Case Study on Secondary Building Materials for a Greener Economy

Abstract

:1. Introduction

2. Materials and Methods

2.1. C&D Waste

2.2. Soil-like Materials

- Soils from urbanized areas (STB) and, in some cases, their subsoils (UB/STB);

- Topsoils from roadside areas in the form of banquet peelings (BSG);

- Dredged sediments from water bodies, partly with marine influence (BAG);

- Admixture of soil-like material and mining waste (BER);

- Alluvial soils with suspected contamination from industry (AUE).

2.3. Incineration Bottom Ash (IBA)

2.4. Analytical Methods

3. Results

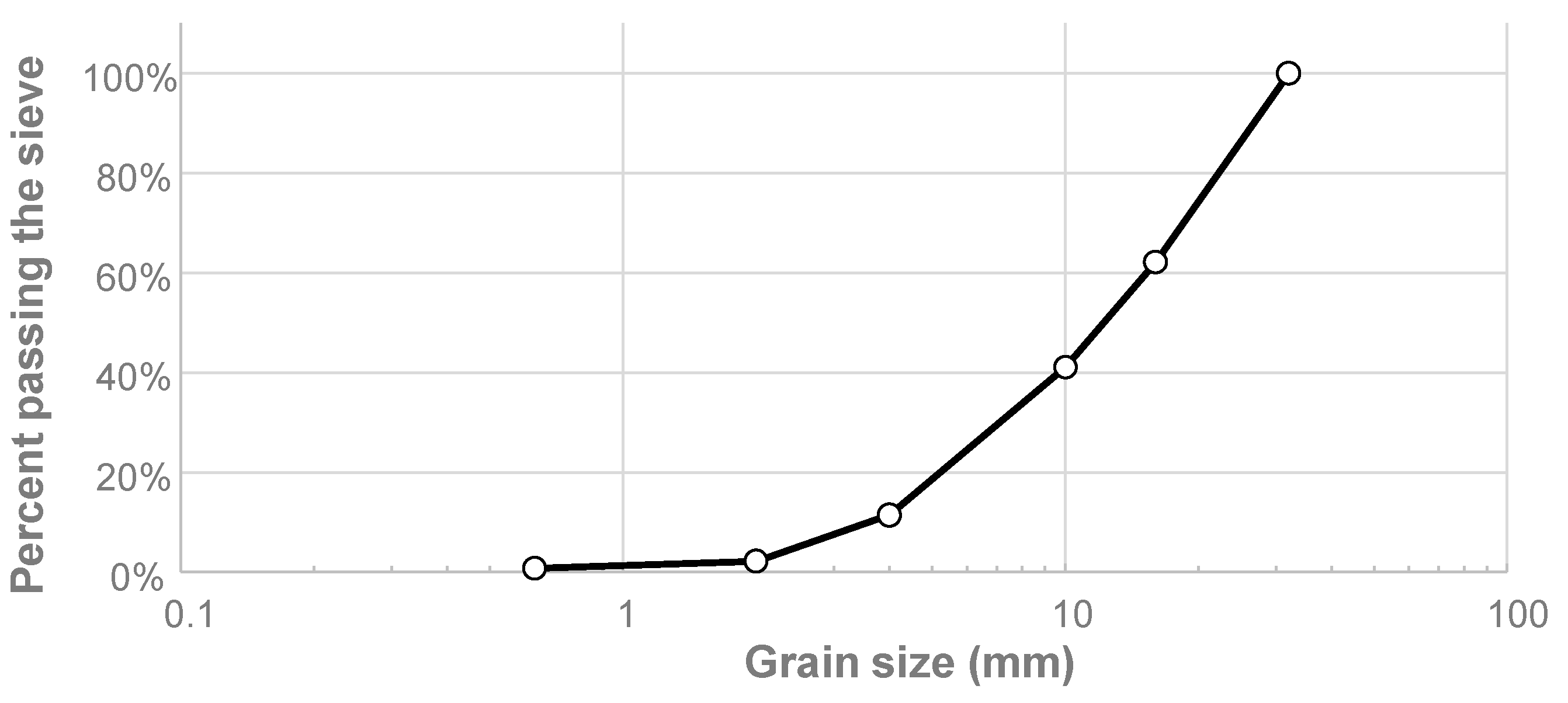

3.1. Sorting of C&D Waste

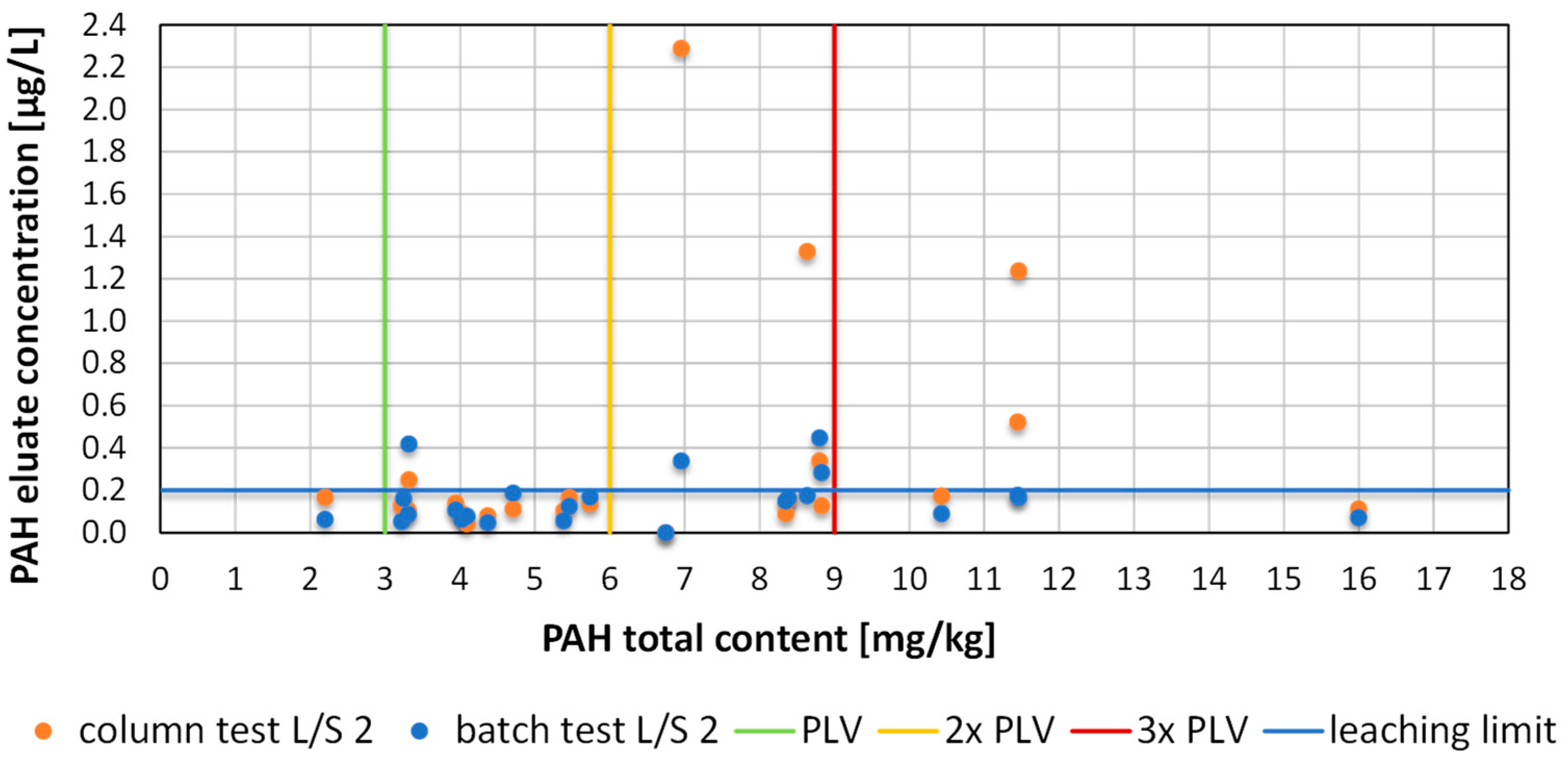

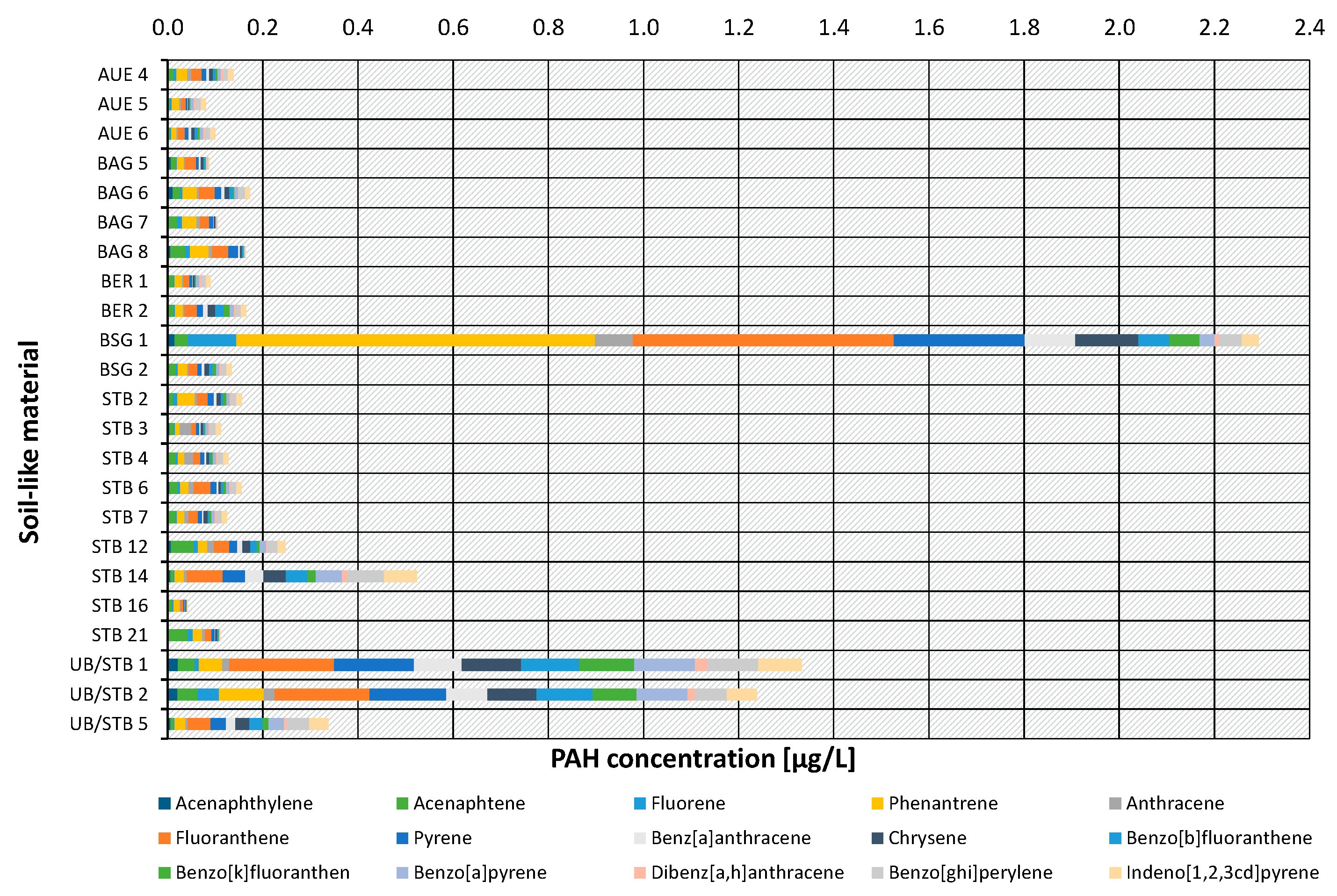

3.2. Assessment of PAH-Containing Soil-like Material

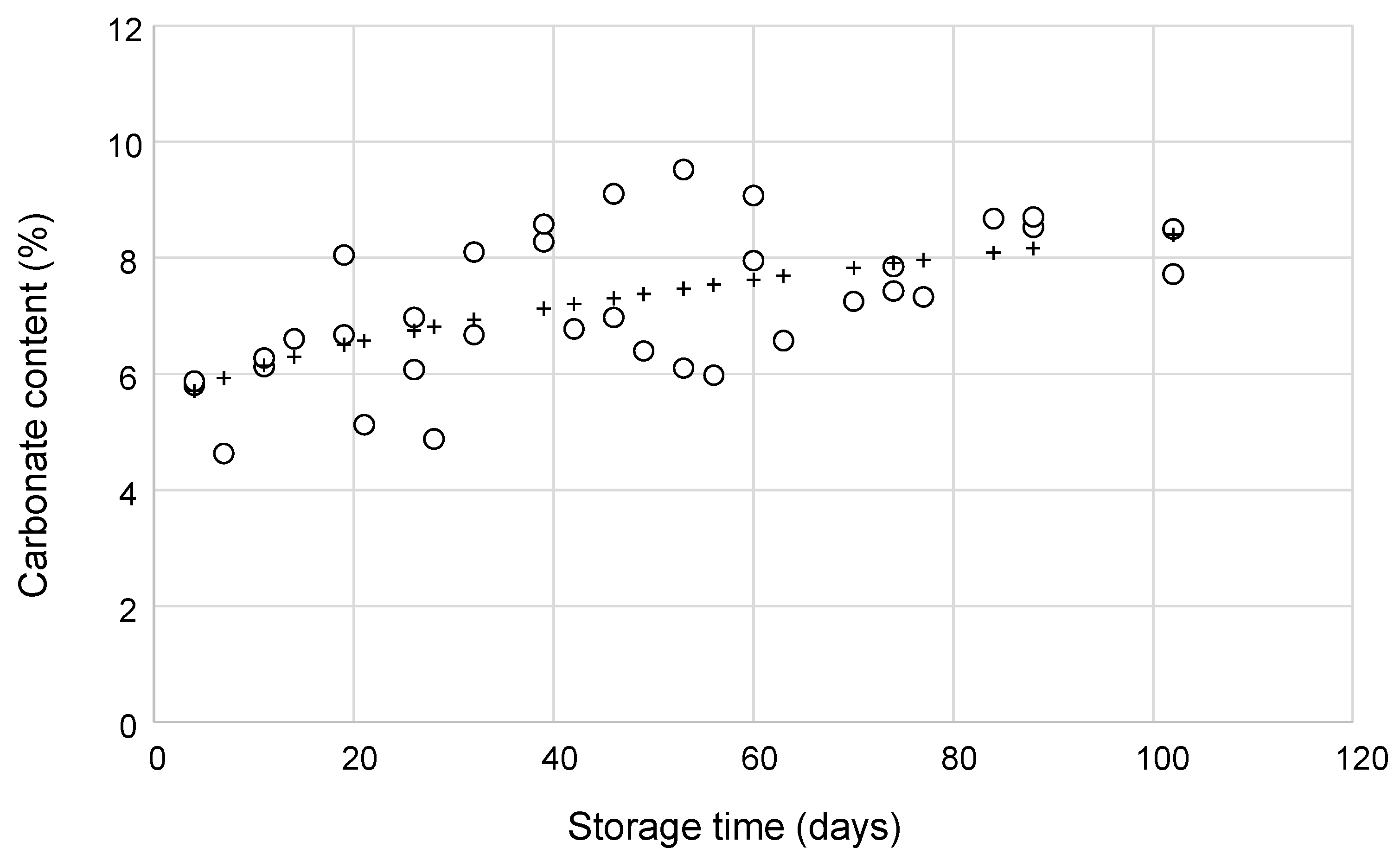

3.3. Environmental Compatability of Incineration Bottom Ash (IBA)

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krausmann, F.; Gingrich, S.; Eisenmenger, N.; Erb, K.-H.; Haberl, H.; Fischer-Kowalski, M. Growth in global materials use, GDP and population during the 20th century. Ecol. Econ. 2009, 68, 2696–2705. [Google Scholar] [CrossRef]

- de Wit, M.; Haigh, L. The Circularity Gap Report 2022; Circle Economy: Amsterdam, The Netherlands, 2022; Available online: www.circularity-gap.world (accessed on 28 February 2023).

- Peduzzi, P.; Moldalieva, Z.; Gallagher, L.; Poussin, C.; Fornacca, D. Sand and Sustainability: Finding New Solutions for Environmental Governance of Global sand Resources; United Nations Environment Programme (UNEP): Geneva, Switzerland, 2019. [Google Scholar]

- Wagner, L.A. Materials in the Economy—Materials Flows, Scarcity and the Environment, Circular, 1221; US Geological Survey: Reston, VA, USA, 2002. [Google Scholar]

- Bundesinstitut für Bau-Stadt-und Raumforschung. ÖKOBAUDAT—Basis for the Building Life Cycle Assessment. 2019. Available online: https://www.zukunftbau.de/publikationen/oekobaudat-basis-for-the-building-life-cycle-assessment (accessed on 20 March 2023).

- Stripple, H. Life Cycle Assessment of Road, A Pilot Study for Inventory Analysis, IVL Report, B 1210 E; IVL Swedish Environmental Research Institute: Gothenburg, Sweden, 2001. [Google Scholar]

- Jullien, A.; Proust, C.; Martaud, T.; Rayssac, E.; Ropert, C. Variability in the environmental impacts of aggregate production. Resour. Conserv. Recycl. 2012, 62, 1–13. [Google Scholar] [CrossRef]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef] [PubMed]

- Marinković, S.; Josa, I.; Braymand, S.; Tošić, N. Sustainability assessment of recycled aggregate concrete structures: A critical view on the current state-of-knowledge and practice. Struct. Concr. 2023, 24, 1956–1979. [Google Scholar] [CrossRef]

- Huang, B.; Zhao, F.; Fishman, T.; Chen, W.-Q.; Heeren, N.; Hertwich, E.G. Building Material Use and Associated Environmental Impacts in China 2000–2015. Environ. Sci. Technol. 2018, 52, 14006–14014. [Google Scholar] [CrossRef]

- Korre, A.; Durucan, S. Life Cycle Assessment of Aggregates, Final Report, EVA025; Waste & Resource Programme WRAP: Banbury, UK, 2009. [Google Scholar]

- Ozcelik, M. Energy consumption analysis for natural aggregate processing and its results (Atabey, Isparta, Turkey). Min. Miner. Depos. 2018, 12, 80–86. [Google Scholar] [CrossRef]

- destatis. Abfallbilanz 2020, Artikelnummer 5321001207004; Statistisches Bundesamt: Wiesbaden, Germany, 2022. [Google Scholar]

- Bundesverband Baustoffe—Steine und Erden. Mineralische Bauabfälle Monitoring 2020, Bericht zum Aufkommen und zum Verbleib Mineralischer Bauabfälle im Jahr 2020; Kreislaufwirtschaft Bau: Berlin, Germany, 2023. [Google Scholar]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V.W.Y. Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: A review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Abis, M.; Bruno, M.; Kuchta, K.; Simon, F.-G.; Grönholm, R.; Hoppe, M.; Fiore, S. Assessment of the synergy between recycling and thermal treatments in municipal solid waste management in Europe. Energies 2020, 13, 6412. [Google Scholar] [CrossRef]

- Bayuseno, A.P.; Schmahl, W.W. Understanding the chemical and mineralogical properties of the inorganic portion of MSWI bottom ash. Waste Manag. 2010, 30, 1509–1520. [Google Scholar] [CrossRef]

- Chandler, A.J.; Eighmy, T.T.; Hartlen, J.; Hjelmar, O.; Kosson, D.S.; Sawell, S.E.; van der Sloot, H.A.; Vehlow, J. Physical Characteristics of Bottom Ash, Municipal Solid Waste Incineration Residues; The International Ash Working Group; In Series in Environmental Science; Elsevier: Amsterdam, The Netherlands, 1997; Chapter 9.1; Volume 67, pp. 342–368. [Google Scholar]

- Šyc, M.; Simon, F.G.; Hyks, J.; Braga, R.; Biganzoli, L.; Costa, G.; Funari, V.; Grosso, M. Metal recovery from incineration bottom ash: State-of-the-art and recent developments. J. Hazard. Mater. 2020, 393, 121017. [Google Scholar] [CrossRef]

- Holm, O.; Simon, F.G. Innovative treatment trains of bottom ash (BA) from municipal solid waste incineration (MSWI) in Germany. Waste Manag. 2017, 59, 229–236. [Google Scholar] [CrossRef]

- Bundesregierung. Verordnung zur Einführung einer Ersatzbaustoffverordnung, zur Neufassung der Bundes-Bodenschutz- und Altlastenverordnung und zur Änderung der Deponieverordnung und der Gewerbeabfallverordnung. Bundesgesetzblatt 2021, Teil I, 2598–2752. [Google Scholar]

- Shooshtarian, S.; Caldera, S.; Maqsood, T.; Ryley, T.; Wong, P.S.P.; Zaman, A. Analysis of factors influencing the creation and stimulation of the Australian market for recycled construction and demolition waste products. Sustain. Prod. Consum. 2022, 34, 163–176. [Google Scholar] [CrossRef]

- Weimann, K.; Giese, L.B.; Mellmann, G.; Simon, F.G. Building materials from waste. Mater. Trans. 2003, 44, 1255–1258. [Google Scholar] [CrossRef]

- Müller, A.; Schnellert, T.; Kehr, K. Gips reduziert: Gipsbestandteile in Betonrezyklaten—Herkunft, Auswirkungen und Abtrennung mittels Setztechnik, Teil 2. AT Miner. Process. 2010, 51, 54–69. [Google Scholar]

- Kalbe, U.; Schatten, R.; Simon, F.-G.; Terytze, K. Novelle der BBodSchV—Perspektiven für die Verwertung von Bodenmaterial. Altlasten Spektrum 2020, 29, 133–140. [Google Scholar] [CrossRef]

- Kalbe, U.; Schatten, R.; Szuppa, T. Monitoringprogramm zur Verwertung von Bodenmaterial gemäß §§ 6-8 Novelle BBodSchV (Extended English Summary Included); UBA Texte 127/2020; Umweltbundesamt: Dessau, Germany, 2020; pp. 1–248. Available online: https://www.umweltbundesamt.de/publikationen/monitoringprogramm-zur-verwertung-von-bodenmaterial (accessed on 20 March 2023).

- Deutscher Ausschuss für Stahlbeton e. V. Beton nach DIN EN 206-1 und DIN 1045-2 mit Rezyklierten Gesteinskörnungen nach DIN EN 12620; Beuth-Verlag: Berlin, Germany, 2010. [Google Scholar]

- Kalbe, U.; Lehnik-Habrink, P.; Bandow, N.; Sauer, A. Validation of European horizontal methods for the analysis of PAH, PCB and dioxins in sludge, treated biowaste and soil. Environ. Sci. Eur. 2019, 31, 29. [Google Scholar] [CrossRef]

- Thomanetz, E. Gefährliche Abfälle und Altlasten. In Einführung in die Kreislaufwirtschaft; Kranert, M., Ed.; Vieweg: Wiesbaden, Germany, 2018. [Google Scholar] [CrossRef]

- Kalbe, U.; Simon, F.-G. Potential Use of Incineration Bottom Ash in Construction: Evaluation of the Environmental Impact. Waste Biomass Valorization 2020, 11, 7055–7065. [Google Scholar] [CrossRef]

- Simon, F.G.; Vogel, C.; Kalbe, U. Antimony and vanadium in incineration bottom ash—Leaching behavior and conclusions for treatment processes. Detritus 2021, 16, 75–81. [Google Scholar] [CrossRef]

- Schnabel, K.; Brück, F.; Pohl, S.; Mansfeldt, T.; Weigand, H. Technically exploitable mineral carbonation potential of four alkaline waste materials and effects on contaminant mobility. Greenh. Gases: Sci. Technol. 2021, 11, 506–519. [Google Scholar] [CrossRef]

- Baciocchi, R.; Costa, G.; Lategano, E.; Marini, C.; Polettini, A.; Pomi, R.; Postorino, P.; Rocca, S. Accelerated carbonation of different size fractions of bottom ash from RDF incineration. Waste Manag. 2010, 30, 1310–1317. [Google Scholar] [CrossRef]

- Nørgaard, K.P.; Hyks, J.; Mulvad, J.K.; Frederiksen, J.O.; Hjelmar, O. Optimizing large-scale ageing of municipal solid waste incinerator bottom ash prior to the advanced metal recovery: Phase I: Monitoring of temperature, moisture content, and CO2 level. Waste Manag. 2019, 85, 95–105. [Google Scholar] [CrossRef] [PubMed]

- Fraser, M.; Haigh, L.; Soria, A.C. The Circularity Gap Report 2023; Circle Economy: Amsterdam, The Netherlands, 2023; Available online: www.circularity-gap.world (accessed on 28 February 2023).

- European Commission. Circular Economy Action Plan, for a Cleaner and More Competitive Europe, KH-04-20-290-EN-N; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Hu, K.; Chen, Y.; Naz, F.; Zeng, C.; Cao, S. Separation studies of concrete and brick from construction and demolition waste. Waste Manag. 2019, 85, 396–404. [Google Scholar] [CrossRef] [PubMed]

- Bruno, M.; Abis, M.; Kuchta, K.; Simon, F.-G.; Grönholm, R.; Hoppe, M.; Fiore, S. Material flow, economic and environmental assessment of municipal solid waste incineration bottom ash recycling potential in Europe. J. Clean. Prod. 2021, 317, 128511. [Google Scholar] [CrossRef]

- Gehrmann, H.-J.; Hiebel, M.; Simon, F.G. Methods for the Evaluation of Waste Treatment Processes. J. Eng. 2017, 2017, 3567865. [Google Scholar] [CrossRef]

- ITAD. Jahresbericht 2019 (Annual Report 2019); ITAD—Interessengemeinschaft der Thermischen Abfallbehandlungsanlagen in Deutschland e.V: Düsseldorf, Germany, 2019; Available online: https://www.itad.de/service/downloads/itad-jahresbericht-2019-webformat.pdf (accessed on 4 February 2021).

| Soil-like Material | ∑16 EPA PAH Total Content [mg/kg] | ∑15 EPA PAH * Column Test L/S 2 [µg/L] | ∑15 EPA PAH * Batch Test L/S 2 [µg/L] | Evaluation of Potential for Utilization | ||

|---|---|---|---|---|---|---|

| PAH | Further Cations | Overall | ||||

| AUE 4 | 5.73 | 0.14 | 0.17 | |||

| AUE 5 | 4.38 | 0.08 | 0.05 | |||

| AUE 6 | 5.40 | 0.10 | 0.06 | |||

| BAG 5 | 8.34 | 0.09 | 0.15 | Ni, Zn, Mo | ||

| BAG 6 | 10.43 | 0.17 | 0.09 | Hg, Zn, Sb, Mo | ||

| BAG 7 | 3.30 | 0.11 | 0.09 | Ni, Zn, Mo | ||

| BAG 8 | 5.46 | 0.16 | 0.12 | Pb, Cd, Cu, Ni, Hg, Zn, Mo | ||

| BER 1 | 4.03 | 0.09 | 0.06 | Cr, Cu, Ni, Hg, Zn, Sb, Mo, Se, V, Sn | ||

| BER 2 | 2.19 | 0.17 | 0.06 | Se | ||

| BSG 1 | 6.96 | 2.29 | 0.34 | Cr, Ni, Sb | ||

| BSG 2 | 3.95 | 0.14 | 0.11 | Ni, Sb | ||

| STB 2 | 8.39 | 0.16 | 0.16 | Pb, Ni, Zn, Sb | ||

| STB 3 | 16.00 | 0.11 | 0.07 | Pb, As, Cd, Cu, Pb, Tl, Sb, Se | ||

| STB 4 | 8.84 | 0.13 | 0.28 | |||

| STB 6 | 3.25 | 0.16 | 0.16 | |||

| STB 7 | 3.23 | 0.13 | 0.05 | |||

| STB 12 | 3.32 | 0.25 | 0.42 | Cu, Sb, Se | ||

| STB 14 | 11.44 | 0.52 | 0.18 | Pb, Se | ||

| STB 16 | 4.10 | 0.04 | 0.08 | Zn | ||

| STB 21 | 4.71 | 0.11 | 0.19 | |||

| UB/STB 1 | 8.64 | 1.33 | 0.17 | Cu, Ni, Sb | ||

| UB/STB 2 | 11.45 | 1.24 | 0.17 | Cu, Ni, Sb | ||

| UB/STB 5 | 8.81 | 0.34 | 0.45 | As, Pb, Cd, Cr, Cu, Ni, Zn, Sb, Co, Mo, V, Sn | ||

| Legend | <2× PLV | leaching limit value kept | utilization allowed | |||

| up to 3× PLV | ||||||

| >3× PLV | leaching limit value exceeded | utilization excluded | ||||

| * naphthalene is not included in leaching analyses | exceedance of total content/lexceedance of leaching limit exceedance of total content and leaching limit | |||||

| Parameter | HMVA-1 | HMVA-2 |

|---|---|---|

| pH | 7–13 | 7–13 |

| Electr. conductivity (µS cm−1) | 2000 | 12,500 |

| Chloride (mg L−1) | 160 | 5000 |

| Sulfate (mg L−1) | 820 | 3000 |

| Antimony (µg L−1) | 10 | 60 |

| Chromium (µg L−1) | 150 | 460 |

| Copper (µg L−1) | 110 | 1000 |

| Molydenum (µg L−1) | 55 | 400 |

| Vanadium (µg L−1) | 55 | 150 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simon, F.-G.; Kalbe, U. Case Study on Secondary Building Materials for a Greener Economy. Appl. Sci. 2023, 13, 6010. https://doi.org/10.3390/app13106010

Simon F-G, Kalbe U. Case Study on Secondary Building Materials for a Greener Economy. Applied Sciences. 2023; 13(10):6010. https://doi.org/10.3390/app13106010

Chicago/Turabian StyleSimon, Franz-Georg, and Ute Kalbe. 2023. "Case Study on Secondary Building Materials for a Greener Economy" Applied Sciences 13, no. 10: 6010. https://doi.org/10.3390/app13106010