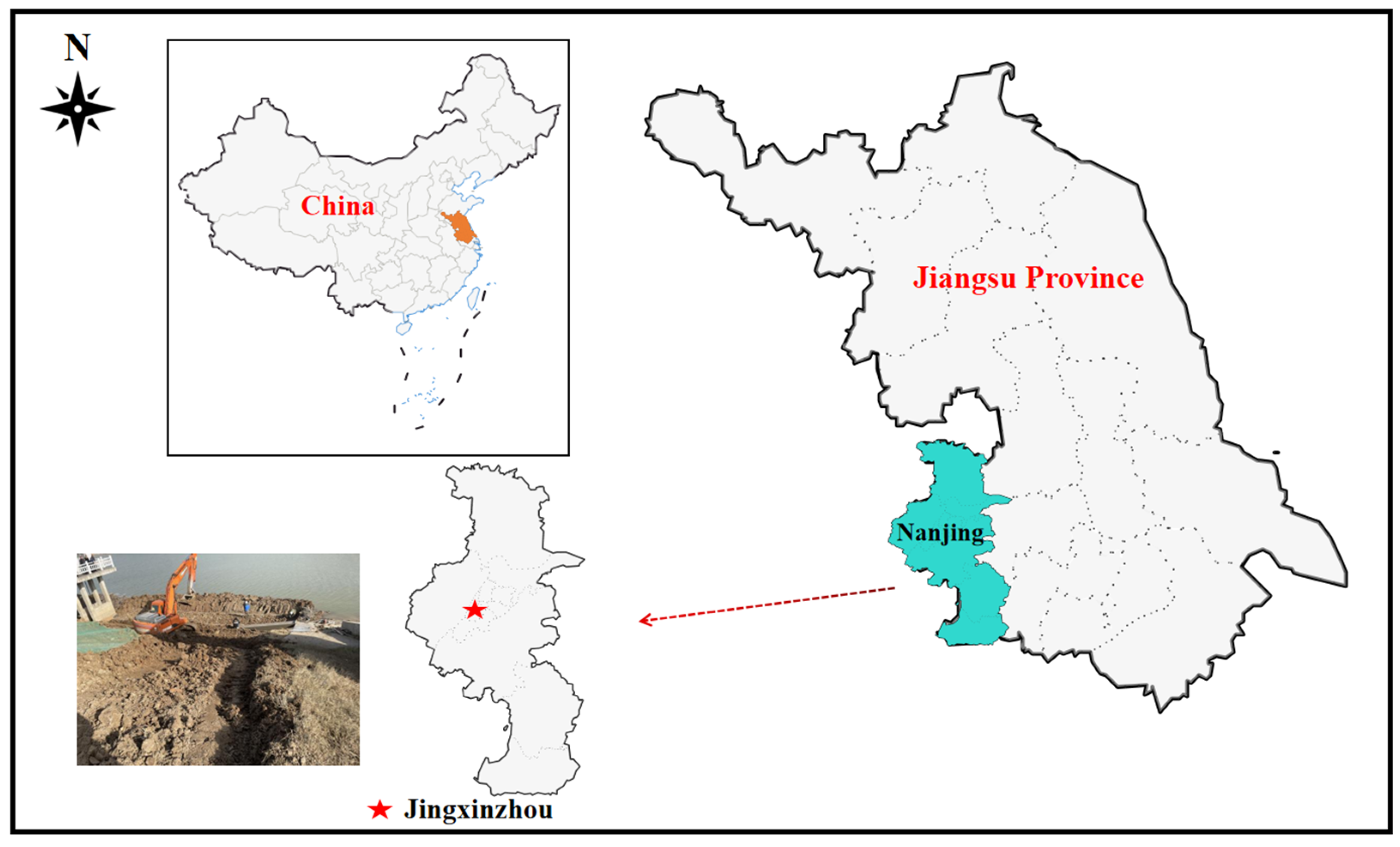

Study on Disintegration and Infiltration Characteristics of Nanjing Jiangxinzhou Embankment Soil

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Disintegration Test

2.3. Variable Head Permeability Test

3. Results

3.1. Disintegration Test

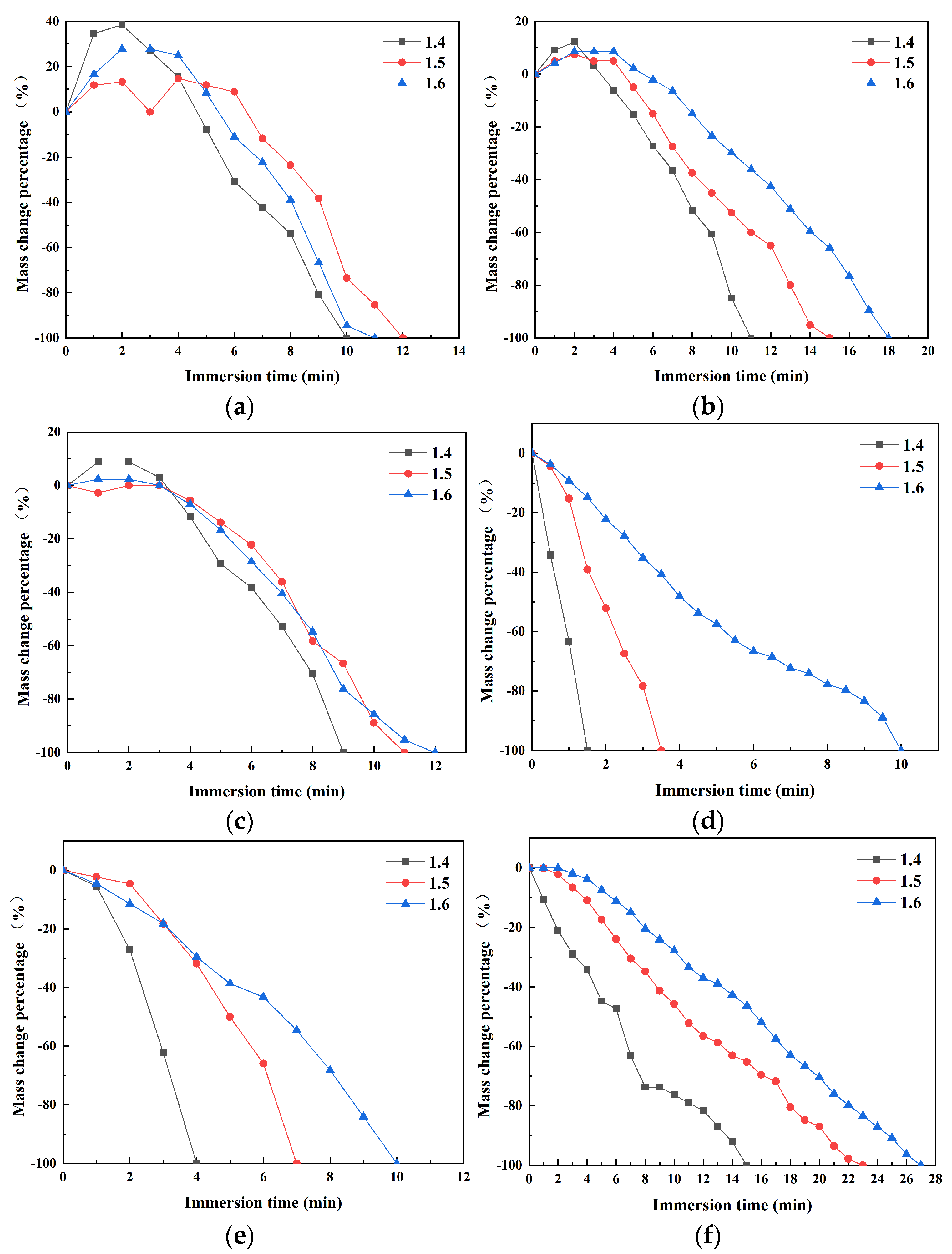

3.1.1. Mass Time Variation Curves

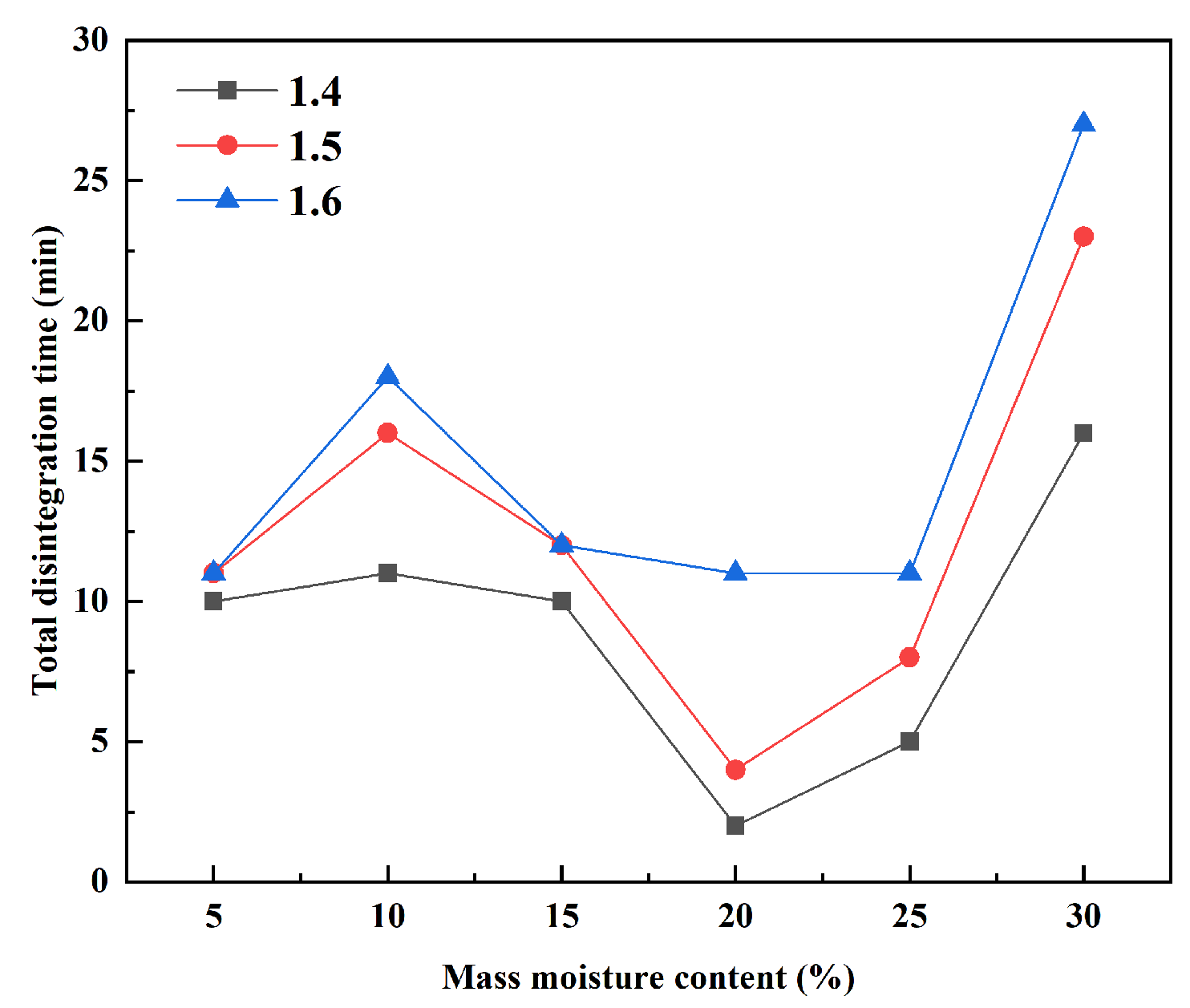

3.1.2. Total Disintegration Time

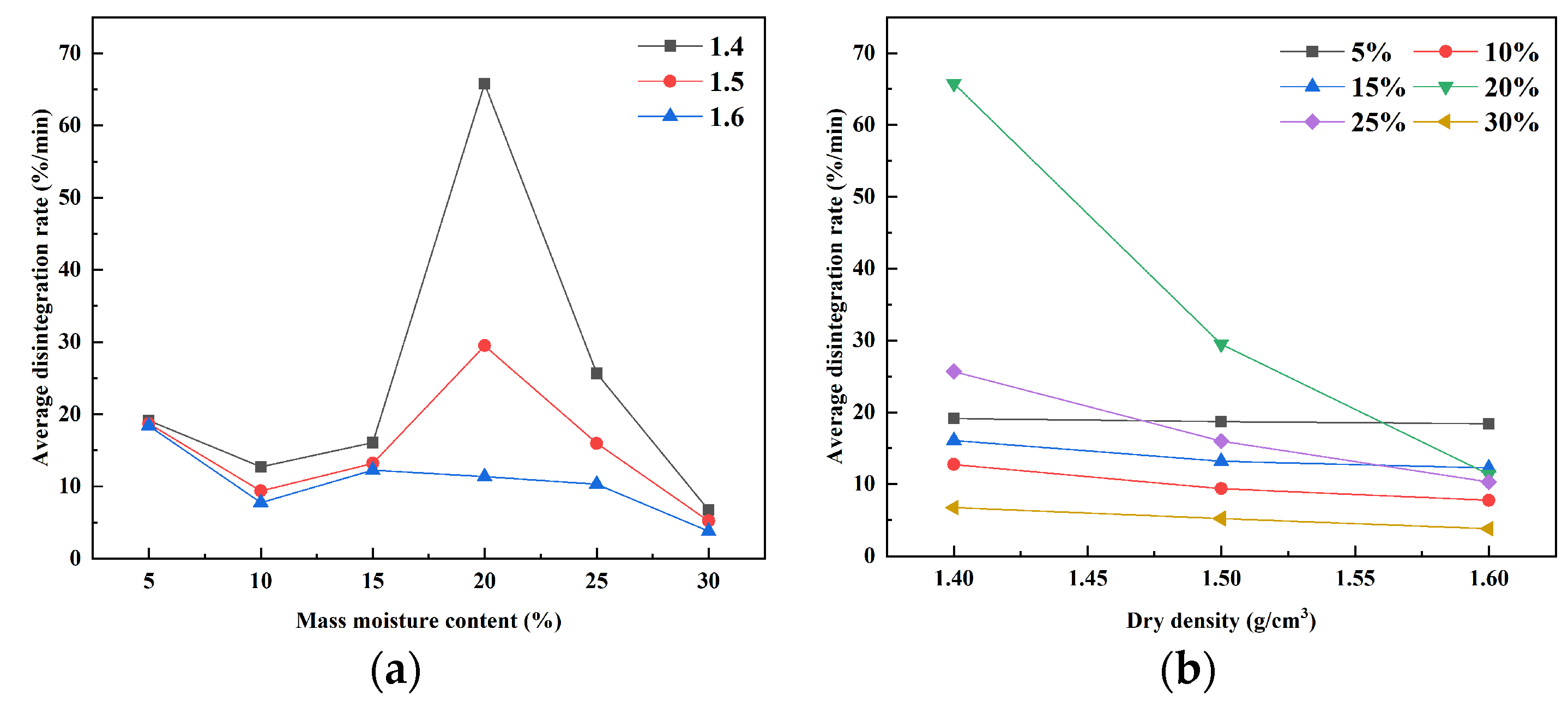

3.1.3. Average Disintegration Rate

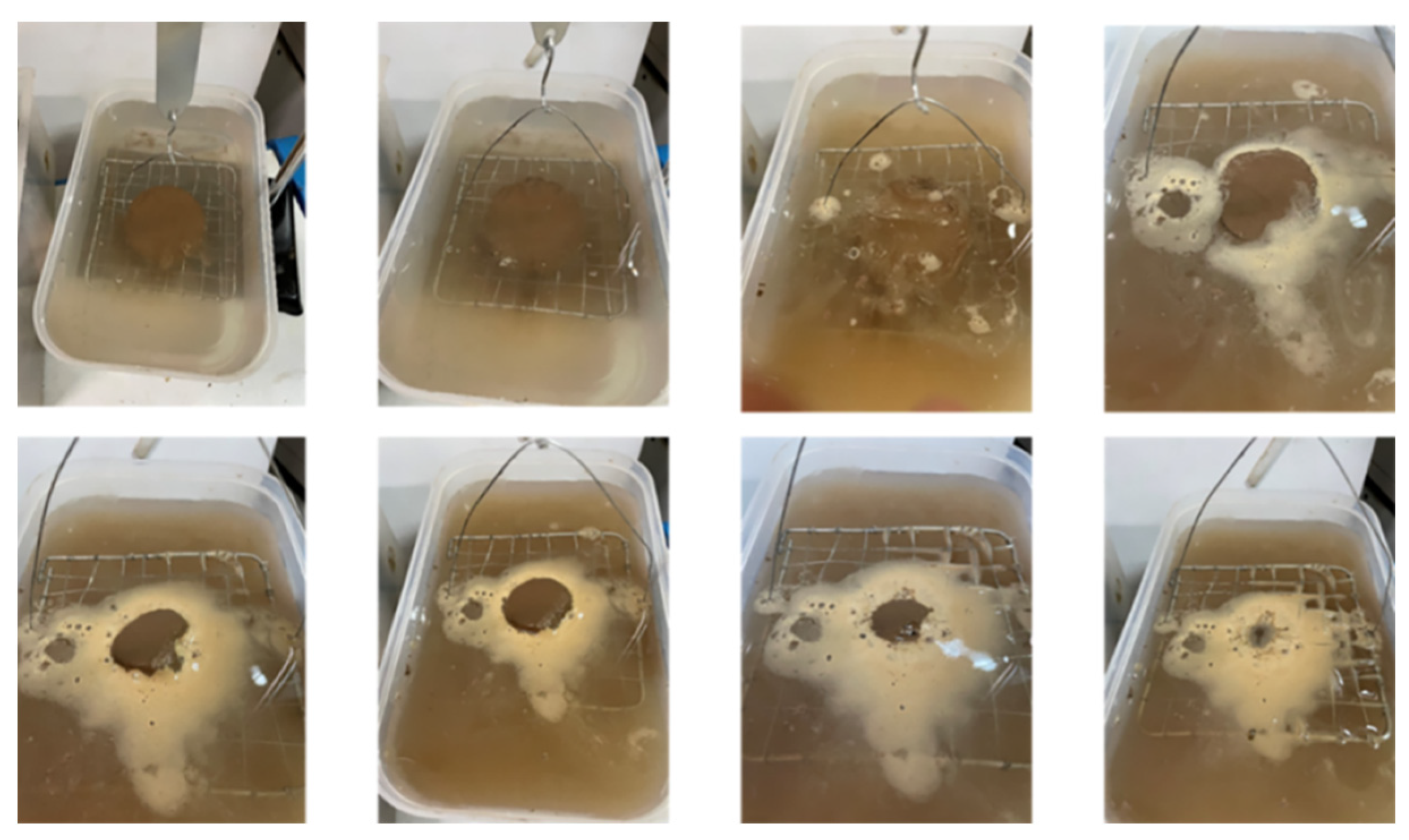

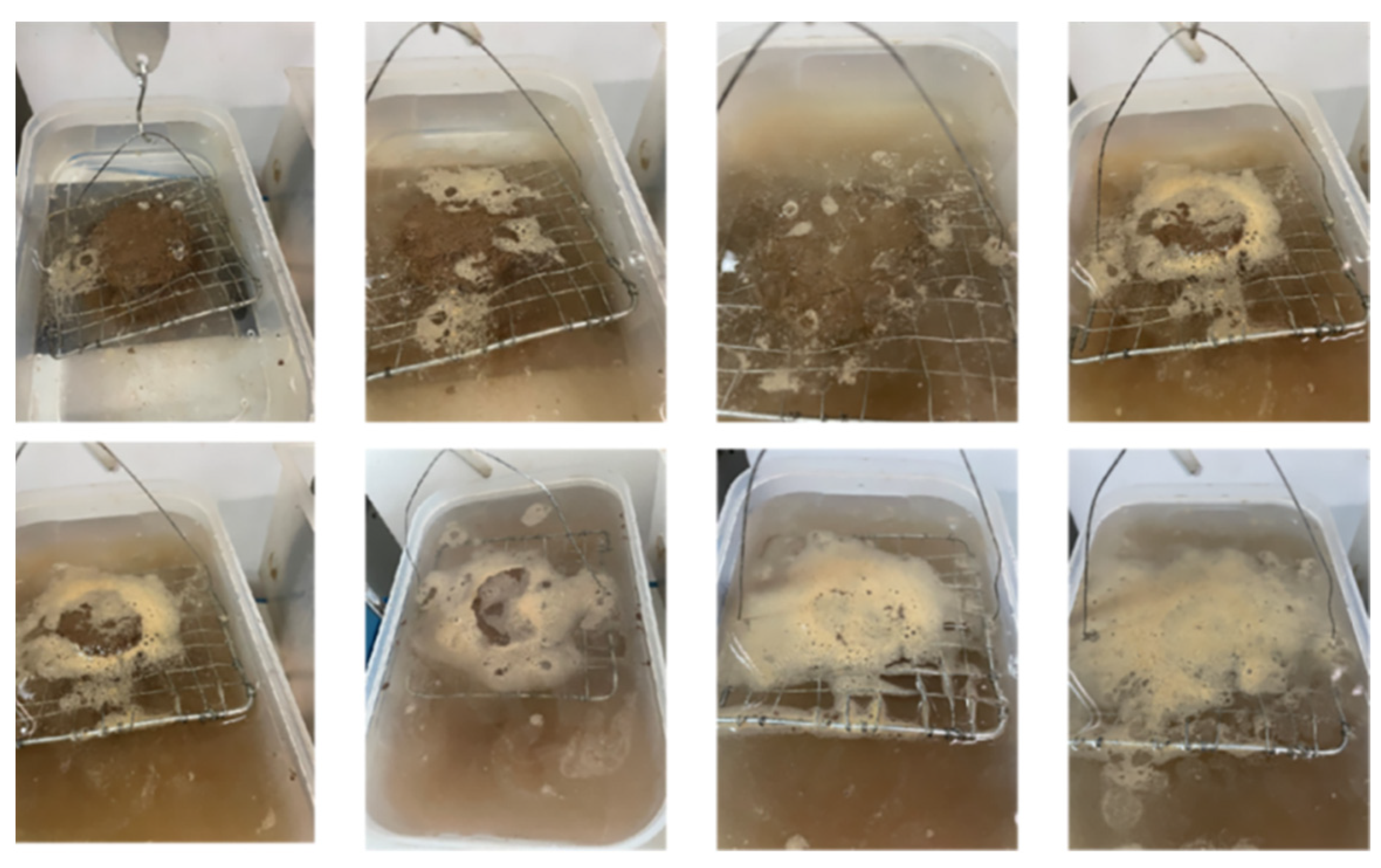

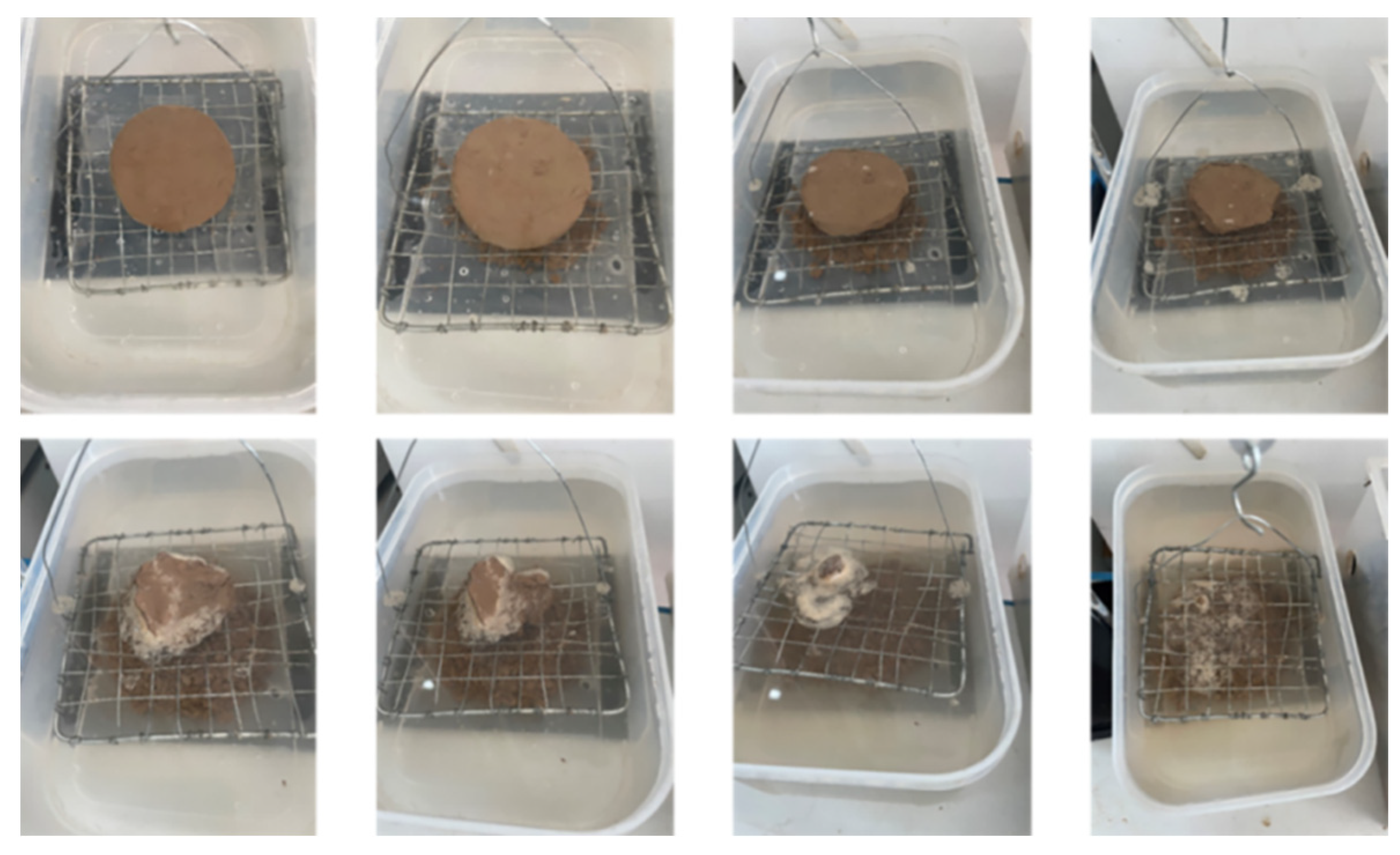

3.1.4. Typical Disintegration Processes of Soil Samples

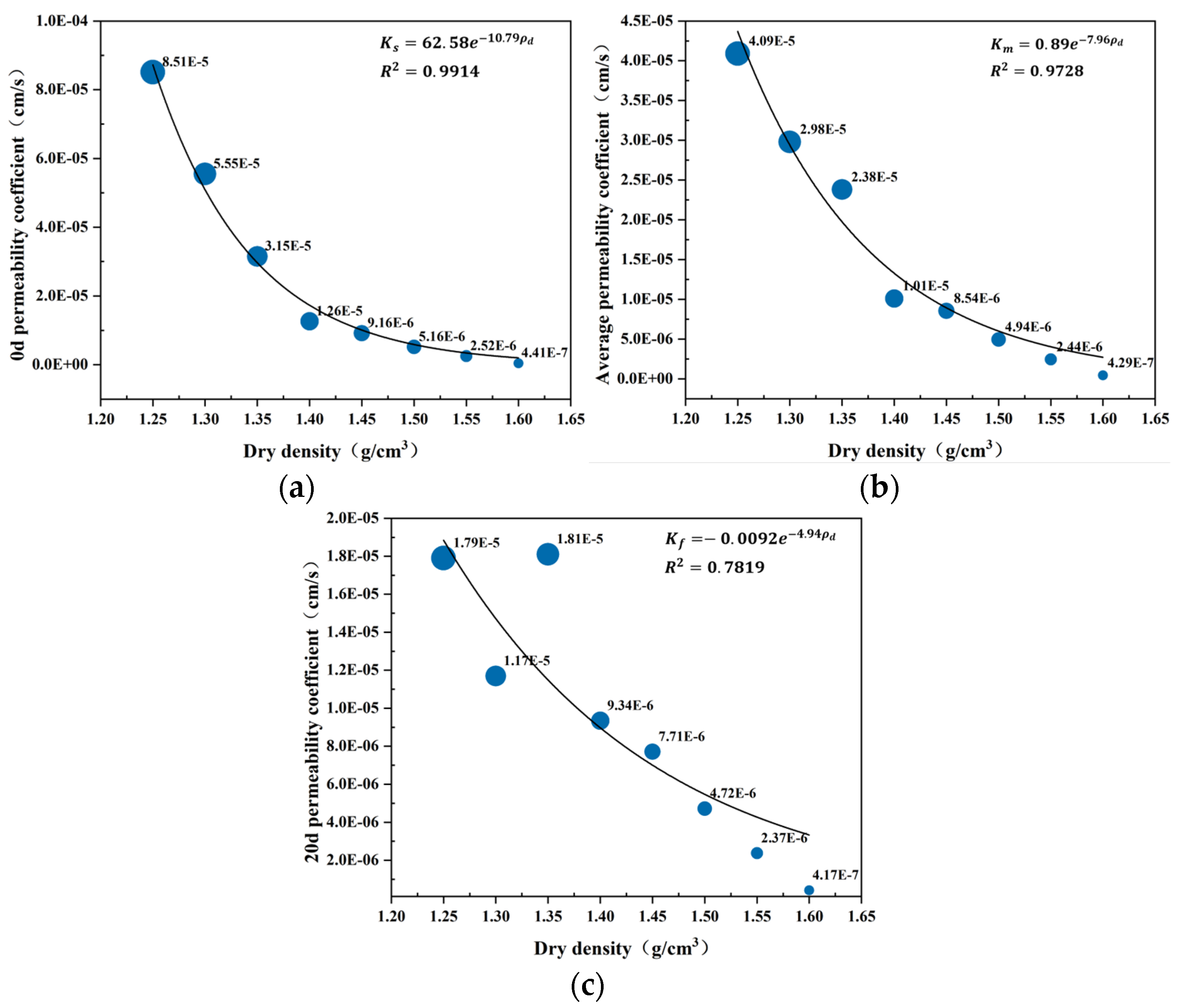

3.2. Variable Head Permeability Test

4. Discussion

4.1. Soil Disintegration

4.2. Permeation Properties

5. Conclusions

- (1)

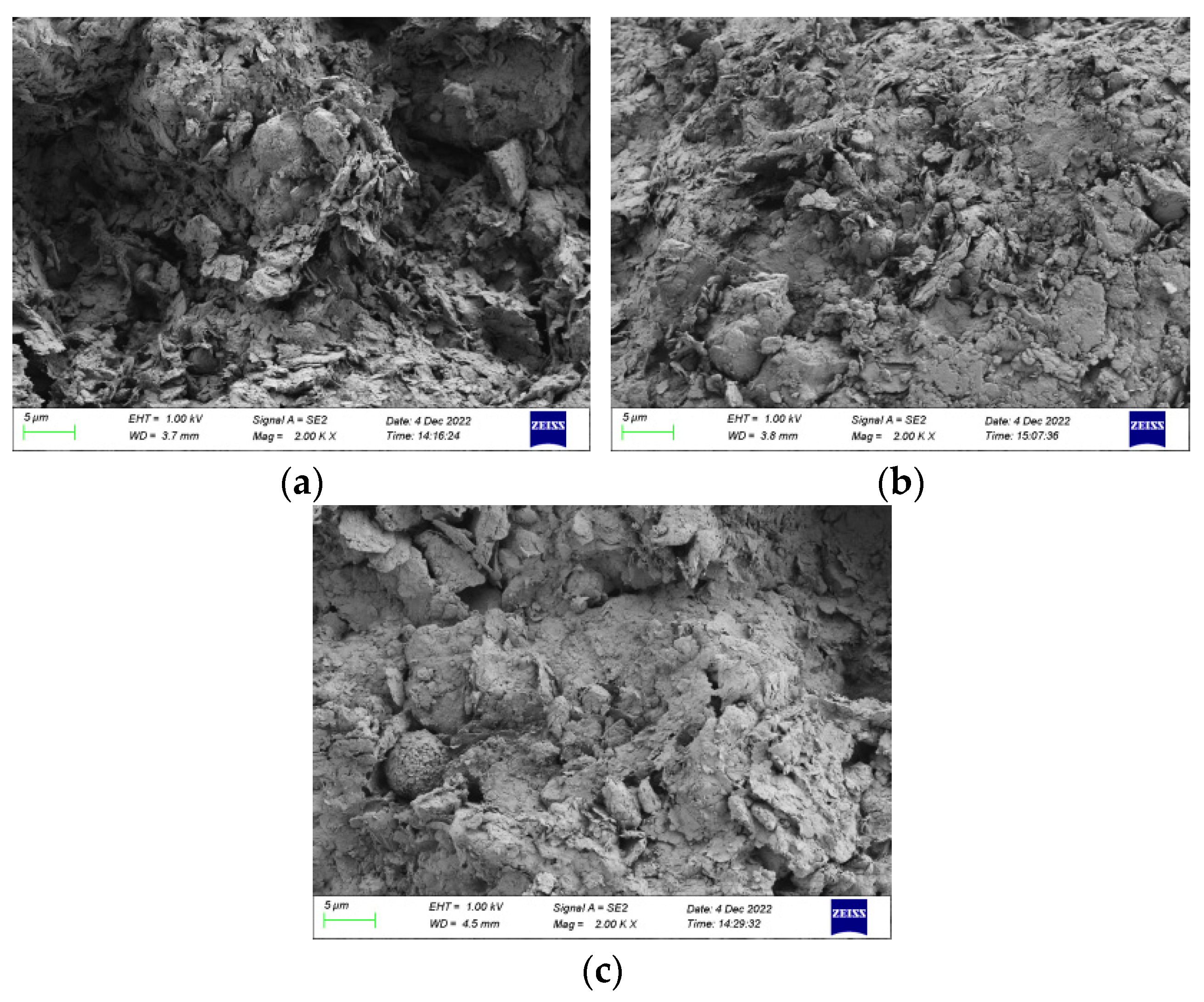

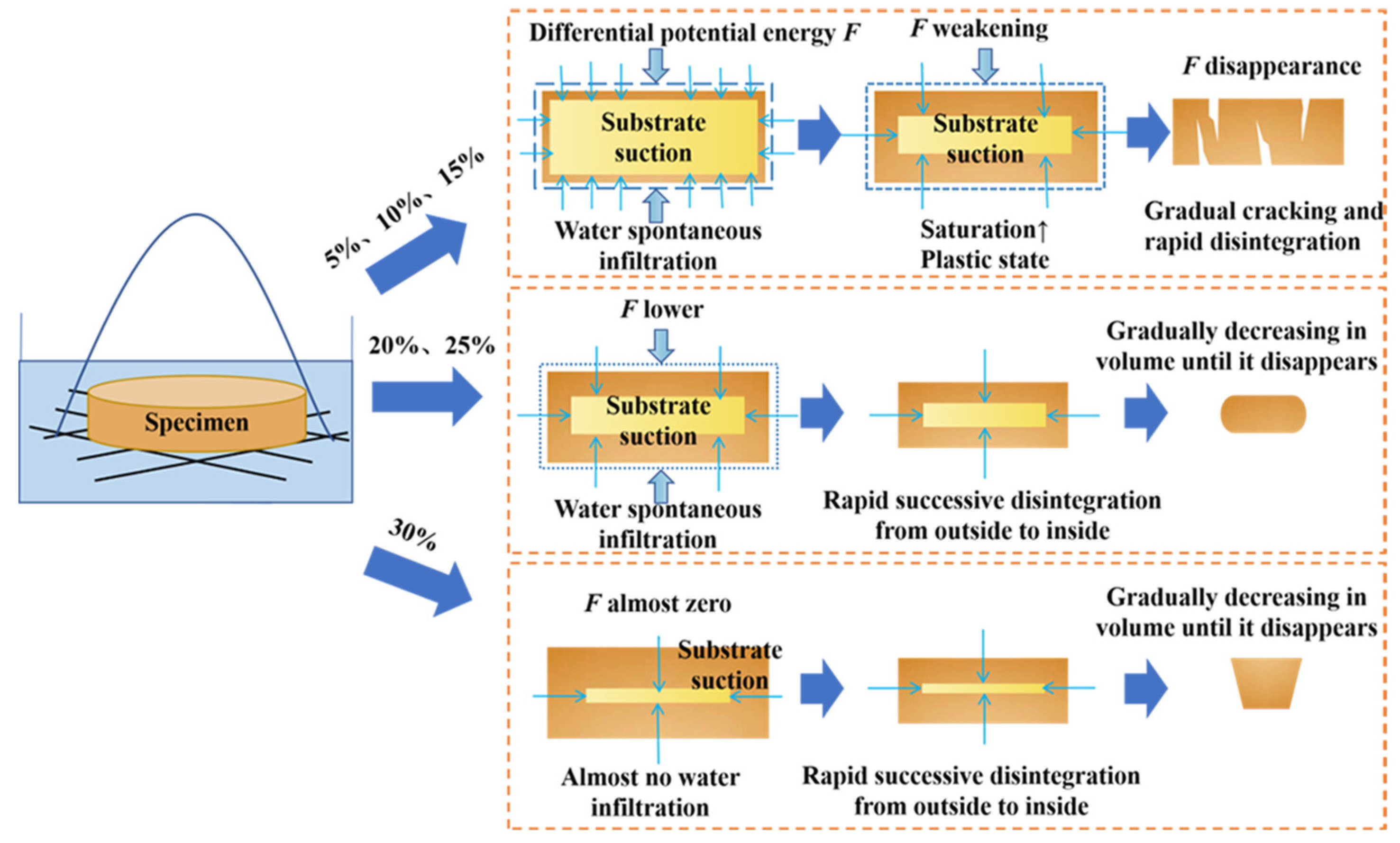

- The pattern of the dry density effect on soil disintegration can be found in Figure 5. In Figure 12, with the rise of dry density, it can be observed that the number of soil particles per unit space of the sample increases, the number of pores decreases, and the structure becomes more compact. Furthermore, increased dry density leads to increased capillary force and matrix suction. The increase in potential energy difference will have a more significant hindering effect on water infiltration and the slower disintegration rate of the sample. Therefore, the disintegration rate decreases with increasing dry density for soil samples with the same water content.

- (2)

- Based on Figure 5a–c, when the water content was low, the water absorption of the sample was more significant than the disintegration amount due to the large matrix suction, and the sample gained weight for a short time. When the water content of the test reached a particular value, there was almost no cementing ability between the soil particles of the sample. The softened sample wedged into the metal mesh under gravity, causing cracking and sudden disintegration. Moreover, there is a threshold water content of around 20%, and it is assumed that the disintegration pattern of the soil may be significantly different depending on the optimum moisture content. The effect of moisture content on the disintegration of the samples was more significant.

- (3)

- The results of the indoor test showed that there were three main disintegration modes of the samples. When the water content was low, including 5%, 10%, and 15%, the disintegration process mainly showed a weight gain disintegration mode (Figure 8). The samples showed continuous and rapid disintegration when the water content rose to 20% and 25% (Figure 9). The samples showed a constant and stable disintegration when the water content was up to 30% (Figure 10). This phenomenon was independent of the dry density of the samples. The disintegration pattern of the samples under different water content conditions is shown in Figure 13.

- (4)

- Infiltration significantly affects the soil’s permeability. After 20 days of immersion, the degree of change in the permeability coefficient weakens as the dry density increases. With the increase in water immersion days, the dissolution of cementing material between soil particles occurs and the particles move to fill the intergranular pore space. The result of pore structure reduction can better explain the phenomenon of soil permeability decreasing with the increase in immersion time.

- (5)

- The disintegration characteristics of soil are affected by many factors, such as initial water content, dry density, temperature, dry and wet cycles, and immersion height. In this paper, only two factors, initial water content and dry density, are considered. Future research can consider the comprehensive influence of multiple factors on the disintegration characteristics. This paper’s comparative analysis of microstructure before and after immersion reveals the microscopic mechanism of permeability change. Therefore, the use of other advanced scientific techniques needs to be considered to achieve further revelation of the microstructural evolution patterns during the permeation process. The current study is mainly an indoor experiment, which needs to be better integrated with the actual problems in the field, and the research scale should be enlarged to combine with the actual engineering problems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qi, Y.-Z.; Jiang, P.-M.; Liu, X.-Y.; Zhang, Y.-L.; Qiu, W.-R.; Wang, T.-G.; Zha, W.-J. Influences of soil disintegration in water on slope stability. Chin. J. Geotech. Eng. 2020, 42, 214–218. (In Chinese) [Google Scholar] [CrossRef]

- Ben-Hur, M.; Lado, M. Effect of soil wetting conditions on seal formation, runoff, and soil loss in arid and semiarid soils—A review. Soil. Res. 2008, 46, 191–202. [Google Scholar] [CrossRef]

- Tang, D.; Liu, Y.; Zhang, W. Engineering Geotechnics; Geological Press: Beijing, China, 1999. (In Chinese) [Google Scholar]

- GB/T50123-2019; Standard for Geotechnical Test Methods. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019. (In Chinese)

- Zhou, H.; Li, H. Soil Disintegration Characteristics of Collapsed Walls and Influencing Factors in Southern China. Open Geosci. 2018, 10, 797–806. [Google Scholar] [CrossRef]

- Qi, Y.; Guan, Y.; Wang, L.; Jiang, P.; Zhang, G. The Influence of Soil Disintegration in Water on SlopeInstability and Failure. Adv. Civ. Eng. 2020, 2020, 8898240. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, A.; Liu, G. Laboratory investigation of disintegration characteristics of purple mudstone under different hydrothermal conditions. J. Mt. Sci. 2012, 9, 127–136. [Google Scholar] [CrossRef]

- Luo, X.; Gao, H.; He, P.; Liu, W. Experimental investigation of dry density, initial moisture content, and temperature for granite residual soil disintegration. Arab. J. Geosci. 2021, 14, 1060. [Google Scholar] [CrossRef]

- Li, C.; Kong, L.; Shu, R.; An, R.; Zhang, X. Disintegration characteristics in granite residual soil and their relationship with the collapsing gully in South China. Open Geosci. 2020, 12, 1116–1126. [Google Scholar] [CrossRef]

- Wang, N.Q.; Wang, Q.T.; Xue, Q.; Liu, X.L. Experimental study of static disintegration on unsaturated soil. Appl. Mech. Mater. 2014, 580–583, 68–72. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, P.; Lan, Z. Experimental study on disintegration behavior of granite residual soil. In Advances in Transportation Geotechnics and Materials for Sustainable Infrastructure; ASCE: Reston, VA, USA, 2014; pp. 98–104. [Google Scholar] [CrossRef]

- Li, X.-A.; Wang, L.; Yan, Y.-L.; Hong, B.; Li, L.-C. Experimental study on the disintegration of loess in the Loess Plateau of China. Bull. Eng. Geol. Environ. 2018, 78, 4907–4918. [Google Scholar] [CrossRef]

- Ze, Z.; Vadim, P.; Svetlana, N.; Zhongqiong, Z.; Junjie, W. Disintegration characteristics of a cryolithogenic clay loam with different water content: Moscow covering loam (prQIII), case study. Eng. Geol. 2019, 258, 105159. [Google Scholar] [CrossRef]

- Zhang, X.W.; Kong, L.W.; Li, J.J. Influence of dry and wet seasons on disintegration characteristics of basalt residual soil from the Leizhou Peninsula, China. Q. J. Eng. Geol. Hydrogeol. 2018, 51, 450–460. [Google Scholar] [CrossRef]

- Tsai, T.-L.; Jang, W.-S. Deformation effects of porosity variation on soil consolidation caused by groundwater table decline. Environ. Earth Sci. 2014, 72, 829–838. [Google Scholar] [CrossRef]

- Kwon, Y. Geotechnical hybrid simulation to investigate the effects of the hydraulic conductivity on one-dimensional consolidation settlement. Mar. Georesour. Geotec. 2016, 34, 219–233. [Google Scholar] [CrossRef]

- Liao, H.; Ji, J.; Zeng, J. Stability analysis of soil slopes considering saturated-unsaturated seepage action. Geotech Nical Eng. 2008, 29, 3229–3234. (In Chinese) [Google Scholar] [CrossRef]

- Tan, X.; Xue, W.; Sara, K. Seepage analysis of earth dams considering spatial variability of hydraulic parameters. Eng. Geol. 2017, 228, 260–269. [Google Scholar] [CrossRef]

- Cai, G.; Zhou, A.; Sheng, D. Permeability function for unsaturated soils with different initial densities. Can. Geotech. J. 2014, 51, 1456–1467. [Google Scholar] [CrossRef]

- Ma, Y.; Chen, W.; Bi, J.; Guo, G.; Jiao, G. Guide Effect of dry density on the coefficient of permeability of loess. J. Geotech. Eng. 2018, 40, 165–170. (In Chinese) [Google Scholar]

- Xu, P.; Zhang, Q.; Hui, Q.; Qu, W.; Li, M. Microstructure and permeability evolution of remolded loess with different dry densities under saturated seepage. Eng. Geol. 2021, 282, 105875. [Google Scholar] [CrossRef]

- Xia, Z.; Zhang, L.; Niu, P.; Liang, Y.; Hu, W.; Xu, W. Effect of dry density initial moisture content slope on disintegration characteristics of purple soils. Chin. Soil. Water Conserve. Sci. 2017, 15, 121–127. (In Chinese) [Google Scholar] [CrossRef]

- Gao, C.; Du, G.; Zhuang, Z.; Zeng, B.; Chen, X.; Cheng, F. Disintegration characteristics of collapsible loess after vibration compaction. Proc. Inst. Civ. Eng. Geotech. Eng. 2021, 176, 86–98. [Google Scholar] [CrossRef]

- Li, X.; Huang, R.; Peng, J. Experimental study on the disintegration of loess. J. Rock. Mech. Eng. 2009, 28, 3207–3213. (In Chinese) [Google Scholar] [CrossRef]

- Wang, J.; Gu, T.; Zhang, M.; Xu, Y.; Kong, J. Experimental study of loess disintegration characteristics. Earth Surf. Process. Landf. 2019, 44, 1317–1329. [Google Scholar] [CrossRef]

- Gao, Y.; Qian, H.; Yang, J.; Feng, J.; Huo, J. Indoor experimental study on the permeability of remodeled Malan loess. South North Water Divers. Water Sci. Technol. 2016, 14, 130–136. (In Chinese) [Google Scholar] [CrossRef]

- Gouy, M. Sur la constitution de la charge électrique à la surface d’un électrolyte. J. Phys. Theor. Appl. 1910, 9, 457–468. [Google Scholar] [CrossRef]

- Chapman, D.L. A contribution to the theory of electrocapillarity. Philos. Mag. 1913, 25, 475–481. [Google Scholar] [CrossRef]

| Specific Gravity Gs | Maximum Dry Density | Optimum Water Content | Liquid Limit wL | Plastic Limit wp | Plasticity Index Ip |

|---|---|---|---|---|---|

| 2.72 | 1.68g/cm3 | 19.86% | 39.17% | 19.48% | 19.69 |

| Experiment No. | Water Content (%) | Dry Density (g/cm3) |

|---|---|---|

| 1–3 | 5 | 1.4, 1.5, 1.6 |

| 4–6 | 10 | |

| 7–9 | 15 | |

| 10–12 | 20 | |

| 13–15 | 25 | |

| 16–18 | 30 |

| Permeability Coefficient Indicator | Dry Density (g/cm3) | |||||||

|---|---|---|---|---|---|---|---|---|

| 1.25 | 1.3 | 1.35 | 1.4 | 1.45 | 1.5 | 1.55 | 1.6 | |

| (cm/s) | 8.51 × 10−5 | 5.55 × 10−5 | 3.15 × 10−5 | 1.26 × 10−5 | 9.17 × 10−6 | 5.16 × 10−6 | 2.52 × 10−6 | 4.41 × 10−7 |

| (cm/s) | 1.79 × 10−5 | 1.17 × 10−5 | 1.81 × 10−5 | 9.34 × 10−6 | 7.71 × 10−6 | 4.72 × 10−6 | 2.37 × 10−6 | 4.17 × 10−7 |

| (cm/s) | −6.72 × 10−5 | −4.38 × 10−5 | −1.34 × 10−5 | −3.26 × 10−6 | −1.45 × 10−6 | −4.40 × 10−7 | −1.50 × 10−7 | −2.40 × 10−8 |

| (cm/s) | −78.97% | −78.92% | −42.54% | −25.87% | −15.83% | −8.53% | −5.95% | −5.44% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Feng, D. Study on Disintegration and Infiltration Characteristics of Nanjing Jiangxinzhou Embankment Soil. Appl. Sci. 2023, 13, 9819. https://doi.org/10.3390/app13179819

Zhang K, Feng D. Study on Disintegration and Infiltration Characteristics of Nanjing Jiangxinzhou Embankment Soil. Applied Sciences. 2023; 13(17):9819. https://doi.org/10.3390/app13179819

Chicago/Turabian StyleZhang, Kun, and Di Feng. 2023. "Study on Disintegration and Infiltration Characteristics of Nanjing Jiangxinzhou Embankment Soil" Applied Sciences 13, no. 17: 9819. https://doi.org/10.3390/app13179819

APA StyleZhang, K., & Feng, D. (2023). Study on Disintegration and Infiltration Characteristics of Nanjing Jiangxinzhou Embankment Soil. Applied Sciences, 13(17), 9819. https://doi.org/10.3390/app13179819