Mechanical Models for Comparative Analysis of Failure Characteristics and Groundwater Inrush of Coal Seam Floors

Abstract

:1. Introduction

2. Theoretical Analysis

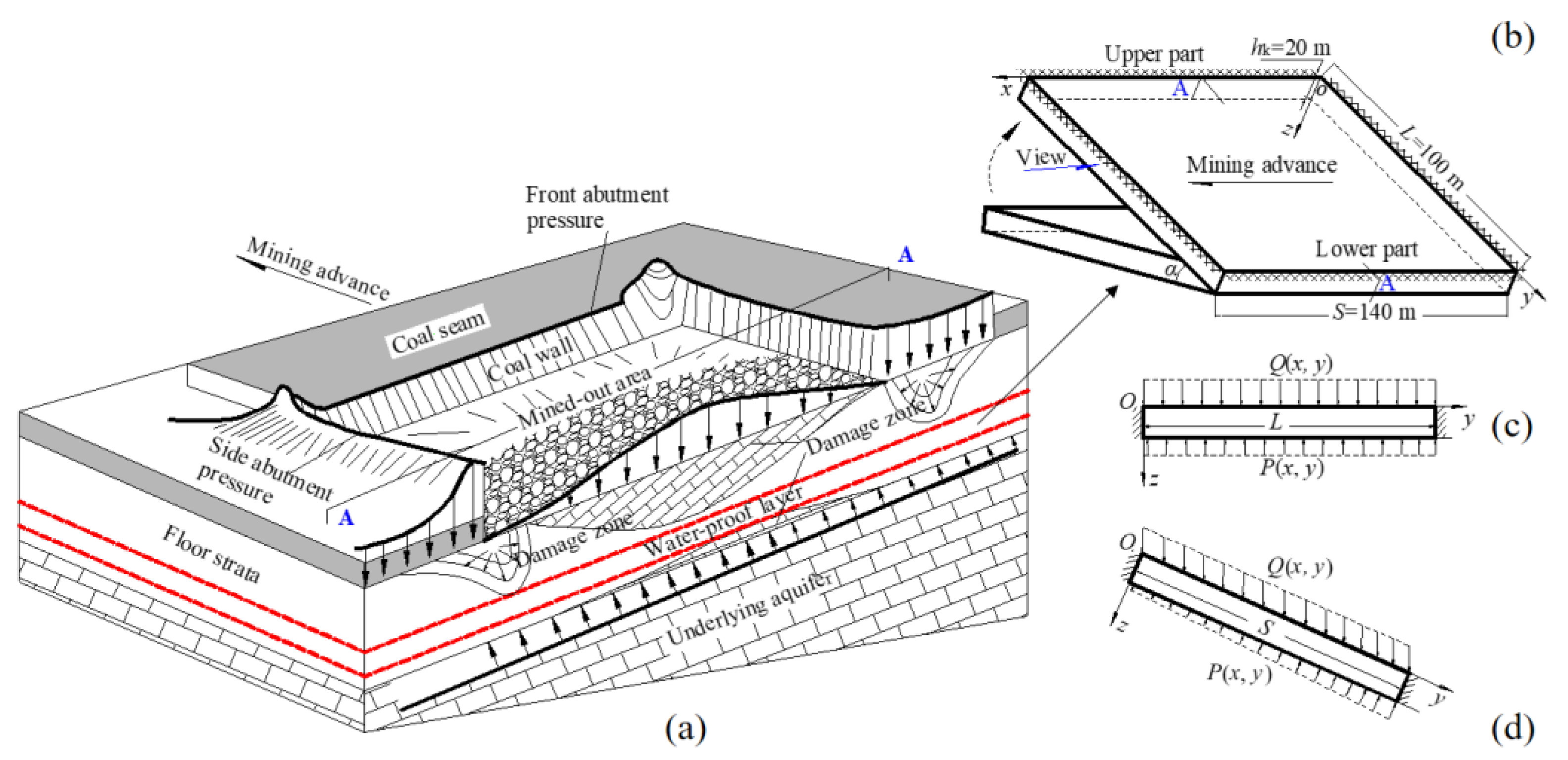

2.1. Hydraulic-Mechanical (HM) Model for Seam Floors

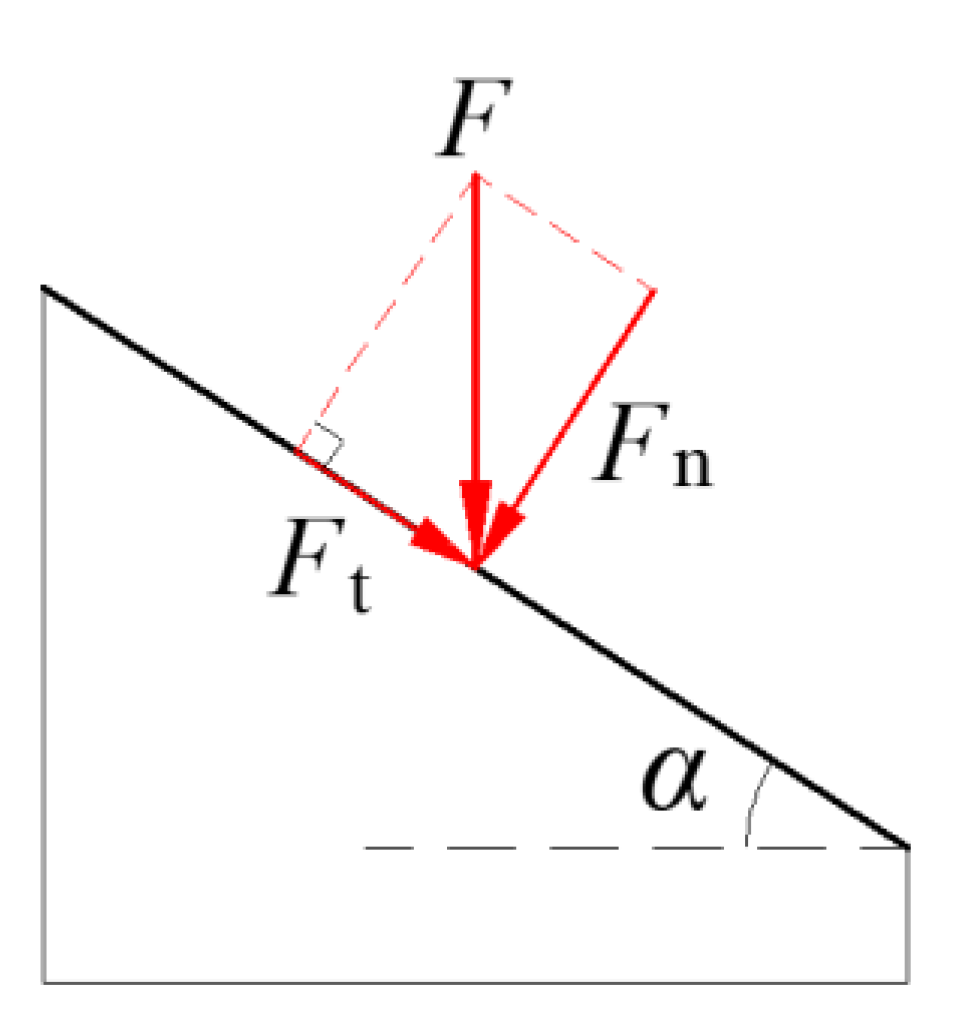

2.2. Analytical Model for Key Strata (KS)

3. Numerical Simulation

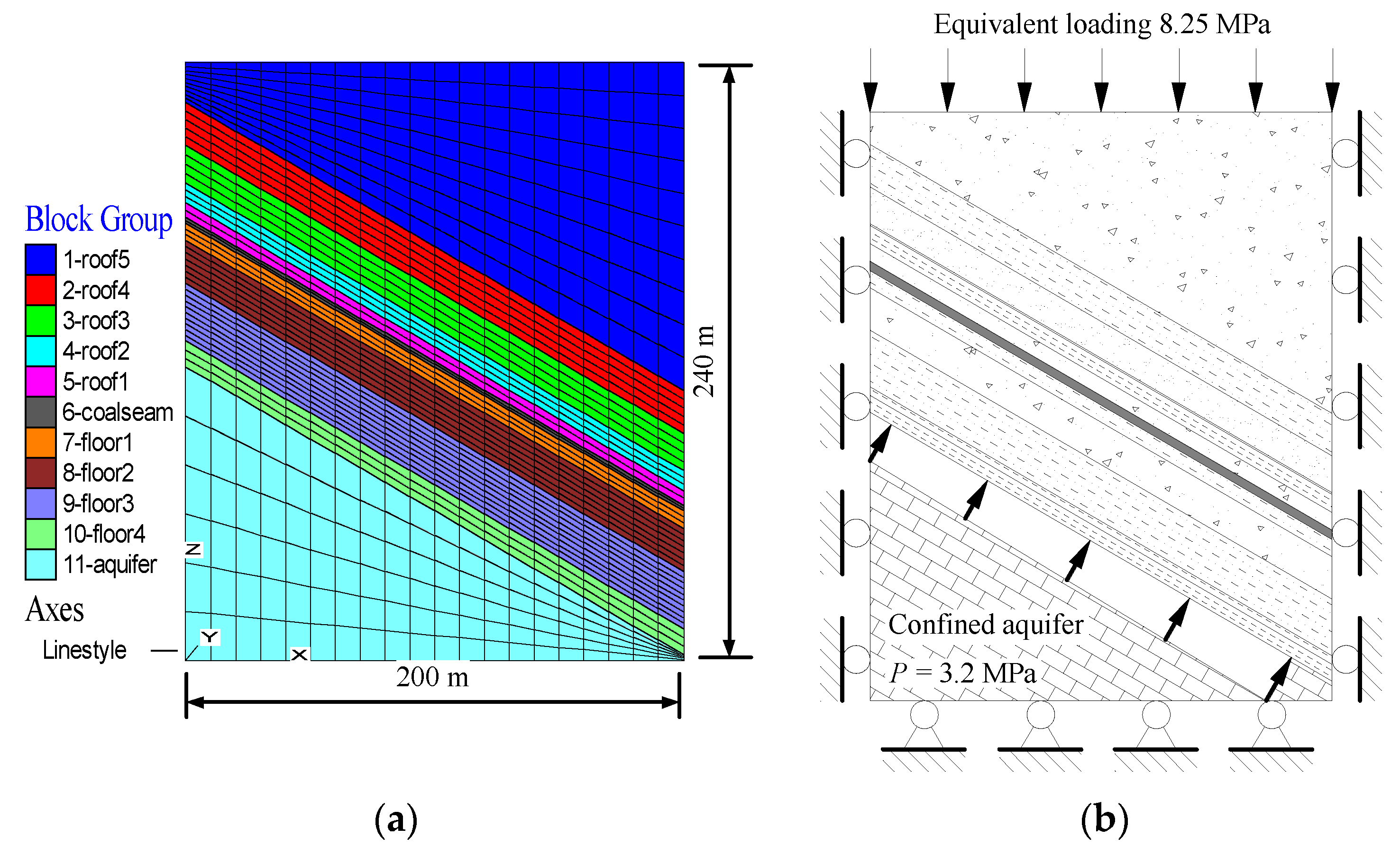

3.1. Modeling Descriptions

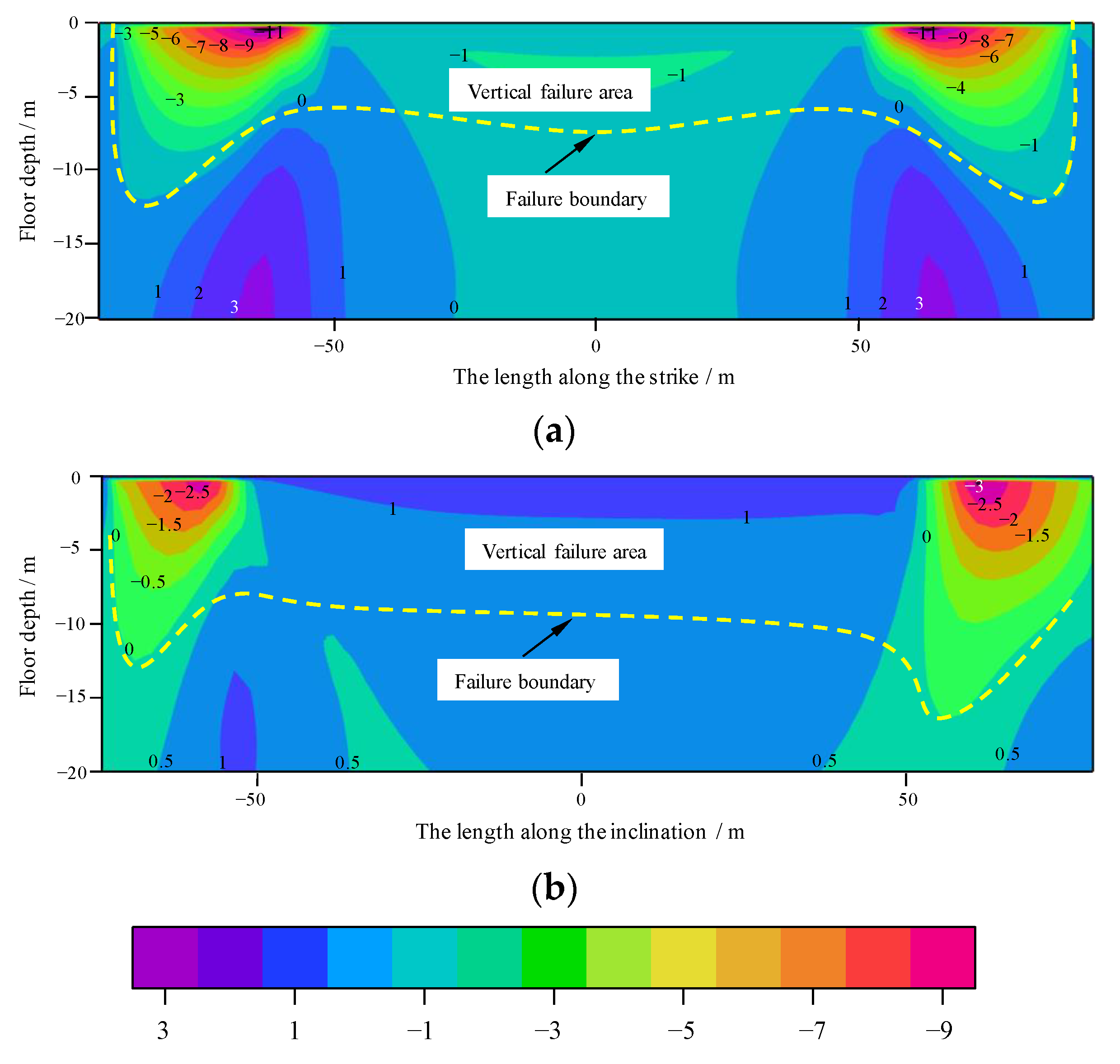

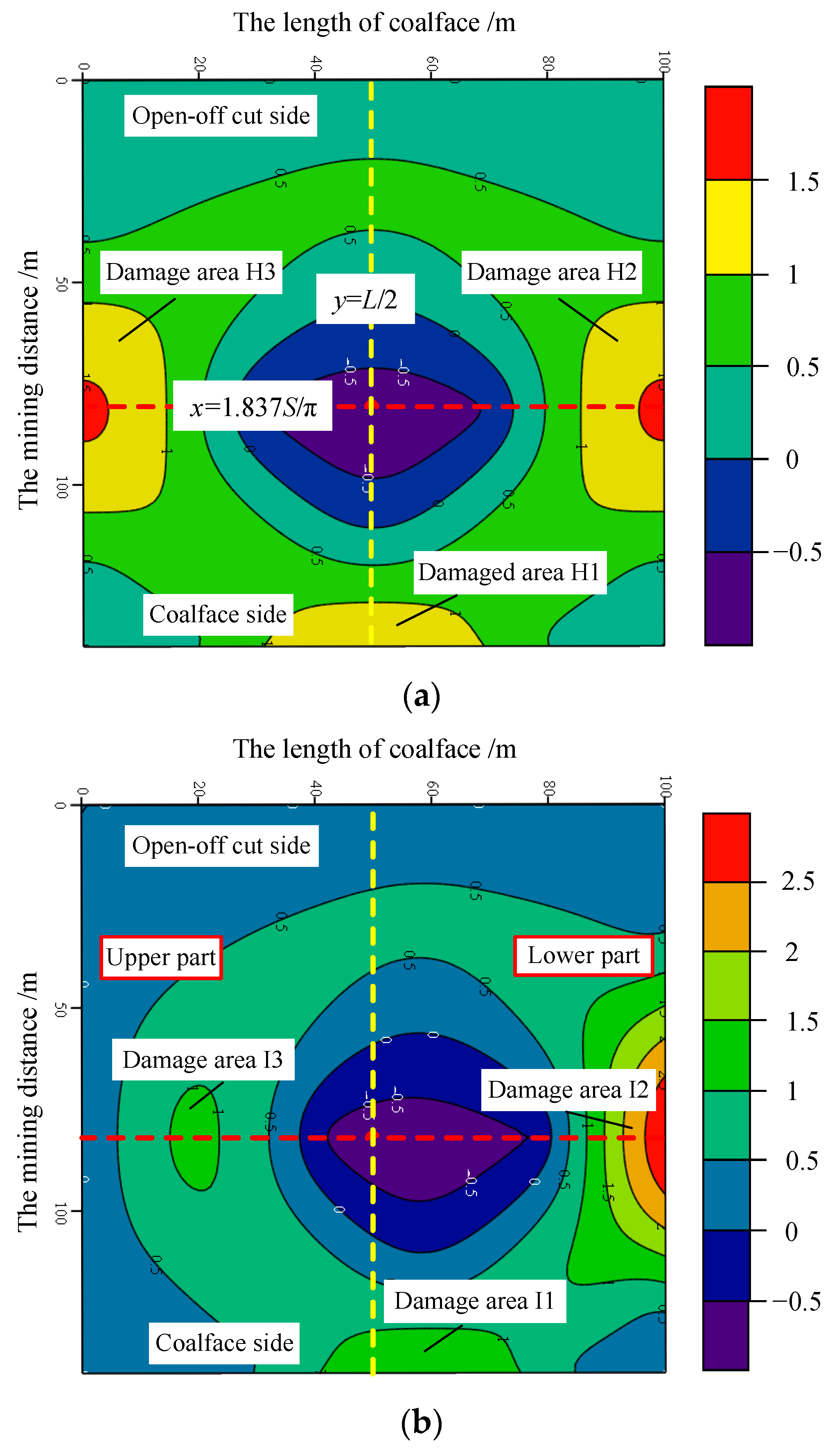

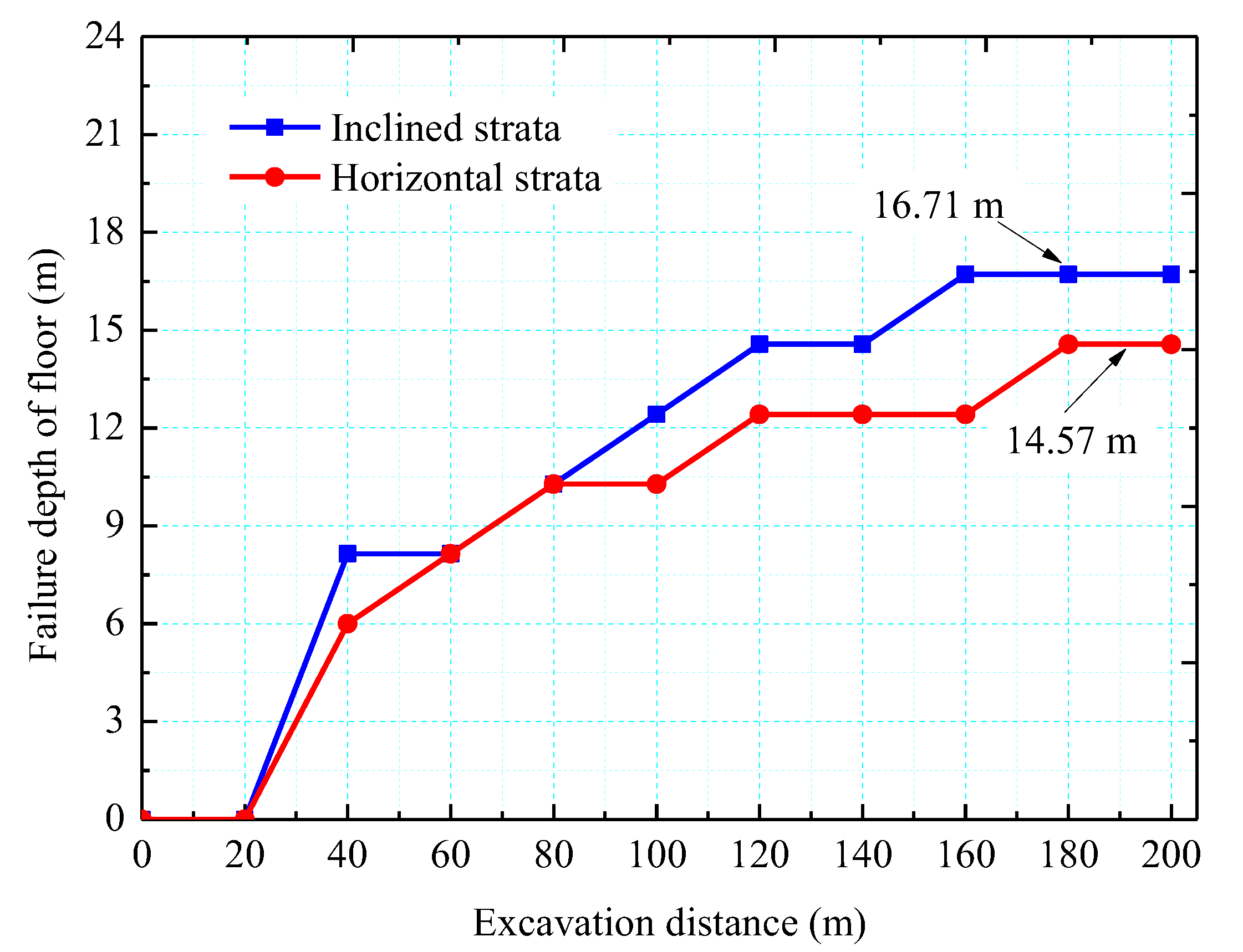

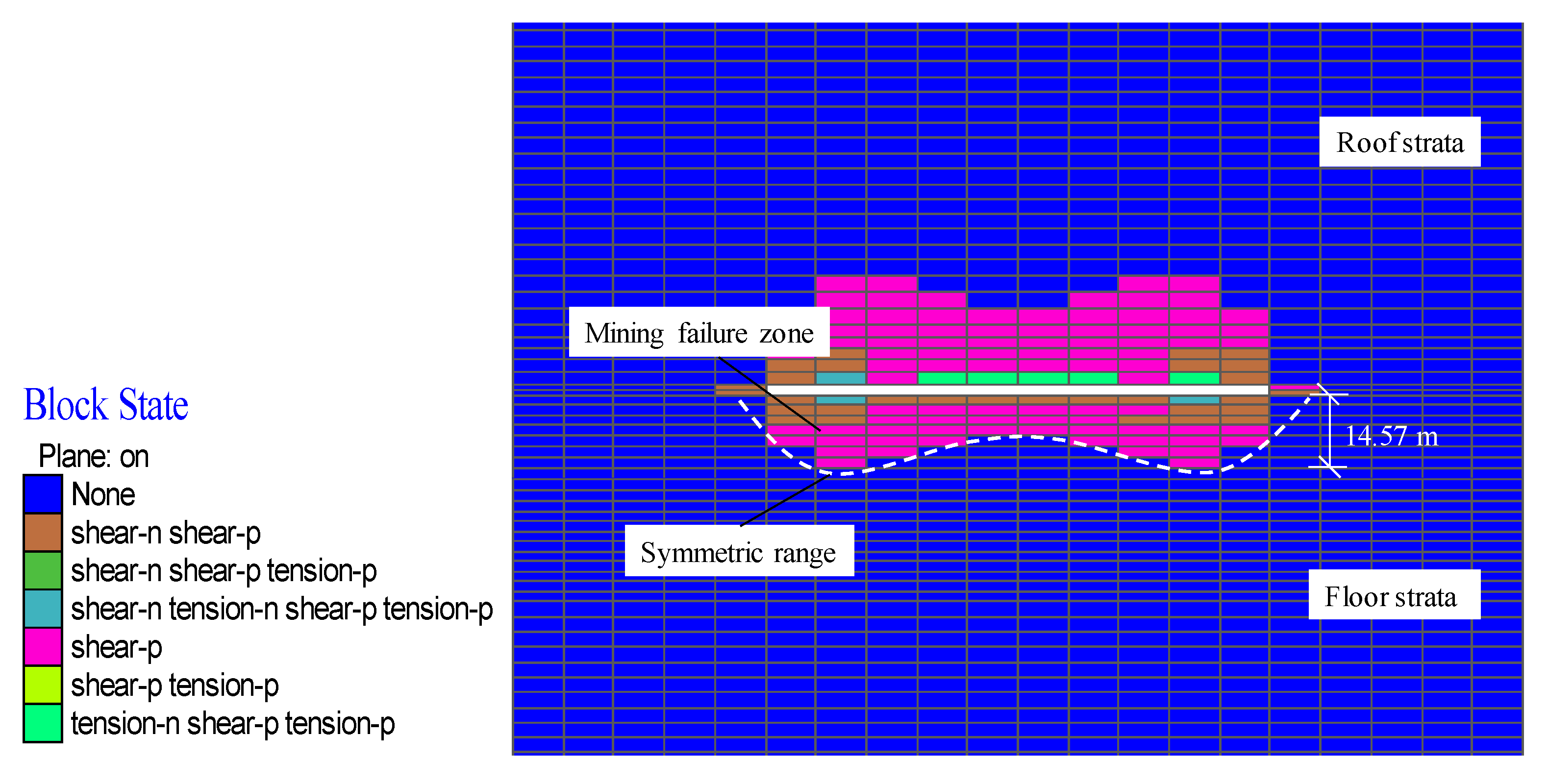

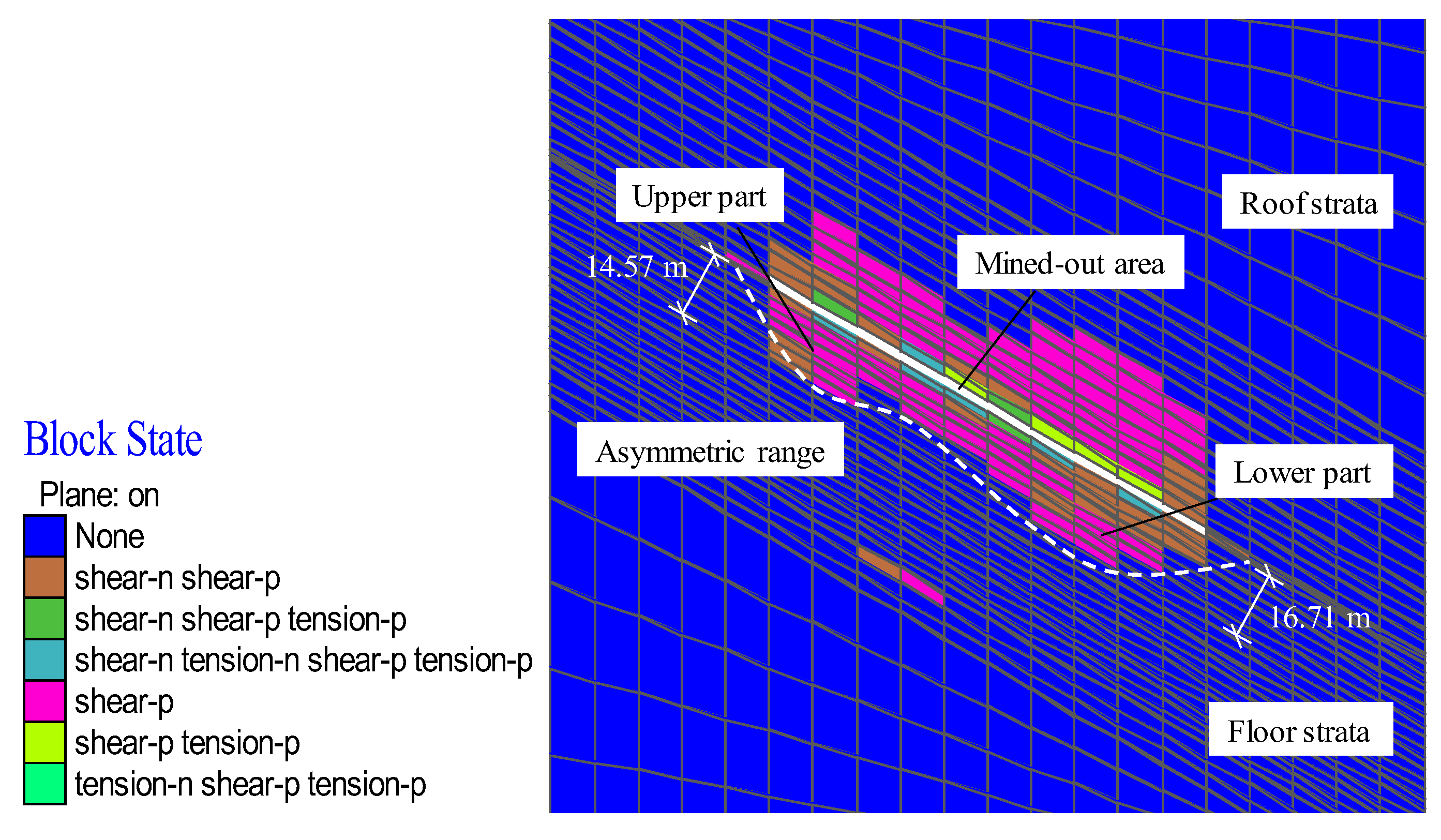

3.2. Numerical Simulation Results

4. Discussion and Conclusions

- (1)

- The results of theoretical calculation and numerical simulation exhibit good agreement regarding the ranges of vertical failure of the horizontal and inclined floors. The characteristic of the horizontal floor after coal mining conforms to an approximately “inverted saddle” shape, and shows geometric symmetry along the inclination. Compared with the horizontal floor, the damage zone at the lower end of the inclined stratum presents a wider and deeper range than the upper end.

- (2)

- The possibility of groundwater inrush through the sides of the goaf is relatively higher for both the horizontal and inclined seam floors, with their theoretical maximum failure depths roughly 12 m, 15 m (the upper part) and 12.5 m (the lower part). The distribution of the vertical failure ranges is generally consistent with water inrush zoning on the key strata. For example, the damage zones of the remaining waterproof layers, such as zones 1, 2 and 3, are dominantly concentrated near the model boundaries under the mined-out area. The ordering of these zones in terms of water-inrush risk from the horizontal and inclined impermeable layer is R(H2) = R(H3) > R(H1) and R(I2) > R(I1) > R(I3), respectively. Therefore, effective countermeasures such as goaf filling and floor grouting should be implemented within areas of high risk after coal excavation.

- (3)

- The proposed analytical models are beneficial to a comparative analysis of the failure modes and instability between horizontal and inclined floors. The representation of the fracturing process of the floor rock mass was limited. However, the presented mechanical models reveal the theoretical mechanism inducing the frequent occurrence of inrush disasters at the stope floor close to the rear goaf or the coal wall. Thus, the study results can provide some valuable references for assessing and managing water-related hazards in deep underground engineering.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bai, H.; Ma, D.; Chen, Z. Mechanical behavior of groundwater seepage in karst collapse pillars. Eng. Geol. 2013, 164, 101–106. [Google Scholar] [CrossRef]

- Farhadian, H.; Katibeh, H.; Huggenberger, P. Empirical model for estimating groundwater flow into tunnel in discontinuous rock masses. Environ. Earth Sci. 2016, 75, 471. [Google Scholar] [CrossRef]

- Ma, D.; Rezania, M.; Yu, H.; Bai, H. Variations of hydraulic properties of granular sandstones during water inrush: Effect of small particle migration. Eng. Geol. 2017, 217, 61–70. [Google Scholar] [CrossRef]

- Wu, Q.; Zhou, W. Prediction of groundwater inrush into coal mines from aquifers underlying the coal seams in China: Vulnerability index method and its construction. Environmental Geology 2008, 56, 245–254. [Google Scholar] [CrossRef]

- Zhang, G.; Jiao, Y.; Ma, C.; Wang, H.; Chen, L.; Tang, Z. Alteration characteristics of granite contact zone and treatment measures for inrush hazards during tunnel construction—A case study. Eng. Geol. 2018, 235, 64–80. [Google Scholar] [CrossRef]

- Huang, Z.; Jiang, Z.; Zhu, S.; Qian, Z.; Cao, D. Characterizing the hydraulic conductivity of rock formations between deep coal and aquifers using injection tests. Int. J. Rock Mech. Min. 2014, 71, 12–18. [Google Scholar] [CrossRef]

- Liu, H.; Li, L.; Li, Z.; Yu, G. Numerical Modelling of Mining-induced Inrushes from Subjacent Water Conducting Karst Collapse Columns in Northern China. Mine Water Environ. 2018, 37, 652–662. [Google Scholar] [CrossRef]

- Mao, D.; Liu, Z.; Wang, W.; Li, S.; Gao, Y.; Xu, Z.; Zhang, C. An application of hydraulic tomography to a deep coal mine: Combining traditional pumping tests with water inrush incidents. J. Hydrol. 2018, 567, 1–11. [Google Scholar] [CrossRef]

- Chen, H.; Qi, H.; Long, R.; Zhang, M. Research on 10-year tendency of China coal mine accidents and the characteristics of human factors. Safety Sci. 2012, 50, 745–750. [Google Scholar] [CrossRef]

- Lamoreaux, J.W.; Wu, Q.; Wanfang, Z. New development in theory and practice in mine water control in China. Carbonate Evaporite 2014, 29, 141–145. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Meng, F. Statistical analysis of large accidents in China’s coal mines in 2016. Nat. Hazards 2018, 92, 311–325. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, K.; Reniers, G.; You, G. Statistical analysis the characteristics of extraordinarily severe coal mine accidents (ESCMAs) in China from 1950 to 2018. Process Saf. Environ. 2020, 133, 332–340. [Google Scholar] [CrossRef]

- Miao, X.; Cui, X.; Wang, J.; Xu, J. The height of fractured water-conducting zone in undermined rock strata. Eng. Geol. 2011, 120, 32–39. [Google Scholar] [CrossRef]

- Meng, Z.; Shi, X.; Li, G. Deformation, failure and permeability of coal-bearing strata during longwall mining. Eng. Geol. 2016, 208, 69–80. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, L. Numerical simulation of mining-induced fracture evolution and water flow in coal seam floor above a confined aquifer. Comput. Geotech. 2015, 67, 157–171. [Google Scholar] [CrossRef]

- Yin, S.; Zhang, J.; Liu, D. A study of mine water inrushes by measurements of in situ stress and rock failures. Nat. Hazards 2015, 79, 1961–1979. [Google Scholar] [CrossRef]

- Zhao, J.; Feng, X.; Jiang, Q.; Zhou, Y. Microseismicity monitoring and failure mechanism analysis of rock masses with weak interlayer zone in underground intersecting chambers: A case study from the Baihetan Hydropower Station, China. Eng. Geol. 2018, 245, 44–60. [Google Scholar] [CrossRef]

- Wang, J.A.; Park, H.D. Fluid permeability of sedimentary rocks in a complete stress–strain process. Eng. Geol. 2002, 63, 291–300. [Google Scholar] [CrossRef]

- Wu, N.; Liang, Z.; Li, Y.; Qian, X.; Gong, B. Effect of confining stress on representative elementary volume of jointed rock masses. Geomech. Eng. 2019, 18, 627–638. [Google Scholar]

- Liang, Z.; Wu, N.; Li, Y.; Li, H.; Li, W. Numerical Study on Anisotropy of the Representative Elementary Volume of Strength and Deformability of Jointed Rock Masses. Rock Mech. Rock Eng. 2019, 52, 4387–4402. [Google Scholar] [CrossRef]

- Castelli, F.; Grasso, S.; Lentini, V.; Sammito, M.S.V. Effects of Soil-Foundation-Interaction on the Seismic Response of a Cooling Tower by 3D-FEM Analysis. Geosciences 2021, 11, 200. [Google Scholar] [CrossRef]

- Liang, Z.; Song, W.; Liu, W. Theoretical models for simulating the failure range and stability of inclined floor strata induced by mining and hydraulic pressure. Int. J. Rock Mech. Min. 2020, 132, 104382. [Google Scholar] [CrossRef]

- Zhu, S.; Jiang, Z.; Zhou, K.; Peng, G.; Yang, C. The characteristics of deformation and failure of coal seam floor due to mining in Xinmi coal field in China. B. Eng. Geol. Environ. 2014, 73, 1151–1163. [Google Scholar] [CrossRef]

- Zhang, J. Investigations of water inrushes from aquifers under coal seams. Int. J. Rock Mech. Min. 2005, 42, 350–360. [Google Scholar] [CrossRef]

- Huang, Z.; Li, X.; Li, S.; Zhao, K.; Zhang, R. Investigation of the hydraulic properties of deep fractured rocks around underground excavations using high-pressure injection tests. Eng. Geol. 2018, 245, 180–191. [Google Scholar] [CrossRef]

- Sun, W.B.; Xue, Y.C.; Yin, L.M.; Zhang, J.M. Experimental study on seepage characteristics of large size rock specimens under three-dimensional stress. Geomech. Eng. 2019, 18, 567–574. [Google Scholar]

- Yang, T.; Liu, H.Y.; Tang, C.A. Scale effect in macroscopic permeability of jointed rock mass using a coupled stress–damage–flow method. Eng. Geol. 2017, 228, 121–136. [Google Scholar] [CrossRef]

- Yu, C.; Tang, S.; Tang, C.; Duan, D.; Zhang, Y.; Liang, Z.; Ma, K.; Ma, T. The effect of water on the creep behavior of red sandstone. Eng. Geol. 2019, 253, 64–74. [Google Scholar] [CrossRef]

- Li, L.C.; Yang, T.H.; Liang, Z.Z.; Zhu, W.C.; Tang, C.A. Numerical investigation of groundwater outbursts near faults in underground coal mines. Int. J. Coal Geol. 2011, 85, 276–288. [Google Scholar]

- Yang, T.H.; Liu, J.; Zhu, W.C.; Elsworth, D.; Tham, L.G.; Tang, C.A. A coupled flow-stress-damage model for groundwater outbursts from an underlying aquifer into mining excavations. Int. J. Rock Mech. Min. 2007, 44, 87–97. [Google Scholar] [CrossRef]

- Sun, J.; Miao, X. Water-Isolating Capacity of an Inclined Coal Seam Floor Based on the Theory of Water-Resistant Key Strata. Mine Water Environ. 2017, 36, 310–322. [Google Scholar] [CrossRef]

- Wu, Q.; Liu, Y.; Liu, D.; Zhou, W. Prediction of Floor Water Inrush: The Application of GIS-Based AHP Vulnerable Index Method to Donghuantuo Coal Mine, China. Rock Mech. Rock Eng. 2011, 44, 591–600. [Google Scholar] [CrossRef]

- Wu, Q.; Zhao, D.; Wang, Y.; Shen, J.; Mu, W.; Liu, H. Method for assessing coal-floor water-inrush risk based on the variable-weight model and unascertained measure theory. Hydrogeol. J. 2017, 25, 2089–2103. [Google Scholar] [CrossRef]

- Li, W.; Liu, Y.; Qiao, W.; Zhao, C.; Yang, D.; Guo, Q. An Improved Vulnerability Assessment Model for Floor Water Bursting from a Confined Aquifer Based on the Water Inrush Coefficient Method. Mine Water Environ. 2018, 37, 196–204. [Google Scholar] [CrossRef]

- Meng, Z.; Li, G.; Xie, X. A geological assessment method of floor water inrush risk and its application. Eng. Geol. 2012, 143–144, 51–60. [Google Scholar] [CrossRef]

- Shi, L.; Qiu, M.; Wang, Y.; Qu, X.; Liu, T. Evaluation of water inrush from underlying aquifers by using a modified water-inrush coefficient model and water-inrush index model: A case study in Feicheng coalfield, China. Hydrogeol. J. 2019, 27, 2105–2119. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, W.; Li, M.; Liu, X. Risk assessment of floor water inrush in coal mines based on secondary fuzzy comprehensive evaluation. Int. J. Rock Mech. Min. 2012, 52, 50–55. [Google Scholar] [CrossRef]

- Zhao, D.; Wu, Q.; Cui, F.; Xu, H.; Zeng, Y.; Cao, Y.; Du, Y. Using random forest for the risk assessment of coal-floor water inrush in Panjiayao Coal Mine, northern China. Hydrogeol. J. 2018, 26, 2327–2340. [Google Scholar] [CrossRef]

- Xu, Z.L. Concise Tutorial on Elasticity; Higher Education Press: Beijing, China, 2002. [Google Scholar]

- Sun, J.; Wang, L.; Zhao, G. Failure Characteristics and Confined Permeability of an Inclined Coal Seam Floor in Fluid-Solid Coupling. Adv. Civ. Eng. 2018, 2018, 2356390. [Google Scholar] [CrossRef]

- Zhang, H.; Wan, Z.; Feng, Z.; Wu, J. Shear-induced permeability evolution of sandstone fractures. Geofluids 2018, 2018, 2416481. [Google Scholar] [CrossRef]

- Shen, M.R.; Chen, J.F. Mechanics of Rock Masses; Tongji University Publishing House: Shanghai, China, 2006. [Google Scholar]

- Sun, W.; Zhang, S.; Guo, W.; Liu, W. Physical Simulation of High-Pressure Water Inrush Through the Floor of a Deep Mine. Mine Water Environ. 2017, 36, 542–549. [Google Scholar] [CrossRef]

- Bukowski, P. Water Hazard Assessment in Active Shafts in Upper Silesian Coal Basin Mines. Mine Water Environ. 2011, 30, 302–311. [Google Scholar] [CrossRef]

- Qian, Z.; Huang, Z.; Song, J. A case study of water inrush incident through fault zone in China and the corresponding treatment measures. Arab. J. Geosci. 2018, 11, 381. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, T.; Zhang, P.; Xu, T.; Wei, J. Formation process and mechanism of seepage channels around grout curtain from microseismic monitoring: A case study of Zhangmatun iron mine, China. Eng. Geol. 2017, 226, 301–315. [Google Scholar] [CrossRef]

- Sainoki, A.; Mitri, H.S. Dynamic behaviour of mining-induced fault slip. Int. J. Rock Mech. Min. 2014, 66, 19–29. [Google Scholar] [CrossRef]

- Sun, J.; Wang, L.G.; Tang, F.R.; Shen, Y.F.; Gong, S.L. Microseismic monitoring failure characteristics of inclined coal seam floor. Rock Soil Mech. 2011, 32, 1589–1595. [Google Scholar]

| No. | γ/(g·cm−3) | G/(MPa) | K/(MPa) | c/(MPa) | φ/(°) | σt/(MPa) | n | k/(m2·(Pa·s)−1) |

|---|---|---|---|---|---|---|---|---|

| Roof 5 | 2.5 | 3.6 × 103 | 4.2 × 103 | 4.5 | 33 | 3.7 | 0.3 | 3 × 10−15 |

| Roof 4 | 2.7 | 2.8 × 103 | 4.5 × 103 | 5.2 | 32 | 3.6 | 0.4 | 5 × 10−14 |

| Roof 3 | 2.6 | 4.3 × 103 | 4.1 × 103 | 5.8 | 32 | 4.2 | 0.3 | 3 × 10−14 |

| Roof 2 | 2.6 | 2.0 × 103 | 3.0 × 103 | 3.2 | 31 | 2.8 | 0.2 | 4 × 10−16 |

| Roof 1 | 2.5 | 3.6 × 103 | 4.2 × 103 | 4.5 | 33 | 3.7 | 0.3 | 3 × 10−15 |

| Coal seam | 1.4 | 0.6 × 103 | 1.3 × 103 | 2.3 | 20 | 1.6 | 0.5 | 3 × 10−13 |

| Floor 1 | 2.7 | 2.8 × 103 | 4.5 × 103 | 5.2 | 32 | 3.6 | 0.4 | 5 × 10−14 |

| Floor 2 | 2.5 | 3.6 × 103 | 4.2 × 103 | 4.5 | 33 | 3.7 | 0.3 | 3 × 10−15 |

| Floor 3 | 2.7 | 2.8 × 103 | 4.5 × 103 | 5.2 | 32 | 3.6 | 0.4 | 5 × 10−14 |

| Floor 4 | 2.6 | 2.0 × 103 | 3.0 × 103 | 3.2 | 31 | 2.8 | 0.2 | 4 × 10−16 |

| Aquifer | 2.5 | 1.6 × 103 | 2.3 × 103 | 2.0 | 30 | 2.2 | 0.7 | 8 × 10−7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, C.; Song, W. Mechanical Models for Comparative Analysis of Failure Characteristics and Groundwater Inrush of Coal Seam Floors. Appl. Sci. 2022, 12, 12164. https://doi.org/10.3390/app122312164

Zhao C, Song W. Mechanical Models for Comparative Analysis of Failure Characteristics and Groundwater Inrush of Coal Seam Floors. Applied Sciences. 2022; 12(23):12164. https://doi.org/10.3390/app122312164

Chicago/Turabian StyleZhao, Chunbo, and Wencheng Song. 2022. "Mechanical Models for Comparative Analysis of Failure Characteristics and Groundwater Inrush of Coal Seam Floors" Applied Sciences 12, no. 23: 12164. https://doi.org/10.3390/app122312164