Review of the Research Progress in Soft Robots

Abstract

:1. Introduction

2. Driven Methods and Materials for Soft Robots

2.1. Fluid-Driven Methods and Their Materials

2.2. Smart Materials and Their Driven Methods

2.2.1. Shape Memory Material (SMM)

2.2.2. Electroactive Polymer (EAP)

2.2.3. Piezoelectric Material

2.2.4. Responsive Hydrogel

2.2.5. Magneto Rheological Fluid (MRF)

2.2.6. Liquid Metal (LM)

2.2.7. Liquid Crystal Elastomer (LCE)

2.3. Chemical Reaction Driven

2.4. Twisted and Coiled Polymer Actuator (TCPA)

- Its fabrication cost is extremely low since it is easily fabricated by commercially available nylon fibers.

- It realizes large deformation over 20%.

- It is flexible and lightweight.

- Its motion is silent.

- The actuation environment is unbounded, such as in water, in wet conditions, or in a magnetic field.

- Compared to the shape memory alloy actuators, a hysteresis property of TCPA is small.

3. 3D Printing Manufacturing Process

3.1. Stereolithography (SLA)

3.2. Digital Light Processing (DLP)

3.3. Fused Deposition Modeling (FDM)

3.4. Direct Ink Writing (DIW)

3.5. Selective Laser Sintering (SLS)

3.6. Shape Deposition Manufacturing (SDM)

3.7. Inkjet Printing (IP)

4. Applications of the Soft Robots

4.1. Bionic Structures

4.2. Gripping Operations

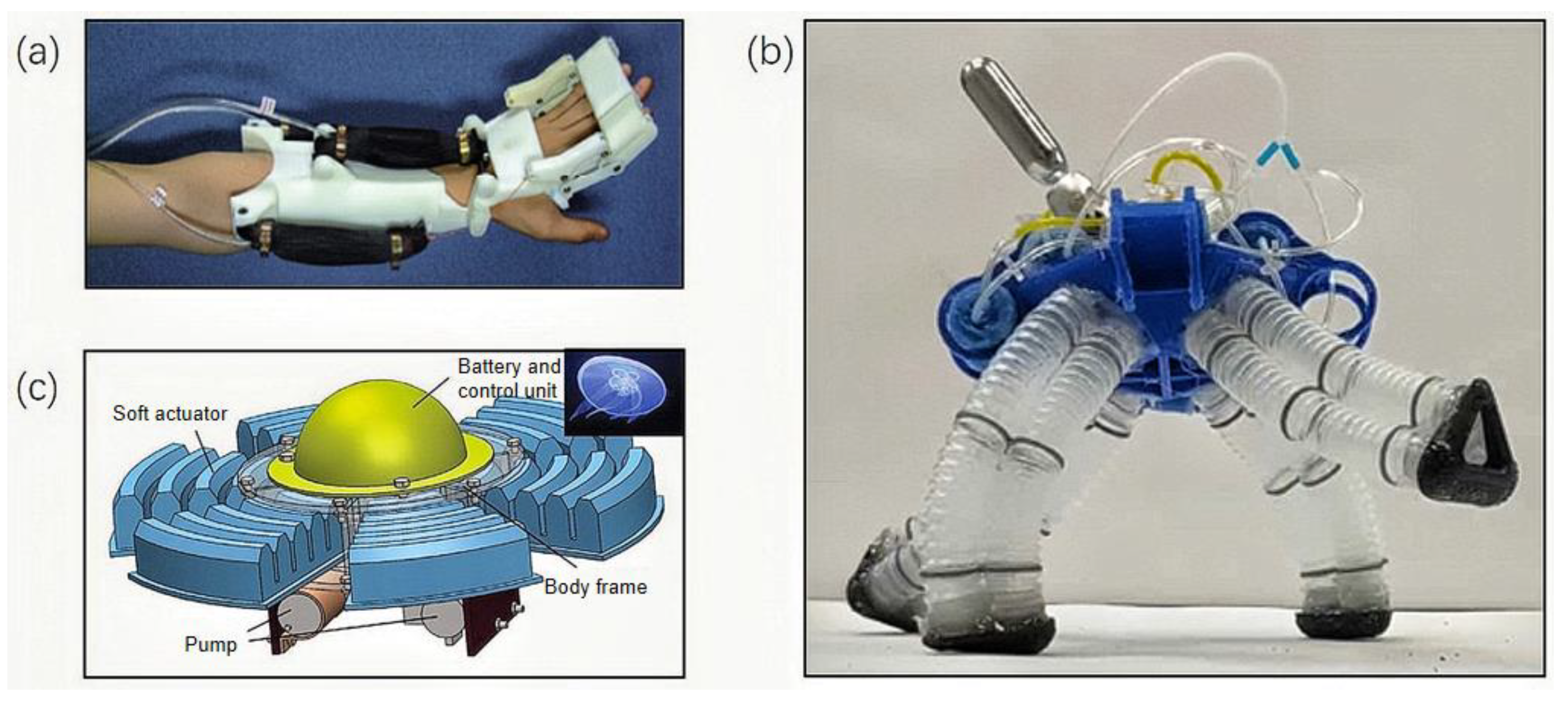

4.3. Medical Rehabilitation

5. Problems of Current Research

5.1. Problems of 3D Printing in Soft Robot Manufacturing

5.2. Problems of Soft Robot Research

6. Conclusions and Prospects

- (1)

- Developing new smart materials [140]. It is necessary to conduct in-depth studies on materials, chemistry, machinery, control and other disciplines, and new smart materials that are non-toxic, pollution-free, high stability, low cost, and large deformation for soft robots should be developed, so as to provide a variety of options for the applications of soft robots.

- (2)

- Developing 3D printing soft materials. More soft materials compatible with 3D printing should be developed to solve the limited range of printable soft materials.

- (3)

- Exploring new 3D printing technology. Traditional 3D printing methods restrict each other in manufacturing cost, printable materials, molding accuracy, printing speed, and universality, which poses new challenges to the 3D printing manufacturing technology of soft robots, and new 3D printing technology that can comprehensively take into account the above issues needs to be explored. In recent years, new technologies such as multi material 3D printing [130], embedded 3D printing [76], and 4D printing [141] have been developing.

- (4)

- Exploring the combination of multiple driven methods, the combination of multiple driven methods can make up for the shortcomings of a single driven method, and enable the soft robot to achieve more complex motion patterns.

- (5)

- Optimization of modeling techniques. The modeling needs to consider the multi-coupling problem to ensure the accuracy of the physical model of soft robots; for example, the finite element analysis software can be used to model and analyze the soft robots, and further optimize the design on the basis of ensuring the accuracy [140].

- (6)

- Optimizing sensor control technology. Optimize sensor control technology to obtain accurate data feedback and meet the requirements of infinite degrees of freedom control.

- (7)

- Optimizing human–computer interaction techniques [140]. Optimizing the hardware and software design of the input and feedback equipment of soft robots, so as to better implement human–computer interaction techniques and facilitate people’s control.

- (8)

- Reducing the production cost of soft robots. In terms of applications, currently, soft robots have good prospects in the field of medical and human health testing, but their production costs are still high, so the research of soft robots in low-cost and industrial production needs to be further advanced.

- (9)

- High-efficiency and high-precision manufacturing of soft robots. Explore the combination of high-efficiency 3D printing technology and high-precision 3D printing technology to meet the requirements of high-efficiency and high-precision manufacturing of soft robots. Therefore, the combination of multiple 3D printing methods with complementary advantages provides the possibility to realize high-efficiency and high-precision manufacturing of soft robots.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Yap, Y.L.; Sing, S.L.; Yeong, W.Y. A review of 3D printing processes and materials for soft robotics. Rapid Prototyp. J. 2020. [Google Scholar] [CrossRef]

- Jin, G.; Sun, Y.; Geng, J.; Yuan, X.; Sun, L. Bioinspired Soft Caterpillar Robot with Ultra-stretchable Bionic Sensors Based on Functional Liquid Metal. Nano Energy 2021, 84, 105896. [Google Scholar] [CrossRef]

- Bao, G.J.; Fang, H.; Chen, L.F.; Wan, Y.H.; Xu, F.; Yang, Q.H. Soft robotics: Academic insights and perspectives through bibliometric analysis. Soft Robot. 2018, 5, 229–241. [Google Scholar] [CrossRef]

- Fan, J.Z.; Wang, S.Q.; Yu, Q.G.; Zhu, Y. Swimming Performance of the Frog-Inspired Soft Robot. Soft Robot. 2020, 5, 615–626. [Google Scholar] [CrossRef] [PubMed]

- Deng, T. Research on Soft Robot System for Minimally Invasive Heart Surgery. Master’s Thesis, Shanghai Jiaotong University, Shanghai, China, 2014. [Google Scholar]

- Walker, I.D. Biologically inspired vine-like and tendril-like robots. In Proceedings of the 2015 Science and Information Conference, London, UK, 28–30 July 2015; pp. 714–720. [Google Scholar] [CrossRef]

- Asghar, Z.; Shah, R.A.; Ali, N. A computational approach to model gliding motion of an organism on a sticky slime layer over a solid substrate. Biomech. Model. Mechanobiol. 2022, 21, 1441–1455. [Google Scholar] [CrossRef] [PubMed]

- Shah, R.A.; Asghar, Z.; Ali, N. Mathematical modeling related to bacterial gliding mechanism at low Reynolds number with Ellis Slime. Eur. Phys. J. Plus 2022, 137, 1–12. [Google Scholar] [CrossRef]

- Nawaz, Y.; Arif, M.S.; Shatanawi, W.; Bibi, M. A New Explicit Numerical Schemes for Time-Dependent PDEs with Application to Pressure Driven Fluid Flow in a Rectangular Duct. Energies 2022, 15, 5145. [Google Scholar] [CrossRef]

- Schaffner, M.; Faber, J.A.; Pianegonda, L.; Rühs, P.A.; Coulter, F.; Studart, A.R. 3D printing of robotic soft actuators with programmable bioinspired architectures. Nat. Commun. 2018, 9, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Chen, Y.; Li, Y.; Michael, Z.; Wei, Y. Bioinspired robotic fingers based on pneumatic actuator and 3D printing of smart material. Soft Robot. 2017, 4, 147–162. [Google Scholar] [CrossRef]

- Kim, Y.; Yuk, H.; Zhao, R. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 2018, 558, 274–279. [Google Scholar] [CrossRef]

- Lei, J.; Ge, Z.H.; Tan, X.M.; Zhang, H.; Chang, B. Research Progress in Driving Mode and Manufacturing Process of Soft Robot. Micro Nano Electron. Technol. 2022, 59, 505–515, 599. [Google Scholar] [CrossRef]

- Geng, Z.; Li, Z. Overview of the application of 4D printing technology in software robot manufacturing. Mech. Eng. Autom. 2022, 216–219. [Google Scholar]

- Wang, H.T.; Peng, X.F.; Lin, B.M. Research Development of Soft Robots. J. South China Univ. Technol. Nat. Sci. Ed. 2020, 48, 94–106. [Google Scholar] [CrossRef]

- Xu, F.; Meng, F.; Fan, B.; Peng, G.; Shen, J.; Jiang, G. Overview of research on software robot drive, modeling and application. J. Nanjing Univ. Posts Telecommun. 2019, 39, 64–75. [Google Scholar] [CrossRef]

- Suzuki, M.; Kamamichi, N. Simple controller design based on internal model control for twisted and coiled polymer actuator. Actuators 2018, 7, 33. [Google Scholar] [CrossRef] [Green Version]

- Petersen, K.H.; Shepherd, R.F. Fluid-driven intrinsically soft robots-ScienceDirect. Robot. Syst. Auton. Platf. 2019, 61–84. [Google Scholar] [CrossRef]

- Guan, Q.; Sun, J.; Liu, Y.; Wereley, N.M.; Leng, J. Novel Bending and Helical Extensile/Contractile Pneumatic Artificial Muscles Inspired by Elephant Trunk. Soft Robot. 2020, 7, 597–614. [Google Scholar] [CrossRef]

- Kim, Y.M.; Jung, S.Y.; Moon, I. Design of a Wearable Upper-Limb Rehabilitation Robot using Parallel Mechanism. In Proceedings of the ICROS-SICE International Joint Conference, Hiroshima, Japan, 10–13 September 2009; pp. 785–789. [Google Scholar]

- Drotman, D.; Jadhav, S.; Sharp, D.; Chan, C.; Tolley, M.T. Electronics-free pneumatic circuits for controlling soft-legged robots. Sci. Robot. 2021, 6, eaay2627. [Google Scholar] [CrossRef]

- Polygerinos, P.; Wang, Z.; Galloway, K.C.; Wood, R.J.; Walsh, C.J. Soft robotic glove for combined assistance and at-home rehabilitation. Robot. Auton. Syst. 2015, 20173, 135–143. [Google Scholar] [CrossRef] [Green Version]

- Zhang, P.; Zhang, C.; Wang, S.; Chen, Z. Motion Characteristic and Analysis of Bionic Jellyfish with Fluid-Driven Soft Actuator. In Proceedings of the 2020 15th IEEE Conference on Industrial Electronics and Applications (ICIEA), Kristiansand, Norway, 9–13 November 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Sanchez, V.; Payne, C.J.; Preston, D.J.; Alvarez, J.T.; Weaver, J.C.; Atalay, A.T.; Boyvat, M.; Vogt, D.M.; Wood, R.J.; Whitesides, G.M.; et al. Smart Thermally Actuating Textiles. Adv. Mater. Technol. 2020, 5, 2000383. [Google Scholar] [CrossRef]

- Luo, Z.J.; Wang, S.; Cheng, G.G. Designing, Manufacturing and Controlling of the Elastic Materials Based Bionic Hand. J. Mech. Eng. 2019, 55, 69–75. [Google Scholar] [CrossRef] [Green Version]

- Jiang, F.; Zhang, Z.; Wang, X.; Cheng, G.; Zhang, Z.; Ding, J. Pneumatically Actuated Self-Healing Bionic Crawling Soft Robot. J. Intell. Robot. Syst. 2020, 100, 445–454. [Google Scholar] [CrossRef]

- Ito, K.; Homma, Y.; Rossiter, J. The soft multi-legged robot inspired by octopus: Climbing various columnarobjects. Adv. Robot. 2020, 34, 1096–1109. [Google Scholar] [CrossRef]

- Li, G.; Chen, X.; Zhou, F.; Liang, Y.; Xiao, Y.; Zhang, Z.; Zhang, M.; Chen, Z.; Song, Y.; Yang, X. Self-powered soft robot in the Mariana Trench. Nature 2021, 591, 66–71. [Google Scholar] [CrossRef]

- Sanusi, K.O.; Ayodele, O.L.; Khan, M.T. A concise review of the applications of NiTi shape-memory alloys in composite materials. S. Afr. J. Sci. 2014, 110, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Degeratu, S.; Rotaru, P.; Boncea, I.; Tarnita, D.; Alboteanu, L. An Overview of the Properties and Industrial Applications of Shape Memory Alloys. In 2018 International Symposium on Fundamentals of Electrical Engineering (ISFEE); IEEE: Piscataway, NJ, USA, 2018. [Google Scholar] [CrossRef]

- Minas, C.; Carnelli, D.; Tervoort, E.; Studart, A.R. 3D Printing of Emulsions and Foams into Hierarchical Porous Ceramics. Adv. Mater. 2016, 28, 9993–9999. [Google Scholar] [CrossRef]

- Liang, C.; Wang, Y.; Yao, T.; Zhu, B. A shape memory alloy–actuated soft crawling robot based on adaptive differential friction and enhanced antagonistic configuration. J. Intell. Mater. Syst. Struct. 2020, 31, 1045389X2094231. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, W.; Reynolds, M.F.; Cao, M.C.; Miskin, M.Z.; Arias, T.A.; Muller, D.A.; Mceuen, P.L.; Cohen, I. Micrometer-sized electrically programmable shape-memory actuators for low-power microrobotics. Sci. Robot. 2021, 6, eabe6663. [Google Scholar] [CrossRef]

- Wang, W.H.; Hu, J.F. Design and experiment of bionic-inchworm micro-robot. Transducer Microsyst. Technol. 2020, 39, 90–93. [Google Scholar] [CrossRef]

- IIT Indore Develops Prototype Jellyfish Robot to Record Marine Life. PTI (2019). Available online: https://www.theweek.in/news/sci-tech/2019/08/04/iit-indore-develops-prototype-jellyfish-robot-to-record-marine-life.html (accessed on 4 August 2019).

- Dalian University of Technology. A Variable Stiffness Lower Limb Exoskeleton Robot Based on Shape Memory Alloy. Chinese Patent CN202010765139.0, 27 October 2020. [Google Scholar]

- Akbari, S.; Sakhaei, A.H.; Panjwani, S.; Kowsari, K.; Ge, Q. Shape Memory Alloy Based 3D Printed Composite Actuators with Variable Stiffness and Large Reversible Deformation. Sens. Actuators A Phys. 2021, 321, 112598. [Google Scholar] [CrossRef]

- Pisani, S.; Genta, I.; Modena, T.; Dorati, R.; Benazzo, M.; Conti, B. Shape-Memory Polymers Hallmarks and Their Biomedical Applications in the Form of Nanofibers. Int. J. Mol. Sci. 2022, 23, 1290. [Google Scholar] [CrossRef]

- Zhang, S.S.; Dang, K.F.; Jiao, Z.W.; Yang, Y.; Li, R.J.; Yu, M.; Guan, Q.H. Shape Memory Polymer Characterization Method and Its Suitability. China Plast. Ind. 2019, 47, 130–133, 151. [Google Scholar]

- Liu, M.; Zhu, S.; Huang, Y.; Lin, Z.; Liu, W.; Yang, L.; Ge, D. A self-healing composite actuator for multifunctional soft robot via photo-welding. Compos. Part B Eng. 2021, 214, 108748. [Google Scholar] [CrossRef]

- Lihu, C.J.; Zhang, S.; Song, J.Z. Shape Memory Polymer Omnipotent Gripper. Physics 2020, 49, 545–547. [Google Scholar] [CrossRef]

- Lin, C.; Lv, J.; Li, Y. 4D-Printed Biodegradable and Remotely Controllable Shape Memory Occlusion Devices. Adv. Funct. Mater. 2019, 29, 1906569. [Google Scholar] [CrossRef]

- Kochetov, R.; Tsekmes, I.A.; Morshuis, P. Short-term and long-term breakdown analysis of electroactive polymer with and without nanofillers. Polym. Test. 2017, 59, 136–141. [Google Scholar] [CrossRef]

- Wu, S.Q. Preparation and Properties of High Dielectric Constant A cry late Elastomer Based Composites. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2018. [Google Scholar]

- Qin, L.; Cao, J.W.; Tang, Y.C.; Zhu, J. Soft Freestanding Planar Artificial Muscle Based on Dielectric Elastomer Actuator. J. Appl. Mech. 2018, 85, 051001. [Google Scholar] [CrossRef]

- Ccab, D.; Xing, G.; Sb, C.; ATCC, D. Power optimization of a conical dielectric elastomer actuator for resonant robotic systems. Extrem. Mech. Lett. 2020, 35, 100619. [Google Scholar] [CrossRef]

- Zhejiang University. A Dielectric Elastomer Spring Structure Artificial Muscle Module and Its Manufacturing Method. Chinese Patent CN202010324030.3, 10 July 2020.

- Sun, W.; Li, B.; Zhang, F.; Fang, C.; Lu, Y.; Gao, X.; Cao, C.; Chen, G.; Zhang, C.; Wang, Z.L. TENG-Bot: Triboelectric nanogenerator powered soft robot made of uni-directional dielectric elastomer. Nano Energy 2021, 45, 106012. [Google Scholar] [CrossRef]

- Wang, D.Z.; Li, G.; Jiang, J.M. Review of Conducting Polymer Research. Synth. Technol. Appl. 2001, 3, 36–39. [Google Scholar]

- Takagi, K.; Nakabo, Y.; Luo, Z.W.; Mukai, T.; Yamamura, M.; Hayakawa, Y. An analysis of the increase of bending response in IPMC dynamics given uniform input//Smart Structures & Materials. In Smart Structures and Materials 2006: Electroactive Polymer Actuators and Devices (EAPAD); SPIE: Bellingham, WA, USA, 2006. [Google Scholar]

- Niu, S.; Luo, Y.; Shen, Y.; Kim, K.J. Enabling earthworm-like soft robot development using bioinspired IPMC-scissor lift actuation structures: Design, locomotion simulation and experimental validation. In Proceedings of the IEEE International Conference on Robotics & Biomimetics IEEE (2015), Zhuhai, China, 6–9 December 2015. [Google Scholar] [CrossRef]

- Liu, X.; Xu, H.; Li, Y. A stretchable and self-healing ionic artificial muscle modified by conductive substances. Appl. Phys. A 2022, 128, 116. [Google Scholar] [CrossRef]

- Zhang, F.X. Modern Piezoelectricity; Science Press: Beijing, China, 2002. [Google Scholar]

- Lim, H.; Kim, S.W.; Song, J.B.; Cha, Y. Thin Piezoelectric Mobile Robot Using Curved Tail Oscillation. IEEE Access 2021, 9, 145477–145485. [Google Scholar] [CrossRef]

- Pan, M.; Yuan, C.; Pickford, T.; Tian, J.; Wan, C. Piezoelectric-Driven Self-Sensing Leaf-Mimic Actuator Enabled by Integration of a Self-Healing Dielectric Elastomer and a Piezoelectric Composite. Adv. Intell. Syst. 2021, 3, 2000248. [Google Scholar] [CrossRef]

- Jung, Y.H.; Hong, S.K.; Wang, H.S.; Han, J.H.; Pham, T.X.; Park, H.; Kim, J.; Kang, S.; Yoo, C.D.; Lee, K.J. Speech Recognition: Flexible Piezoelectric Acoustic Sensors and Machine Learning for Speech Processing. Adv. Mater. 2020, 32, 200024. [Google Scholar] [CrossRef]

- Wei, Y.; Zeng, Q.; Hu, Q.; Wang, M.; Tao, J.; Wang, L. Self-cleaned electrochemical protein imprinting biosensor basing on a thermo-responsive memory hydrogel. Biosens Bioelectron 2018, 99, 136–141. [Google Scholar] [CrossRef]

- Cao, Z.Q.; Wang, G.J. Multi-stimuli-responsive polymer materials:particles, films, and bulk gels. Chem. Rec. 2016, 16, 1398–1435. [Google Scholar] [CrossRef]

- Tan, Y.; Wang, D.; Xu, H.X.; Yang, Y.; Wang, X.L.; Tian, F.; Xu, P.; An, W.; Zhao, X.; Xu, S. Rapid Recovery Hydrogel Actuators in Air with Bionic Large-Ranged Gradient Structure. ACS Appl. Mater. Interfaces 2018, 10, 40125–40131. [Google Scholar] [CrossRef]

- Zhu, H.; Xu, B.; Wang, Y.; Pan, X.; Qu, Z.; Mei, Y. Self-powered locomotion of a hydrogel water strider. Sci. Robot. 2021, 6, eabe7925. [Google Scholar] [CrossRef]

- Yang, F.; Zhao, J.; Koshut, W.J.; Watt, J.; Riboh, J.C.; Gall, K.; Wiley, B.J. A Synthetic Hydrogel Composite with the Mechanical Behavior and Durability of Cartilage. Adv. Funct. Mater. 2020, 30, 2003451. [Google Scholar] [CrossRef]

- Yang, J.J.; Yan, H.; Dai, J.; Zhang, H.S. A review on magnetorheological fluid: Properties and applications. Chem. Ind. Eng. Prog. 2017, 36, 247–260. [Google Scholar] [CrossRef]

- Nishida, T.; Okatani, Y.; Tadakuma, K. Development of Universal Robot Gripper Using MRα Fluid. Int. J. Hum. Robot. 2016, 13, 1650017. [Google Scholar] [CrossRef]

- Yu, J.J.; Cai, S.B.; Xu, F. Compliant joint control of magneto-rheological fluid based on fractional-order PID algorithm. Comput. Integr. Manuf. Syst. 2020, 26, 393–401. [Google Scholar] [CrossRef]

- Hua, D.Z.; Liu, X.H.; Zhao, X.; Lu, H.; Li, Z.Q.; Liu, X.F. Design and Experiments of Spherical Magnetic Actuated Robot Based on Magnetorheological Fluid. J. South China Univ. Technol. Nat. Sci. Ed. 2021, 49, 151–160. [Google Scholar] [CrossRef]

- Liu, J. Rise of the Liquid Metal Science, Technology and Industry: Advancements and Opportunities. Chin. J. Eng. Sci. 2020, 22, 93. [Google Scholar] [CrossRef]

- Cooper, C.B.; Arutselvan, K.; Liu, Y.; Armstrong, D.; Lin, Y.; Khan, M.R.; Genzer, J.; Dickey, M.D. Sensors: Stretchable Capacitive Sensors of Torsion, Strain, and Touch Using Double Helix Liquid Metal Fibers. Adv. Funct. Mater. 2017, 27, 1605630. [Google Scholar] [CrossRef]

- Gao, Q.; Li, H.; Zhang, J.; Xie, Z.; Zhang, J.; Wang, L. Microchannel Structural Design For a Room-Temperature Liquid Metal Based Super-stretchable Sensor. Sci. Rep. 2019, 9, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Khan, H.; Mahmood, N.; Zavabeti, A.; Elbourne, A.; Rahman, A.; Zhang, B.Y.; Krishnamurthi, V.; Atkin, P.; Ghasemian, M.B.; Yang, J.; et al. Liquid metal-based synthesis of high performance monolayer SnS piezoelectric nanogenerators. Nat. Commun. 2020, 11, 1–8. [Google Scholar] [CrossRef]

- Ambulo, C.P.; Burroughs, J.J.; Boothby, J.M.; Kim, H.; Shankar, M.R.; Ware, T.H. Four-dimensional Printing of Liquid Crystal Elastomers. ACS Appl. Mater. Interfaces 2017, 9, 42. [Google Scholar] [CrossRef]

- Wie, J.J.; Shankar, M.R.; White, T.J. Supplementary Movie 2. Nat. Commun. 2016, 7, 1. [Google Scholar]

- Wang, C.J.; Sim, K.; Chen, J.; Kim, H.; Rao, Z.L.; Li, Y.H.; Chen, W.Q.; Song, J.Z.; Verduzco, R.; Yu, C.J. Adaptive Soft Robots: Soft Ultrathin Electronics Innervated Adaptive Fully Soft Robots. Adv. Mater. 2018, 30, 1706695. [Google Scholar] [CrossRef]

- Wehner, M.; Tolley, M.T.; Mengü, Y.; Parl, Y.L.; Wood, R.J. Pneumatic Energy Sources for Autonomous and Wearable Soft Robotics. Soft Robotics 2014, 1, 263–274. [Google Scholar] [CrossRef] [Green Version]

- Bartlett, N.W.; Tolley, M.T.; Overvelde, J.; Weaver, J.C.; Mosadegh, B.; Bertoldi, K.; Whitesides, G.M.; Wood, R.J. A 3D-printed, functionally graded soft robot powered by combustion. Science 2015, 349, 161–165. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, H.L.; Yao, J.T.; Zhou, P.; Zhao, W.; Zhao, Y. Untethered, High-load Soft Gripping Robots: A Review. J. Mech. Eng. 2020, 56, 28–42. [Google Scholar] [CrossRef]

- Wehner, M.; Truby, R.L.; Fitzgerald, D.J.; Mosadegh, B.; Whitesides, G.M.; Lewis, J.A.; Wood, R.J. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 2016, 536, 451–455. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- He, X.T.; Liu, Y.Z.; Jiao, Z.W.; Yu, Y.; Yang, W.M.; Ma, H.P. Design of Chemical Reaction Self-driven Rolling Robot. Trans. Chin. Soc. Agric. Mach. 2021, 52, 410–417. [Google Scholar] [CrossRef]

- Pelrine, E.R.; Roy, D.R.; Jose, P.J. Electrostriction of polymer dielectrics with compliant electrodes as a means of actuation Sensors and Actuators. Sens. Actuators A Phys. 1998, 64, 77–85. [Google Scholar] [CrossRef]

- Alici, G.; Huynh, N.N. Predicting force output of trilayer polymer actuators. Sens. Actuators A Phys. 2006, 132, 616–625. [Google Scholar] [CrossRef]

- Saharan, L.; de Andrade, M.J.; Saleem, W.; Baughman, R.H.; Tadesse, Y. iGrab: Hand orthosis powered by twisted and coiled polymer muscles. Smart Mater. Struct. 2017, 26, 105048. [Google Scholar] [CrossRef]

- Sutton, L.; Moein, H.; Rafiee, A.; Madden, J.D.W.; Menon, C. Design of an assistive wrist orthosis using conductive nylon actuators. In Proceedings of the 2016 6th IEEE International Conference on Biomedical Robotics and Biomechatronics (BioRob), Singapore, 26–29 June 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1074–1079. [Google Scholar] [CrossRef]

- Wu, L.; de Andrade, M.J.; Brahme, T.; Tadesse, Y.; Baughman, R.H. A reconfigurable robot with tensegrity structure using nylon artificial muscle. SPIE 2016, 9799, 950–960. [Google Scholar] [CrossRef]

- Li, H.; Liu, L.; Xiao, T.; Ang, H. Design and simulative experiment of an innovative trailing edge morphing mechanism driven by artificial muscles embedded in skin. Smart Mater. Struct. 2016, 25, 095004. [Google Scholar] [CrossRef]

- Luong, T.A.; Seo, S.; Koo, J.C.; Choi, H.R.; Moon, H. Differential Hysteresis Modeling with Adaptive Parameter Estimation of a Super-Coiled Polymer Actuator; IEEE: Piscataway, NJ, USA, 2017; pp. 607–612. [Google Scholar] [CrossRef]

- Chen, Y.X. Experimental Research on 3D Printing Technology with Soft Materials for Soft Robotics. Master’s Thesis, Soochow University, Suzhou, China, 2020. [Google Scholar]

- Yang, Y.Q. Study On Flexural Behavior And Vibration Characteristics Of Curved Shell Sandwich Structure With Foldcore. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2019. [Google Scholar]

- Griffith, M.L.; Halloran, J.W. Freeform Fabrication of Ceramics via Stereolithography. J. Am. Ceram. Soc. 1996, 79, 2601–2608. [Google Scholar] [CrossRef] [Green Version]

- Ge, Q.; Li, Z.Q.; Wang, Z.L.; Kowsari, K.; Zhang, W. Projection micro stereolithography based 3D printing and its applications. Int. J. Extrem. Manuf. 2020, 2, 022004. [Google Scholar] [CrossRef]

- Yin, Q.; Guo, Q.; Wang, Z.; Chen, Y.; Cheng, P. 3D-Printed Bioinspired Cassie–Baxter Wettability for Controllable Microdroplet Manipulation. ACS Appl. Mater. Interfaces 2020, 13, 1979–1987. [Google Scholar] [CrossRef] [PubMed]

- Cai, L.; Chen, G.; Tian, J.; Su, B.; He, M. Three-dimensional Printed Ultrahighly Sensitive Bioinspired Ionic Skin Based on Submicrometer-Scale Structures by Polymerization Shrinkage. Chem. Mater. 2021, 33, 2072–2079. [Google Scholar] [CrossRef]

- Chen, G.S. Study and Application of Nano-composites Reinforced PMMA Resin and DLP Light Curing Technology in Dental Denture Base Manufacture. Ph.D. Thesis, South China University of Technology, Guangzhou, China, 2020. [Google Scholar]

- Zhu, W.; Li, J.; Leong, Y.J.; Yew, J.; Isaac, L.; Xin, R. 3D-Printed Artificial Microfish. Adv. Mater. 2015, 27, 4411–4417. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hong, H.; Seo, Y.B.; Kim, D.Y.; Lee, J.S.; Lee, J.Y.; Lee, H.; Md, O.A.; Sultan, T.; Lee, O.J.; Kim, S.H.; et al. Digital light processing 3D printed silk fibroin hydrogel for cartilage tissue engineering. Biomaterials 2020, 232, 119679. [Google Scholar] [CrossRef]

- Tang, M.; Xie, Q.; Gimple, R.C.; Zhong, Z.; Tam, T.; Tian, J.; Kidwell, R.L.; Wu, Q.; Prager, B.C.; Qiu, Z.; et al. Three-dimensional bioprinted glioblastoma microenvironments model cellular dependencies and immune interactions. Cell Res. 2020, 30, 833–853. [Google Scholar] [CrossRef]

- Xu, D.D. The Preparation and Fused Deposition Modeling Process of Polylactic Acid/Organic Modified Montmorillonite Nanocomposite Filaments. Master’s Thesis, Ningbo Institute of Materials Technology & Engineering, Ningbo, China, 2018. [Google Scholar]

- Hu, F.; Wang, W.; Cheng, J.; Bao, Y. Origami spring–inspired metamaterials and robots: An attempt at fully programmable robotics. Sci. Prog. 2020, 103, 0036850420946162. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, X.Y.; Li, Z. Prediction study on bond strength and modulus of fused deposition modeling product. J. Chem. Ind. Eng. China 2019, 70, 2727–2736, 2822. [Google Scholar] [CrossRef]

- Hua, D.C.; Zhang, X.Q.; Ji, Z.Y.; Yan, C.Y.; Yu, B. 3D printing of shape changing composites for constructing flexible paper-based photothermal bilayer actuator. J. Mater. Chem. C 2018, 6, 2123–2131. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Zahedi, S.A.; Ismail, S.O. 3D printing of PEEK–cHAp scaffold for medical bone implant. Bio-Des. Manuf. 2021, 4, 44–59. [Google Scholar] [CrossRef]

- Griffith, M.L.; Halloran, J.W. 3D printing for soft robotics-A review. Sci. Technol. Adv. Mater. 2018, 19, 243–262. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Zhang, Q.; Yang, T.; Liu, Y.; Liu, R. 3D printing of multi-scalable structures via high penetration near-infrared photopolymerization. Nat. Commun. 2020, 11, 3462. [Google Scholar] [CrossRef] [PubMed]

- Zheng, R.; Chen, Y.; Chi, H.; Qiu, H.; Xue, H.; Bai, H. 3D Printing of a Polydimethylsiloxane/Polytetrafluoroethylene Composite Elastomer and its Application in a Triboelectric Nanogenerator. ACS Appl. Mater. Interfaces 2020, 12, 57441–57449. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Zhu, L.; Tang, S.; Wen, W.; Lu, L.; Liu, M.; Zhou, C.; Luo, B. Fabrication and evaluation of a chitin whisker/poly(L-lactide) composite scaffold by the direct trisolvent-ink writing method for bone tissue engineering. Nanoscale 2020, 12, 18225–18239. [Google Scholar] [CrossRef] [PubMed]

- Shirazi, S.; Gharehkhani, S.; Mehrali, M. A review on powder-based additive manufacturing for tissue engineering: Selective laser sintering and inkjet 3D printing. Sci. Technol. Adv. Mater. 2015, 16, 033502. [Google Scholar] [CrossRef]

- Japanese Bionic Robots Move Like Animals and 3D Printing is Integrated 2017. Available online: https://www.sohu.com/a/212856831_181700 (accessed on 27 April 2021).

- Wei, T.; Zhang, X.W.; Sun, H.Q.; Mao, M.Y. Selective laser sintering and performances of porous titanium implants. West China, J. Stomatol. 2018, 36, 532–538. [Google Scholar] [CrossRef]

- Sun, S.; Gan, X.; Wang, Z.; Fu, D.; Pu, W.; Xia, H. Dynamic healable polyurethane for selective laser sintering. Addit. Manuf. 2020, 33, 101176. [Google Scholar] [CrossRef]

- Cho, K.J.; Koh, J.S.; Kim, S.; Chu, W.S.; Hong, Y.; Ahn, S.H. Review of manufacturing processes for soft biomimetic robots. Int. J. Precis. Eng. Man. 2009, 10, 171–181. [Google Scholar] [CrossRef]

- Kim, S.; Spenko, M.; Trujillo, S.; Heyneman, B.; Santos, D.; Cutkosky, M.R. Smooth vertical surface climbing with directional adhesion. IEEE Trans. Robot. 2008, 24, 65–74. [Google Scholar] [CrossRef]

- Hawkes, E.W.; Eason, E.V.; Asbeck, A.T.; Cutkosky, M.R. The gecko’s toe: Scaling directional adhesives for climbing applications. IEEE ASME Trans. Mechatron. 2013, 18, 518–526. [Google Scholar] [CrossRef]

- Gafford, J.; Ding, Y.; Harris, A.; Mckenna, T.; Walsh, C.J. Shape Deposition Manufacturing of a Soft, Atraumatic, and Deployable Surgical Grasper. J. Med. Devices 2014, 8, 030927. [Google Scholar] [CrossRef] [Green Version]

- Li, N. Simulation and Experimental Study of Laser Irradiation Temperature Field Based on Frozen Slurry 3D Printing. Master’s Thesis, Xi’an Technological University, Xi’an, China, 2019. [Google Scholar]

- Dun, C.; Kuang, W.; Kempf, N.; Saeidi-Javash, M.; Singh, D.J.; Zhang, Y. 3D Printing of Solution-Processable 2D Nanoplates and 1D Nanorods for Flexible Thermoelectrics with Ultrahigh Power Factor at Low-Medium Temperatures. Adv. Sci. 2019, 6, 1901788. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maccurdy, R.; Katzschmann, R.; Kim, Y.; Rus, D. Printable Hydraulics: A Method for Fabricating Robots by 3D Co-Printing Solids and Liquids. Computerence 2016, 2012, 1687–9503. [Google Scholar]

- Nano Dimension Launched a New and Larger 3D Printer, Dragonfly 2020 Pro (2017). Available online: http://www.dayinpai.com/topic/post/f12151 (accessed on 27 April 2021).

- Zhang, Y.F.; Ng, C.J.X.; Chen, Z.; Zhang, W.; Panjwani, S.; Kowsari, K.; Yang, H.Y.; Ge, Q. Miniature Pneumatic Actuators for Soft Robots by High-Resolution Multimaterial 3D Printing. Adv. Mater. Technol. 2019, 4, 1900427. [Google Scholar] [CrossRef]

- Jackson, J.A.; Messner, M.C.; Dudukovic, N.A.; Smith, W.L.; Bekker, L. Field responsive mechanical metamaterials. Sci. Adv. 2018, 4, eaau6419. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Odent, J.; Wallin, T.J.; Pan, W. Highly elastic, transparent, and conductive 3D-printed ionic composite hydrogels. Adv. Funct. Mater. 2017, 27, 1701807. [Google Scholar] [CrossRef]

- Tawk, C.; in het Panhuis, M.; Spinks, G.M.; Gursel, A. Bioinspired 3d printable soft vacuum actuators for locomotion robots, grippers and artificial muscles. Soft Robot. 2018, 5, 685–694. [Google Scholar] [CrossRef]

- Nadgorny, M.; Xiao, Z.; Chen, C.; Connal, A.L. Three-dimensional printing of pH-responsive and functional polymers on an affordable desktop printer. ACS Appl. Mater. Interfaces 2016, 8, 28946–28954. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Zhang, N.; Hingorani, H. Fast-response, stiffness-tunable soft actuator by hybrid multimaterial 3D printing. Adv. Funct. Mater. 2019, 29, 1806698. [Google Scholar] [CrossRef]

- Yirmibesoglu, O.D.; Morrow, J.; Walker, S.; Gosrich, W.; Menguc, Y. Direct 3D Printing of Silicone Elastomer Soft Robots and Their Performance Comparison with Molded Counterparts; IEEE: Piscataway, NJ, USA, 2018; pp. 295–302. [Google Scholar] [CrossRef]

- Jeon, S.; Hoshiar, A.K.; Kim, K.; Lee, S.; Kim, J.Y.; Nelson, B.J.; Cha, H.J.; Yi, B.J. A magnetically controlled soft microrobot steering a guidewire in a three-dimensional phantom vascular network. Soft Robot. 2019, 6, 54–68. [Google Scholar] [CrossRef] [Green Version]

- Scharff, R.B.N.; Doubrovski, E.L.; Poelman, W.A.; Jonker, P.P.; Geraedts, J.M.P. Towards behavior design of a 3D-printed soft robotic hand[M]//Soft Robotics: Trends, Applications and Challenges; Springer: Cham, Switzerland, 2017; pp. 23–29. [Google Scholar]

- Zatopa, A.; Walker, S.; Menguc, Y. Fully soft 3D-printed electroactive fluidic valve for soft hydraulic robots. Soft Robot. 2018, 5, 258–271. [Google Scholar] [CrossRef] [PubMed]

- Fei, Y.; Pang, W. Analysis on nonlinear turning motion of multi-spherical soft robots. Nonlinear Dyn. 2017, 88, 883–892. [Google Scholar] [CrossRef]

- Mateos L, A. Bionic Sea Urchin Robot with Foldable Telescopic Actuator//2020 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM); IEEE: Piscataway, NJ, USA, 2020. [Google Scholar]

- Yan, C.; Zhang, X.; Ji, Z.; Wang, X.; Zhou, F. 3D-Printed Electromagnetic Actuator for Bionic Swimming Robot. J. Mater. Eng. Perform. 2021, 16, 6579–6587. [Google Scholar] [CrossRef]

- Yan, X.K.; Zhang, L. Design and Simulation Analysis of Robotic Arm Based on Bionic Jellyfish Robot. Ordnance Ind. Autom. 2019, 38, 62–65, 69. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, X.; Chen, Y.; Wainwright, D.K.; Kenaley, C.P.; Gong, Z.; Liu, Z.; Liu, H.; Guan, J.; Wang, T. A biorobotic adhesive disc for underwater hitchhiking inspired by the remora suckerfish. Sci. Robot. 2017, 2, eaan8072. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, G.B.; Chen, D.S.; Chen, K.W.; Zhang, Z.Q. The Current Research Status and Development Strategy on Biomimetic Robot. J. Mech. Eng. 2015, 51, 27–44. [Google Scholar] [CrossRef]

- Wang, C.J.; Li, S. Research Status of the Soft Robot. Micronanoelectronic Technol. 2019, 56, 948–955, 991. [Google Scholar] [CrossRef]

- Hao., Y.; Gong, Z.; Xie, Z.; Guan, S.; Yang, X. Universal soft pneumatic robotic gripper with variable effective length. In Proceedings of the 2016 35th Chinese Control Conference (CCC), Chengdu, China, 27–29 July 2016; pp. 6109–6114. [Google Scholar]

- Wei, S.J.; Wang, T.Y.; Gu, G.Y. Design of a Soft Pneumatic Robotic Gripper Based on Fiber-reinforced Actuator. J. Mech. Eng. 2017, 53, 29–38. [Google Scholar] [CrossRef]

- Gunderman, A.L.; Collins, J.; Myer, A.; Threlfall, R.; Chen, Y. Tendon-Driven Soft Robotic Gripper for Berry Harvesting. IEEE Robot. Autom. Lett. 2021, 7, 2652–2659. [Google Scholar] [CrossRef]

- Shen, J.Z.; Zhao, X.L.; Zhang, F. Design and ergonomic evaluation of flexible rehabilitation gloves. J. Text. Res. 2020, 41, 119–127. [Google Scholar] [CrossRef]

- Lessard, S.; Pansodtee, P.; Robbins, A.; Trombadore, J.M.; Kurniawan, S.; Teodorescu, S. A Soft Exosuit for Flexible Upper-Extremity Rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. A Publ. IEEE Eng. Med. Biol. Soc. 2018, 26, 1604–1617. [Google Scholar] [CrossRef] [PubMed]

- Dong, H.; Lin, M.; Gu, S.C.; Cao, Y.; Wei, L. Motion characteristics of soft bionic tongue based on multi-directional pneumatic actuator. J. Beijing Univ. Aeronaut. Astronaut. 2019, 45, 1882–1893. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, J.; Li, T.; Liu, K.; Liu, H.; Ma, S. Overview of research on 3D printing manufacturing technology of software robot. J. Mech. Eng. 2021, 57, 186–198. [Google Scholar] [CrossRef]

- Dong, X.; Feng, X. Research Status and Prospect of Soft Robot. Mod. Manuf. Technol. Equip. 2022, 58, 70–73+85. [Google Scholar] [CrossRef]

- Kuang, X.; Roach, D.J.; Wu, J.; Hamel, C.M.; Ding, Z.; Wang, T.; Dunn, M.L.; Qi, H.J. Advances in 4D printing: Materials and applications. Adv. Funct. Mater. 2019, 29, 1805290. [Google Scholar] [CrossRef]

- Wen, L.; Wang, H. Perspective of Soft Robotics: Structure, Actuation, and Control. Jiqiren/Robot 2018, 40, 577. [Google Scholar] [CrossRef]

| Advantages | Disadvantages | |

|---|---|---|

| SMA | Simple fabrication, low cost, light weight, high power density, and high driving force | Easy aging of material, difficult to accurately control the accuracy, and low driven frequency |

| SMP | Large deformation, light weight, and simple structure | Driving force of SMP driven is smaller than SMA, less stable, less precise control |

| EAP | Fast response, lighter material mass, and higher driven efficiency | high driven voltage for electronic EAP, ionic EAP requires a wet environment, and poorer load-bearing capacity and stability |

| Piezoelectric material | High response speed, high operating stress and frequency, and large operable bandwidth | The high driven voltage required and the small amount of driven displacement produced. |

| Responsive hydrogel | Biocompatibility, permeability, and responsiveness to external stimuli | The preparation and control process is complex and the driven cannot be precisely controlled |

| LM | Good fluidity, strong electrical conductivity, excellent thermal characteristics, and easy to realize solid-liquid conversion | The manufacturing process is more complicated and there is a risk of leakage of liquid during the working process. |

| LCE | Unique bi-directional shape memory, large deformation, fast response time, and scalability | Lower mechanical properties and higher preparation cost |

| Advantages | Disadvantages | ||

|---|---|---|---|

| Fluid driven | Pneumatic driven | Good safety, low production cost, large deformation, and light weight | Low output force, hysteresis, and external air supply required |

| Hydraulic driven | Fast response speed, large output force, circular loop, and lower working noise | Heavy weight, external hydraulic pump, and high energy consumption | |

| Chemical reaction driven | Fast response and large output force | Low energy utilization, poor stability, poor controllability, and short service life | |

| Classification | Materials | Advantages | Disadvantages | Applications |

|---|---|---|---|---|

| SLA | Photosensitive modified silicone materials | Accurate control of the shape and size of the part | Cannot achieve multi-material printing | Octopus like robots [76] |

| Hydrogel materials | Smooth surface | Materials with generally toxic | Micro soft robot [116] | |

| Need extra print support and manually remove | Magnetic response octahedron [117] | |||

| Curl or break when cured | Flexible sensor [118] | |||

| DLP | Photopolymer | Fast formation | High purity liquid photopolymer | Software gripper |

| High precision | ||||

| High surface finish | ||||

| Low cost | ||||

| Safe and reliable | ||||

| FDM | TPU, SMP, P2VP, ABS | Low cost | Long molding time | Soft gripper [119] |

| Materials with accessibility, compatibility, and usability | Low precision of material extrusion nozzle and molding effect | pH response parts [120] | ||

| Small environmental pollution | Need extra print support and manually remove | |||

| DIW | Silicone rubber | Fast printing speed | Low accuracy | Software gripper [121] |

| Silicone, hydrogel | Low cost | Need extra print support | crawling robot [122] | |

| Liquid metal | Widely used | Magnetic elastomer [123] | ||

| Nano silver | Easy to operate | |||

| SLS | TPU and other thermoplastic materials | Materials with accessibility and usability | Laser radiation | Soft gripper [124] |

| High precision | High cost | |||

| High reducibility | Low efficiency | |||

| Function test or assembly simulation for sample | Limited by material | |||

| SDM | Active agent mixing material | High manufacturing accuracy | Rough surface | Soft gripper [124] |

| Thermoplastic materials | Process complicated equipment | High cost | Crawling robot | |

| High control requirements | ||||

| Fatigue failure | ||||

| IP | Tangoplus materials | Simple molding mechanism | The print head blockage | The print head blockage |

| Vero white materials | Fast molding speed | Difficult to control the size of the ink droplets | Hardness gradient distribution software driver [125] | |

| No internal stress | The printing process accompanied by nozzle offset | |||

| No additional support | The printed product with serious grain | |||

| Low cost |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, K.; Chen, W.; Yang, W.; Jiao, Z.; Yu, Y. Review of the Research Progress in Soft Robots. Appl. Sci. 2023, 13, 120. https://doi.org/10.3390/app13010120

Liu K, Chen W, Yang W, Jiao Z, Yu Y. Review of the Research Progress in Soft Robots. Applied Sciences. 2023; 13(1):120. https://doi.org/10.3390/app13010120

Chicago/Turabian StyleLiu, Kerun, Weiwei Chen, Weimin Yang, Zhiwei Jiao, and Yuan Yu. 2023. "Review of the Research Progress in Soft Robots" Applied Sciences 13, no. 1: 120. https://doi.org/10.3390/app13010120