A Perspective on Emerging Inter-Disciplinary Solutions for the Sustainable Management of Food Waste

Abstract

:1. Introduction

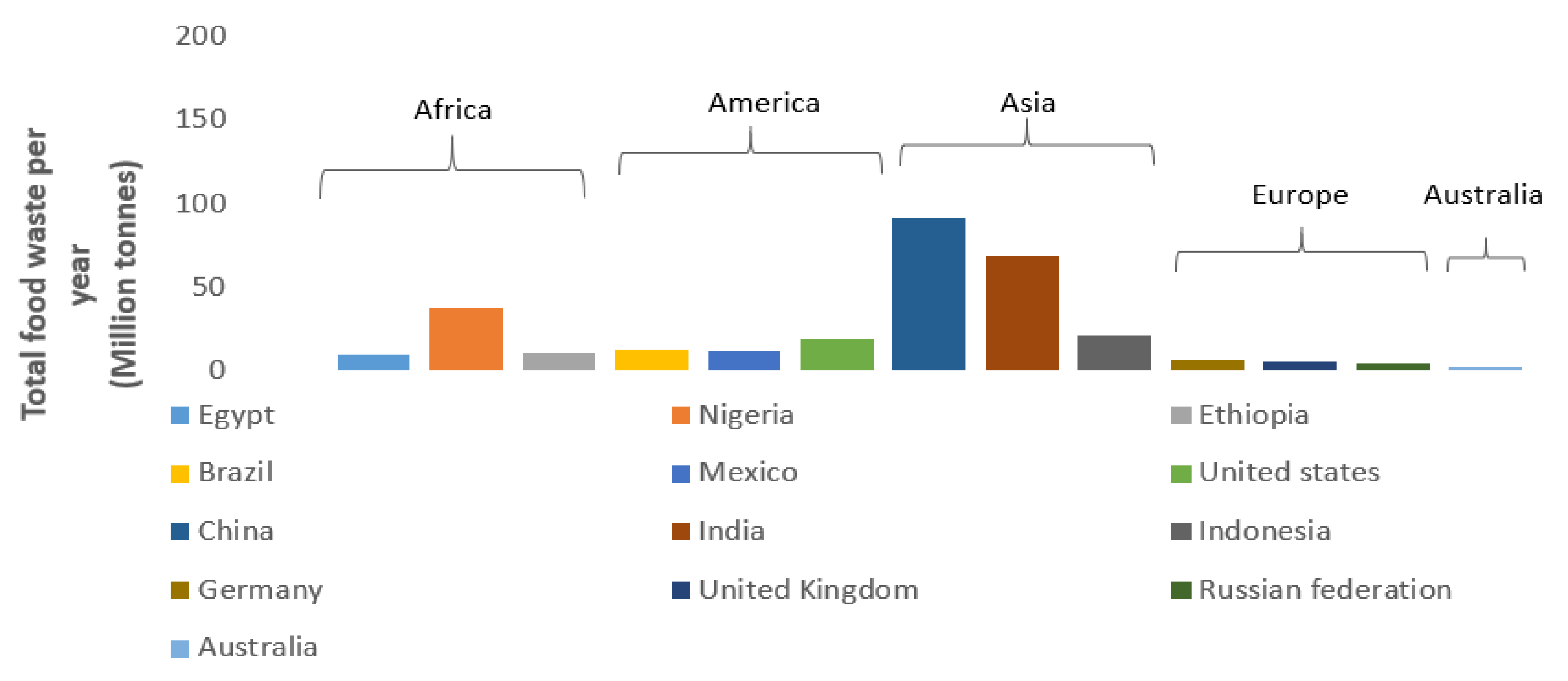

2. Food Waste in the Global Context

3. Food Associated Waste Generation during the COVID-19 Pandemic

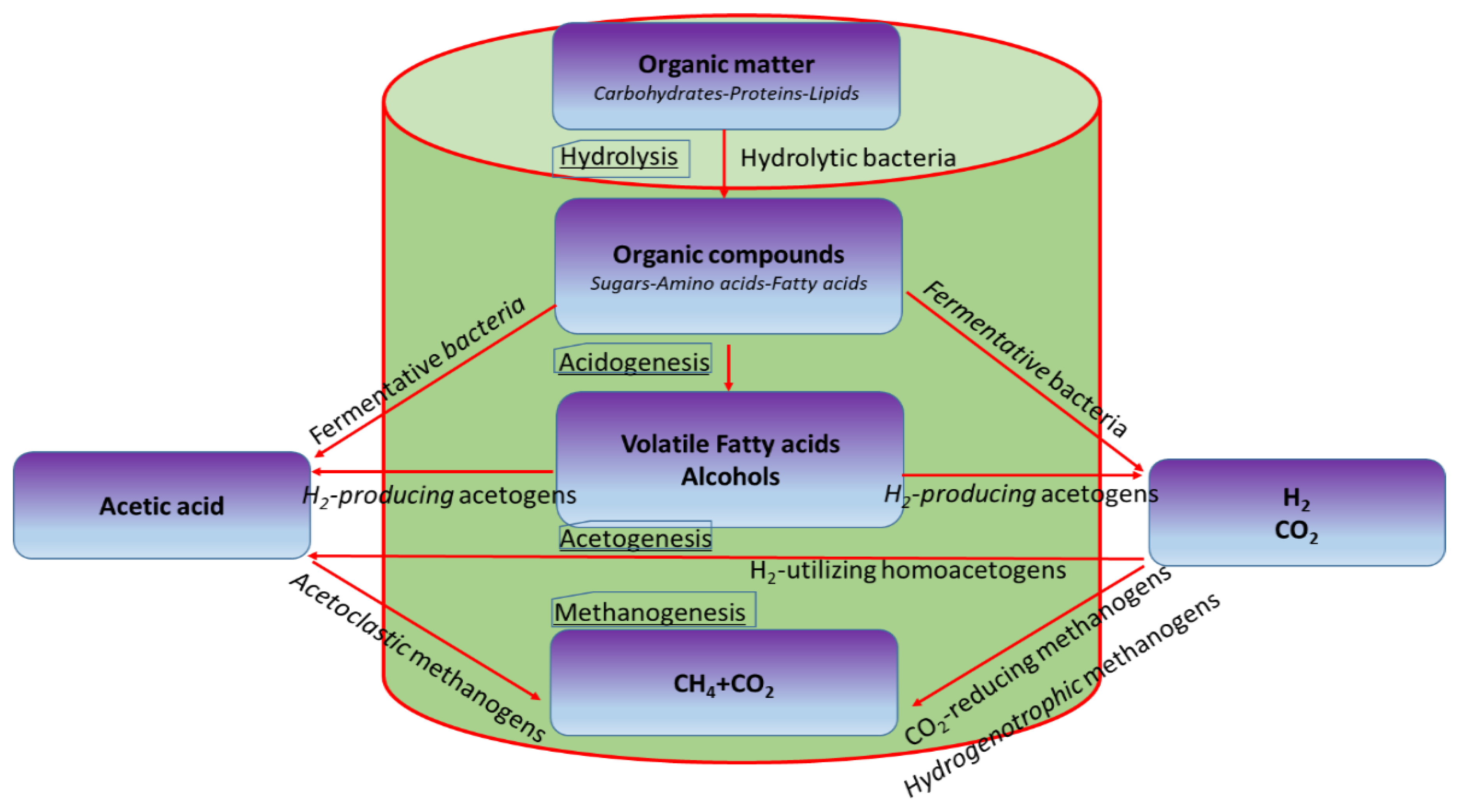

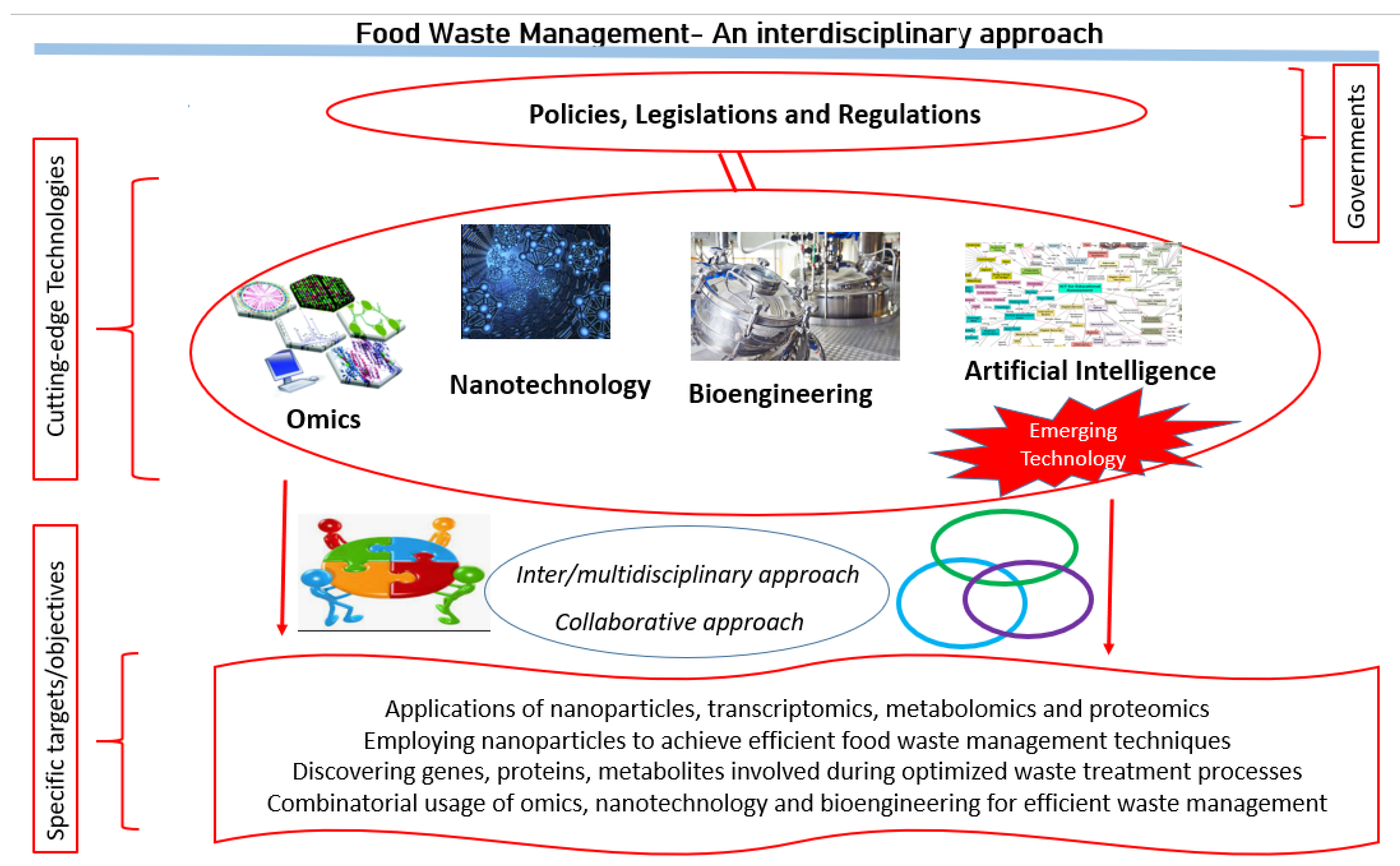

4. Food Waste Management, Regulations, and Biological Treatment Technologies

5. Current and Prospective Interdisciplinary Food Waste Management Initiatives Utilizing Anaerobic Digestion Systems

5.1. Initiatives Founded on the Discipline of Nanotechnology

5.2. Initiatives Supported by Omics and Bioengineering Disciplines

5.3. Initiatives Founded on Artificial Intelligence and Machine Learning

6. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United Nations Environment Programme. Food Waste Index Report 2021; United Nations: Nairobi, Kenya, 2021; Available online: https://www.unep.org/resources/report/unep-food-waste-index-report-20 (accessed on 21 April 2022).

- Campanaro, S.; Treu, L.; Rodriguez, L.M.; Kovalovszki, A.; Ziels, R.M.; Maus, I.; Zhu, X.; Kougias, P.G.; Basile, A.; Luo, G.; et al. New Insights from the Biogas Microbiome by Comprehensive Genome-Resolved Metagenomics of Nearly 1600 Species Originating from Multiple Anaerobic Digesters. Biotechnol. Biofuels 2020, 13. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aday, S.; Aday, M.S. Impact of COVID-19 on the Food Supply Chain. Food Qual. Saf. 2020, 4, 167–180. [Google Scholar] [CrossRef]

- Shangulyyev, R.; Kim, S.; Lee, S.H. Understanding Food Loss and Waste—Why Are We Losing and Wasting Food? Foods 2019, 8, 297. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Yuan, Z.; Tang, Y. Enhancing Food Security and Environmental Sustainability: A Critical Review of Food Loss and Waste Management. Resour. Environ. Sustain. 2021, 4, 100023. [Google Scholar] [CrossRef]

- Giudice, F.; Caferra, R.; Morone, P. COVID-19, the food system and the circular economy: Challenges and opportunities. Sustainability 2020, 12, 7939. [Google Scholar] [CrossRef]

- Sharma, H.B.; Vanapalli, K.R.; Cheela, V.S.; Ranjan, V.P.; Jaglan, A.K.; Dubey, B.; Goel, S.; Bhattacharya, J. Challenges, opportunities, and innovations for effective solid waste management during and post COVID-19 pandemic. Resour. Conserv. Recycl. 2020, 162, 105052. [Google Scholar] [CrossRef]

- Vanapalli, K.R.; Sharma, H.B.; Ranjan, V.P.; Samal, B.; Bhattacharya, J.; Dubey, B.K.; Goel, S. Challenges and strategies for effective plastic waste management during and post COVID-19 pandemic. Sci. Total Environ. 2021, 750, 141514. [Google Scholar] [CrossRef]

- Guerra-Rodríguez, S.; Oulego, P.; Rodríguez, E.; Singh, D.N.; Rodríguez-Chueca, J. Towards the Implementation of Circular Economy in the Wastewater Sector: Challenges and Opportunities. Water 2020, 12, 1431. [Google Scholar] [CrossRef]

- EMF. Delivering the Circular Economy—A Toolkit for Policy Makers; Ellen MacArthur Foundation (EMF): Isle of Wight, UK, 2015. [Google Scholar]

- DEFRA. Food and Drink Waste Hierarchy: Deal with Surplus and Waste. Department for Environment, Food & Rural Affairs (DEFRA). 2018. Available online: www.gov.uk/government/publications/food-and-drink-waste-hierarchy-deal-with-surplus-andwaste/food-and-drink-waste-hierarchy-deal-with-surplus-and-waste (accessed on 28 July 2022).

- Slorach, P.C.; Jeswani, H.K.; Cuéllar-Franca, R.; Azapagic, A. Environmental and Economic Implications of Recovering Resources from Food Waste in a Circular Economy. Sci. Total Environ. 2019, 693, 133516. [Google Scholar] [CrossRef]

- Zaman, A.; Reynolds, C. The economic and bio-energy production potential of South Australian food waste using Anaerobic digestion. In Proceedings of the Unmaking Waste 2015 Conference Proceedings, Adelaide, SA, Australia, 22–24 May 2015; p. 12. [Google Scholar]

- Lombardi, L.; Carnevale, E.; Corti, A. A Review of Technologies and Performances of Thermal Treatment Systems for Energy Recovery from Waste. Waste Manag. 2015, 37, 26–44. [Google Scholar] [CrossRef]

- Astrup, T.F.; Tonini, D.; Turconi, R.; Boldrin, A. Life Cycle Assessment of Thermal Waste-to-Energy Technologies: Review and Recommendations. Waste Manag. 2015, 37, 104–115. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dalla Vecchia, C.; Mattioli, A.; Bolzonella, D.; Palma, E.; Cruz Viggi, C.; Aulenta, F. Impact of Magnetite Nanoparticles Supplementation on the Anaerobic Digestion of Food Wastes: Batch and Continuous-Flow Investigations. Chem. Eng. Trans. 2016, 49, 1–6. [Google Scholar] [CrossRef]

- Tweib, S.A.; Rahman, R.; Kalil, M.S. A literature review on the Composting. In International Conference on Environment and Industrial Innovation IPCBEE; IACSIT Press: Singapore, 2011; Volume 12, pp. 24–127. [Google Scholar]

- Diener, R.G.; Collins, A.R.; Martin, J.H.; Bryan, W.B. Composting of source-separated municipal solid waste for agricultural utilization—A conceptual approach for closing the loop. Appl. Eng. Agric. 1993, 9, 427–436. [Google Scholar] [CrossRef]

- Sánchez, Ó.J.; Ospina, D.A.; Montoya, S. Compost Supplementation with Nutrients and Microorganisms in Composting Process. Waste Manag. 2017, 69, 136–153. [Google Scholar] [CrossRef]

- Pham, T.P.T.; Kaushik, R.; Parshetti, G.K.; Mahmood, R.; Balasubramanian, R. Food Waste-to-Energy Conversion Technologies: Current Status and Future Directions. Waste Manag. 2015, 38, 399–408. [Google Scholar] [CrossRef]

- Zheng, M.; Orbell, J.D.; Fairclough, R.J. Household Food Waste Treatment Technologies-A Systematic Review. Athens Proceedings, Victoria University, Melbourne. 2017. Available online: http://uest.ntua.gr/athens2017/proceedings/pdfs/Athens2017_Zheng_Orbell_Fairclough.pdf (accessed on 29 July 2022).

- Zhang, Q.; Hu, J.; Lee, D.-J. Biogas from Anaerobic Digestion Processes: Research Updates. Renew. Energy 2016, 98, 108–119. [Google Scholar] [CrossRef]

- André, L.; Pauss, A.; Ribeiro, T. Solid Anaerobic Digestion: State-of-Art, Scientific and Technological Hurdles. Bioresour. Technol. 2018, 247, 1027–1037. [Google Scholar] [CrossRef]

- Siddique, M.N.I.; Wahid, Z.A. Achievements and Perspectives of Anaerobic Co-Digestion: A Review. J. Clean. Prod. 2018, 194, 359–371. [Google Scholar] [CrossRef]

- Xu, F.; Li, Y.; Ge, X.; Yang, L.; Li, Y. Anaerobic Digestion of Food Waste—Challenges and Opportunities. Bioresour. Technol. 2018, 247, 1047–1058. [Google Scholar] [CrossRef]

- Coderoni, S.; Perito, M.A. Sustainable Consumption in the Circular Economy. An Analysis of Consumers’ Purchase Intentions for Waste-to-Value Food. J. Clean. Prod. 2020, 252, 119870. [Google Scholar] [CrossRef]

- Fuess, L.T.; Kiyuna, L.S.M.; Ferraz, A.D.N.; Júnior; Persinoti, G.F.; Squina, F.M.; Garcia, M.L.; Zaiat, M. Thermophilic Two-Phase Anaerobic Digestion Using an Innovative Fixed-Bed Reactor for Enhanced Organic Matter Removal and Bioenergy Recovery from Sugarcane Vinasse. Appl. Energy 2017, 189, 480–491. [Google Scholar] [CrossRef] [Green Version]

- Malla, M.A.; Dubey, A.; Yadav, S.; Kumar, A.; Hashem, A.; Abd Allah, E.F. Understanding and Designing the Strategies for the Microbe-Mediated Remediation of Environmental Contaminants Using Omics Approaches. Front. Microbiol. 2018, 9, 1132. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Misra, B.B.; Langefeld, C.; Olivier, M.; Cox, L.A. Integrated Omics: Tools, Advances and Future Approaches. J. Mol. Endocrinol. 2019, 62, R21–R45. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pandey, A.; Tripathi, P.H.; Tripathi, A.H.; Pandey, S.C.; Gangola, S. Omics Technology to Study Bioremediation and Respective Enzymes. In Smart Bioremediation Technologies; Academic Press: Cambridge, MA, USA, 2019; pp. 23–43. [Google Scholar] [CrossRef]

- Bernat, K.; Cydzik-Kwiatkowska, A.; Wojnowska-Baryła, I.; Karczewska, M. Physicochemical properties and biogas productivity of aerobic granular sludge and activated sludge. Biochem. Eng. J. 2017, 117, 43–51. [Google Scholar] [CrossRef]

- Romero-Güiza, M.; Vila, J.; Mata-Alvarez, J.; Chimenos, J.; Astals, S. The role of additives on anaerobic digestion: A review. Renew. Sustain. Eng. Rev. 2016, 58, 1486–1499. [Google Scholar] [CrossRef]

- He, D.-Q.; Luo, H.-W.; Huang, B.-C.; Qian, C.; Yu, H.-Q. Enhanced dewatering of excess activated sludge through decomposing its extracellular polymeric substances by a Fe@ Fe2O3-based composite conditioner. Bioresour. Technol. 2016, 218, 526–532. [Google Scholar] [CrossRef]

- Dermatas, D.; Panagiotakis, I. Remediation of contaminated soil. In Encyclopedia of Sustainability Science and Technology; Meyers, R.A., Ed.; Springer: New York, NY, USA, 2012; pp. 2430–2454. [Google Scholar]

- Naik, B.N.; Masih, H.; Singh, A. Bioengineering Approach for Sewage Sludge Degradation through Aerobic Thermophilic Process. J. Bangladesh Acad. Sci. 2014, 37, 159–163. [Google Scholar] [CrossRef] [Green Version]

- Witten, I.H.; Frank, E.; Hall, M.A. (Eds.) Data Mining Practical Machine Learning Tools and Techniques; Morgan Kaufmann Publishers: Burlington, MA, USA, 2011. [Google Scholar]

- Wang, L.; Long, F.; Liao, W.; Liu, H. Prediction of Anaerobic Digestion Performance and Identification of Critical Operational Parameters Using Machine Learning Algorithms. Bioresour. Technol. 2020, 298, 122495. [Google Scholar] [CrossRef]

- Walid, F.; El Fkihi, S.; Benbrahim, H.; Tagemouati, H. Modeling and Optimization of Anaerobic Digestion: A Review. E3S Web Conf. 2021, 229, 01022. [Google Scholar] [CrossRef]

- Wade, M.J. Not Just Numbers: Mathematical Modelling and Its Contribution to Anaerobic Digestion Processes. Processes 2020, 8, 888. [Google Scholar] [CrossRef]

- Bongards, M.; Gaida, D.; Trauer, O.; Wolf, C. Intelligent automation and IT for the optimization of renewable energy and wastewater treatment processes. Energy Sustain. Soc. 2014, 4, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Kara, S.; Mueller, J.J.; Liese, A. Online analysis methods for monitoring of bioprocesses. Chem. Today 2011, 29, 38–41. [Google Scholar]

- Liao, M.; Yao, Y. Applications of Artificial Intelligence-based Modeling for Bioenergy Systems: A Review. GCB Bioenergy 2021, 13, 774–802. [Google Scholar] [CrossRef]

- Ghanavati, H. Biogas production systems: Operation, process control, and troubleshooting. In Biogas; Springer: Cham, Switzerland; Berlin/Heidelberg, Germany, 2018; pp. 199–219. [Google Scholar] [CrossRef]

- Wang, Y.; Huntington, T.; Scown, C.D. Tree-Based Automated Machine Learning to Predict Biogas Production for Anaerobic Co-Digestion of Organic Waste. ACS Sustain. Chem. Eng. 2021, 9, 12990–13000. [Google Scholar] [CrossRef]

- Cakmakci, M. Adaptive Neuro-Fuzzy Modelling of Anaerobic Digestion of Primary Sedimentation Sludge. Bioprocess Biosyst. Eng. 2007, 30, 349–357. [Google Scholar] [CrossRef] [PubMed]

- Kusiak, A.; Wei, X. Prediction of Methane Production in Wastewater Treatment Facility: A Data-Mining Approach. Ann. Oper. Res. 2011, 216, 71–81. [Google Scholar] [CrossRef]

- Zhang, Z.; Zeng, Y.; Kusiak, A. Minimizing Pump Energy in a Wastewater Processing Plant. Energy 2012, 47, 505–514. [Google Scholar] [CrossRef]

- Loizia, P.; Neofytou, N.; Zorpas, A.A. The Concept of Circular Economy Strategy in Food Waste Management for the Optimization of Energy Production through Anaerobic Digestion. Environ. Sci. Pollut. Res. 2018, 26, 14766–14773. [Google Scholar] [CrossRef]

- Casals, E.; Barrena, R.; García, A.; González, E.; Delgado, L.; Busquets-Fité, M.; Font, X.; Arbiol, J.; Glatzel, P.; Kvashnina, K.; et al. Programmed iron oxide nanoparticles disintegration in anaerobic digesters boosts biogas production. Small 2014, 10, 2801–2808. [Google Scholar] [CrossRef]

- Bremges, A.; Maus, I.; Belmann, P.; Eikmeyer, F.; Winkler, A.; Albersmeier, A.; Pühler, A.; Schlüter, A.; Sczyrba, A. Deeply Sequenced Metagenome and Metatranscriptome of a Biogas-Producing Microbial Community from an Agricultural Production-Scale Biogas Plant. GigaScience 2015, 4, 33. [Google Scholar] [CrossRef] [Green Version]

- Inaba, R.; Nagoya, M.; Kouzuma, A.; Watanabe, K. Metatranscriptomic Evidence for Magnetite Nanoparticle-Stimulated Acetoclastic Methanogenesis under Continuous Agitation. Appl. Environ. Microbiol. 2019, 85, e01733-19. [Google Scholar] [CrossRef] [PubMed]

- Sakiewicz, P.; Piotrowski, K.; Ober, J.; Karwot, J. Innovative Artificial Neural Network Approach for Integrated Biogas—Wastewater Treatment System Modelling: Effect of Plant Operating Parameters on Process Intensification. Renew. Sustain. Energy Rev. 2020, 124, 109784. [Google Scholar] [CrossRef]

- FAO. Global Food Losses and Food Waste—Extent, Causes and Prevention; FAO: Rome, Italy, 2011. [Google Scholar]

- Shurson, G.C. “What a Waste”—Can We Improve Sustainability of Food Animal Production Systems by Recycling Food Waste Streams into Animal Feed in an Era of Health, Climate, and Economic Crises? Sustainability 2020, 12, 7071. [Google Scholar] [CrossRef]

- DEFF & CSIR. Food Waste Prevention & Management: A Guideline for South Africa, 1st ed.; DEFF & CSIR: Pretoria, South Africa, 2021. [Google Scholar]

- FAO. Food Wastage Footprint: Full-Cost Accounting, Final Report; FAO: Rome, Italy, 2014. [Google Scholar]

- Chalak, A.; Abou-Daher, C.; Chaaban, J.; Abiad, M.G. The global economic and regulatory determinants of household food waste generation: A cross-country analysis. Waste Manag. 2016, 48, 418–422. [Google Scholar] [CrossRef] [PubMed]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; van Otterdijk, R.; Meybeck, A. Global Food Losses and Food Waste; FAO: Rome, Italy, 2011. [Google Scholar]

- Lazell, J. Consumer Food Waste Behaviour in Universities: Sharing as a Means of Prevention. J. Consum. Behav. 2016, 15, 430–439. [Google Scholar] [CrossRef]

- Bond, M.; Meacham, T.; Bhunnoo, R.; Benton, T. Food Waste within Global Food Systems; Global Food Security; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Lipinski, B.; Hanson, C.; Lomax, J.; Kitinoja, L.; Waite, R.; Searchinger, T. Reducing Food Loss and Waste. Available online: http://pdf.wri.org/reducing_food_loss_and_waste.pdf (accessed on 28 July 2022).

- Scherhaufer, S.; Moates, G.; Hartikainen, H.; Waldron, K.; Obersteiner, G. Environmental Impacts of Food Waste in Europe. Waste Manag. 2018, 77, 98–113. [Google Scholar] [CrossRef] [PubMed]

- Rutten, M. The Economic Impacts of (Reducing) Food Waste and Losses: A Graphical Exposition. Available online: https://www.researchgate.net/publication/253240278_WORKING_PAPER_Wageningen_School_of_SocialSciences_The_Economic_Impacts_of_Reducing_Food_Waste_and_Losses_A_Graphical_Exposition (accessed on 24 November 2021).

- Buzby, J.C.; Hyman, J. Total and per capita value of food loss in the United States. Food Policy 2012, 37, 561–570. [Google Scholar] [CrossRef]

- Syroegina, A. Retailer’s Role in Reducing Food Waste: Case Study of Finnish Retailers. Master’s Thesis, Aalto University School of Business, Espoo, Finland, 2016. [Google Scholar]

- Schneider, F. Review of food waste prevention on an international level. In Proceedings of the Institution of Civil Engineers-Waste and Resource Management, London, UK, 1 November 2013; Volume 166, pp. 187–203. [Google Scholar]

- Thyberg, K.L.; Tonjes, D.J. Drivers of Food Waste and Their Implications for Sustainable Policy Development. Resour. Conserv. Recycl. 2016, 106, 110–123. [Google Scholar] [CrossRef]

- Rogers, E.; Rozeboom, D.; Zangaro, C. In Times of Supply Chain Disruption, how do I Appropriately Dispose of My Livestock Mortalities? Michigan State University Extension Newsletter. 2020. Available online: https://www.canr.msu.edu/news/in-times-of-supply-chain-disruption-how-do-ippropriatelydispose-of-my-livestock-mortalities (accessed on 15 August 2020).

- Aldaco, R.; Hoehn, D.; Laso, J.; Margallo, M.; Ruiz-Salmón, J.; Cristobal, J.; Kahhat, R.; Villanueva-Rey, P.; Bala, A.; Batlle-Bayer, L.; et al. Food Waste Management during the COVID-19 Outbreak: A Holistic Climate, Economic and Nutritional Approach. Sci. Total Environ. 2020, 742, 140524. [Google Scholar] [CrossRef]

- Song, G.; Gao, X.; Fullana-i-Palmer, P.; Lv, D.; Zhu, Z.; Wang, Y.; Bayer, L.B. Shift from Feeding to Sustainably Nourishing Urban China: A Crossing-Disciplinary Methodology for Global Environment-Food-Health Nexus. Sci. Total Environ. 2019, 647, 716–724. [Google Scholar] [CrossRef]

- Schanes, K.; Dobernig, K.; Gözet, B. Food Waste Matters—A Systematic Review of Household Food Waste Practices and Their Policy Implications. J. Clean. Prod. 2018, 182, 978–991. [Google Scholar] [CrossRef]

- ReFED. COVID-19, U.S. Food System Review. 2020. Available online: https://www.refed.com/content-hub/refeds-covid-19-u-s-food-system-review/ (accessed on 19 August 2022).

- Jámbor, A.; Czine, P.; Balogh, P. The impact of the Coronavirus on agriculture: First evidence based on global newspapers. Sustainability 2020, 12, 4535. [Google Scholar] [CrossRef]

- Di Marcantonio, F.; Twum, E.K.; Russo, C. COVID-19 Pandemic and Food Waste: An Empirical Analysis. Agronomy 2021, 11, 1063. [Google Scholar] [CrossRef]

- Pappalardo, G.; Cerroni, S.; Nayga, R.M., Jr.; Yang, W. Impact of COVID-19 on Household Food Waste: The Case of Italy. Front. Nutr. 2020, 7, 291. [Google Scholar] [CrossRef] [PubMed]

- Garnett, T. Food Sustainability: Problems, Perspectives and Solutions. Proc. Nutr. Soc. 2013, 72, 29–39. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Boschini, M.; Falasconi, L.; Giordano, C.; Franco, S.; Cicatiello, C.; Marangon, F.; Troiano, S. Preliminary results of a methodology for determining food waste in primary school canteens. Ital. Rev. Agric. Econ. 2017, 72, 303–310. [Google Scholar]

- Dansero, E.; Marino, D.; Mazzocchi, G.; Nicolarea, Y. Lo Spazio Delle Politiche Locali del Cibo: Temi, Esperienze eProspettive; Rete delle Politiche Locali del Cibo: Rome, Italy, 2019. [Google Scholar]

- Giordano, C.; Falasconi, L.; Boschini, M.; Segrè, A. Detecting Drivers of Household Food Waste in Italy: Methodological Assessment of a Diary Study. In Proceedings of the SIDEA 2016 Conference, Bolzano, Italy, 22–24 September 2016; p. 11. [Google Scholar]

- Fattibene, D. From farm to land fill: How Rome tackles its food waste. In Collection Monografias Cidob; Istituto Aari Internazionali (IAI): Rome, Italy, 2018. [Google Scholar]

- Aramyan, L.H.; Beekman, G.; Galama, J.; van der Haar, S.; Visscher, M.; Zeinstra, G.G. Moving from Niche to Norm: Lessons from Food Waste Initiatives. Sustainability 2021, 13, 7667. [Google Scholar] [CrossRef]

- Chiaraluce, G.; Bentivoglio, D.; Finco, A. Circular Economy for a Sustainable Agri-Food Supply Chain: A Review for Current Trends and Future Pathways. Sustainability 2021, 13, 9294. [Google Scholar] [CrossRef]

- Topi, C.; Bilinska, M. The economic case for the circular economy: From food waste to resource. In Food Waste Reduction and Valorisation—Sustainability Assessment and Policy Analysis, 1st ed.; Morone, P., Papendiek, F., Tartiu, V., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 25–41. [Google Scholar]

- Magarini, A.; de Cunto, A.; Porreca, E. Food Losses and Waste in European Cities; Comune di Milano: Milano, Italy, 2018. [Google Scholar]

- Rodrigo-Ilarri, J.; Vargas-Terranova, C.-A.; Rodrigo-Clavero, M.-E.; Bustos-Castro, P.-A. Advances on the Implementation of Circular Economy Techniques in Rural Areas in Colombia under a Sustainable Development Framework. Sustainability 2021, 13, 3816. [Google Scholar] [CrossRef]

- SDSN. SDG Guide. Available online: https://sdg.guide/ (accessed on 3 June 2021).

- SDSN; Telos. The 2019 SDG Index and Dashboards Report for European Cities; Telos: Tilburg, The Netherlands, 2019. [Google Scholar]

- Cavalli, L.; Farnia, L. Per un’Italia Sostenibile: L’SDSN Italia SDGs City Index 2018; Fondazione Eni Enrico Mattei: Milano, Italy, 2019. [Google Scholar]

- Abejón, R.; Laso, J.; Margallo, M.; Aldaco, R.; Blanca-Alcubilla, G.; Bala, A.; Fullana-i-Palmer, P. Environmental Impact Assessment of the Implementation of a Deposit-Refund System for Packaging Waste in Spain: A Solution or an Additional Problem? Sci. Total Environ. 2020, 721, 137744. [Google Scholar] [CrossRef]

- ReFED. A Roadmap to Reduce U.S. Food Waste by 20 Percent. Retrieved October 6th 2019. 2016. Available online: https://www.refed.com/downloads/ReFED_Report_2016.pdf (accessed on 15 December 2021).

- Bandyopadhyay, J.; Dalvi, G. Can interactive installations bring about behaviour change? Using interactive installation to change food waste behaviours. In International Conference on Research into Design; Springer: Berlin, Germany, 2017. [Google Scholar]

- Lim, V.; Funk, M.; Marcenaro, L.; Regazzoni, C.; Rauterberg, M. Designing for action: An evaluation of Social Recipes in reducing food waste. Int. J. Hum.-Comput. Stud. 2017, 100, 18–32. [Google Scholar] [CrossRef]

- Comber, R.; Thieme, A. Designing beyond Habit: Opening Space for Improved Recycling and Food Waste Behaviors through Processes of Persuasion, Social Influence and Aversive Affect. Pers. Ubiquitous Comput. 2012, 17, 1197–1210. [Google Scholar] [CrossRef]

- Ganglbauer, E.; Fitzpatrick, G.; Comber, R. Negotiating food waste: Using a practice lens to inform design. ACM Trans. Comput. Interact. 2013, 20, 1–25. [Google Scholar] [CrossRef]

- National Zero Waste Council. National Food Waste Reduction Strategy. 2017. Available online: http://www.nzwc.ca/focus/food/national-food-wastestrategy/Documents/NFWRS-Strategy.pdf (accessed on 17 December 2021).

- Arevalo-Gallegos, A.; Ahmad, Z.; Asgher, M.; Parra-Saldivar, R.; Iqbal, H.M.N. Lignocellulose: A Sustainable Material to Produce Value-Added Products with a Zero Waste Approach—A Review. Int. J. Biol. Macromol. 2017, 99, 308–318. [Google Scholar] [CrossRef] [PubMed]

- Asgher, M.; Wahab, A.; Bilal, M.; Nasir Iqbal, H.M. Lignocellulose Degradation and Production of Lignin Modifying Enzymes by Schizophyllum Commune IBL-06 in Solid-State Fermentation. Biocatal. Agric. Biotechnol. 2016, 6, 195–201. [Google Scholar] [CrossRef]

- Bilal, M.; Iqbal, H.M.N. Sustainable Bioconversion of Food Waste into High-Value Products by Immobilized Enzymes to Meet Bio-Economy Challenges and Opportunities—A Review. Food Res. Int. 2019, 123, 226–240. [Google Scholar] [CrossRef]

- Vandermeersch, T.; Alvarenga, R.; Ragaert, P.; Dewulf, J. Environmental sustainability assessment of food waste valorization options. Resour. Conserv. Recycl. 2014, 87, 57–64. [Google Scholar] [CrossRef]

- Wen, Z.; Wang, Y.; De Clercq, D. What is the true value of food waste? A case study of technology integration in urban food waste treatment in Suzhou City, China. J. Clean. Prod. 2016, 118, 88–96. [Google Scholar] [CrossRef]

- Martin-Rios, C.; Demen-Meier, C.; Gössling, S.; Cornuz, C. Food waste management innovations in the foodservice industry. Waste Manag. 2018, 79, 196–206. [Google Scholar] [CrossRef] [Green Version]

- Martin-Rios, C.; Hofmann, A.; Mackenzie, N. Sustainability Oriented Innovations in FoodWaste Management Technology. Sustainability 2021, 13, 210. [Google Scholar] [CrossRef]

- Paritosh, K.; Kushwaha, S.K.; Yadav, M.; Pareek, N.; Chawade, A.; Vivekanand, V. Food Waste to Energy: An Overview of Sustainable Approaches for Food Waste Management and Nutrient Recycling. BioMed Res. Int. 2017, 2017, 2370927. [Google Scholar] [CrossRef] [PubMed]

- Mutungwazi, A.; Ijoma, G.N.; Matambo, T.S. The Significance of Microbial Community Functions and Symbiosis in Enhancing Methane Production during Anaerobic Digestion: A Review. Symbiosis 2020, 83, 1–24. [Google Scholar] [CrossRef]

- Divya, D.; Gopinath, L.R.; Merlin Christy, P. A Review on Current Aspects and Diverse Prospects for Enhancing Biogas Production in Sustainable Means. Renew. Sustain. Energy Rev. 2015, 42, 690–699. [Google Scholar] [CrossRef]

- Spanjers, H.; van Lier, J.B. Instrumentation in Anaerobic Treatment—Research and Practice. Water Sci. Technol. 2006, 53, 63–76. [Google Scholar] [CrossRef] [PubMed]

- Bajpai, P. Anaerobic Technology in Pulp and Paper Industry; Springer: Singapore, 2017. [Google Scholar] [CrossRef]

- Madigan, M.T.; Martinko, J.M.; Dunlap, P.V.; Clark, D.P. Brock biology of microorganisms 12th edn. Int. Microbiol. 2008, 11, 65–73. [Google Scholar]

- Singh, S.K.; Kadi, S.; Prashanth, B.; Nayak, S.K. Factors Affecting Anaerobic Digestion of Organic Waste. Int. J. Eng. Res. Mech. Civ. Eng. 2018, 3, 2456-1290. [Google Scholar]

- Kangle, K.M.; Kore, V.S.; Kore, S.; Kulkani, G.S. Recent trends in anaerobic codigestion: A review. Univers. J. Environ. Res. Technol. 2012, 2, 210–219. [Google Scholar]

- Rajendran, K.; Aslanzadeh, S.; Taherzadeh, M.J. Household Biogas Digesters—A Review. Energies 2012, 5, 2911–2942. [Google Scholar] [CrossRef]

- Guo, J.; Peng, Y.; Ni, B.-J.; Han, X.; Fan, L.; Yuan, Z. Dissecting Microbial Community Structure and Methane-Producing Pathways of a Full-Scale Anaerobic Reactor Digesting Activated Sludge from Wastewater Treatment by Metagenomic Sequencing. Microb. Cell Factories 2015, 14, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Guo, M.; Song, W.; Buhain, J. Bioenergy and Biofuels: History, Status, and Perspective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- Sterling, M.C., Jr.; Lacey, R.E.; Engler, C.R.; Ricke, S.C. Effects of Ammonia Nitrogen on H2 and CH4 Production during Anaerobic Digestion of Dairy Cattle Manure. Bioresour. Technol. 2001, 77, 9–18. [Google Scholar] [CrossRef]

- Lemmer, A.; Naegele, H.-J.; Sondermann, J. How Efficient Are Agitators in Biogas Digesters? Determination of the Efficiency of Submersible Motor Mixers and Incline Agitators by Measuring Nutrient Distribution in Full-Scale Agricultural Biogas Digesters. Energies 2013, 6, 6255–6273. [Google Scholar] [CrossRef]

- Rajendran, K.; Aslanzadeh, S.; Johansson, F.; Taherzadeh, M.J. Experimental and Economical Evaluation of a Novel Biogas Digester. Energy Convers. Manag. 2013, 74, 183–191. [Google Scholar] [CrossRef]

- Costa, J.C.; Oliveira, J.V.; Alves, M.M. Response Surface Design to Study the Influence of Inoculum, Particle Size and Inoculum to Substrate Ratio on the Methane Production from Ulex Sp. Renew. Energy 2016, 96, 1071–1077. [Google Scholar] [CrossRef] [Green Version]

- Majd, S.S.; Abdoli, M.A.; Karbassi, A.; Pourzamani, H.R.; Rezaee, M. Effect of physical and chemical operating parameters on anaerobic digestion of manure and biogas production: A review. J. Environ. Health Sustain. Dev. 2017, 1, 235–247. [Google Scholar]

- Abu Qdais, H.; Bani Hani, K.; Shatnawi, N. Modeling and Optimization of Biogas Production from a Waste Digester Using Artificial Neural Network and Genetic Algorithm. Resour. Conserv. Recycl. 2010, 54, 359–363. [Google Scholar] [CrossRef]

- Olatunji, K.O.; Ahmed, N.A.; Ogunkunle, O. Optimization of Biogas Yield from Lignocellulosic Materials with Different Pretreatment Methods: A Review. Biotechnol. Biofuels 2021, 14, 1–34. [Google Scholar] [CrossRef]

- Ahen, F.; Amankwah-Amoah, J. Sustainable Waste Management Innovations in Africa: New Perspectives and Research Agenda for Improving Global Health. Sustainability 2021, 13, 6646. [Google Scholar] [CrossRef]

- Issah, A.-A.; Kabera, T.; Kemausuor, F. Biogas Optimisation Processes and Effluent Quality: A Review. Biomass Bioenergy 2020, 133, 105449. [Google Scholar] [CrossRef]

- Ariunbaatar, J. Methods to Enhance Anaerobic Digestion of Food Waste. Ph.D. Thesis, Paris-East Créteil University, Créteil, France, 2014. Available online: https://tel.archives-ouvertes.fr/tel-01206170 (accessed on 12 June 2022).

- Ilo, O.P.; Simatele, M.D.; Nkomo, S.L.; Mkhize, N.M.; Prabhu, N.G. Methodological Approaches to Optimising Anaerobic Digestion of Water Hyacinth for Energy Efficiency in South Africa. Sustainability 2021, 13, 6746. [Google Scholar] [CrossRef]

- Postawa, K.; Szczygieł, J.; Kułażyński, M. Innovations in Anaerobic Digestion: A Model-Based Study. Biotechnol. Biofuels 2021, 14, 1–11. [Google Scholar] [CrossRef]

- Beale, D.J.; Karpe, A.V.; McLeod, J.D.; Gondalia, S.V.; Muster, T.H.; Othman, M.Z.; Palombo, E.A.; Joshi, D. An ‘Omics’ Approach towards the Characterisation of Laboratory Scale Anaerobic Digesters Treating Municipal Sewage Sludge. Water Res. 2016, 88, 346–357. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Liu, F.; Yu, J.; Wang, Q.; Li, Z.; Liu, K.; Xu, C.; Yu, H.; Xiao, L. Proteomics Reveal Biomethane Production Process Induced by Carbon Nanotube. Environ. Res. 2021, 200, 111417. [Google Scholar] [CrossRef] [PubMed]

- Eduok, S.; Ferguson, R.; Jefferson, B.; Villa, R.; Coulon, F. Aged-Engineered Nanoparticles Effect on Sludge Anaerobic Digestion Performance and Associated Microbial Communities. Sci. Total Environ. 2017, 609, 232–241. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luna-delRisco, M.; Orupõld, K.; Dubourguier, H.-C. Particle-Size Effect of CuO and ZnO on Biogas and Methane Production during Anaerobic Digestion. J. Hazard. Mater. 2011, 189, 603–608. [Google Scholar] [CrossRef]

- Abdelsalam, E.; Samer, M.; Attia, Y.A.; Abdel-Hadi, M.A.; Hassan, H.E.; Badr, Y. Effects of Co and Ni Nanoparticles on Biogas and Methane Production from Anaerobic Digestion of Slurry. Energy Convers. Manag. 2017, 141, 108–119. [Google Scholar] [CrossRef]

- Raupach, M.J.; Amann, R.; Wheeler, Q.D.; Roos, C. The Application of “-Omics” Technologies for the Classification and Identification of Animals. Org. Divers. Evol. 2015, 16, 1–12. [Google Scholar] [CrossRef]

- Rodríguez, E.; García-Encina, P.A.; Stams, A.J.M.; Maphosa, F.; Sousa, D.Z. Meta-Omics Approaches to Understand and Improve Wastewater Treatment Systems. Rev. Environ. Sci. Bio/Technol. 2015, 14, 385–406. [Google Scholar] [CrossRef]

- Salehi Jouzani, G.; Sharafi, R. New “Omics” Technologies and Biogas Production. Biofuel Biorefinery Technol. 2018, 6, 419–436. [Google Scholar] [CrossRef]

- Roume, H.; Heintz-Buschart, A.; Muller, E.E.L.; May, P.; Satagopam, V.P.; Laczny, C.C.; Narayanasamy, S.; Lebrun, L.A.; Hoopmann, M.R.; Schupp, J.M.; et al. Comparative Integrated Omics: Identification of Key Functionalities in Microbial Community-Wide Metabolic Networks. NPJ Biofilms Microbiomes 2015, 1, 1–11. [Google Scholar] [CrossRef]

- Hassa, J.; Maus, I.; Off, S.; Pühler, A.; Scherer, P.; Klocke, M.; Schlüter, A. Metagenome, Metatranscriptome, and Metaproteome Approaches Unraveled Compositions and Functional Relationships of Microbial Communities Residing in Biogas Plants. Appl. Microbiol. Biotechnol. 2018, 102, 5045–5063. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hahnke, S.; Maus, I.; Wibberg, D.; Tomazetto, G.; Pühler, A.; Klocke, M.; Schlüter, A. Complete Genome Sequence of the Novel Porphyromonadaceae Bacterium Strain ING2-E5B Isolated from a Mesophilic Lab-Scale Biogas Reactor. J. Biotechnol. 2015, 193, 34–36. [Google Scholar] [CrossRef] [PubMed]

- Güllert, S.; Fischer, M.A.; Turaev, D.; Noebauer, B.; Ilmberger, N.; Wemheuer, B.; Alawi, M.; Rattei, T.; Daniel, R.; Schmitz, R.A.; et al. Deep Metagenome and Metatranscriptome Analyses of Microbial Communities Affiliated with an Industrial Biogas Fermenter, a Cow Rumen, and Elephant Feces Reveal Major Differences in Carbohydrate Hydrolysis Strategies. Biotechnol. Biofuels 2016, 9, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Sundberg, C.; Al-Soud, W.A.; Larsson, M.; Alm, E.; Yekta, S.S.; Svensson, B.H.; Sørensen, S.J.; Karlsson, A. 454 Pyrosequencing Analyses of Bacterial and Archaeal Richness in 21 Full-Scale Biogas Digesters. FEMS Microbiol. Ecol. 2013, 85, 612–626. [Google Scholar] [CrossRef] [Green Version]

- Vanwonterghem, I.; Jensen, P.D.; Ho, D.P.; Batstone, D.J.; Tyson, G.W. Linking Microbial Community Structure, Interactions and Function in Anaerobic Digesters Using New Molecular Techniques. Curr. Opin. Biotechnol. 2014, 27, 55–64. [Google Scholar] [CrossRef] [PubMed]

- Ziganshin, A.M.; Liebetrau, J.; Pröter, J.; Kleinsteuber, S. Microbial Community Structure and Dynamics during Anaerobic Digestion of Various Agricultural Waste Materials. Appl. Microbiol. Biotechnol. 2013, 97, 5161–5174. [Google Scholar] [CrossRef] [PubMed]

- Langley, S.R.; Dwyer, J.; Drozdov, I.; Yin, X.; Mayr, M. Proteomics: From Single Molecules to Biological Pathways. Cardiovasc. Res. 2012, 97, 612–622. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.-Y.; Kraková, L.; Wu, J.-H.; Pangallo, D.; Jeszeová, L.; Liu, B.; Yasui, H. Community and Proteomic Analysis of Anaerobic Consortia Converting Tetramethylammonium to Methane. Archaea 2017, 2017, 2170535. [Google Scholar] [CrossRef] [Green Version]

- Joyce, A.; Ijaz, U.Z.; Nzeteu, C.; Vaughan, A.; Shirran, S.L.; Botting, C.H.; Quince, C.; O’Flaherty, V.; Abram, F. Linking Microbial Community Structure and Function During the Acidified Anaerobic Digestion of Grass. Front. Microbiol. 2018, 9, 540. [Google Scholar] [CrossRef]

- Heyer, R.; Kohrs, F.; Reichl, U.; Benndorf, D. Metaproteomics of Complex Microbial Communities in Biogas Plants. Microb. Biotechnol. 2015, 8, 749–763. [Google Scholar] [CrossRef]

- Heyer, R.; Schallert, K.; Siewert, C.; Kohrs, F.; Greve, J.; Maus, I.; Klang, J.; Klocke, M.; Heiermann, M.; Hoffmann, M.; et al. Metaproteome Analysis Reveals That Syntrophy, Competition, and Phage-Host Interaction Shape Microbial Communities in Biogas Plants. Microbiome 2019, 7, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.; Fan, X.; Shi, X.; Lian, S.; Qiao, J.; Guo, R. Metabolomics Reveals Stage-Specific Metabolic Pathways of Microbial Communities in Two-Stage Anaerobic Fermentation of Corn-Stalk. Biotechnol. Lett. 2014, 36, 1461–1468. [Google Scholar] [CrossRef] [PubMed]

- Sasaki, D.; Sasaki, K.; Tsuge, Y.; Morita, M.; Kondo, A. Comparison of Metabolomic Profiles of Microbial Communities between Stable and Deteriorated Methanogenic Processes. Bioresour. Technol. 2014, 172, 83–90. [Google Scholar] [CrossRef] [PubMed]

- Córdova-Suárez, M.; Sosa-Cárdenas, J.; Cifuentes-Suárez, Y.; Sánchez-Almeida, L. Long-Term Evaluation of Biogas Energy Potential Based on the Neuronal Network Approach. E3S Web Conf. 2020, 167, 05006. [Google Scholar] [CrossRef]

- Sathish, S.; Vivekanandan, S. Parametric Optimization for Floating Drum Anaerobic Bio-Digester Using Response Surface Methodology and Artificial Neural Network. Alex. Eng. J. 2016, 55, 3297–3307. [Google Scholar] [CrossRef] [Green Version]

- Güçlü, D.; Yılmaz, N.; Ozkan-Yucel, U.G. Application of Neural Network Prediction Model to Full-Scale Anaerobic Sludge Digestion. J. Chem. Technol. Biotechnol. 2011, 86, 691–698. [Google Scholar] [CrossRef]

- Dalmau, J.; Comas, J.; Rodríguez-Roda, I.; Latrille, E.; Steyer, J.-P. Selecting the Most Relevant Variables for Anaerobic Digestion Imbalances: Two Case Studies. Water Environ. Res. 2010, 82, 492–498. [Google Scholar] [CrossRef] [Green Version]

- Beltramo, T.; Klocke, M.; Hitzmann, B. Prediction of the Biogas Production Using GA and ACO Input Features Selection Method for ANN Model. Inf. Process. Agric. 2019, 6, 349–356. [Google Scholar] [CrossRef]

- Ilamathi, P.; Selladurai, V.; Balamurugan, K. Predictive modelling and optimization of nitrogen oxides emission in coal power plant using Artificial Neural Network and Simulated Annealing. IAES Int. J. Artif. Intell. 2012, 1, 11. [Google Scholar]

- Mougari, N.E.; Largeau, J.F.; Himrane, N.; Hachemi, M.; Tazerout, M. Application of Artificial Neural Network and Kinetic Modeling for the Prediction of Biogas and Methane Production in Anaerobic Digestion of Several Organic Wastes. Int. J. Green Energy 2021, 18, 1584–1596. [Google Scholar] [CrossRef]

- Park, J.-G.; Jun, H.-B.; Heo, T.-Y. Retraining Prior State Performances of Anaerobic Digestion Improves Prediction Accuracy of Methane Yield in Various Machine Learning Models. Appl. Energy 2021, 298, 117250. [Google Scholar] [CrossRef]

- Cinar, S.; Cinar, S.O.; Wieczorek, N.; Sohoo, I.; Kuchta, K. Integration of Artificial Intelligence into Biogas Plant Operation. Processes 2021, 9, 85. [Google Scholar] [CrossRef]

- Ramachandran, A.; Rustum, R.; Adeloye, A.J. Review of Anaerobic Digestion Modeling and Optimization Using Nature-Inspired Techniques. Processes 2019, 7, 953. [Google Scholar] [CrossRef] [Green Version]

- Murnleitner, E.; Becker, T.M.; Delgado, A. State Detection and Control of Overloads in the Anaerobic Wastewater Treatment Using Fuzzy Logic. Water Res. 2002, 36, 201–211. [Google Scholar] [CrossRef]

- Punal, A.; Rodriguez, J.; Carrasco, E.F.; Roca, E.; Lema, J.M. Expert system for the on-line diagnosis of anaerobic wastewater treatment plants. Water Sci. Technol. 2002, 45, 195–200. [Google Scholar] [CrossRef] [PubMed]

- Srisertpol, J.; Srinakorn, P.; Kheawnak, A.; Chamniprasart, K. Estimation of Biogas Production from Shrimp Pond Sediment Using the Artificial Intelligence. Appl. Mech. Mater. 2012, 260–261, 695–700. [Google Scholar] [CrossRef]

- Genovesi, A.; Harmand, J.; Steyer, J.-P. Integrated fault detection and isolation: Application to a winery’s wastewater treatment plant. Appl. Intell. 2000, 13, 59–76. [Google Scholar] [CrossRef]

- Tumer, A.E.; Edebali, S. An artificial neural network model for wastewater treatment plant of Konya. Int. J. Intell. Syst. 2015, 3, 131–135. [Google Scholar] [CrossRef]

- Gaida, D.; Wolf, C.; Meyer, C.; Stuhlsatz, A.; Lippel, J.; Bäck, T.; Bongards, M.; McLoone, S. State Estimation for Anaerobic Digesters Using the ADM1. Water Sci. Technol. 2012, 66, 1088–1095. [Google Scholar] [CrossRef]

- Sin, G.; Al, R. Activated Sludge Models at the Crossroad of Artificial Intelligence—A Perspective on Advancing Process Modeling. NPJ Clean Water 2021, 4, 1–7. [Google Scholar] [CrossRef]

| Bioprocess Engineering Techniques | Nanotechnology Techniques | Omics Techniques | Artificial Intelligence | Treatment Method | Biogas Yield/% Increase | References |

|---|---|---|---|---|---|---|

| Surface-state engineering | Fe3O4 (magnetite) nanoparticles (MNPs) | TNA | TNA | Wastewater sludge | 234% | [49] |

| Batch and continuous-flow mesophilic anaerobic digestion | Magnetite nanoparticles | TNA | TNA | Food waste | Batch = 33% Continuous = 8% | [16] |

| Wet biogas fermentations Dry biogas fermentations | TNA | Comparative metagenomics | TNA | Agricultural waste | 810.5 I/kg oDM 698.2 I/kg oDM | [50] |

| Two-phased anaerobic digestion (TPAD) | TNA | TNA | Digester and Biomethanation sub models | Cattle manure Maize silage | Biogas production from 9.06 to 9.59% | [125] |

| Active sludge technology–BIODENIPHO Separated closed fermenting chambers-SCFC | TNA | TNA | Artificial neural networks model | Wastewater treatment plant (WWT) | Max yield = 4050 m3/day | [52] |

| Rice paddy and acetate-supplemented continuously agitated anaerobic cultures | Magnetite nanoparticles | Metagenomics, Metatranscriptomics and Metabarcoding | TNA | Organic waste | BYER | [51] |

| 20% w:v FOG Laboratory scale digesters | TNA | Metagenomics: Metabolomics | TNA | Wastewater treatment plant | 264.1 ± 76.5 mL/day | [126] |

| Pressurised anaerobic tubes | Conductive nanomaterials | Tandem mass tag (TMT) proteomics technology | TNA | Mineral salt media | BYER | [127] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chidi, B.S.; Okudoh, V.I.; Hutchinson, U.F.; Ngongang, M.M.; Maphanga, T.; Madonsela, B.S.; Shale, K.; Lim, J.W.; Ntwampe, S.K.O. A Perspective on Emerging Inter-Disciplinary Solutions for the Sustainable Management of Food Waste. Appl. Sci. 2022, 12, 11399. https://doi.org/10.3390/app122211399

Chidi BS, Okudoh VI, Hutchinson UF, Ngongang MM, Maphanga T, Madonsela BS, Shale K, Lim JW, Ntwampe SKO. A Perspective on Emerging Inter-Disciplinary Solutions for the Sustainable Management of Food Waste. Applied Sciences. 2022; 12(22):11399. https://doi.org/10.3390/app122211399

Chicago/Turabian StyleChidi, Boredi Silas, Vincent Ifeanyi Okudoh, Ucrecia Faith Hutchinson, Maxwell Mewa Ngongang, Thabang Maphanga, Benett Siyabonga Madonsela, Karabo Shale, Jun Wei Lim, and Seteno Karabo Obed Ntwampe. 2022. "A Perspective on Emerging Inter-Disciplinary Solutions for the Sustainable Management of Food Waste" Applied Sciences 12, no. 22: 11399. https://doi.org/10.3390/app122211399