Effect of Human Hair Fibers on the Performance of Concrete Incorporating High Dosage of Silica Fume

Abstract

1. Introduction

2. Materials and Method

2.1. Materials and Mix Proportioning

2.2. Mixing and Casting Procedure

2.3. Testing Program

2.4. Response Surface Method

3. Results and Discussion

3.1. Compressive Strength

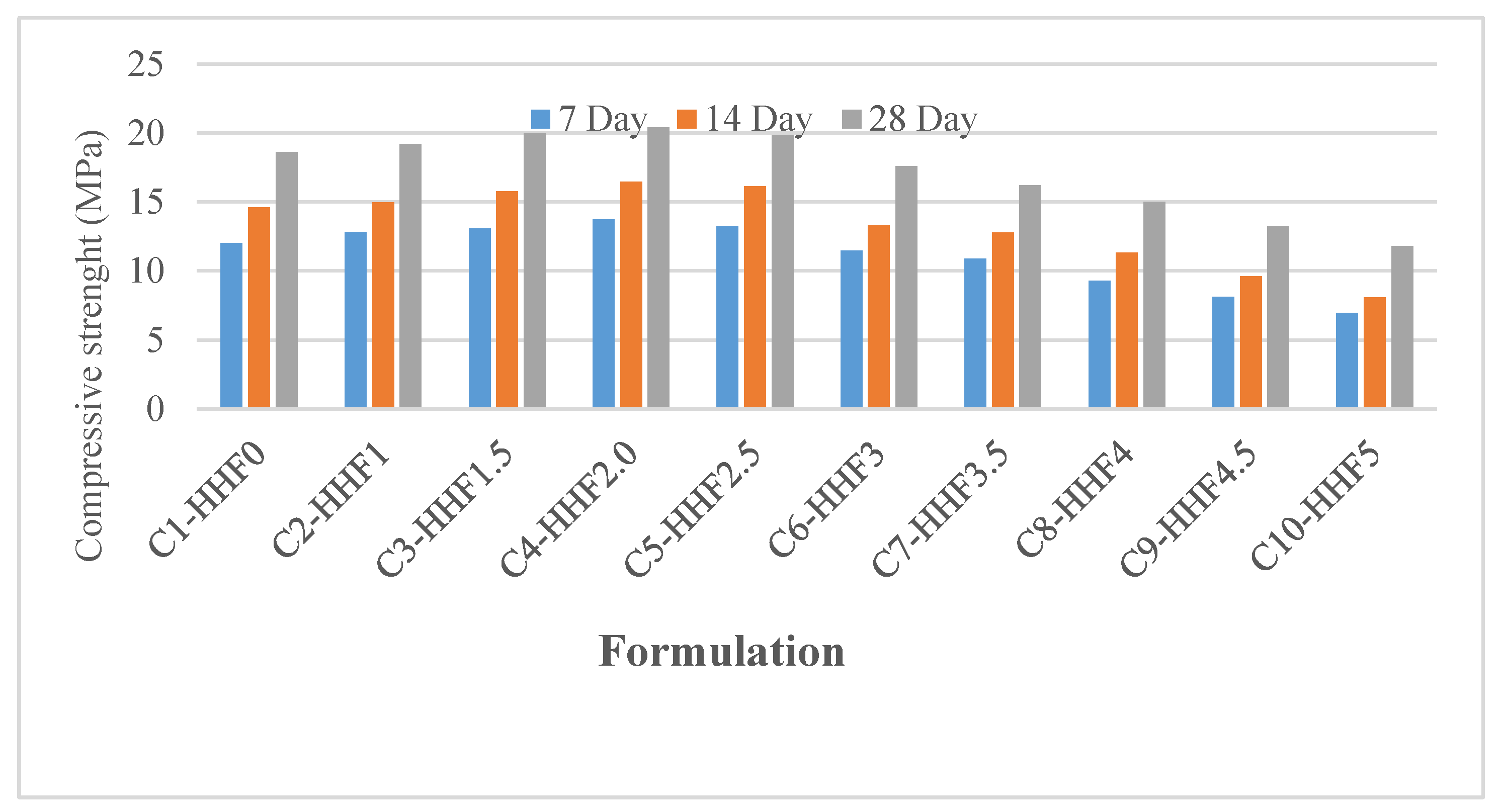

3.1.1. Human Hair Fiber Concrete Compressive Strength

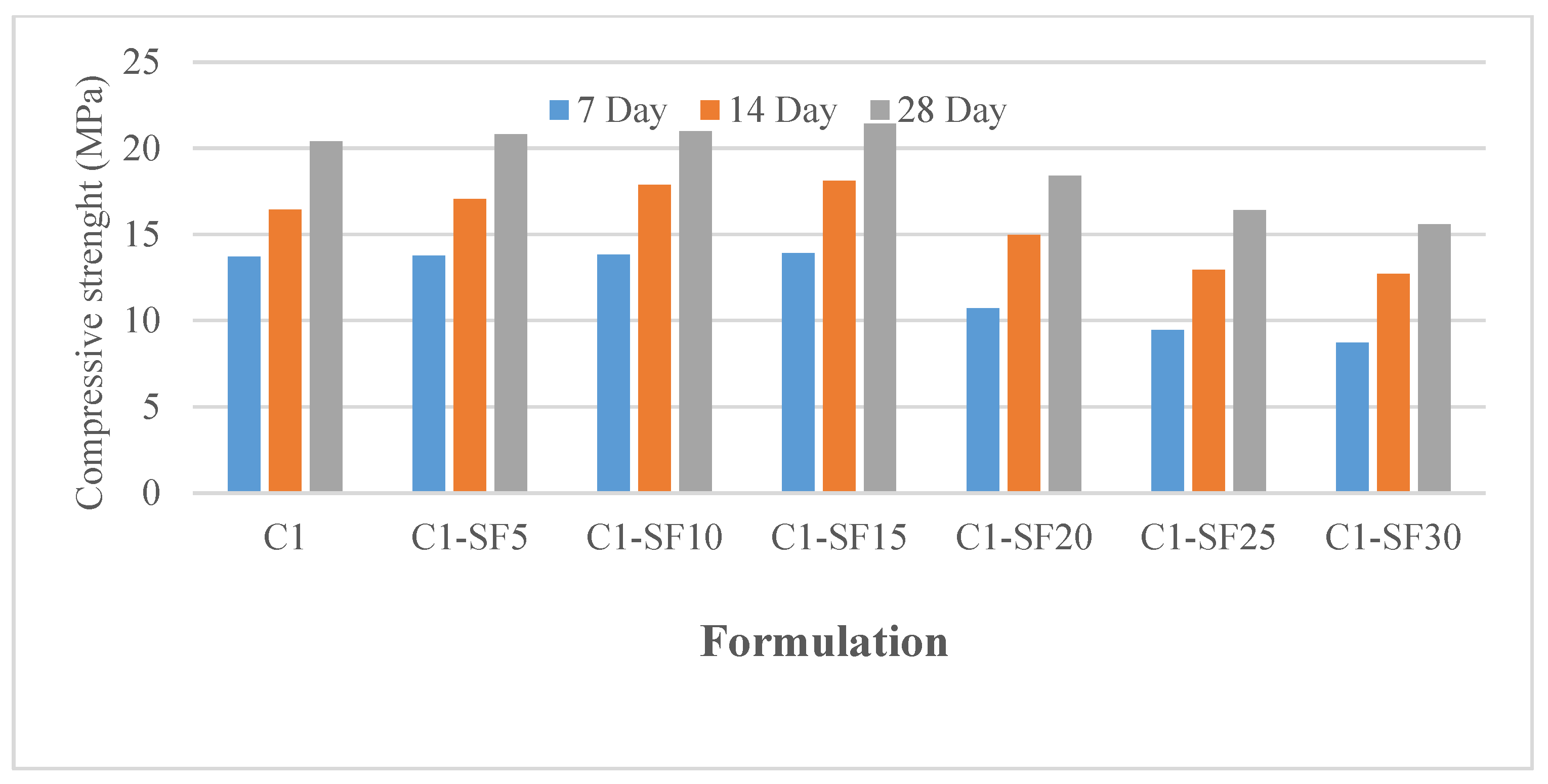

3.1.2. Effect on HHFC Compressive Strength with Replacement of Cement by Silica Fume

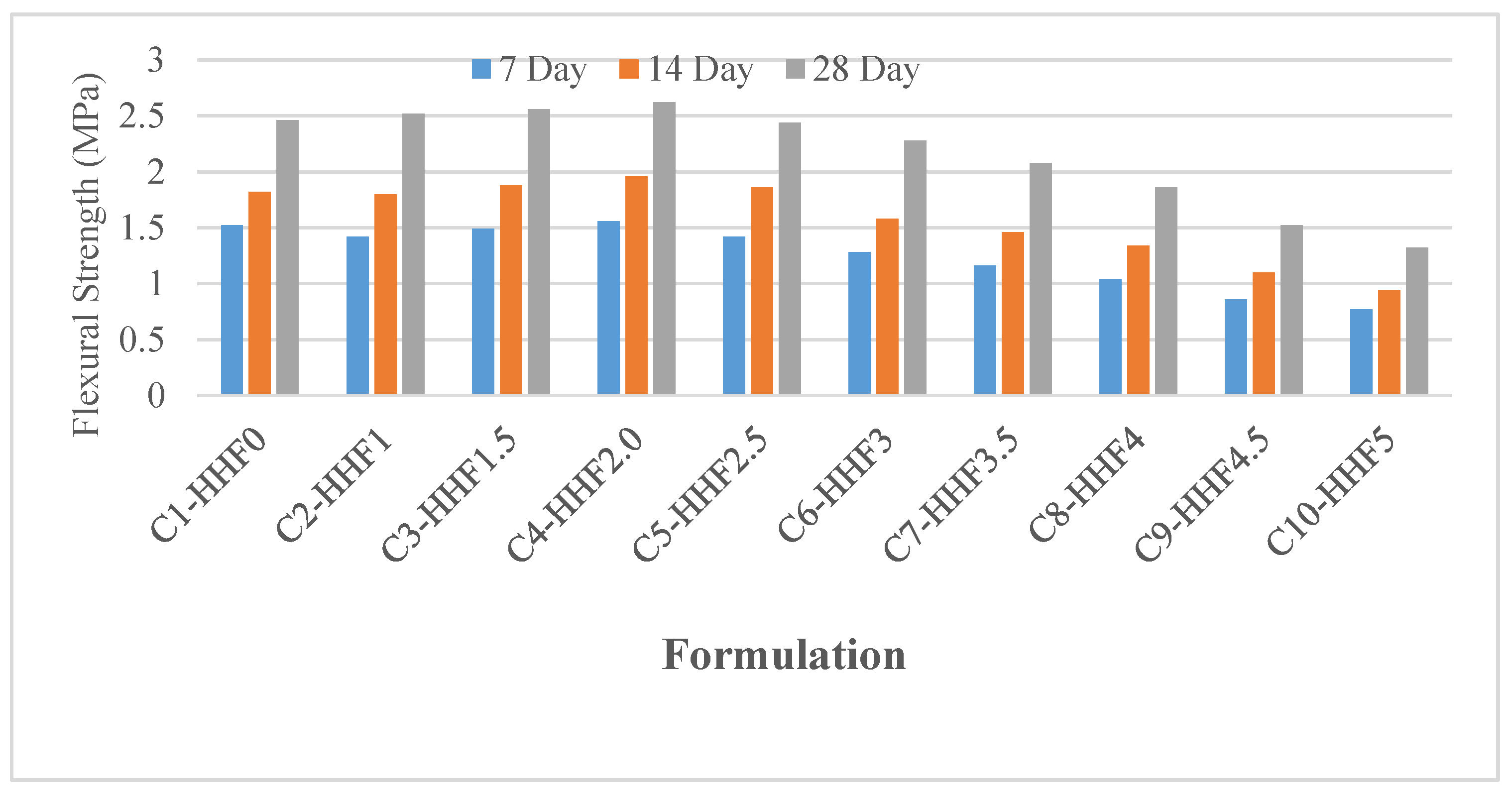

3.1.3. Effect on HHFC Compressive Strength with Replacement of Cement by Silica Fume Using RSM

3.2. Flexural Strength

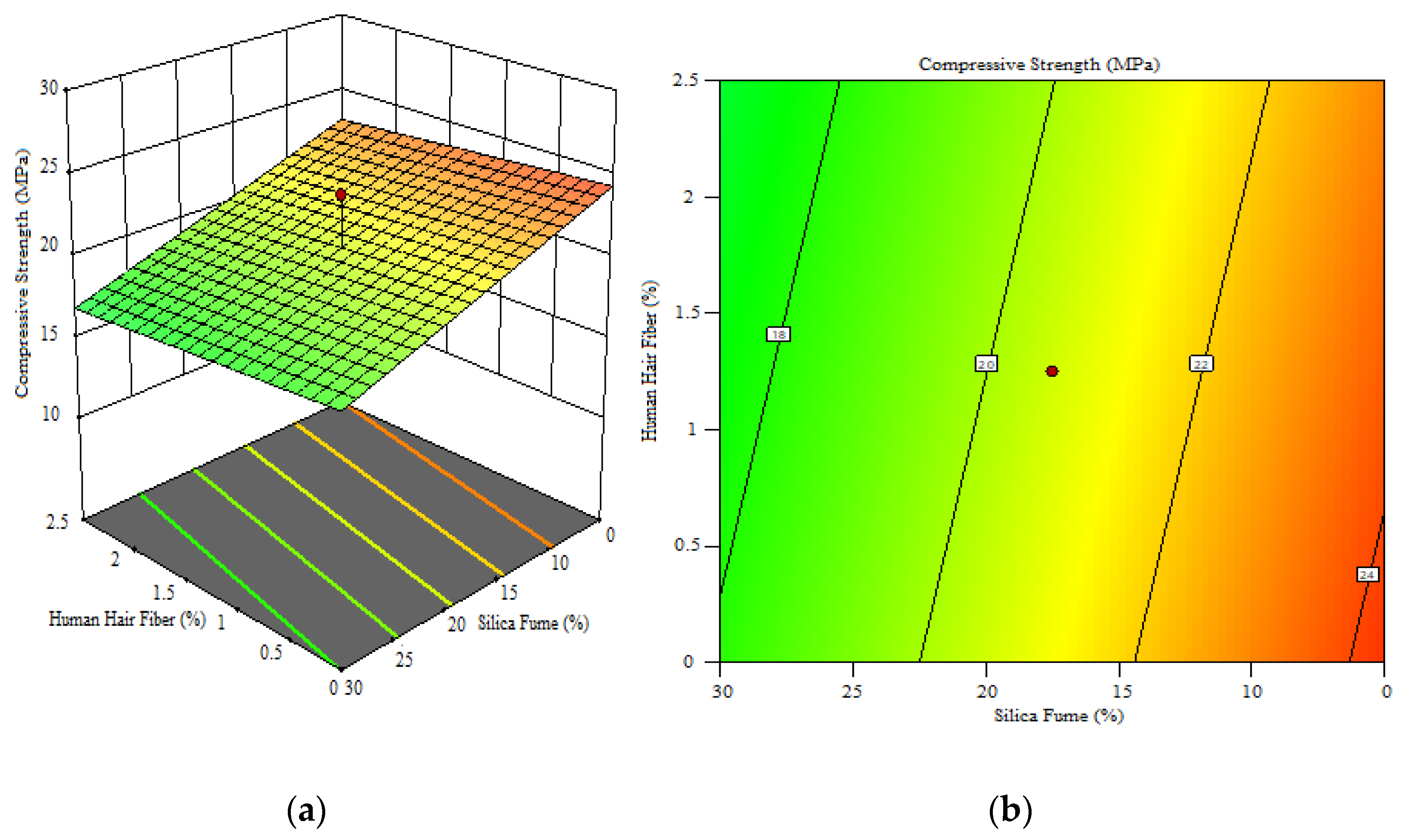

3.2.1. Human Hair Fiber Concrete Flexural Strength

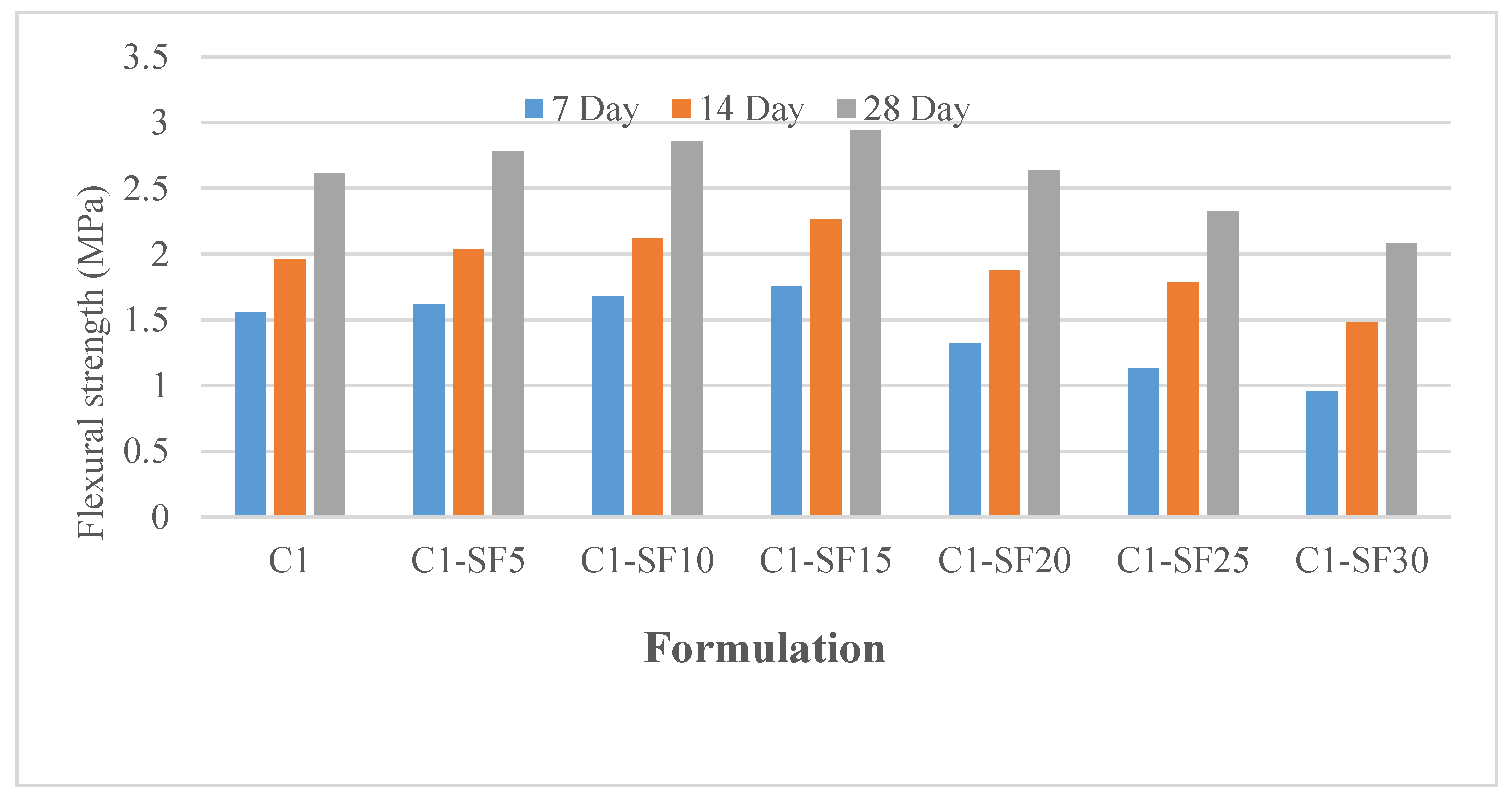

3.2.2. Effect on HHFC Concrete Flexural Strength with Replacement of Cement by Silica Fume

3.2.3. Effect on HHFC Flexural Strength with Replacement of Cement by Silica Fume Using RSM

3.3. Split Tensile Strength

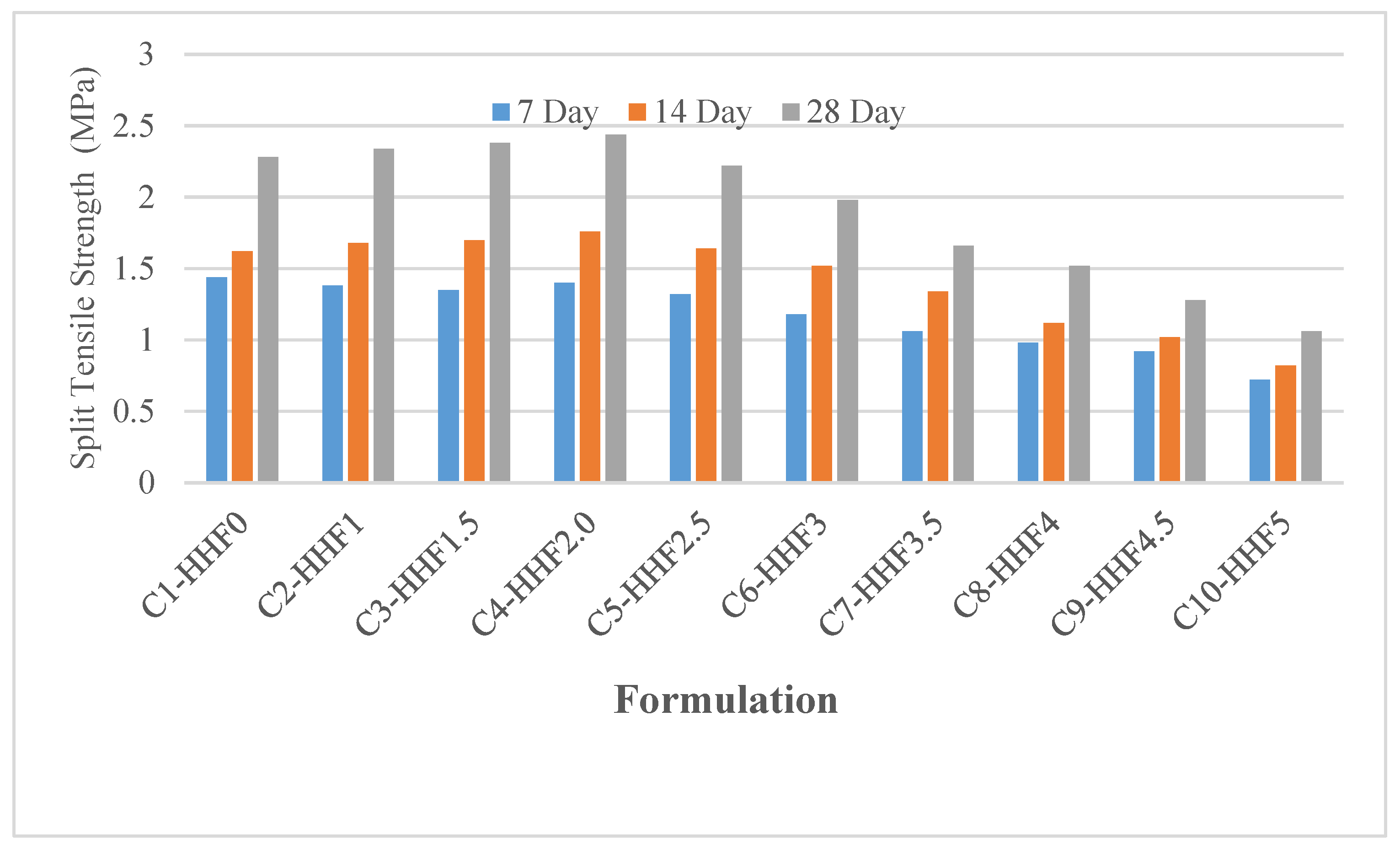

3.3.1. Human Hair Fiber Concrete Split Tensile Strength

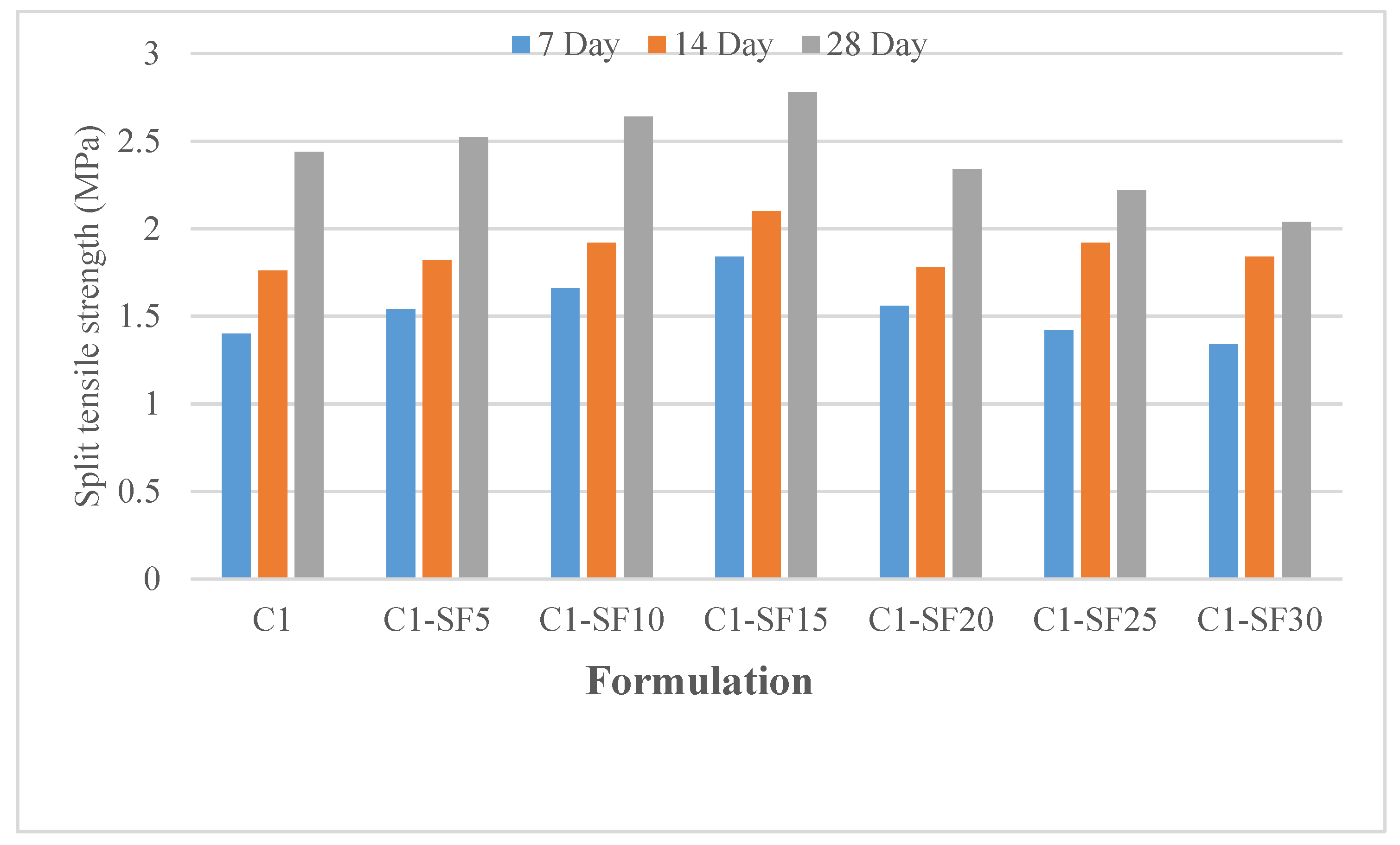

3.3.2. Effect on HHFC Concrete Split Tensile Strength with Replacement of Cement by Silica Fume

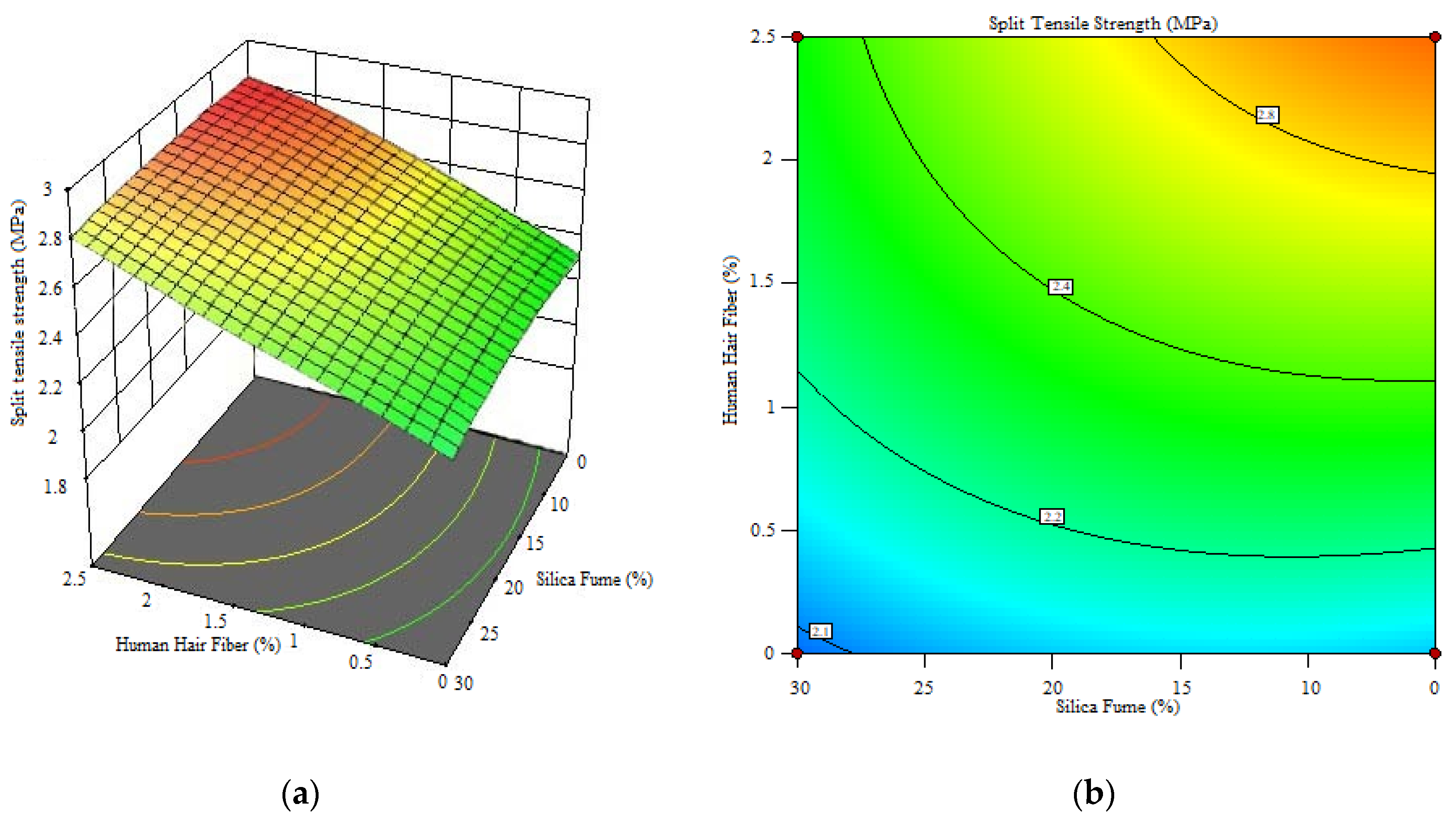

3.3.3. Effect on HHFC Concrete Split Tensile Strength with Replacement of Cement by Silica Fume Using RSM

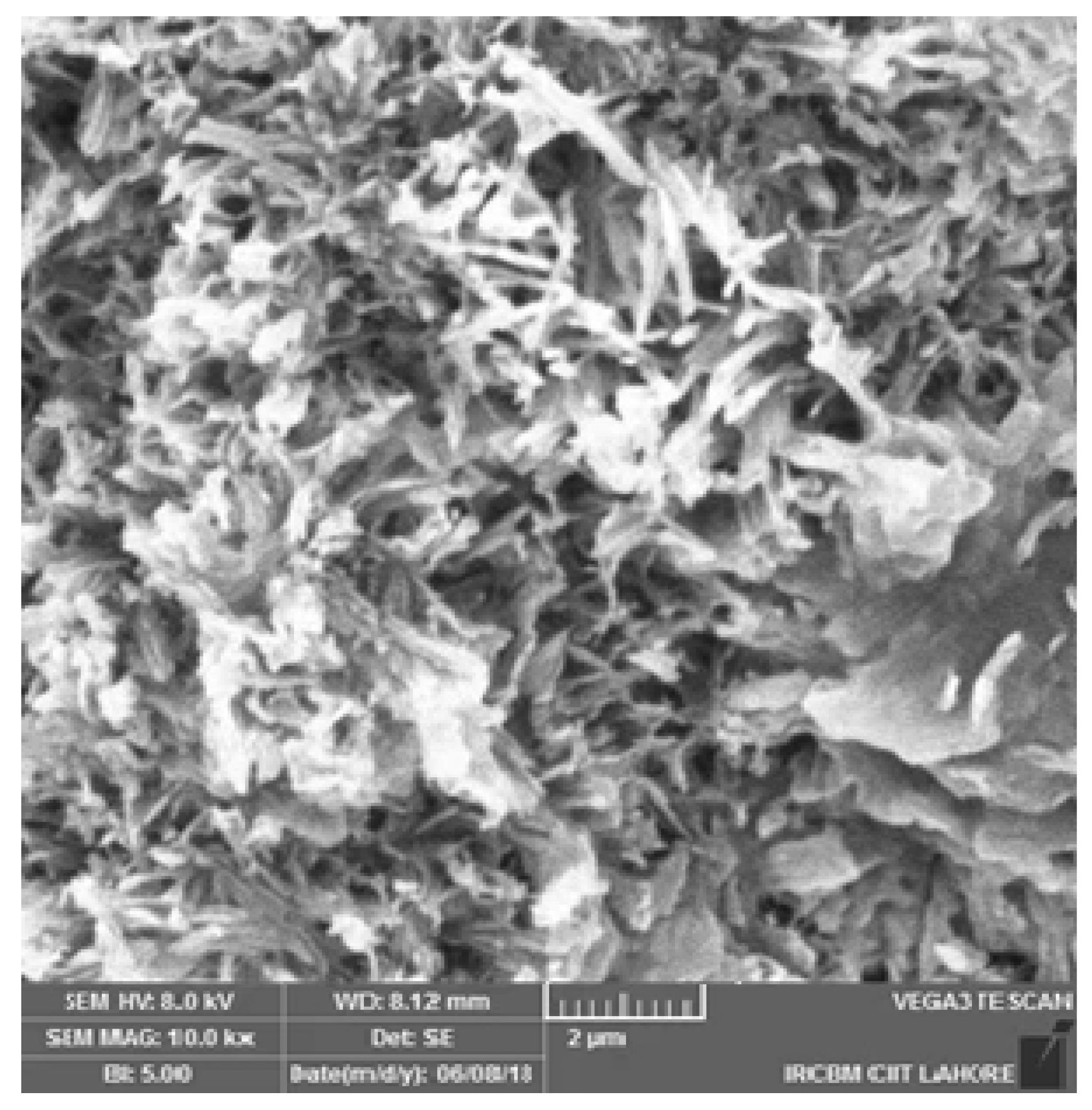

3.4. SEM of Human Hair Fiber and Silica Fume

4. Anova

4.1. Anova Analysis

4.2. Optimization and Experimental Validation

5. Conclusions

- Using human hair in concrete enhances the ductility of the material by minimizing the formation of macro cracks by crack bridging effect.

- Test results suggest that using 2% human hair fiber and replacing 15% of the cement with SF produces the best flexure, compression, and split tensile strengths.

- The optimum fiber and SF dosages were found to be 2% and 15%, respectively, based on experimental and RSM results. Due to the amalgamation of fibers, the results at larger dosages were conflicting.

- To see if the predictive models were statistically significant, researchers utilized a two-way ANOVA with a significance level of less than 0.05 p-value. The residual error and pure error from the lack of fit are insignificant. The adjusted and expected R2 indicate that the predictive model accurately reflects the variable-response relationship and is suitable for testing.

- A linear equation was proposed to relate the compressive strengths of SF and human hair fiber in human hair fiber concrete. The RSM model and equations utilized to calculate human hair fiber concrete’s compressive, split tensile, and flexural strengths were accurate. The prediction model results validate the experimental data, revealing a slight variance.

- The use of human hair and silica fume could reduce the environmental impact of concrete; however, a lifecycle assessment should be carried out to assess the actual potential environmental benefits.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zeyad, A.M.; Khan, A.H.; Tayeh, B.A. Durability and strength characteristics of high-strength concrete incorporated with volcanic pumice powder and polypropylene fibers. J. Mater. Res. Technol. 2020, 9, 806–813. [Google Scholar] [CrossRef]

- Huseien, G.F.; Shah, K.W.; Sam, A.R.M. Sustainability of nanomaterials based self-healing concrete: An all-inclusive insight. J. Build. Eng. 2019, 23, 155–171. [Google Scholar] [CrossRef]

- Althoey, F.; Hakeem, I.Y.; Hosen, A.; Qaidi, S.; Isleem, H.F.; Hadidi, H.; Shahapurkar, K.; Ahmad, J.; Ali, E. Behavior of Concrete Reinforced with Date Palm Fibers. Materials 2022, 15, 7923. [Google Scholar] [CrossRef] [PubMed]

- Hussain, Z.; Pu, Z.; Hussain, A.; Ahmed, S.; Shah, A.U.; Ali, A.; Ali, A. Effect of fiber dosage on water permeability using a newly designed apparatus and crack monitoring of steel fiber–reinforced concrete under direct tensile loading. Struct. Health Monit. 2021, 21, 147592172110528. [Google Scholar] [CrossRef]

- Ahmed, S.; Hussain, A.; Hussain, Z.; Pu, Z.; Ostrowski, K.A.; Walczak, R. Effect of Carbon Black and Hybrid Steel-Polypropylene Fiber on the Mechanical and Self-Sensing Characteristics of Concrete Considering Different Coarse Aggregates’ Sizes. Materials 2021, 14, 7455. [Google Scholar] [CrossRef] [PubMed]

- Piérard, J.; Dooms, B.; Cauberg, N. Durability Evaluation of Different Types of UHPC. In Proceedings of the International Symposium on Ultra-High Performance Fibre-Reinforced Concrete, UHPFRC 2013, Marseille, France, 1–3 October 2013; pp. 275–284. [Google Scholar]

- Monteiro, V.M.D.A.; Lima, L.R.; Silva, F.D.A. On the mechanical behavior of polypropylene, steel and hybrid fiber reinforced self-consolidating concrete. Constr. Build. Mater. 2018, 188, 280–291. [Google Scholar] [CrossRef]

- de Azevedo, A.R.; Marvila, M.T.; Tayeh, B.A.; Cecchin, D.; Pereira, A.C.; Monteiro, S.N. Technological performance of açaí natural fibre reinforced cement-based mortars. J. Build. Eng. 2021, 33, 101675. [Google Scholar] [CrossRef]

- Li, B.; Chi, Y.; Xu, L.; Shi, Y.; Li, C. Experimental investigation on the flexural behavior of steel-polypropylene hybrid fiber reinforced concrete. Constr. Build. Mater. 2018, 191, 80–94. [Google Scholar] [CrossRef]

- Hubert, M.; Desmettre, C.; Charron, J.-P. Influence of fiber content and reinforcement ratio on the water permeability of reinforced concrete. Mater. Struct. 2015, 48, 2795–2807. [Google Scholar] [CrossRef]

- Li Shin, K.J.; Bae, W.; Choi, S.-W.; Son, M.W.; Lee, K.M. Parameters influencing water permeability coefficient of cracked concrete specimens. Constr. Build. Mater. 2017, 151, 907–915. [Google Scholar] [CrossRef]

- Li, X.; Li, D.; Xu, Y. Modeling the effects of microcracks on water permeability of concrete using 3D discrete crack network. Compos. Struct. 2019, 210, 262–273. [Google Scholar] [CrossRef]

- Elsayed, M.; Tayeh, B.A.; Kamal, D. Effect of crumb rubber on the punching shear behaviour of reinforced concrete slabs with openings. Constr. Build. Mater. 2021, 311, 125345. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Pirritano, F.; Serna, P.; Ferrara, L. Effect of crystalline admixtures on the self-healing capability of early-age concrete studied by means of permeability and crack closing tests. Constr. Build. Mater. 2016, 114, 447–457. [Google Scholar] [CrossRef]

- Bheel, N.; Awoyera, P.; Aluko, O.; Mahro, S.; Viloria, A.; Sierra, C.A.S. Sustainable composite development: Novel use of human hair as fiber in concrete. Case Stud. Constr. Mater. 2020, 13, e00412. [Google Scholar] [CrossRef]

- Lawler, J.S.; Zampini, D.; Shah, S.P. Permeability of cracked hybrid fiber-reinforced mortar under load. ACI Mater. J. 2002, 99, 379–385. [Google Scholar]

- Balachandar, M.; Ramnath, B.V.; Kumar, S.A.; Sankar, G.S. Experimental evaluation on Mechanical Properties of Natural Fiber Polymer Composites with Human Hair. Mater. Today: Proc. 2019, 16, 1304–1311. [Google Scholar] [CrossRef]

- Manjunatha, M.; Kvgd, B.; Vengala, J.; Manjunatha, L.; Shankara, K.; Patnaikuni, C.K. Experimental study on the use of human hair as fiber to enhance the performance of concrete: A novel use to reduce the disposal challenges. Mater. Today: Proc. 2021, 47, 3966–3972. [Google Scholar] [CrossRef]

- Meghwar, S.L.; Khaskheli, G.B.; Kumar, A. Human Scalp Hair as Fiber Reinforcement in Cement Concrete. Mehran Univ. Res. J. Eng. Technol. 2020, 39, 443–452. [Google Scholar] [CrossRef]

- Khedr, A.-Z.A.; Nagib, S.M. The new pozzolan (silica fume) has attracted the attention of many researchers. J. Mater. Civ. Eng. 1995, 6, 357–375. [Google Scholar] [CrossRef]

- Bhanja, S.; Sengupta, B. Influence of silica fume on the tensile strength of concrete. Cem. Concr. Res. 2005, 35, 743–747. [Google Scholar] [CrossRef]

- Althoey, F.; Zaid, O.; De-Prado-Gil, J.; Palencia, C.; Ali, E.; Hakeem, I.; Martínez-García, R. Impact of sulfate activation of rice husk ash on the performance of high strength steel fiber reinforced recycled aggregate concrete. J. Build. Eng. 2022, 54, 104610. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, L.; Wang, Y.; Li, Q.; Xiao, Z. Prediction model of long-term chloride diffusion into plain concrete considering the effect of the heterogeneity of materials exposed to marine tidal zone. Constr. Build. Mater. 2018, 159, 297–315. [Google Scholar] [CrossRef]

- Jatana, N.; Currie, A. Hitting the Targets—Population and The SDGs; Population Matters: London, UK, 2020. [Google Scholar]

- Tripathi, D.; Kumar, R.; Mehta, P.K.; Singh, A. Silica fume mixed concrete in acidic environment. Mater. Today: Proc. 2020, 27, 1001–1005. [Google Scholar] [CrossRef]

- Cai, C.; Wu, Q.; Song, P.; Zhou, H.; Akbar, M.; Ma, S. Study on diffusion of oxygen in coral concrete under different preloads. Constr. Build. Mater. 2021, 319, 126147. [Google Scholar] [CrossRef]

- erformance of açaí natural fibre reinforced cement-based mortars. J. Build. Eng. 2020, 33, 101675. [CrossRef]

- Shohag, J.M.R.I.; Islam, K.K.; Bhuiyan, M.N.I. Human Hair Waste Addition on Performance of Plain Concrete. J. Civ. Constr. Eng. 2022, 8, 39–47. [Google Scholar] [CrossRef]

- ASTM. Annual Book of ASTM Standards; American Society for Testing and Materials Annual, Sec. 4; ASTM: Philadelphia, PA, USA, 1992. [Google Scholar]

- ISO 10904:2011, Fibre-Cement Corrugated Sheets and Fittings for Roofing and Cladding. 2011. Available online: https://www.iso.org/standard/46368.html (accessed on 14 November 2022).

- Alyousef, R.; Alabduljabbar, H.; Mohammadhosseini, H.; Mohamed, A.M.; Siddika, A.; Alrshoudi, F.; Alaskar, A. Utilization of sheep wool as potential fibrous materials in the production of concrete composites. J. Build. Eng. 2020, 30, 101216. [Google Scholar] [CrossRef]

- Abdelmelek, N.; Lubloy, E. Flexural strength of silica fume, fly ash, and metakaolin of hardened cement paste after exposure to elevated temperatures. J. Therm. Anal. 2021, 147, 7159–7169. [Google Scholar] [CrossRef]

- Santos, F.D.; Taguba, M.A.M.; Alzona, A.R.; Basada, R.C.S.; Elbit, J.M.A.; Nones, G.L.; Olido, K.P.M.; Ramos, E.U.G. Optimization of the compressive strength of hair fiber reinforced concrete using central composite design. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 771, p. 012059. [Google Scholar]

- Ponikiewski, T.; Katzer, J.; Bugdol, M.; Rudzki, M. Determination of 3D porosity in steel fibre reinforced SCC beams using X-ray computed tomography. Constr. Build. Mater. 2014, 68, 333–340. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Haruna, S.; Wahab, M.M.B.A.; Liew, M. Optimization and characterization of cast in-situ alkali-activated pastes by response surface methodology. Constr. Build. Mater. 2019, 225, 776–787. [Google Scholar] [CrossRef]

- Duval, R.; Kadri, E.H. Influence of Silica Fume on the Workability and the Compressive Strength of High-Performance Concretes. Cem. Concr. Res. 1998, 28, 533–547. [Google Scholar] [CrossRef]

- Umar, T.; Yousaf, M.; Akbar, M.; Abbas, N.; Hussain, Z.; Ansari, W.S. An Experimental Study on Non-Destructive Evaluation of the Mechanical Characteristics of a Sustainable Concrete Incorporating Industrial Waste. Materials 2022, 15, 7346. [Google Scholar] [CrossRef] [PubMed]

- Abbas, N.; Yousaf, M.; Akbar, M.; Saeed, M.A.; Huali, P.; Hussain, Z. An Experimental Investigation and Computer Modeling of Direct Tension Pullout Test of Reinforced Concrete Cylinder. Inventions 2022, 7, 77. [Google Scholar] [CrossRef]

- Ali, A.; Hussain, Z.; Akbar, M.; Elahi, A.; Bhatti, S.; Imran, M.; Zhang, P.; Ndam, N.L. Influence of Marble Powder and Polypropylene Fibers on the Strength and Durability Properties of Self-Compacting Concrete (SCC). Adv. Mater. Sci. Eng. 2022, 2022, 9553382. [Google Scholar] [CrossRef]

| Author(s) | Human Hair Fiber Concrete | Lab Experiment | SEM Analysis | RSM Anova | Methodology | Reference |

|---|---|---|---|---|---|---|

| Balachandar, M et al., 2019 | HHF Concrete | √ | × | × | Laboratory testing | [17] |

| Manjunatha et al., 2021 | HHF Concrete | √ | × | × | Laboratory testing | [18] |

| Meghwar, S.L et al., 2020 | HHF Concrete | √ | × | × | Laboratory testing | [19] |

| Shohag, J.M.R.I et al., 2022 | SF-enhanced Concrete | √ | × | × | Laboratory testing | [28] |

| This Research Work | HHF, Silica fume Concrete | √ | √ | √ | Laboratory testing/ SEM/ RSM |

| Oxide (%) | OPC-Type 1 | SF |

|---|---|---|

| CaO | 65 | 0.25 |

| SiO2 | 17.15 | 95 |

| Na2O | 1.86 | 0.1 |

| MgO | 1.74 | 0.4 |

| Al2O3 | 5.6 | 0.2 |

| K2O | 1.19 | 1.2 |

| Fe2O3 | 3.21 | 0.05 |

| SO3 | 2.66 | 0.1 |

| TiO2 | 0.32 | - |

| P. size μm | 20 ± 1 | 0.2 |

| Property | Fine Aggregate | Coarse Aggregate | Range | Standard |

|---|---|---|---|---|

| Aggregate particle size | Less than 4.75 mm | 20 mm nominal size | 4.75 mm to 20 mm | ASTM: C192/C 192M-06 |

| Specific gravity | 2.65 | 2.72 | 2.5 to 3.0 | AASHTO T 85-88 |

| Fineness modulus | 2.7 | 4.3 | 2.5 to 5.0 | AASHTO T 85-88 |

| Mix Design | Cement Kg/m3 | Fine Aggregate Kg/m3 | Coarse Aggregate Kg/m3 | Water Kg/m3 | Human Hair Fiber Kg/m3 | Silica Fume Kg/m3 | Superplasticizer Kg/m3 | Slump Test |

|---|---|---|---|---|---|---|---|---|

| C1 | 383 | 727 | 1103 | 191.6 | 0 | 0 | 4.5 | 50 mm |

| C2 | 383 | 727 | 1103 | 191.6 | 1.91 | 0 | 4.5 | 48 mm |

| C3 | 383 | 727 | 1103 | 191.6 | 3.83 | 0 | 4.5 | 46 mm |

| C4 | 383 | 727 | 1103 | 191.6 | 5.75 | 0 | 4.5 | 45 mm |

| C5 | 383 | 727 | 1103 | 191.6 | 7.85 | 0 | 4.5 | 41 mm |

| C6 | 383 | 727 | 1103 | 191.6 | 9.5 | 0 | 4.5 | 38 mm |

| C7 | 383 | 727 | 1103 | 191.6 | 11.41 | 0 | 4.5 | 32 mm |

| C8 | 383 | 727 | 1103 | 191.6 | 13.32 | 0 | 4.5 | 27 mm |

| C9 | 383 | 727 | 1103 | 191.6 | 15.23 | 0 | 4.5 | 22 mm |

| C10 | 383 | 727 | 1103 | 191.6 | 17.14 | 0 | 4.5 | 19 mm |

| C1 | 383 | 727 | 1103 | 191.6 | 7.85 | 0 | 4.5 | 45 mm |

| C1-SF5 | 363.85 | 727 | 1103 | 191.6 | 7.85 | 19.15 | 4.5 | - |

| C1-SF10 | 383 | 727 | 1103 | 191.6 | 7.85 | 38.3 | 4.5 | - |

| C1-SF15 | 325.55 | 727 | 1103 | 191.6 | 7.85 | 57.45 | 4.5 | - |

| C1-SF20 | 306.4 | 727 | 1103 | 191.6 | 7.85 | 76.6 | 4.5 | - |

| C1-SF25 | 287.25 | 727 | 1103 | 191.6 | 7.85 | 95.75 | 4.5 | - |

| C1-SF30 | 268.10 | 727 | 1103 | 191.6 | 7.85 | 114.9 | 4.5 | - |

| Sr.No | Test | Standard |

|---|---|---|

| 1 | Soundness Test of Cement | ASTM C187-16 |

| 2 | Setting Time of Cement | ASTM C403 |

| 3 | Fineness Modulus of Sand | ASTM C136 |

| 4 | Abrasion Value of Coarse Aggregates | ASTM C 535 |

| 5 | Crushing Strength and Impact Value of Coarse Aggregates | ASTM D5821 |

| 6 | Flakiness, Elongation, and Angularity No. of Course Aggregates | ASTM D 4791 |

| 7 | Specific Gravity and Water Absorption of Coarse Aggregates | ASTM D7172-14 |

| 8 | Slump Test | ASTM C143 |

| 9 | Compression Test | ATSM C39 |

| 10 | Flexural Test | ASTM C1161-18 |

| 10 | Split Tensile Test | ASTM C496 |

| 12 | Scanning Electron Microscopy (SEM) | ASTM C1723-16 |

| 13 | RSM | Design Expert |

| Model | Source | Sum of Squares | df | Mean Square | F-Value | p-Value | Significance of the Model |

|---|---|---|---|---|---|---|---|

| Compressive Strength | Model | 139.90 | 3 | 46.63 | 5.82 | 0.0124 | Significant |

| A-Cement | 130.41 | 1 | 130.41 | 16.28 | 0.0020 | ||

| B-Human Hair Fiber | 5.40 | 1 | 5.40 | 0.6746 | 0.4289 | ||

| C-Silica Fume | 5.01 | 1 | 5.01 | 0.6259 | 0.4456 | ||

| Residual | 88.13 | 11 | 8.01 | ||||

| Cor Total | 228.03 | 14 | |||||

| Split Tensile Strength | Model | 6.24 | 3 | 2.08 | 5.59 | 0.0141 | Significant |

| A-Cement | 0.2982 | 1 | 0.2982 | 0.8013 | 0.3899 | ||

| B-Human Hair Fiber | 3.40 | 1 | 3.40 | 9.15 | 0.0116 | ||

| C-Silica Fume | 2.54 | 1 | 2.54 | 6.83 | 0.0241 | ||

| Residual | 4.09 | 11 | 0.3722 | ||||

| Cor Total | 10.34 | 14 | |||||

| Model | 6.24 | 3 | 2.08 | 5.59 | 0.0141 | Significant | |

| A-Cement | 0.2982 | 1 | 0.2982 | 0.8013 | 0.3899 | ||

| Flexural Strength | Model | 0.8897 | 9 | 0.0989 | 7.50 | 0.0117 | Significant |

| A-Marble Powder | 0.6440 | 1 | 0.6440 | 48.89 | 0.0004 | ||

| B-PP Fiber | 0.0179 | 1 | 0.0179 | 1.36 | 0.2880 | ||

| C-Cement | 0.0005 | 1 | 0.0005 | 0.0394 | 0.8492 | ||

| Residual | 0.0790 | 6 | 0.0132 | ||||

| Lack of Fit | 0.0789 | 5 | 0.0158 | 159.28 | 0.0601 | Significant | |

| Pure Error | 0.0001 | 1 |

| Model Terms | Compressive Strength | Split Tensile Strength | Flexural Strength | Source | Sequential p-Value |

|---|---|---|---|---|---|

| Std. Dev | 2.83 | 0.1207 | 0.6101 | Linear | <0.0001 |

| Mean | 20.59 | 2.33 | 9.81 | Linear | <0.0001 |

| C.V% | 13.74 | 5.18 | 6.22 | Linear | <0.0001 |

| R2 | 0.8852 | 0.8720 | 0.8674 | Linear | <0.0001 |

| Adj. R2 | 0.8672 | 0.8520 | 0.8210 | Linear | <0.0001 |

| Pred. R2 | 0.8642 | 0.8487 | 0.8143 | Linear | <0.0001 |

| Sample | Human Hair Fiber (HHF %) | Silica Fume (SF %) | Compressive Strength (MPa) | Flexural Strength (MPa) | Splitting Tensile Strength (MPa) |

|---|---|---|---|---|---|

| 1 | 2 | 15 | 21.45 | 2.94 | 2.78 |

| 2 | 2 | 15 | 21.44 | 2.94 | 2.78 |

| 3 | 2 | 15 | 21.45 | 2.96 | 2.8 |

| 4 | 2 | 30 | 15.6 | 2.08 | 2.02 |

| Mean | - | - | 19.985 | 2.75 | 2.595 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akbar, M.; Umar, T.; Hussain, Z.; Pan, H.; Ou, G. Effect of Human Hair Fibers on the Performance of Concrete Incorporating High Dosage of Silica Fume. Appl. Sci. 2023, 13, 124. https://doi.org/10.3390/app13010124

Akbar M, Umar T, Hussain Z, Pan H, Ou G. Effect of Human Hair Fibers on the Performance of Concrete Incorporating High Dosage of Silica Fume. Applied Sciences. 2023; 13(1):124. https://doi.org/10.3390/app13010124

Chicago/Turabian StyleAkbar, Muhammad, Tariq Umar, Zahoor Hussain, Huali Pan, and Guoqiang Ou. 2023. "Effect of Human Hair Fibers on the Performance of Concrete Incorporating High Dosage of Silica Fume" Applied Sciences 13, no. 1: 124. https://doi.org/10.3390/app13010124

APA StyleAkbar, M., Umar, T., Hussain, Z., Pan, H., & Ou, G. (2023). Effect of Human Hair Fibers on the Performance of Concrete Incorporating High Dosage of Silica Fume. Applied Sciences, 13(1), 124. https://doi.org/10.3390/app13010124