczuk-Vasilev, E. Effect of heat treatments on the physicochemical and sensory properties of the longissimus thoracis muscle in unweaned Limousin calves. Meat Sci. 2022, 192, 108881. [Google Scholar] [CrossRef] [PubMed]

- Suleman, R.; Wang, Z.; Aadil, R.M.; Hui, T.; Hopkins, D.L.; Zhang, D. Effect of cooking on the nutritive quality, sensory properties and safety of lamb meat: Current challenges and future prospects. Meat Sci. 2020, 167, 108172. [Google Scholar] [CrossRef] [PubMed]

- Wall, K.R.; Kerth, C.R.; Miller, R.K.; Alvarado, C. Grilling temperature effects on tenderness, juiciness, flavor and volatile aroma compounds of aged ribeye, strip loin, and top sirloin steaks. Meat Sci. 2019, 150, 141–148. [Google Scholar] [CrossRef]

- Augustyńska-Prejsnar, A.; Sokołowicz, Z.; Hanus, P.; Ormian, M.; Kačániová, M. Quality and Safety of Marinating Breast Muscles of Hens from Organic Farming after the Laying Period with Buttermilk and Whey. Animals 2020, 10, 2393. [Google Scholar] [CrossRef]

- Latoch, A.; Libera, J. Quality and safety of pork steak marinated in fermented dairy products and sous-vide cooked. Sustainability 2019, 11, 5644. [Google Scholar] [CrossRef] [Green Version]

- Needham, T.; Laubser, J.G.; Kotrba, R.; Bureš, D.; Hoffman, L.C. Influence of ageing on the physical qualities of the longissimus thoracis et lumborum and biceps femoris muscles from male and female free-ranging common eland (Taurotragus oryx). Meat Sci. 2020, 159, 107922. [Google Scholar] [CrossRef]

- Perez-Juan, M.; Kondjoyan, A.; Picouet, P.; Realini, C.E. Effect of Marination and Microwave Heating on the Quality of Semimembranosus and Semitendinosus Muscles from Friesian Mature Cows. Meat Sci. 2012, 92, 107–114. [Google Scholar] [CrossRef]

- Żochowska-Kujawska, J.; Lachowicz, K.; Sobczak, M. Effects of fibre type and kefir, wine lemon, and pineapple marinades on texture and sensory properties of wild boar and deer longissimus muscle. Meat Sci. 2012, 92, 675–680. [Google Scholar] [CrossRef] [PubMed]

- Lawrence, M.T.; Lawrence, T.E. At-home methods for tenderizing meat using blade tenderization, lime juice and pineapple puree. Meat Sci. 2021, 17, 108487. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Tian, H.; Hu, S.; Dong, L.; Zhang, J.; Yu, X.; Han, M.; Xu, X. The effect of in-package cold plasma on the formation of polycyclic aromatic hydrocarbons in charcoal-grilled beef steak with different oils or fats. Food Chem. 2022, 371, 131384. [Google Scholar] [CrossRef]

- Vidal, N.P.; Manful, C.; Pham, T.H.; Wheeler, E.; Stewart, P.; Keough, D.; Thomas, R. Novel unfiltered beer-based marinades to improve the nutritional quality, safety, and sensory perception of grilled ruminant meats. Food Chem. 2020, 302, 125326. [Google Scholar] [CrossRef] [PubMed]

| Attribute | LL | SM |

|---|---|---|

| Moisture (%) | 74.03 a (0.29) | 74.85 a (0.24) |

| Protein (%) | 22.59 a (0.10) | 22.41 a (0.18) |

| Fat (%) | 2.37 a (0.22) | 1.59 b (0.14) |

| Ash (%) | 1.09 a (0.009) | 1.21 a (0.047) |

| pH | 5.67 a (0.009) | 5.69 a (0.007) |

| Free water (%) | 27.5 b (0.6) | 31.9 a (0.6) |

| Thawing loss (%) | 2.02 b (0.21) | 5.6 a (0.5) |

| LL | SM | p Value | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Raw | SV | SVGrill | SVMar | Raw | SV | SVGrill | SVMar | M | T | M × T | |

| L* | 37.3 d (0.4) | 42.0 b (0.8) | 39.1 cd (0.6) | 46.3 a (0.5) | 36.7 d (0.6) | 39.7 c (0.5) | 31.9 e (0.5) | 45.6 a (0.3) | ** | *** | *** |

| a* | 22.6 a (0.4) | 14.3 c (0.1) | 8.9 ef (0.1) | 9.2 e (0.2) | 20.8 b (0.3) | 12.7 d (0.6) | 7.8 f (0.2) | 5.0 g (0.1) | *** | *** | ** |

| b* | 11.8 de (0.3) | 12.8 c (0.1) | 12.1 cd (0.2) | 11.2 e (0.2) | 13.0 bc (0.3) | 14.2 a (0.2) | 13.8 ab (0.2) | 13.5 abc (0.2) | *** | ** | NS |

| C | 25.5 a (0.5) | 19.2 b (0.1) | 15.1 cd (0.2) | 14.5 d (0.2) | 24.6 a (0.3) | 19.2 b (0.4) | 15.9 c (0.2) | 14.4 d (0.2) | ** | *** | NS |

| h | 27.6 f (0.3) | 41.7 d (0.3) | 53.4 c (0.6) | 50.4 cd (0.7) | 31.8 e (0.5) | 48.7 d (1.5) | 60.7 b (0.6) | 69.6 a (0.3) | *** | *** | *** |

| ΔE* | - | 10.0 d (0.6) | 14.1 c (0.6) | 16.5 ab (0.5) | - | 9.1 d (0.8) | 14.3 bc (0.4) | 18.2 a (0.4) | NS | *** | * |

| NBS unit | - | 9.2 d (0.5) | 13.0 c (0.5) | 15.2 ab (0.4) | - | 8.4 d (0.7) | 13.2 bc (0.3) | 16.7 a (0.3) | NS | *** | * |

| Attribute | LL | SM | p Value | ||||||

|---|---|---|---|---|---|---|---|---|---|

| SV | SVGrill | SVMar | SV | SVGrill | SVMar | M | T | M × T | |

| Yield (%) | 78.7 a (0.7) | 76.2 a (1.2) | 75.6 a (1.1) | 70.7 b (0.3) | 65.1 c (0.6) | 69.5 b (0.4) | *** | *** | * |

| WBSF (N) | 20.5 cd (0.6) | 19.1 d (0.5) | 15.0 e (0.4) | 28.4 a (0.7) | 23.2 b (0.8) | 22.4 bc (0.6) | *** | *** | * |

| Tenderness (points) | 7.3 b (0.2) | 7.3 b (0.2) | 7.7 ab (0.1) | 7.3 b (0.2) | 6.5 c (0.2) | 8.3 a (0.2) | NS | ** | * |

| Juiciness (points) | 7.5 a (0.2) | 6.9 a (0.2) | 7.2 a (0.2) | 6.7 a (0.3) | 5.2 b (0.3) | 6.6 a (0.2) | * | * | NS |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tkacz, K.; Modzelewska-Kapituła, M. Marinating and Grilling as Methods of Sensory Enhancement of Sous Vide Beef from Holstein-Friesian Bulls. Appl. Sci. 2022, 12, 10411. https://doi.org/10.3390/app122010411

Tkacz K, Modzelewska-Kapituła M. Marinating and Grilling as Methods of Sensory Enhancement of Sous Vide Beef from Holstein-Friesian Bulls. Applied Sciences. 2022; 12(20):10411. https://doi.org/10.3390/app122010411

Chicago/Turabian StyleTkacz, Katarzyna, and Monika Modzelewska-Kapituła. 2022. "Marinating and Grilling as Methods of Sensory Enhancement of Sous Vide Beef from Holstein-Friesian Bulls" Applied Sciences 12, no. 20: 10411. https://doi.org/10.3390/app122010411