Abstract

Food products often consist of several phases. Comminuted meat products, for example, are multiphase systems consisting of structured meat particles and unstructured batter-like substance. To develop and understand the processing of these products, it is important to understand the sensory and mechanical perception principles. To this end, two-phase food prototypes consisting of mixtures of ground beef and beef batter were prepared and subjected to sensory, texture, and oral processing analysis. The oral processing analysis focused on the biomechanical data of the chewing process, namely the kinematics of jaw movement and electromyographic activity. The ground meat served as the anisotropic phase and the meat dough as the isotropic phase. A significant increase in muscle activity, duration per bite, and occlusion time with increasing proportion of fibrous particles was demonstrated (p < 0.05). In contrast, a higher proportion of isotropic substance resulted in significantly higher amplitudes of jaw movement and faster jaw kinetics (p < 0.05). In mixed regimes, the system responded mainly according to the dominant phase, with sensory or mechanical response changing at a critical point. In combination with texture and sensory data, a holistic characterization of the food models could be performed.

1. Introduction

Processed meat products such as ground beef, burgers, sausages, or meatloaf are well accepted food products with complex structure and texture. The structure of meat is highly directional, ranging from the orientation of actin and myosin filaments on the molecular scale to the elongated structure of muscle fiber bundles on the macroscale [1]. In general, oriented or direction dependent structures can be described as anisotropic, meaning that the direction of observation changes, opposed to isotropy, the properties of the material [2]. Processing of meat products often involves shearing or shredding followed by dissolution of the myofibrillar protein [3]. This can be either intentional, as in the production of meat batter for cooked sausage production, or unintentional due to sub-optimal processing conditions or malfunction worn processing equipment [4]. In either case, there is lysis of muscle fiber cells, leakage of sarcoplasmic and fibrillar protein, and loss of the anisotropic structure. The resulting structures can be described by the model of a multiphase system consisting of a gel-like phase and an anisotropically structured phase.

To establish analytical methods that correlate with the gel-like structure, also referred to as amount of non-intact cells (ANIC) in minced meat products, Berger, et al. [5] developed a model system consisting of meat batter and ground meat, representing a two-phase system of anisotropic and isotropic structured matter. In their work, the histological ANIC significantly (p < 0.01) correlated with metmyoglobin content (r = 0.924), drip loss (r = −0.834), and firmness (r = −0.499) on samples with 0–100% replacement of minced meat by meat batter consisting of finely comminuted beef. This is a big accomplishment for analyzing the ANIC in raw minced meat samples with more rapid methods. The effect of ANIC in the end-product on human perception was not an issue of this work. From a quality control and economic perspective, the impact of ANIC on consumer perception is of great importance. The more precisely the threshold for the acceptable ANIC is defined, the closer the process can be steered in that direction, improving throughput and blade life, and potentially reduce waste streams by optimizing reprocessing rates. Texture studies are used to predict mechanical perception and determine this detection limit. However, due to the complexity of multiphase anisotropic systems, studying the texture of anisotropic foods can be challenging. When material is mechanically anisotropic at the macroscopic level, the anisotropic index (AI) calculated from deformation tests parallel and perpendicular to the direction of anisotropy showed great potential as a meaningful feature [6,7]. Moreover, macroscopic mechanical differences often do not accurately reflect sensory impression. Current methods are a good tool to characterize materials in a macroscopic materials science approach, but do not capture the time-dependent change that a product undergoes during chewing. As an example, mastication changes foods due to cutting, shearing, and grinding between the teeth, wetting by saliva, softening by compression between the teeth or tongue and palate, or even chemical changes due to processes catalyzed by salivary enzymes [8,9].

In this study, we characterize anisotropic structures in complex multi-phase food systems through an oral processing approach combined with sensory- and texture analysis. We focus on biomechanical characteristics of mastication in terms of kinematics of jaw movement and muscle activity. For this work, the ANIC was not determined histologically and therefore is substituted by the amount of “batter-like substance” (BLS) throughout the whole article. The BLS is simulated by finely comminuted beef, and not to be confused with conventional meat batter. It is hypothesized that the increase in BLS is reflected in reduced movement kinetics of the jaw, decreased consumption time, and less muscle activity required to break down the food. This change might be caused by the microstructure of meat particles, which is more robust compared to a meat batter system and is not as easily transferred to a bound paste like and swallowable state.

2. Materials and Methods

2.1. Preparation of Food Model Matrices

Food prototypes were prepared as described by Berger, Gibis, Witte, Terjung, and Weiss [5]. Cuts from flank of two heifers were visually standardized to a fat content of approx. 20% according to the GEHA meat processing system (class: R IV [10]) and cut into cubes of 5 × 5 × 5 cm prior to mincing. The standardized meat cubes were mixed in a paddle mixer (RC-40, Equipamientos Cárnicos, S.L. (Mainca), Barcelona, Spain) for 1 min at 32 rpm and subsequently stored over night at 1 °C. Following, the cubes were first minced to 13 mm particle size, mixed with a paddle mixer for 30 s at 32 rpm and then minced to 2.4 mm particle size with a grinder (Forschungsautomatenwolf Typ AE 130, Maschinenfabrik Seydelmann KG, Aalen, Germany) set to a speed of 20 rpm at the feeding screw and 187 rpm at the grinder screw.

For production of the isotropic meat batter, which was to simulate the BLS (batter-like substance), a part of the minced meat was chopped for 2 min at 3000 rpm using a bowl chopper (K20, Maschinenfabrik Seydelmann KG, Aalen, Germany).

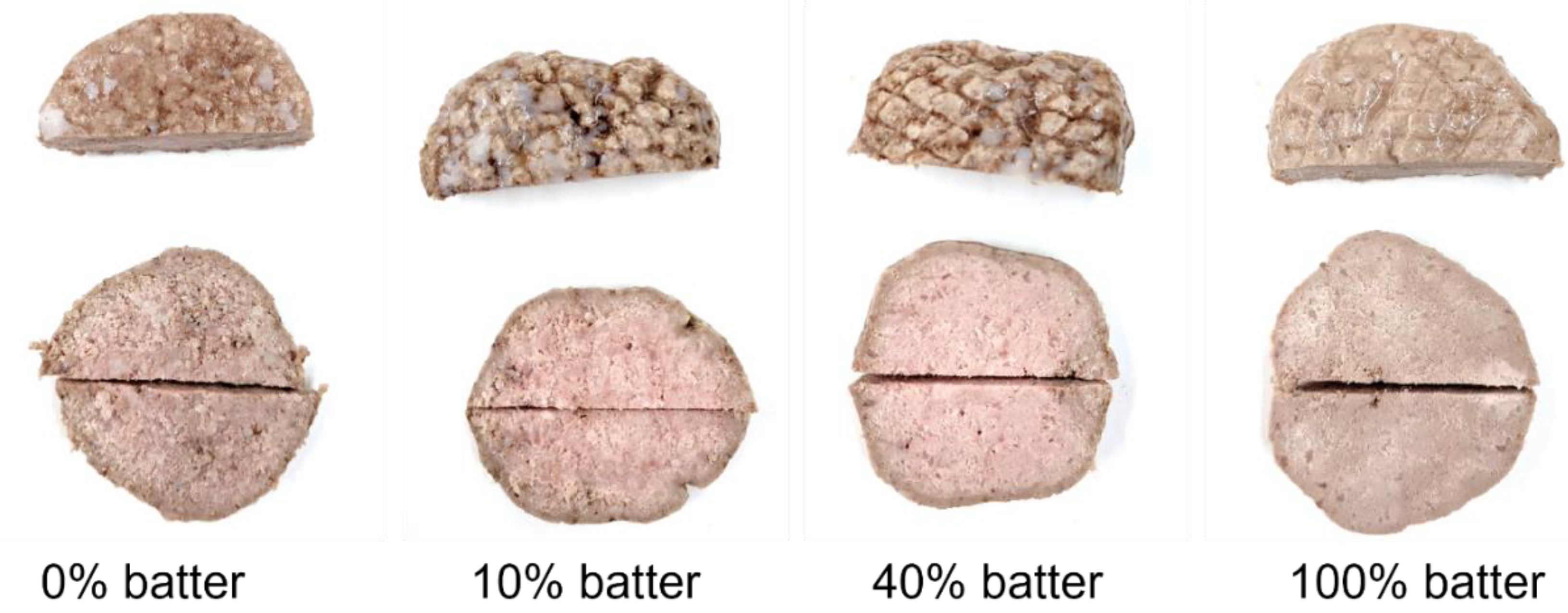

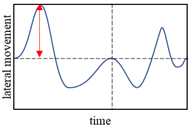

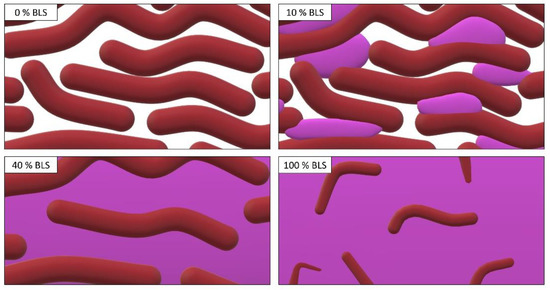

Batches containing 0%, 10%, 40%, and 100% meat batter were produced by carefully mixing minced meat of 2.4 mm particle size with the respective amount of meat batter by hand until homogeneously distributed. The masses were then formed into patties of approximately 70 g, using a patty-press (Burgerpresse, Hela Gewürzwerk Hermann Laue GmbH, Ahrensburg, Germany). The patties were then steam cooked in a processing chamber (Unigar 1800, Ness GmbH, Remshalden, Germany) to a core temperature of 70 °C. In a subsequent process step, the patties were showered for 5 min with cold water (10 °C). As the finished patties (Figure 1) were dry and cold they were put in 90 µm thick Polyamid/Polyethylen bags (allfo GmbH, Waltenhofen, Germany) with an oxygen permeability of ≤80 (75% rh) and water vapor permeability of ≤3 (85% rh). Bags were vacuum sealed with a packaging machine (C500, Multivac, Wolfertschwenden, Germany) at 50 mbar and stored at 1 °C until further examination.

Figure 1.

Example pictures of the cooked patty-style samples with increasing amount of BLS shown from the outside (upper row) and inside (lower row); from left to right: 0, 10, 40, 100% BLS.

2.2. Characterization of the Produced Food Model Matrices

2.2.1. Mechanical Properties

To estimate the mechanical properties of the samples, a two-cycle compression test was conducted. Cylindrical shapes of the four samples with different amount of meat batter were punched out to a diameter of 2 cm and cut to an equal length of 1.5 cm. Punching out was conducted by carefully screwing a pipe geometry with sharpened edges into the sample. Samples were then stored at ambient temperature (20 °C) wrapped in plastic foil until temperature had equilibrated to 20 ± 1 °C (ca. 1 h).

Texture analysis was carried out with a texture analyzer model 3365 (Instron Corp., Norwood, MA, USA) equipped with a plate-plate geometry (steel/aluminum). The two-cycle compression test was set to a compression of 75% with a traversal speed of 1.5 mm/s. Typical mechanical properties were calculated as described by Breene [11]. Since none of the samples showed a clear breaking point, it is focused on maximal force at first compression, area under the curve of first compression, and the ratio of peak area of second to first compression. The latter is used to express the internal cohesion of the sample and is referred to as cohesiveness.

2.2.2. Sensory

Samples with different amounts of BLS (n = 4) were presented to the panelists (n = 19 panelists) in cubes of (1.5 × 1.5 × 2 cm). The samples temperature was adjusted to room temperature (20 °C) prior to consumption. The sensory study was conducted in a sensory lab with separated cabins for each panelist, non-distracting environment, and controlled light conditions (clear white). The panelists were asked after each sample to subjectively rate it based on the hardness, fibrousness, juiciness, and subjective energy requirement for the process of mastication on a scale from 0 (non-detectable) to 10 (very intense). The method was conducted as described for the conventional profiling (DIN 10967-1, L 00.90-11/1-4) [12]. Additionally, the overall acceptance was rated from 0 (unpleasant) to 10 (most favorable). Panelists were instructed to rate the hardness based on the first bite of every sample, and the required energy as a total impression of the whole mastication process expressed as the subjective mechanical work and time needed to form a swallowable bolus. Juiciness was rated according to the moisture feeling in the mouth, taking into account salivary flow, water binding of the sample and lubrication by juice release. Fibrousness and overall acceptance should be rated subjectively with reference to the typically expected sensory impression of minced meat products.

2.2.3. Electromyography and Kinematics of Jaw Movement

Subjects. This study was approved by the Ethics Committee of the University of Hohenheim, and all participants gave informed consent after receiving a detailed introduction into the purpose of research, the measuring principle, collected data, and the overall aim of this study. In total, 8 subjects voluntarily participated (4 females, 4 males, age 25–56 years). The subjects did not receive any monetary compensation for participation. All subjects stated that they are in good state of dental health, free of pain and did not recently receive a dental treatment.

Measuring procedure. The subjects were equipped with five reflective tracer points (Qualisys, Illinois, USA). Four on the cranium and one on the mandibula for recording of the masticatory movement. Additionally, surface electrodes were applied, as they had already in earlier studies shown great potential as research tool in food texture sciences [13,14]. The EMG surface electrodes (Noraxon, Scottsdale, AZ, USA) were placed on the left and right masseter. Electrodes were positioned centered over the muscle and in direction of the muscle fiber orientation, as determined by palpation [15]. Before application of the electrodes, facial hair was removed, and the skin was wiped with disinfectant (Antisept 77, Ernst GmbH & Co., KG, Kamen, Germany).

The samples were presented to the panelists cut to equal size (1.5 × 1.5 × 2 cm). Temperature of the samples was adjusted to room temperature (20 °C) prior to consumption. Samples were consumed four times, however the first run served as adaption run, according to preventing recording any effect coming from the sensory discovery of the product [16], resulting in n = 3 evaluated mastication sequences per sample and panelist. Panelists were instructed to consume the whole sample at once and swallow and chew as they would habitually do. Therefore, the sample was placed in the oral cavity before starting the measurement. As soon as the panelist was ready, the sequence was started by a trigger input of the panelist. As all the sample was swallowed terminally and the mouth was clear, the sequence was manually stopped by another trigger input. Panelists were instructed to rinse their mouth with tap water (20 °C) after consumption of each sample.

Data acquisition. To track the 3D movement of the jaw, three Miqus M3 cameras equipped with infrared light sources (Qualisys, Göteborg, Sweden) were placed in front of the panelist, ensuring that each tracer is always seen by at least two cameras. Cameras were operated at 100 Hz. Calibration of the camera system was evaluated as good, if the precision was better than 0.35 mm.

Acquisition of the EMG signal was carried out by a surface EMG system (ultium EMG, Noraxon, Scottsdale, AZ, USA), consisting of signal transmitters and a receiver station. Data were acquired at a sampling rate of 2000 Hz, amplified (×500) and directly low- and high pass filtered (10–500 Hz) by the system. The camera system and EMG-system were connected over a camera sync unit (Qualisys, Göteborg, Sweden) equipped with a trigger input signal.

3. Data Preparation and Modelling

3.1. Feature Extraction

Automated processing of the acquired raw data was performed in MATLAB (MathWorks, Natick, MA, USA). In a first step, head movement was subtracted from the coordinates of the mandibula. The so calculated coordinates directly correspond to the three movement directions of the mandibula (x = forth/back, y = left/right, z = open/close).

Calculation of jaw movement velocities was performed by numerically deriving the vertical distance over time. Opening and closing velocities were defined as minimal and maximal numerical derivatives of the travelled distance over time between two opening positions. The occlusal duration was calculated as the sum of points with an absolute velocity of less than 15 mm/s during one cycle, excluding the first and last ten values of one cycle, to account idle points at the maximum opening position.

To enable numerical integration of the EMG signal, a root-mean-square filter (step width: 100) was applied to the high- and low pass filtered, rectified EMG signal. To simplify the further calculations and analysis of the EMG signal, the mean value of both masseter muscles was calculated. A standardization among subjects, as typically carried out [17,18,19,20,21], was not necessary since the applied statistical model calculates error terms for each subject.

Features provided in Table 1 were calculated during the constant chewing sequence. The location of the constant chewing sequence was indicated manually. For the constant sequence, initial food arrangement movements with the jaw or tongue were excluded and the sequence was terminated as soon as irregularities such as: (i) a long closing time between two opening positions, (ii) two opening positions without an occlusion (<3 mm) in between, or (iii) transition to an irregular opening distance were noticed.

Table 1.

Features calculated from 3D- and EMG-data with brief description of calculation and explanation of each feature.

Features from Table 1 were calculated from one maximal opening position to the subsequent one. Features that were calculated for the whole breakdown sequence initiate at the first opening position, and end right after the last point of swallow (manual indication). For the entire sequence, only the convex hull provided additional information, which is why other features are not shown in this study. The convex hull describes the volume that all 3D coordinates of one sequence enclosed. The point of swallow is typically located right after the oral rearrangement stage during which food residues are collected from the whole oral cavity and brought to the back of the tongue where a swallowable bolus is formed.

3.2. Statistical Model

Derived features from the raw data (as explained in Table 1) were statistically analyzed using the software SAS 9.4 (SAS, Cary, NC, USA). The data were evaluated according to Piepho and Edmondson [22], using the procedure “GLIMMIX” which fits linear mixed models, applying the method of restricted maximum likelihood. The model was designed so that each chewing sequence represents one unit of observation and each chew-event of one sequence was indicated as a repetitive measurement. The four samples with increasing amounts of BLS were assigned corresponding fractions of BLS as a continuous variable. To normalize the chewing progress, uniformly distributed numbers between 0 and 1 were assigned to each chewing sequence, where 0 was assigned to the first chew event, and 1 to the last chew-event in each sequence. The model-dependent variable y representing any of the chew-associated features from Table 1 was then fit with factors ( and ) according to Equation (1) with amount of batter B and the relative time indicator C as continuous variables. Main effects (B, C), the interaction of each factor (C × B), and quadratic terms (C2, B2) were computed.

For data that were calculated over one complete chewing cycle, each panelist was treated as a subject with every single chewing sequence as a repeated measurement. Specifically, the random residual r was modelled by fitting random effects for the panelist, and the sample nested within the panelist. Serial correlation was accounted for by modelling the errors for the series of measurements on each sample and repetition of one sequence according to a first-order autoregressive model [AR(1)]. The model statement is the same as described in Equation (1), but all terms including C are eliminated.

Sensory- and texture analysis data were evaluated calculating a one-way ANOVA (p < 0.05). Variances were tested for homogeneity with a Levene’s test (p < 0.05). Subsequently, a Tukey test (p < 0.05) was performed, comparing the mean values between samples of different amounts of BLS.

4. Results and Discussion

The produced samples with different ratios of BLS are evaluated based on their mechanical, sensorial, and oral processing properties. The amount of simulated BLS is to be understood as finely comminuted meat, and not to be confused with a typical meat batter in which ice, fat, and spices are incorporated. The following section presents data from tests performed on the four samples with 0–100% simulated BLS.

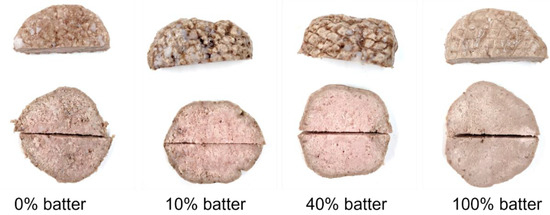

4.1. Determination of Mechanical Properties

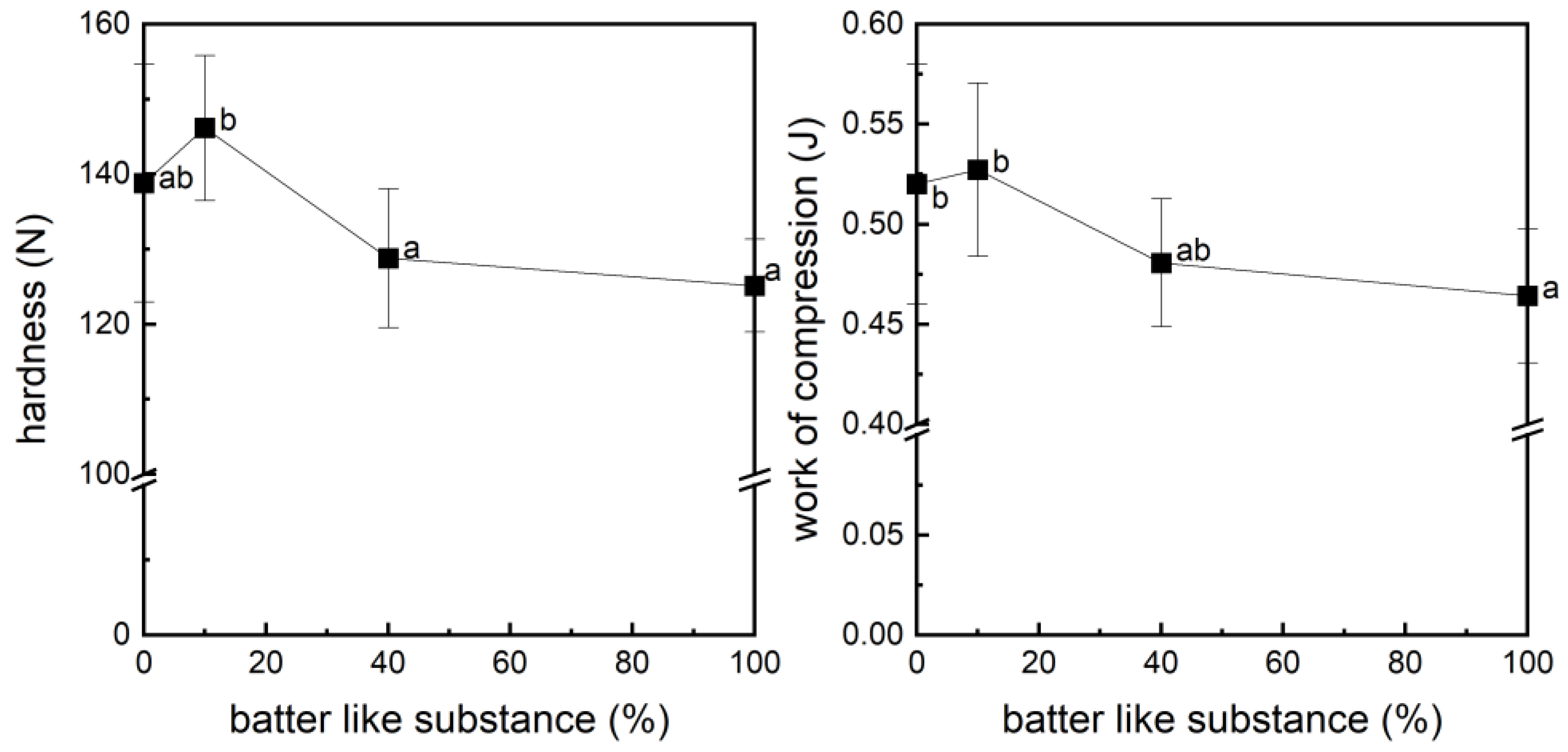

The two-cycle compression test provide information about the macroscopic mechanical resilience and breaking behavior. The obtained data (Figure 2) suggest that at 10% BLS, the hardness and work for first compression is with 146.1 N and 0.53 J, the highest of all samples. At higher amounts of BLS, the hardness decreases further down to 122.8–128.8 N, significantly lower than the sample with 10% BLS. A similar behavior was found for the work of first compression, but in this case, the only significant difference was between samples with 0–10% batter-like substance with values between 0.52 and 0.53 J and the sample with 100% BLS at 0.43 J. As hypothesized, the BLS might have a binding effect, compensating for the lower amount of meat pieces, resulting in no significant (p < 0.05) change in hardness from 0 to 10% BLS, with a slight but insignificant increase toward 10% BLS. Globally, the hardness and work decrease, supposedly due to the lack of structured and solid meat particles and standard deviation decreases, which can be drawn as an indicator for a more homogenous sample. The here-conducted effect goes in accordance with the work by Berger, Gibis, Witte, Terjung, and Weiss [5], who investigated the raw meat sample. In their work, an increase in firmness was described up to 25% BLS, dropping toward the sample consisting of 100% BLS. The authors came up with a mechanistic model describing the dependencies and mixing effects, concluding that the properties of the sample are defined by the predominant component with 25% of BLS as critical amount above which properties change from dispersed to emulsified [5].

Figure 2.

Hardness (N) and total work (J) of the first compression cycle from samples containing 0–100% BLS as determined by a two-cycle compression test to 75% deformation. Superscript letters (a,b) next to datapoints indicate significant differences according to a Tukey test (p < 0.05).

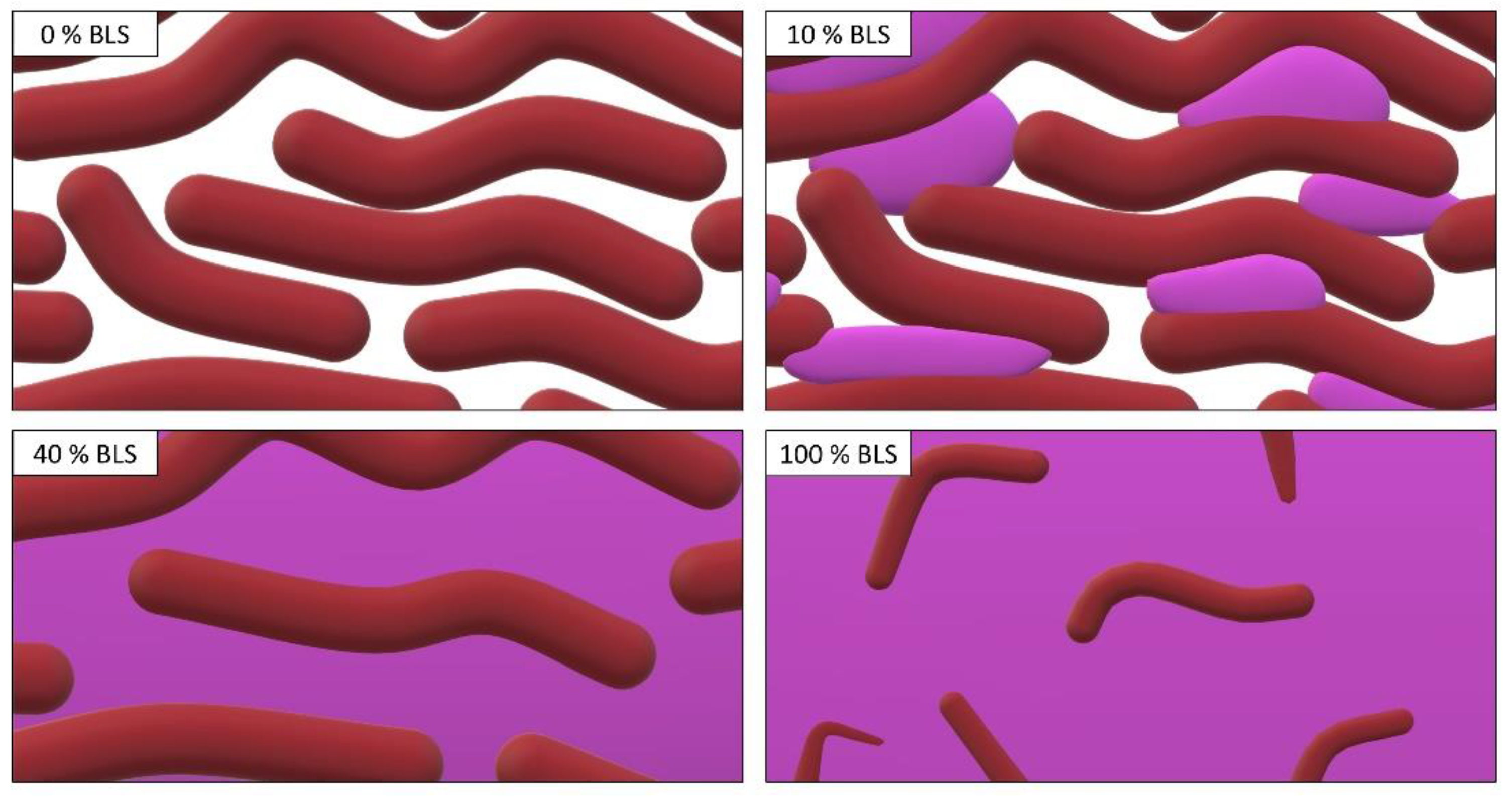

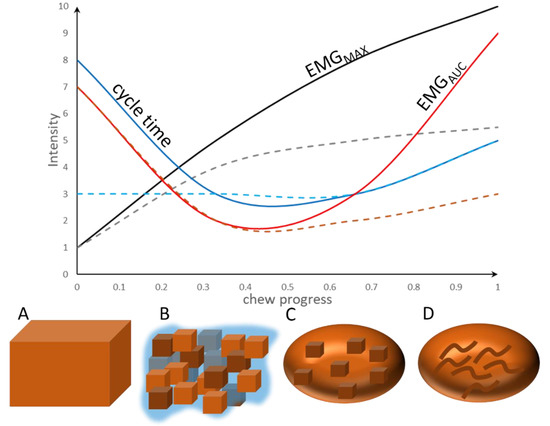

The cohesiveness steadily increased with increasing amount of BLS from 0.21 to 0.28, whereas the sample with 0% BLS showed the significantly lowest cohesiveness. This figuratively demonstrates the transition from a particulate system over to a gel-filled with particles to a pure gel and demonstrates the binding effect of the BLS as mechanistically shown in Figure 3. The binding effect of solubilized meat proteins was already described in-depth in a study by Tornberg [23]. Upon cell lysis, solubilized meat proteins go into solution with available water and ions, forming a cohesive mass which can form an irreversible gel when heated. Even though no salt was added to the system of the present study, the lysis of muscle cells sets free entrapped ions, thereby increasing the solubility of the salt soluble myofibrillar proteins.

Figure 3.

Mechanistic illustration of the meat fibers (brown elongated structures) interacting with the binding BLS (purple matter). Captions in the upper left corner correspond to the amount of BLS.

4.2. Sensory

To get insights on how different amounts of BLS are sensorially perceived, 19 panelists were asked to rate the samples according to the attributes of hardness, fibrousness, juiciness, energy for breakdown, and overall acceptance on a scale from 0 to 10 (Table 2).

Table 2.

Sensory scores for selected attributes on a scale from 0 to 10, with 5 as reference value. 0 = worst, 10 = best.

Four of the five tested sensory attributes are negatively responding to an increase of BLS. This goes along the previous found results (Figure 2 and Figure 3) and was as before mentioned already described in the literature as effect of decreasing structured particles [5]. Only the hardness showed a different tendency, which was similar to the effect seen in the two-cycle compression test. Samples with 0–40% provoked the same perception with a slight tendency of higher hardness scores toward 40%. Plain batter was subjectively rated to be softer than the 40% sample; however not significantly on a level of p < 0.05. Subjective energy for mastication, juiciness, and fibrousness of the sample with 100% BLS showed significantly lower values (p < 0.05) compared to samples containing a structured phase.

4.3. Food Oral Processing

4.3.1. General Trends of Oral Processing

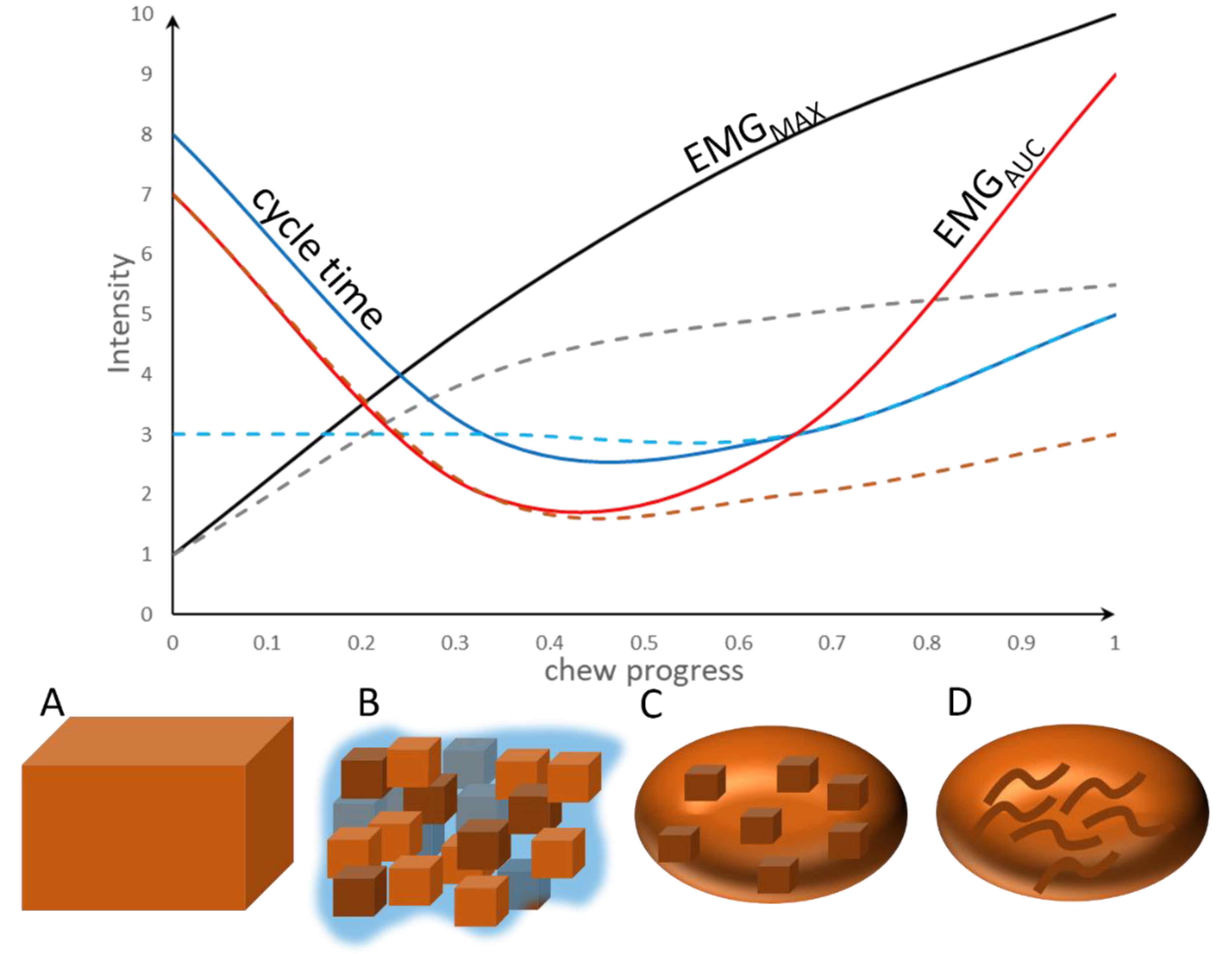

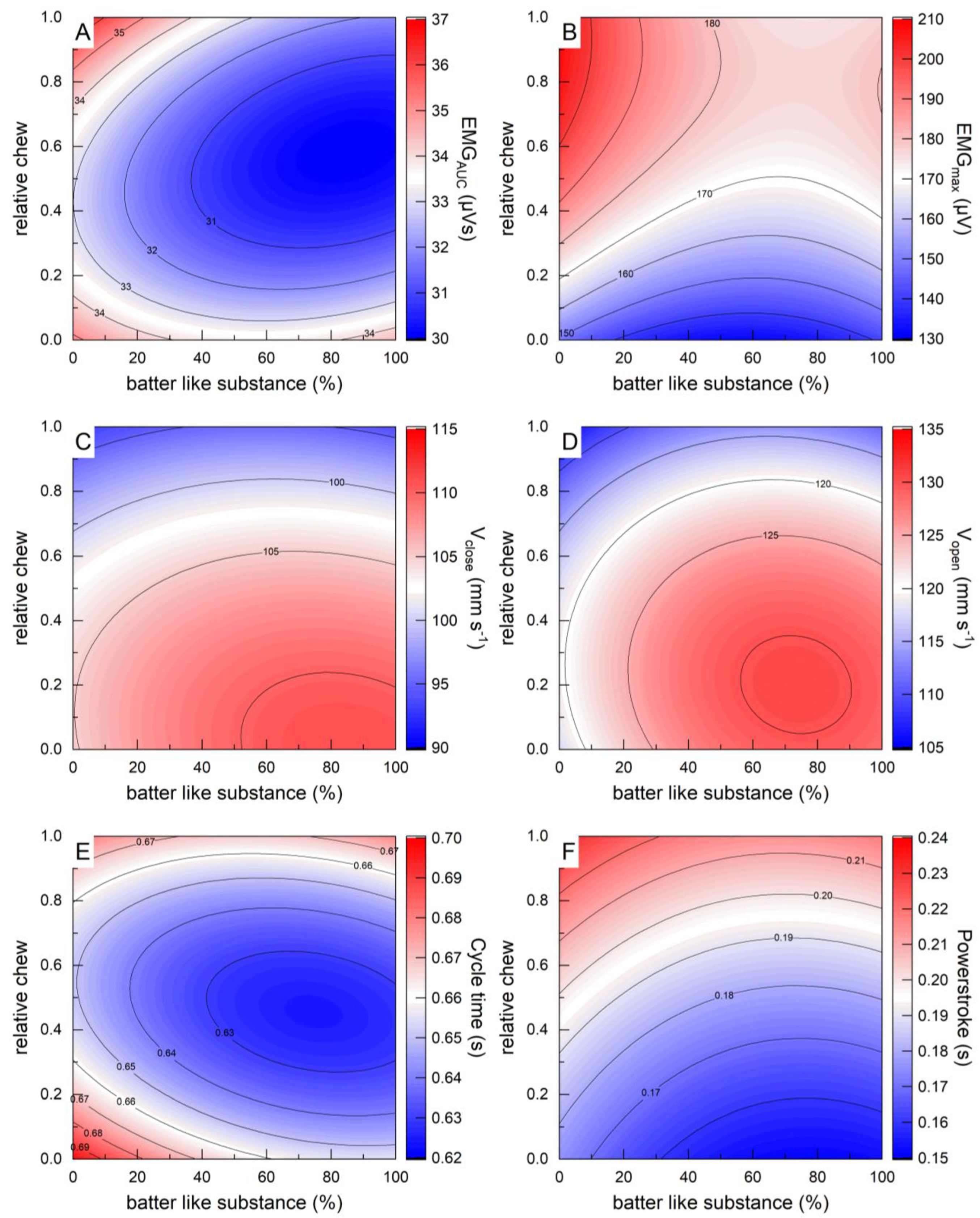

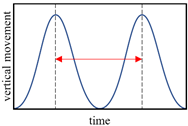

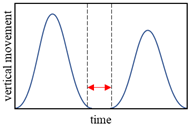

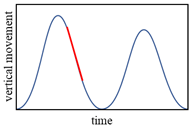

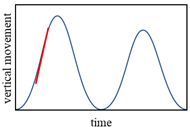

Before discussing in depth influences of the amount of BLS on mastication behavior, general trends for the mastication process can be read from the calculated model, which is depicted in Figure 4:

Figure 4.

Schematic illustration of the food transition from a solid cube to a swallowable bolus during oral processing. Cycle time, maximal muscle activity-, and the integral of muscle activity per bite are shown for fully anisotropic (–) and isotropic samples (- -). (A–D) show a hypothesized structure of the matter during oral processing. Dark brown particles and fibrils illustrate structured- and softened meat particles, light brown matter displays meat batter.

- Initial structure breakdown appears to take place in the very first bites (Figure 4A,B). In this section, bites take long with an indistinct grinding stage. Muscle activity peaks are low, indicating low effort cutting movements. EMGAUC is comparably high because of long cycle times. Velocities are, despite long cycle times, rather fast to enable quick cutting of the samples. Other work also demonstrated that hardness increased the movement area of the jaw [24]. This supports the high velocity at long cycle times, assuming that the initial sample is harder than the swallowable bolus [25].

- Cycle time drops immediately as mastication progresses. As figuratively shown in Figure 4B,C, BLS is mixed with saliva and a transition to a paste-like state is hypothesized [26]. However, power stroke phase steadily gets longer, indicating more grinding activity. Koç, et al. [27] already described this stage and refer to it as power stroke. During the power stroke, structures which do not exhibit a breaking behavior at cutting movements are ground to smaller particle sizes or to soften the structure and thereby enhance the swallowability [27]. This is also reflected in higher muscle activity peaks, while the EMGAUC first experiences a descent due to the rapid drop in cycle time. The velocity slowly decreases.

- Toward the end of the mastication process, cycle time increases again, now simultaneously with the increase of the power stroke duration. This is reflected in increased peak- and AUC values of the muscle activity. The velocity of the jaw further falls rapidly, indicating that mastication is mainly short movement, high power grinding of food material [28]. This is applied to soften remaining structured particles and enable swallowing of the bolus (Figure 4C,D).

4.3.2. Influence of Batter-Like Substance (BLS)

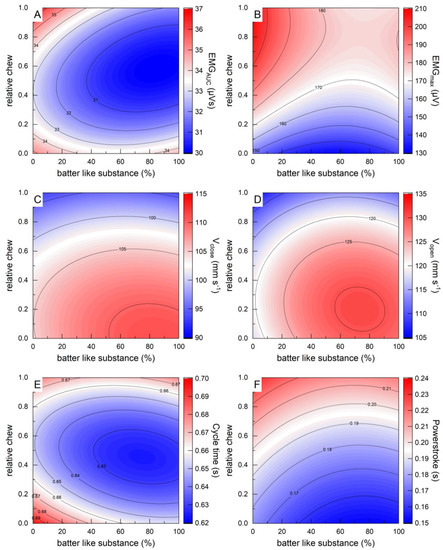

It was observed that the muscle activity was initially on one level (~34–35 µVs), decreasing across all sample compositions to about 33 µVs in the first quarter of mastication (Figure 5A). From there on, samples with high amounts of BLS phase lead to a further decrease below 31 µVs with a slight increase toward the end, while samples composed of structured material show a strong increase to >37µVs in the last quarter. Hence, it is hypothesized that all samples need similar initial work for being broken down. Further processing of the individual particles then strongly depends on their microstructure. Fibrous meat particles require more work for softening and bolus formation as opposed to isotropic gel-like particles [27]. The impact of structured particles is also reflected in an increased maximal EMG value at the late stages of mastication (Figure 5B). Again, all measured samples initially are in a similar region of EMGMAX values (130–150 µV), increasing until half of the mastication sequence has passed. From there on the increase flattens, however, structured material reaches higher ultimate peak muscle activities (>200 µV) than batter-like material (~180 µV); an effect, that is most likely based on further necessary softening of structured particles to enable the formation of a swallowable bolus. It appears that below 40% of structured phase, the characteristics of the batter-like phase dominate, and structured particles are not frequently selected for further softening. This might be due to the already sufficient binding and lubrication by the batter-like phase.

Figure 5.

Illustration of the linear mixed model (Equation (1)) for integral of muscle activity (A), maximal muscle activity (B), opening- (C) and closing velocity, (D), cycle time (E) and duration of power stroke (F) as calculated in SAS for the variable of relative time over the sequence of mastication and amount of BLS in percent.

The vertical velocity of jaw movement is decreasing over the term of mastication, with a steeper slope toward the last quarter of mastication (Figure 5C,D). Samples with low amount of structured particles seem to induce faster jaw movements. We hypothesize that as the amount of fibrous or anisotropic substance increases, grinding the food between the molars requires higher levels of energy and therefore takes longer. We hypothesize that unlike the structured phase, the batter-like phase is efficiently transferred to a paste-like state and can act as a lubricating and binding phase early in the chewing phase, reducing friction between the structured particles and facilitating the formation of a bolus as described by Devezeaux de Lavergne, van de Velde and Stieger [8]. The structured particles must be softened before they are selectable for bolus formation to be eventually swallowed [29]. The time required per bite is initially higher, decreases throughout mastication, and then rises again (Figure 5E). For sample with more structured particles, the effect is shifted toward longer cycle times but follows the same path. Lillford [30] described the mastication pathway of dry tough steak similar to the observed one: first, the meat’s macrostructure has to be broken down, requiring predominantly cutting action. Then, the sample is transferred to a paste-like state which can form a cohesive bolus by further processing. The duration of the power stroke significantly increased over time and with decreasing amount of batter. In theory, the system is first roughly comminuted and cut, with almost no grinding action. The further the system is broken down, the more likely hard particles are entrapped between the teeth, inducing a more extensive power stroke phase to soften and grind the remaining hard particles. The effect on occlusal duration is strongest between 0 and 50% of BLS. Further increase leads to no further noteworthy change in cycle time (Figure 5F). The longer occlusal durations can be called in as an explanation for the increased EMGAUC toward the end of mastication in systems with low amounts of batter. Additionally, calculated model expressions of the features can be found in Table 3.

Table 3.

Model terms of the oral processing parameters fit in SAS (Equation (1)) for the samples with 0–100% BLS. The intercept corresponds to the sample with 0% BLS, effects of chew and batter are given over the duration of one sequence (relative time 0–1) and amount of BLS (0–100%), respectively.

The convex hull V calculated for the entire chewing sequence provides additional information about the mastication process. As the amount of BLS (B) increased from 0–100%, the model describes an increase in the convex hull V of the jaw by the equation:

describing a strong increase from 0 to 50% BLS and a flattening of the curve for higher amounts. While fibrous meat pieces are less likely to fall apart under mechanical loading, but rather remain in the composite of structured sarcomeres and fiber bundles, gel-like structures fail under the load of masticatory forces [30]. This could result in many small food particles being dispersed throughout the oral cavity, which eventually need to be reunited at the back of the tongue to form a swallowable bolus, promoting greater movement of the tongue and thus the jaw.

4.4. Comparison of Methods

The macroscopic mechanical observations could be used to reveal the dominating composite structure, as also proposed by Berger, Gibis, Witte, Terjung, and Weiss [5] for similar samples in raw state: at low amounts of batter, the systems mechanical behavior follows the one of dispersed particle systems, high amounts of batter lead to elastic properties as in emulsified systems [31]. In between a mixed system comparable with a filled gel describes the material best [32]. The characteristics of oral processing of food were not in accordance with mechanical analysis: while oral processing data suggest a strong effect of BLS between 0 and 40% in this study, leveling upon further increase, texture analysis determined a maximum of hardness and work at 10% batter added.

As a supplement to the work of Berger, Gibis, Witte, Terjung, and Weiss [5], this work could determine the direct influences of the amount of BLS, and the linear related ANIC, on the mastication pattern. Although the transversion point of 40–60% of meat batter addition for oral processing characteristics is above their proposed point of transition (25% BLS), the general principle of how the system reacts in mixed regimes compared to the plain substances is in accordance. Both studies suggest a non-linear mixing behavior of structural, mechanical, sensorial, or chemical properties where the dominant phase dictates the behavior of the material with little impact on the secondary phase.

A figurative comparison of the here applied methods can be found in Table 4. The discrepancy between texture analysis and food oral processing could be due to different length scales and kinetics of deformation. The two-cycle compression test was operated at a compression level of 75% while the compression between the teeth is higher and operated at higher traversal speed. Typical particle sizes, expressed as d50, achieved by human mastication after a completed mastication process are in the range of 0.82–3.04 mm [33]. Jalabert-Malbos et al. [34] studied the particle size distribution of different food products, including meat products such as ham and chicken breast, measuring particle sizes of 1.28 mm and 1.60 mm, respectively. Considering that the two-cycle compression test was performed with samples of 15 mm height and a compression of 75%, the length scales of compression are likely to agree only for the first few bites until the macroscopic structure of the sample is broken down into smaller fragments. In addition, teeth, due to their 3D surface structure, allow the food to be crushed, cut, and compressed, while the texture analyzer only compresses the food between two smooth surfaces [35]. Therefore, the texture analyzer has to be understood as an approximation to the mastication process, but not as a direct measure for sensory attributes.

Table 4.

Significant differences between the samples with increasing amount of BLS visualized for each of the three applied measurement methods.

Phenomena not investigated in this experimental approach were, for example, tribological, rheological, and flavor-chemical effects. The strong sensory deviation of the 100% BLS sample could in theory be explained by strong differences in a property that was not revealed by the applied methods. The absence of any structured meat particles could also make this food prototype—in terms of perception—a completely different type of food. A reasonable cause for this difference could be found, for example, in tribological properties. Tribology generally studies the surface interaction between food and human skin by measuring the surface friction. The 100% batter-like sample could have strongly deviating tribological properties from the 40% sample, which still contains many rough particles protruding from the smooth surface of the gel [36]. As Sarkar and Krop [37] already elaborated in their review, tribology and sensory properties can be linked to one another, especially for attributes such as creaminess and smoothness. The wetting behavior of meat particles and gel-like substances most likely differ from each other. The mechanical disintegration properties of the prototypes could be the same, resulting in similar mechanical properties, but the tactile sensation on the oral mucosa and during swallowing is completely different [37]. However, it has to be noted that the number of panelists for this experiment was with n = 19 rather low, hand results have to be treated with caution.

5. Conclusions

Multiphase food prototypes were studied in terms of texture, sensory, and dynamic biomechanical data of the chewing process. Several fundamental insights into the food models were obtained from each examination of two-phase systems with different partitions of anisotropic and isotropic material. In particular, sensory studies (n = 19) revealed that the sample without fibrous material was perceived as significantly different from the samples containing structured particles. The presence of structured material seems to improve the sensory properties and overall acceptability of the samples. The texture studies suggest the presence of three different classes of food models: cohesive gel-like systems, particle-filled gels, and particulate systems with almost no binding between the individual subunits, depending on the share of batter-like substance (BLS). In tracking the dynamic process of mastication, the study showed that significant correlations exist between the amount of batter or the combined effect of amount of batter and relative progress of mastication with certain established masticatory properties. An increase in structured material induced greater muscle activity and longer durations per chew, while an increase in BLS induced greater jaw movement volumes, amplitudes, and velocities. In the range of ~50% BLS, a critical point was determined. Mastication physics responded differently to an increase in BLS above that point. For example, peak muscle activity did not steadily increase as for predominantly structured samples but flattened toward the end of mastication. Further, cycle time responded to the critical point with longer initial cycle times below ~50% BLS. Interestingly, the most pronounced effects in oral processing were found between the samples from 0–40% BLS. With this being the relevant range of batter for practical applications, the importance of oral processing as a tool in food science is underlined.

Author Contributions

Conceptualization, D.O., L.M.B. and J.W.; methodology, D.O.; software, D.O.; validation, D.O., L.M.B. and M.G.; formal analysis, D.O.; investigation, D.O.; resources, J.W.; data curation, D.O.; writing—original draft preparation, D.O.; writing—review and editing, D.O., L.M.B., M.G. and J.W.; visualization, D.O.; supervision, J.W.; project administration, J.W.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and approved by the Institutional Ethics Committee of the University of Hohenheim (30 March 2021).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data can be obtained from the Authors on request.

Acknowledgments

The Authors would like to thank all panel members that helped generate the oral processing and sensory data.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Listrat, A.; Lebret, B.; Louveau, I.; Astruc, T.; Bonnet, M.; Lefaucheur, L.; Picard, B.; Bugeon, J. How muscle structure and composition influence meat and flesh quality. Sci. World J. 2016, 2016, 3182746. [Google Scholar] [CrossRef] [PubMed]

- Oppen, D.; Grossmann, L.; Weiss, J. Insights into characterizing and producing anisotropic food structures. Crit. Rev. Food Sci. Nutr. 2022, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Tyszkiewicz, I.; Kłossowska, B.M.; Wieczorek, U.; Jakubiec-Puka, A. Mechanical Tenderisation of Pork Meat: Protein and Water Release due to Tissue Damage. J. Sci. Food Agric. 1997, 73, 179–185. [Google Scholar] [CrossRef]

- Haack, E.; Schnäckel, W.; Haack, O. Probleme, Ursachen und Lösungen: Grundlagen und Vorgänge bei der Fleischbeabeitung mit Maschinen der Wolftechnologie. Fleischwirtschaft 2003, 83, 52–56. [Google Scholar]

- Berger, L.M.; Gibis, M.; Witte, F.; Terjung, N.; Weiss, J. Influence of meat batter addition in ground beef on structural properties and quality parameters. Eur. Food Res. Technol. 2022, 248, 2509–2520. [Google Scholar] [CrossRef]

- Ilic, J.; Van Den Berg, M.; Oosterlinck, F. How do we eat meat–the role of structure, mechanics, oral processing, and sensory perception in designing meat analogs. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Zlatibor, Serbia, 26–29 September 2021; Volume 854, p. 012036. [Google Scholar] [CrossRef]

- Dekkers, B.L.; Nikiforidis, C.V.; van der Goot, A.J. Shear-induced fibrous structure formation from a pectin/SPI blend. Innov. Food Sci. Emerg. Technol. 2016, 36, 193–200. [Google Scholar] [CrossRef]

- Devezeaux de Lavergne, M.; van de Velde, F.; Stieger, M. Bolus matters: The influence of food oral breakdown on dynamic texture perception. Food Funct. 2017, 8, 464–480. [Google Scholar] [CrossRef]

- Boehm, M.W.; Yakubov, G.E.; Stokes, J.R.; Baier, S.K. The role of saliva in oral processing: Reconsidering the breakdown path paradigm. J. Texture Stud. 2020, 51, 67–77. [Google Scholar] [CrossRef]

- Hack, K.-H.; Buckenhüskes, H.J.; Hoff, W.; Hullemann, G.; Keck, W.; Nagel, E.; Staffe, E. Zerlegen, Standardisieren, Kalkulieren: Praxis-Handbuch der Material-und Betriebswirtschaft; Deutscher Fleischer-Verband: Frankfurt, Germany, 2001. [Google Scholar]

- Breene, W.M. Application of texture profile analysis to instrumental food texture evaluation. J. Texture Stud. 1975, 6, 53–82. [Google Scholar] [CrossRef]

- BVL. Amtliche Sammlung von Untersuchungsverfahren nach § 64 LFGB, § 38 TabakerzG, § 28b GenTG; Beuth Verlag: Berlin, Germany, 2021. [Google Scholar]

- Funami, T.; Ishihara, S.; Kohyama, K. Use of electromyography in measuring food texture. In Food Texture Design and Optimization; John Wiley & Sons: Hoboken, NJ, USA, 2014; pp. 283–307. [Google Scholar] [CrossRef]

- Vinyard, C.J.; Fiszman, S. Using electromyography as a research tool in food science. Curr. Opin. Food Sci. 2016, 9, 50–55. [Google Scholar] [CrossRef]

- Stegeman, D.; Hermens, H. Standards for surface electromyography: The European project Surface EMG for non-invasive assessment of muscles (SENIAM). Enschede Roessingh Res. Dev. 2007, 10, 8–12. [Google Scholar]

- Le Révérend, B.; Saucy, F.; Moser, M.; Loret, C. Adaptation of mastication mechanics and eating behaviour to small differences in food texture. Physiol. Behav. 2016, 165, 136–145. [Google Scholar] [CrossRef] [PubMed]

- Mathoniere, C.; Mioche, L.; Dransfield, E.; Culioli, J. Meat texture characterisation: Comparison of chewing patterns, sensory and mechanical measures. J. Texture Stud. 2000, 31, 183–203. [Google Scholar] [CrossRef]

- Braxton, D.; Dauchel, C.; Brown, W.E. Association between chewing efficiency and mastication patterns for meat, and influence on tenderness perception. Food Qual. Prefer. 1996, 7, 217–223. [Google Scholar] [CrossRef]

- Kohyama, K.; Mioche, L. Chewing behavior observed at different stages of mastication for six foods, studied by electromyography and jaw kinematics in young and elderly subjects. J. Texture Stud. 2004, 35, 395–414. [Google Scholar] [CrossRef]

- Foster, K.D.; Woda, A.; Peyron, M.A. Effect of texture of plastic and elastic model foods on the parameters of mastication. J. Neurophysiol. 2006, 95, 3469–3479. [Google Scholar] [CrossRef]

- Koç, H.; Çakir, E.; Vinyard, C.J.; Essick, G.; Daubert, C.R.; Drake, M.A.; Osborne, J.; Foegeding, E.A. Adaptation of oral processing to the fracture properties of soft solids. J. Texture Stud. 2014, 45, 47–61. [Google Scholar] [CrossRef]

- Piepho, H.P.; Edmondson, R.N. A tutorial on the statistical analysis of factorial experiments with qualitative and quantitative treatment factor levels. J. Agron. Crop. Sci. 2018, 204, 429–455. [Google Scholar] [CrossRef]

- Tornberg, E. Effects of heat on meat proteins—Implications on structure and quality of meat products. Meat Sci. 2005, 70, 493–508. [Google Scholar] [CrossRef]

- Piancino, M.G.; Bracco, P.; Vallelonga, T.; Merlo, A.; Farina, D. Effect of bolus hardness on the chewing pattern and activation of masticatory muscles in subjects with normal dental occlusion. J. Electromyogr. Kinesiol. 2008, 18, 931–937. [Google Scholar] [CrossRef]

- Pu, D.; Duan, W.; Huang, Y.; Zhang, L.; Zhang, Y.; Sun, B.; Ren, F.; Zhang, H.; Tang, Y. Characterization of the dynamic texture perception and the impact factors on the bolus texture changes during oral processing. Food Chem. 2021, 339, 128078. [Google Scholar] [CrossRef] [PubMed]

- Hutchings, J.B.; Lillford, P.J. The perception of food texture—the philosophy of the breakdown path. J. Texture Stud. 1988, 19, 103–115. [Google Scholar] [CrossRef]

- Koç, H.; Drake, M.; Vinyard, C.J.; Essick, G.; van de Velde, F.; Foegeding, E.A. Emulsion filled polysaccharide gels: Filler particle effects on material properties, oral processing, and sensory texture. Food Hydrocoll. 2019, 94, 311–325. [Google Scholar] [CrossRef]

- Lillford, P. Texture and breakdown in the mouth: An industrial research approach. J. Texture Stud. 2018, 49, 213–218. [Google Scholar] [CrossRef]

- Woda, A.; Foster, K.; Mishellany, A.; Peyron, M.A. Adaptation of healthy mastication to factors pertaining to the individual or to the food. Physiol. Behav. 2006, 89, 28–35. [Google Scholar] [CrossRef] [PubMed]

- Lillford, P.J. The importance of food microstructure in fracture physics and texture perception. J. Texture Stud. 2011, 42, 130–136. [Google Scholar] [CrossRef]

- Gravelle, A.J.; Barbut, S.; Marangoni, A.G. Influence of particle size and interfacial interactions on the physical and mechanical properties of particle-filled myofibrillar protein gels. RSC Adv. 2015, 5, 60723–60735. [Google Scholar] [CrossRef]

- Devezeaux de Lavergne, M.; Tournier, C.; Bertrand, D.; Salles, C.; van de Velde, F.; Stieger, M. Dynamic texture perception, oral processing behaviour and bolus properties of emulsion-filled gels with and without contrasting mechanical properties. Food Hydrocoll. 2016, 52, 648–660. [Google Scholar] [CrossRef]

- Bornhorst, G.M.; Singh, R.P. Bolus formation and disintegration during digestion of food carbohydrates. Compr. Rev. Food Sci. Food Saf. 2012, 11, 101–118. [Google Scholar] [CrossRef]

- Jalabert-Malbos, M.-L.; Mishellany-Dutour, A.; Woda, A.; Peyron, M.-A. Particle size distribution in the food bolus after mastication of natural foods. Food Qual. Prefer. 2007, 18, 803–812. [Google Scholar] [CrossRef]

- Agrawal, K.R.; Lucas, P.W.; Prinz, J.F.; Bruce, I.C. Mechanical properties of foods responsible for resisting food breakdown in the human mouth. Arch. Oral Biol. 1997, 42, 1–9. [Google Scholar] [CrossRef]

- Shewan, H.M.; Pradal, C.; Stokes, J.R. Tribology and its growing use toward the study of food oral processing and sensory perception. J. Texture Stud. 2020, 51, 7–22. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, A.; Krop, E.M. Marrying oral tribology to sensory perception: A systematic review. Curr. Opin. Food Sci. 2019, 27, 64–73. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).