Studies of the Cracking Behaviour of High-Pressure Laminates

Abstract

:1. Introduction

- The dimensional movement of the carrier board does not match the dimensional movement of the laminate (also mentioned by [16]).

- Cutouts with a too-low radius and too-small drill diameter for fittings/screws.

- Overly wide spans without a sturdy framework.

- Non-uniform glue lines and foreign bodies in the glue line.

- Lack of acclimatization of laminate and substrate before assembly.

2. Materials and Methods

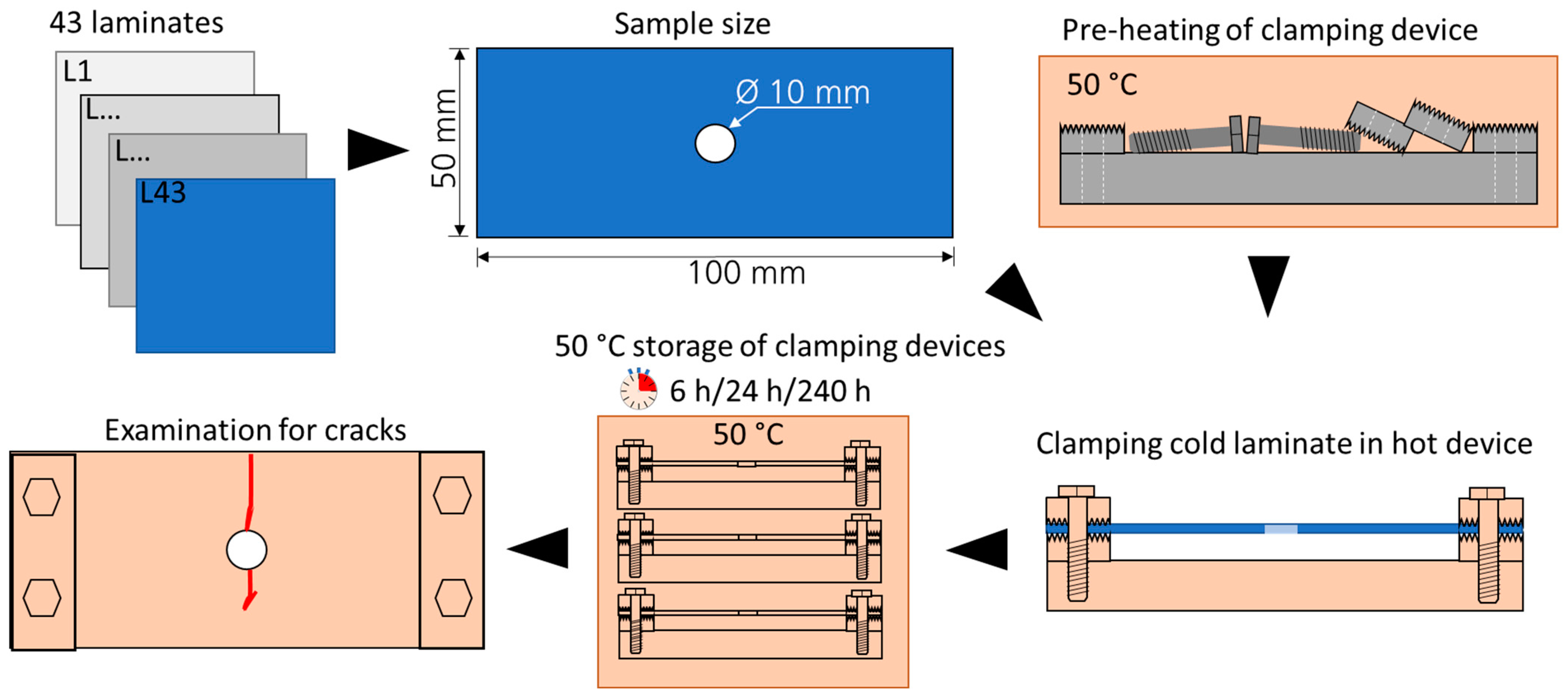

- Resistance to cracking under stress (EN 438-2 (23)): Laminates were clamped in a metal device that had been heated to 50 °C. After 6 h storage at 50 °C, the samples were removed from the oven and the clamps and rated for cracking. Diverging from the standard, the number of replicas for the 6 h testing time was increased from one to three. Additionally, the test was repeated for a prolonged time in the oven (24 and 240 h). These prolonged tests were made with a single sample per time interval.

- Tensile strength at 50 °C: This test was created to simulate the conditions of resistance to the cracking test (EN 438-2(23)). Five samples in accordance with the standard (including the drill hole) were stored at 50 °C for 6 h. Subsequently, the tensile strength was determined with a speed of 0.1 mm/min within a climate chamber at 50 °C.

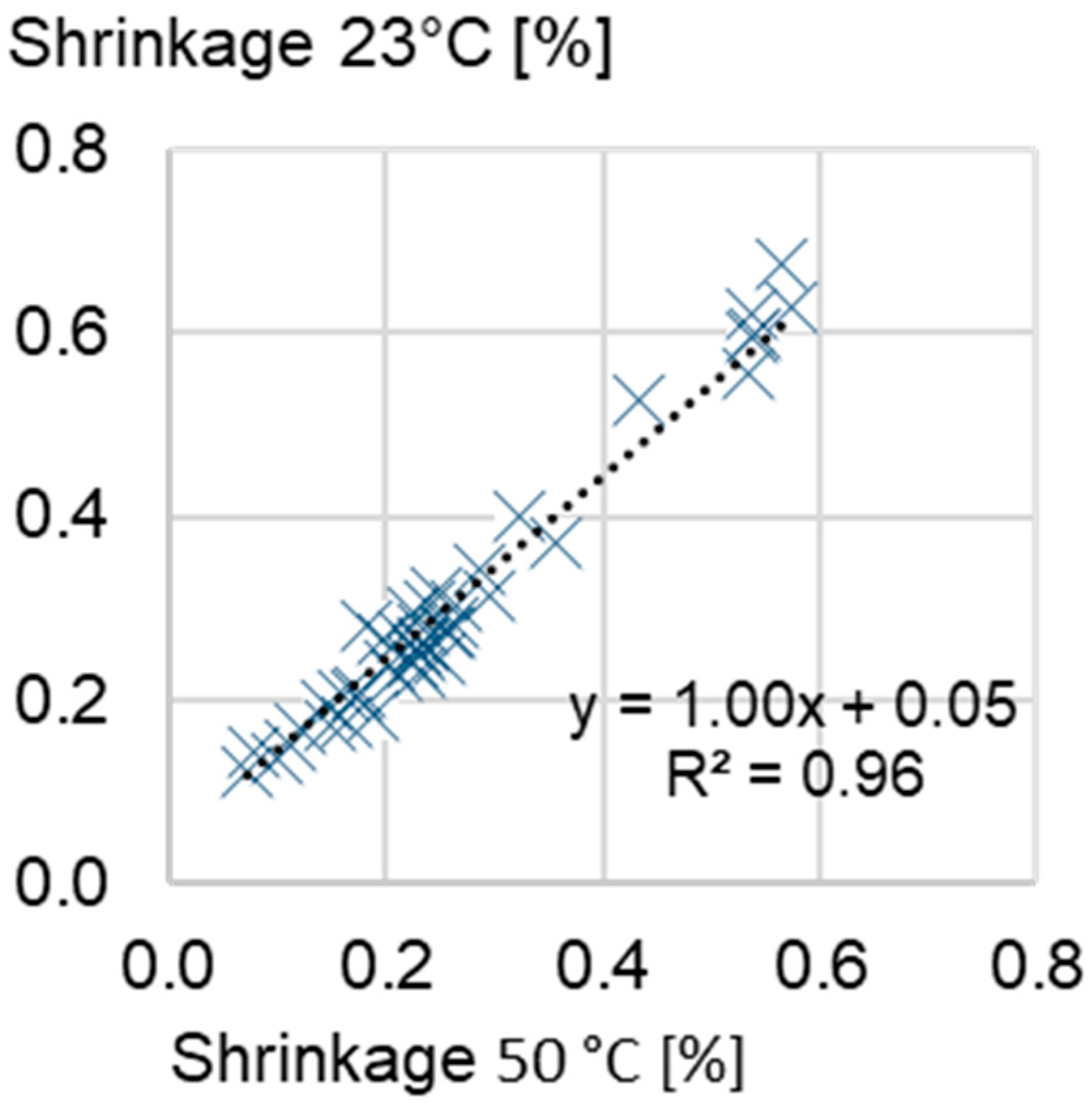

- Change in length and mass at 50 °C: Three samples per laminate were stored at 50 °C. The length and the mass of the three replicas were determined in accordance with EN 318 after 6-, 24, and 240-h storage. In order to exclude the possible effects of the temperature during the measurement, two sets of samples were measured independently: one set was measured within a larger climate chamber at 50 °C and the other set was measured 10 min after moving the samples from the oven to a room at 23 °C.

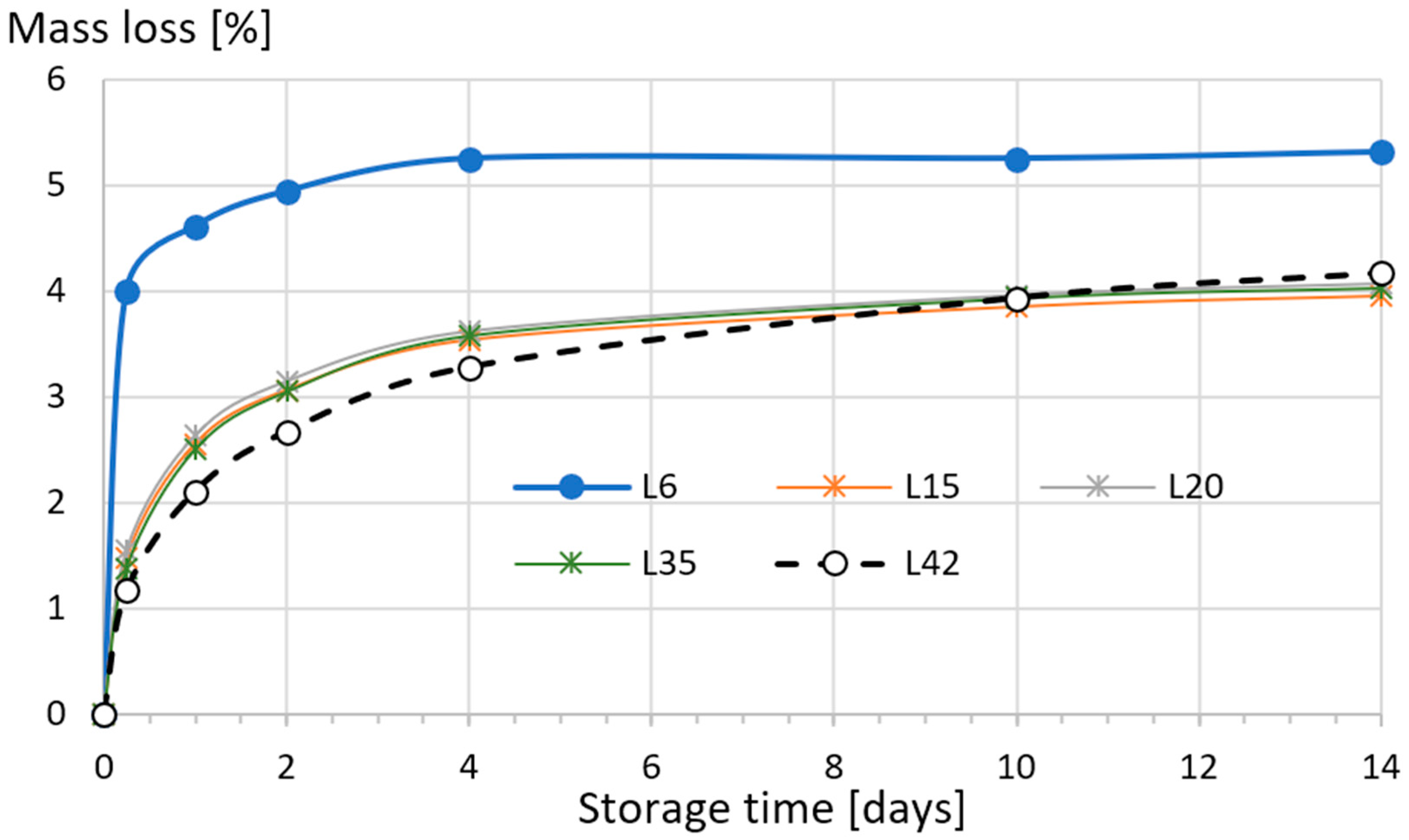

- With the intention to determine the time needed to reach the equilibrium moisture content, the mass loss of five of the laminates was also monitored in further time intervals.

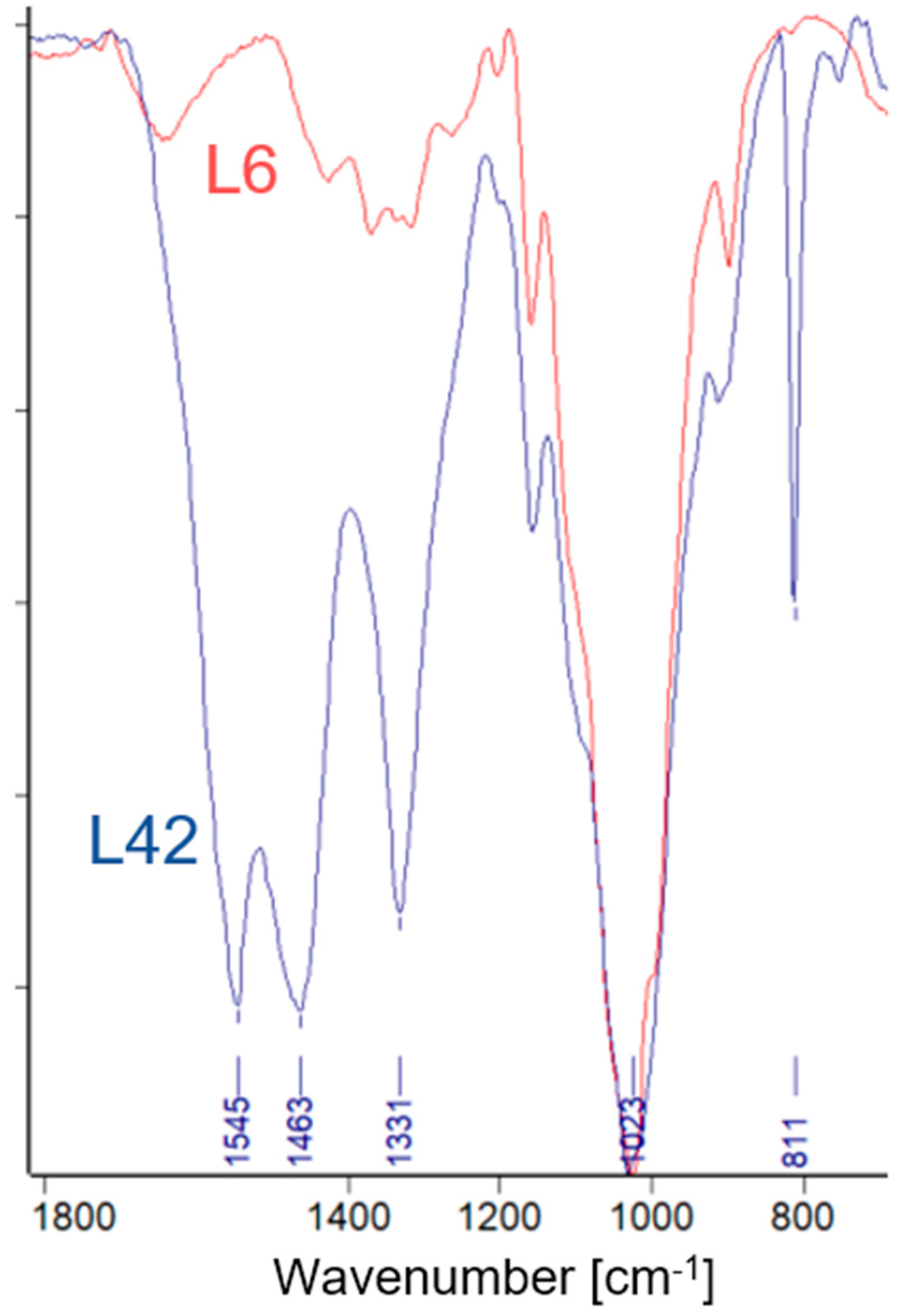

- Infrared Spectroscopy (IR-ATR): The powder of the surface was scratched from the backing layers using a doctor’s blade. The powder was analysed in a Tensor 27 (Bruker) with 32 scans. The baseline-corrected spectra were normalized to the peak at 1023 cm−1.

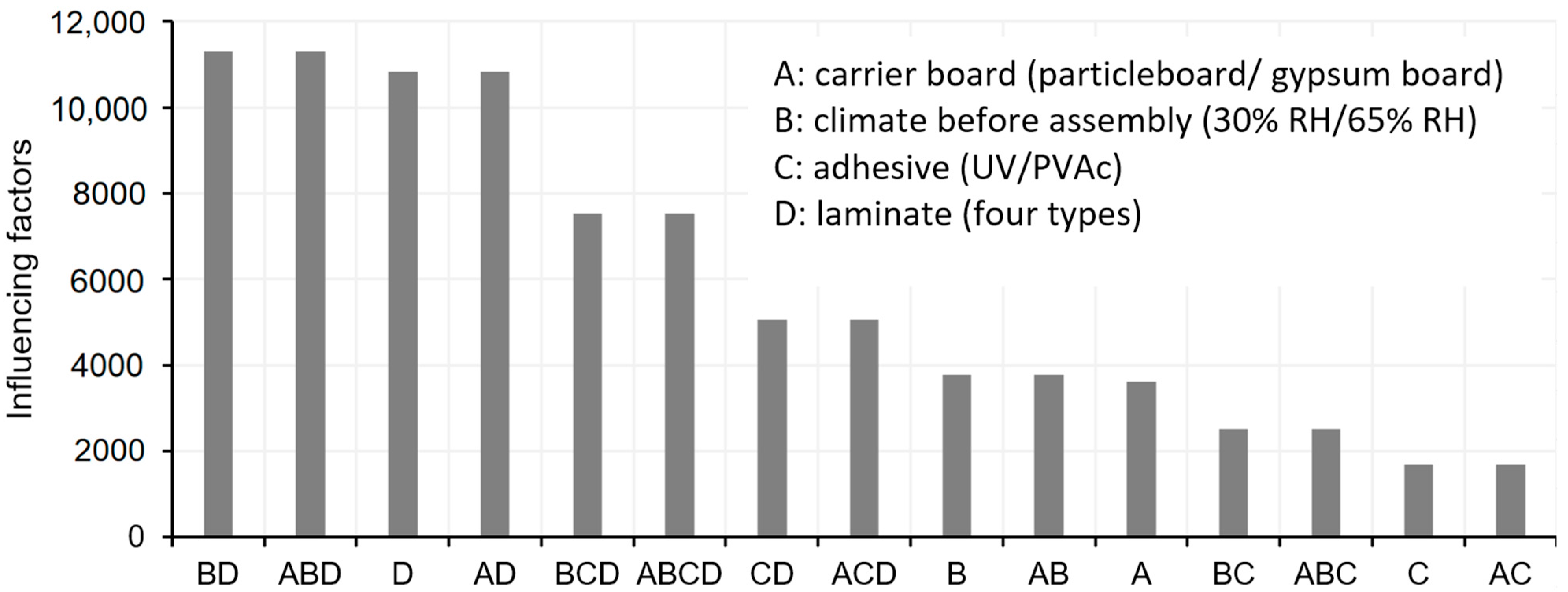

3. Results

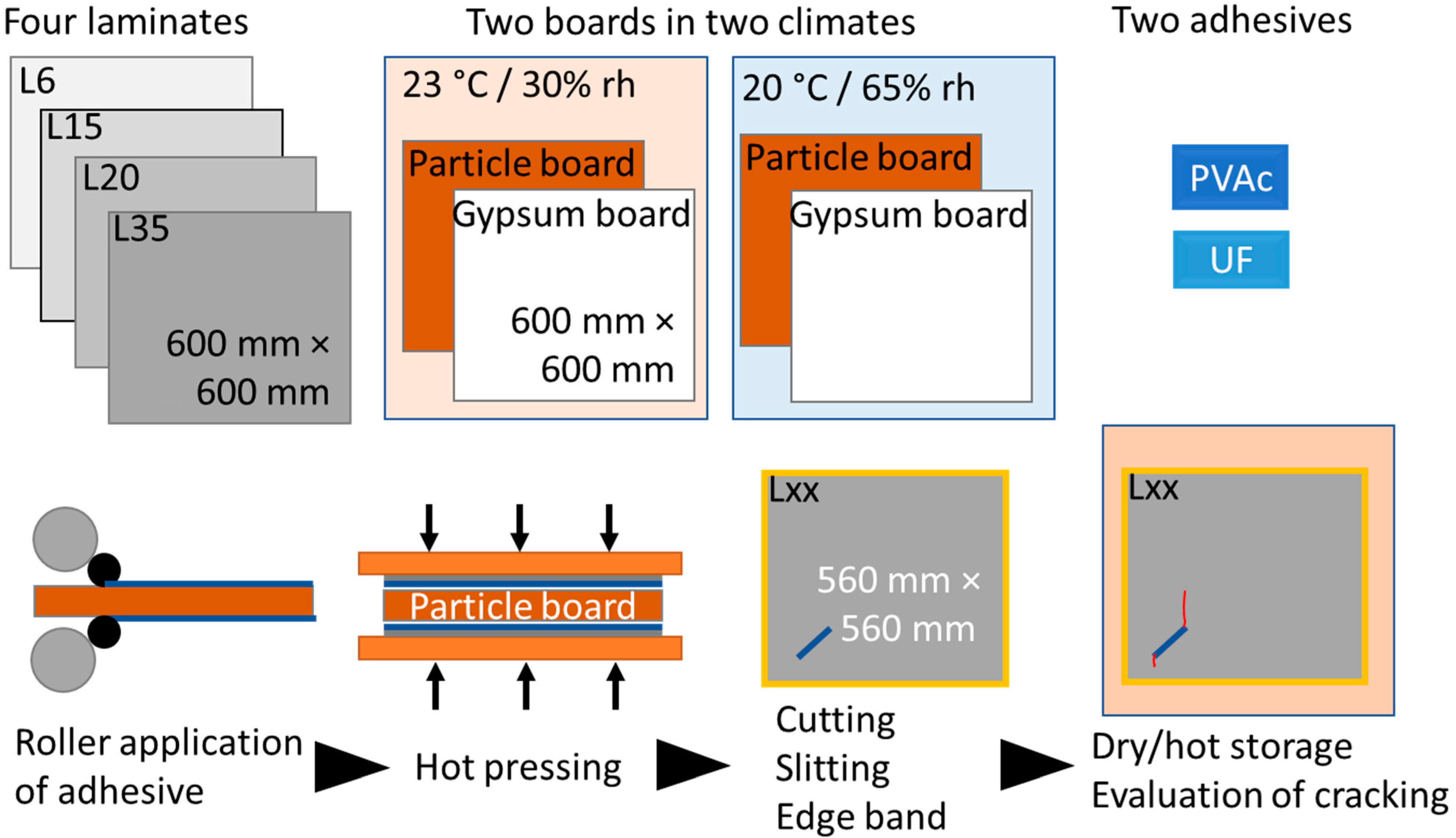

Properties of Laminates on Carrier Boards

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lohmann, U.; Blosen, M. Holz-Lexikon, 4th ed.; DRW-Verl.: Leinfelden-Echterdingen, Germany, 2003; ISBN 3-87181-355-9. [Google Scholar]

- Eyerer, P.; Elsner, P.; Hirth, T. Die Kunststoffe und Ihre Eigenschaften, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2005; ISBN 3-540-21410-0. [Google Scholar]

- Nemli, G. Factors affecting some quality properties of the decorative surface overlays. J. Mater. Process. Technol. 2008, 195, 218–223. [Google Scholar] [CrossRef]

- ICDLI. Processing HPL Compact Laminates, Frankfurt / Main, Germany. 2017. Available online: https://www.icdli.com/TL%20170614%20%20Processing%20HPL%20compact%20laminates.pdf (accessed on 24 October 2022).

- ICDLI. Characteristics and Possibilities of Use for Decorative High Pressure Laminates (HPL), Frankfurt / Main, Germany. 2017. Available online: https://www.pro-hpl.org/assets/uploads/prohpl/files/TL_171218_Characteristcs_and_Possibilities_if_Use_for_Decorative_High_Pressure_Laminates_HPL.pdf (accessed on 24 October 2022).

- Pankoke, W. Development and state of engineering in the continuous production of decorative high-pressure laminates. Holz Roh Werkst. 1981, 39, 271–274. [Google Scholar] [CrossRef]

- Wu, Q.; Suchsland, O. Prediction of Moisture Content and Moisture Gradient of an overlaid particleboard. Wood Fiber. Sci. 1996, 28, 227–239. [Google Scholar]

- Wu, Q. Development of an Interactive Computer Simulation Model for Designing Laminated Composite Panels. 2005. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.704.161&rep=rep1&type=pdf (accessed on 11 January 2019).

- Oehler, H. Schwindung und Verzug von harzbasierten Laminaten. Abschlussbericht Aif 17547 N. 2016. Available online: https://www.aif.de/foerderangebote/igf-industrielle-gemeinschaftsforschung/igf-projektdatenbank.html?tx_igf_search%5Baction%5D=detail&tx_igf_search%5Bcontroller%5D=Search&tx_igf_search%5Bitem%5D=7843&tx_igf_search%5Bterm%5D=Schwindung%20und%20Verzug%20von%20harzbasierten%20Laminaten&cHash=0d96ec06cafed35638a9de4ad06aaf3f (accessed on 24 October 2022).

- Thébault, M.; Kandelbauer, A.; Müller, U.; Zikulnig-Rusch, E.; Lammer, H. Factors influencing the processing and technological properties of laminates based on phenolic resin impregnated papers. Eur. J. Wood Prod. 2017, 75, 785–806. [Google Scholar] [CrossRef]

- Suchsland, O.; Yonggang, F.; Danping, X. The hygroscopic warping of laminated panels. For. Prod. J. 1995, 45, 57–63. [Google Scholar]

- Magina, S.; Santos, M.D.; Ferra, J.; Cruz, P.; Portugal, I.; Evtuguin, D.; Santos, M. High Pressure Laminates with Antimicrobial Properties. Materials 2016, 9, 100. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Henriques, A.; Almeida, M.; Paiva, N.; Ferra, J.; Martins, J.; Carvalho, L.; Magalhães, F.D. Improving hydrophobic and oleophobic performances of high-pressure laminates. Eur. J. Wood Prod. 2018, 76, 1685–1695. [Google Scholar] [CrossRef]

- Burdurlu, E.; Ozgenc, O. Effect of different layer structures on some resistance characteristics of high-pressure laminates. For. Prod. J. 2009, 59, 69–75. [Google Scholar]

- National Electrical Manufacturers Association. High-Pressure Decorative Laminates; NEMA: Rosslyn, VA, USA, 1905; p. LD 3-2005. [Google Scholar]

- Maloney, T.M. Modern Particleboard and Dry-Process Fiberboard Manufacturing; Miller Freeman: San Francisco, CA, USA, 1977; ISBN 0-87930-063-9. [Google Scholar]

- Lukowsky, D. Failure Analysis of Wood and Wood-Based Products; McGraw-Hill Education: New York, NY, USA; Chicago, IL, USA; San Francisco, CA, USA, 2015; ISBN 9780071839372. [Google Scholar]

- EN 438-2; High-Pressure Decorative Laminates (HPL) Part 2: Determination of Properties. European Committee for Standardization: Brussels, Belgium, 2019.

- Heebink, D.M.; Haskel, H.H. Effect of heat and humidity on the properties of high pressure laminates. For. Prod. J. 1962, 12, 542–548. [Google Scholar]

- Anonymous. HPL in der Außenanwendung: HPL nach EN 438, Frankfurt/Main, Germany. 2015. Available online: https://www.pro-hpl.org/assets/uploads/prohpl/files/HPL_in_der_Aussenanwendung_Juni_2015.pdf (accessed on 24 October 2022).

- Cardarelli, F. Materials Handbook; Springer International Publishing: Cham, Germany, 2018; ISBN 978-3-319-38923-3. [Google Scholar]

- Pizzi, A.; Ibeh, C.C. Aminos. Handbook of Thermoset Plastics; Elsevier: Amsterdam, The Netherlands, 2014; pp. 75–91. ISBN 9781455731077. [Google Scholar]

- Gypsum Association. Gypsum Board Typical Mechanical and Physical Properties GA-235. 2019. Available online: https://www.americangypsum.com/sites/default/files/2022-01/ga-235_gypsum_board_typical_mechanical_and_physical_properties.pdf (accessed on 24 October 2022).

- Niemz, P.; Sonderegger, W.U. Holzphysik: Physik des Holzes und der Holzwerkstoffe; Fachbuchverlag Leipzig im Carl Hanser Verlag: München, Germany, 2017; ISBN 978-3446445260. [Google Scholar]

| Laminate | Thickness | Ft438 6 h 50 °C | Shrinkage 50 °C % | Laminate | Thickness | Ft438 6 h 50 °C | Shrinkage 50 °C % | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| no. | mm | N/mm² | 6 h | 24 h | 240 h | no. | mm | N/mm² | 6 h | 24 h | 240 h | ||

| L1 | 0.15 | 36 | 6.3 | 0.35 | 0.68 | 0.82 | L22 | 0.69 | 30 | 4.8 | 0.06 | 0.21 | 0.34 |

| L2 | 0.17 | 39 | 5.8 | 0.25 | 0.56 | 0.71 | L23 | 0.53 | 31 | 2.3 | 0.10 | 0.29 | 0.41 |

| L3 | 0.14 | 33 | 2.7 | 0.28 | 0.62 | 0.80 | L24 | 0.69 | 42 | 4.0 | 0.08 | 0.24 | 0.41 |

| L4 | 0.17 | 48 | 4.8 | 0.26 | 0.53 | 0.69 | L25 | 0.51 | 25 | 2.7 | 0.08 | 0.25 | 0.40 |

| L5 | 0.20 | 46 | 2.5 | 0.31 | 0.63 | 0.86 | L26 | 0.78 | 31 | 4.3 | 0.10 | 0.30 | 0.47 |

| * L6 | 0.19 | 34 | 3.1 | 0.31 | 0.6 | 0.79 | L27 | 0.51 | 26 | 3.7 | 0.09 | 0.27 | 0.41 |

| L7 | 0.19 | 37 | 7.5 | 0.29 | 0.59 | 0.76 | L28 | 0.70 | 30 | 1.6 | 0.05 | 0.17 | 0.31 |

| L8 | 0.38 | 36 | 3.4 | 0.13 | 0.37 | 0.46 | L29 | 0.52 | 26 | 4.2 | 0.10 | 0.30 | 0.45 |

| L9 | 0.66 | 53 | 7.5 | 0.06 | 0.21 | 0.38 | L30 | 0.64 | 28 | 1.3 | 0.08 | 0.24 | 0.37 |

| L10 | 0.59 | 44 | 3.3 | 0.09 | 0.26 | 0.33 | L31 | 0.71 | 35 | 4.3 | 0.10 | 0.27 | 0.42 |

| L11 | 0.58 | 36 | 2.0 | 0.08 | 0.26 | 0.36 | L32 | 0.89 | 30 | 2.8 | 0.05 | 0.18 | 0.33 |

| L12 | 0.49 | 32 | 4.6 | 0.09 | 0.23 | 0.37 | L33 | 0.73 | 35 | 6.8 | 0.03 | 0.18 | 0.41 |

| L13 | 0.62 | 40 | 5.4 | 0.11 | 0.28 | 0.44 | L34 | 0.66 | 38 | 4.2 | 0.04 | 0.20 | 0.34 |

| L14 | 0.66 | 39 | 4.6 | 0.09 | 0.24 | 0.37 | * L35 | 0.78 | 30 | 1.9 | 0.10 | 0.32 | 0.51 |

| * L15 | 0.57 | 39 | 6.9 | 0.09 | 0.26 | 0.37 | L36 | 0.95 | 33 | 2.5 | 0.05 | 0.21 | 0.38 |

| L16 | 0.49 | 37 | 4.7 | 0.09 | 0.26 | 0.40 | L37 | 0.67 | 33 | 5.4 | 0.10 | 0.28 | 0.43 |

| L17 | 0.68 | 33 | 8.3 | 0.03 | 0.17 | 0.31 | L38 | 1.13 | 41 | 5.0 | 0.02 | 0.12 | 0.23 |

| L18 | 0.69 | 42 | 5.0 | 0.03 | 0.14 | 0.26 | L39 | 1.22 | 50 | 7.3 | 0.04 | 0.15 | 0.27 |

| L19 | 0.52 | 32 | 6.1 | 0.09 | 0.27 | 0.48 | L40 | 1.11 | 36 | 1.8 | 0.03 | 0.14 | 0.27 |

| * L20 | 0.64 | 33 | 2.6 | 0.09 | 0.32 | 0.50 | L41 | 1.11 | 40 | 0.7 | 0.10 | 0.27 | 0.44 |

| L21 | 0.42 | 29 | 3.1 | 0.15 | 0.34 | 0.46 | L42 | 1.42 | 48 | 9.2 | 0.11 | 0.29 | 0.52 |

| L43 | 1.35 | 42 | 5.9 | 0.19 | 0.40 | 0.69 | |||||||

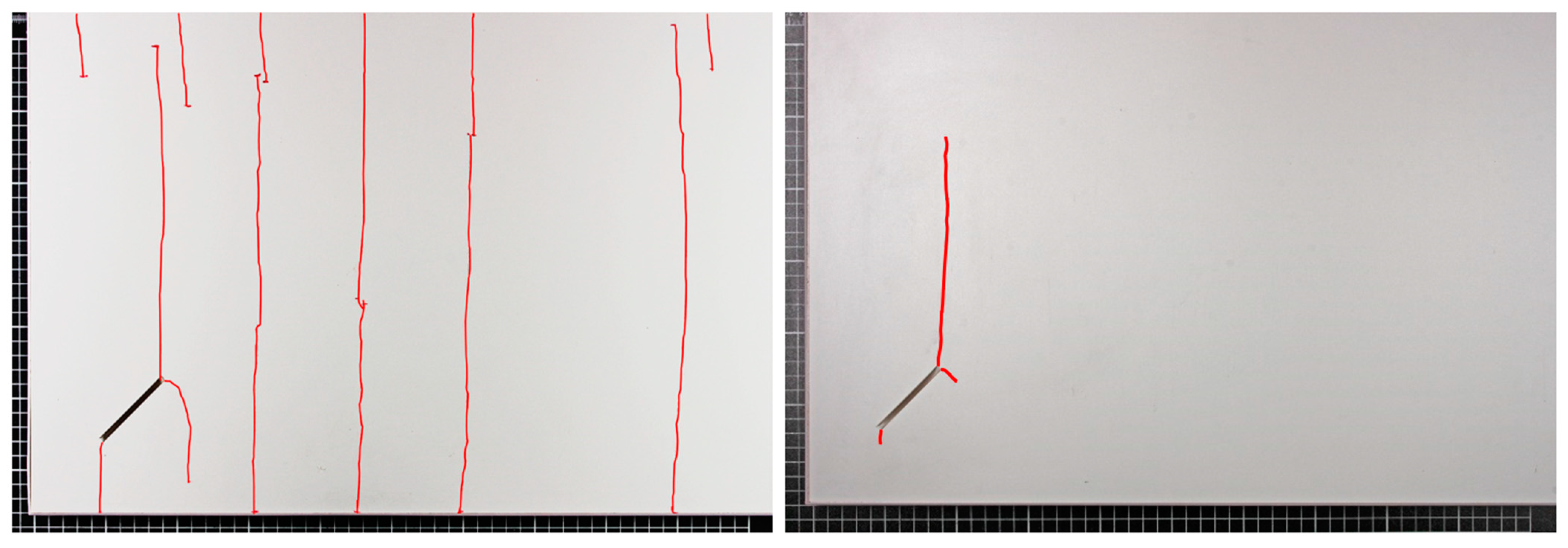

| Laminate L6 | Laminate L15 | Laminate L35 | Laminate L20 | |

|---|---|---|---|---|

| Sum of crack length per face | 244 cm | 45 cm | 12 cm | 4 cm |

| Time to crack EN 438-2 (23) | <6 h | <240 h | >240 h | >240 h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lukowsky, D.; Meder, M. Studies of the Cracking Behaviour of High-Pressure Laminates. Appl. Sci. 2022, 12, 12816. https://doi.org/10.3390/app122412816

Lukowsky D, Meder M. Studies of the Cracking Behaviour of High-Pressure Laminates. Applied Sciences. 2022; 12(24):12816. https://doi.org/10.3390/app122412816

Chicago/Turabian StyleLukowsky, Dirk, and Mark Meder. 2022. "Studies of the Cracking Behaviour of High-Pressure Laminates" Applied Sciences 12, no. 24: 12816. https://doi.org/10.3390/app122412816

APA StyleLukowsky, D., & Meder, M. (2022). Studies of the Cracking Behaviour of High-Pressure Laminates. Applied Sciences, 12(24), 12816. https://doi.org/10.3390/app122412816