1. Introduction

Gluten is described as a “protein component from wheat, rye, barley, oats or their crossbred varieties and derivatives thereof, to which some individuals are intolerant and that is insoluble in water and 0.5 mol/L NaCl” by the Codex Alimentarius [

1]. These are some of the most consumed cereals in the world and are frequently utilized in food processing; thus, patients suffering from gluten disorders require particularly careful treatment. Gluten-related disorders, such as celiac disease (CD), are among the most common food hypersensitivities worldwide, with a prevalence of around 1% in countries including Türkiye with a population of predominantly European origin [

2,

3]. Other gluten-related disorders include dermatitis herpetiformis, gluten ataxia, non-celiac gluten sensitivity, and wheat allergy. Together, these conditions affect 1–6% of the global population [

4]. Currently, the only recognized treatment strategy for these disorders is a gluten-free diet for life [

5].

For a healthy lifestyle, people with gluten disorders must eliminate gluten from their diet and eat gluten-free foods on a regular basis. Currently, gluten-free foods are being consumed not only by those with gluten intolerance, but also by people who are interested in consuming them for health and wellness or weight control [

6]. Following a gluten-free diet can be challenging due to the contamination of “gluten free” products, inaccurate labeling, societal pressures, and the widespread presence of gluten in food and medication. As a result, accidental ingestion of gluten is common. While most people with celiac disease can tolerate small amounts of gluten, such as 10 mg per day, there is a wide range of tolerance among individuals, and some may experience adverse effects from even small amounts of gluten exposure, such as inflammation in the small intestine, resulting in damage to the intestinal mucosa and eventually leading to problems with nutrient absorption [

7,

8,

9,

10]. By combining toxicity data with observed food intakes, it has been determined that it is safe to consume gluten-free products (GFPs) that have a gluten contamination level of less than 20 mg/kg. This threshold of 20 ppm for gluten-free foods has been endorsed by official organizations such as the Codex Alimentarius [

1,

11].

Products that do not contain gluten can be divided into two categories: those that are naturally gluten-free and those that have been processed to remove gluten. However, it can be challenging to completely avoid gluten in one’s diet because gluten is a commonly used ingredient that can easily spread to products that are typically gluten-free during various stages of the production process, including growing, milling, storing, manufacturing, restaurants, and households [

12,

13,

14]. Additionally, wheat flour or purified gluten is often added to various food products to improve their technological structure.

In recent years, due to an increasing interest in healthy eating and the rise in gluten-related disorders, there has been a growing demand for gluten-free products. In response to this demand, the food industry has increased its supply of gluten-free products. However, with an increasing variety and number of products, there are concerns that contamination-related issues may become a major problem. The lack of data on contamination is a cause for concern.

Immunological techniques such as ELISA are typically utilized in protein-based methods. The use of immunological approaches for gluten detection is prevalent. Each technique used to determine the amount of gluten present has unique characteristics, such as the format, the type of buffer used to extract the samples, the time and temperature required for extraction, the characteristics of the antibodies, the recognition epitope, and the reference material used for calibration. The distinct characteristics of each gluten quantification method and the lack of an authorized reference material may result in consistent variations in the obtained outcomes. Additionally, incorrect gluten measurement, improper product labeling, and insufficient consumer knowledge can cause unintentional consumption of high levels of gluten, which can potentially compromise the health of individuals with celiac disease [

14].

Apart from these methods, proteomic approaches can be used for the identification of gluten allergens. Utilizing a proteomic approach that explores peptide biomarkers appears to be the most effective strategy in creating a sensitive and broadly applicable method for detecting gluten in both raw and cooked food items. However, as MS equipment becomes more accessible, the broad application of this precise and sensitive method will become more feasible. Various methods such as electrophoresis, chromatography, mass spectrometry, combined techniques, and genomic approaches can be employed to isolate and identify cereal proteins [

15].

Therefore, we decided to conduct a study using the R5 ELISA method, which is the only method approved by the EU regulations, to contribute to the literature on gluten-free product contamination currently available in Turkey.

2. Materials and Methods

2.1. Preparation of Food Samples

An experimental design was conducted to analyze the foods used for meal preparation or consumed as snacks in the daily lives of individuals who eat gluten-free by choice or who are required to eat gluten-free. The selected products were selected from the same product groups from different brands. Gluten analyses were performed in a private laboratory where all gluten cross-contamination measures were taken by selecting varied brands of the same products produced in Turkey and offered for sale in randomly selected large chain markets in and around Izmir Province between 2021 and 2023.

The 71 selected food products such as gluten-free flour, dried fruits, snacks, biscuits, sauces, and mixed cereals were carefully identified and divided into 2 main categories: naturally gluten-free products (NGF, n:45) and labeled gluten-free products (LGF, n:26).

For the powdered samples, homogeneous weighing was carried out, followed by the extraction procedure. In other samples in the form of particles, a sufficient amount of sample was ground with a knife grinder to ensure a homogeneous mixture, and then weighing and extraction were performed. Before preparing each new food sample, pieces of the grinder were dismantled, treated individually with detergent, rinsed with ethanol (70%), and set aside to dry. Before the samples were analyzed, in order to prevent contamination, they were kept at room temperature.

2.2. Sample Extraction Procedure

Samples were weighed at 0.25 g per 50 mL centrifuge tube as described in the kit procedure used. Then, after adding 2.5 mL of cocktail solution, the tube was sealed. The samples were shaken in a vortex for 5–10 s and incubated at 50 °C in a water bath for 40 min. Each sample was added to 7.5 mL of 80% ethanol and vortexed after cooling at room temperature. Subsequently, the tubes were shaken for 1 h in a shaker, and then centrifuged for 10 min at 2500× g. The supernatant formed after centrifugation was taken out of a new Eppendorf tube and kept at ambient temperature.

Extracted samples were diluted with sample diluent buffer in ELISA RIDASCREEN® at a ratio of 1: 12.5, with a final dilution factor of 500.

2.3. Gluten Analysis and Quantification

The amount of gluten in every food product was evaluated using RIDASCREEN® Gliadin (Art. No. R7001), which is an R5 sandwich enzyme immunoassay based on a specific monoclonal antibody to celiac toxic amino acid prolamin sequences to determine gliadin as a measure of gluten in food, and the cocktail solution R-7006 was used for the extraction (R-Biopharm, Darmstadt, Germany).

The kit is based on the antigen–antibody reaction. The general procedure is as follows: Plate wells are coated with R5 antibodies specific to gliadins. When standards and samples are loaded into the wells, gliadin is bound by these antibodies, forming an antigen–antibody complex. Unbound components are removed in the washing step. Then, the R5 antibody bound to peroxidase is added (conjugate) and the antibody–antigen–antibody (sandwich) complex is formed, after which the washing step is repeated. The enzyme is incubated by adding a substrate and chromogen. The bound conjugate turns the colorless chromogen into a blue color. Coloring is stopped with a stopping reagent.

Before starting the analysis phase, concentrated solutions such as “Sample diluent buffer”, “Wash buffer”, and “Enzyme conjugate” in the kit were diluted as indicated in the protocol and used. Samples and standards included in the kit were pipetted at 100 µL into the plate wells. Three washing processes were carried out manually with phosphate buffer solution (PBS) following a 30 min incubation period at room temperature. Each well received a dose of enzyme conjugate before the plate underwent a 30 min incubation period. Then, the washing step was repeated. Following the addition of the substrate and chromogen, each well underwent a 30 min incubation. Following the use of the “Stop solution,” the reaction was stopped, and a microplate reader was used to measure the optical density in the plate wells. At 450 nm, the absorbance was measured, and the data were generated using the RIDA® SOFT (R-Biopharm, Darmstadt, Germany) Win software program to create a calibration curve from the standards; the samples were analyzed according to this standard curve to calculate the gluten content. The intricate composition of gluten, which comprises various proteins with distinct solubility levels, necessitates the selection of an appropriate calibrator specific to the target protein to accurately measure its concentration. The calibration graph is established based on this complex structure, and the spectrophotometric method is utilized to validate the generated calibrations.

Gluten-free samples were extracted using cocktail solution, and the ELISA procedure was performed. Gluten-free samples were run 10 times each, where the average of the concentrations obtained should be less than 3 mg/kg, as specified in the kit procedure. The results of the studies were calculated as LOD (mean + 3 SD). Repeatability in the limit of detection/limit of identification studies (mean + 10 SD) should be less than 5 mg/kg. In the studies, appropriate results were obtained below these values in the acceptance criteria.

The results were adjusted to fall within the calibration range by diluting samples with absorbance values higher than the highest standard. As the result of the device was read as the gliadin concentration g/mL, the dilution factor was added and converted to mg/kg (ppm). The gluten concentration was calculated by multiplying the outcome by two. The kit’s diagnostic limit for gluten is 5 mg/kg (ppm).

Food samples were classified into 3 groups according to the gluten concentration. The first group comprised samples with gluten levels below 20 ppm, which were considered gluten-free. The second group comprised samples whose gluten level was between 20 and 100 ppm. This group was considered to have a low gluten content. The third group comprised samples with a gluten content of more than 100 ppm, which were considered to have serious gluten contamination.

2.4. Performance Assessment

To evaluate the test performance, Fera’s Proficiency Testing Division (FAPAS®) QC Material cake mix (T27326AQC, 20 g) was used, and the table below shows the results.

As shown in

Table 1, FAPAS

® performed 57 analyses throughout the survey to identify the test material’s gluten level, which was 13.3 mg/kg, with a z-score range of 6.7 to 20 mg/kg. The gluten content of the cake mix was found to be 12.6 mg/kg, with a range of 7.5–18.1 mg/kg as a result of 30 analyses. The consistency between the assigned and measured results shows the reliability of the analysis performed.

The accuracy of the analysis was demonstrated by the agreement between the intended and measured outcomes.

2.5. Data Analysis

Data analyses were performed using Microsoft Excel Software (ver. 2017, Microsoft, Redmond, WA, USA). Fisher’s test was used to compare the proportions of samples that were contaminated (>20 ppm) and not contaminated (<20 ppm) within each group. Results were considered to be significant when p < 0.05.

3. Results and Discussion

The gluten analysis results of a sum of 71 food samples, of which 45 (

Table 2) were naturally gluten-free (rice flour, various dried fruits, red pepper flakes, corn flour, potato starch, pestil, canned peas and garniture, maize semolina, sweet corn) and 26 were processed food samples labeled as “gluten free” (bread, breadcrumbs, cake flour, cookie flour, pastry flour, bread flour, cracker, biscuits, pepper and tomato paste, ketchup, spicy chickpeas, gullac, oatmeal peanut chocolate, pistachio with sauce), are shown in

Table 2 and

Table 3. Statistical analysis showed that the two groups did not differ from each other (

p > 0.05).

The maximum amount of gluten that is permitted in foods marketed as “gluten free” is laid forth in the Codex Alimentarius [

1] rules for gluten-free foods. According to the Codex Alimentarius guidelines, foods that bear the term “gluten free” must have a gluten content of no more than 20 mg/kg (ppm). This limit is based on scientific research that shows that the majority of celiac disease sufferers are able to handle this amount of gluten without experiencing any adverse health effects. Therefore, food products that meet the Codex Alimentarius criteria for gluten-free labeling can be consumed without risk by people who have celiac disease or gluten intolerance. However, it is still important for individuals with these conditions to carefully read food labels and check for any potential sources of gluten, and to be vigilant for cross-contamination during food preparation.

A gluten value that is immeasurable or below 5 mg/kg does not necessarily mean that there is absolutely no gluten present in the food product. If a food product contains any measurable amount of gluten between 5 mg/kg and 20 mg/kg, it is an indication of the presence of gluten and therefore considered to be contaminated with gluten. Partners in the sector should discuss the adoption of 5 mg/kg as the highest limit, which would take the place of the current Codex Alimentarius restriction of 20 mg/kg [

6].

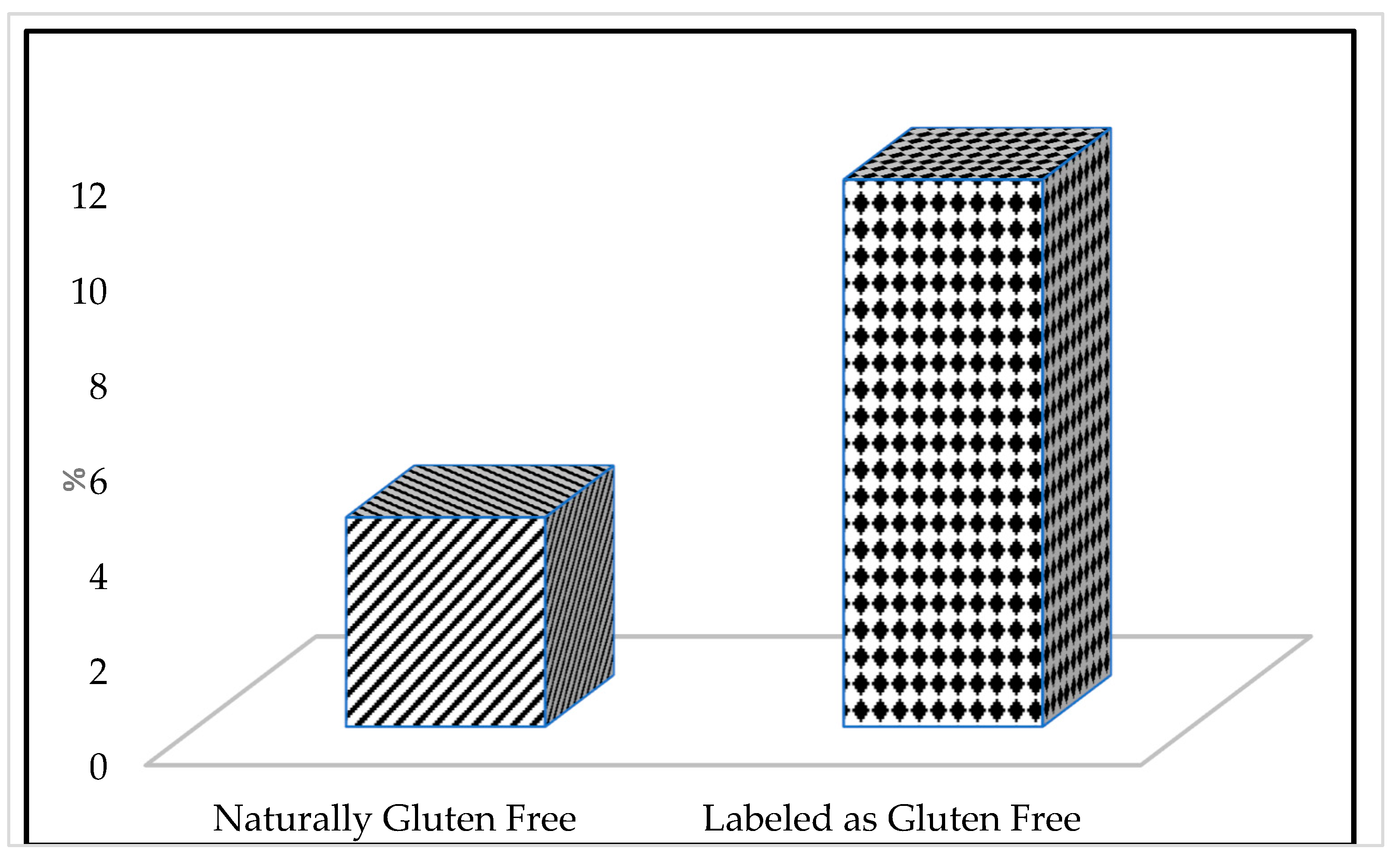

In total, 66 out of 67 samples below 20 mg/kg returned results below the kit’s diagnostic limit (5 mg/kg). Contamination was detected in approximately 7% of the analyzed products. Gluten contamination was detected in 2 out of 45 products (4.4%) that were considered naturally gluten-free, while gluten contamination was detected in 3 out of 26 products (11.5%) that were labeled gluten-free (

Figure 1).

Although one of these products (gluten-free cake flour) was below the legal limit set out in the Codex Alimentarius, it may pose a problem for individuals who must eat gluten-free.

Another contaminated product, gluten-free bread, was slightly over the legal limit (23 mg/kg). Although the gluten-free bread sample is in the low-gluten product group, its labeling is inappropriate. This product should have been offered for sale as “low gluten” instead of “gluten free”. While some people with gluten intolerance or celiac disease may be able to tolerate small amounts of gluten, it is generally recommended that they avoid all sources of gluten to prevent potential health risks. Therefore, bread that contains more than 5 ppm of gluten, even if it is “gluten free,” may not be suitable for people with celiac disease or gluten sensitivity to consume.

The gluten-free breadcrumb sample did not meet the FDA’s requirements for gluten-free labeling since it contained 293.7 mg/kg of gluten, which is more than the legal limit of 100 mg/kg. Foods marked “gluten free” may contain up to 20 mg/kg of gluten at the most. Foods that exceed this limit may pose a risk to patients with celiac disease or gluten intolerance. There may be two reasons for this result. Either the manufacturer may have made a false declaration, or the product may have been exposed to high contamination during the drying and crushing processes applied in the production method. Based on this result, it can be considered that food processing methods may cause contamination. It should be noted here that the processing lines should be regularly inspected for contamination.

In the case of red pepper flakes, which are made from dried chili peppers, it is not common for them to contain gluten, as gluten is found in rye, barley, and wheat. However, some spices can be processed in facilities that also handle gluten-containing grains, which may result in cross-contamination. For people with celiac disease or gluten sensitivity, it is important to be cautious when consuming products that may contain gluten, and to check the labeling and ingredient lists carefully.

Hence, compared to products that are naturally gluten-free, products that are certified gluten-free have a noticeably increased chance of contamination. This shows that products sold as gluten-free should be more heavily inspected, and the method of their production should be considered.

The evaluation of the samples according to the Codex Alimentarius [

1] is shown in

Figure 2.

When the percentage (%) was evaluated according to the legislation, 94.37% of the samples were found to be gluten-free, 4.23% were found to contain a very low content of gluten, and 1.40% were beyond the limit.

Upon examining earlier investigations, it becomes clear that, although it is uncommon, gluten contamination can be found in naturally gluten-free items as well as goods that have a “gluten free” label.

In a study carried out in Sweden by Størsrud et al. [

16], 9 (40.9%) of 22 naturally gluten-free goods were found to have more than 20 mg/kg of gluten via an enzyme-linked immunosorbent assay (ELISA) with a monoclonal antibody to gliadin. In another study conducted in Slovakia by Olexová et al. [

17], it was determined that 3 (17.7%) of 17 samples, including 13 processed gluten-free biscuit goods and 4 naturally gluten-free cereal flours, were positive for gluten using a polymerase chain reaction-based method. Verma et al. [

10] determined the gluten content of 32 gluten-free-labeled/naturally gluten-free products collected from Italian stores using the Ridascreen Gliadin sandwich R5 enzyme-linked immunosorbent assay R-7001. In total, 26 of the products (81%) did not reach the criterion value of 20 mg/kg. Six of them (19%) had values between 30 mg/kg and 53 mg/kg.

In a study conducted in Canada, gluten levels above the legal limits were determined in 9% of 77 “gluten free”-labeled goods using an R5 enzyme-linked immunosorbent assay (ELISA) [

18]. In Lebanon, 173 food samples with a “gluten free” label were gathered over the course of two years in a study by Hassan et al. [

19] to ascertain the degree of gluten contamination in foods marketed as “gluten free”. In the analyses performed, the presence of contamination (gluten concentration > 20 ppm) was observed using the ELISA technique in 10 (6%) of 173 samples. In an American investigation, 1.1% of 275 goods with the claim “gluten free” contained more than 20 ppm of gluten [

20]. In that study, the authors used two different ELISA kits, namely wheat protein sandwich ELISA (181GD) and R5 monoclonal-based Ridascreen Gliadin sandwich ELISA (R7001). Verma et al. [

10] gathered 200 samples at random throughout Italy, 93 of which were marked “gluten free” and 107 of which were naturally gluten-free despite not bearing the label. In the analyses, gluten levels exceeding 20 ppm were detected in 1% of the samples labeled “gluten free” and 8% of the naturally gluten-free samples using the R5 ELISA Kit. In essence, gluten contamination may arise from any combination of agricultural, milling, and manufacturing practices [

6].

Naturally gluten-free foods may become contaminated at any point in the food chain, including during their growth, harvest, storage, or processing. This causes gluten-free foods to turn into gluten-containing foods [

12]. In the study of Thompson et al. [

21], when 22 naturally gluten-free seeds, grains, and flour samples were analyzed to detect gluten levels through the use of the Ridascreen Gliadin sandwich R5 enzyme-linked immunosorbent assay, it was determined that 32% of the samples had gluten levels higher than 20 ppm. When samples obtained from Canadian stores that sell naturally gluten-free flours and starches were tested for gluten contamination using the ELISA method, 1.1% of 268 samples with a “gluten free” label and 10.1% of 298 samples without a “gluten free” label were found to be gluten-free. It has been reported that naturally gluten-free foods can become contaminated (gluten levels > 20 ppm) [

22].

A study conducted in India evaluated gluten contamination in various cereal-based food products (

n = 160) made from naturally gluten-free cereals, using the ELISA method. The study found that 46.5% of the tested products had a gluten content below 20 mg/kg. The study also reported that 35.9% of the flour samples made from naturally gluten-free grains and 85% of the oat samples purchased from local mills were contaminated with gluten. Among the products labeled as gluten-free (

n = 51), only five samples showed gluten contamination above 20 mg/kg [

23]. It has been observed that the supply of products from local producers increases the risk of gluten contamination.

In the study of Bustamante et al. [

5], the development of 3141 grain-based gluten-free food products was observed using the enzyme-linked immunosorbent test (ELISA) technique from 1998 to 2016. Eight distinct categories of chosen foods were looked at: flours, pasta, snacks, breakfast cereals/bars, yeasts, bakery goods, breads, and doughs. They were split into two categories: those with gluten-free labeling and those that are only declared to be gluten-free. As a result, 371 samples tested positive for gluten, with breakfast cereals and bars having the highest contamination levels. There has also been a decrease in gluten detection over the years. In fact, while the snack and yeast groups have a high gluten content, they have entered the gluten-free category over the years.

Regarding the proportion of contaminated products (7%), as well as the amount of gluten present in such products, our research indicates that there is little gluten contamination in gluten-free products available on the Turkish market.