Dynamic Characteristic Master Curve and Parameters of Different Asphalt Mixtures

Abstract

:1. Introduction

2. Acquisition of Dynamic Principal Curve

3. Characteristic Parameters of Master Curves

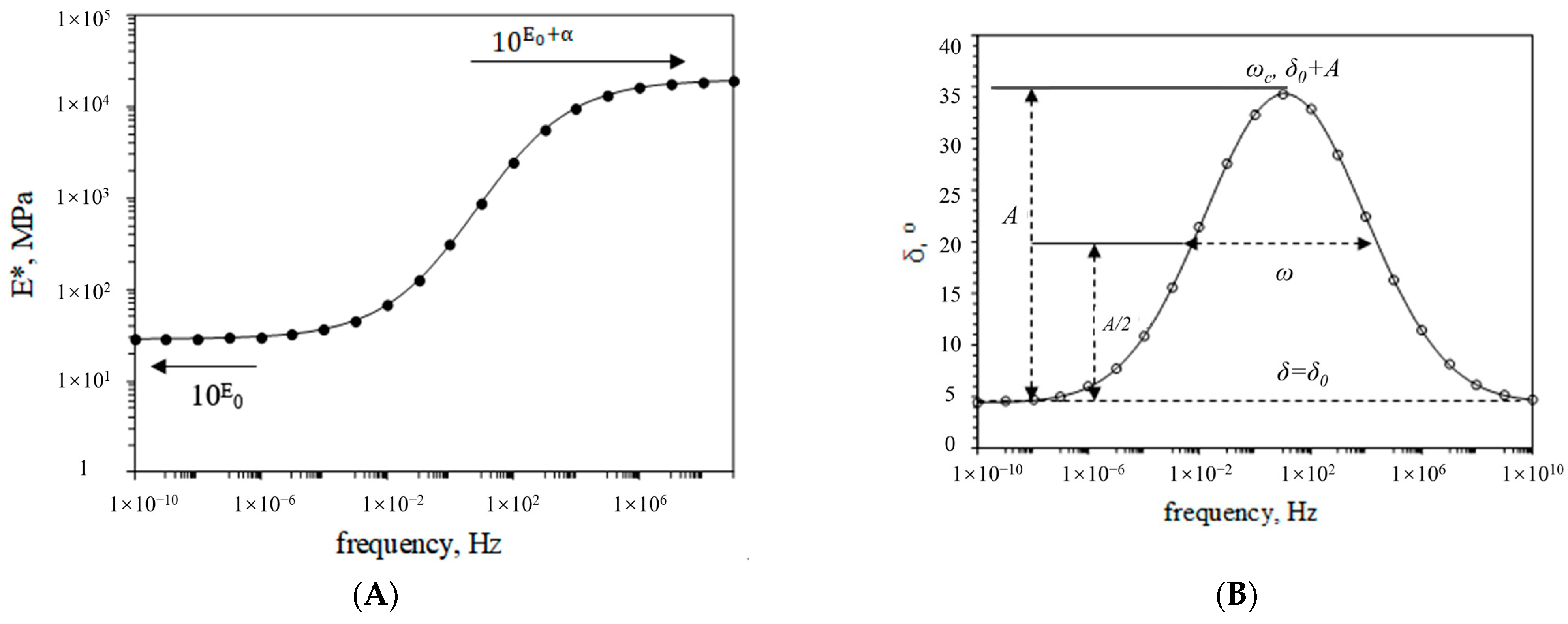

3.1. Modulus Master Curve Parameters

3.2. Phase Angle Master Curve Parameters

3.2.1. δ0, A, and ω

3.2.2. Phase Angle Peak Position Parameter-ωc

4. Master Curves of Different Asphalt Mixture

5. Conclusions

- (1)

- The modulus master curve parameters (E0, α, γ) of asphalt mixtures are closely related to the mineral voidage (VMA), mixture density (γf), and asphalt content (Pb%) of the asphalt mixture. For the same kind of asphalt mixture, because the gradation of mineral aggregate is fixed, the volume parameters are almost the same, and the ultimate modulus of the mixture at different temperatures is unique. When the temperature changes or the asphalt changes, the shape parameter β of the modulus master curve changes regularly, which brings different dynamic responses, and the lower β will show higher modulus characteristics.

- (2)

- Asphalt is the source of the viscoelasticity of the asphalt mixture. Although the influence of particle gradation of the mixture will bring about the change of modulus, the phase angle of the mixture depends on the viscoelastic properties of the asphalt. The initial phase angle (δ0) in the main curve is positively correlated with asphalt penetration and negatively correlated with softening point and viscosity, the peak height A is negatively correlated with penetration and softening point viscosity, and the viscoelastic interval represented by FWHM (ω) is negatively correlated with penetration, but positively correlated with the softening point and viscosity.

- (3)

- The peak position parameter ωc of the phase angle master curve can evaluate the relaxation characteristics of the mixture and avoid the complex process of model calculation. In the comparison of the relaxation time of the asphalt mixture, the relaxation time of the foam cold-recycled mixture is the largest, which is significantly higher than that of other forms of asphalt mixture; emulsified asphalt cold-recycled mixture is equivalent to AC20 and LSPM30 mixtures; SBS-modified asphalt mixture has the best relaxation characteristics; different relaxation times indicate different crack resistance, the longer the relaxation time, the worse the crack resistance. However, less relaxation time (less viscosity) leads to a large viscous flow in a very short time, creating a large rutting, which is one of the most serious issues in asphalt pavement on heavy-duty roadways.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Song, R.Y.; Xie, X.Z. Dynamic property master curves of visco-elastical material. Noise Vib. Control 1985, S1 (Suppl. S1), 25–32. [Google Scholar]

- Liu, F.Q.; Tang, X.Y. Polymer Physics; Higher Education Press: Bejing, China, 2004. [Google Scholar]

- Menglan, Z.; Xinzhe, H.; Jie, L.; Qun, L. Relationship between dynamic properties of asphalt binders and mixtures. Cent. South Highw. Eng. 2003, 4, 11–15. [Google Scholar]

- Jin, L. Experimental Study on Master Curve of Failure Strength of Asphalt Mixture. Master’s Thesis, Dalian University of Technology, Dalian, China, 2019. [Google Scholar]

- Wang, H.P.; Yang, J.; Shi, X.Q.; Zhou, W.Z. Research of dynamic modulus and master curve of high modulus asphalt mixture. J. Highw. Trans. Res. Dev. 2015, 32, 12–17. [Google Scholar]

- Hu, L.Y.; Zhen, Q.H.; Yu, F.; Chen, J.L.; Luo, R. Master Curve Drawing of Axial Transverse Dynamic Modulus Based on the Same Time-temperature Equivalent Factor. J. Wuhan Univ. Technol. Transp. Sci. Eng. 2019, 43, 146–152. [Google Scholar]

- Song, X.J.; Zeng, M.L.; Fan, L. Relationship between back-calculated modulus of asphalt pavement and dynamic modulus of asphalt mixture. China Civ. Eng. J. 2019, 52, 121–128. [Google Scholar]

- Song, X.J.; Fan, L. Durations of Stress Response in Asphalt Pavement under Moving Load. J. Hunan Univ. Nat. Sci. 2018, 45, 71–76. [Google Scholar]

- Guo, L.; Xu, Q.; Zeng, G.; Wu, W.; Zhou, M.; Yan, X.; Zhang, X.; Wei, J. Comparative Study on Complex Modulus and Dynamic Modulus of High-Modulus Asphalt Mixture. Coatings 2021, 11, 1502. [Google Scholar] [CrossRef]

- He, M.J.; Zhang, H.D.; Chen, W.X.; Dong, X.X. Polymer Physics; Fudan University Press: Shanghai, China, 2007. [Google Scholar]

- Song, X.; Zeng, M.; Fan, L. Relationship among dynamic properties of pavement asphalt materials. J. Build. Mater. 2018, 21, 920–925. [Google Scholar]

- Xiao, C.F.N.; Gui, Z.L. Continuous relaxation time spectrum of asphalt mixture based on master curve of dynamic modulus. J. S. China Univ. Technol. Nat. Sci. Ed. 2008, 10, 76–80. [Google Scholar]

- Wang, Z.C.; Guo, N.S.; Zhao, Y.H.; Chen, Z.D. Determination and conversion of relaxation and retardation time spectrum of asphalt mixtures. J. Beijing Univ. Technol. 2019, 45, 168–176. [Google Scholar]

- Zhu, J.; Ahmed, A.; Said, S.; Dinegdae, Y.; Lu, X. Experimental analysis and predictive modelling of linear viscoelastic response of asphalt mixture under dynamic shear loading. Constr. Build. Mater. 2022, 328, 12095. [Google Scholar]

- Han, D.; Yuan, M.; Hu, H. Establishing prediction master curve of dynamic modulus of asphalt mixture considering randomness of aggregate morphology. Constr. Build. Mater. 2021, 294, 123575. [Google Scholar]

- Shi, Y.; Liu, H.; Wang, G. Modeling of asphalt mixture-screed interaction: A nonlinear dynamic vibration model for improving paving density. Constr. Build. Mater. 2021, 311, 125296. [Google Scholar]

- Pablo, M.V.; Silvio, L.S.; Pedro, O.B.A.; Cléber, F.; Luciano, P.S.; Deividi, S.P. Dynamic modulus master curve construction of asphalt mixtures: Error analysis in different models and field scenarios. Constr. Build. Mater. 2021, 301, 124343. [Google Scholar]

- Zhang, J.; Zhang, X.; Liang, M.; Jiang, H.; Wei, J.; Yao, Z. Influence of different rejuvenating agents on rheological behavior and dynamic response of recycled asphalt mixtures incorporating 60% RAP dosage. Constr. Build. Mater. 2020, 238, 117778. [Google Scholar]

- Bueno, L.D.; Schuster, S.L.; Specht, L.P.; da Pereira, D.S.; do Nascimento, L.A.H.; Kim, Y.R.; Brenner, M.G.B. Asphalt pavement design optimisation: A case study using viscoelastic continuum damage theory. Int. J. Pavement Eng. 2020, 23, 1070–1082. [Google Scholar] [CrossRef]

- Ling, M.; Luo, X.; Gu, F.; Lytton, R.L. Time-temperature-aging-depth shift functions for dynamic modulus master curves of asphalt mixtures. Constr. Build. Mater. 2017, 157, 943–951. [Google Scholar] [CrossRef]

- Specht, L.P.; de Babadopulos, L.F.A.L.; di Benedetto, H.; Cedric Sauzeat, S.J.B. Application of the theory of viscoelasticity to evaluate the resilient modulus test in asphalt mixes. Constr. Build. Mater. 2017, 149, 648–658. [Google Scholar] [CrossRef]

- Su, N.; Xiao, F.; Wang, J.; Amirkhanian, S. Precision analysis of sigmoidal master curve model for dynamic modulus of asphalt mixtures. J. Mater. Civ. Eng. 2018, 30, 04018290. [Google Scholar] [CrossRef]

- Eric, L.T.; Vaillancourt, M.; Perraton, D.; di Benedetto, H. Linear viscoelastic (LVE) properties of asphalt mixtures with different glass aggregates and hydrated lime content. Int. J. Pavement Eng. 2020, 21, 1170–1179. [Google Scholar]

- Mangiafico, S.; Sauzeat, C.; Di Benedetto, H. 2S2P1D model calibration error from user panel for one bitumen and one bituminous mixture. Adv. Mater. Sci. Eng. 2019, 2019, 6547025. [Google Scholar] [CrossRef] [Green Version]

| Mixture Type | ZH50-AC20 | ZH70-AC20 | ZH90-AC20 |

|---|---|---|---|

| Penetration grade | 50 | 70 | 90 |

| Asphalt content (Pb) % | 4.3 | 4.4 | 4.3 |

| Mixture density (γf) g/cm3 | 2.42436 | 2.42498 | 2.4296 |

| Mixture void percent (Vv) % | 4.59 | 4.42 | 4.4 |

| Aggregate void ratio (VMA) % | 14.15 | 14.1 | 14.4 |

| Asphalt saturation (VFA) % | 67.32 | 68.54 | 68.47 |

| Type | Temperature, °C | Fitting Parameters for E* Master Curve | Fitting Parameters for δ Master Curve | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| E0 | α | β | γ | R2 | δ0 | A | ωc | ω | R2 | ||

| ZH50-AC20 | 20 | 1.4522 | 2.844 | −1.537 | −0.664 | 0.997 | 4.436 | 29.961 | −2.084 | 2.893 | 0.989 |

| 30 | −0.743 | −0.889 | |||||||||

| 40 | −0.046 | 0.161 | |||||||||

| 50 | 0.561 | 1.074 | |||||||||

| ZH70-AC20 | 20 | 1.4926 | 2.7866 | −1.339 | −0.694 | 0.995 | 15.259 | 19.253 | −1.607 | 2.063 | 0.990 |

| 30 | −0.607 | −0.551 | |||||||||

| 40 | 0.149 | 0.536 | |||||||||

| 50 | 0.924 | 1.654 | |||||||||

| ZH90-AC20 | 20 | 1.3762 | 2.9551 | −0.998 | −0.627 | 0.996 | 18.223 | 16.309 | −1.216 | 2.025 | 0.987 |

| 30 | −0.461 | −0.364 | |||||||||

| 40 | 0.156 | 0.624 | |||||||||

| 50 | 0.846 | 1.725 | |||||||||

| Mixture Type | Temperature, °C | ωc | 10ωc, Hz | τ, s |

|---|---|---|---|---|

| ZH50-AC20 | 20 | −2.084 | 0.008 | 121.34 |

| 30 | −0.889 | 0.129 | 7.74 | |

| 40 | 0.161 | 1.449 | 0.69 | |

| 50 | 1.074 | 11.858 | 0.08 | |

| ZH70-AC20 | 20 | −1.607 | 0.025 | 40.46 |

| 30 | −0.551 | 0.281 | 3.56 | |

| 40 | 0.536 | 3.436 | 0.29 | |

| 50 | 1.654 | 45.082 | 0.02 | |

| ZH90-AC20 | 20 | −1.216 | 0.061 | 16.44 |

| 30 | −0.364 | 0.433 | 2.31 | |

| 40 | 0.624 | 4.207 | 0.24 | |

| 50 | 1.725 | 53.088 | 0.02 |

| Code | Asphalt Type | Mixture Type | Pb, % | Vv, % | VMA, % | VFA, % |

|---|---|---|---|---|---|---|

| ZH50-AC20 | Pen-grade 50 | HMA, AC20 | 4.3 | 4.6 | 14.2 | 67.32 |

| ZH70-AC20 | Pen-grade 70 | HMA, AC20 | 4.4 | 4.4 | 14.1 | 68.54 |

| ZH90-AC20 | Pen-grade 90 | HMA, AC20 | 4.3 | 4.4 | 14.4 | 68.47 |

| SBS-SMA13 | SBS modified asphalt | HMA, SMA13 | 6 | 4.2 | 17.1 | 75.6 |

| MAC-AC20 | MAC modified asphalt | HMA, AC20 | 4.4 | 4.3 | 13.4 | 68.3 |

| ZH70-AC-25 | Pen-grade 70 | HMA, AC25 | 4.1 | 4.1 | 12.6 | 68 |

| MAC-LSPM30 | MAC modified asphalt | HMA, LSPM30 | 3.2 | 15.2 | 23.5 | / |

| SBS-AC13 | SBS modified asphalt | HMA, AC13 | 6.2 | 2.4 | 15.2 | 82.9 |

| E-CRM | Emulsified asphalt | Cold recycling | 3.5 (plus 1.5%cement) | 10.2 | / | / |

| F-CRM1 | Formed asphalt | Cold recycling | 3 (plus 1.5%cement) | 11.5 | / | / |

| F-CRM2 | Formed asphalt | Cold recycling | 3 (plus 1.5%cement) | 12.0 | / | / |

| Mixture Type | δ0, ° | A, ° | ωc, Hz | ω, Hz | A/ω |

| F-CRM-2 | 1.53 | 17.94 | 0.08 | 1233.81 | 0.01 |

| F-CRM-1 | 4.29 | 12.92 | 0.10 | 800.49 | 0.02 |

| MAC-AC20 | 5.35 | 22.63 | 0.57 | 303.40 | 0.07 |

| ZH50-AC20 | 4.44 | 29.96 | 1.45 | 781.38 | 0.04 |

| E-CRM | 1.20 | 31.10 | 1.53 | 432.83 | 0.07 |

| MAC-LSPM30 | 5.64 | 19.05 | 1.86 | 259.68 | 0.07 |

| SBS-SMA13 | 6.16 | 22.34 | 3.37 | 187.31 | 0.12 |

| ZH70-AC20 | 15.26 | 19.25 | 3.44 | 115.51 | 0.17 |

| ZH70-AC25 | 5.70 | 26.40 | 3.92 | 148.42 | 0.18 |

| ZH90-AC20 | 18.22 | 16.31 | 4.21 | 105.94 | 0.15 |

| SBS-AC13 | 8.62 | 23.98 | 8.96 | 56.52 | 0.42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, S.; Fan, L.; Ma, T.; Dong, Z.; Zhang, Y.; Zhang, X. Dynamic Characteristic Master Curve and Parameters of Different Asphalt Mixtures. Appl. Sci. 2022, 12, 3619. https://doi.org/10.3390/app12073619

Ma S, Fan L, Ma T, Dong Z, Zhang Y, Zhang X. Dynamic Characteristic Master Curve and Parameters of Different Asphalt Mixtures. Applied Sciences. 2022; 12(7):3619. https://doi.org/10.3390/app12073619

Chicago/Turabian StyleMa, Shijie, Liang Fan, Tao Ma, Zhao Dong, Yuzhen Zhang, and Xiaomeng Zhang. 2022. "Dynamic Characteristic Master Curve and Parameters of Different Asphalt Mixtures" Applied Sciences 12, no. 7: 3619. https://doi.org/10.3390/app12073619