Microstructure and Phase Transformation Temperature of NiTiNb Shape Memory Alloy Prepared by Laser Solid Forming Using Mixed Powder

Abstract

:1. Introduction

2. Experimental

2.1. Material and Process Parameters

2.2. Characterization Method

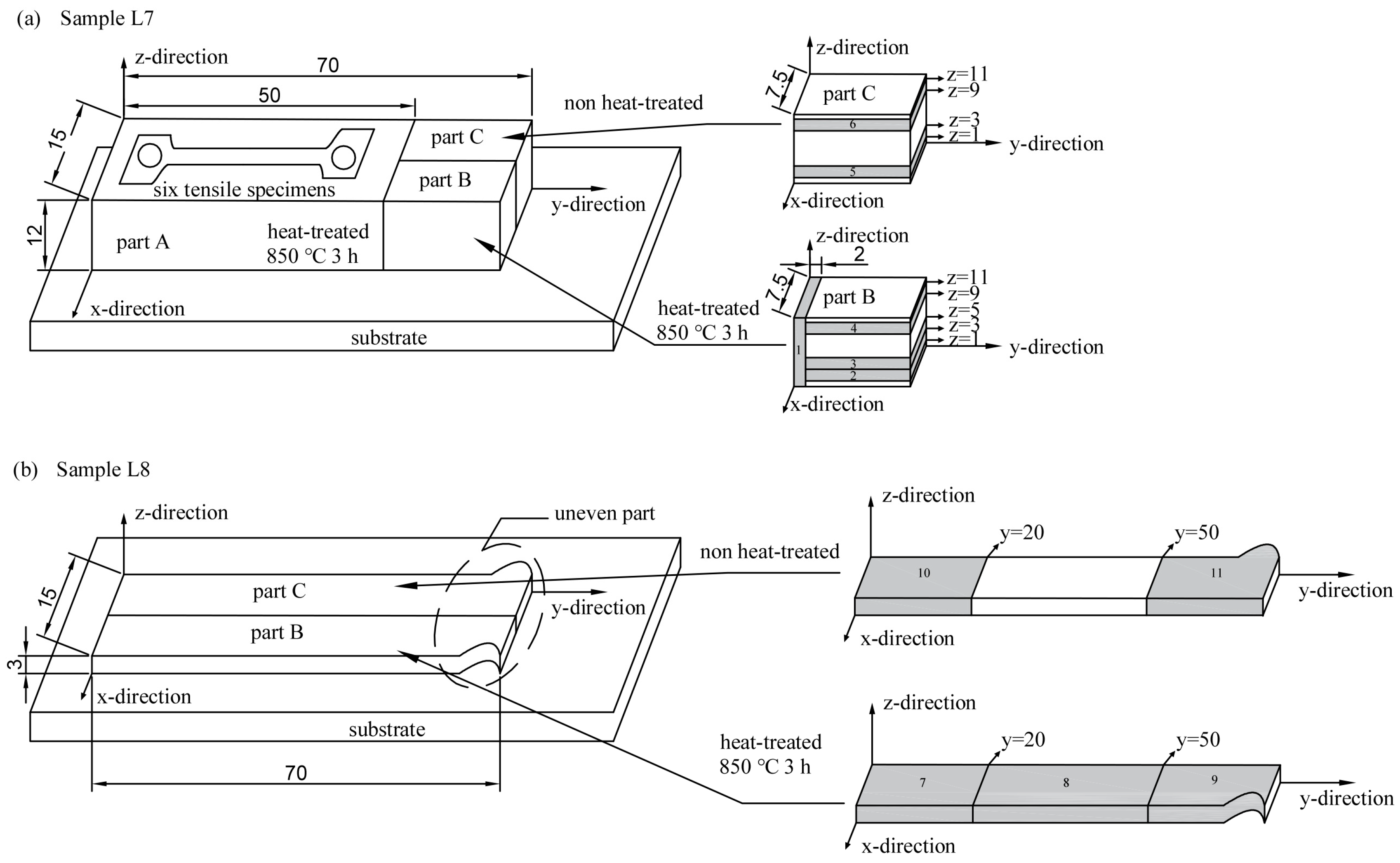

- Samples L1-L6 are heated to 950 °C and kept for 15 h;

- Sample L7 part A is heated to 850 °C and kept for 3 h;

- Sample L7 part B is heated to 850 °C and kept for 3 h;

- Sample L7 part C is not annealed;

- Sample L8 part B is heated to 850 °C and kept for 3 h;

- Sample L8 part C is not annealed.

3. Results and Discussion

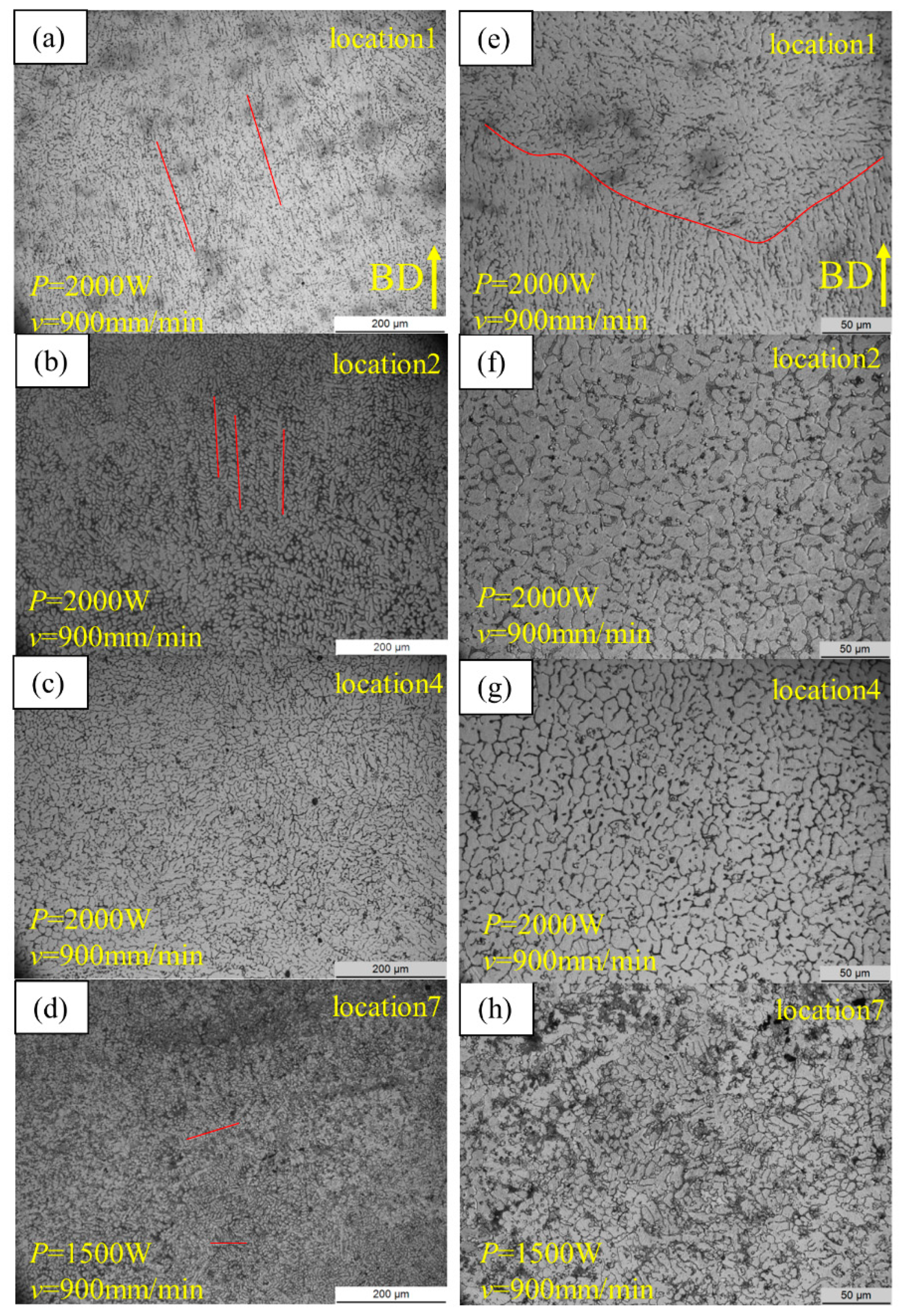

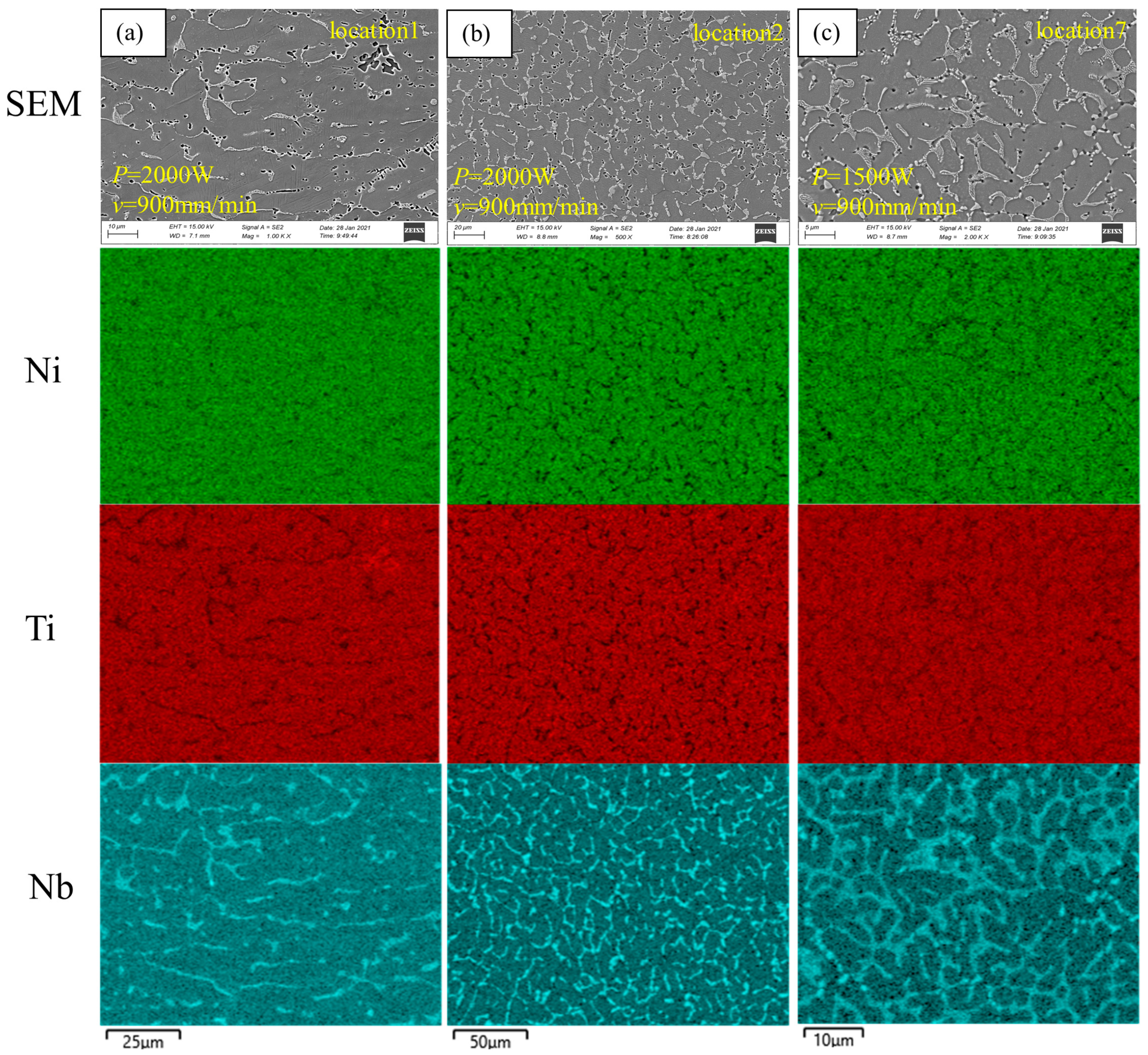

3.1. Microstructure Analysis of NiTiNb Prepared by LSF

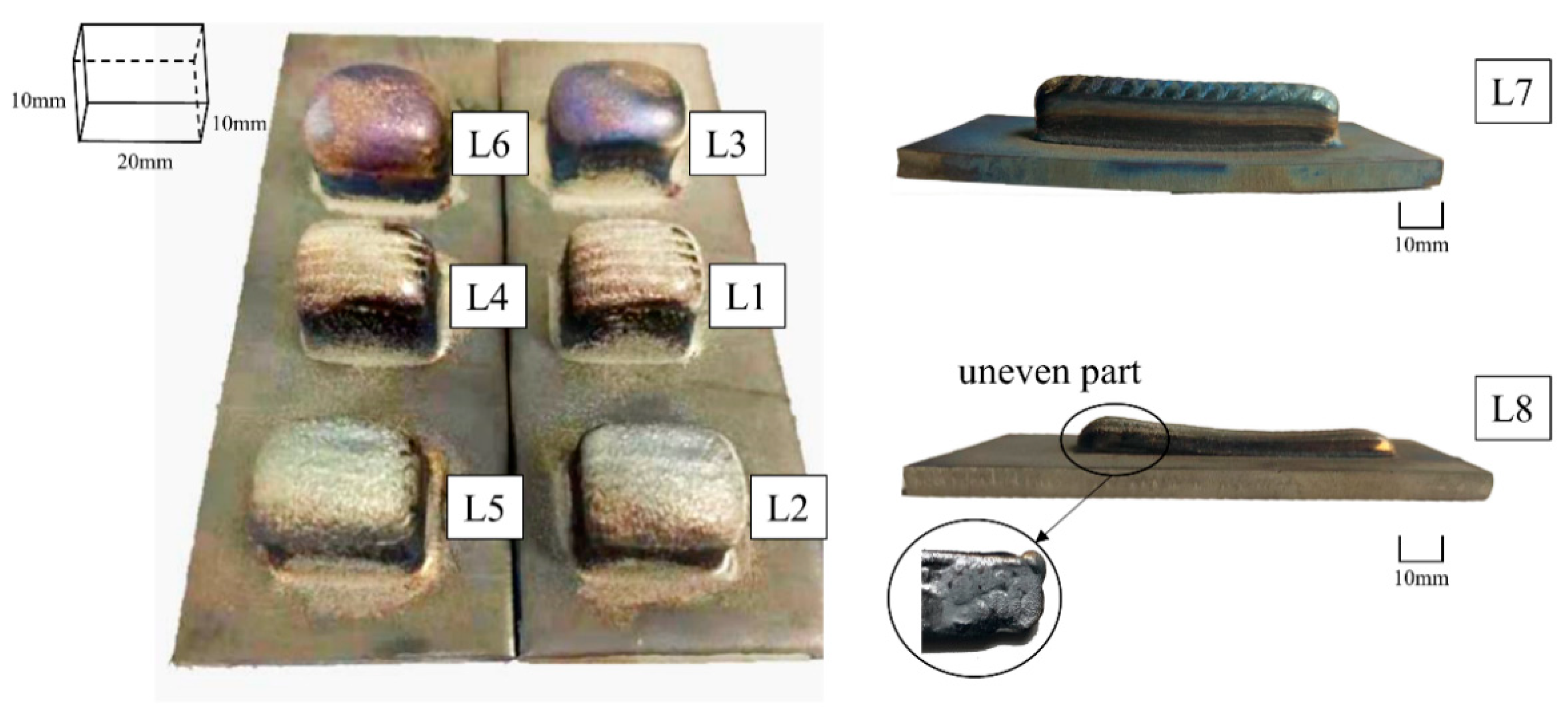

3.1.1. Macroscopic Morphology

3.1.2. Microstructure Features

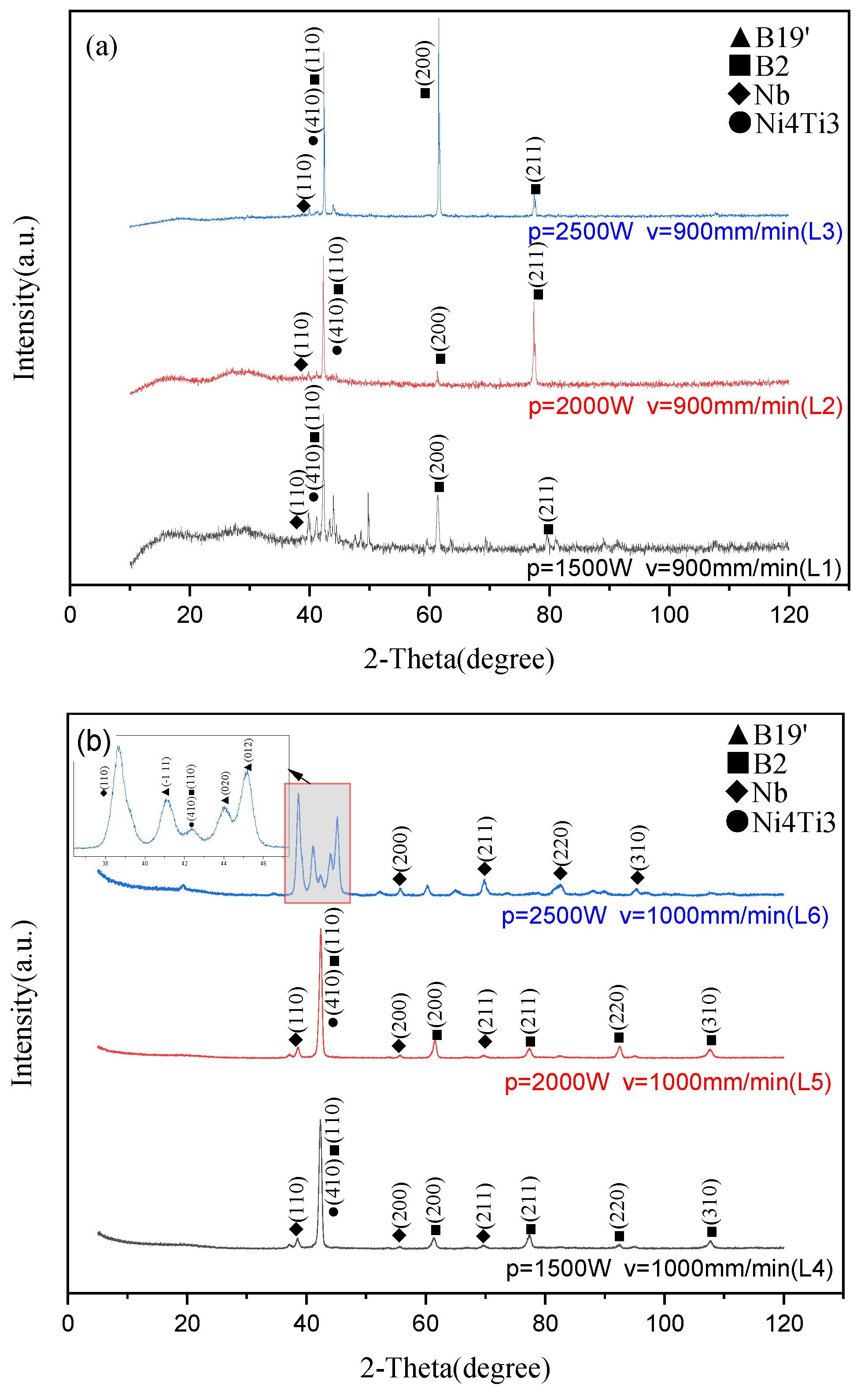

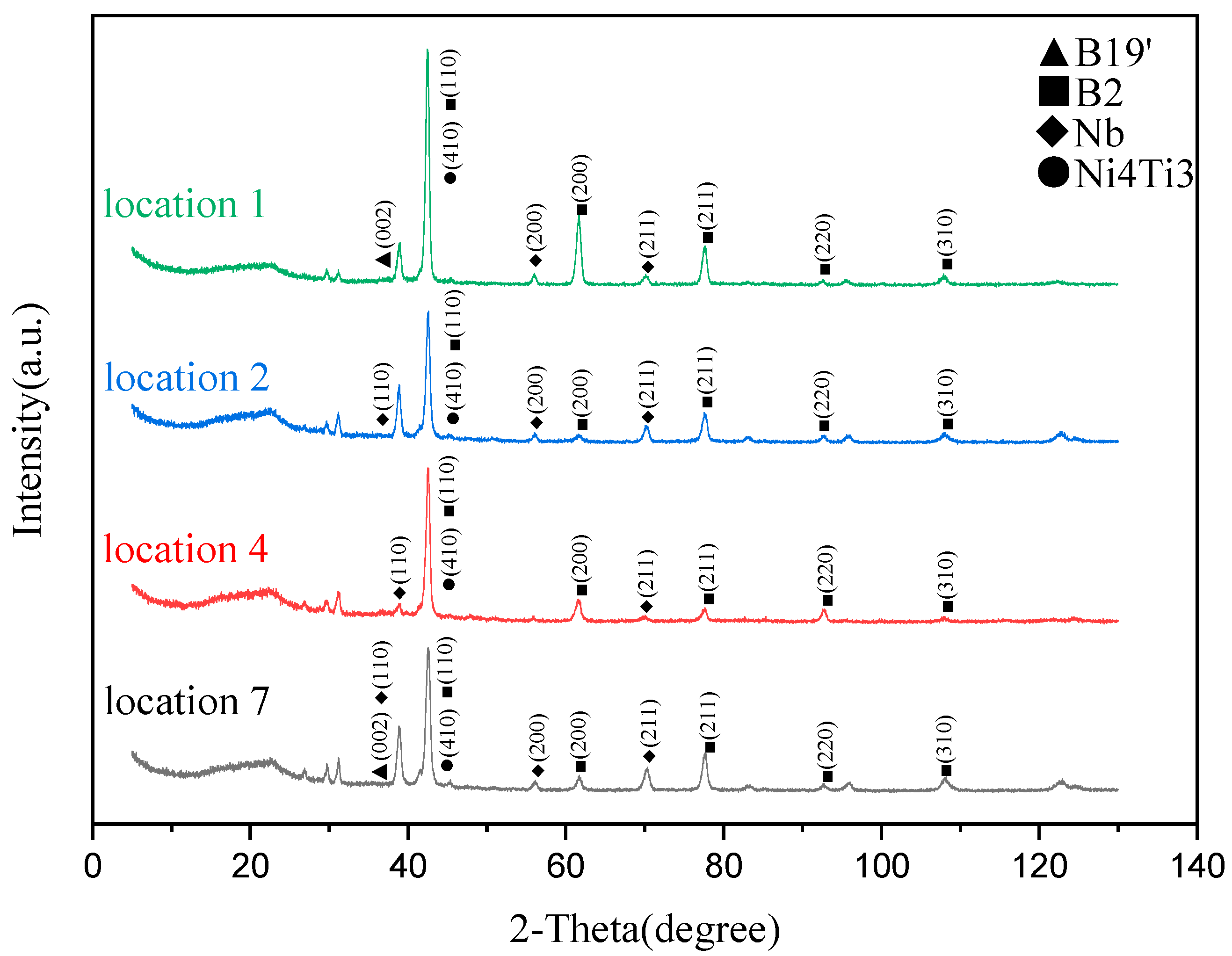

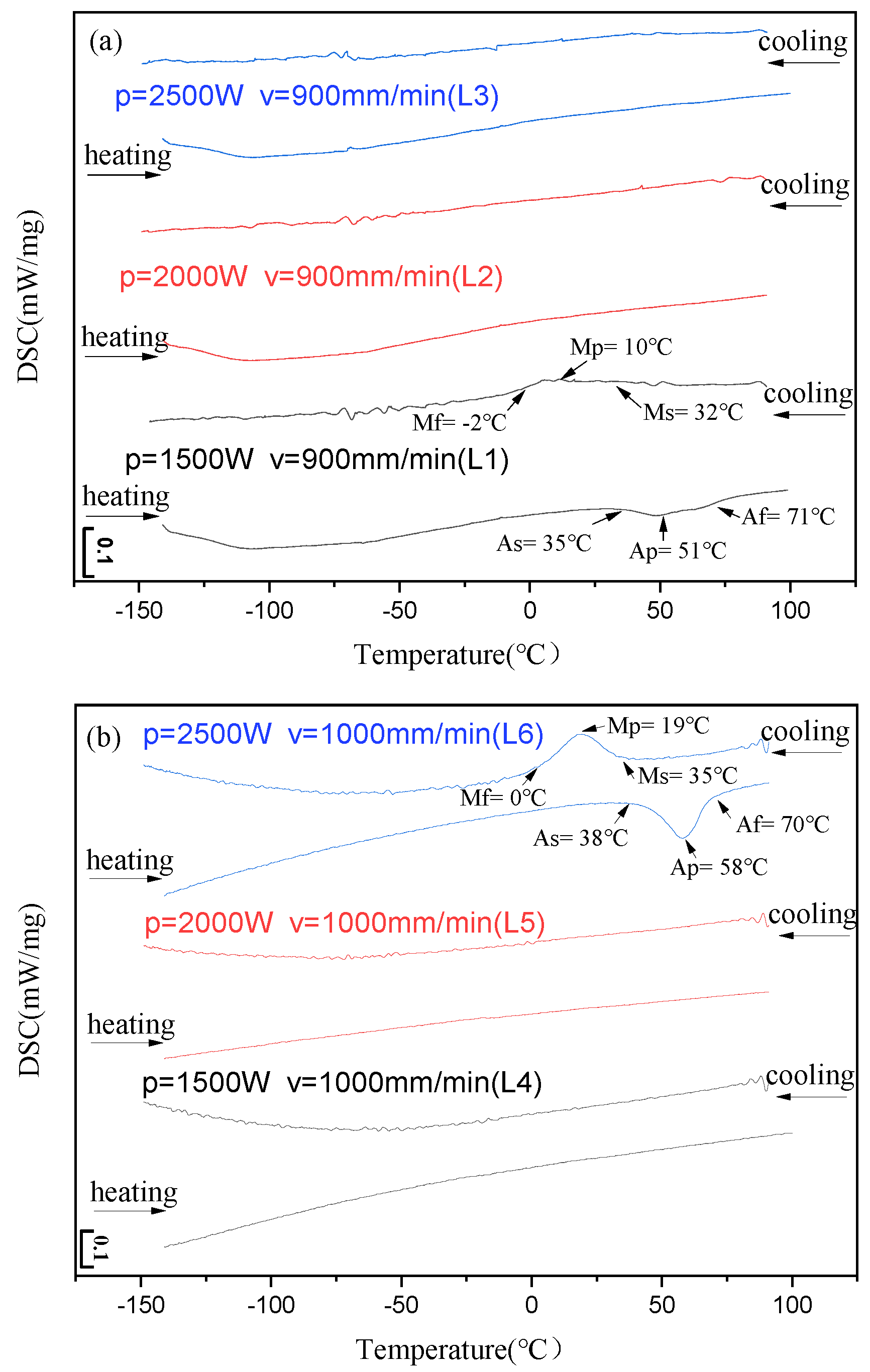

3.2. Phase Transformation of NiTiNb Prepared by LSF

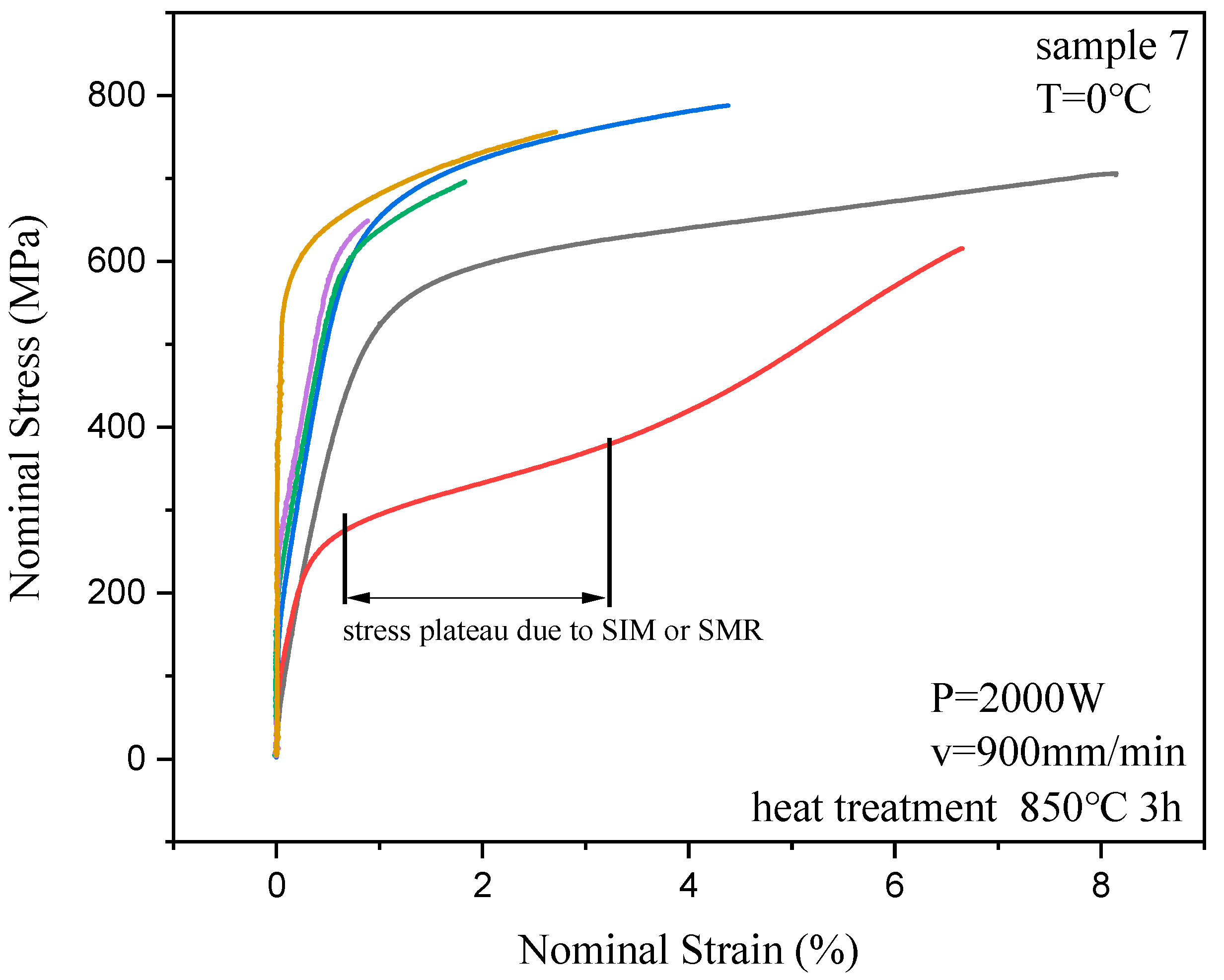

3.3. Mechanical Properties of NiTiNb Prepared by LSF

4. Conclusions

- (1)

- The LSF process parameter combination of 2000 W laser power and 900 mm/min scanning speed can fully melt the Ni + Ti + Nb mixed powder, and obtain a sample with a small size deviation, no serious oxidation on the surface, and a good metallurgical bond between the powder and the substrate.

- (2)

- The microstructure of LSF-NiTiNb alloy is mainly composed of NiTi matrix and Nb phase, and Nb is mainly enriched in grain boundaries. As the laser power increases, the grain size increases, and the proportion of equiaxed crystals increases, the martensite transformation temperature increases.

- (3)

- Heat treatment at 850 °C for 3 h will increase the phase transformation temperature and hysteresis of LSF-NiTiNb and change the phase transformation behavior from one-step B2–B19′ to two-step B2–R–B19′. However, the inhomogeneity of the microstructure results in different phase transformation temperatures and phase transformation behaviors in the same sample.

- (4)

- The tensile properties of the heat-treated LSF-NiTiNb samples with different building heights are significantly different due to the uneven microstructure. The maximum elongation reaches 8% and the minimum elongation is only 0.8%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Zheng, Y.F.; Zhang, B.B.; Wang, B.L.; Wang, Y.B.; Li, L.; Yang, Q.B.; Cui, L.S. Introduction of antibacterial function into biomedical TiNi shape memory alloy by the addition of element Ag. Acta Biomater. 2011, 7, 2758–2767. [Google Scholar] [CrossRef] [PubMed]

- Rondelli, G. Corrosion resistance tests on NiTi shape memory alloy. Biomaterials 1996, 17, 2003–2008. [Google Scholar] [CrossRef]

- Miyazaki, S.; Kohiyama, Y.; Otsuka, K.; Duerig, T.W. Effects of several factors on the ductility of the Ti-Ni alloy. Mater. Sci. Forum 1991, 56–58, 765–770. [Google Scholar] [CrossRef]

- Frenzel, J.; George, E.P.; Dlouhy, A.; Somsen, C.; Wagner, F.X.; Eggeler, G. Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 2007, 58, 3444–3458. [Google Scholar] [CrossRef]

- Hartl, D.J.; Lagoudas, D.C. Aerospace applications of shape memory alloys. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2007, 221, 535–552. [Google Scholar] [CrossRef] [Green Version]

- Carpenter, B. Lightweight Flexible Solar Array Experiment. NASA/GSFC EO-1 Technology Validation Report. 2001. Available online: https://ntrs.nasa.gov/api/citations/20010086984/downloads/20010086984.pdf (accessed on 1 December 2021).

- Krishna, B.V.; Bose, S.; Bandyopadhyay, A. Fabrication of porous NiTi shape memory alloy structures using laser engineered net shaping. J. Biomed. Mater. Res. Part B Appl. Biomater. 2009, 89, 481–490. [Google Scholar] [CrossRef]

- Yang, Z.; Li, H.; Zhang, Y.; Liu, X.; Gu, Q.; Liu, Y. Tailoring of microstructure and shape memory properties of hot-forged NiTiNb alloy by multi-pass ECAP at high temperatures. Mater. Sci. Eng. A 2021, 828, 142011. [Google Scholar] [CrossRef]

- Yang, Z.; Li, H.; Zhang, Y.; Liu, X.; Gu, Q.; Liu, Y. ECAP based regulation mechanism of shape memory properties of NiTiNb alloys. J. Alloy. Compd. 2022, 897, 163184. [Google Scholar] [CrossRef]

- Elahinia, M.; Moghaddam, N.S.; Andani, M.T.; Amerinatanzi, A.; Bimber, B.A.; Hamilton, R.F. Fabrication of NiTi through additive manufacturing: A review. Prog. Mater. Sci. 2016, 83, 630–663. [Google Scholar] [CrossRef] [Green Version]

- Hassan, M.R.; Mehrpouya, M.; Dawood, S. Review of the machining difficulties of nickel-titanium based shape memory alloys. Appl. Mech. Mater. 2014, 564, 533–537. [Google Scholar] [CrossRef]

- Weinert, K.; Petzoldt, V. Machining of NiTi based shape memory alloys. Mater. Sci. Eng. A 2004, 378, 180–184. [Google Scholar] [CrossRef]

- Frenzel, J.; Zhang, Z.; Somsen, C.; Neuking, K.; Eggeler, G. Influence of carbon on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 2007, 55, 1331–1341. [Google Scholar] [CrossRef]

- Abdullah, Z.; Razali, R.; Subuki, I.; Omar, M.A.; Ismail, M.H. An overview of Powder Metallurgy (PM) method for porous nickel titanium Shape Memory Alloy (SMA). Adv. Mater. Res. 2016, 1133, 269–274. [Google Scholar] [CrossRef]

- Yi, X.; Wang, H.; Sun, K.; Gao, W.; Sun, B.; Shen, G.; Meng, X.; Gao, Z.; Cai, W. Characterization of high-strength Ti–Ni shape memory alloys prepared by hot pressed sintering. J. Alloy. Compd. 2021, 854, 157159. [Google Scholar] [CrossRef]

- Elahinia, M.H.; Hashem, M.; Tabesh, M.; Bhaduri, S.B. Manufacturing and processing of NiTi implants: A review. Prog. Mater. Sci. 2012, 57, 911–946. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Liu, Y.; An, J.; Chua, C.K.; Shen, Y.F.; Kuo, C.N. A review of selective laser melted NiTi shape memory alloy. Materials 2018, 11, 519. [Google Scholar] [CrossRef] [Green Version]

- Khorasani, A.; Ghasemi, B.; Rolfe, I.G. Additive manufacturing a powerful tool for the aerospace industry. Rapid Prototyp. J. 2022, 28, 87–100. [Google Scholar] [CrossRef]

- Yakout, M.A.M.; Elbestawi, S.C. Veldhuis, S. Nangle-Smith, Influence of thermal properties on residual stresses in SLM of aerospace alloys. Rapid Prototyp. J. 2019, 26, 213–222. [Google Scholar] [CrossRef]

- Gibson, I.; Cheung, L.K.; Chow, S.P.; Cheung, W.L.; Beh, S.L.; Savalani, M.; Lee, S.H. The use of rapid prototyping to assist medical applications. Rapid Prototyp. J. 2006, 12, 53–58. [Google Scholar] [CrossRef] [Green Version]

- Hamilton, R.F.; Bimber, B.A.; Andani, M.T.; Elahinia, M. Multi-scale shape memory effect recovery in NiTi alloys additive manufactured by selective laser melting and laser directed energy deposition. J. Mater. Process. Technol. 2017, 250, 55–64. [Google Scholar] [CrossRef]

- Zhou, Q.; Hayat, M.D.; Chen, G.; Cai, S.; Qu, X.; Tang, H.; Cao, P. Selective electron beam melting of NiTi: Microstructure, phase transformation and mechanical properties. Mater. Sci. Eng. A 2019, 744, 290–298. [Google Scholar] [CrossRef]

- Fu, J.; Hu, Z.; Song, X.; Zhai, W.; Long, Y.; Li, H.; Fu, M. Micro selective laser melting of NiTi shape memory alloy: Defects, microstructures and thermal/mechanical properties. Opt. Laser Technol. 2020, 131, 106374. [Google Scholar] [CrossRef]

- Ke, Y.; Xiong, J. Microstructure and mechanical properties of double-wire feed GTA additive manufactured 308L stainless steel. Rapid Prototyp. J. 2020, 26, 1503–1513. [Google Scholar] [CrossRef]

- Fang, X.; Ren, C.; Zhang, L.; Wang, C.; Huang, K.; Lu, B. A model of bead size based on the dynamic response of CMT-based wire and arc additive manufacturing process parameters. Rapid Prototyp. J. 2021, 27, 741–753. [Google Scholar] [CrossRef]

- Tang, S.; Wang, G.; Song, H.; Li, R.; Zhang, H. A novel method of bead modeling and control for wire and arc additive manufacturing. Rapid Prototyp. J. 2021, 27, 311–320. [Google Scholar] [CrossRef]

- Dai, F.; Zhang, H.; Li, R. Process planning based on cylindrical or conical surfaces for five-axis wire and arc additive manufacturing. Rapid Prototyp. J. 2020, 26, 1405–1420. [Google Scholar] [CrossRef]

- Kulkarni, J.D.; Goka, S.B.; Parchuri, P.K.; Yamamoto, H.; Ito, K.; Simhambhatla, S. Microstructure evolution along build direction for thin-wall components fabricated with wire-direct energy deposition. Rapid Prototyp. J. 2021, 27, 1289–1301. [Google Scholar] [CrossRef]

- Bimber, B.A.; Hamilton, R.F.; Keist, J.; Palmer, T.A. Anisotropic microstructure and superelasticity of additive manufactured NiTi alloy bulk builds using laser directed energy deposition. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 2016, 674, 125–134. [Google Scholar] [CrossRef]

- Bormann, T.; Mueller, B.; Schinhammer, M.; Kessler, A.; Thalmann, P.; de Wild, M. Microstructure of selective laser melted nickel-titanium. Mater. Charact. 2014, 94, 189–202. [Google Scholar] [CrossRef]

- Saedi, S.; Moghaddam, N.S.; Amerinatanzi, A.; Elahinia, M.; Karaca, H.E. On the effects of selective laser melting process parameters on microstructure and thermomechanical response of Ni-rich NiTi. Acta Mater. 2018, 144, 552–560. [Google Scholar] [CrossRef]

- Polozov, I.; Popovich, A. Microstructure and mechanical properties of NiTi-based eutectic shape memory alloy produced via selective laser melting in-situ alloying by Nb. Materials 2021, 14, 2696. [Google Scholar] [CrossRef] [PubMed]

- Haberland, C.; Elahinia, M.; Walker, J.M.; Meier, H.; Frenzel, J. On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing. Smart Mater. Struct. 2014, 23, 104002. [Google Scholar] [CrossRef]

- Bormann, T.; Schumacher, R.; Mueller, B.; Mertmann, M.; de Wild, M. Tailoring Selective Laser Melting Process Parameters for NiTi Implants. J. Mater. Eng. Perform. 2012, 21, 2519–2524. [Google Scholar] [CrossRef] [Green Version]

- Zhao, C.; Liang, H.; Luo, S.; Yang, J.; Wang, Z. The effect of energy input on reaction, phase transition and shape memory effect of NiTi alloy by selective laser melting. J. Alloy. Compd. 2020, 817, 153288. [Google Scholar] [CrossRef]

- Yang, Y.; Zhan, J.B.; Sun, Z.Z.; Wang, H.L.; Lin, J.X.; Liu, Y.J.; Zhang, L.C. Evolution of functional properties realized by increasing laser scanning speed for the selective laser melting fabricated NiTi alloy. J. Alloy. Compd. 2019, 804, 220–229. [Google Scholar] [CrossRef]

- Speirs, M.; Wang, X.; Baelen, S.V.; Ahadi, A.; Dadbakhsh, S.; Kruth, J.P.; Humbeeck, J.V. On the transformation behavior of NiTi shape-memory alloy produced by SLM. Shape Mem. Superelasticity 2016, 2, 310–316. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Speirs, M.; Kustov, S.; Vrancken, B.; Li, X.; Kruth, J.P.; Humbeeck, J.V. Selective laser melting produced layer-structured NiTi shape memory alloys with high damping properties and Elinvar effect. Scr. Mater. 2018, 146, 246–250. [Google Scholar] [CrossRef]

- Franco, B.E.; Ma, J.; Loveall, B.; Tapia, G.A.; Karayagiz, K.; Liu, J.; Elwany, A.; Arroyave, R.; Karaman, I. A sensory material approach for reducing variability in additively manufactured metal parts. Sci. Rep. 2017, 7, 3604. [Google Scholar] [CrossRef]

- Xu-Fei, L.U.; Lin, X.; Liang, M.A.; Cao, Y.; Huang, W.-D. Effect of scanning path on thermo-mechanical field of laser solid forming TC4 part. J. Mater. Eng. 2019, 47, 55–62. [Google Scholar]

- Xingke, Z. Additive manufacturing NiTi shape memory alloy and its application in aeronautical manufacturing. Aeronaut. Manuf. Technol. 2016, 507, 34–41. [Google Scholar]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A study of the micro structural evolution during selective laser melting of Ti-6Al-4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Hamilton, R.F.; Palmer, T.A.; Bimber, B.A. Spatial characterization of the thermal-induced phase transformation throughout as-deposited additive manufactured NiTi bulk builds. Scr. Mater. 2015, 101, 56–59. [Google Scholar] [CrossRef]

- Wang, X.; Kustov, S.; Van Humbeeck, J. A short review on the microstructure, transformation behavior and functional properties of NiTi shape memory alloys fabricated by selective laser melting. Materials 2018, 11, 1683. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, Z.; Xu, Z.; Guo, Y.; Xin, R.; Liu, R.; Jiang, C.; Li, L.; Zhang, Z.; Ren, L. Study on properties of SLM-NiTi shape memory alloy under the same energy density. J. Mater. Res. Technol. 2021, 13, 241–250. [Google Scholar] [CrossRef]

- Gu, D.; He, B. Finite element simulation and experimental investigation of residual stresses in selective laser melted Ti-Ni shape memory alloy. Comput. Mater. Sci. 2016, 117, 221–232. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Dutkiewicz, J.; Rogal, L.; Kalita, D.; Weglowski, M.; Blacha, S.; Berent, K.; Czeppe, T.; Antolak-Dudka, A.; Durejko, T.; Czujko, T. Superelastic effect in NiTi alloys manufactured using electron beam and focused laser rapid manufacturing methods. J. Mater. Eng. Perform. 2020, 29, 4463–4473. [Google Scholar] [CrossRef]

- Collins, P.C.; Brice, D.A.; Samimi, P.; Ghamarian, I.; Fraser, H.L. Microstructural control of additively manufactured metallic materials. Annual Review of Materials Research; Clarke, D.R., Ed.; Annual Reviews Inc.: Palo Alto, CA, USA, 2016; Volume 46, pp. 63–91. [Google Scholar]

- Krishna, B.V.; Bose, S.; Bandyopadhyay, A. Laser processing of net-shape NiTi shape memory alloy. Metall. Mater. Trans. A 2007, 38, 1096–1103. [Google Scholar] [CrossRef]

- Wang, X.; Li, K.; Schryvers, D.; Verlinden, B.; Van Humbeeck, J. R-phase transition and related mechanical properties controlled by low-temperature aging treatment in a Ti-50.8 at.% Ni thin wire. Scr. Mater. 2014, 72–73, 21–24. [Google Scholar] [CrossRef]

- Fan, Q.C.; Sun, M.Y.; Zhang, Y.H.; Wang, Y.Y.; Zhang, Y.; Peng, H.B.; Sun, K.H.; Fan, X.H.; Huang, S.K.; Wen, Y.H. Influence of precipitation on phase transformation and mechanical properties of Ni-rich NiTiNb alloys. Mater. Charact. 2019, 154, 148–160. [Google Scholar] [CrossRef]

- Wang, T.; Zhu, Y.Y.; Zhang, S.Q.; Tang, H.B.; Wang, H.M. Grain morphology evolution behavior of titanium alloy components during laser melting deposition additive manufacturing. J. Alloy. Compd. 2015, 632, 505–513. [Google Scholar] [CrossRef]

- Khalil-Allafi, J.; Dlouhy, A.; Eggeler, G. Ni4Ti3-precipitation during aging of NiTi shape memory alloys and its influence on martensitic phase transformations. Acta Mater. 2002, 50, 4255–4274. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Speirs, M.; Van Humbeeck, J.; Kruth, J.-P. Laser additive manufacturing of bulk and porous shape-memory NiTi alloys: From processes to potential biomedical applications. MRS Bull. 2016, 41, 765–774. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Zhan, J.B.; Li, B.; Lin, J.X.; Gao, J.J.; Zhang, Z.Q.; Ren, L.; Castany, P.; Gloriant, T. Laser beam energy dependence of martensitic transformation in SLM fabricated NiTi shape memory alloy. Materialia 2019, 6, 100305. [Google Scholar] [CrossRef]

- Sam, J.; Franco, B.; Ma, J.; Karaman, I.; Mabe, J.H. Tensile actuation response of additively manufactured nickel-titanium shape memory alloys. Scr. Mater. 2018, 146, 164–168. [Google Scholar] [CrossRef]

- Ma, J.; Franco, B.; Tapia, G.; Karayagiz, K.; Elwany, A. Spatial control of functional response in 4D-printed active metallic structures. Sci. Rep. 2017, 7, 46707. [Google Scholar] [CrossRef]

- Halani, P.R.; Kaya, I.; Shin, Y.C.; Karaca, H.E. Phase transformation characteristics and mechanical characterization of nitinol synthesized by laser direct deposition. Mater. Sci. Eng. A 2013, 559, 836–843. [Google Scholar] [CrossRef]

- Zamani, N.; Khamesee, M.B.; Khan, M.I. Novel laser processed shape memory alloy actuator design with an embedded strain gauge sensor using dual resistance measurements. Part I: Fabrication and model-based position estimation. Sens. Actuators A Phys. 2017, 263, 234–245. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Cavaleiro, A.J.; Schell, N.; Stark, A.; Miranda, R.M.; Ocana, J.L.; Braz Fernandes, F.M. Effects of laser processing on the transformation characteristics of NiTi: A contribute to additive manufacturing. Scr. Mater. 2018, 152, 122–126. [Google Scholar] [CrossRef]

- Fan, G.L.; Chen, W.; Yang, S.; Zhu, J.H.; Ren, X.B.; Otsuka, K. Origin of abnormal multi-stage martensitic transformation behavior in aged Ni-rich Ti-Ni shape memory alloys. Acta Mater. 2004, 52, 4351–4362. [Google Scholar] [CrossRef]

- Levitas, V.I.; Roy, A.M.; Preston, D.L. Multiple twinning and variant-variant transformations in martensite: Phase-field approach. Phys. Rev. B 2013, 88, 054113. [Google Scholar] [CrossRef] [Green Version]

- Levitas, V.I.; Javanbakht, M. Surface-induced phase transformations: Multiple scale and mechanics effects and morphological transitions. Phys. Rev. Lett. 2011, 107, 175701. [Google Scholar] [CrossRef]

- Javanbakht, M.; Sadegh Ghaedi, M. Thermal induced nanovoid evolution in the vicinity of an immobile austenite-martensite interface. Comput. Mater. Sci. 2020, 172, 109339. [Google Scholar] [CrossRef]

- Levitas, V.I.; Roy, A.M. Multiphase phase field theory for temperature- and stress-induced phase transformations. Phys. Rev. B 2015, 91, 174109. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Yu, J.; Liu, J.; Chen, L.; Humbeeck, J.V. Effect of process parameters on the phase transformation behavior and tensile properties of NiTi shape memory alloys fabricated by selective laser melting. Addit. Manuf. 2020, 36, 101545. [Google Scholar] [CrossRef]

| Parameter | P (W) | v (mm/min) | h (mm) | t (mm) | EV (J/mm3) | Specimen Size (mm × mm × mm) | |

|---|---|---|---|---|---|---|---|

| Sample | |||||||

| L1 | 1500 | 900 | 5 | 0.3 | 66.67 | 20 × 10 × 10 | |

| L2 | 2000 | 900 | 5 | 0.6 | 44.44 | ||

| L3 | 2500 | 900 | 5 | 0.9 | 37 | ||

| L4 | 1500 | 1000 | 5 | 0.3 | 60 | ||

| L5 | 2000 | 1000 | 5 | 0.6 | 40 | ||

| L6 | 2500 | 1000 | 5 | 0.9 | 33.33 | ||

| L7 | 2000 | 900 | 5 | 0.4 | 66.67 | 70 × 15 × 12 | |

| L8 | 1500 | 900 | 5 | 0.3 | 66.67 | ||

| Location | Ni (at%) | Ti (at%) | Nb (at%) |

|---|---|---|---|

| 1 | 49.67 | 41.93 | 8.39 |

| 2 | 44.99 | 46.32 | 8.69 |

| 7 | 45.12 | 44.82 | 10.06 |

| TTs (°C) | Ms | Mp | Mf | As | Ap | Af | Ap − Mp | EV (J/mm3) | |

|---|---|---|---|---|---|---|---|---|---|

| Sample | |||||||||

| L1 | 32 | 10 | −2 | 35 | 51 | 71 | 41 | 66.67 | |

| L6 | 35 | 19 | 0 | 38 | 58 | 70 | 39 | 33.33 | |

| TTs (°C) | Rs | Rf | Ms | Mf | As | Af | Rp | Mp | Ap | Ap − Mp | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Location | |||||||||||

| 2 | 7.4 | −16.8 | −23.1 | −67.3 | −24.1 | 16.9 | −6.3 | −37.4 | 3.7 | 41.1 | |

| 3 | — | — | −3.8 | −70.4 | −28.1 | 23.5 | — | −36.4 | −2.4 | 34 | |

| 4 | — | — | — | — | — | — | — | — | — | — | |

| 5 | — | — | −25.1 | −67.8 | −31.5 | 13.7 | — | −38.8 | −3.6 | 35.2 | |

| 6 | — | — | — | — | — | — | — | — | — | — | |

| 7 | 9.6 | −17.5 | −33.2 | −69.4 | −18.1 | 16.1 | 2.5 | −52.1 | −4.1 | 48 | |

| 8 | — | — | −16.9 | −70.9 | −24.8 | 21.3 | — | −31.5 | −0.9 | 30.6 | |

| 9 | 18.6 | −4 | −17.5 | −61.6 | −22.3 | 27 | 5.5 | −38 | −2.7 | 35.3 | |

| 10 | — | — | −53.8 | −88.3 | −58.6 | −22.3 | — | −65.8 | −33.4 | 32.4 | |

| 11 | — | — | −53.1 | −98.6 | −61.1 | −6.9 | — | −80.8 | −48.3 | 32.5 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, Q.; Li, H.; Yang, Z.; Zhang, Y.; Liu, X.; Li, G. Microstructure and Phase Transformation Temperature of NiTiNb Shape Memory Alloy Prepared by Laser Solid Forming Using Mixed Powder. Appl. Sci. 2022, 12, 2371. https://doi.org/10.3390/app12052371

Gu Q, Li H, Yang Z, Zhang Y, Liu X, Li G. Microstructure and Phase Transformation Temperature of NiTiNb Shape Memory Alloy Prepared by Laser Solid Forming Using Mixed Powder. Applied Sciences. 2022; 12(5):2371. https://doi.org/10.3390/app12052371

Chicago/Turabian StyleGu, Qingfei, Heng Li, Zhiwei Yang, Yanhong Zhang, Xin Liu, and Guangjun Li. 2022. "Microstructure and Phase Transformation Temperature of NiTiNb Shape Memory Alloy Prepared by Laser Solid Forming Using Mixed Powder" Applied Sciences 12, no. 5: 2371. https://doi.org/10.3390/app12052371

APA StyleGu, Q., Li, H., Yang, Z., Zhang, Y., Liu, X., & Li, G. (2022). Microstructure and Phase Transformation Temperature of NiTiNb Shape Memory Alloy Prepared by Laser Solid Forming Using Mixed Powder. Applied Sciences, 12(5), 2371. https://doi.org/10.3390/app12052371