Study on Correction Method of Internal Joint Operation Curve Based on Unsteady Flow

Abstract

:1. Introduction

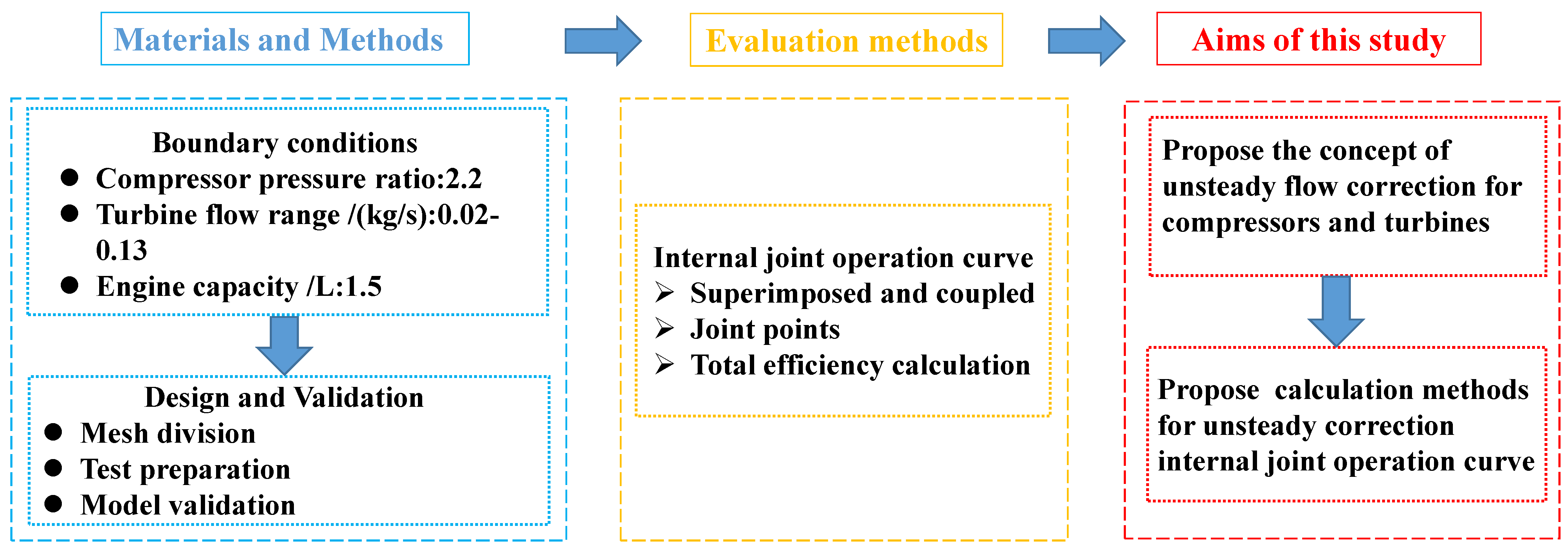

2. Materials and Methods

2.1. Research Methodology and Research Objects

- the admission and the mixed gas are considered as ideal gases, affected by temperature and gas composition.

- the working fluid is in a uniform state, the inlet and outlet kinetic energy are negligible, and the inlet gas and the residual exhaust gas are completely mixed instantaneously.

- during the heat release process, the working fluid in the system is heated externally according to the established heat release law.

2.2. Mathematical Model

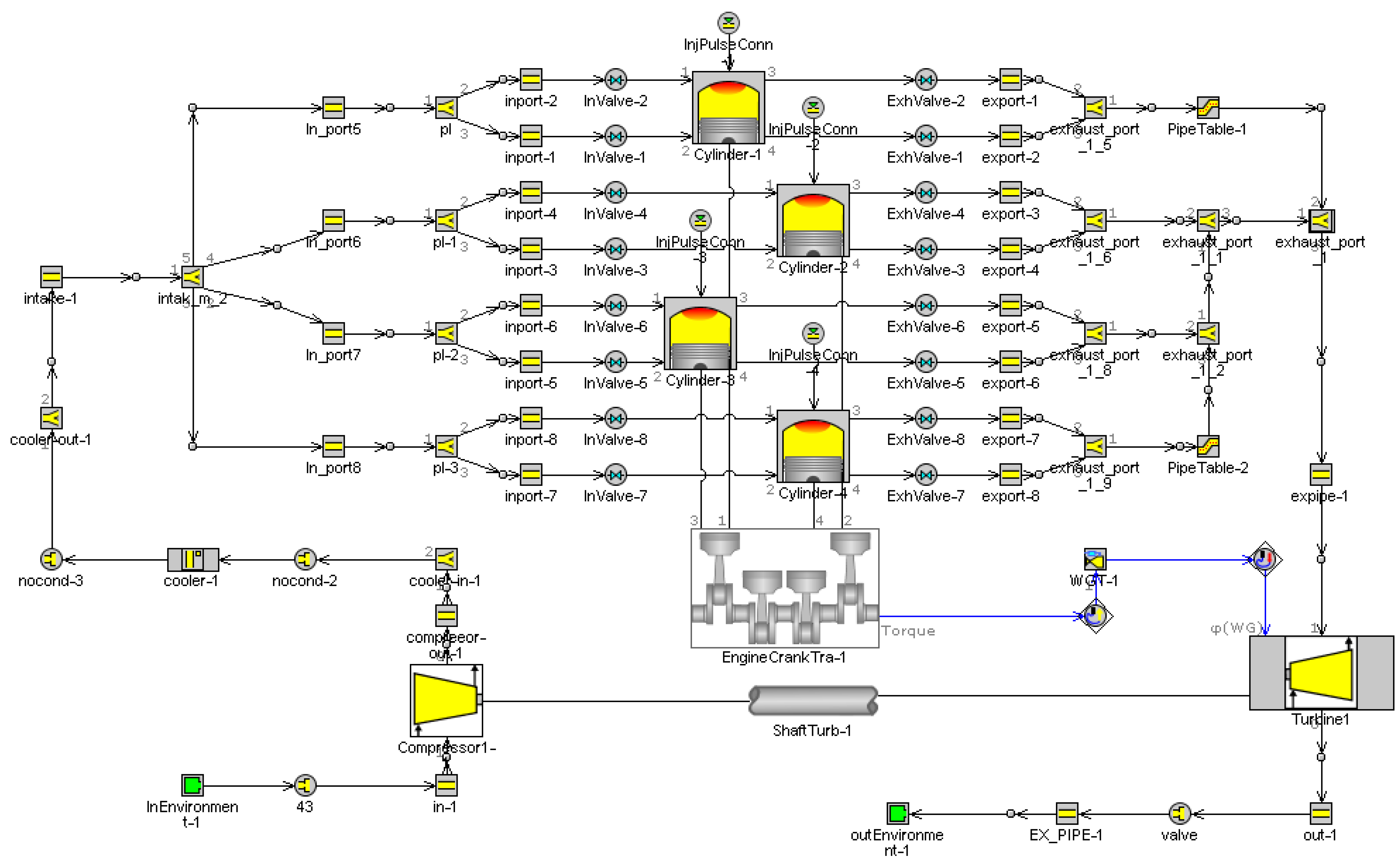

2.3. Design and Validation of the Model

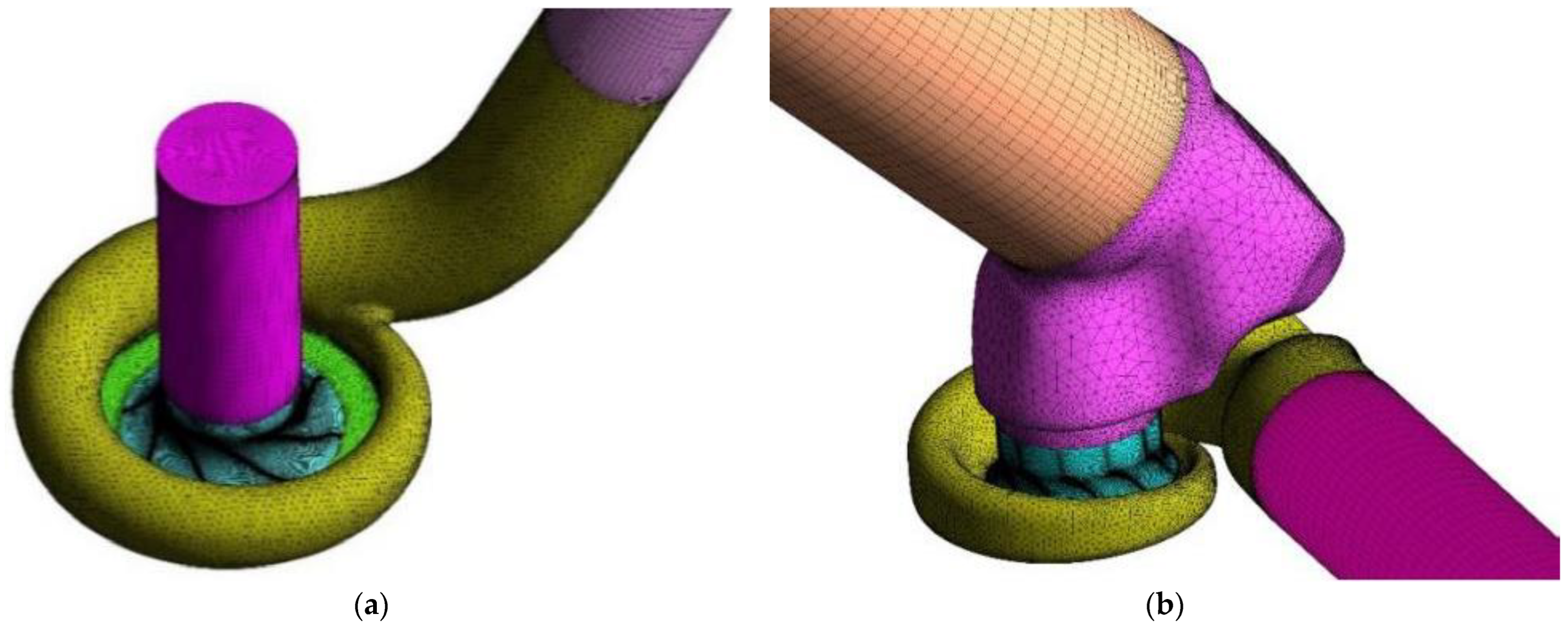

2.3.1. Mesh Division

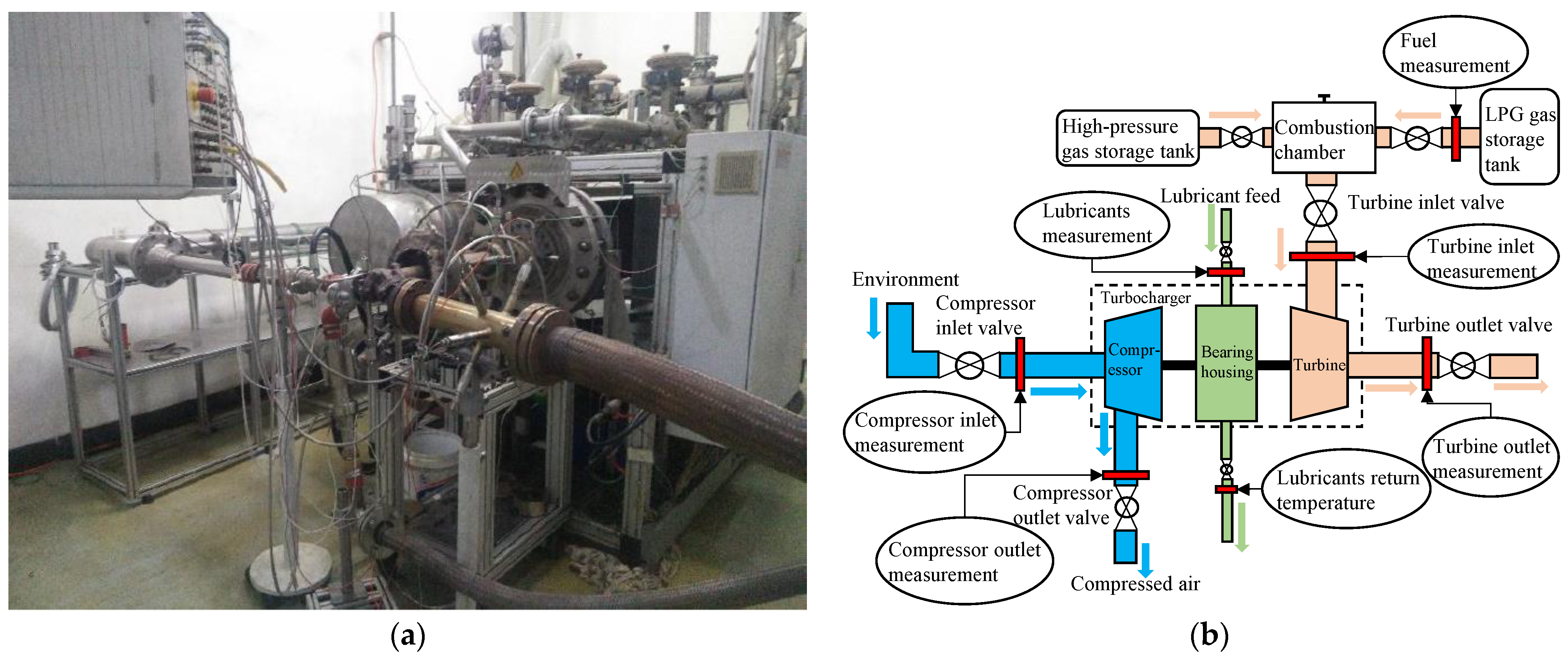

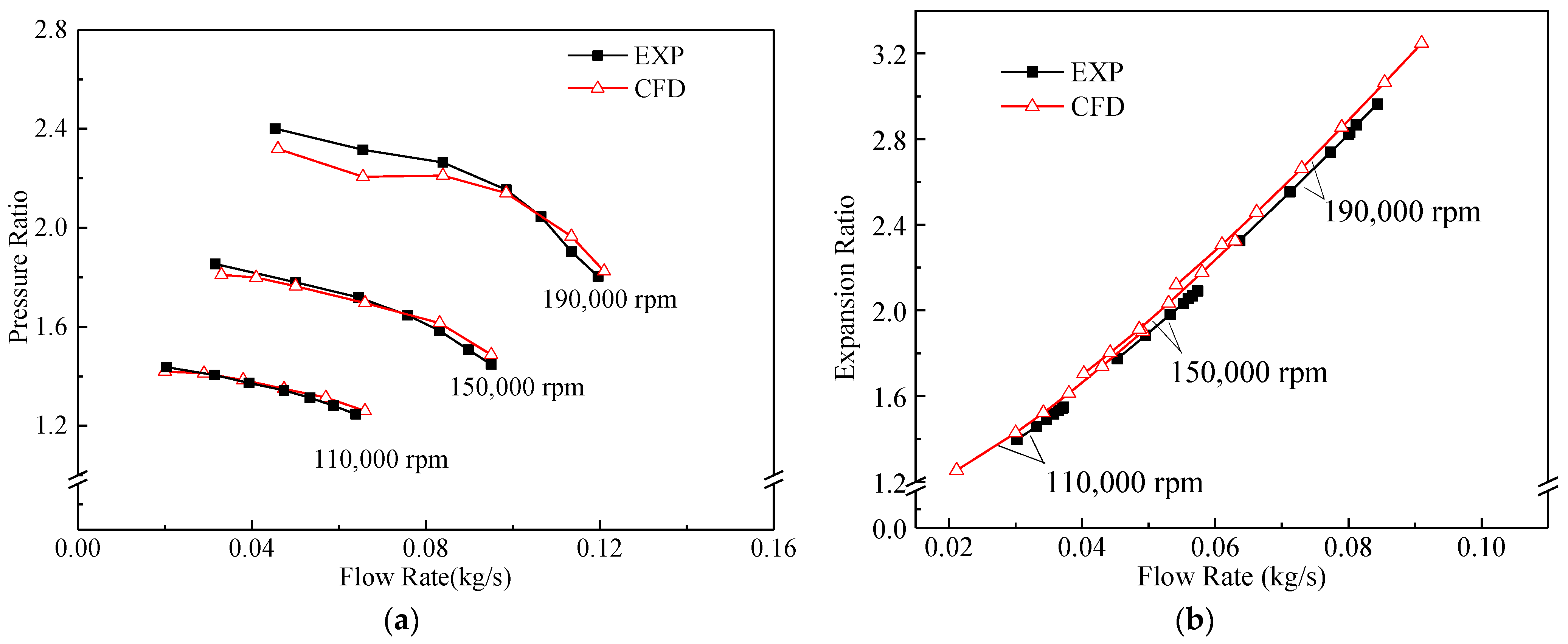

2.3.2. Test Preparation and Validation

2.3.3. Internal Joint Operation Curve Analysis

3. Results

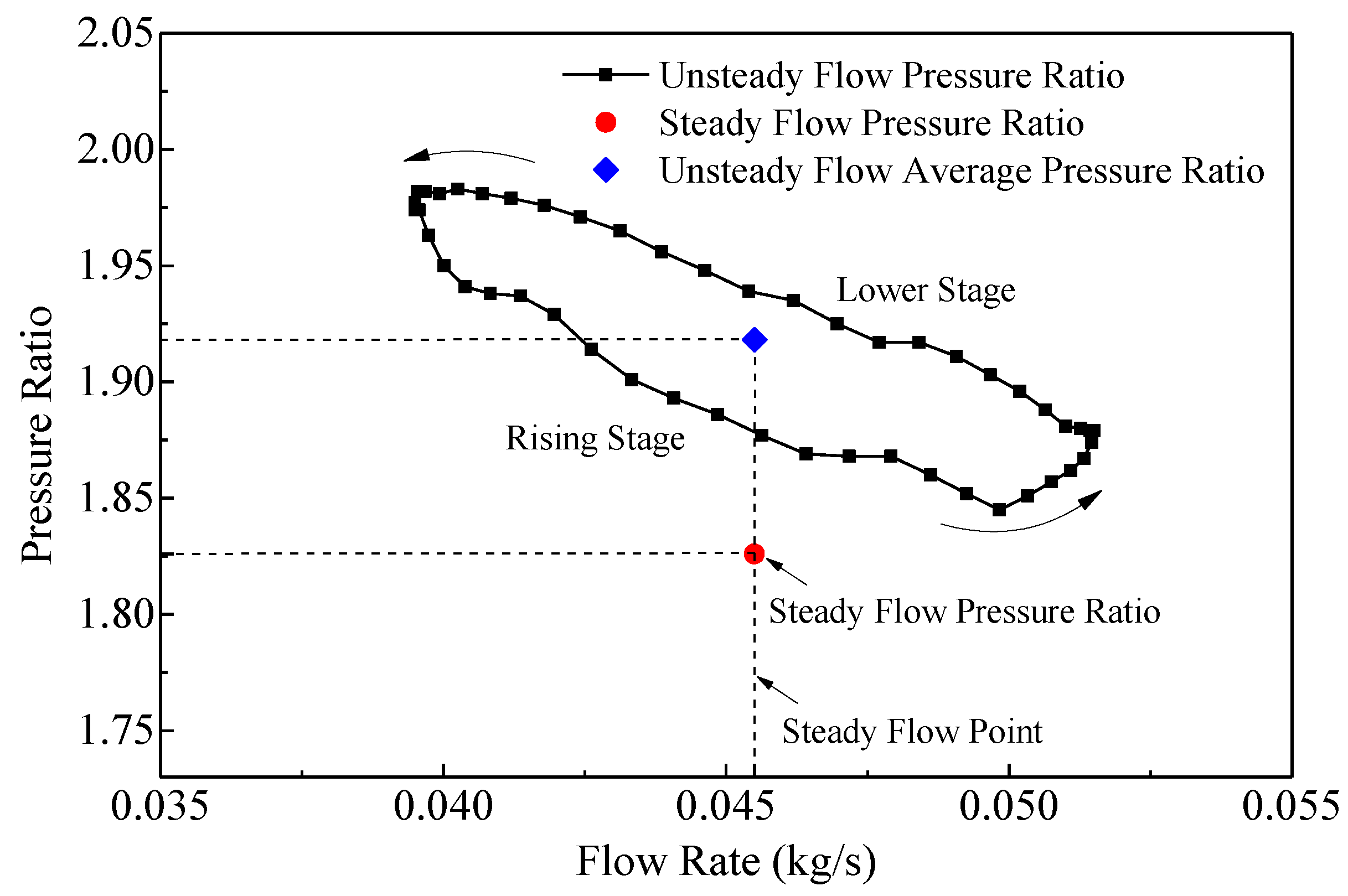

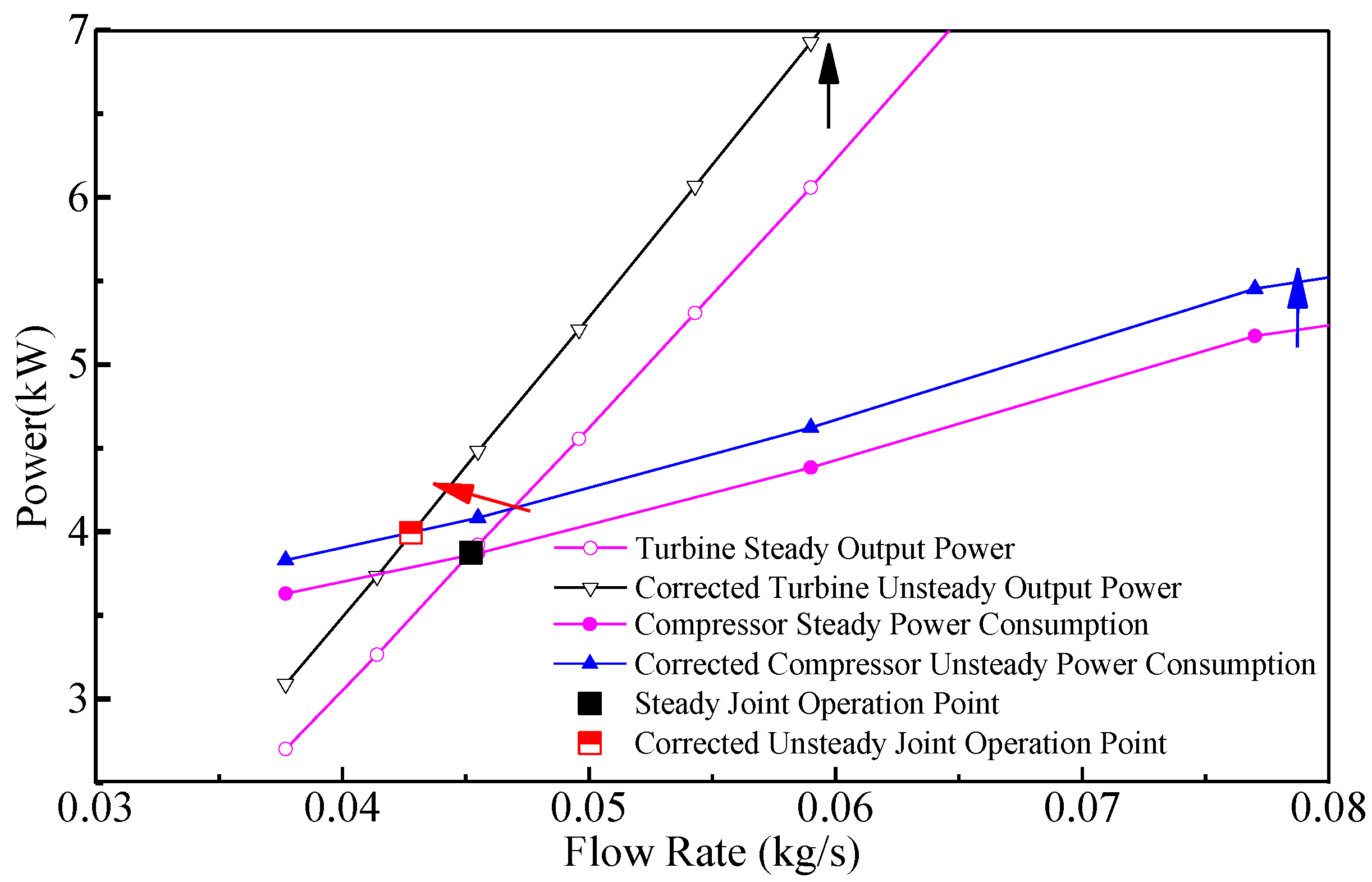

3.1. Concept and Calculation Method of Unsteady Correction for Compressor

3.2. Concept and Calculation Method of Unsteady Correction for Turbine

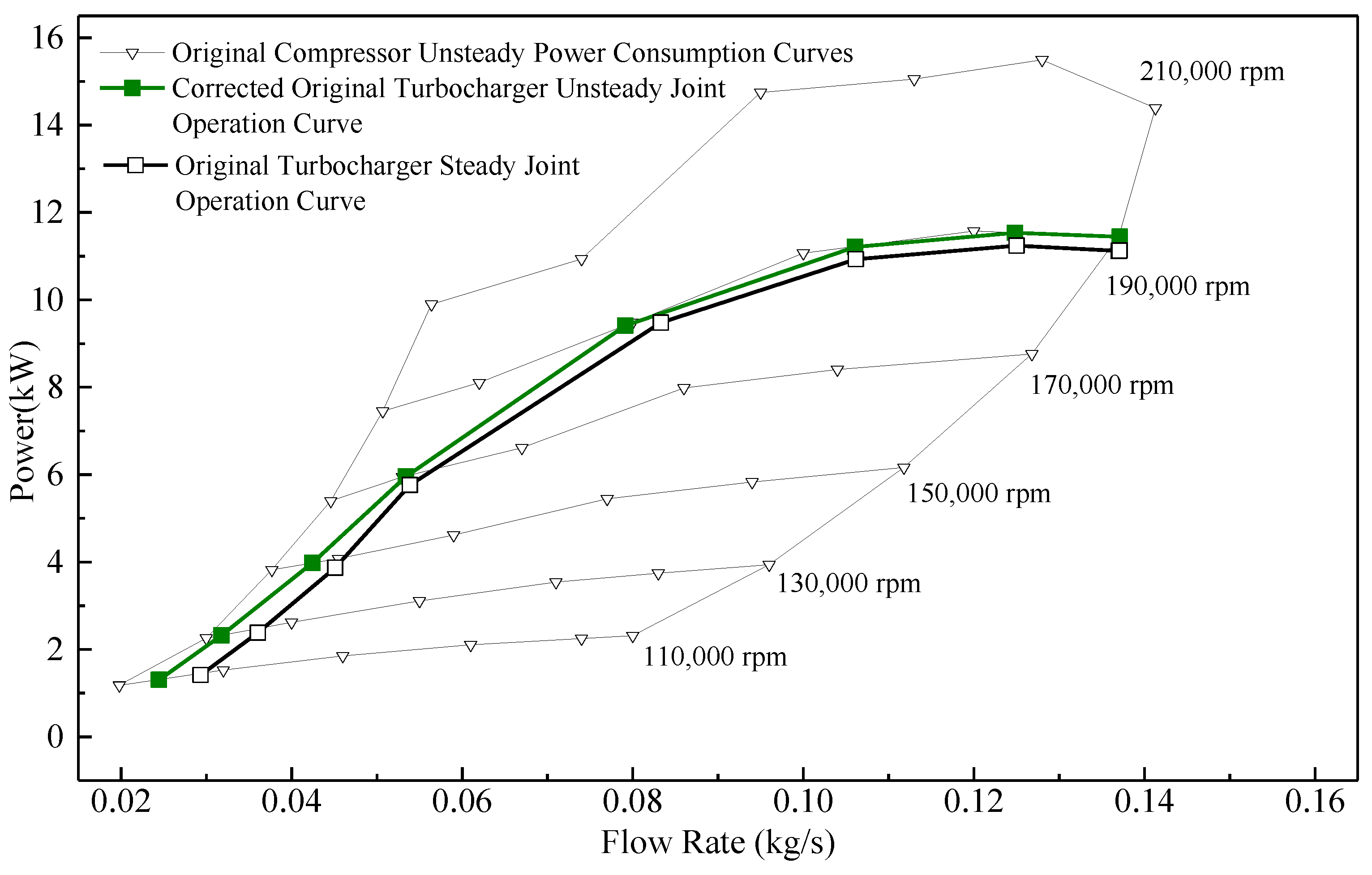

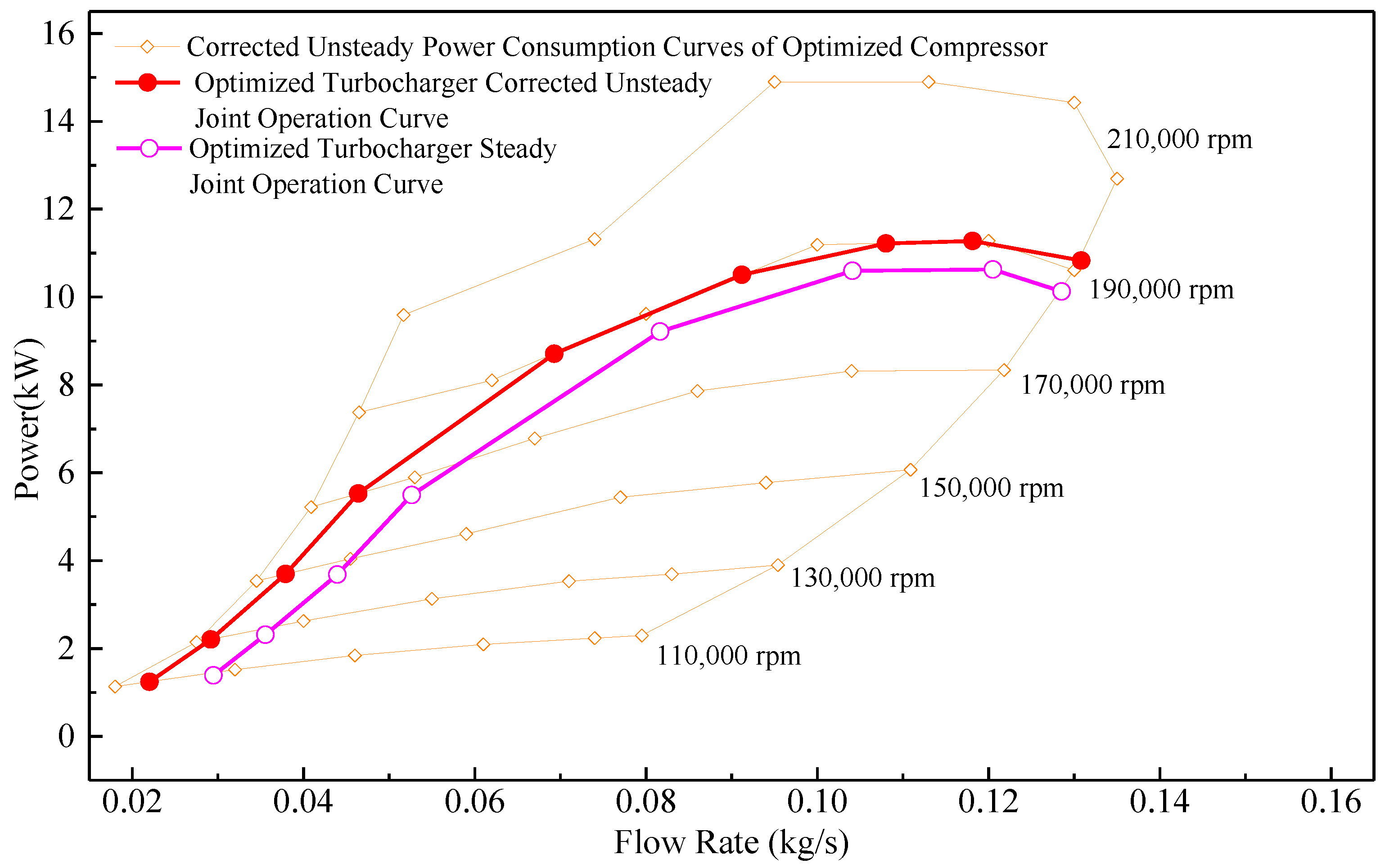

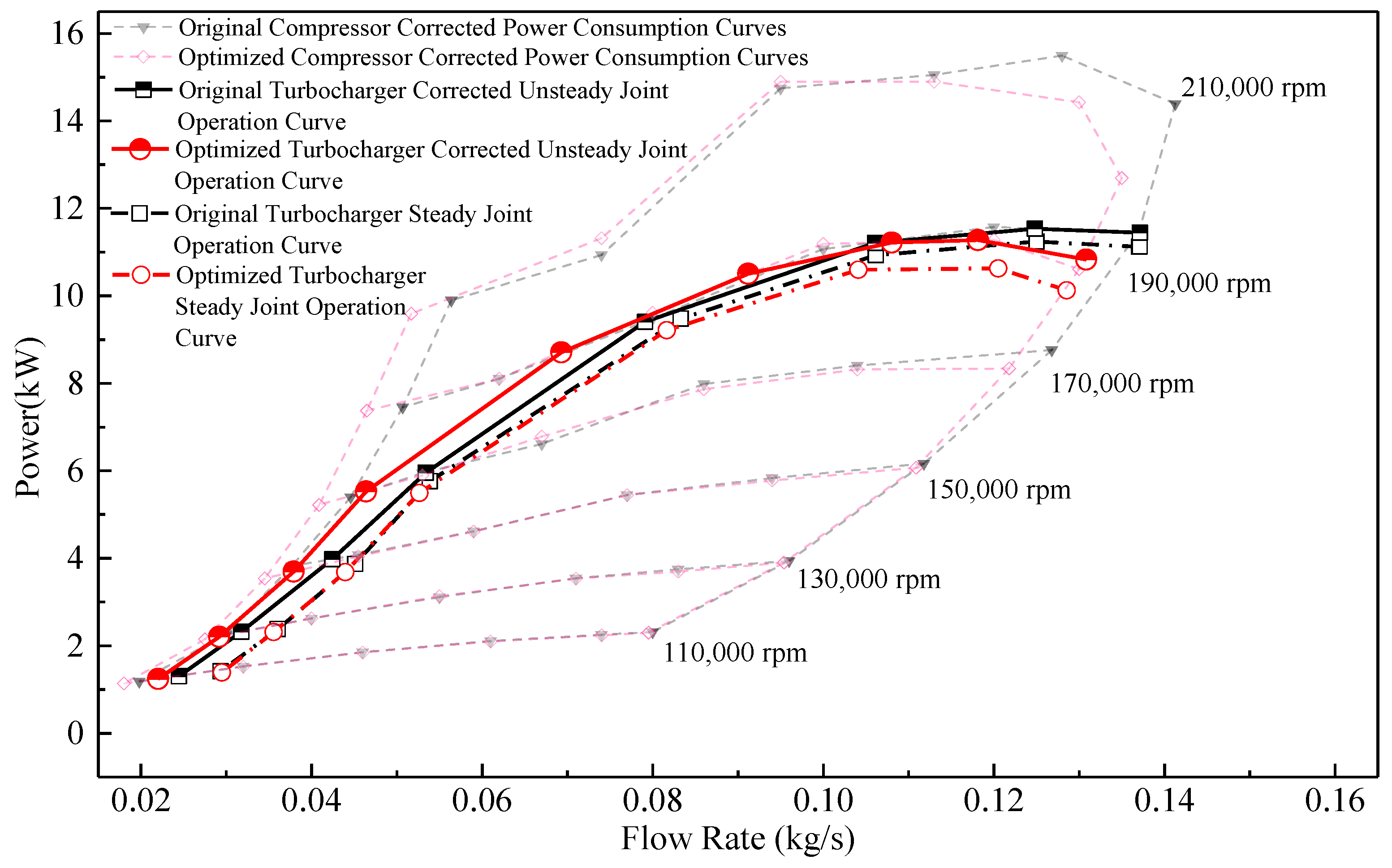

3.3. Simultaneous Unsteady Correction at Compressor and Turbine

4. Discussion

5. Conclusions

- (1)

- There is a difference in performance between the unsteady flow and the steady flow of the compressor, with the average value of the unsteady flow performance being 4.4% to 5.4% higher than the corresponding steady flow value. The unsteady flow power consumption coefficient for the combined conditions is calculated as the correction coefficient for the compressor unsteady flow, and the pulse energy utilization coefficient is used as the correction coefficient for the turbine unsteady flow.

- (2)

- The turbocharger performance is closer to the actual operating condition after accounting for the unsteady coefficient correction at the compressor and the turbine. The internal joint operating curve shifts both to the left and up, with the left shift being larger.

- (3)

- The main difference between the corrected internal joint operating curves of the two turbochargers is at the medium–low-speed range. The original turbocharger’s surge margin is reduced by 4.6% to 11.8%, and the optimized turbocharger’s surge margin is reduced by 15.2% to 21.9% in the medium–low-speed range.

- (4)

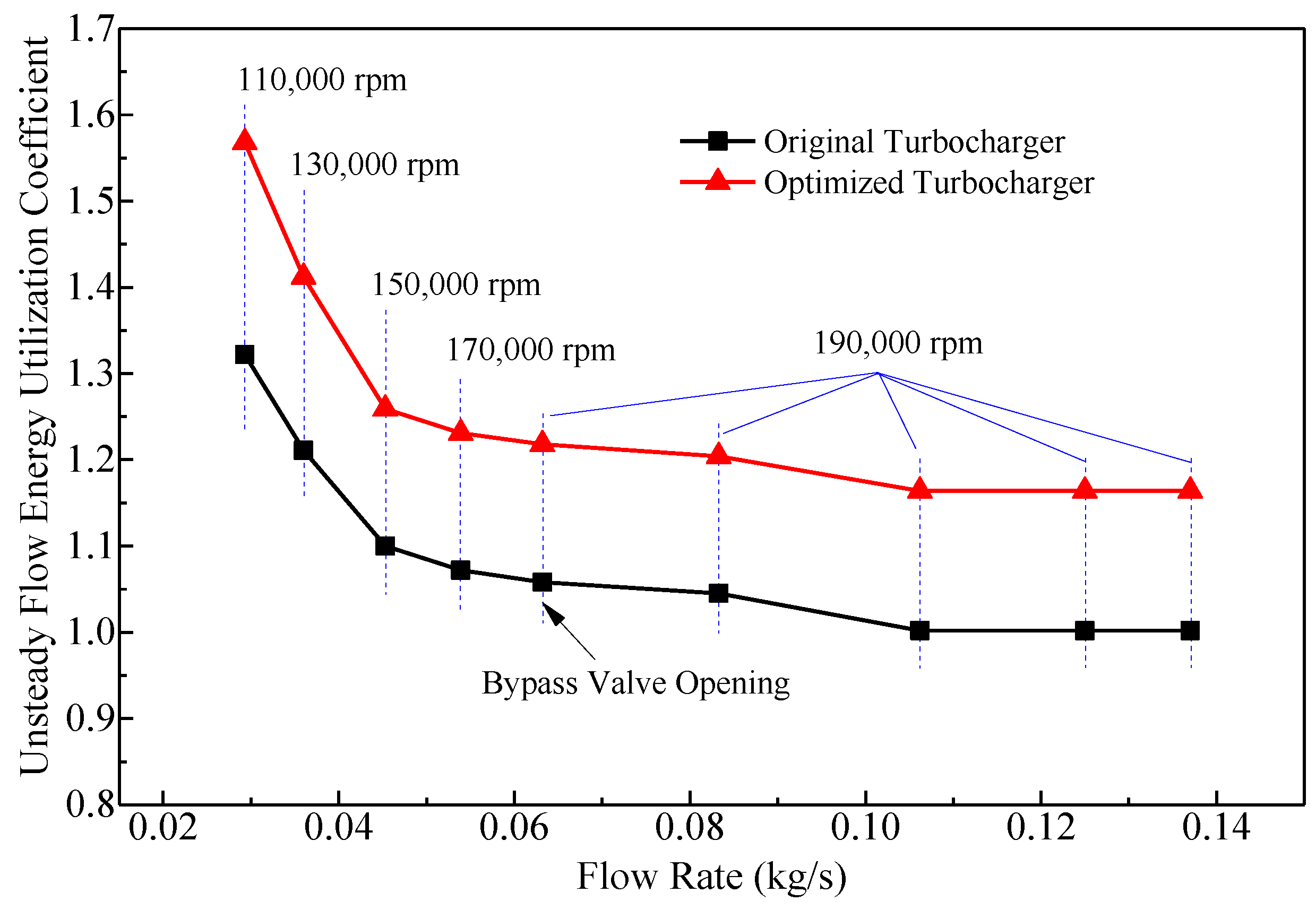

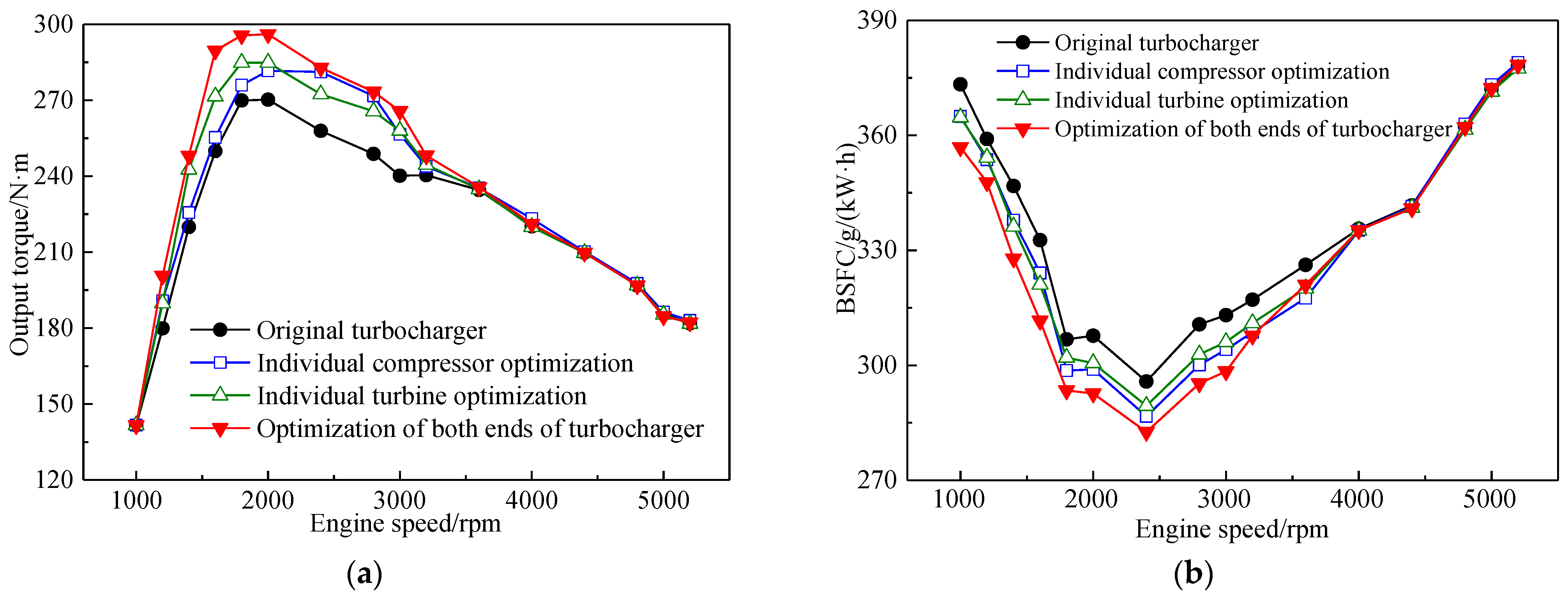

- The concept of the turbocharger unsteady flow energy utilization factor is proposed to quantitatively assess the turbocharger energy utilization. The overall unsteady flow energy utilization advantage of the optimized turbocharger is significant, especially in the medium–low-speed range, where it is more than 14.5% higher than the original turbocharger. The optimized turbocharger increases the maximum torque by 9.6% and decreases the minimum BSFC by 4.4% compared to the original engine. Therefore, compared with the internal joint operation curve with steady flow, the curve with unsteady flow correction was closer to the actual engine performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Andreoni, V.; Galmarini, S. Drivers in CO2 emissions variation: A decomposition analysis for 33 world countries. Energy 2016, 103, 27–37. [Google Scholar] [CrossRef]

- Dong, K.; Hochman, G.; Timilsina, G.R. Do drivers of CO2 emission growth alter overtime and by the stage of economic development? Energy Policy 2020, 140, 11420. [Google Scholar] [CrossRef]

- Andre, M.; Rapone, M. Analysis and modelling of the pollutant emissions from European cars regarding the driving characteristics and test cycles. Atmos. Environ. 2009, 43, 986–995. [Google Scholar] [CrossRef]

- Fontaras, G.; Dilara, P. The of European passenger car characteristics 2000–2010 and its effects on real-world CO2 emissions and CO2 reduction policy. Energy Policy 2012, 10, 719–730. [Google Scholar] [CrossRef]

- Guo, N.; Zhang, X.; Zou, Y.; Guo, L.; Du, G. Real-time predictive energy management of plug-in hybrid electric vehicles for coordination of fuel economy and battery degradation. Energy 2021, 214, 119070. [Google Scholar] [CrossRef]

- Guo, N.; Zhang, X.; Zou, Y. Real-Time Predictive Control of Path Following to Stabilize Autonomous Electric Vehicles Under Extreme Drive Conditions. Automot. Innov. 2022. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Zhao, C.; Dai, B.; Li, Z.H. Dynamic Simulation of Permanent Magnet Synchronous Motor (PMSM) Electric Vehicle Based on Simulink. Energies 2022, 15, 1134. [Google Scholar] [CrossRef]

- Guo, N.; Zhang, X.; Zou, Y.; Du, G.; Wang, C.; Guo, L. Predictive Energy Management of Plug-in Hybrid Electric Vehicles by Real-time Optimization and Data-driven Calibration. IEEE Trans. Veh. Technol. 2021, 71, 5677–5691. [Google Scholar] [CrossRef]

- Lu, D.Y.; Theotokatos, G.; Zhang, J.D.; Zeng, H.; Cui, K.Y. Comparative Assessment and Parametric Optimisation of Large Marine Two-Stroke Engines with Exhaust Gas Recirculation and Alternative Turbocharging Systems. J. Mar. Sci. Eng. 2022, 10, 351. [Google Scholar] [CrossRef]

- Liu, R.L.; Zhang, Z.J.; Yang, C.H.; Jiao, Y.F.; Zhou, G.M.; Ma, J.M. Influence of altitude on matching characteristic of electronic-controlled pneumatic two-stage turbocharging system with diesel engine. Proc. Inst. Mech. Eng. Part A 2020, 235, 94–105. [Google Scholar] [CrossRef]

- Galindo, J.; Fajardo, P.; Navarro, R.; Garcia-Cuevas, L.M. Characterization of a radial turbocharger turbine in pulsating flow by means of CFD and its application to engine modeling. Appl. Energy 2013, 103, 116–127. [Google Scholar] [CrossRef]

- Teo, A.E.; Chiong, M.S.; Yang, M.; Romagnoli, A.; Martinez-Botas, R.F.; Rajoo, S. Performance evaluation of low-pressure turbine, turbo-compounding and air-Brayton cycle as engine waste heat recovery method. Energy 2019, 166, 895–907. [Google Scholar] [CrossRef]

- Molinari, M.; Dawes, W.N. Review of evolution of compressor design process and future perspectives. Proc. Inst. Mech. Eng. Part C 2006, 220, 761–771. [Google Scholar] [CrossRef]

- Zhang, L.; He, R.Y.; Wang, S.L.; Zhang, Q. A review of rotating stall in vaneless diffuser of centrifugal compressor. J. Therm. Sci. 2020, 29, 323–342. [Google Scholar] [CrossRef]

- Niu, Z.T.; Sun, Z.Z.; Wang, B.T.; Zheng, X.Q. Effects of nonaxisymmetric volute on rotating stall in the vaneless diffuser of centrifugal compressors. J. Eng. Gas Turbines Power 2022, 144, 051015. [Google Scholar] [CrossRef]

- Xu, Y.D.; Zhang, X.M.; Lv, Q.Y.; Mu, G.Z. Design of compressor impeller under high Reynolds number conditions. Ind. Lubr. Tribol. 2022, 74, 1–9. [Google Scholar] [CrossRef]

- Suriyanarayanan, V.; Rendu, Q.; Vahdati, M.; Salles, L. Effect of manufacturing tolerance in flow past a compressor blade. J. Turbomach. 2022, 144, 041005. [Google Scholar] [CrossRef]

- Yang, M.Y.; Shu, M.Y.; Yang, B.J.; Martinez-Botas, R.; Deng, K.Y. Unsteady response of performance for centrifugal compressor under pulsating backpressure condition. Aerosp. Sci. Technol. 2022, 126, 107589. [Google Scholar] [CrossRef]

- Galindo, J.; Serrano, J.R.; Climent, H.; Tiseira, A. Experiments and modelling of surge in small centrifugal compressor for automotive engines. Exp. Therm. Fluid Sci. 2008, 32, 818–826. [Google Scholar] [CrossRef]

- Cao, D.M.; Yuan, C.J.; Wang, D.X.; Huang, X.Q. Transition from Unsteady Flow Inception to Rotating Stall and Surge in a Transonic Compressor. J. Therm. Sci. 2022, 31, 120–129. [Google Scholar] [CrossRef]

- Silvia, M.; Massimo, C.; Giorgio, Z. Pulsating flow performance of a turbocharger compressor for automotive application. Int. J. Heat Fluid Flow 2014, 45, 158–165. [Google Scholar] [CrossRef]

- Zhu, S.; Deng, K.; Liu, S. Modeling and extrapolating mass flow characteristics of a radial turbocharger turbine. Energy 2015, 87, 628–637. [Google Scholar] [CrossRef]

- Chen, S.L.; Ma, C.C.; Zhang, H.; Xu, C.; Lei, F.; Feng, T.; Cao, G.; Yang, H.Q.; Wei, C.F. Engine performance improvements through turbocharger matching and turbine design. Energy Sci. Eng. 2022, 10, 3384–3396. [Google Scholar] [CrossRef]

- Salameh, G.; Chesse, P.; Chalet, D. Mass flow extrapolation model for automotive turbine and confrontation to experiments. Energy 2019, 167, 325–336. [Google Scholar] [CrossRef]

- Ketata, A.; Driss, Z. Characterization of double-entry turbine coupled with gasoline engine under in- and out-phase admission. Energy 2021, 236, 121447. [Google Scholar] [CrossRef]

- Serrano, J.R.; Arnau, F.J.; Dolz, V.; Tiseira, A.; Cervelló, C. A model of turbocharger radial turbines appropriate to be used in zero- and one-dimensional gas dynamics codes for internal combustion engines modelling. Energy Convers. Manag. 2008, 49, 3729–3745. [Google Scholar] [CrossRef]

- Costiuc, I.; Chiru, A.; Costiuc, L. A Review of Engine’s Performance When Supercharging by a Pressure Wave Supercharger. Energies 2022, 15, 2721. [Google Scholar] [CrossRef]

- Serrano, J.R.; Arnau, F.J.; García-Cuevas, L.M.; Pablo, S.; Raymond, C. Experimental validation of a one-dimensional twin-entry radial turbine model under non-linear pulse conditions. Int. J. Engine Res. 2019, 22, 390–406. [Google Scholar] [CrossRef]

- Roberto, M.; Maw, L.S.; Mihai, M. Influence of Pulse Characteristics on Turbocharger Radial Turbine. J. Eng. Gas Turbines Power 2022, 144, 021018. [Google Scholar] [CrossRef]

- Wang, Z.H.; Ma, C.C.; Zhang, H.; Zhu, F. A novel pulse-adaption flow control method for a turbocharger turbine: Elastically restrained guide vane. Proc. Inst. Mech. Eng. Part C 2020, 234, 2581–2594. [Google Scholar] [CrossRef]

- Duan, Y.F.; Shi, X.Y.; Kang, Y.; Liao, Y.; Duan, L.S. Effect of Hydrous Ethanol Combined with EGR on Performance of GDI Engine. In Proceedings of the SAE 2020 World Congress and Exhibition, Detroit, MI, USA, 14 April 2016. [Google Scholar] [CrossRef]

- Broatch, A.; Galindo, J.; Navarro, R.; Garcia-Tiscar, J. Numerical and experimental analysis of automotive turbocharger compressor aeroacoustics at different operating conditions. Int. J. Heat Fluid Flow 2016, 61, 245–255. [Google Scholar] [CrossRef] [Green Version]

- Colaciti, A.K.; Lopez, L.; Navarro, H.A.; Cabezas-Gomez, L. Numerical simulation of a radial diffuser turbulent airflow. Appl. Math. Comput. 2007, 189, 1491–1504. [Google Scholar] [CrossRef]

- Campobasso, M.S.; Piskopakis, A.; Drofelnik, J.; Jackson, A. Turbulent Navier-Stokes analysis of an oscillating wing in a power-extraction regime using the shear stress transport turbulence model. Comput. Fluids 2013, 88, 136–155. [Google Scholar] [CrossRef]

- Fan, H.C.; Ni, J.M.; Shi, X.Y.; Qu, D.Y.; Zheng, Y.; Zheng, Y.H. Simulation of a combined nozzled and nozzleless twin-entry turbine for improved efficiency. J. Eng. Gas Turbines Power 2019, 141, 051019. [Google Scholar] [CrossRef]

- Fan, H.C.; Ni, J.M.; Shi, X.Y.; Jiang, N.; Qu, D.Y.; Zheng, Y.; Zheng, Y.H. Unsteady performance simulation analysis of a waste-gated turbocharger turbine under different valve opening conditions. In Proceedings of the SAE 2017 International Powertrains, Fuels and Lubricants Meeting, Detroit, MI, USA, 8 October 2017. [Google Scholar] [CrossRef]

- Galindo, J.; Tiseira, A.; Fajardo, P.; Garcıa-Cuevas, L.M. Development and validation of a radial variable geometry turbine model for transient pulsating flow applications. Energy Convers. Manag. 2014, 85, 190–203. [Google Scholar] [CrossRef]

- Yin, S.; Ni, J.M.; Fan, H.C.; Shi, X.Y.; Huang, R. A Study of Evaluation Method for Turbocharger Turbine Based on Joint Operation Curve. Sustainability 2022, 14, 9952. [Google Scholar] [CrossRef]

- Liu, X.F.; Zhao, L. Approximate Nonlinear Modeling of Aircraft Engine Surge Margin Based on Equilibrium Manifold Expansion. Chin. J. Aeronaut. 2012, 22, 663–674. [Google Scholar] [CrossRef] [Green Version]

- Pan, T.Y.; Li, Q.S.; Yuan, W.; Lu, H.N. Effects of axisymmetric arc-shaped slot casing treatment on partial surge initiated instability in a transonic axial flow. Aerosp. Sci. Technol. 2017, 69, 257–268. [Google Scholar] [CrossRef]

- Taburri, M.; Chiara, F.; Canova, M.; Wang, Y.Y. A model-based methodology to predict the compressor behaviour for the simulation of turbocharged engines. Proc. Inst. Mech. Eng. Part D 2012, 226, 560–574. [Google Scholar] [CrossRef]

- Niazmand, A.; Farzaneh-Gord, M.; Deymi-Dashtebayaz, M. Exergy analysis and entropy generation of a reciprocating compressor applied in CNG stations carried out on the basis models of ideal and real gas. Appl. Therm. Eng. 2017, 124, 1279–1291. [Google Scholar] [CrossRef]

- Alshammari, F.; Elashmawy, M.; Ben Hamida, M.B. Effects of working fluid type on powertrain performance and turbine design using experimental data of a 7.25L heavy-duty diesel engine. Energy Convers. Manag. 2021, 231, 113828. [Google Scholar] [CrossRef]

| Parameter | Profile | Parameter | Profile |

|---|---|---|---|

| Inlet diameter of compressor impeller/mm | 32.1 | Inlet diameter of turbine impeller/mm | 37.6 |

| Outlet diameter of compressor impeller/mm | 44 | Outlet diameter of turbine impeller/mm | 33.1 |

| Number of compressor impeller blades | 8 | Number of turbine impeller blades | 11 |

| Height of diffuser/mm | 2.5 | Turbine impeller inlet blade angle/deg | 0 |

| Compressor pressure ratio | 2.2 | Turbine impeller inlet blade height/mm | 5.1 |

| Radial and axial tip clearance/mm | 0.5 | Turbine impeller axial length/mm | 18.9 |

| Volute nozzle width/mm | 5.0 | Turbine impeller exit mean blade angle/deg | 56.4 |

| Engine capacity/L | 1.5 | Turbine flow range/(kg/s) | 0.02–0.13 |

| Parameter | Profile |

|---|---|

| Computer | Workstation |

| Operation system | Windows |

| RAM | 48 GB |

| Number of Cores | 24 |

| Fluid Domain | Mesh Type | Element Number |

|---|---|---|

| Inlet duct | Structured mesh | 71,995 |

| Impeller single-blade channel | Structured mesh | 239,868 |

| Wheel back clearance | Unstructured mesh | 334,446 |

| Diffuser | Unstructured mesh | 406,381 |

| Separate compressor volute | Unstructured mesh | 515,346 |

| Outlet transition | Structured mesh | 110,449 |

| Total elements | 3,357,561 |

| Fluid Domain | Mesh Type | Element Number |

|---|---|---|

| Inlet duct | Structured mesh | 73,219 |

| Separate Turbine Volute | Unstructured mesh | 620,189 |

| Impeller single-blade channel | Structured mesh | 203,038 |

| Wheel back clearance | Unstructured mesh | 242,283 |

| Outlet transition | Unstructured mesh | 527,878 |

| Outlet duct | Structured mesh | 169,575 |

| Total elements | 3,866,562 |

| Pressure Ratio | Efficiency/% | Power Consumption/kW | |

|---|---|---|---|

| Steady flow | 1.83 | 64.38 | 3.87 |

| Unsteady flow | 1.91 | 67.40 | 4.08 |

| Degree of deviation/% | 4.4 | 4.7 | 5.4 |

| Structure | Steady Efficiency/% | Steady Power Consumption /kW | Unsteady Efficiency/% | Unsteady Power Consumption/kW | Degree of Deviation/% | Power Consumption Coefficient |

|---|---|---|---|---|---|---|

| Original compressor | 64.38 | 3.87 | 67.40 | 4.08 | 5.4 | 1.054 |

| Optimized compressor | 65.10 | 3.75 | 68.25 | 4.04 | 7.7 | 1.077 |

| Structure | 110,000 rpm | 130,000 rpm | 150,000 rpm | 170,000 rpm | 190,000 rpm |

|---|---|---|---|---|---|

| Original compressor | 1.042 | 1.049 | 1.054 | 1.042 | 1.028 |

| Optimized compressor | 1.047 | 1.063 | 1.077 | 1.068 | 1.058 |

| Structure | 110,000 rpm | 130,000 rpm | 150,000 rpm | 170,000 rpm | 190,000 rpm |

|---|---|---|---|---|---|

| Original turbine | 1.518 | 1.331 | 1.143 | 1.087 | 1.030 |

| Optimized turbine | 1.790 | 1.563 | 1.335 | 1.284 | 1.232 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, S.; Ni, J.; Fan, H.; Shi, X.; Huang, R. Study on Correction Method of Internal Joint Operation Curve Based on Unsteady Flow. Appl. Sci. 2022, 12, 11943. https://doi.org/10.3390/app122311943

Yin S, Ni J, Fan H, Shi X, Huang R. Study on Correction Method of Internal Joint Operation Curve Based on Unsteady Flow. Applied Sciences. 2022; 12(23):11943. https://doi.org/10.3390/app122311943

Chicago/Turabian StyleYin, Sheng, Jimin Ni, Houchuan Fan, Xiuyong Shi, and Rong Huang. 2022. "Study on Correction Method of Internal Joint Operation Curve Based on Unsteady Flow" Applied Sciences 12, no. 23: 11943. https://doi.org/10.3390/app122311943