Experimental Investigation and Micromechanics-Based Analytical Modeling of Creep and Relaxation Behaviors of Beishan Granite

Abstract

:1. Introduction

2. Experimental Study

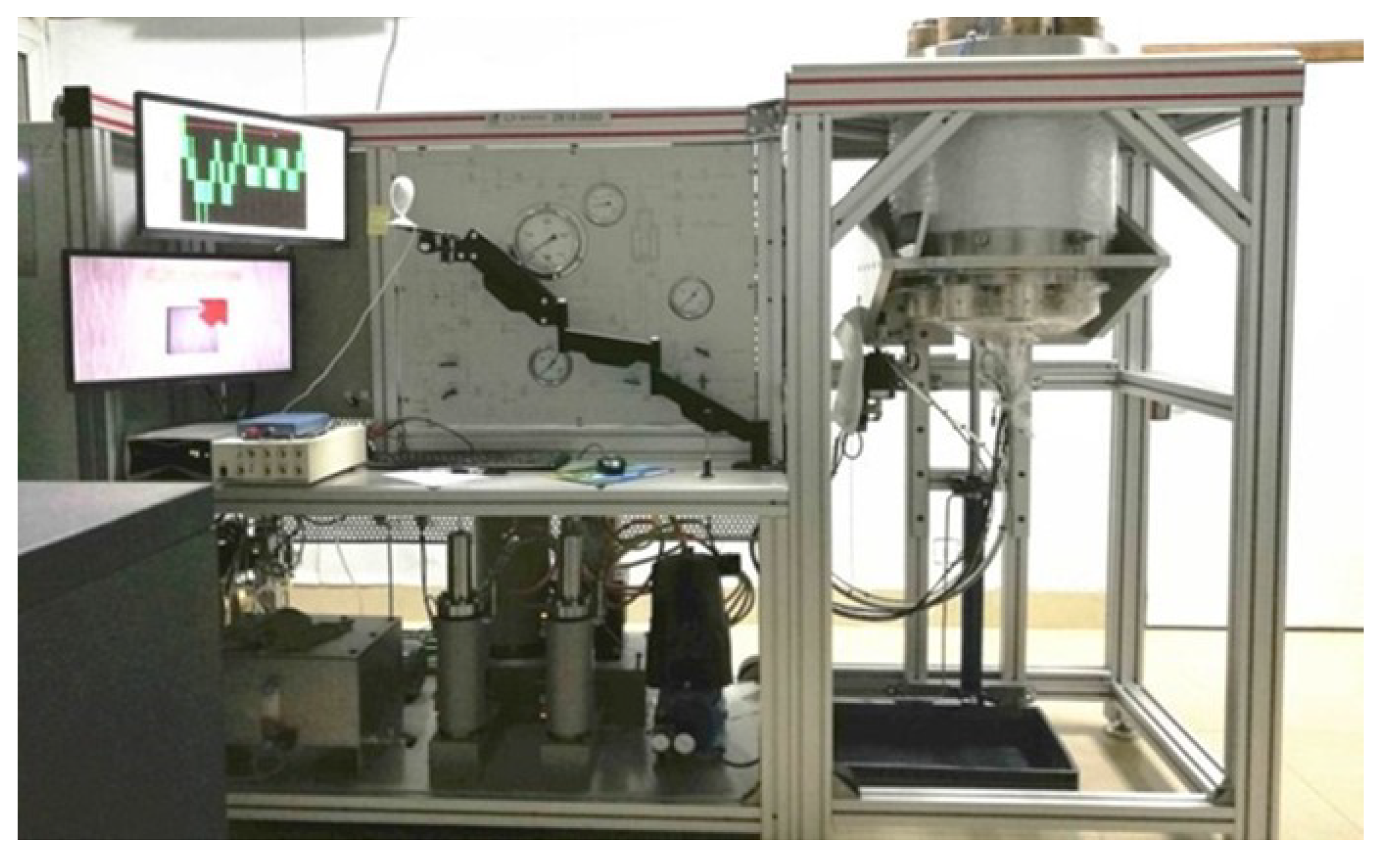

2.1. Sample Preparations and Testing Procedures

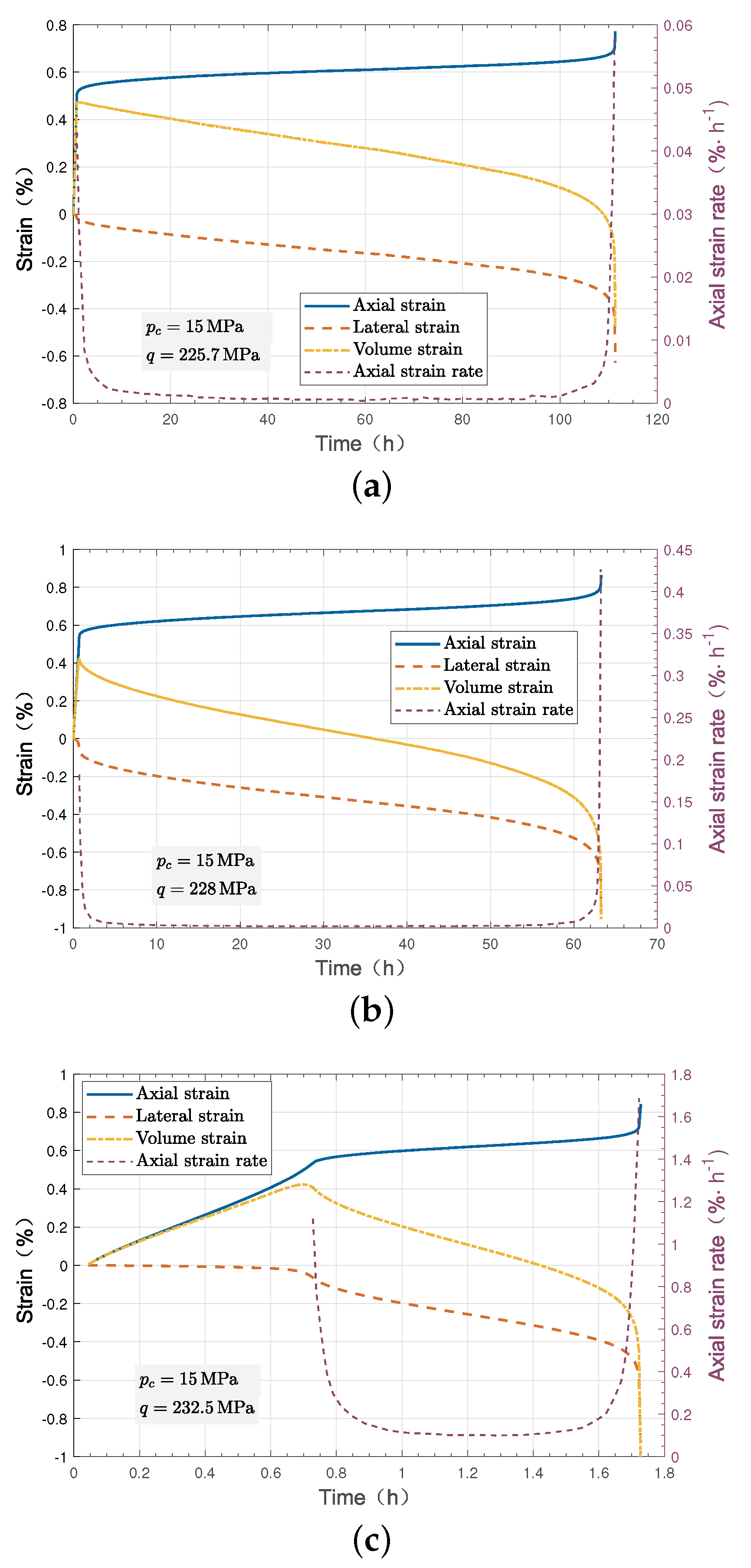

2.2. Experimental Results

3. Formulation of the Plastic Damage Model

3.1. Free Energy and State Equations

3.2. Plasticity Criterion and Damage Evolution

4. Analytical Prediction of Short- and Long-Term Strengths under Conventional Triaxial Compression

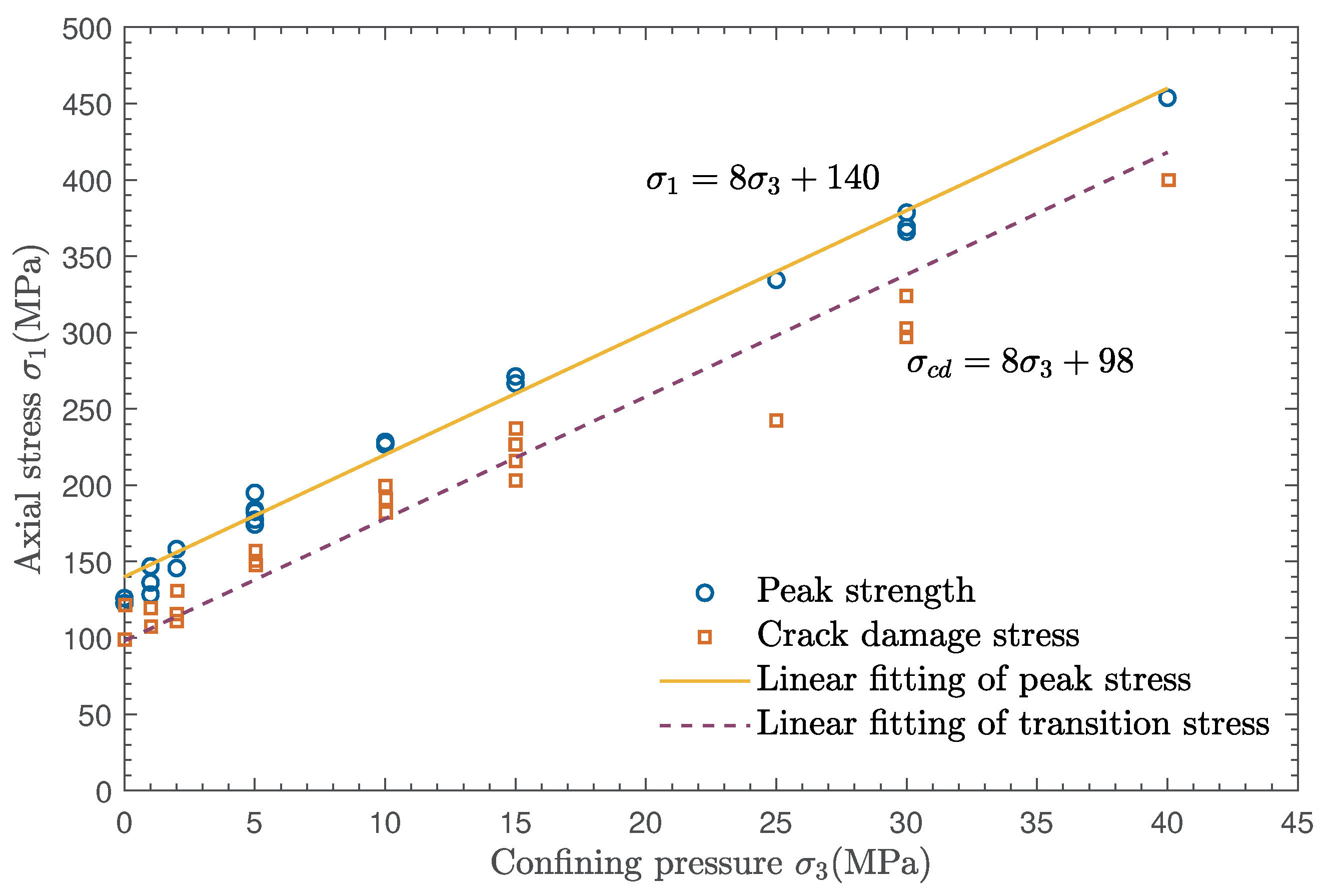

4.1. Short-Term Strength

4.2. Long-Term Strength

4.3. Computation Algorithm

- (1)

- Instantaneous stage: The following quantities are assumed to have been completely determined by giving a new damage increment for the loading step: , , .

- (2)

- Time-dependent stage: Combining the time-dependent damage criterion, the internal variable , , , can be updated by giving a new time increment for the loading step.

- (3)

- Time-dependent stage: We check and determine the accumulated plastic multipliers if plastic flow occurs.

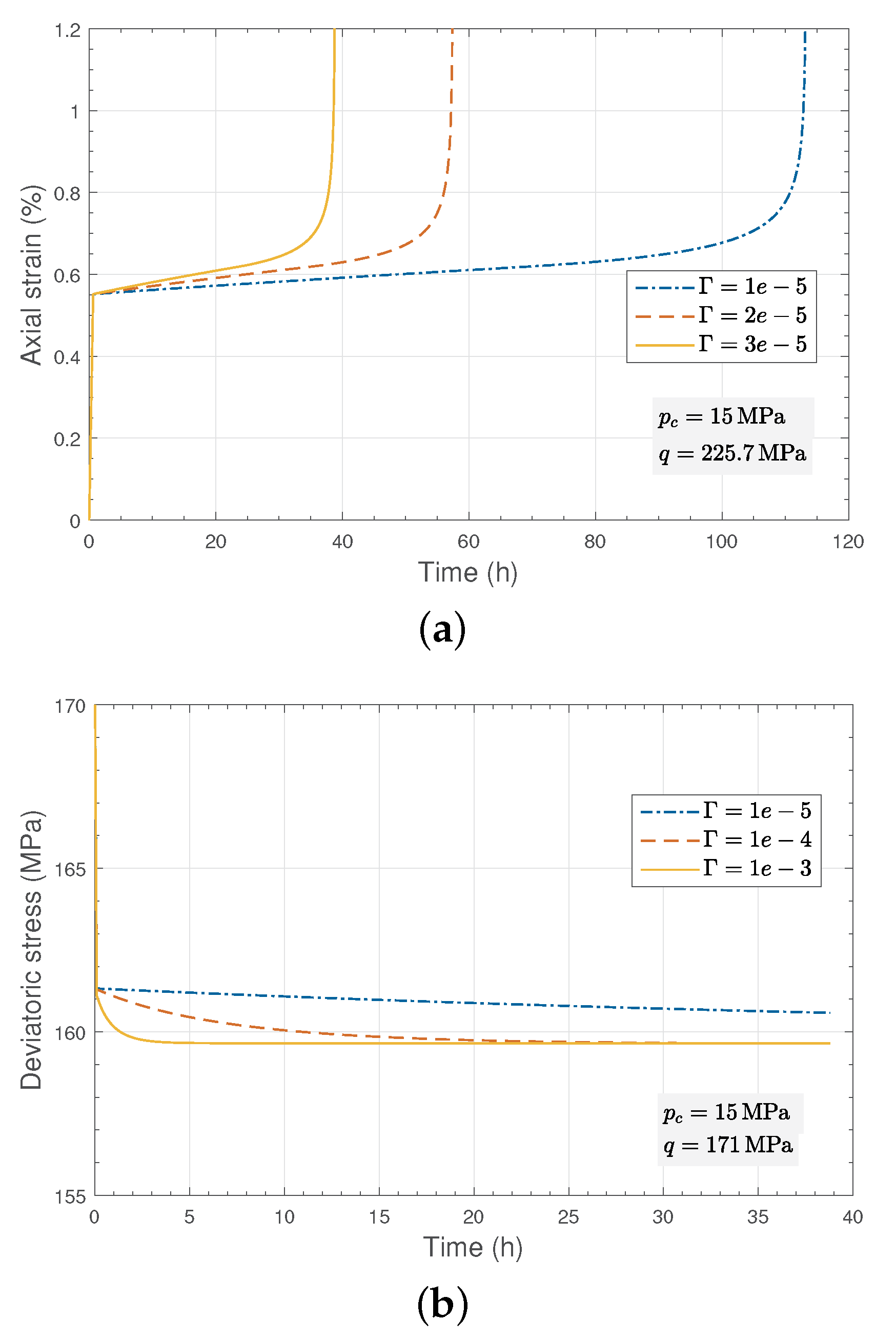

4.4. Analytical Prediction

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J. On area-specific underground research laboratory for geological disposal of high-level radioactive waste in China. J. Rock Mech. Geotech. Eng. 2014, 6, 99–104. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Zhao, Y.A.; Gao, M.; Huang, S.T.; Wang, J.; Wu, L.; Cai, H. Integrated Geo-information Database for Geological Disposal of High-Level Radioactive Waste in China. In Spatial Data Handling in Big Data Era; Springer: Berlin/Heidelberg, Germany, 2017; pp. 21–30. [Google Scholar]

- Zhao, X.; Cai, M.; Wang, J.; Ma, L. Damage stress and acoustic emission characteristics of the Beishan granite. Int. J. Rock Mech. Min. Sci. 2013, 64, 258–269. [Google Scholar] [CrossRef]

- Liu, J.; Chen, L.; Wang, C.; Man, K.; Wang, L.; Wang, J.; Su, R. Characterizing the mechanical tensile behavior of Beishan granite with different experimental methods. Int. J. Rock Mech. Min. Sci. 2014, 69, 50–58. [Google Scholar] [CrossRef]

- Benge, M.; Lu, Y.; Katende, A.; Rutqvist, J.; Crandall, D.; Haecker, A.; King, G.; Renk, J.B.; Radonjic, M.; Bunger, A. Connecting Geomechanical Properties with Potential for Proppant Embedment and Production Decline for the Emerging Caney Shale, Oklahoma. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, TX, USA, 28 July 2021. [Google Scholar]

- Benge, M.; Lu, Y.; Jones, J.; Bunger, A.; Haecker, A.; Rihn, A.; Crandall, D.; Luo, G.; Radonjic, M. Mechanical Properties of Nominally Ductile and Brittle Zones Within the Caney Shale Formation. In Proceedings of the 55th US Rock Mechanics/Geomechanics Symposium, Online, 18–25 June 2021. [Google Scholar]

- Massion, C.; Lu, Y.; Crandall, D.; Bunger, A.; Radonjic, M. Graphene nanoplatelets reinforced cement as a solution to leaky wellbores reinforcing weak points in hydrated Portland cement with graphene nanoparticles improves mechanical and chemical durability of wellbore cements. Cem. Concr. Compos. 2022, 133, 104726. [Google Scholar] [CrossRef]

- Lu, Y.; Cha, M. Thermally induced fracturing in hot dry rock environments-Laboratory studies. Geothermics 2022, 106, 102569. [Google Scholar] [CrossRef]

- Wang, Q.; Xin, Z.; Jiang, B.; Sun, H.; Xiao, Y.; Bian, W.; Li, L. Comparative experimental study on mechanical mechanism of combined arches in large section tunnels. Tunn. Undergr. Space Technol. 2020, 99, 103386. [Google Scholar] [CrossRef]

- Li, J.; Deng, S.; Wang, M.; Huang, H. Weak disturbance-triggered seismic events: An experimental and numerical investigation. Bull. Eng. Geol. Environ. 2019, 78, 2943–2955. [Google Scholar] [CrossRef]

- Brantut, N.; Heap, M.J.; Meredith, P.G.; Baud, P. Time-dependent cracking and brittle creep in crustal rocks: A review. J. Struct. Geol. 2013, 52, 17–43. [Google Scholar] [CrossRef]

- Higgins, J.; Lu, Y.; Benge, M.; Gunaydin, D.; Bunger, A.; Kelley, M. Triaxial Deformation Rate Analysis for Stress Estimation in the Sedimentary and Basement Rocks from the FutureGen Carbon Sequestration Project. In Proceedings of the 56th US Rock Mechanics/Geomechanics Symposium, Santa Fe, NM, USA, 26 June 2022. [Google Scholar]

- Haupt, M. A constitutive law for rock salt based on creep and relaxation tests. Rock Mech. Rock Eng. 1991, 24, 179–206. [Google Scholar] [CrossRef]

- Yang, S.Q.; Jing, H.W.; Cheng, L. Influences of pore pressure on short-term and creep mechanical behavior of red sandstone. Eng. Geol. 2014, 179, 10–23. [Google Scholar] [CrossRef]

- Heap, M.; Baud, P.; Meredith, P.; Bell, A.; Main, I. Time-dependent brittle creep in Darley Dale sandstone. J. Geophys. Res. Solid Earth 2009, 114. [Google Scholar] [CrossRef] [Green Version]

- Paraskevopoulou, C.; Perras, M.; Diederichs, M.; Amann, F.; Löw, S.; Lam, T.; Jensen, M. The three stages of stress relaxation-Observations for the time-dependent behaviour of brittle rocks based on laboratory testing. Eng. Geol. 2017, 216, 56–75. [Google Scholar] [CrossRef]

- Jiang, Q.; Wang, B.; Feng, X.T.; Fan, Q.X.; Wang, Z.; Pei, S.; Jiang, S. In situ failure investigation and time-dependent damage test for columnar jointed basalt at the Baihetan left dam foundation. Bull. Eng. Geol. Environ. 2019, 78, 3875–3890. [Google Scholar] [CrossRef]

- Szczepanik, Z.; Milne, D.; Kostakis, K.; Eberhardt, E. Long term laboratory strength tests in hard rock. In Proceedings of the 10th ISRM Congress, Sandton, South Africa, 8–12 September 2003. [Google Scholar]

- Mishra, B.; Verma, P. Uniaxial and triaxial single and multistage creep tests on coal-measure shale rocks. Int. J. Coal Geol. 2015, 137, 55–65. [Google Scholar] [CrossRef]

- Liu, A.; Lin, W.; Jiang, J. Laboratory and constitutive analysis of relaxation tests for time-dependent properties of discontinuities. Constr. Build. Mater. 2019, 227, 116688. [Google Scholar] [CrossRef]

- Huang, P.; Zhang, J.; Spearing, A.S.; Chai, J.; Dong, C. Experimental study of the creep properties of coal considering initial damage. Int. J. Rock Mech. Min. Sci. 2021, 139, 104629. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, C.; Fei, X.; Jang, B.A.; Liu, D. Time-dependent behavior of rock joints considering asperity degradation. J. Struct. Geol. 2019, 121, 1–9. [Google Scholar] [CrossRef]

- Zhang, Q.; Luo, Z.; Zhao, C.; Jang, B.A.; Zhang, R. Modeling the cyclic relaxation behavior of the artificial discontinuity. Mech. Adv. Mater. Struct. 2021, 28, 111–117. [Google Scholar] [CrossRef]

- Yang, D.S.; Chen, L.F.; Yang, S.Q.; Chen, W.Z.; Wu, G.J. Experimental investigation of the creep and damage behavior of Linyi red sandstone. Int. J. Rock Mech. Min. Sci. 2014, 72, 164–172. [Google Scholar] [CrossRef]

- Hou, R.; Zhang, K.; Tao, J. Effects of initial damage on time-dependent behavior of sandstone in uniaxial compressive creep test. Arch. Min. Sci. 2019, 64, 687–707. [Google Scholar]

- Li, X.; Konietzky, H. Numerical simulation schemes for time-dependent crack growth in hard brittle rock. Acta Geotech. 2015, 10, 513–531. [Google Scholar] [CrossRef]

- Dascalu, C.; Francois, B.; Keita, O. A two-scale model for subcritical damage propagation. Int. J. Solids Struct. 2010, 47, 493–502. [Google Scholar] [CrossRef] [Green Version]

- Shao, J.F.; Chau, K.T.; Feng, X. Modeling of anisotropic damage and creep deformation in brittle rocks. Int. J. Rock Mech. Min. Sci. 2006, 43, 582–592. [Google Scholar] [CrossRef]

- Miura, K.; Okui, Y.; Horii, H. Micromechanics-based prediction of creep failure of hard rock for long-term safety of high-level radioactive waste disposal system. Mech. Mater. 2003, 35, 587–601. [Google Scholar] [CrossRef]

- Pietruszczak, S.; Lydzba, D.; Shao, J.F. Description of creep in inherently anisotropic frictional materials. J. Eng. Mech. 2004, 130, 681–690. [Google Scholar] [CrossRef]

- Shao, J.F.; Zhu, Q.Z.; Su, K. Modeling of creep in rock materials in terms of material degradation. Comput. Geotech. 2003, 30, 549–555. [Google Scholar] [CrossRef]

- Zhou, H.; Jia, Y.; Shao, J.F. A unified elastic–plastic and viscoplastic damage model for quasi-brittle rocks. Int. J. Rock Mech. Min. Sci. 2008, 45, 1237–1251. [Google Scholar] [CrossRef]

- Wang, J.; Chen, L.; Su, R.; Zhao, X. The Beishan underground research laboratory for geological disposal of high-level radioactive waste in China: Planning, site selection, site characterization and in situ tests. J. Rock Mech. Geotech. Eng. 2018, 10, 411–435. [Google Scholar] [CrossRef]

- Zoback, M.D.; Tsukahara, H.; Hickman, S. Stress measurements at depth in the vicinity of the San Andreas fault: Implications for the magnitude of shear stress at depth. J. Geophys. Res. Solid Earth 1980, 85, 6157–6173. [Google Scholar] [CrossRef] [Green Version]

- Singh, A.; Zoback, M.D. Predicting variations of the least principal stress with depth: Application to unconventional oil and gas reservoirs using a log-based viscoelastic stress relaxation model. Geophysics 2022, 87, MR105–MR116. [Google Scholar] [CrossRef]

- Snee, J.E.L.; Zoback, M.D. State of stress in areas of active unconventional oil and gas development in North America. AAPG Bull. 2022, 106, 355–385. [Google Scholar] [CrossRef]

- Zhao, L.Y.; Zhu, Q.Z.; Shao, J.F. A micro-mechanics based plastic damage model for quasi-brittle materials under a large range of compressive stress. Int. J. Plast. 2018, 100, 156–176. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, Q.; Zhu, Q. Experimental investigation and micromechanics-based damage modeling of the stress relaxation mechanical properties in gray sandstone. Comput. Geotech. 2022, 149, 104829. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhao, L.; Shao, J. Analytical and numerical analysis of frictional damage in quasi brittle materials. J. Mech. Phys. Solids 2016, 92, 137–163. [Google Scholar] [CrossRef]

- Zhu, Q.Z.; Kondo, D.; Shao, J. Micromechanical analysis of coupling between anisotropic damage and friction in quasi brittle materials: Role of the homogenization scheme. Int. J. Solids Struct. 2008, 45, 1385–1405. [Google Scholar] [CrossRef]

- Eshelby, J.D. The Determination of the Elastic Field of an Ellipsoidal Inclusion, and Related Problems. Proc. R. Soc. Lond. 1957, 241, 376–396. [Google Scholar]

- Mori, T.; Tanaka, K. Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 1973, 21, 571–574. [Google Scholar] [CrossRef]

- Benveniste, Y. On the Mori-Tanaka’s method in cracked bodies. Mech. Res. Commun. 1986, 13, 193–201. [Google Scholar] [CrossRef]

- Zhu, Q.; Shao, J. Micromechanics of rock damage: Advances in the quasi-brittle field. J. Rock Mech. Geotech. Eng. 2017, 9, 29–40. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhao, L.; HX, L.; Shao, J. Fast explicit integral algorithms with comparative studies for Shao-Zhu-Su rock rheological model. Chin. J. Rock Mech. Eng. 2016, 35, 242–249. (In Chinese) [Google Scholar]

- Martin, C.; Chandler, N. The progressive fracture of Lac du Bonnet granite. Proc. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1994, 31, 643–659. [Google Scholar] [CrossRef]

- Read, R.; Chandler, N.; Dzik, E. In situ strength criteria for tunnel design in highly-stressed rock masses. Int. J. Rock Mech. Min. Sci. 1998, 35, 261–278. [Google Scholar] [CrossRef]

- Yuan, S.S.; Zhu, Q.Z.; Zhao, L.Y.; Chen, L.; Shao, J.F.; Zhang, J. Micromechanical modelling of short-and long-term behavior of saturated quasi-brittle rocks. Mech. Mater. 2020, 142, 103298. [Google Scholar] [CrossRef]

- Yu, Q.J.; Zhu, Q.Z.; Chen, L.; Shao, J.F. Experimental investigation and semi-analytical simulation of instantaneous and time-dependent damage behaviors of Beishan granite. Rock Mech. Rock Eng. 2022, 55, 2341–2352. [Google Scholar] [CrossRef]

| Deviatoric Stress q | Stage | ||||

|---|---|---|---|---|---|

| 225.7 MPa | I | 1.0 | 2.1 | 4.3 | 2.1 |

| II | 6.9 | 1.8 | 7.1 | 2.0 | |

| III | 1.3 | 4.0 | 5.9 | 3.1 | |

| 228 MPa | I | 9.6 | 1.9 | 1.8 | 2.2 |

| II | 6.1 | 1.5 | 1.9 | 6.2 | |

| III | 1.2 | 3.7 | 4.3 | 2.1 | |

| 232.5 MPa | I | 8.6 | 1.1 | 1.1 | 1.4 |

| II | 3.5 | 9.7 | 1.0 | 2.8 | |

| III | 8.0 | 2.4 | 1.7 | 8.2 |

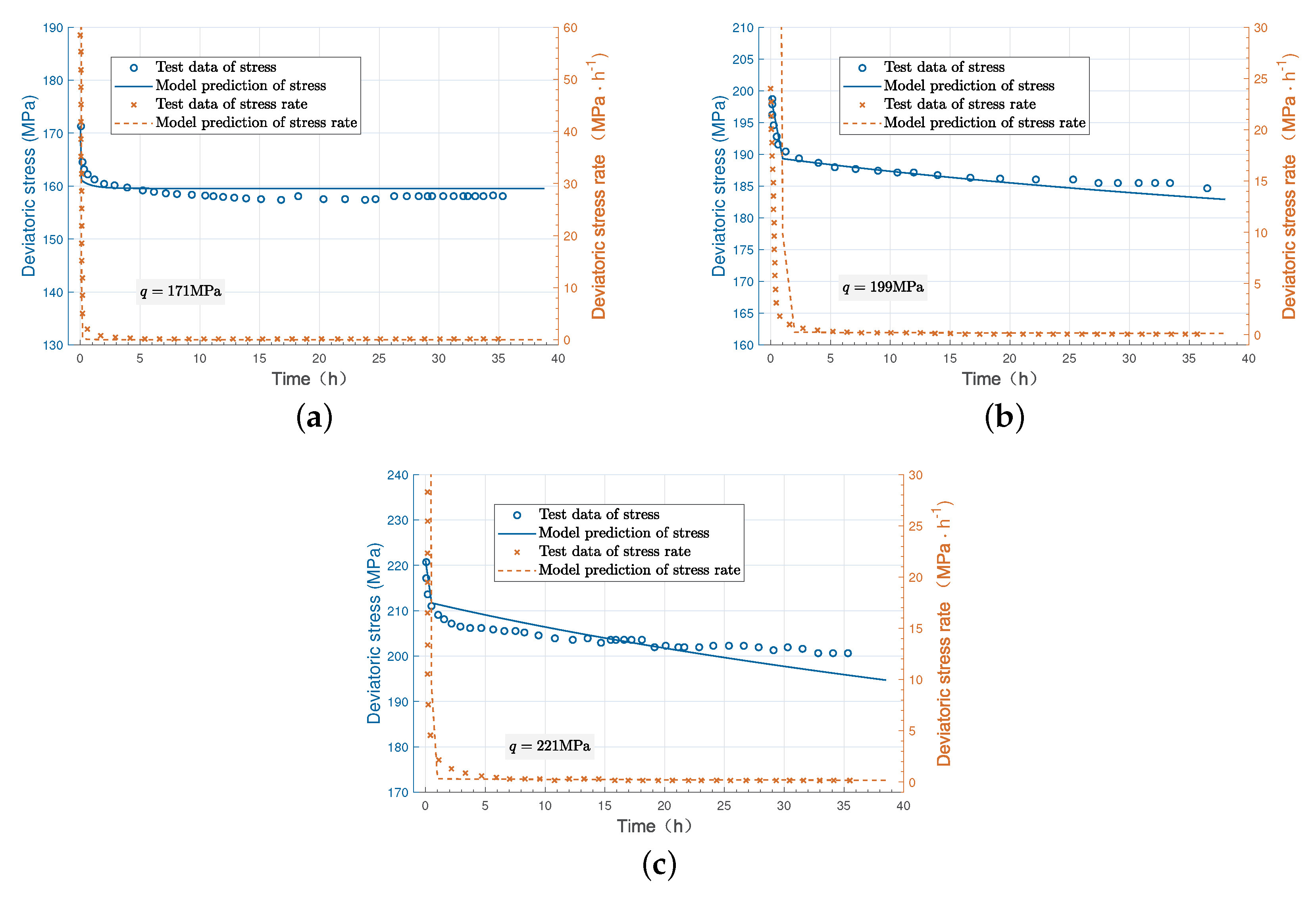

| q (MPa) | (MPa) | (MPa) | ||||

|---|---|---|---|---|---|---|

| 171 MPa | 3.984 | 158.1 | 0.061 | 0.075 | 80.4% | 0.013 |

| 199 MPa | 4.584 | 180 | 0.067 | 0.076 | 88.4% | 0.053 |

| 221 MPa | 5.381 | 202.6 | 0.079 | 0.083 | 94.6% | 0.051 |

| Parameters | (MPa) | C | ||||

|---|---|---|---|---|---|---|

| Values | 45,000 | 0.15 | 8 | 1.71 | 0.012 | 2.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Q.; Zhu, Q.; Lu, Y.; Luo, Z. Experimental Investigation and Micromechanics-Based Analytical Modeling of Creep and Relaxation Behaviors of Beishan Granite. Appl. Sci. 2022, 12, 12083. https://doi.org/10.3390/app122312083

Yu Q, Zhu Q, Lu Y, Luo Z. Experimental Investigation and Micromechanics-Based Analytical Modeling of Creep and Relaxation Behaviors of Beishan Granite. Applied Sciences. 2022; 12(23):12083. https://doi.org/10.3390/app122312083

Chicago/Turabian StyleYu, Qiaojuan, Qizhi Zhu, Yunxing Lu, and Zhanyou Luo. 2022. "Experimental Investigation and Micromechanics-Based Analytical Modeling of Creep and Relaxation Behaviors of Beishan Granite" Applied Sciences 12, no. 23: 12083. https://doi.org/10.3390/app122312083

APA StyleYu, Q., Zhu, Q., Lu, Y., & Luo, Z. (2022). Experimental Investigation and Micromechanics-Based Analytical Modeling of Creep and Relaxation Behaviors of Beishan Granite. Applied Sciences, 12(23), 12083. https://doi.org/10.3390/app122312083