Design of Liquid–Air Hybrid Cooling Garment and Its Effect on Local Thermal Comfort

Abstract

:1. Introduction

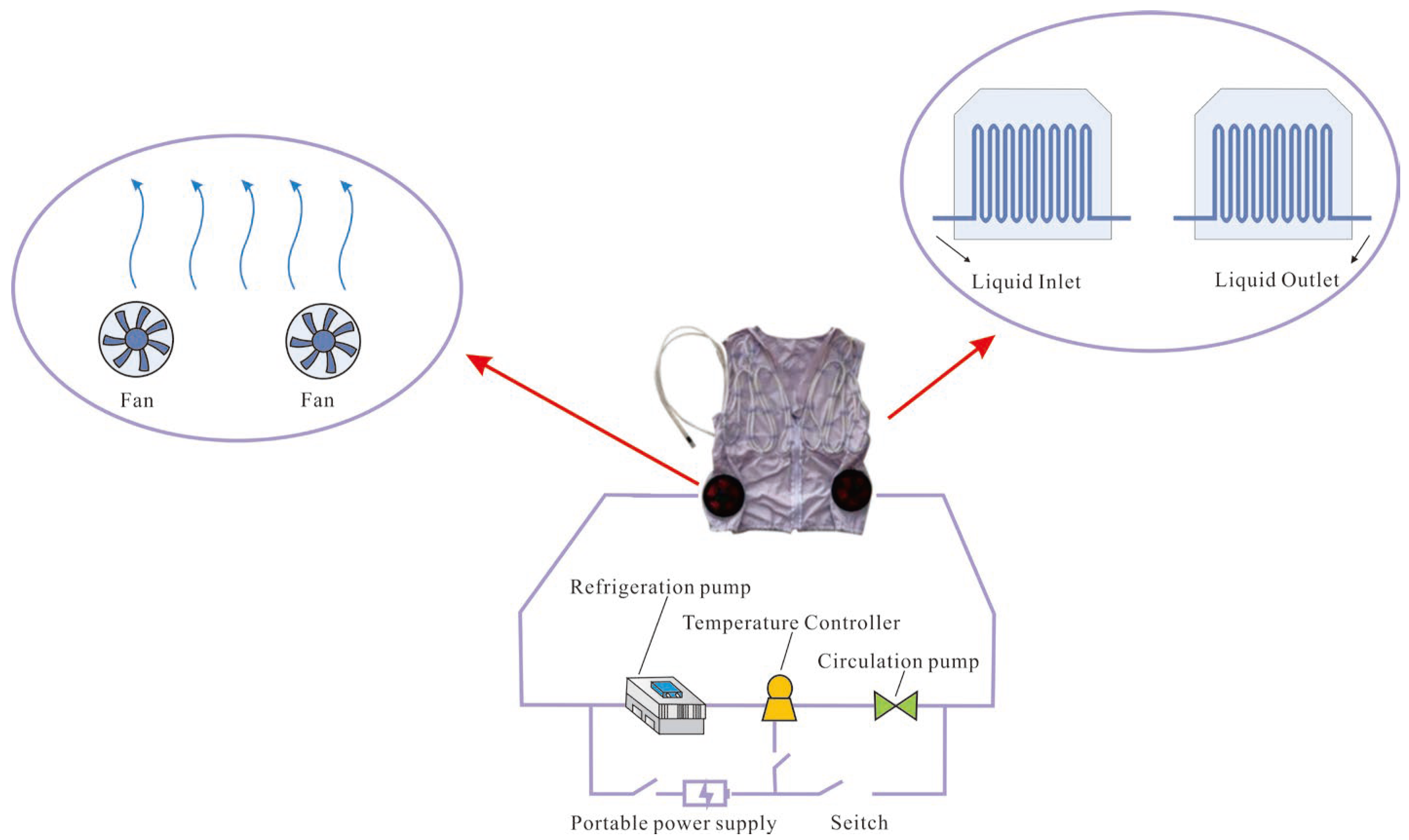

2. A general Description of the Designed Cooling Garments and the Control Garment

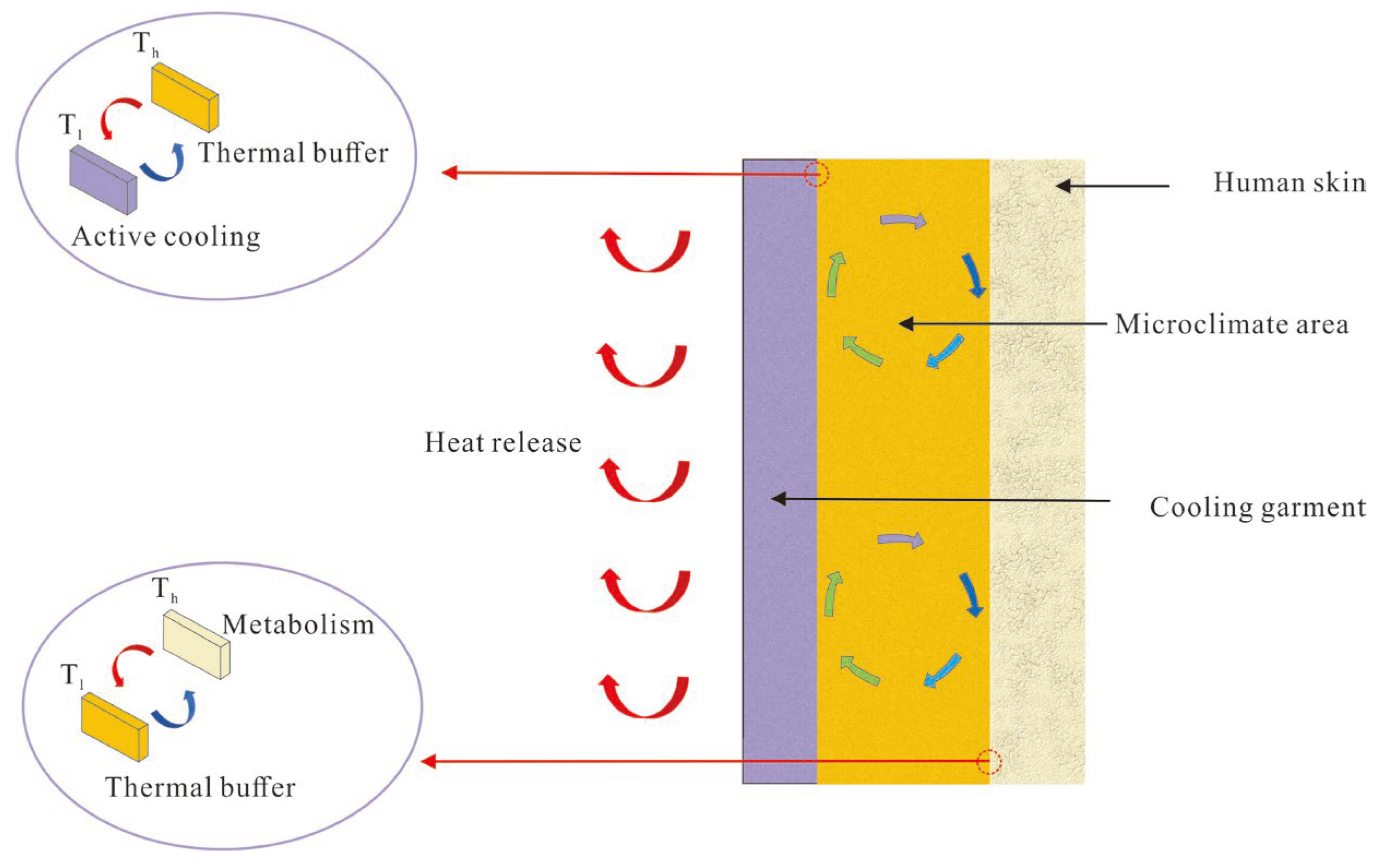

2.1. Heat Exchange Processes in the Micro-Climate under Clothing

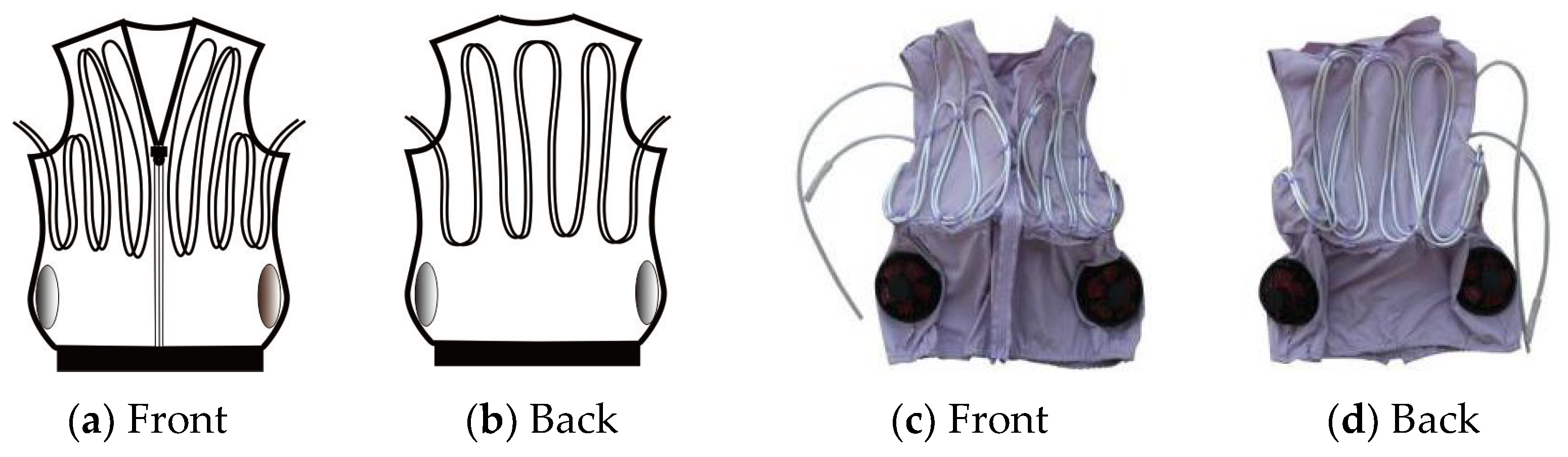

2.2. The Design Idea of the Cooling Garments and the Control Garment

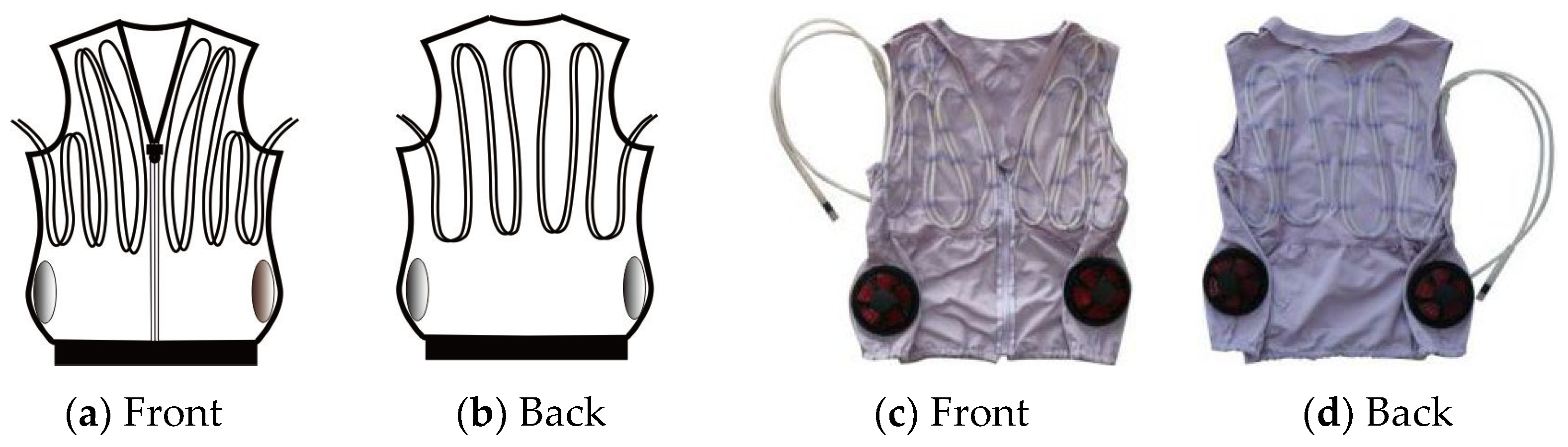

3. A Detailed Description of the Designed Cooling Garments and the Control Garment

3.1. Clothing Size and Textile Martials

3.2. Liquid Pipe Materials of the Cooling Garments

3.3. The Liquid Cooling System of the Cooling Garments

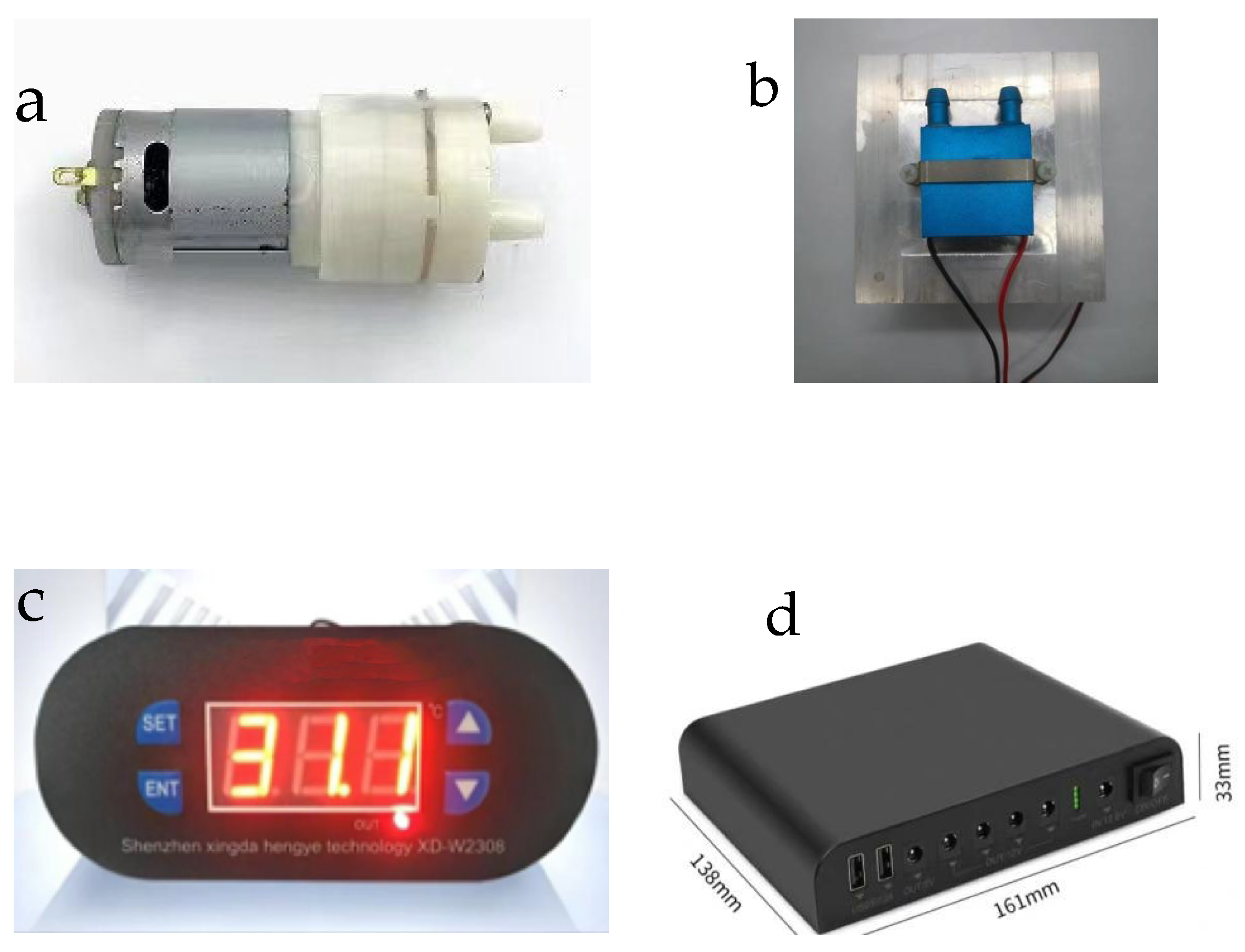

3.3.1. The Components of the Liquid Cooling System

3.3.2. The Circuit System

3.3.3. The Assembling of the Liquid Cooling System

3.4. The Air Ventilation System of the Cooling Garments

4. Methods

4.1. Participants of the Experiment

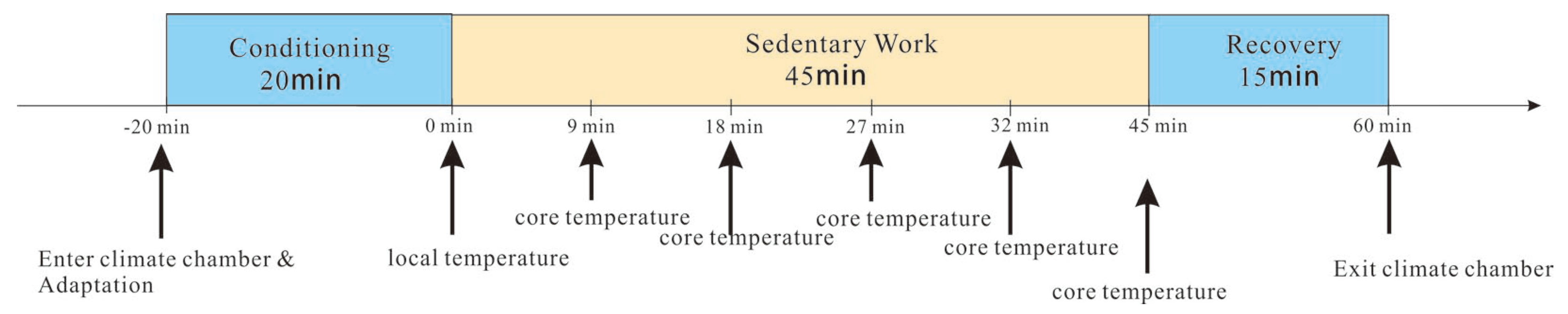

4.2. Experimental Protocol and Test Conditions

4.3. Calculations

4.4. Statistical Analysis

5. Results

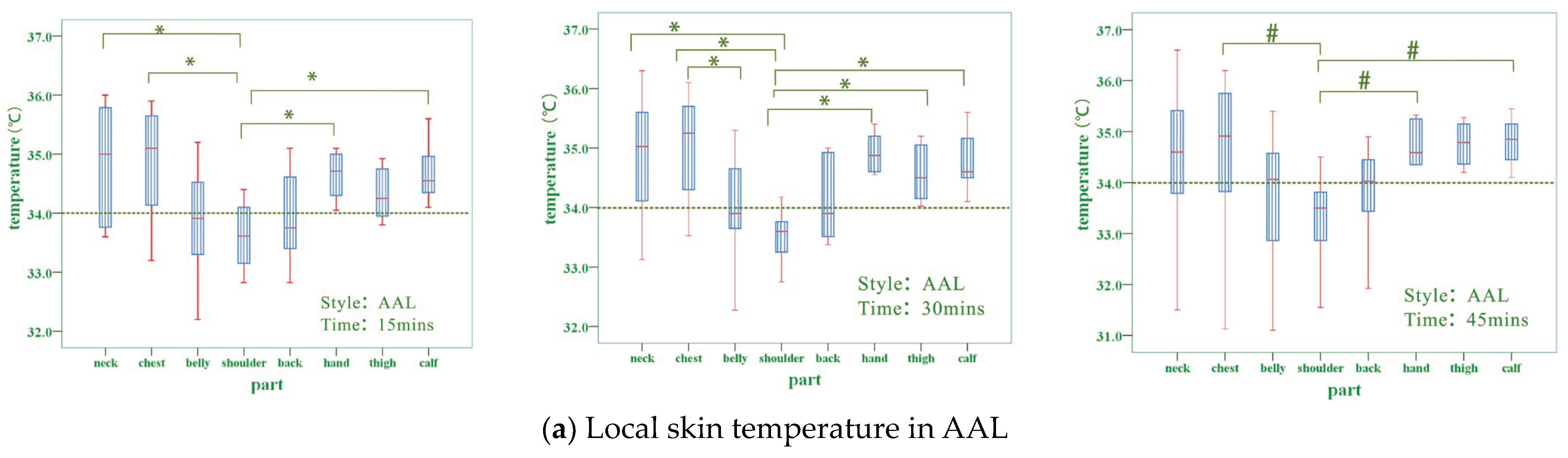

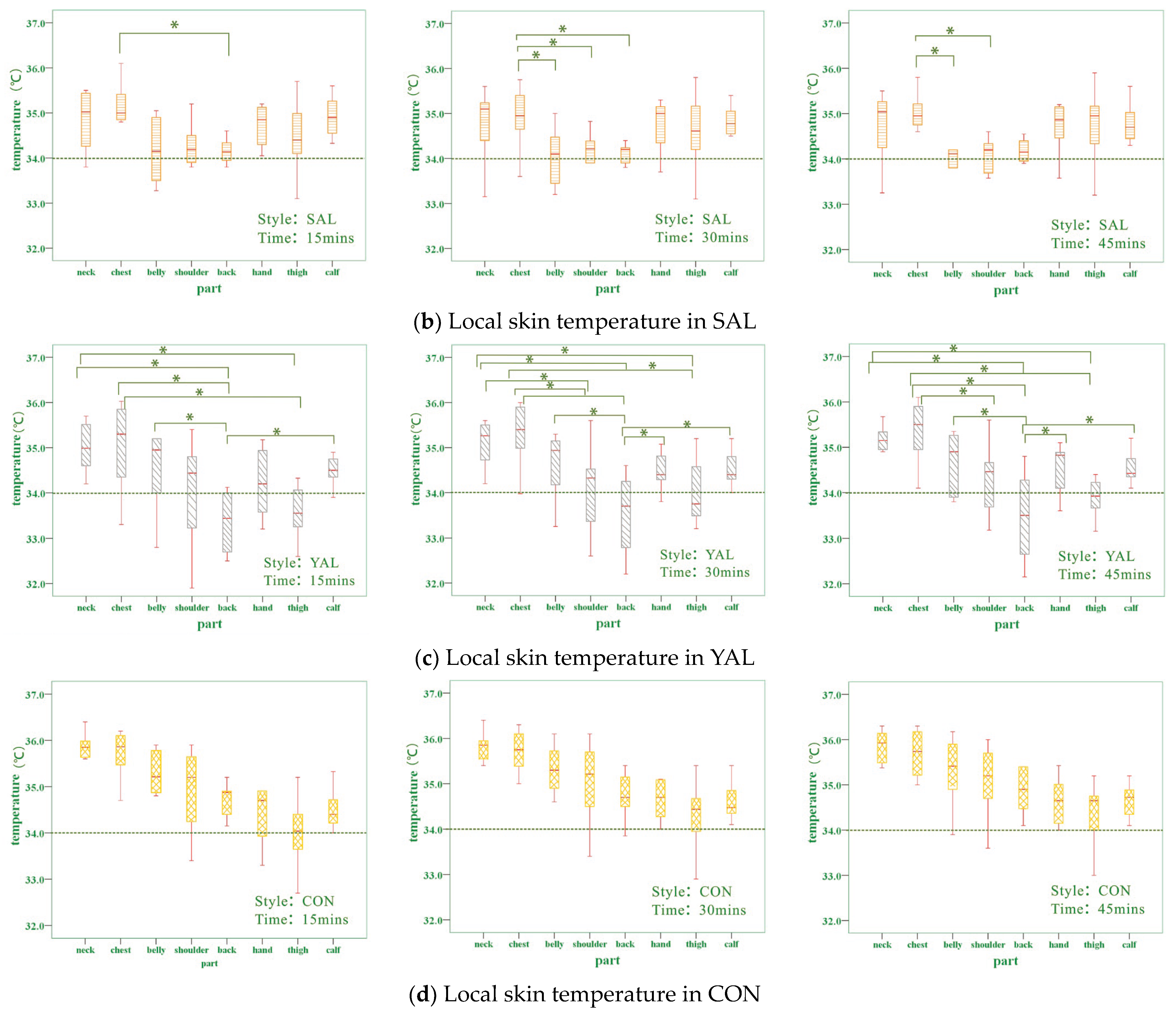

5.1. Local Skin Temperature

5.2. Core, Mean Skin, and Mean Torso Temperatures

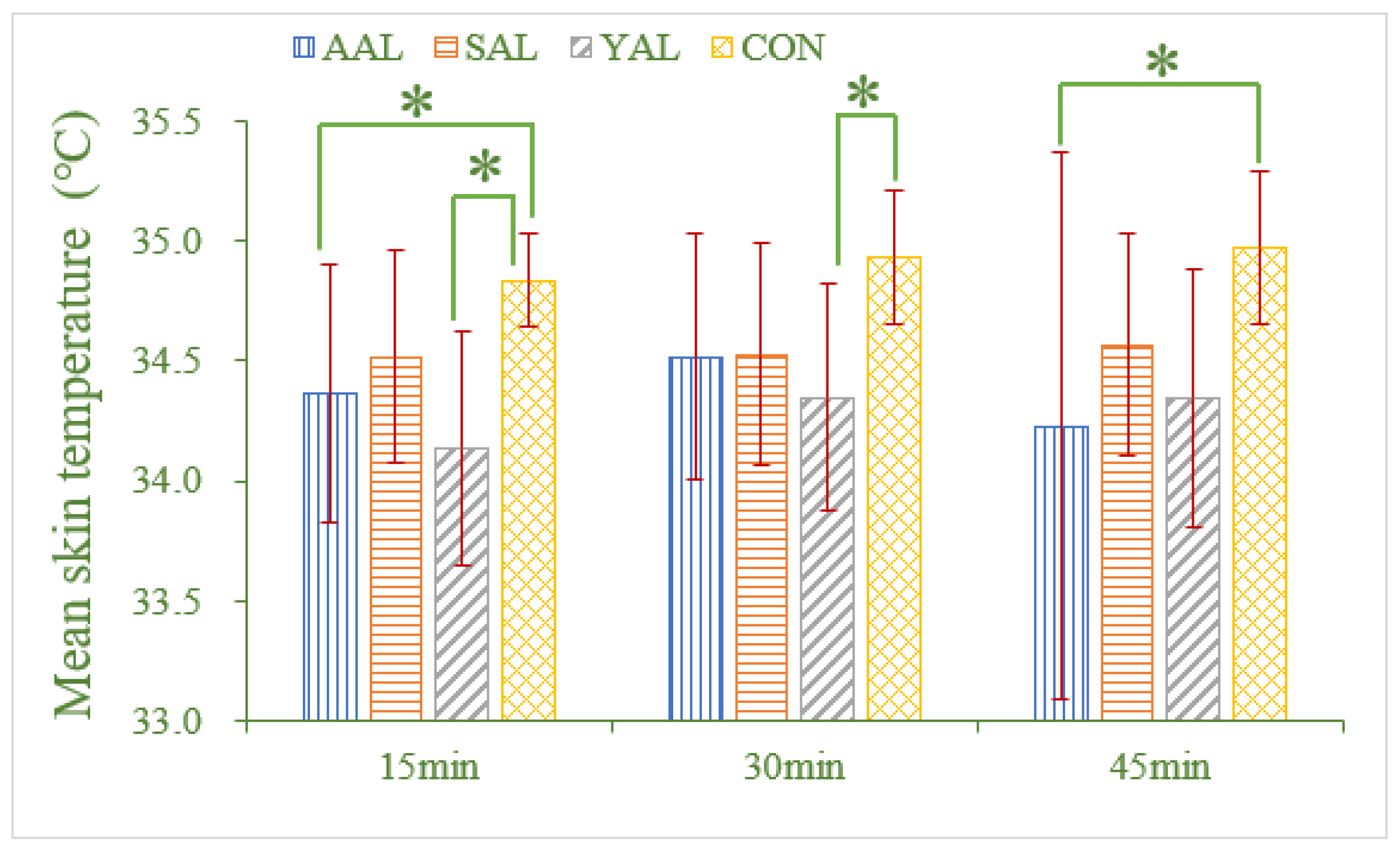

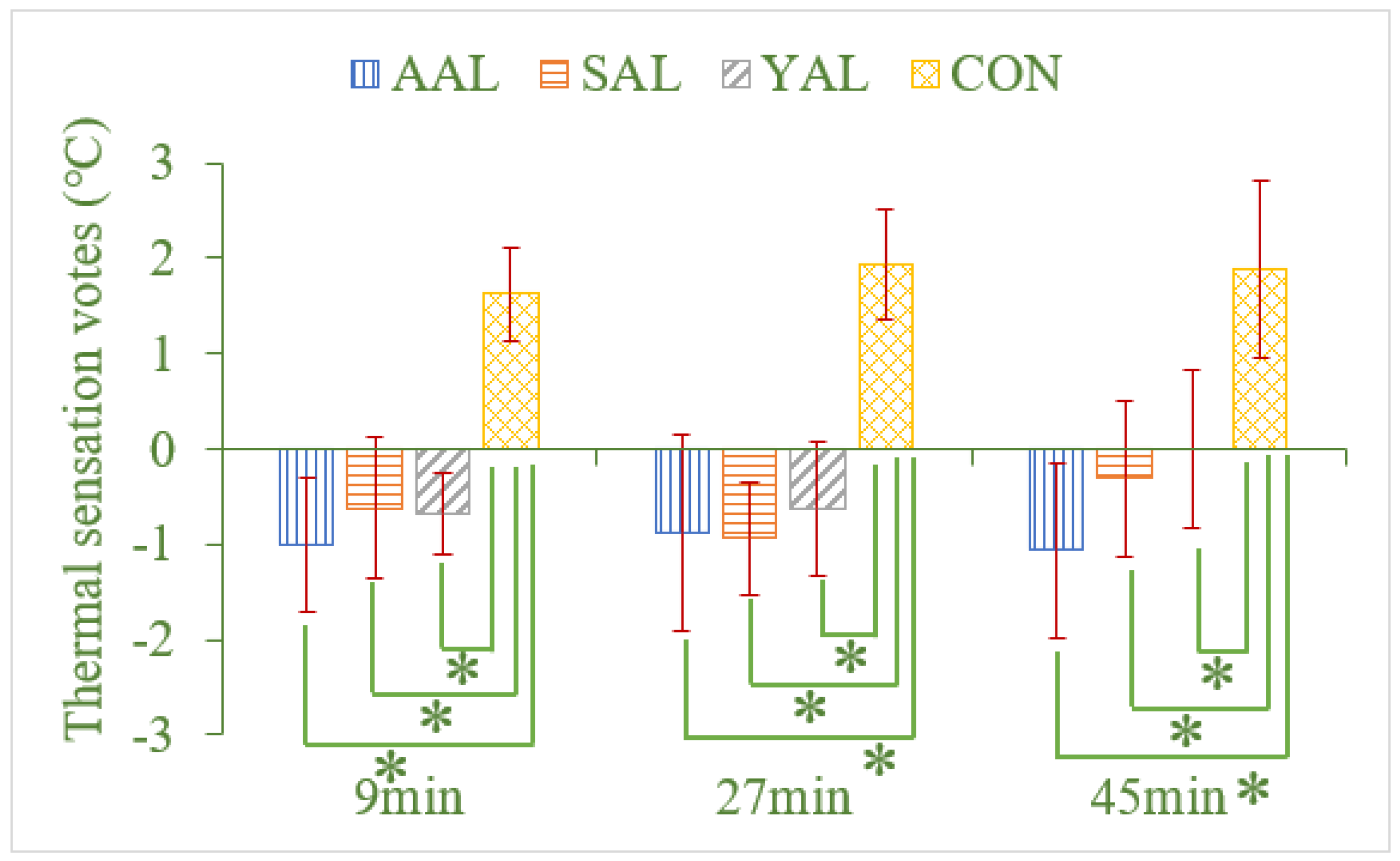

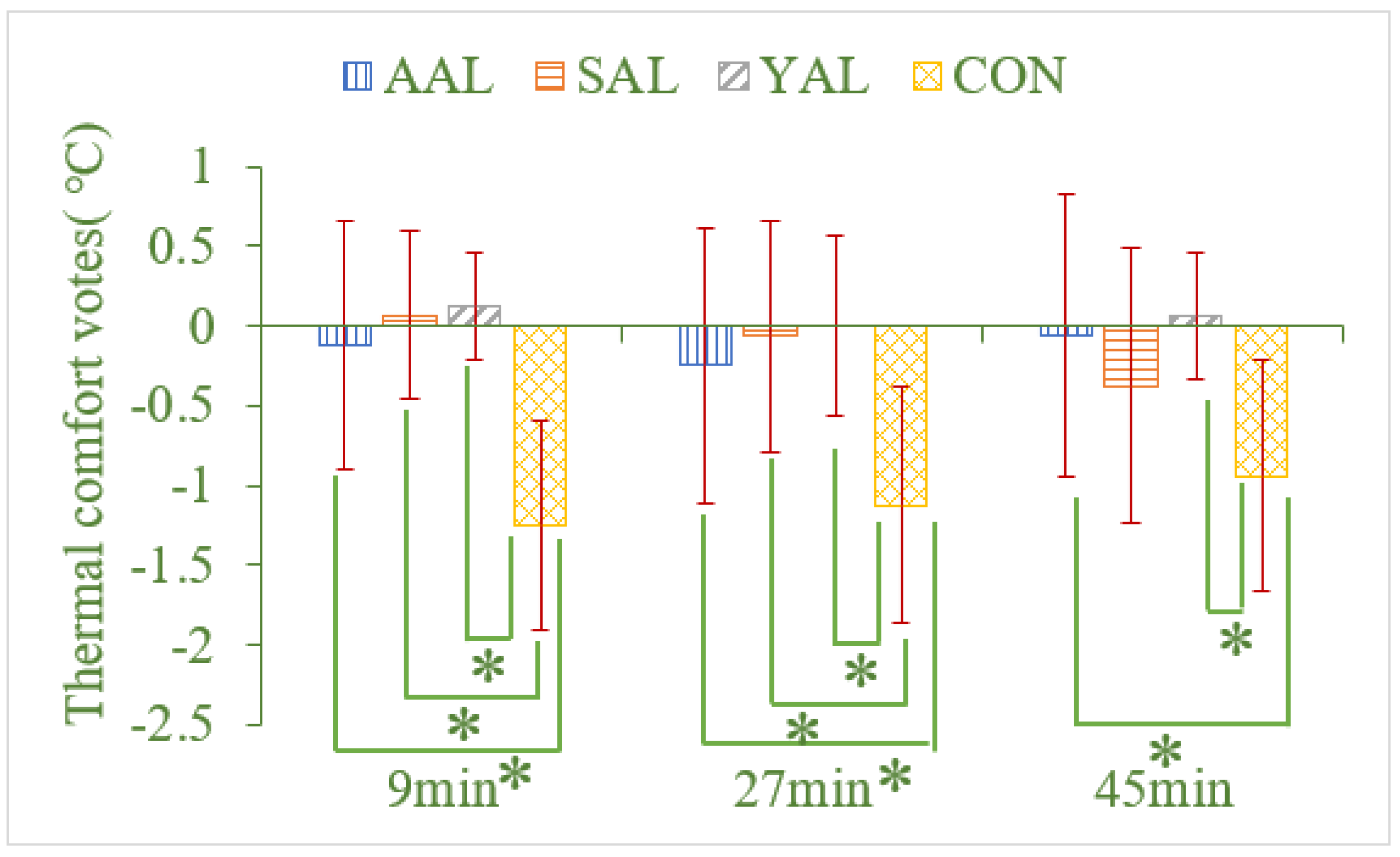

5.3. Perceptual Responses

6. Discussion

6.1. Effect of Liquid–Air Hybrid Cooling on Cooling Performance

6.2. The Effect of Different Pipe Materials on Cooling Performance

6.3. The Effect of Different Forms of Garment Design on Cooling Performance

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, H.; Arens, E.; Zhai, Y. A review of the corrective power of personal comfort systems in non-neutral ambient environments. Build. Environ. 2015, 91, 15–41. [Google Scholar] [CrossRef]

- Burton, D.R.; Collier, L. The Development of Water Conditioned Suits; Tech. Note ME-400; Royal Aircraft Establishment: Farnborough, UK, 1964. [Google Scholar]

- Yang, J.; Wang, F.; Song, G.; Li, R.; Raj, U. Effects of clothing size and air ventilation rate on cooling performance of air ventilation clothing in a warm condition. Int. J. Occup. Saf. Ergon. 2022, 28, 354–363. [Google Scholar] [CrossRef] [PubMed]

- Nunneley, S.A. Water cooled garments: A review. Space Life Sci. 1970, 2, 335–360. [Google Scholar] [CrossRef] [PubMed]

- Falcone, T.; Cordella, F.; Molinaro, V.; Zollo, L.; Del Ferraro, S. Real-time human core temperature estimation methods and their application in the occupational field: A systematic review. Measurement 2021, 183, 109776. [Google Scholar] [CrossRef]

- Bue, G.; Trevino, L. Thermal analysis of lightweight liquid cooling garments using highly conductive materials. SAE Trans. 2005, 114, 425–433. [Google Scholar]

- Wang, T.; Wang, L.; Bai, L.; Lin, G.; Bu, X.; Liu, X.; Xie, G. Experimental study on the performance of a liquid cooling garment with the application of MEPCMS. Energy Convers. Manag. 2013, 5, 359–364. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Wang, J.; Zhang, M.; Jia, M.; Wang, Q. Man-portable cooling garment with cold liquid circulation based on thermoelectric refrigeration. Appl. Therm. Eng. 2022, 200, 117730. [Google Scholar] [CrossRef]

- Ku, Y.T.E.; Montgomery, L.D.; Lee, H.C.; Luna, B.; Webbon, B.W. Physiologic and functional responses of MS patients to body cooling. Am. J. Phys. Med. Rehabil. 2000, 79, 427–434. [Google Scholar] [CrossRef]

- Speckman, K.L.; Allan, A.E.; Sawka, M.N.; Young, A.J.; Muza, S.R.; Pandolf, K.B. Perspectives in microclimate cooling involving protective clothing in hot environments. Int. J. Ind. Ergon. 1988, 3, 121–147. [Google Scholar] [CrossRef]

- McLellan, T.M.; Selkirk, G.A. The management of heat stress for the firefighter: A review of work conducted on behalf of the Toronto Fire Service. Ind. Health 2006, 44, 414–426. [Google Scholar] [CrossRef]

- Kayacan, O.; Kurbak, A. Effect of garment design on liquid cooling garments. Text. Res. J. 2010, 80, 1442–1455. [Google Scholar] [CrossRef]

- Bogdan, A.; Chludzinska, M. Assessment of thermal comfort using personalized ventilation. HV ACR Res. 2010, 16, 529–542. [Google Scholar] [CrossRef]

- Ghaddar, N.; Ghali, K.; Harathani, J. Modulated air layer heat and moisture transport by ventilation and diffusion from clothing with open aperture. J. Heat Transf. 2005, 127, 287–297. [Google Scholar] [CrossRef]

- Gonzalez, J.A.; Berglund, L.G.; Endrusick, T.L.; Kolka, M.A. Forced Ventilation of Protective Garments for Hot Industries; Army Research Institute of Environmental Medicine: Natick, MA, USA, 2006; USARIEM Publication; no. ADA460047. [Google Scholar]

- Kaczmarczyk, J.; Melikov, A.; Bolashikov, Z.; Nikolaev, L.; Fanger, P.O. Human response to five designs of personalized ventilation. HV ACR Res. 2006, 12, 367–384. [Google Scholar] [CrossRef]

- Ke, Y.; Havenith, G.; Zhang, X.; Li, X.; Li, J. Effects of wind and clothing apertures on local clothing ventilation rates and thermal insulation. Text. Res. J. 2014, 84, 941–952. [Google Scholar] [CrossRef]

- Ke, Y.; Li, J.; Havenith, G. An improved experimental method for local clothing ventilation measurement. Int. J. Ind. Ergon. 2014, 44, 75–81. [Google Scholar] [CrossRef]

- Ueda, H.; Havenith, G. The Effect of Fabric Air Permeability on Clothing Ventilation; Elsevier Ergonomics Book Series; Elsevier: Amsterdam, The Netherlands, 2005; Volume 3, pp. 343–346. [Google Scholar]

- Desruelle, A.; Hoef, A.; Candas, V. Local moderate ventilation and thermoregulatory responses in man exercising in an impermeable garment. In Proceedings of the 6th International Conference on Environmental Ergonomic, Montebello, QC, Canada, 25–30 September 1994; pp. 62–63. [Google Scholar]

- Hadid, A.; Yanovich, R.; Erlich, T.; Khomenok, G.; Moran, D.S. Effect of a personal ambient ventilation system on physiological strain during heat stress wearing a ballistic vest. Eur. J. Appl. Physiol. 2008, 104, 311. [Google Scholar] [CrossRef]

- Zhao, M.; Gao, C.; Wang, F.; Kuklane, K.; Holmér, I.; Li, J. A study on local cooling of garments with ventilation fans and openings placed at different torso sites. Int. J. Ind. Ergon. 2013, 43, 232–237. [Google Scholar] [CrossRef]

- Yi, W.; Zhao, Y.; Chan, A.P.C. Evaluating the Effectiveness of Cooling Vest in a Hot and Humid Environment. Ann. Occup. Hyg. 2017, 61, 481. [Google Scholar] [CrossRef]

- Del, F.S.; Falcone, T.; Morabito, M.; Messeri, A.; Bonafede, M.; Marinaccio, A.; Gao, C.; Molinaro, V. Cooling garments against environmental heat conditions in occupational fields: Measurements of the effect of a ventilation jacket on the total thermal insulation. Int. J. Ind. Ergon. 2021, 86, 103230. [Google Scholar]

- Chinevere, T.D.; Cadarette, B.S.; Goodman, D.A.; Ely, B.R.; Cheuvront, S.N.; Sawka, M.N. Efficacy of body ventilation system for reducing strain in warm and hot climates. Eur. J. Appl. Physiol. 2008, 103, 307. [Google Scholar] [CrossRef] [PubMed]

- Chan, A.P.C.; Zhang, Y.; Wang, F.; Wong, F.F.; Chan, D.W. A field study of the effectiveness and practicality of a novel hybrid person-al cooling vest worn during rest in Hong Kong construction industry. J. Therm. Biol. 2017, 70, 21–27. [Google Scholar] [CrossRef] [PubMed]

- Chan, A.P.; Yang, Y.; Song, W. Evaluating the usability of a commercial cooling vest in the Hong Kong industries. Int. J. Occup. Saf. Ergon. 2018, 24, 73–81. [Google Scholar] [CrossRef] [PubMed]

- Otani, H.; Fukuda, M.; Tagawa, T. Cooling between exercise bouts and post-exercise with the fan cooling jacket on thermal strain in hot-humid environments. Front. Physiol. 2021, 12, 640400. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Xu, M.; Bian, C. Experimental comparison of local direct heating to improve thermal comfort of workers. Build. Environ. 2020, 177, 106884. [Google Scholar] [CrossRef]

- Wang, F.; Ke, Y.; Raj, U.; Yang, B.; Xu, P.; Noor, N. Effect of cooling strategies on overall performance of a hybrid personal cooling system incorporated with phase change materials (PCMs) and electric fans. J. Therm. Biol. 2020, 92, 102665. [Google Scholar] [CrossRef] [PubMed]

- Guo, T.H.; Shang, B.F.; Duan, B.; Luo, X.B. Design and testing of a liquid-cooled garment for hot environments. J. Therm. Biol. 2015, 49–50, 47–50. [Google Scholar] [CrossRef]

- Shitzer, A. Thermal protective garment using independent regional control of coolant temperature. Aerosp. Med. Hum. Perform. 1973, 1, 49–59. [Google Scholar]

- Young, A.J.; Sawka, M.N.; EpStein, Y.; Decristofano, B.A.R.R.Y.; Pandolf, K.B. Cooling different body surfaces during upper and lower body exercise. J. Appl. Physiol. 1987, 63, 1218–1223. [Google Scholar] [CrossRef]

- Kim, D.E.; LaBat, K. Design process for developing a liquid cooling garment hood. Ergonomics 2010, 6, 818–828. [Google Scholar] [CrossRef]

- Hamilton, R.L. Body Cooling System. US 20130142656 A1, 6 June 2013. [Google Scholar]

- Koscheyev, V.S.; Leon, G.R.; Treviño, R.C. An advanced physiological based shortened liquid cooling/warming garment for comfort management in routine and emergency EVA. SAE Trans. 2002, 111, 274–280. [Google Scholar]

- Mochida, T. Mean Skin Temperature Weighted by Skin Area, Heat Transfer Coefficients and Thermal Sensitivity; Research Report; Engineering Department of Hokkaido University: Sapporo, Japan, 1983; Volume 115, pp. 1–10. [Google Scholar]

- Gao, C.; Kuklane, K.; Wang, F.; Holmér, I. Personal cooling with phase change materials to improve thermal comfort from a heat wave perspective. Indoor Air 2012, 22, 523–530. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Cao, B.; Ju, Y.; Zhu, Y. The effects of local cooling at different torso parts in improving body thermal comfort in hot indoor environments. Energy Build. 2019, 198, 528–541. [Google Scholar] [CrossRef]

- Li, Z.; Yuan, T.; Hu, P.; Jia, Q.; Wang, Q.; Xu, Y. Performance research of portable thermoelectric cooling garment under different working conditions. Int. J. Refrig. 2023. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Y.; Huang, Y.; Chen, W. Effects of liquid cooling garment on physiological and psychological strain of firefighter in hot and warm environments. J. Therm. Biol. 2023, 112, 103487. [Google Scholar] [CrossRef]

| Clothing Length | Chest Width | Hip Width | Waist Width | Cross Shoulder |

|---|---|---|---|---|

| 58 | 100 | 100 | 116 | 40 |

| Style | Structure | Pipe Material | Material | Fabric Gram Weight |

|---|---|---|---|---|

| AAL | Upper and lower splicing | Aluminum tube | Polyester, nylon, and cotton blended non-stretch fabric | 180 g/m2 |

| SAL | Upper and lower splicing | Silicone tube | Polyester, nylon, and cotton blended non-stretch fabric | 180 g/m2 |

| YAL | Internal and external splicing | Silicone tube | Polyester, nylon, and cotton blended non-stretch fabric, Polyester mesh fabric | 180 g/m2, 73 g/m2 |

| CON | – | – | Polyester, nylon, and cotton blended non-stretch fabric | 180 g/m2 |

| Style | Pipe Material | Inner Diameter | Outer Diameter | Density | Length | Weight |

|---|---|---|---|---|---|---|

| AAL | Aluminum tube | 4 mm | 6 mm | 2.7 g/cm3 | 8.4 m | 356 g |

| SAL | Silicone tube | 4 mm | 6 mm | 2.2 g/cm3 | 8.4 m | 290 g |

| YAL | Silicone tube | 4 mm | 6 mm | 2.2 g/cm3 | 8.4 m | 290 g |

| Scale | Thermal Sensation Vote (TSV) | Thermal Comfort Vote (TCV) |

|---|---|---|

| −3 | Cold | Very uncomfortable |

| −2 | Cool | Uncomfortable |

| −1 | Slightly cool | Slightly uncomfortable |

| 0 | Neutral | Comfortable |

| 1 | Slightly warm | Very comfortable |

| 2 | Warm | – |

| 3 | Hot | – |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Zhao, M. Design of Liquid–Air Hybrid Cooling Garment and Its Effect on Local Thermal Comfort. Appl. Sci. 2023, 13, 9414. https://doi.org/10.3390/app13169414

Wang W, Zhao M. Design of Liquid–Air Hybrid Cooling Garment and Its Effect on Local Thermal Comfort. Applied Sciences. 2023; 13(16):9414. https://doi.org/10.3390/app13169414

Chicago/Turabian StyleWang, Wanwan, and Mengmeng Zhao. 2023. "Design of Liquid–Air Hybrid Cooling Garment and Its Effect on Local Thermal Comfort" Applied Sciences 13, no. 16: 9414. https://doi.org/10.3390/app13169414

APA StyleWang, W., & Zhao, M. (2023). Design of Liquid–Air Hybrid Cooling Garment and Its Effect on Local Thermal Comfort. Applied Sciences, 13(16), 9414. https://doi.org/10.3390/app13169414