Information Gap Decision Theory-Based Stochastic Optimization for Smart Microgrids with Multiple Transformers

Abstract

:Featured Application

Abstract

1. Introduction

- (1)

- A stochastic optimization framework based on IGDT is proposed to study the optimal scheduling of smart grid industrial parks considering transformer loss, two-part tariff, distributed ES, and other factors;

- (2)

- It is proposed to use IGDT to deal with the uncertainty of net load. Compared with traditional robust optimization, the IGDT optimization model proposed in this paper has both economy and robustness;

- (3)

- Starting from the practical application, considering the transformer loss and multi-microgrid collaborative scheduling in the smart grid industrial park it is verified that distributed ES and multi-microgrid interconnection have great advantages in reducing the cost of the park.

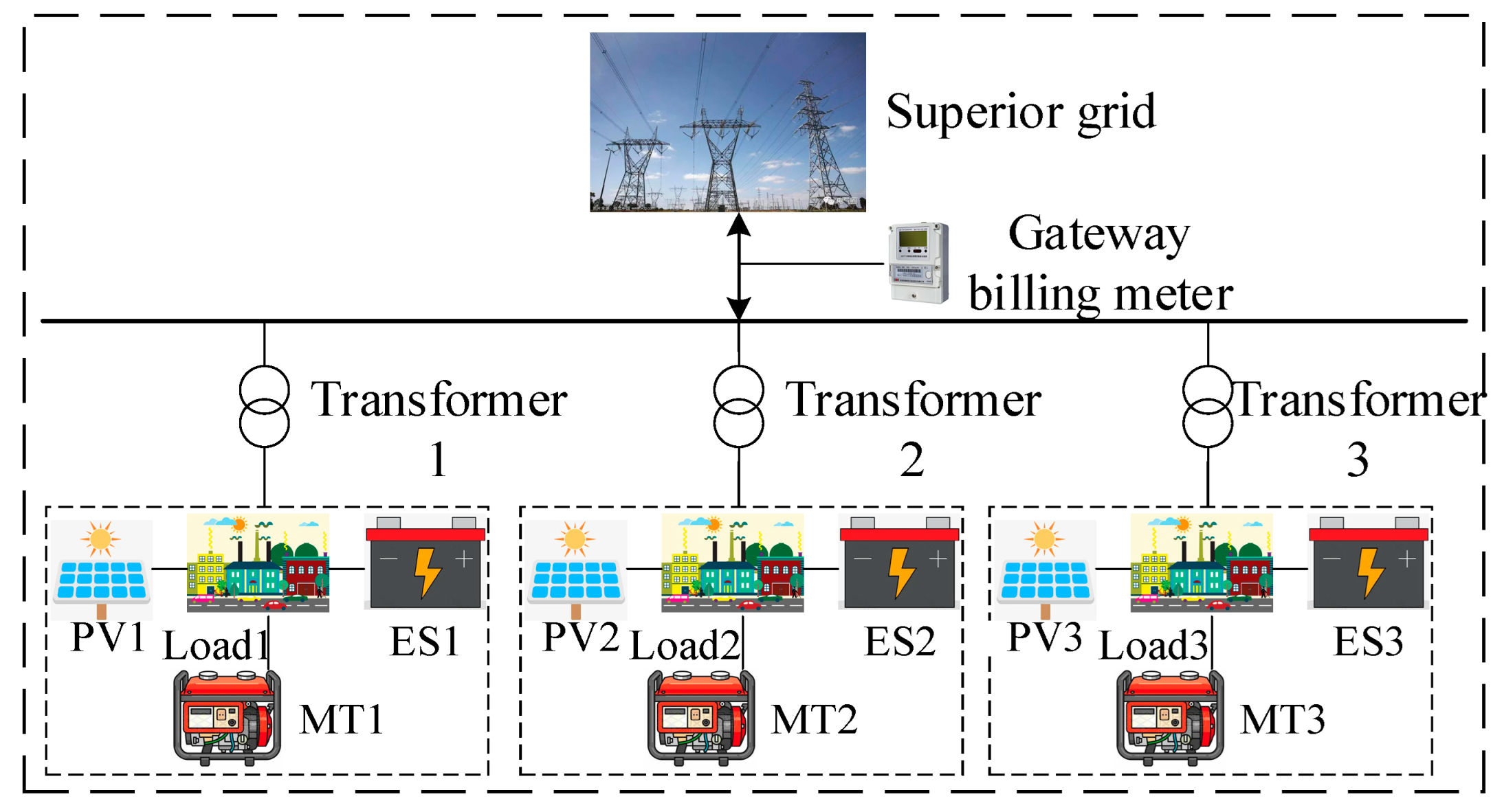

2. IGDT-Based Optimization Model for Industrial Parks

2.1. Economic Model of Industrial Parks

- (2)

- Power balance constraints

2.2. IGDT Stochastic Scheduling for Industrial Parks with Multiple Transformers

3. Case Study

3.1. Analysis of the Cost Deviation Factor Results

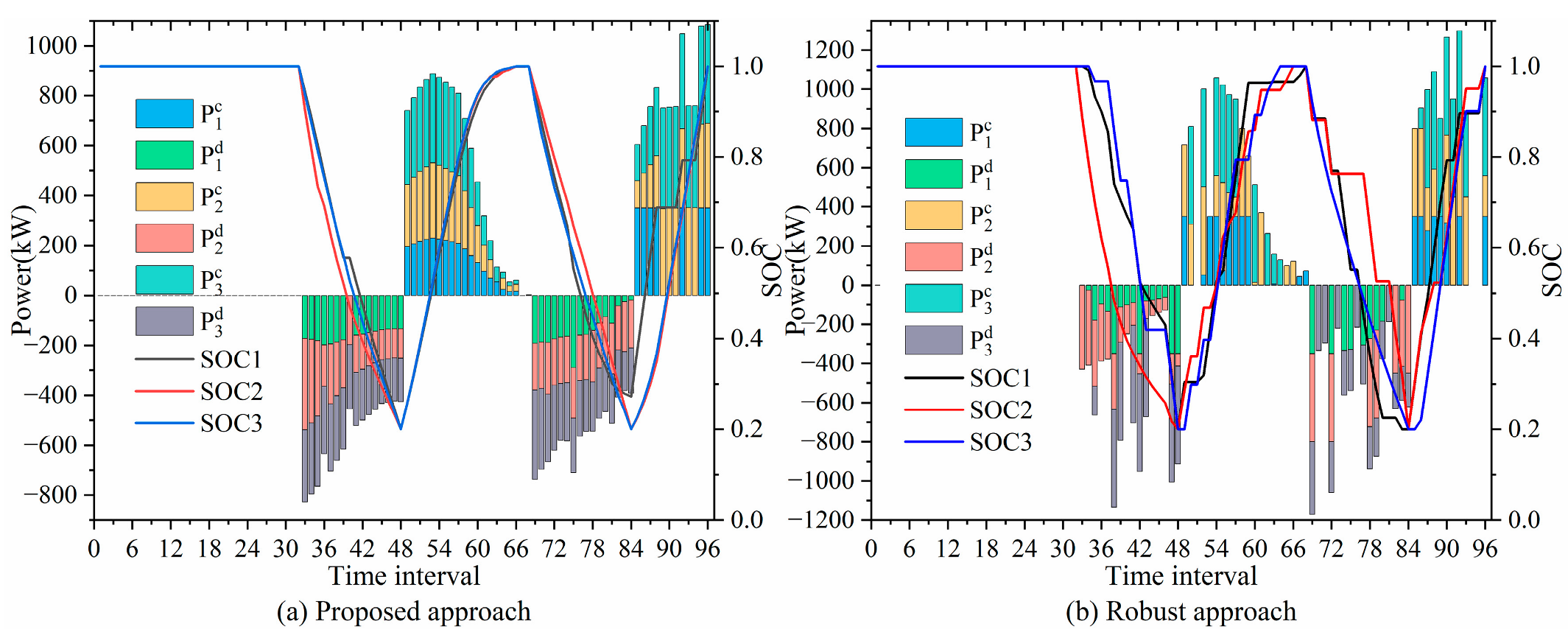

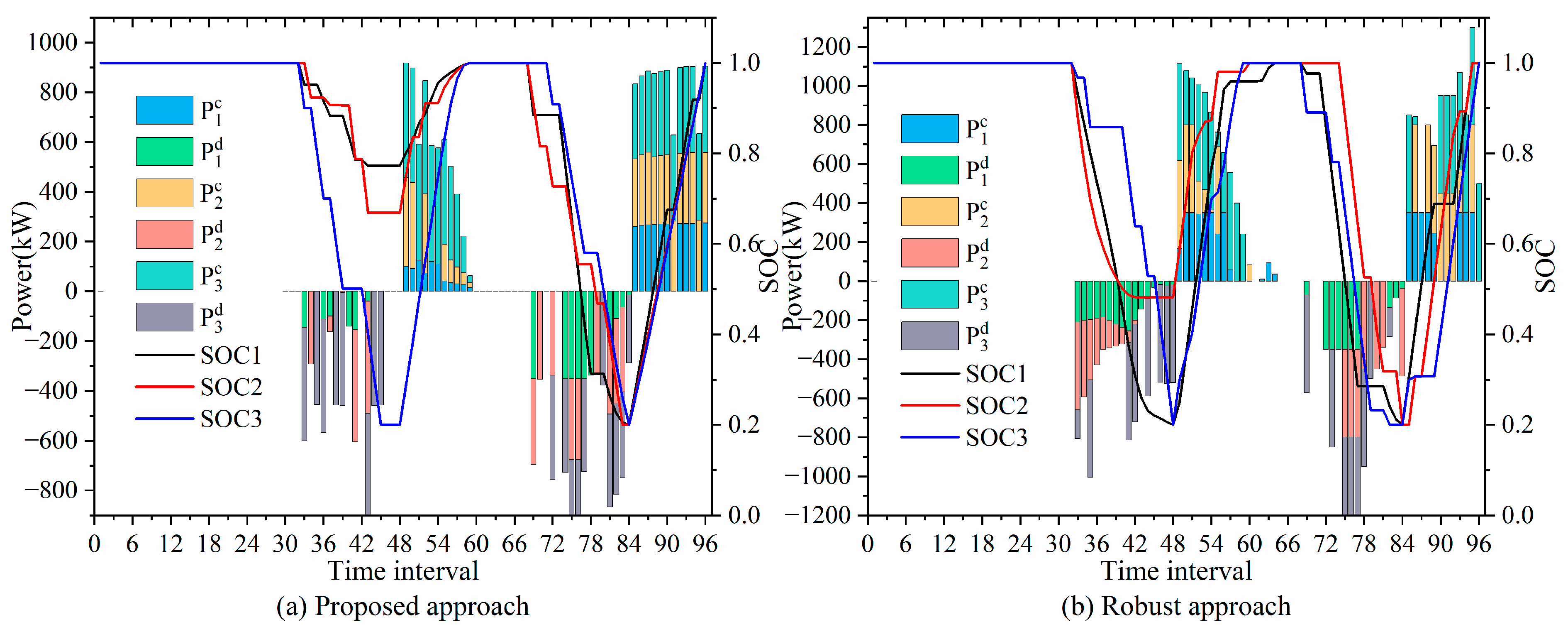

3.2. Optimization Results of Distributed ES

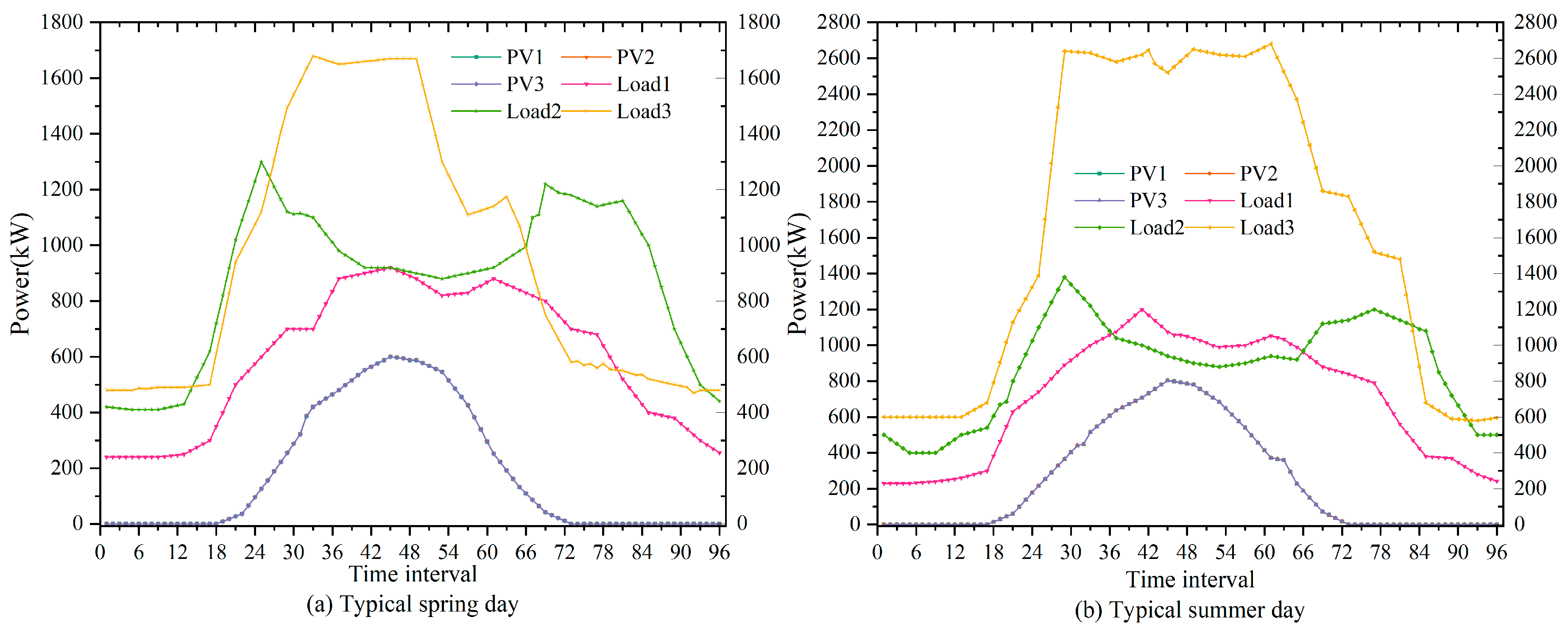

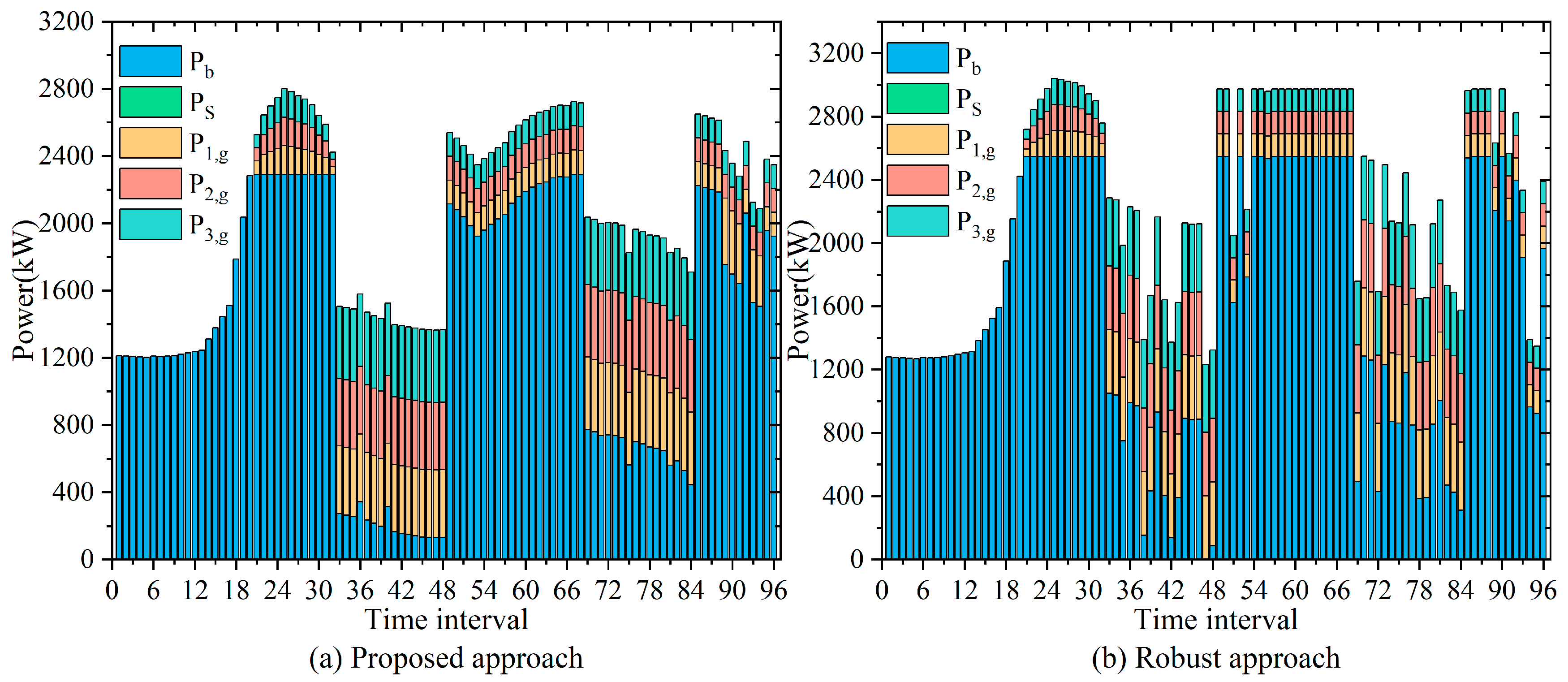

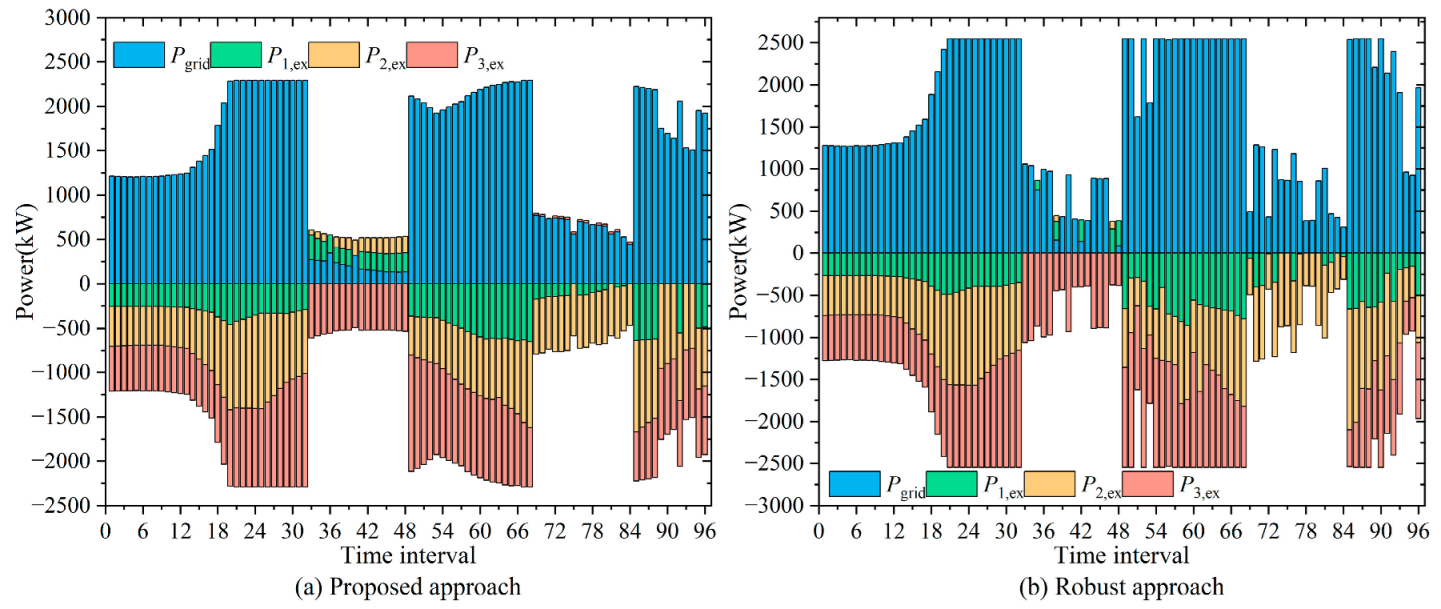

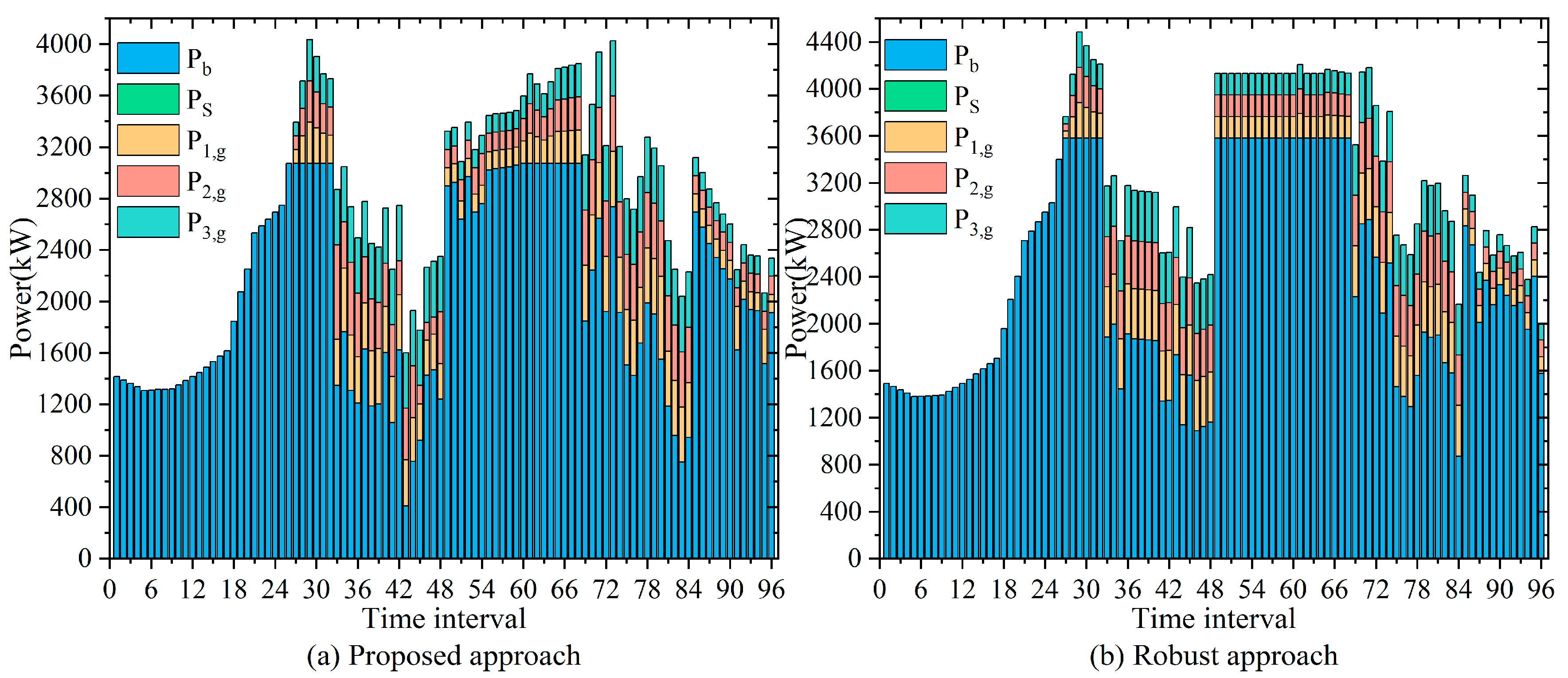

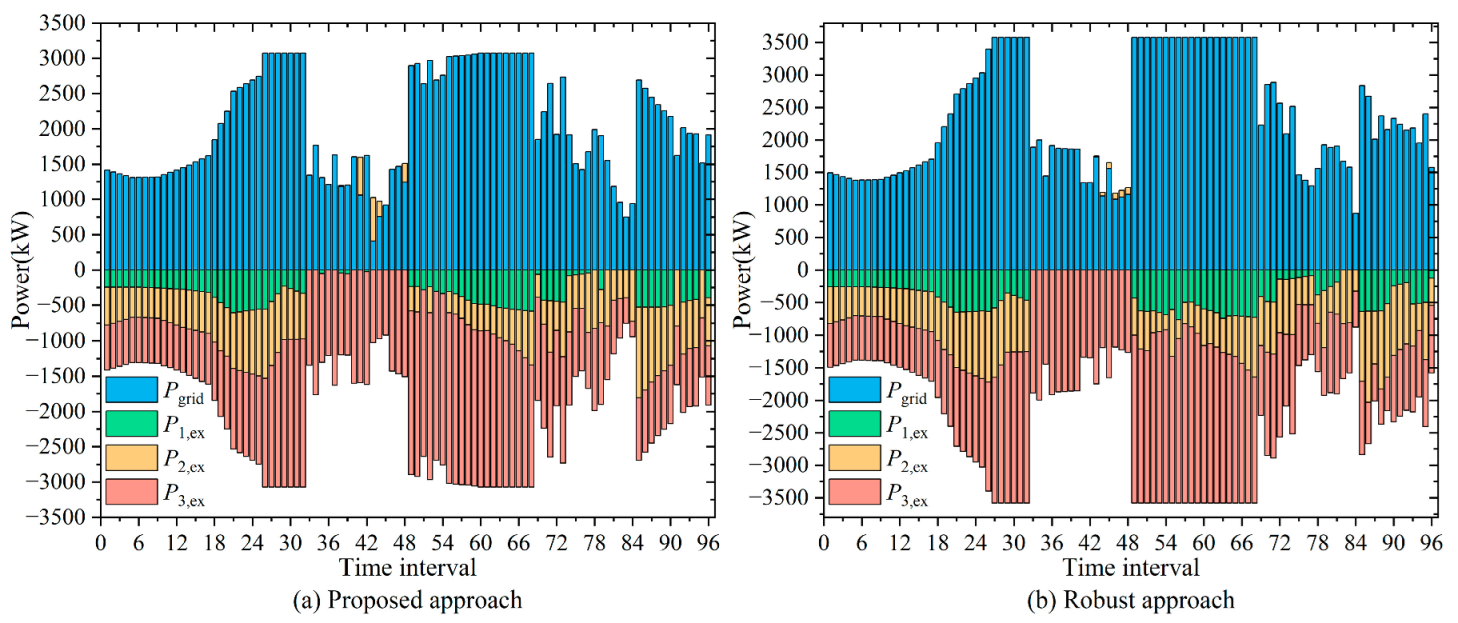

3.3. Optimization Results of a Typical Spring Day

3.4. Optimization Results of a Typical Summer Day

4. Conclusions

- (1)

- In practical operations, the utilization of distributed ES exhibits superior economic advantages compared to centralized ES. This finding suggests that implementing distributed ES can effectively reduce transformer losses and subsequently lower overall costs within the industrial park;

- (2)

- The proposed IGDT model demonstrates both economic efficiency and robustness. In comparison to the traditional robust optimization approach, the IGDT model proves to be more suitable for real-world industrial park operations. It strikes a balance between economic optimization and robust decision making, making it a viable choice for operational control in industrial parks;

- (3)

- The collaboration and interaction among multiple microgrids within the industrial park contribute to load peak reduction and the promotion of renewable energy consumption. This result showcases the positive impacts of multi-microgrid systems in improving the overall efficiency and sustainability of industrial park operations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Z.; Wu, L.; Xu, Y.; Wang, L.; Yang, N. Distributed tri-layer risk-averse stochastic game approach for energy trading among multi-energy microgrids. Appl. Energy 2023, 331, 120282. [Google Scholar] [CrossRef]

- Zheng, J.H.; Guo, J.C.; Li, Z.; Wu, Q.H.; Zhou, X.X. Optimal design for a multi-level energy exploitation unit based on hydrogen storage combining methane reactor and carbon capture, utilization and storage. J. Energy Storage 2023, 62, 106929. [Google Scholar]

- Wan, Y.; Kober, T.; Schildhauer, T.; Schmidt, T.J.; McKenna, R.; Densing, M. Conditions for profitable operation of P2X energy hubs to meet local demand with energy market access. Adv. Appl. Energy 2023, 10, 100127. [Google Scholar]

- Wald, D.; Johnson, K.; King, J.; Comden, J.; Bay, C.J.; Chintala, R.; Vijayshankar, S.; Vaidhynathan, D. Shifting demand: Reduction in necessary storage capacity through tracking of renewable energy generation. Adv. Appl. Energy 2023, 10, 100131. [Google Scholar] [CrossRef]

- Zou, B.; Peng, J.; Yin, R.; Li, H.; Li, S.; Yan, J.; Yang, H. Capacity configuration of distributed photovoltaic and battery system for office buildings considering uncertainties. Appl. Energy 2022, 319, 119243. [Google Scholar] [CrossRef]

- Fu, X.Q.; Zhou, Y.Z. Collaborative optimization of PV greenhouses and clean energy systems in rural areas. IEEE Trans. Sustain. Energy 2022, 14, 642–656. [Google Scholar] [CrossRef]

- Fu, X.; Zhou, Y.; Wei, Z.; Wang, Y. Optimal operation strategy for a rural microgrid considering greenhouse load control. CSEE J. Power Energy Syst. 2023; early access. [Google Scholar]

- Fang, J.; Xu, Q.; Tang, R.; Xia, Y.; Ding, Y.; Fang, L. Research on demand management of hybrid energy storage system in industrial park based on variational mode decomposition and Wigner–Ville distribution. J. Energy Storage 2021, 42, 103073. [Google Scholar] [CrossRef]

- Qu, Z.L.; Chen, J.J.; Peng, K.; Zhao, Y.L.; Rong, Z.K.; Zhang, M.Y. Enhancing stochastic multi-microgrid operational flexibility with mobile energy storage system and power transaction. Sustain. Cities Soc. 2021, 71, 102962. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, M.; Yang, H.; Wang, X.; Xu, J.; Hu, X. Decentralized and coordinated scheduling model of interconnected multi-microgrid based on virtual energy storage. Int. J. Electr. Power Energy Syst. 2023, 148, 108990. [Google Scholar]

- Arefifar, S.A.; Ordonez, M.; Mohamed YA, R.I. Energy management in multi-microgrid systems—Development and assessment. IEEE Trans. Power Syst. 2016, 32, 910–922. [Google Scholar] [CrossRef]

- Nawaz, A.; Zhou, M.; Wu, J.; Long, C. A comprehensive review on energy management, demand response, and coordination schemes utilization in multi-microgrids network. Appl. Energy 2022, 323, 119596. [Google Scholar]

- Parisio, A.; Wiezorek, C.; Kyntäjä, T.; Elo, J.; Strunz, K.; Johansson, K.H. Cooperative MPC-based energy management for networked microgrids. IEEE Trans. Smart Grid 2017, 8, 3066–3074. [Google Scholar] [CrossRef]

- Li, Y.; Wang, R.; Yang, Z. Optimal scheduling of isolated microgrids using automated reinforcement learning-based multi-period forecasting. IEEE Trans. Sustain. Energy 2021, 13, 159–169. [Google Scholar] [CrossRef]

- Liu, J.; Chen, J.; Yan, G.; Chen, W.; Xu, B. Clustering and dynamic recognition based auto-reservoir neural network: A wait-and-see approach for short-term park power load forecasting. iScience 2023, 26, 107456. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhou, J.; Chen, B. Review of wind power scenario generation methods for optimal operation of renewable energy systems. Appl. Energy 2020, 280, 115992. [Google Scholar]

- Cao, Y.; Li, D.; Zhang, Y.; Tang, Q.; Khodaei, A.; Zhang, H.; Han, Z. Optimal energy management for multi-microgrid under a transactive energy framework with distributionally robust optimization. IEEE Trans. Smart Grid 2021, 13, 599–612. [Google Scholar] [CrossRef]

- Zou, Y.; Xu, Y.; Zhang, C. A risk-averse adaptive stochastic optimization method for transactive energy management of a multi-energy microgrid. IEEE Trans. Sustain. Energy 2023, 14, 1599–1611. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Q.; Wang, L.; Feng, W. Robust optimization for energy transactions in multi-microgrids under uncertainty. Appl. Energy 2018, 217, 346–360. [Google Scholar] [CrossRef]

- Majidi, M.; Mohammadi-Ivatloo, B.; Soroudi, A. Application of information gap decision theory in practical energy problems: A comprehensive review. Appl. Energy 2019, 249, 157–165. [Google Scholar]

- Munoz-Alvarez, D.; Tong, L. On the efficiency of connection charges—Part I: A stochastic framework. IEEE Trans. Power Syst. 2017, 33, 3822–3833. [Google Scholar] [CrossRef]

- Gregoratti, D.; Matamoros, J. Distributed energy trading: The multiple-microgrid case. IEEE Trans. Ind. Electron. 2014, 62, 2551–2559. [Google Scholar] [CrossRef]

- Jiao, P.H.; Chen, J.J.; Qi, B.X.; Zhao, Y.L.; Peng, K. Electricity price driven active distribution network planning considering uncertain wind power and electricity price. Int. J. Electr. Power Energy Syst. 2019, 107, 422–437. [Google Scholar] [CrossRef]

- Mirzaei, M.A.; Sadeghi-Yazdankhah, A.; Mohammadi-Ivatloo, B.; Marzband, M.; Shafie-khah, M.; Catalão, J.P.S. Integration of emerging resources in IGDT-based robust scheduling of combined power and natural gas systems considering flexible ramping products. Energy 2019, 189, 116195. [Google Scholar] [CrossRef]

- Salimi, M.; Nasr, M.A.; Hosseinian, S.H.; Gharehpetian, G.B.; Shahidehpour, M. Information gap decision theory-based active distribution system planning for resilience enhancement. IEEE Trans. Smart Grid 2020, 11, 4390–4402. [Google Scholar] [CrossRef]

- Jordehi, A.R.; Javadi, M.S.; Shafie-khah, M.; Catalão, J.P. Information gap decision theory (IGDT)-based robust scheduling of combined cooling, heat and power energy hubs. Energy 2021, 231, 120918. [Google Scholar] [CrossRef]

- Campo, P.J.; Morari, M. Robust model predictive control. In Proceedings of the 1987 American Control Conference, Minneapolis, MN, USA, 10–12 June 1987; pp. 1021–1026. [Google Scholar]

- Bertsekas, D.P. Nonlinear Programming, 2nd ed.; Athena Scientific: Belmont, MA, USA, 1999. [Google Scholar]

- Wenzhi, S.; Zhang, H.; Tseng, M.L.; Weipeng, Z.; Xinyang, L. Hierarchical energy optimization management of active distribution network with multi-microgrid system. J. Ind. Prod. Eng. 2022, 39, 210–229. [Google Scholar] [CrossRef]

| Microgrid | MT Rated Power (kW) | ES Rated Power (kW) | ES Rated Capacity (kWh) |

|---|---|---|---|

| 1 | 800 | 350 | 800 |

| 2 | 800 | 450 | 1000 |

| 3 | 850 | 500 | 1200 |

| 0.01 | 0.02 | 0.03 | 0.04 | 0.05 | ||

|---|---|---|---|---|---|---|

| Cost(CNY) | MT | 12,797.6756 | 12,926.5608 | 13,075.4533 | 13,200.2291 | 13,071.3108 |

| ES | 1480.3489 | 1480.3492 | 1480.3495 | 14,918.847 | 1462.4225 | |

| Grid | 24,842.6745 | 25,101.1227 | 25,339.5636 | 25,590.5863 | 26,136.3004 | |

| Total | 39,120.6990 | 39,508.0327 | 39,895.3664 | 40,282.7001 | 40,670.0337 | |

| 0.00884 | 0.01729 | 0.02487 | 0.03272 | 0.04283 | ||

| 0.01 | 0.02 | 0.03 | 0.04 | 0.05 | ||

|---|---|---|---|---|---|---|

| Cost(CNY) | MT | 13,172.5418 | 13,253.6666 | 13,122.6272 | 13,297.1882 | 13,436.1970 |

| ES | 1171.7510 | 1185.7495 | 1188.6066 | 1184.6710 | 1194.382 | |

| Grid | 41,518.1605 | 41,976.2072 | 42,657.4839 | 43,039.9528 | 43,444.3274 | |

| Total | 55,862.4533 | 56,415.6233 | 56,968.7177 | 57,521.8120 | 58,074.9064 | |

| 0.00560 | 0.01516 | 0.02455 | 0.03323 | 0.04244 | ||

| 0.01 | 0.02 | 0.03 | 0.04 | 0.05 | |

|---|---|---|---|---|---|

| Distributed ES | 39,120.6995 | 39,508.0332 | 39,895.3668 | 40,282.7005 | 40,670.0341 |

| Centralized ES | 39,519.2745 | 39,910.5545 | 40,301.8344 | 40,693.1144 | 41,084.3943 |

| 0.01 | 0.02 | 0.03 | 0.04 | 0.05 | |

|---|---|---|---|---|---|

| Distributed ES | 55,862.4533 | 56,415.6233 | 56,968.7177 | 57,521.8120 | 58,074.9064 |

| Centralized ES | 56,247.3610 | 56,803.1515 | 57,361.1702 | 57,918.0747 | 58,474.9794 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rong, S.; Zhao, Y.; Wang, Y.; Chen, J.; Guan, W.; Cui, J.; Liu, Y. Information Gap Decision Theory-Based Stochastic Optimization for Smart Microgrids with Multiple Transformers. Appl. Sci. 2023, 13, 9305. https://doi.org/10.3390/app13169305

Rong S, Zhao Y, Wang Y, Chen J, Guan W, Cui J, Liu Y. Information Gap Decision Theory-Based Stochastic Optimization for Smart Microgrids with Multiple Transformers. Applied Sciences. 2023; 13(16):9305. https://doi.org/10.3390/app13169305

Chicago/Turabian StyleRong, Shuang, Yanlei Zhao, Yanxin Wang, Jiajia Chen, Wanlin Guan, Jiapeng Cui, and Yanlong Liu. 2023. "Information Gap Decision Theory-Based Stochastic Optimization for Smart Microgrids with Multiple Transformers" Applied Sciences 13, no. 16: 9305. https://doi.org/10.3390/app13169305

APA StyleRong, S., Zhao, Y., Wang, Y., Chen, J., Guan, W., Cui, J., & Liu, Y. (2023). Information Gap Decision Theory-Based Stochastic Optimization for Smart Microgrids with Multiple Transformers. Applied Sciences, 13(16), 9305. https://doi.org/10.3390/app13169305