Mechanical and Fatigue Behavior of Cellular Structure Ti-6Al-4V Alloy Femoral Stems: A Finite Element Analysis

Abstract

:1. Introduction

2. Material and Methods

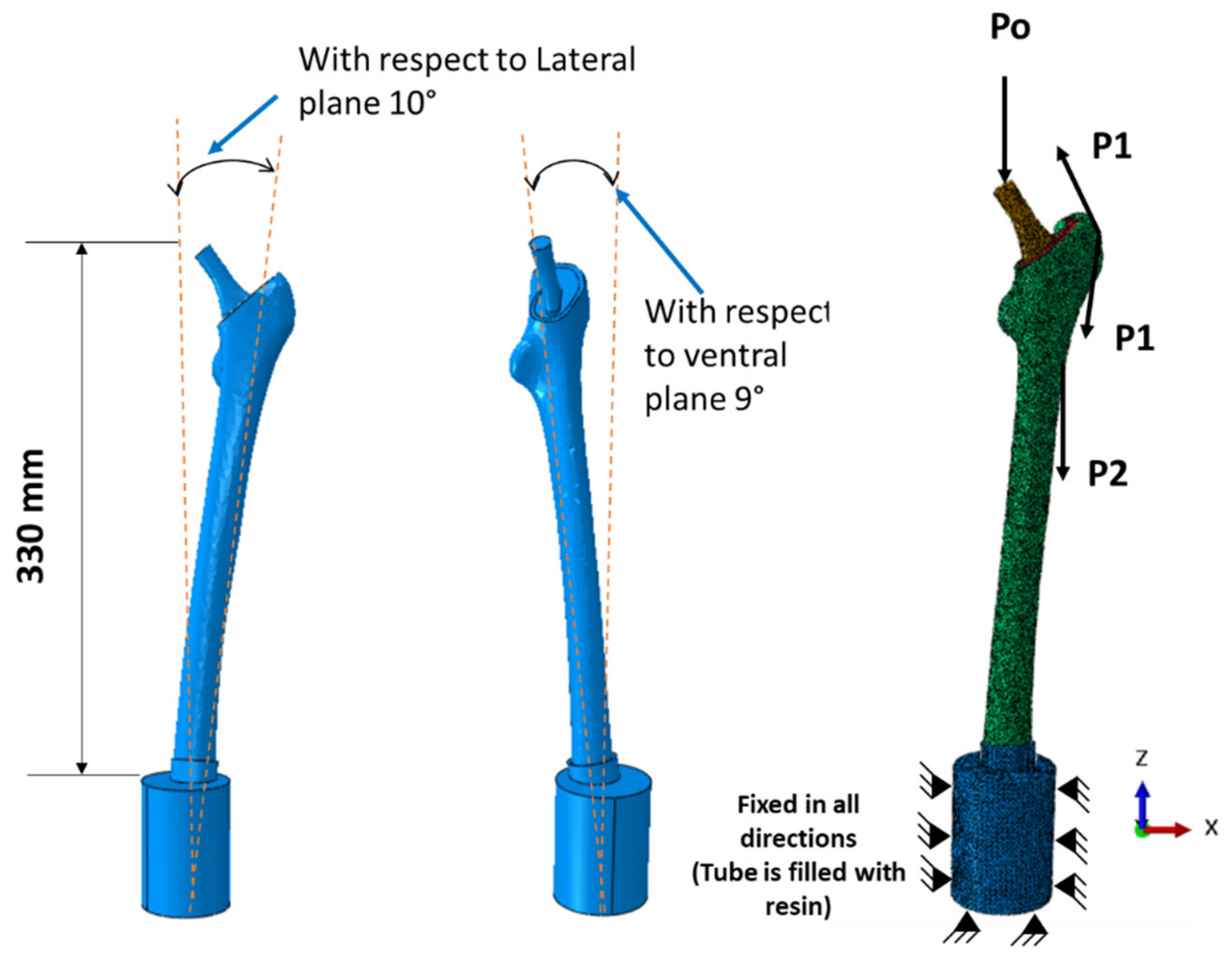

2.1. Finite Element Model

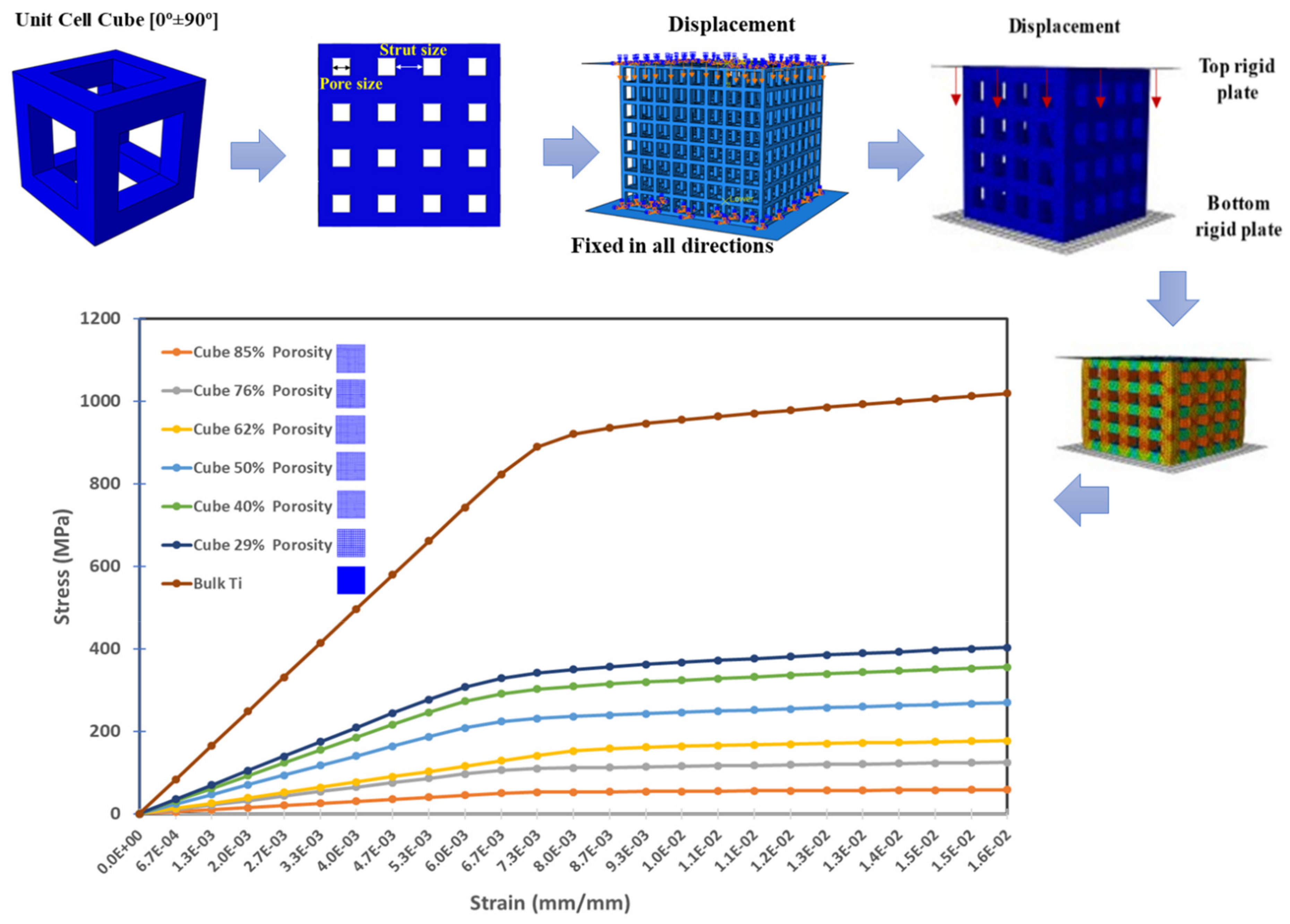

2.1.1. Porous Microstructure

- Vp: Volumetric porosity

- L2: cubic pore inner dimension

- N: Number of pores in a single cube face

- x: Full cube dimension

- t: Strut thickness

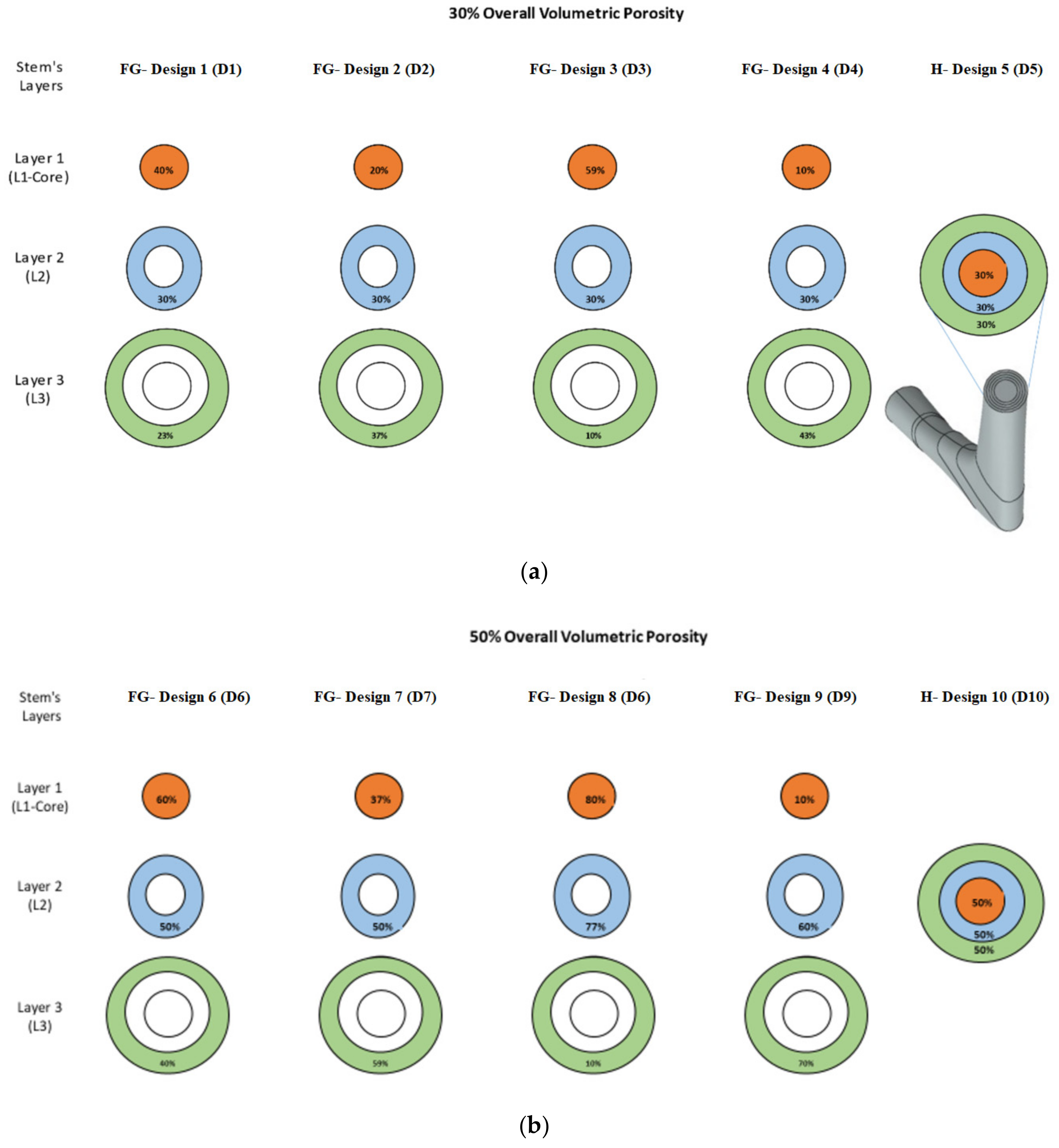

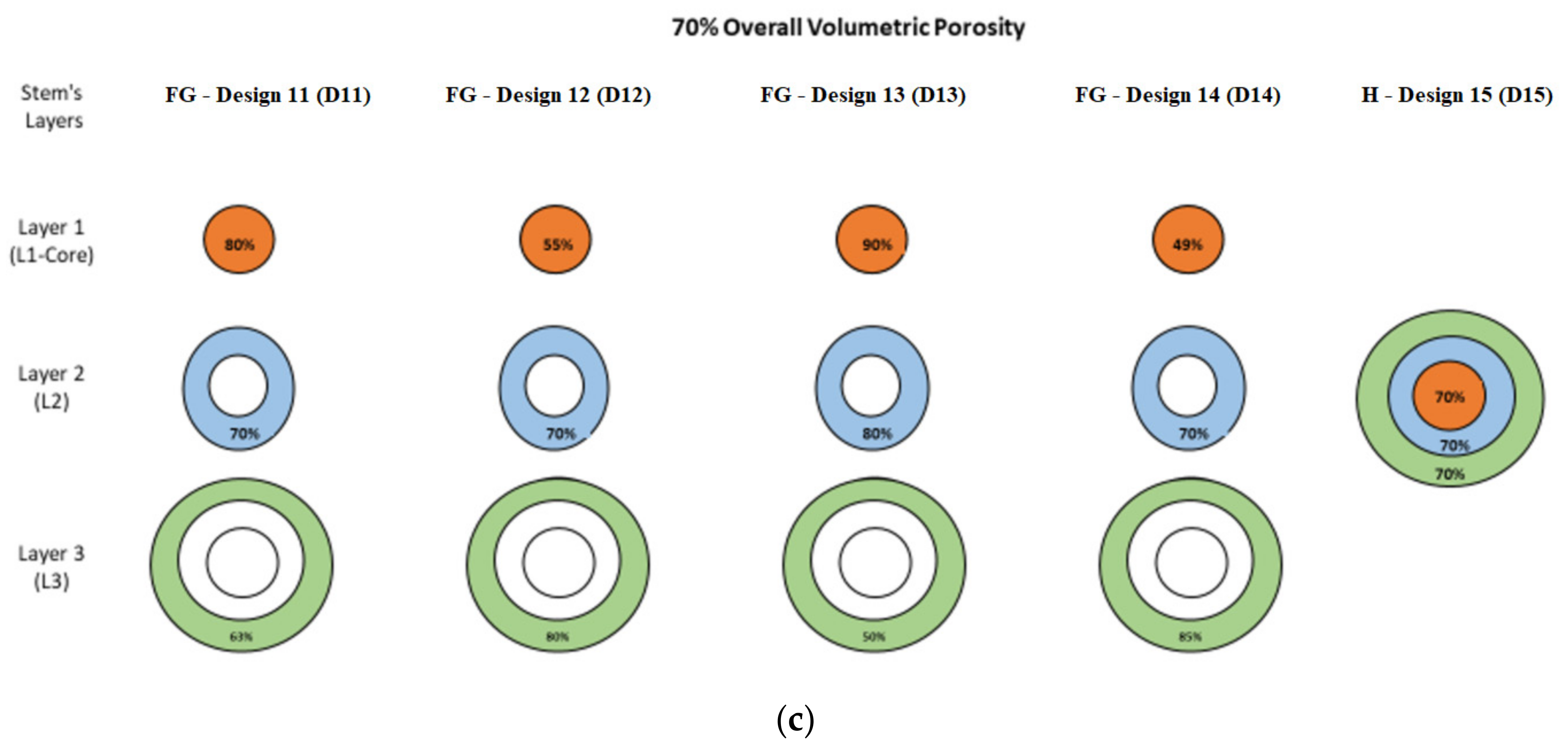

2.1.2. Porous Stem Design

- A: Stem’s radial Layer cross-sectional Area

- : Stems radial Layer Volumetric Porosity

- : Average functionally graded Porosity along the stem’s layers

- : Average homogeneous Porosity along the stem’s layers

- : Stem Homogenous porosity.

| Bone Material | Young’s Modulus (GPa) | Shear Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|

| Spongy Bone (Trabecular bone) | 0.4 | ||

| Cortical bone | Exx = 11.5 | Gxy = 3.6 | νxy = 0.51 |

| Eyy = 11.5 | Gyz = 3.3 | νyz = 0.31 | |

| Ezz = 17 | Gzx = 3.3 | νzx = 0.31 |

2.2. Fatigue Analysis of the Designed Porous Stems

- : Surface quality factor.

- : Size factor.

- : Reliability factor.

- : Temperature factor.

- : Stress concentration factor.

- : Miscellaneous factor.

- For Ti6Al4V [37]: 0.54

3. Result and Discussion

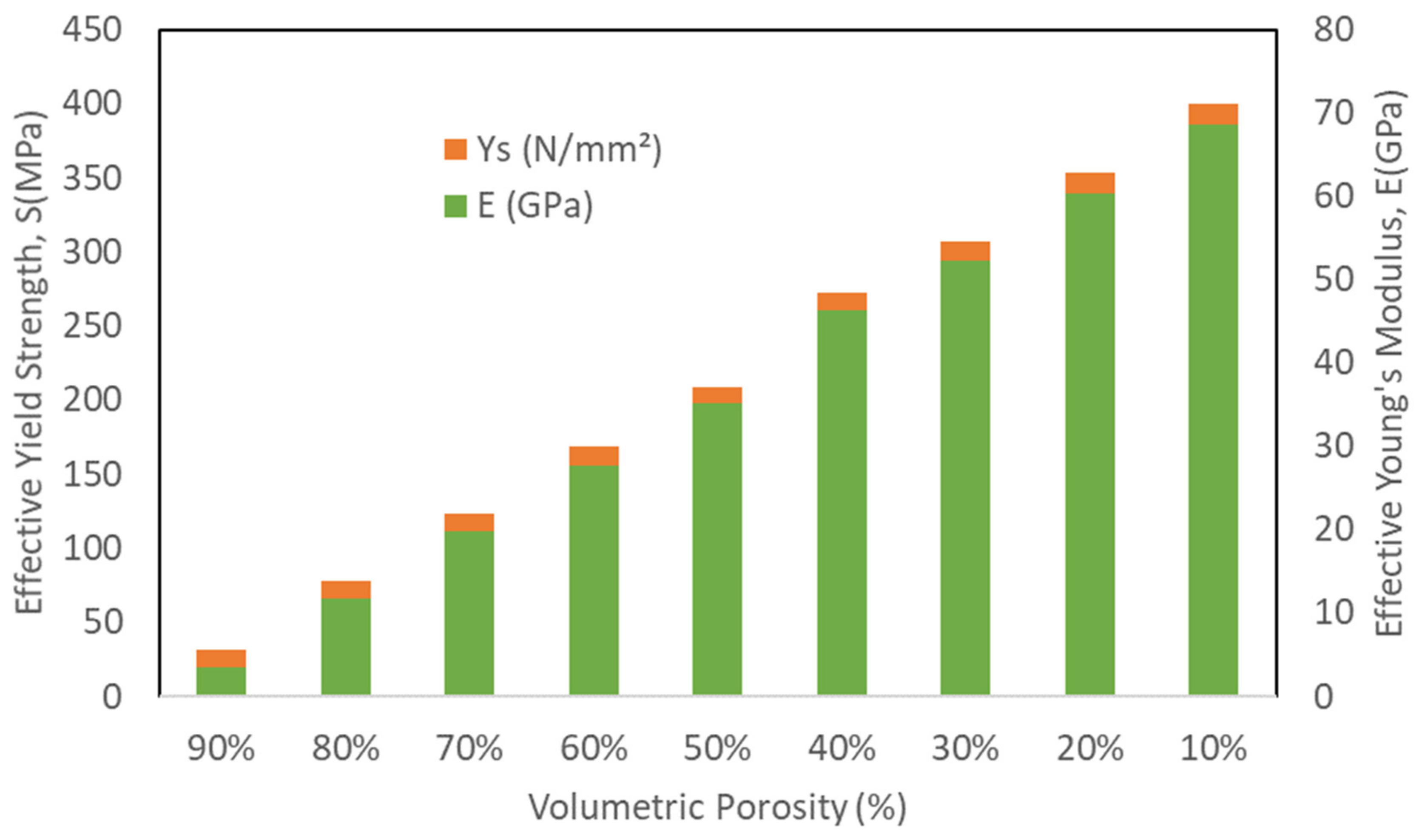

3.1. Mechanical Properties of the Porous Structures

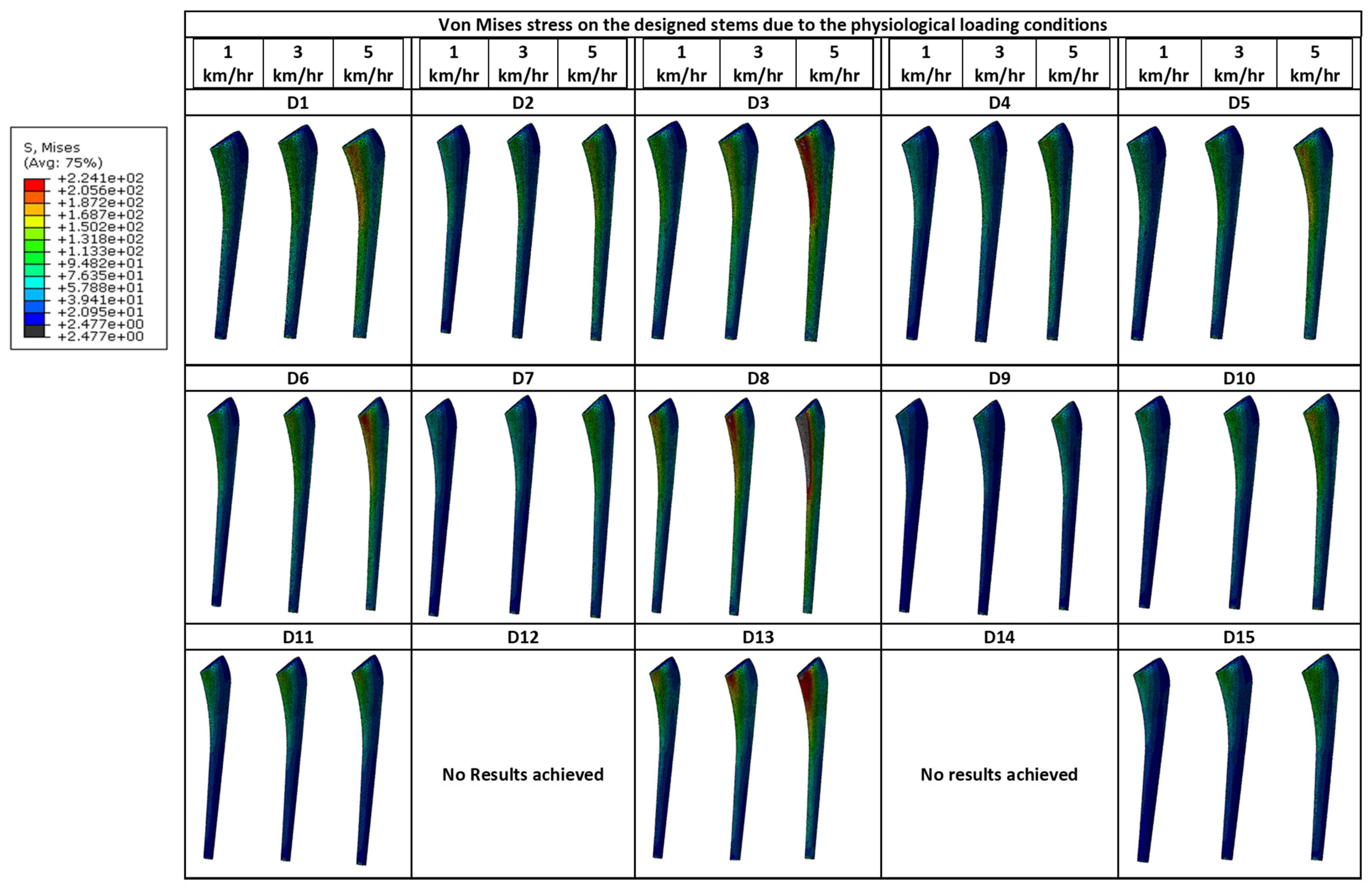

3.2. Stresses in Porous Stem Layers

3.2.1. Stem-Bone Model Validation

3.2.2. Stresses in Porous Stem’s Section

3.3. Fatigue Factor of Safety (Soderberg Approach)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Petrolo, L.; Testi, D.; Taddei, F.; Viceconti, M. Effect of a virtual reality interface on the learning curve and on the accuracy of a surgical planner for total hip replacement. Comput. Methods Programs Biomed. 2010, 97, 86–91. [Google Scholar] [CrossRef] [PubMed]

- Holzwarth, U.; Cotogno, G. Total Hip Arthroplasty: State of the Art, Prospects and Challenges; European Commisson: Brussels, Belgium, 2012. [Google Scholar] [CrossRef]

- Mehboob, H.; Tarlochan, F.; Mehboob, A.; Chang, S.-H.; Ramesh, S.; Harun, W.S.W.; Kadirgama, K. A novel design, analysis and 3D printing of Ti-6Al-4V alloy bio-inspired porous femoral stem. J. Mater. Sci. Mater. Med. 2020, 31, 78. [Google Scholar] [CrossRef] [PubMed]

- Harrison, N.; Field, J.R.; Quondamatteo, F.; Curtin, W.; McHugh, P.E.; Mc Donnell, P. Preclinical trial of a novel surface architecture for improved primary fixation of cementless orthopaedic implants. Clin. Biomech. 2014, 29, 861–868. [Google Scholar] [CrossRef] [PubMed]

- Zameer, S.; Haneef, M. Fatigue Life Estimation of Artificial Hip Joint Model Using Finite Element Method. Mater. Today Proc. 2015, 2, 2137–2145. [Google Scholar] [CrossRef]

- Lin, Y.-T.; Wu, J.S.-S.; Chen, J.-H. The study of wear behaviors on abducted hip joint prostheses by an alternate finite element approach. Comput. Methods Programs Biomed. 2016, 131, 143–155. [Google Scholar] [CrossRef]

- Mehboob, H.; Ahmad, F.; Tarlochan, F.; Mehboob, A.; Chang, S.H. A comprehensive analysis of bio-inspired design of femoral stem on primary and secondary stabilities using mechanoregulatory algorithm. Biomech. Model. Mechanobiol. 2020, 19, 2213–2226. [Google Scholar] [CrossRef]

- Alkhatib, S.E.; Mehboob, H.; Tarlochan, F. Finite Element Analysis of Porous Titanium Alloy Hip Stem to Evaluate the Biomechanical Performance During Walking and Stair Climbing. J. Bionic Eng. 2019, 16, 1103–1115. [Google Scholar] [CrossRef]

- Mehboob, H.; Tarlochan, F.; Mehboob, A.; Chang, S.-H. Finite element modelling and characterization of 3D cellular microstructures for the design of a cementless biomimetic porous hip stem. Mater. Des. 2018, 149, 101–112. [Google Scholar] [CrossRef]

- Tarlochan, F.; Mehboob, H.; Mehboob, A.; Chang, S.-H. Influence of functionally graded pores on bone ingrowth in cementless hip prosthesis: A finite element study using mechano-regulatory algorithm. Biomech. Model. Mechanobiol. 2017, 17, 701–716. [Google Scholar] [CrossRef]

- Al Zoubi, N.F.; Tarlochan, F.; Mehboob, H.; Jarrar, F. Design of Titanium Alloy Femoral Stem Cellular Structure for Stress Shielding and Stem Stability: Computational Analysis. Appl. Sci. 2022, 12, 1548. [Google Scholar] [CrossRef]

- De Krijger, J. The Effect of Stress Ratio on the Fatigue Behavior of Additively Manufactured Porous Biomaterials; Delft University of Technology: Delft, The Netherlands, 2016. [Google Scholar]

- Holt, G.; Hook, S.; Hubble, M. Revision total hip arthroplasty: The femoral side using cemented implants. Int. Orthop. 2010, 35, 267–273. [Google Scholar] [CrossRef] [Green Version]

- NJR 10th Annual Report 2013. Available online: https://www.njrcentre.org.uk/njrcentre/News-and-Events/NJR-10th-Annual-Report-2013 (accessed on 5 February 2022).

- Aaos-Ajrr-Annual-Report-Preview_Final. Available online: https://www.aaos.org/globalassets/registries/2020-aaos-ajrr-annual-report-preview_final.pdf (accessed on 26 March 2022).

- Pabinger, C.; Lothaller, H.; Portner, N.; Geissler, A. Projections of hip arthroplasty in OECD countries up to 2050. HIP Int. 2018, 28, 498–506. [Google Scholar] [CrossRef]

- Eisenbarth, E.; Velten, D.; Müller, M.; Thull, R.; Breme, J. Biocompatibility of β-stabilizing elements of titanium alloys. Biomaterials 2004, 25, 5705–5713. [Google Scholar] [CrossRef]

- Learmonth, I.D.; Young, C.; Rorabeck, C. The operation of the century: Total hip replacement. Lancet 2007, 370, 1508–1519. [Google Scholar] [CrossRef]

- Jetté, B.; Brailovski, V.; Simoneau, C.; Dumas, M.; Terriault, P. Development and in vitro validation of a simplified numerical model for the design of a biomimetic femoral stem. J. Mech. Behav. Biomed. Mater. 2018, 77, 539–550. [Google Scholar] [CrossRef]

- Simoneau, C.; Terriault, P.; Jetté, B.; Dumas, M.; Brailovski, V. Development of a porous metallic femoral stem: Design, manufacturing, simulation and mechanical testing. Mater. Des. 2017, 114, 546–556. [Google Scholar] [CrossRef]

- Murr, L.E. Strategies for creating living, additively manufactured, open-cellular metal and alloy implants by promoting osseointegration, osteoinduction and vascularization: An overview. J. Mater. Sci. Technol. 2018, 35, 231–241. [Google Scholar] [CrossRef]

- Ryan, G.; Pandit, A.; Apatsidis, D.P. Fabrication methods of porous metals for use in orthopaedic applications. Biomaterials 2006, 27, 2651–2670. [Google Scholar] [CrossRef]

- Darwich, A.; Nazha, H.; Daoud, M. Effect of Coating Materials on the Fatigue Behavior of Hip Implants: A Three-dimensional Finite Element Analysis. J. Appl. Comput. Mech. 2020, 6, 284–295. [Google Scholar] [CrossRef]

- Senalp, A.Z.; Kayabasi, O.; Kurtaran, H. Static, dynamic and fatigue behavior of newly designed stem shapes for hip prosthesis using finite element analysis. Mater. Des. 2007, 28, 1577–1583. [Google Scholar] [CrossRef]

- Janssen, D.; van Aken, J.; Scheerlinck, T.; Verdonschot, N. Finite element analysis of the effect of cementing concepts on implant stability and cement fatigue failure. Acta Orthop. 2009, 80, 319–324. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yavari, S.A.; Ahmadi, S.; Wauthle, R.; Pouran, B.; Schrooten, J.; Weinans, H.; Zadpoor, A.A. Relationship between unit cell type and porosity and the fatigue behavior of selective laser melted meta-biomaterials. J. Mech. Behav. Biomed. Mater. 2015, 43, 91–100. [Google Scholar] [CrossRef] [PubMed]

- Wauthle, R.; Vrancken, B.; Beynaerts, B.; Jorissen, K.; Schrooten, J.; Kruth, J.-P.; Van Humbeeck, J. Effects of build orientation and heat treatment on the microstructure and mechanical properties of selective laser melted Ti6Al4V lattice structures. Addit. Manuf. 2015, 5, 77–84. [Google Scholar] [CrossRef]

- ISO 7206-4; Implants for Surgery—Partial and Total Hip Joint Prostheses—Part 4: Determination of Endurance Properties and Performance of Stemmed Femoral Components. ISO: Geneva, Switzerland, 2010.

- Oshkour, A.; Davoodi, M.; Abu Osman, N.; Yau, Y.; Tarlochan, F.; Abas, W.W. Finite element analysis of circumferential crack behavior in cement–femoral prosthesis interface. Mater. Des. 2013, 49, 96–102. [Google Scholar] [CrossRef] [Green Version]

- Yeni, Y.N.; Wu, B.; Huang, L.; Oravec, D. Mechanical Loading Causes Detectable Changes in Morphometric Measures of Trabecular Structure in Human Cancellous Bone. J. Biomech. Eng. 2013, 135, 054505. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Limmahakhun, S.; Oloyede, A.; Sitthiseripratip, K.; Xiao, Y.; Yan, C. Stiffness and strength tailoring of cobalt chromium graded cellular structures for stress-shielding reduction. Mater. Des. 2017, 114, 633–641. [Google Scholar] [CrossRef]

- Bergmann, G.; Graichen, F.; Rohlmann, A. Hip joint loading during walking and running, measured in two patients. J. Biomech. 1993, 26, 969–990. [Google Scholar] [CrossRef]

- Heller, M.; Bergmann, G.; Kassi, J.-P.; Claes, L.; Haas, N.; Duda, G. Determination of muscle loading at the hip joint for use in pre-clinical testing. J. Biomech. 2005, 38, 1155–1163. [Google Scholar] [CrossRef]

- Alkhatib, S.E.; Tarlochan, F.; Mehboob, H.; Singh, R.; Kadirgama, K.; Harun, W.S.W. Finite element study of functionally graded porous femoral stems incorporating body-centered cubic structure. Artif. Organs 2019, 43, E152–E164. [Google Scholar] [CrossRef]

- Oshkour, A.; Abu Osman, N.; Bayat, M.; Afshar, R.; Berto, F. Three-dimensional finite element analyses of functionally graded femoral prostheses with different geometrical configurations. Mater. Des. 2014, 56, 998–1008. [Google Scholar] [CrossRef]

- Marghitu, D.B.; Diaconescu, C.I.; Ciocirlan, B.O. Mechanical Engineer’s Handbook; Marghitu, D.B., Ed.; Academic Press: San Diego, CA, USA, 2001; pp. 119–188. [Google Scholar] [CrossRef]

- Chern, A.H.; Nandwana, P.; Yuan, T.; Kirka, M.M.; Dehoff, R.R.; Liaw, P.K.; Duty, C.E. A review on the fatigue behavior of Ti-6Al-4V fabricated by electron beam melting additive manufacturing. Int. J. Fatigue 2018, 119, 173–184. [Google Scholar] [CrossRef]

- Hedayati, R.; Hosseini-Toudeshky, H.; Sadighi, M.; Mohammadi-Aghdam, M.; Zadpoor, A. Computational prediction of the fatigue behavior of additively manufactured porous metallic biomaterials. Int. J. Fatigue 2016, 84, 67–79. [Google Scholar] [CrossRef] [Green Version]

- Ahmadi, S.M.; Hedayati, R.; Li, Y.; Lietaert, K.; Tümer, N.; Fatemi, A.; Rans, C.D.; Pouran, B.; Weinans, H.; Zadpoor, A.; et al. Fatigue performance of additively manufactured meta-biomaterials: The effects of topology and material type. Acta Biomater. 2018, 65, 292–304. [Google Scholar] [CrossRef] [Green Version]

- De Krijger, J.; Rans, C.; Van Hooreweder, B.; Lietaert, K.; Pouran, B.; Zadpoor, A.A. Effects of applied stress ratio on the fatigue behavior of additively manufactured porous biomaterials under compressive loading. J. Mech. Behav. Biomed. Mater. 2017, 70, 7–16. [Google Scholar] [CrossRef] [Green Version]

- Gerhardt, D.M.J.M.; Ter Mors, T.G.; Hannink, G.; Van Susante, J.L.C. Resurfacing hip arthroplasty better preserves a normal gait pattern at increasing walking speeds compared to total hip arthroplasty. Acta Orthop. 2019, 90, 231–236. [Google Scholar] [CrossRef] [Green Version]

- Morri, M.; Natali, E.; Tosarelli, D. At discharge gait speed and independence of patients provides a challenges for rehabilitation after total joint arthroplasty: An observational study. Arch. Physiother. 2016, 29, 6. [Google Scholar] [CrossRef] [Green Version]

| Sample | Strut Size (t) | Number of Pores/Unit Cells Enclosed within Each Dimensional Direction the Cubic | Pore Size (L2) | Volumetric Porosity (%) |

|---|---|---|---|---|

| (mm) | (N) | (mm) | ||

| 1 | 0.30 | 10 | 1.36 | 90% |

| 2 | 0.30 | 12 | 1.00 | 85% |

| 3 | 0.30 | 14 | 0.80 | 80% |

| 4 | 0.32 | 15 | 0.72 | 76% |

| 5 | 0.32 | 17 | 0.60 | 70% |

| 6 | 0.34 | 18 | 0.49 | 62% |

| 7 | 0.34 | 18 | 0.47 | 60% |

| 8 | 0.36 | 20 | 0.38 | 50% |

| 9 | 0.38 | 21 | 0.30 | 40% |

| 10 | 0.40 | 23 | 0.23 | 30% |

| 11 | 0.42 | 24 | 0.18 | 20% |

| 12 | 0.44 | 26 | 0.11 | 10% |

| Force (Body Weight (BW) = 900 N) | % Po | 1 km/hr (Po = 293% BW) | 3 km/hr (Po = 293% BW) | 5 km/hr (Po = 293% BW) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fx | Fy | Fz | Fx | Fy | Fz | Fx | Fy | Fz | ||

| Po | 100 | −599 | −363 | −2542 | −719 | −437 | −3054 | −962 | −584 | −4086 |

| P1 | 44 | 643 | 8 | 959 | 772 | 57.3 | 1152 | 1034 | 76.7 | 1542 |

| P1-proximal | 8 | 79.9 | 129 | 146 | 95.9 | 154 | 175 | 128 | 206 | 235.4 |

| P1-distal | 8 | −5.5 | −7.8 | −10 | −6.7 | −9.3 | −253 | −8.9 | −12.5 | −338 |

| P2 | 40 | −10 | 205 | −1030 | −12 | 246 | −1237 | −16 | 329.9 | 1656 |

| Ultimate Tensile Strength (Su), Endurance Limit, Elastic Moduli and Yield Strength (Ys) for the Designed Porous Structures | |||||

|---|---|---|---|---|---|

| Volumetric Porosity | E (GPa) | Ys (MPa) | Su (MPa) | Reduction Factor | Se (MPa) |

| 90% | 3.50 | 31.14 | 33.27 | 0.54 | 17.97 |

| 85% | 7.60 | 50.17 | 58.47 | 31.58 | |

| 80% | 11.68 | 77.52 | 90.99 | 49.13 | |

| 77% | 14.13 | 91.37 | 107.46 | 58.03 | |

| 76% | 16.18 | 105.95 | 113.50 | 61.29 | |

| 70% | 19.76 | 123.28 | 165.13 | 89.17 | |

| 63% | 25.67 | 156.80 | 243.15 | 131.30 | |

| 62% | 24.09 | 152.26 | 177.27 | 95.72 | |

| 60% | 27.78 | 168.77 | 216.30 | 116.80 | |

| 59% | 28.42 | 172.35 | 219.77 | 118.68 | |

| 55% | 32.01 | 192.74 | 239.53 | 129.34 | |

| 50% | 35.12 | 208.31 | 269.29 | 145.42 | |

| 49% | 36.59 | 218.67 | 283.16 | 152.91 | |

| 43% | 41.86 | 248.55 | 323.20 | 174.53 | |

| 40% | 46.33 | 272.75 | 355.63 | 192.04 | |

| 37% | 46.67 | 275.81 | 359.83 | 194.31 | |

| 30% | 52.23 | 307.13 | 402.87 | 217.55 | |

| 23% | 58.12 | 340.69 | 450.32 | 243.17 | |

| 20% | 60.38 | 353.50 | 468.43 | 252.95 | |

| 10% | 68.52 | 399.66 | 533.69 | 288.20 | |

| Bulk Ti | 123.59 | 888.89 | 1018.67 | 550.08 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Zoubi, N.F.; Tarlochan, F.; Mehboob, H. Mechanical and Fatigue Behavior of Cellular Structure Ti-6Al-4V Alloy Femoral Stems: A Finite Element Analysis. Appl. Sci. 2022, 12, 4197. https://doi.org/10.3390/app12094197

Al Zoubi NF, Tarlochan F, Mehboob H. Mechanical and Fatigue Behavior of Cellular Structure Ti-6Al-4V Alloy Femoral Stems: A Finite Element Analysis. Applied Sciences. 2022; 12(9):4197. https://doi.org/10.3390/app12094197

Chicago/Turabian StyleAl Zoubi, Naser Fawzi, Faris Tarlochan, and Hassan Mehboob. 2022. "Mechanical and Fatigue Behavior of Cellular Structure Ti-6Al-4V Alloy Femoral Stems: A Finite Element Analysis" Applied Sciences 12, no. 9: 4197. https://doi.org/10.3390/app12094197

APA StyleAl Zoubi, N. F., Tarlochan, F., & Mehboob, H. (2022). Mechanical and Fatigue Behavior of Cellular Structure Ti-6Al-4V Alloy Femoral Stems: A Finite Element Analysis. Applied Sciences, 12(9), 4197. https://doi.org/10.3390/app12094197