Numerical and Experimental Research on the Laser-Water Jet Scribing of Silicon

Abstract

1. Introduction

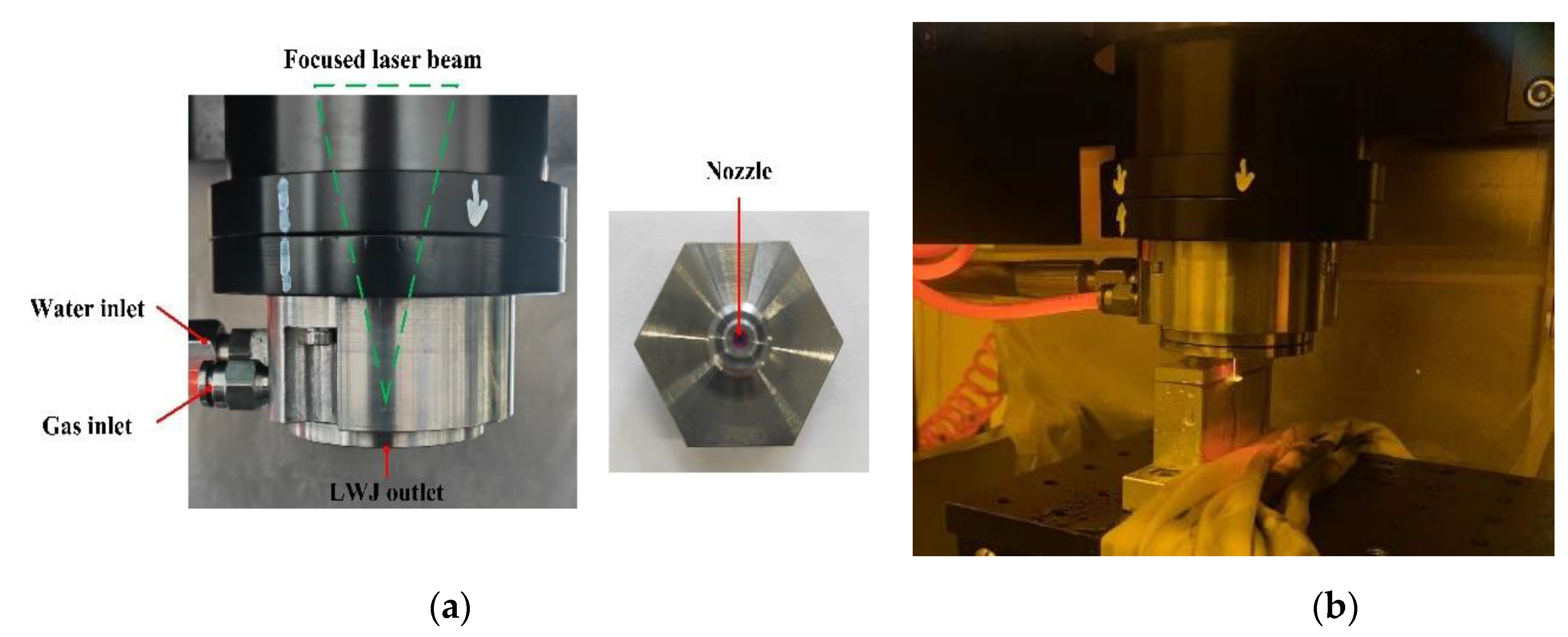

2. Numerical Simulation and Experimental Setup

2.1. Theoretical Background

- (1)

- Generalized Hooke equations describing the thermal stress [18]:where , , and are the normal stresses along X, Y, and Z axes, respectively. G is the shear modulus, , where E is the elasticity modulus, and μ is the Poisson’s ratio. , , and are the normal strain along X, Y, and Z axes, respectively. e is the volumetric strain, . is the Lame constant, . is the thermal stress coefficient, , where is the linear expansion coefficient. , , and are the theoretical elastic shear strain. , , and are the shear stress.

- (2)

- Dynamic displacement equations describing the thermoelastic force [18]:where is Laplace operator, . , , and are the displacement along X, Y, and Z axes, respectively.

- (3)

- Deformation compatibility equation describing the thermoelastic force [18]:where is the volumetric stress, .

2.2. Numerical Setup

- The density of the substrate remained constant, neglecting the absorption of laser energy. The surrounding temperature was 300 K throughout the whole calculation process.

- When the temperature of one element reached the melting point, it was assumed to be ablated from the substrate.

- The fluid dynamics of the melting material was neglected considering the scouring effect of the waterjet.

- The influence of the assisted gas atmosphere on the substrate ablation was neglected.

3. Experimental Setup

4. Results and Discussion

4.1. Ablation Mechanism of Silicon

4.2. Morphological Evolution of Silicon

- (1)

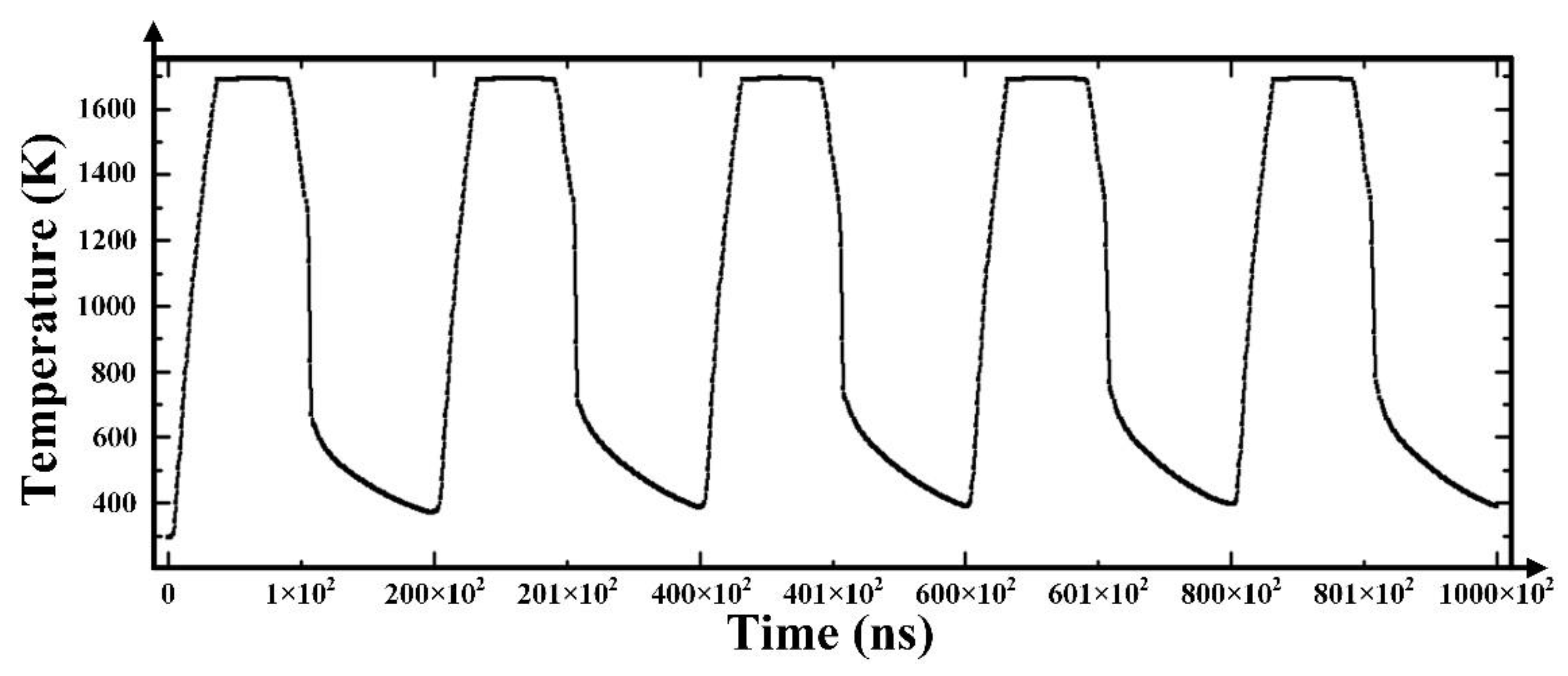

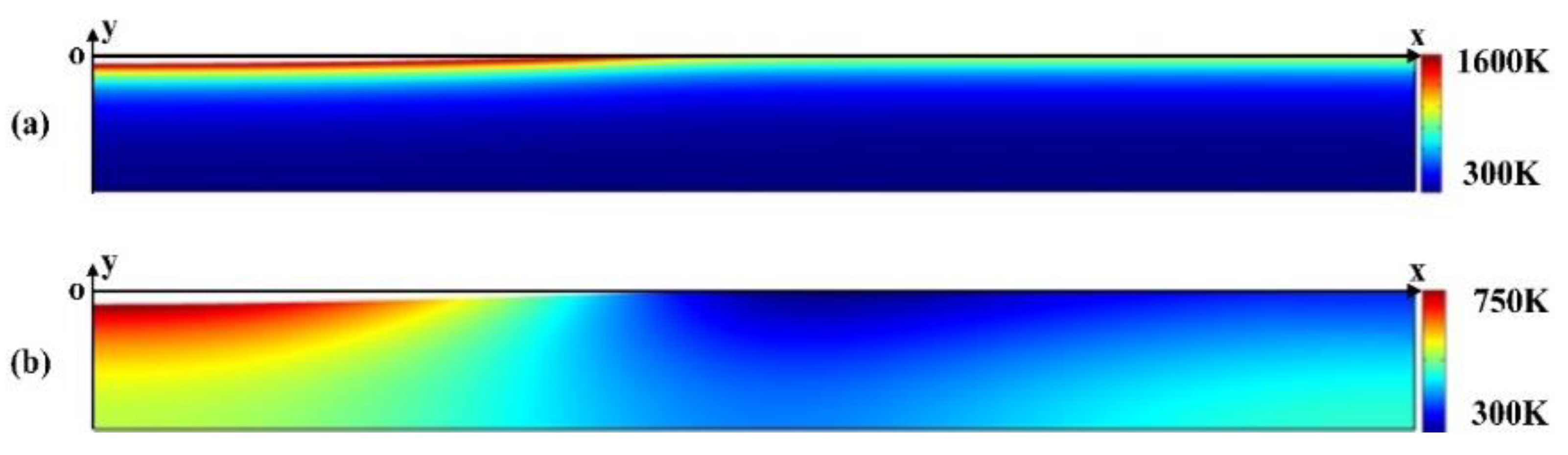

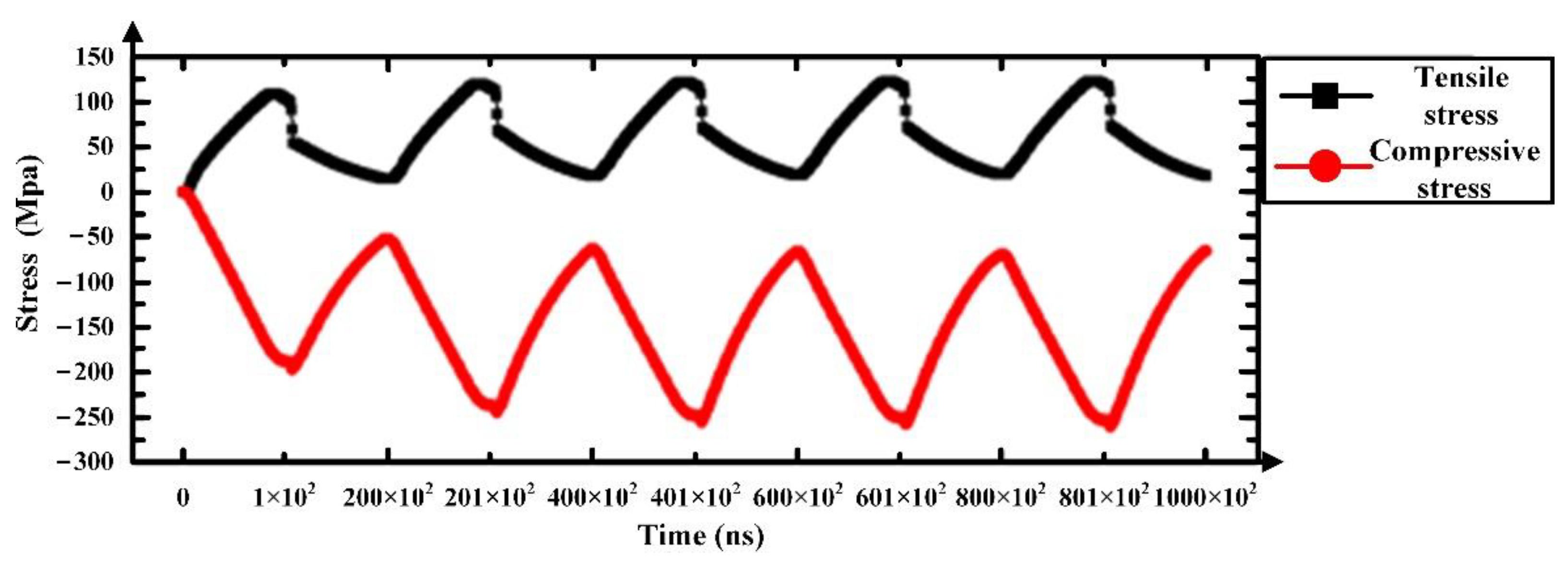

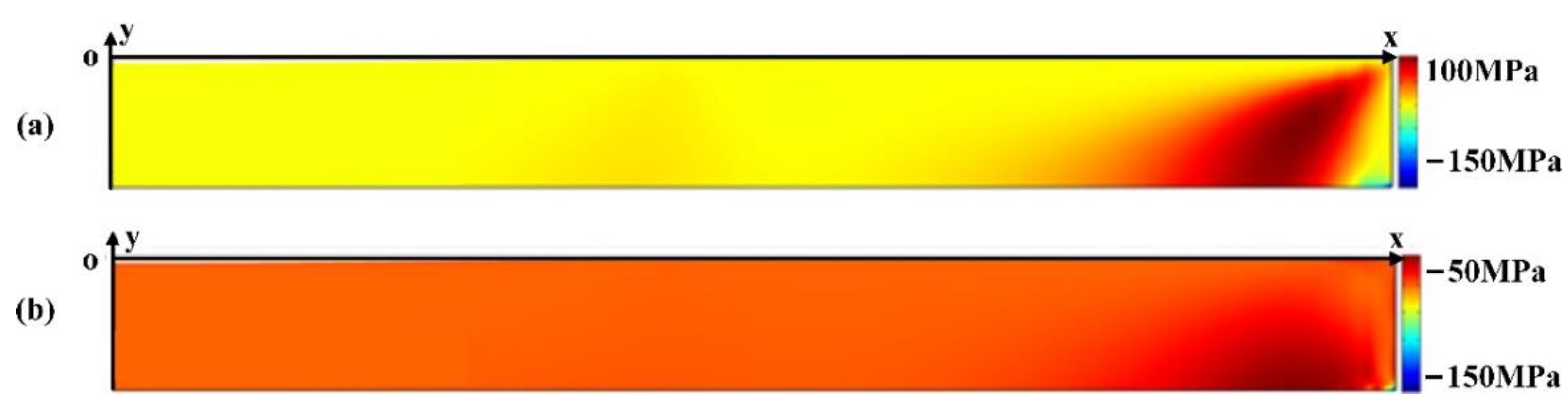

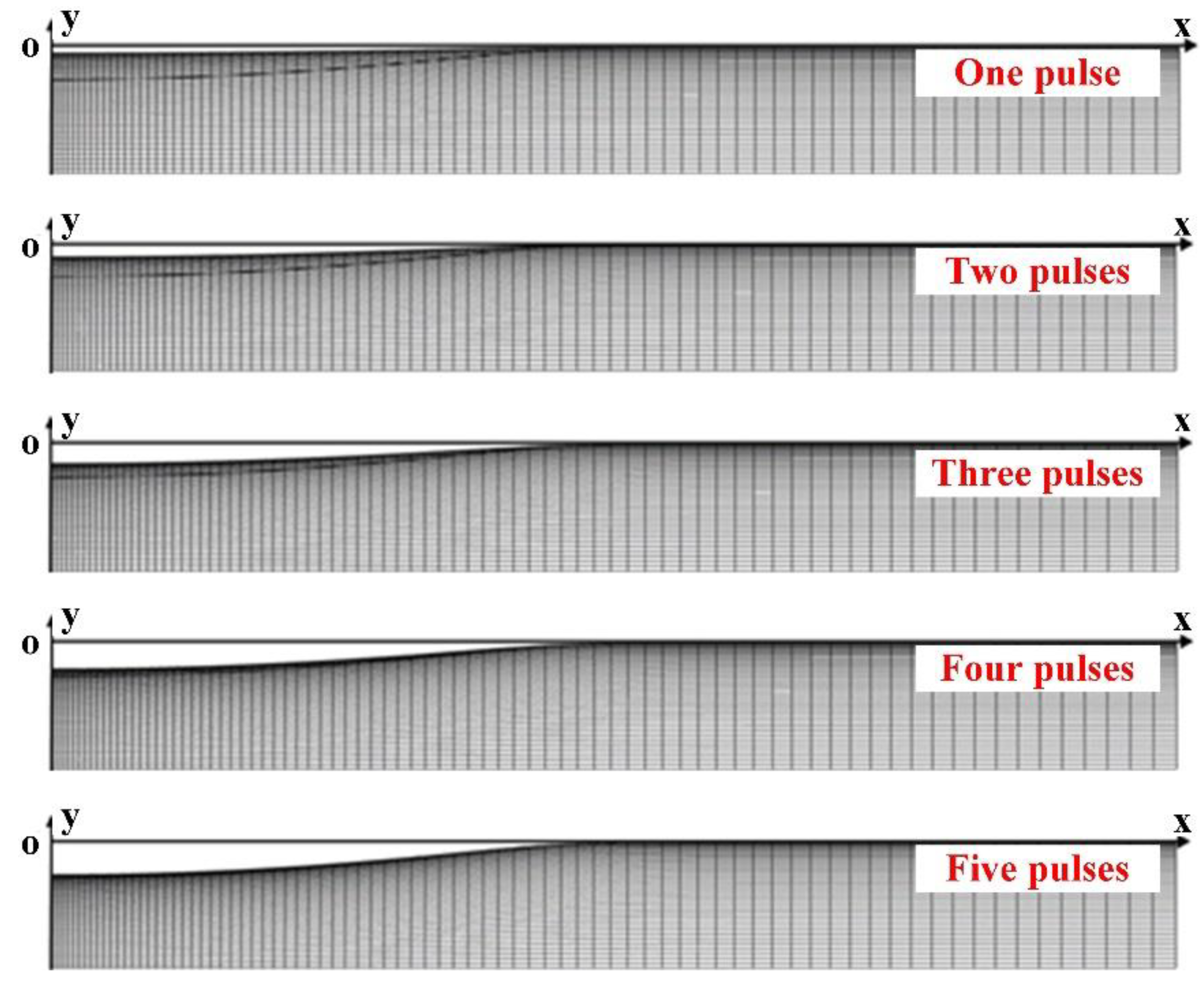

- In the initial stage of laser pulse incidence, the laser photons interacted with the silicon lattice. The vibration of the silicon lattice led to the rapid heating up of the surface layer. Thermal-induced tensile and compressive stresses started to generate in the machining region.

- (2)

- During the laser pulse incidence, thermal conduction occupied a principal position compared with thermal convection induced by the scouring effect of the waterjet. The temperature of the surface layer increased in a nonlinear way. Tensile and compressive stress gradually concentrated on the edge of the substrate. Part of the surface layer was ablated.

- (3)

- At the end of laser pulse, the tensile and compressive stresses reached the peak value, which resulted from the compound action of the laser-induced thermal effect and the waterjet-induced scouring effect. However, these two stresses could hardly modulate the substrate ablation process. The micro-pit was formed temporarily.

- (4)

- During the interval of laser pulse, the waterjet scoured the machining region, which cooled down the local temperature surrounding the pit significantly. The tensile and compressive stresses gradually released to the initial state.

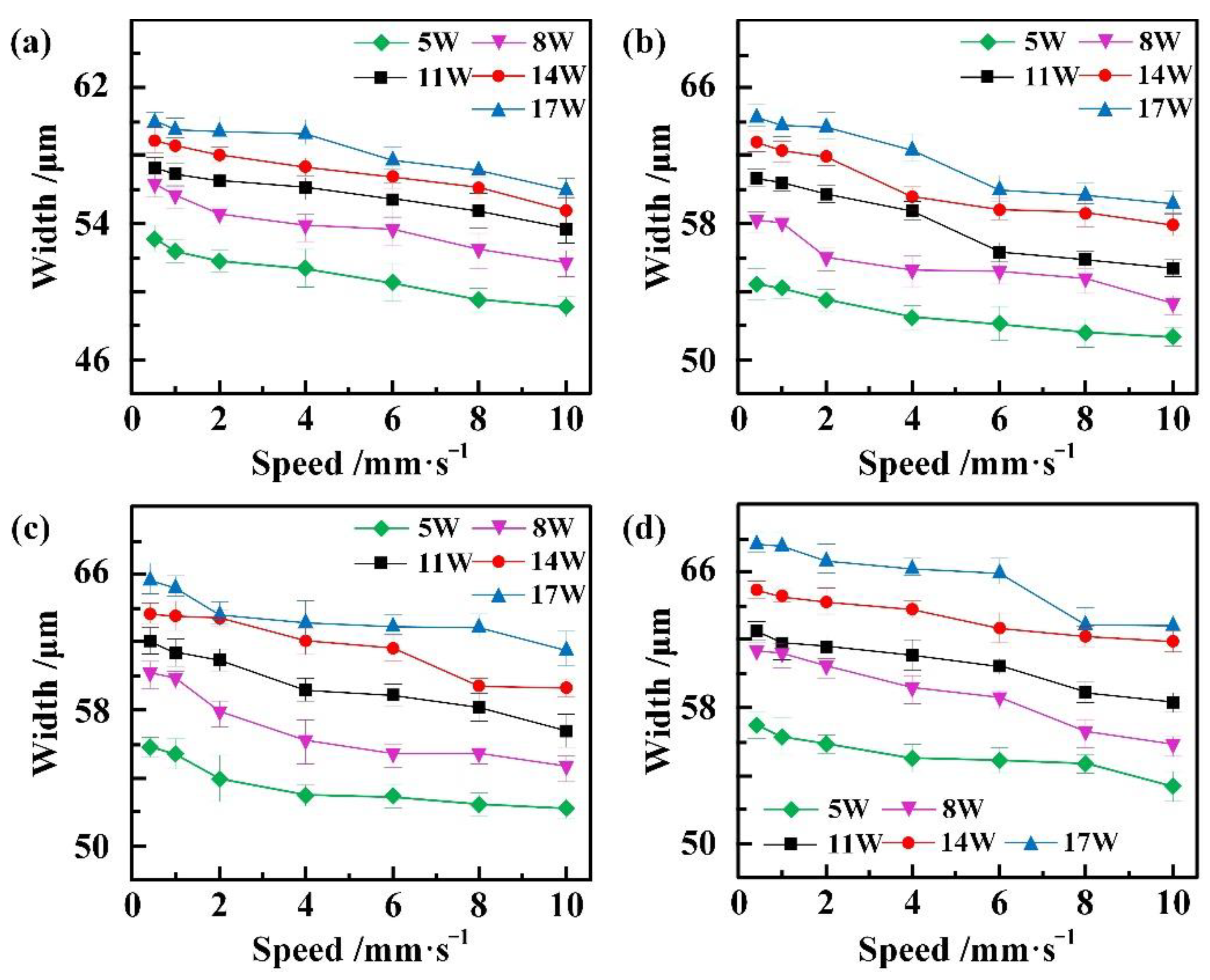

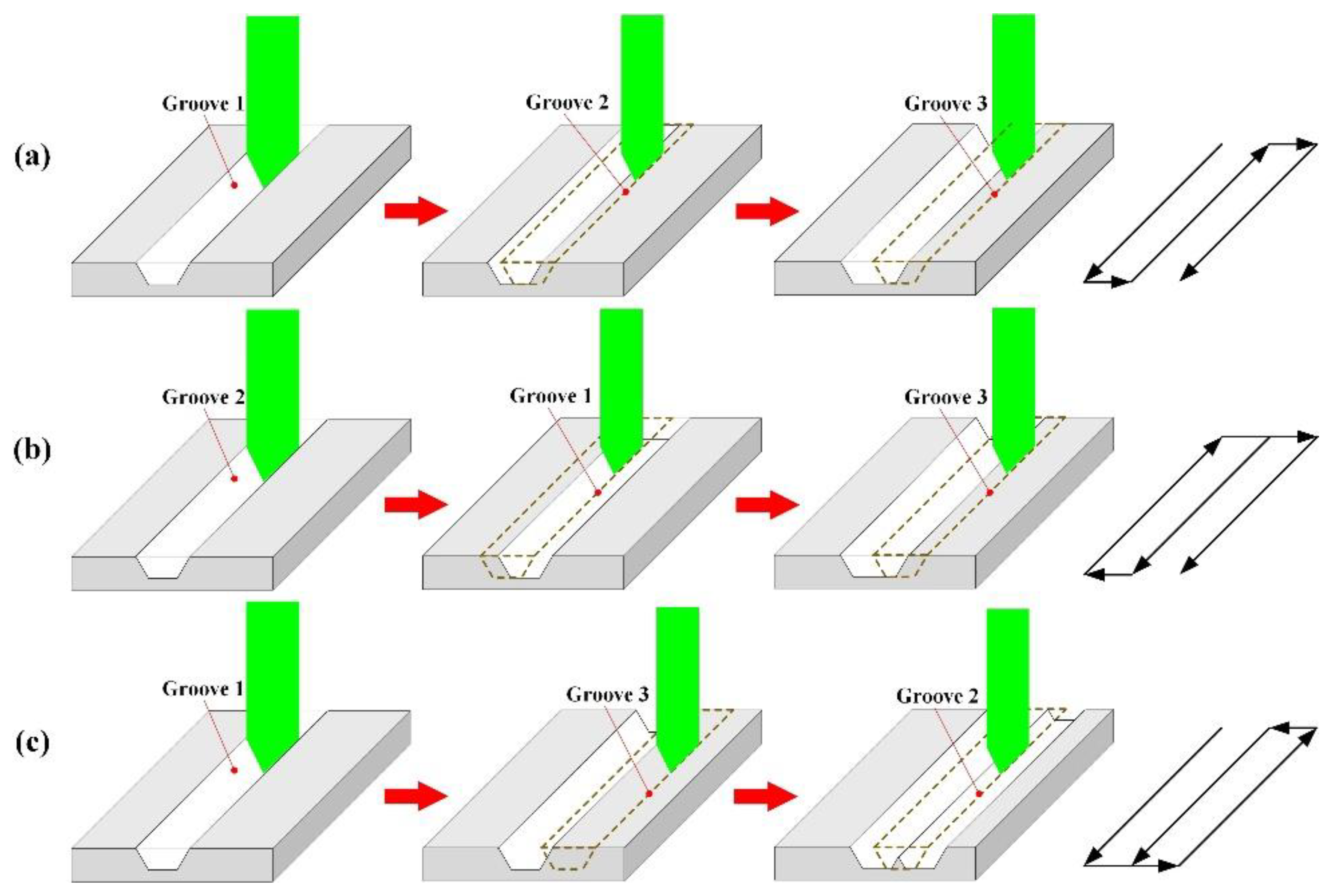

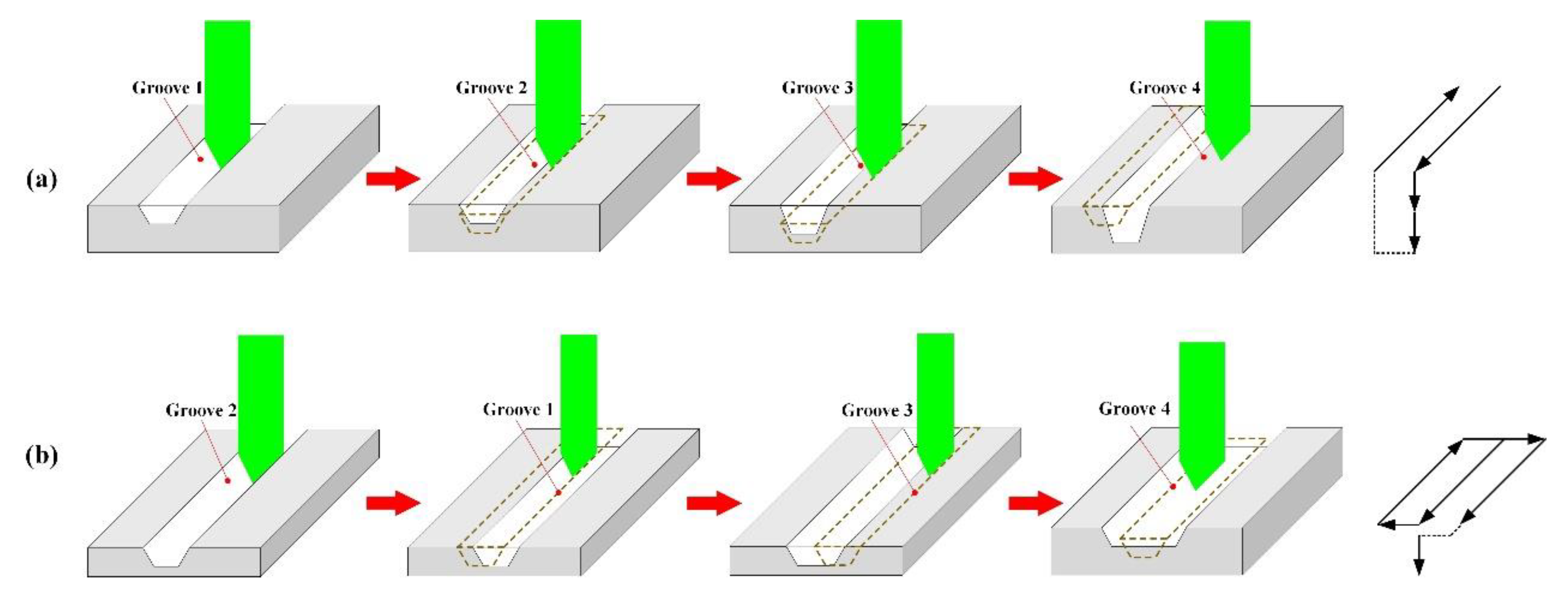

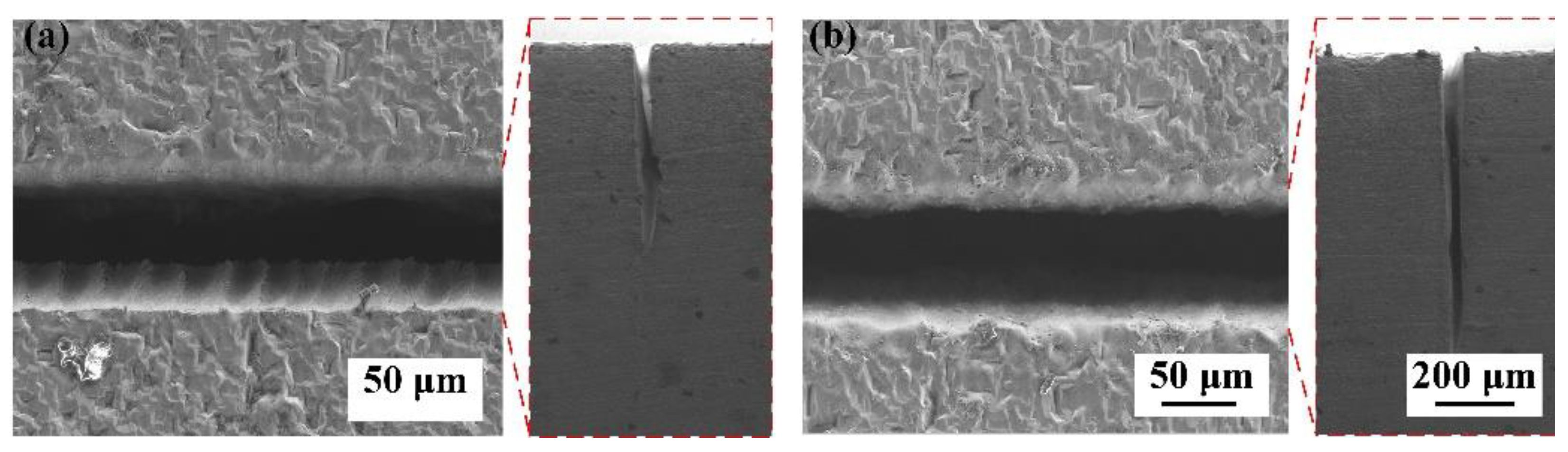

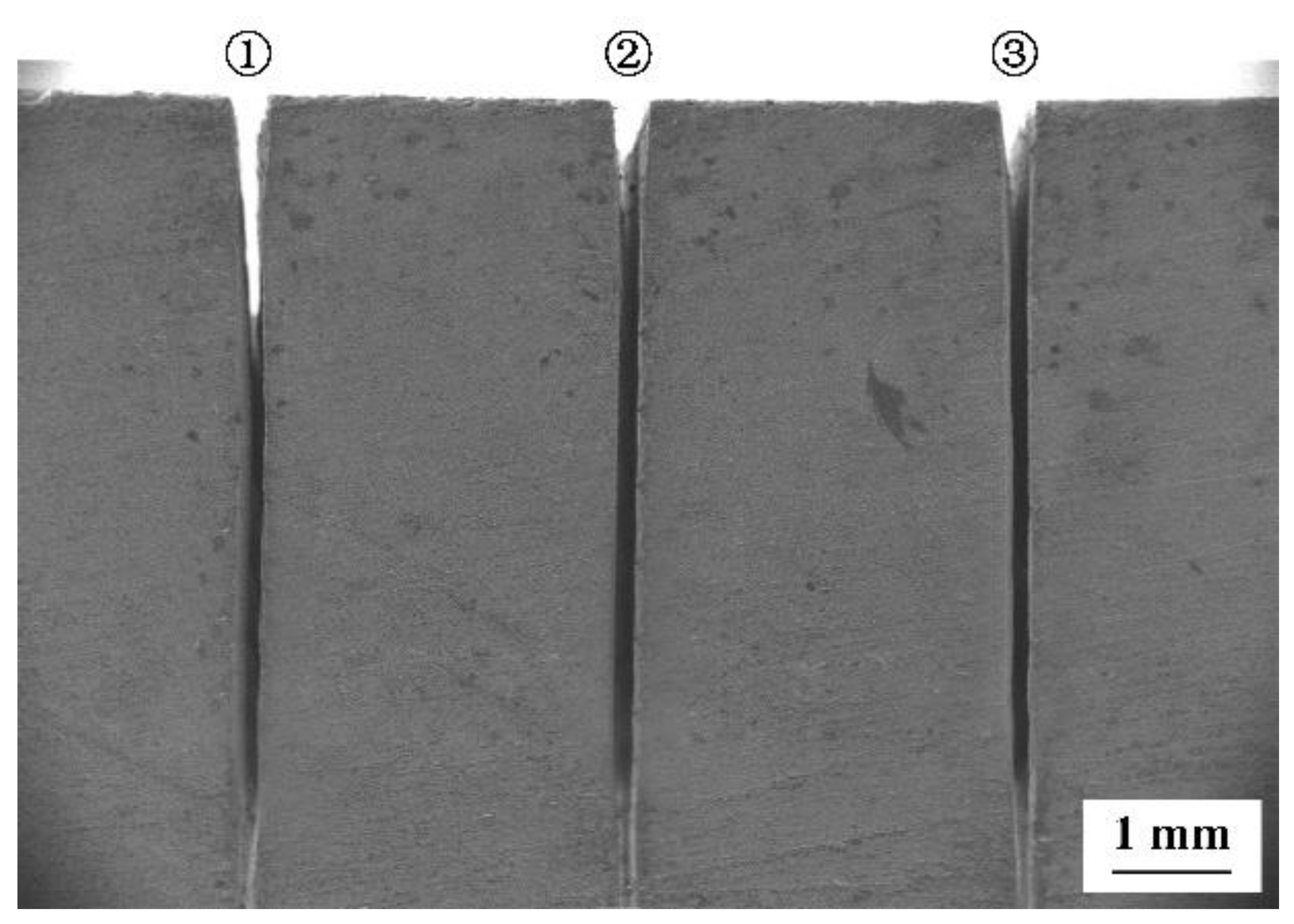

4.3. Fabrication of Micro-Grooves with Large DTWR

5. Conclusions

- (1)

- During LWJ machining, the maximum values of generated tensile and compressive stresses were approximately 122 MPa and 253 MPa, respectively, which were far lower than the tensile strength and compressive strength. The maximum temperature exceeded 1730 K, which was higher than melting point of the substrate. Therefore, the dominated substrate ablation mechanism was the laser-induced thermal effect.

- (2)

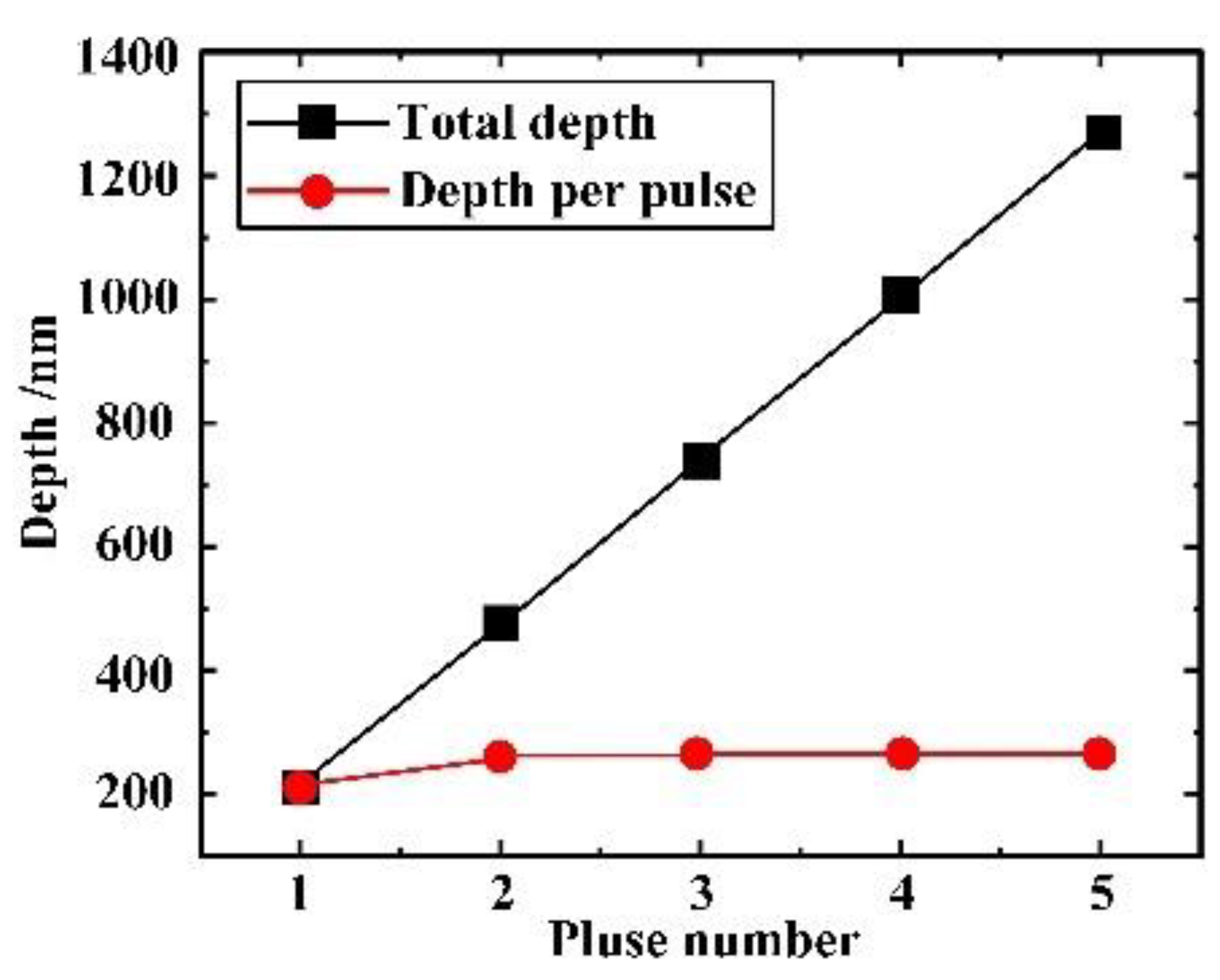

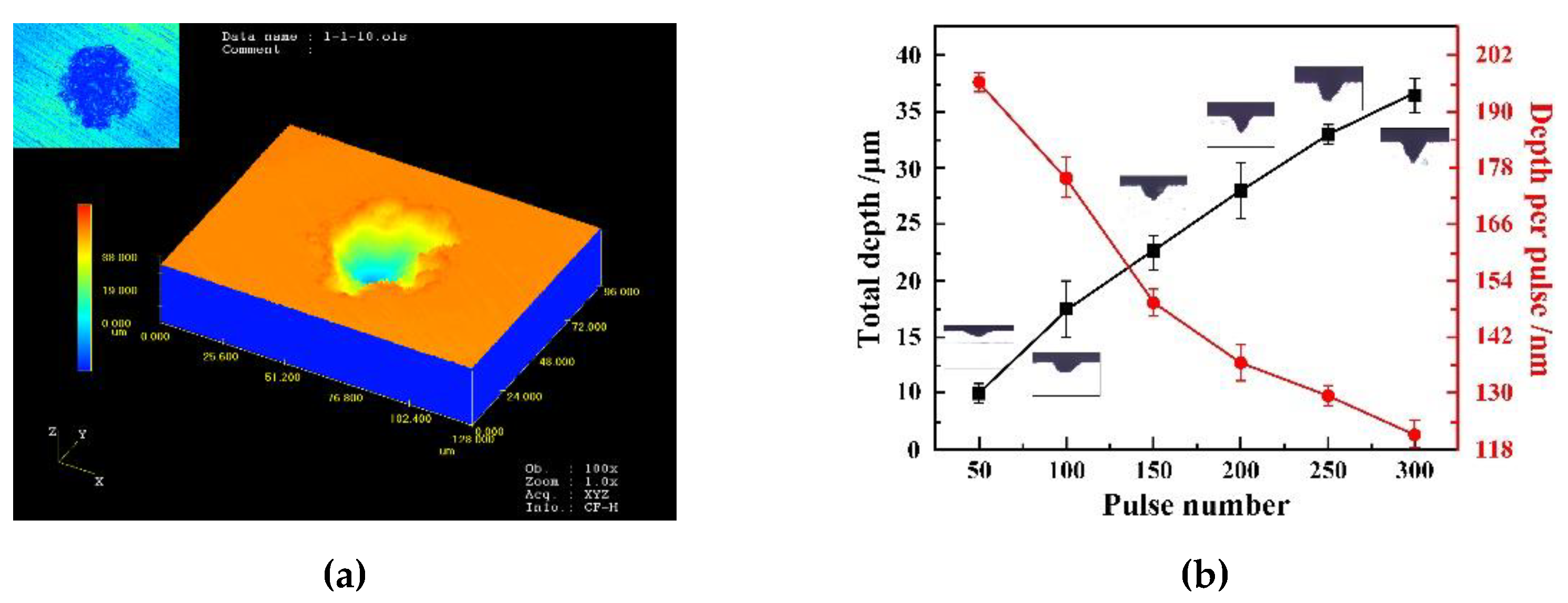

- The ablation volume per pulse decreased with increasing laser pulses for single-spot ablation, which could be attributed to the reflection, refraction, and absorption of laser energy by the water deposited in the ablated structure.

- (3)

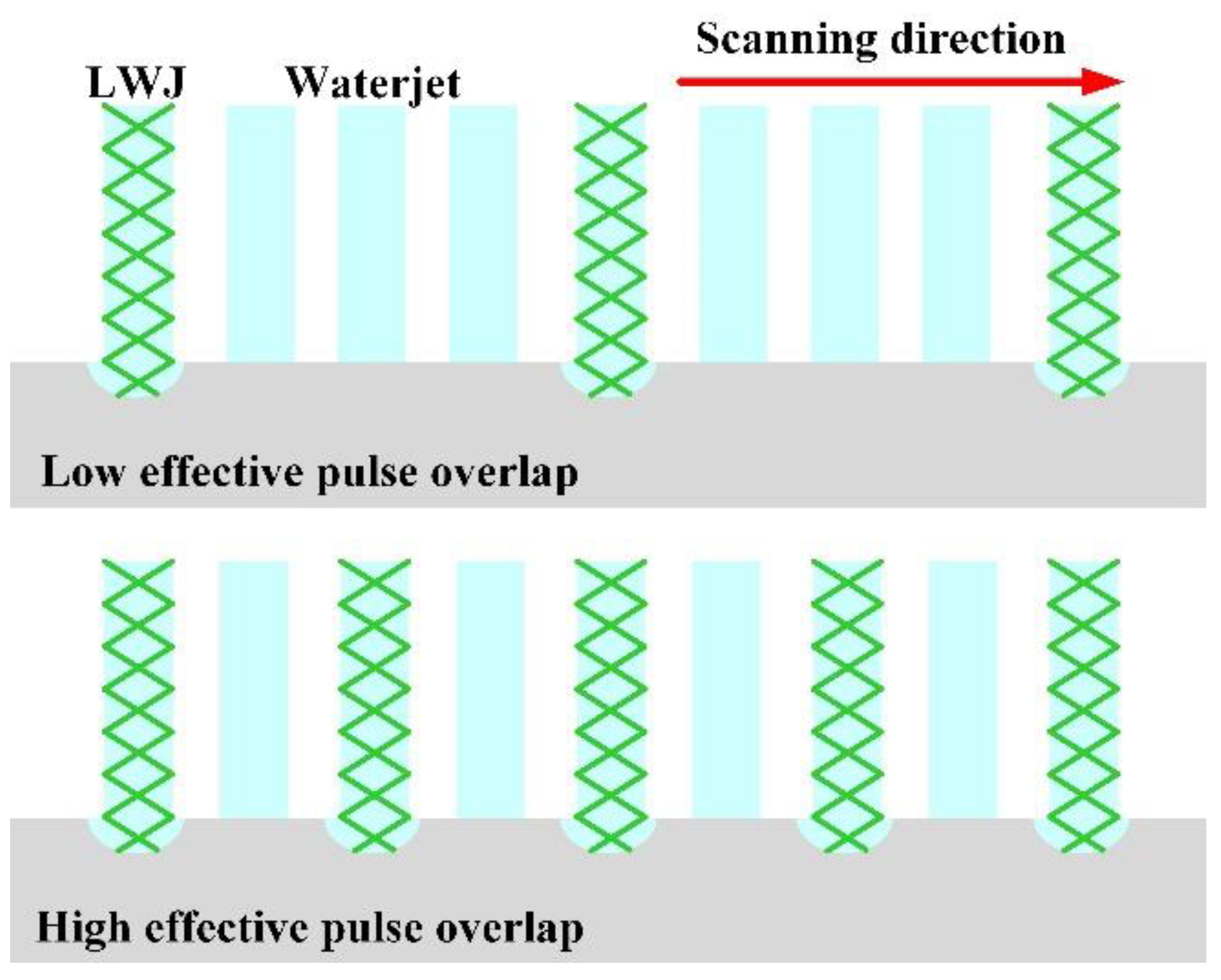

- Laser pulse energy and effective pulse overlap were the main factors affecting the groove depth for single-row scribing as they decided the incident laser fluence in the unit area. The groove width was not sensitive to the parameter variation as it was mainly dominated by the applied LWJ diameter. The 213 sequence on the same layer and the surface-to-depth sequence on different layers were the most suitable scanning strategies for fabrication of micro-grooves with large DTWR and low taper considering that these strategies provided effective channels for water and slag ejection.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Akinwande, D.; Huyghebaert, C.; Wang, C.-H.; Serna, M.I.; Goossens, S.; Li, L.-J.; Wong, H.-S.P.; Koppens, F.H.L. Graphene and two-dimensional materials for silicon technology. Nature 2019, 573, 507–518. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Arevalo, A.; Li, H.; Foulds, I.G. Low-cost silicon wafer dicing using a craft cutter. Microsyst. Technol. 2014, 21, 1411–1414. [Google Scholar] [CrossRef][Green Version]

- Lee, H.H.; Zhao, E.; Chen, D.; Zhang, N.; Chen, S.-C. Dual-beam stealth laser dicing based on electrically tunable lens. Precis. Eng. 2020, 66, 374–381. [Google Scholar] [CrossRef]

- Cai, Y.; Wang, M.; Zhang, H.; Yang, L.; Fu, X.; Wang, Y. Laser cutting sandwich structure glass–silicon–glass wafer with laser induced thermal–crack propagation. Opt. Laser Technol. 2017, 93, 49–59. [Google Scholar] [CrossRef]

- Zhao, C.; Cai, Y.; Ding, Y.; Yang, L.; Wang, Z.; Wang, Y. Investigation on the crack fracture mode and edge quality in laser dicing of glass-anisotropic silicon double-layer wafer. J. Mater. Process. Technol. 2019, 275, 116356. [Google Scholar] [CrossRef]

- Richerzhagen, B.; Housh, R.; Wagner, F.; Manley, J. Waterjet guided laser cutting: A powerful hybrid technology for fine cutting and grooving. In Proceedings of the Advanced Laser Applications Conference & Exposition, AnnArbor, MI, USA, 1 January 2004; pp. 1–4. [Google Scholar]

- Li, J.Y.; Li, Y.; Ding, Y.; Wang, Y.; Yang, L.J. Research on the selection of light source and material removal in water jet guided laser processing. Trans. Beijing. Inst. Technol. 2022, 42, 36–45. [Google Scholar] [CrossRef]

- Liu, Y.; Wei, M.; Zhang, T.; Qiao, H.; Li, H. Overview on the development and critical issues of water jet guided laser machining technology. Opt. Laser Technol. 2020, 137, 106820. [Google Scholar] [CrossRef]

- Li, C.-F.; Johnson, D.; Kovacevic, R. Modeling of waterjet guided laser grooving of silicon. Int. J. Mach. Tools Manuf. 2003, 43, 925–936. [Google Scholar] [CrossRef]

- Kray, D.; Hopman, S.; Spiegel, A.; Richerzhagen, B.; Willeke, G.P. Study on the edge isolation of industrial silicon solar cells with waterjet-guided laser. Sol. Energy Mater. Sol. Cells 2007, 91, 1638–1644. [Google Scholar] [CrossRef]

- Qiao, H.; Zhihe, C.; Jianfeng, C.; Zhao, J. Experimental study on water jet guided laser micro-machining of mono-crystalline silicon. Opt. Laser Technol. 2021, 140, 107057. [Google Scholar] [CrossRef]

- Sun, D.; Han, F.; Ying, W. The experimental investigation of water jet–guided laser cutting of CFRP. Int. J. Adv. Manuf. Technol. 2019, 102, 719–729. [Google Scholar] [CrossRef]

- Cheng, B.; Ding, Y.; Li, Y.; Li, J.; Xu, J.; Li, Q.; Yang, L. Coaxial helical gas assisted laser water jet machining of SiC/SiC ceramic matrix composites. J. Mater. Process. Technol. 2021, 293, 117067. [Google Scholar] [CrossRef]

- Li, C.Q.; Yang, L.J.; Wang, Y. Experimental Study on Water-Jet Guided Laser Machining Magnesium Alloy. Mater. Sci. Forum 2012, 723, 476–480. [Google Scholar] [CrossRef]

- Cheng, B.; Ding, Y.; Li, Y.; Yang, L. Theoretical and Experimental Investigation on SiC/SiC Ceramic Matrix Composites Machining with Laser Water Jet. Appl. Sci. 2022, 12, 1214. [Google Scholar] [CrossRef]

- Ding, Y.; Yang, L.; Hong, M. Enhancement of pulsed laser ablation assisted with continuous wave laser irradiation. Sci. China Ser. G Physics Mech. Astron. 2018, 62, 34211. [Google Scholar] [CrossRef]

- Webb, B.; Ma, C.-F. Single-Phase Liquid Jet Impingement Heat Transfer. Adv. Heat Transf. 1995, 26, 105–217. [Google Scholar] [CrossRef]

- Muskhelishvili, N.I. Some Basic Problems of the Mathematical Theory of Elasticity; Springer Science & Business Media: Cham, Switzerland, 2013; pp. 5–84. [Google Scholar]

- Desai, P.D. Thermodynamic Properties of Iron and Silicon. J. Phys. Chem. Ref. Data 1986, 15, 967–983. [Google Scholar] [CrossRef]

- Marimuthu, S.; Dunleavey, J.; Liu, Y.; Smith, B.; Kiely, A.; Antar, M. Water-jet guided laser drilling of SiC reinforced aluminium metal matrix composites. J. Compos. Mater. 2019, 53, 3787–3796. [Google Scholar] [CrossRef]

- Marimuthu, S.; Smith, B. Water-jet guided laser drilling of thermal barrier coated aerospace alloy. Int. J. Adv. Manuf. Technol. 2021, 113, 177–191. [Google Scholar] [CrossRef]

- Adelmann, B.; Ngo, C.; Hellmann, R. High aspect ratio cutting of metals using water jet guided laser. Int. J. Adv. Manuf. Technol. 2015, 80, 2053–2060. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Wavelength | 532 nm |

| Pulse duration | 100 ns |

| Repetition rate | 1–200 KHz |

| Average power | 50 W (max) |

| Pulse energy | 1.2 mJ (max) |

| M2 | 2 |

| Temperature /K | Thermal Conductivity /kW·m−1·K−1 | Specific Heat /J·kg−1·K−1 | Linear Thermal Expansion Coefficient /10−6·K−1 |

|---|---|---|---|

| 300 | 156 | 713 | 2.63 |

| 400 | 105 | 785 | 3.24 |

| 500 | 80 | 832 | 3.84 |

| 600 | 64 | 849 | 4.00 |

| 700 | 52 | 866 | 4.14 |

| 800 | 43 | 883 | 4.24 |

| 900 | 35.6 | 899 | 4.33 |

| 1000 | 31 | 916 | 4.42 |

| 1100 | 28 | 933 | 4.51 |

| 1200 | 26.1 | 950 | |

| 1300 | 24.8 | 967 | |

| 1400 | 23.7 | 983 | |

| 1500 | 22.7 | 1000 | |

| 1600 | 21.9 | 1017 |

| Group | Laser Pulse Energy/mJ | Laser Power/W | Scanning Speed/mm·s−1 | Distance between Neighboring Laser Spot/μm | |

|---|---|---|---|---|---|

| 1 | 1.1 | 0.45 | 5 | 10 | 0.9 |

| 1.2 | 0.45 | 17 | 10 | 0.26 | |

| 2 | 2.1 | 0.45 | 5 | 10 | 0.9 |

| 2.2 | 1.05 | 5 | 10 | 2.1 | |

| 3 | 3.1 | 0.45 | 5 | 2 | 0.9 |

| 3.2 | 0.45 | 5 | 10 | 4.5 | |

| Laser Power | Repetition Rate | Scanning Interval | Scanning Time | Scanning Speed |

|---|---|---|---|---|

| 20 W | 10 kHz | 20 μm | 1 | 10 mm/s |

| Laser Power | Repetition Rate | Scanning Interval on the Same Layer | Scanning Interval along Depth | Scanning Layer along Depth | Scanning Time | Scanning Speed |

|---|---|---|---|---|---|---|

| 20 W | 10 kHz | 20 μm | 100 μm | 6 | 1 | 10 mm/s |

| Laser Power | Repetition Rate | Scanning Interval on the Same Layer | Scanning Interval along Depth | Scanning Layer along Depth | Scanning Time | Scanning Speed |

|---|---|---|---|---|---|---|

| 50 W | 10 kHz | 20μm | 100μm | 60 | 1 | 10 mm/s |

| Groove Number | Entrance Width/μm | Bottom Width/μm | Depth/μm | DTWR | Taper |

|---|---|---|---|---|---|

| 1 | 306.4 | 161.3 | 5778.6 | 18.86 | 0.013 |

| 2 | 307.2 | 164.6 | 5831.1 | 18.98 | 0.012 |

| 3 | 305.6 | 151.5 | 5815.5 | 19.03 | 0.013 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Ding, Y.; Cheng, B.; Cao, J.; Yang, L. Numerical and Experimental Research on the Laser-Water Jet Scribing of Silicon. Appl. Sci. 2022, 12, 4057. https://doi.org/10.3390/app12084057

Li Y, Ding Y, Cheng B, Cao J, Yang L. Numerical and Experimental Research on the Laser-Water Jet Scribing of Silicon. Applied Sciences. 2022; 12(8):4057. https://doi.org/10.3390/app12084057

Chicago/Turabian StyleLi, Yuan, Ye Ding, Bai Cheng, Junjie Cao, and Lijun Yang. 2022. "Numerical and Experimental Research on the Laser-Water Jet Scribing of Silicon" Applied Sciences 12, no. 8: 4057. https://doi.org/10.3390/app12084057

APA StyleLi, Y., Ding, Y., Cheng, B., Cao, J., & Yang, L. (2022). Numerical and Experimental Research on the Laser-Water Jet Scribing of Silicon. Applied Sciences, 12(8), 4057. https://doi.org/10.3390/app12084057