Active Flow Control of a Supercritical Airfoil and Flap with Sweeping Jets

Abstract

Featured Application

Abstract

1. Introduction

2. Experimental Set-Up

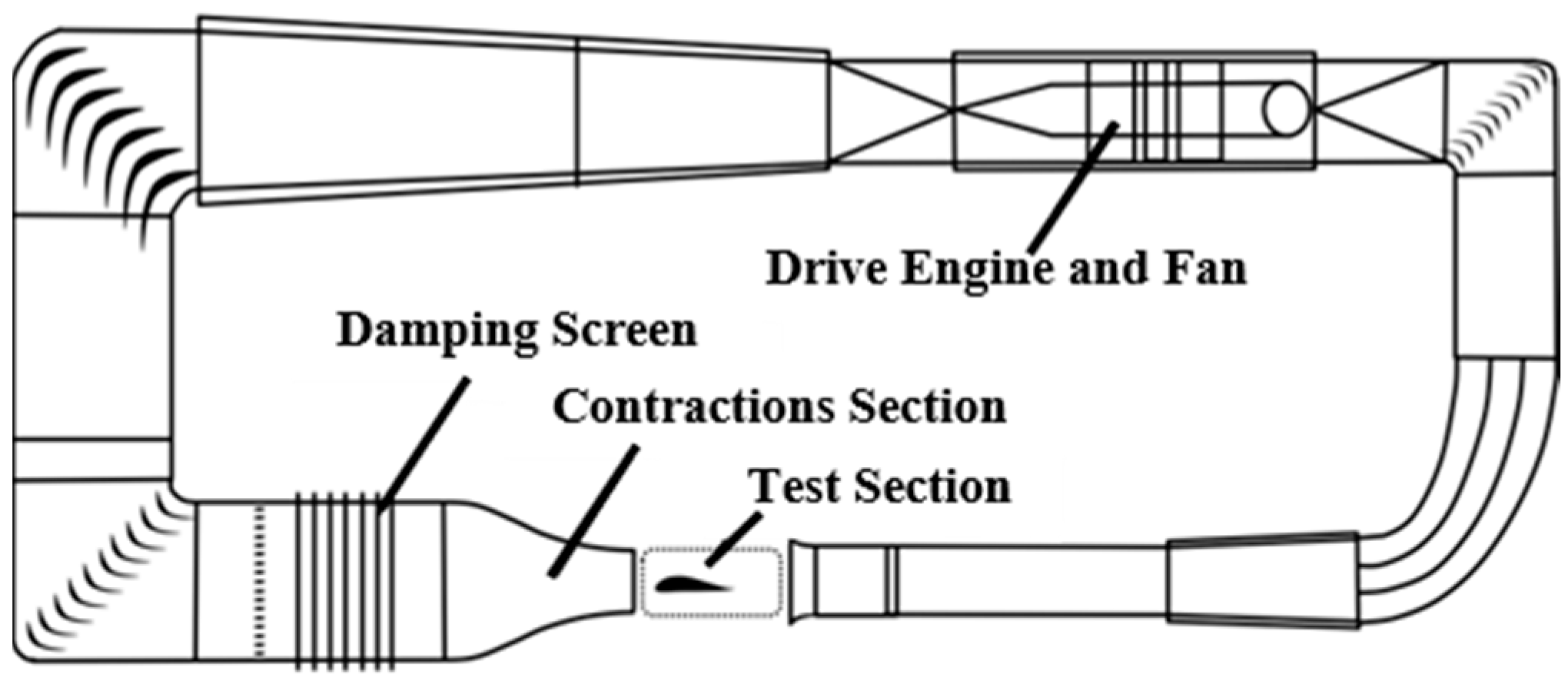

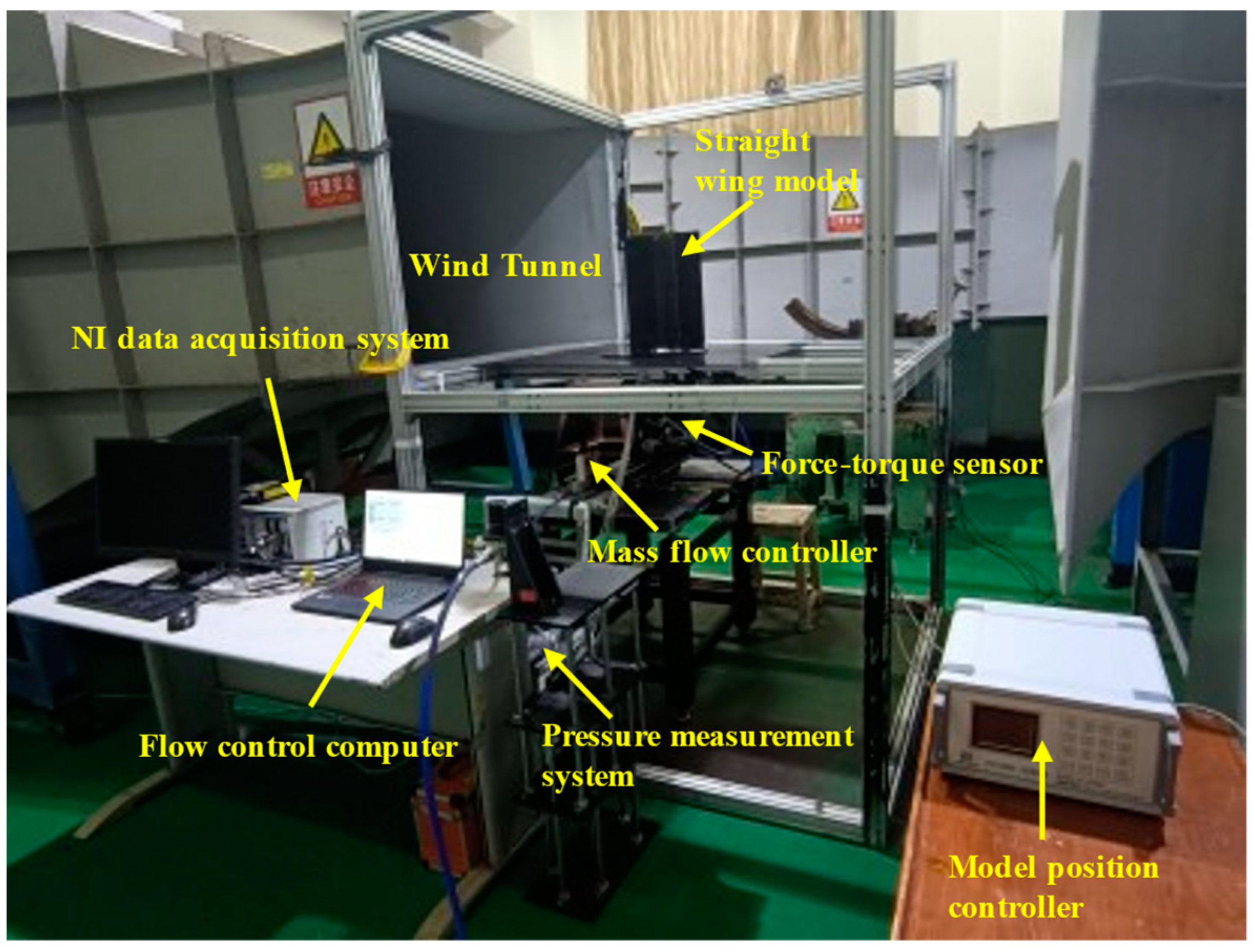

2.1. Testing Facilities

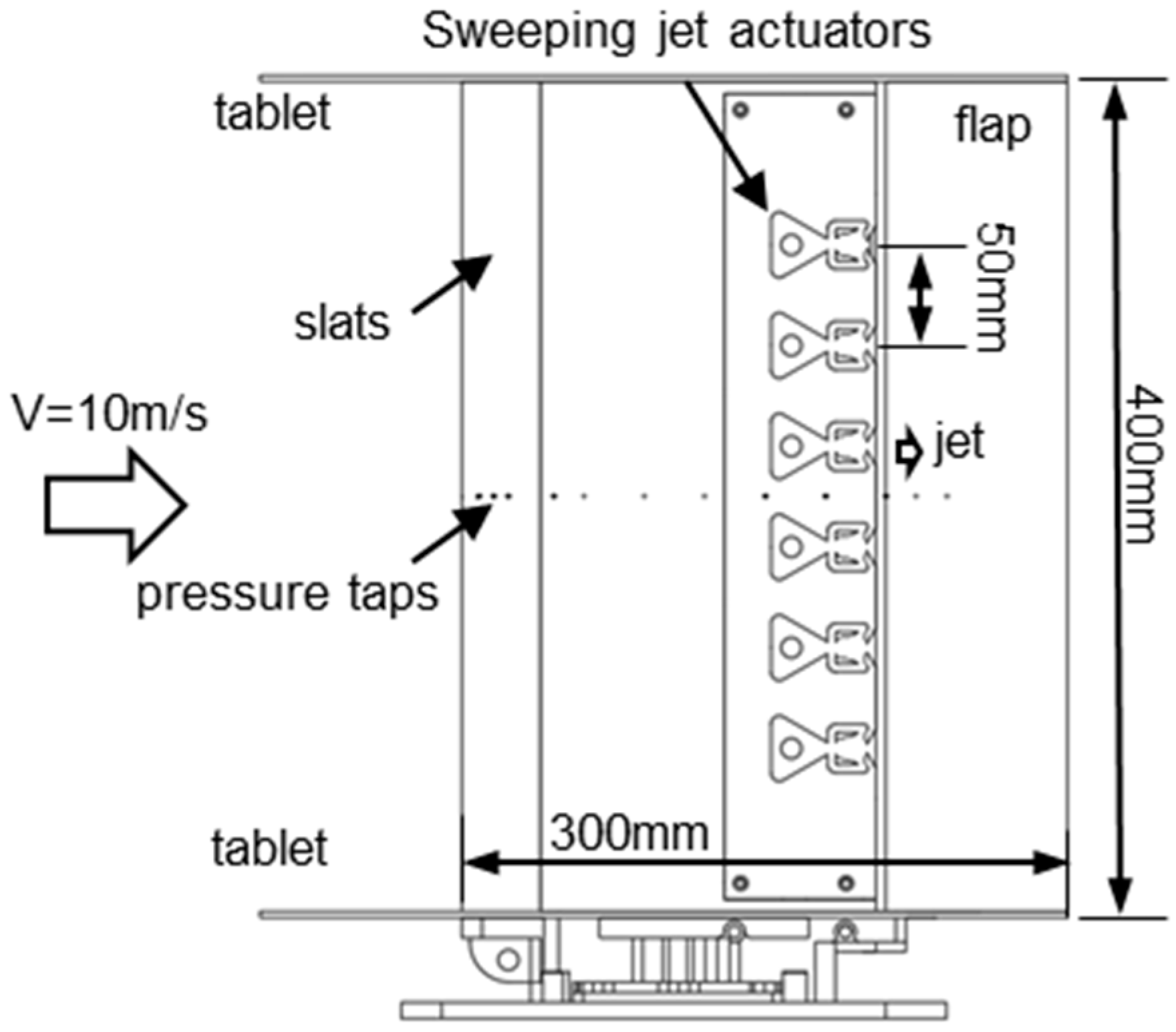

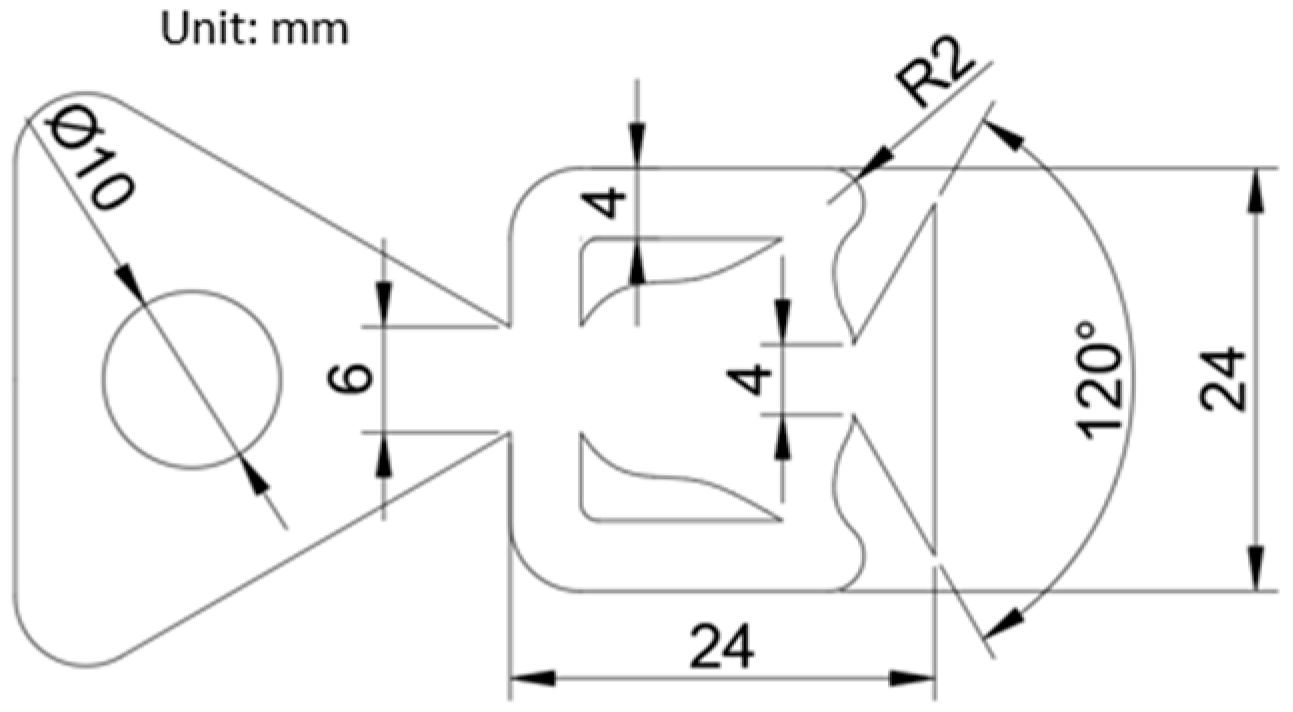

2.2. Models

2.3. Equipment and Measurement Instrumentation

3. Results and Discussion

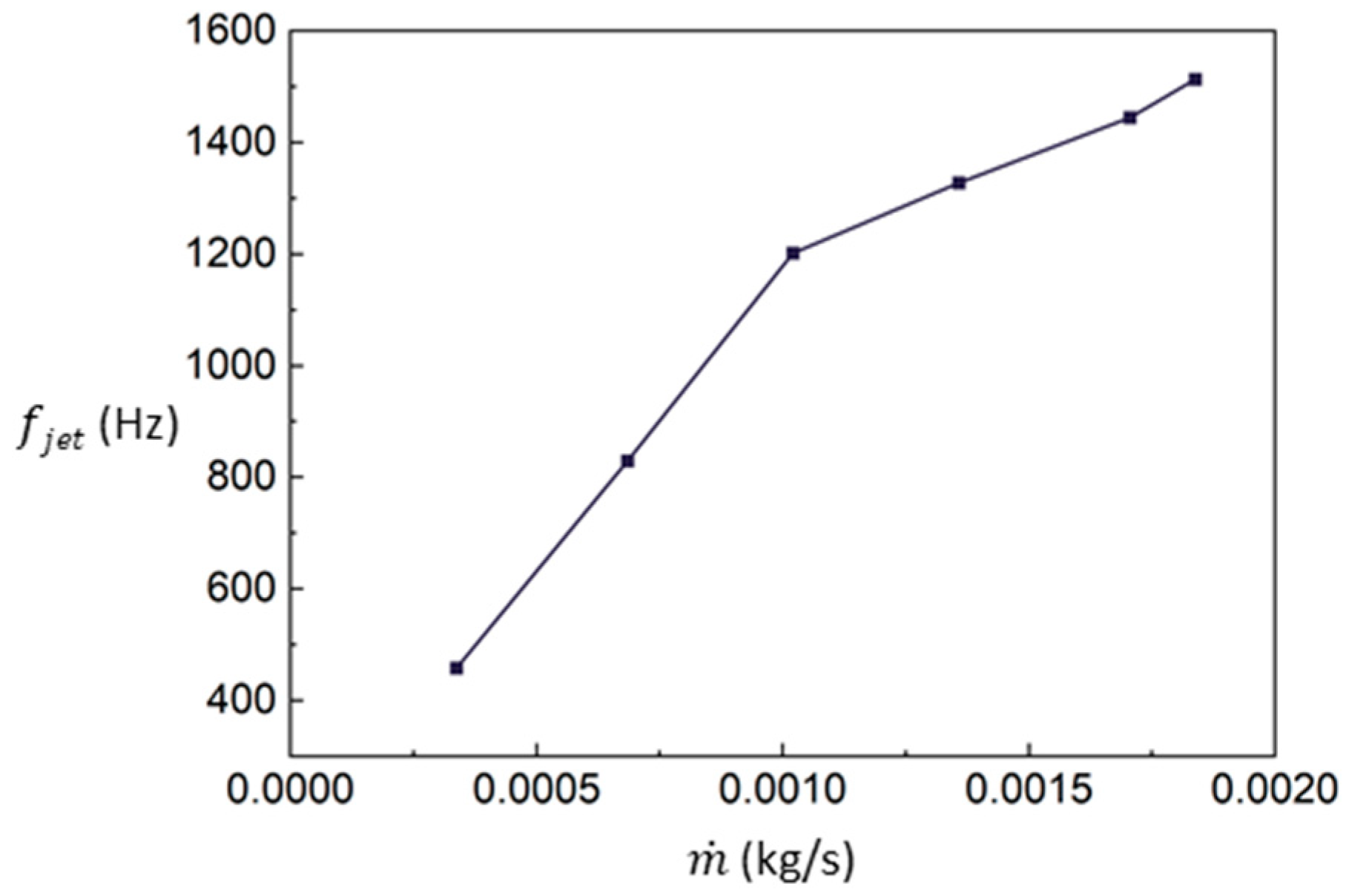

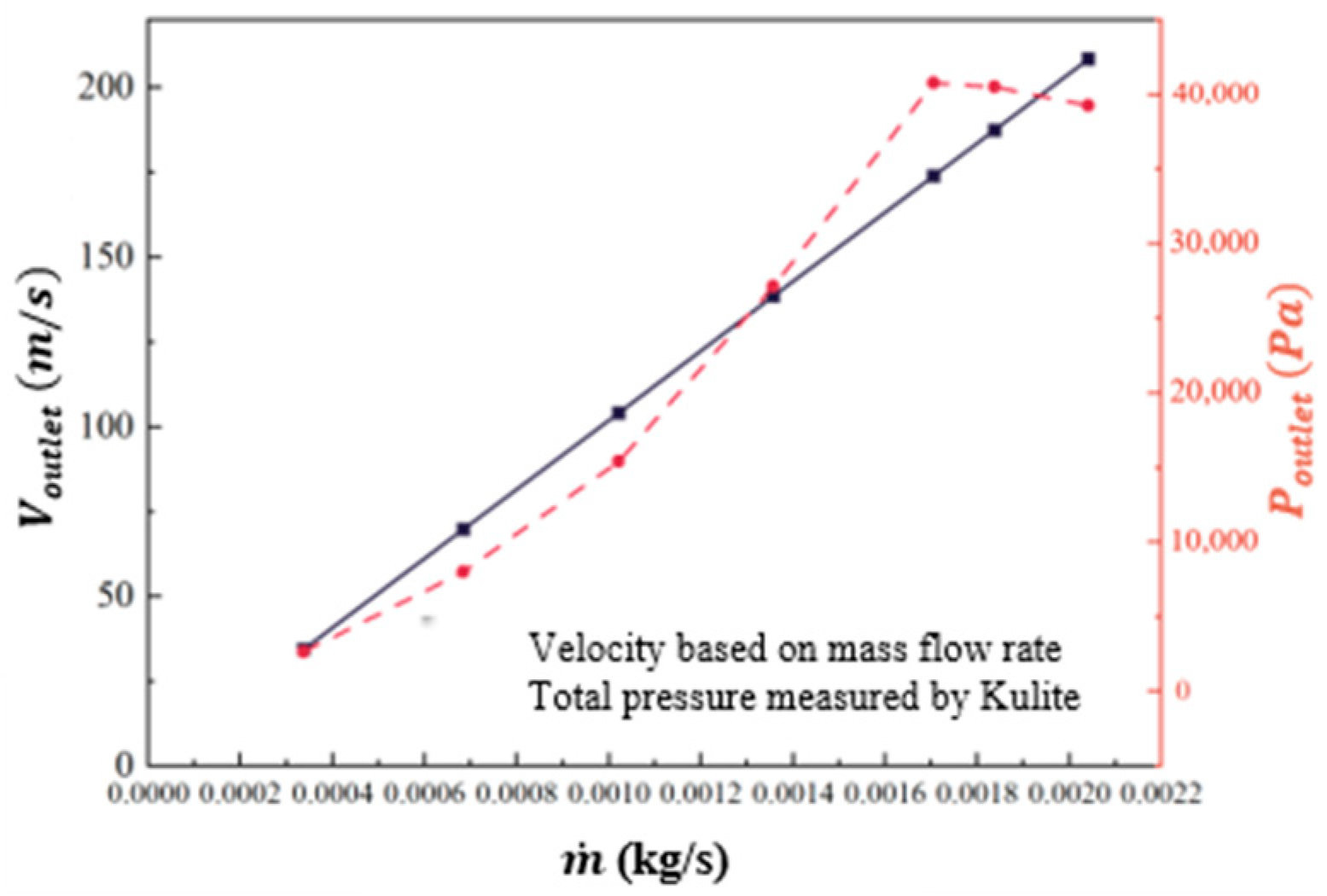

3.1. Basic Characteristics of the Sweeping Jet Actuator

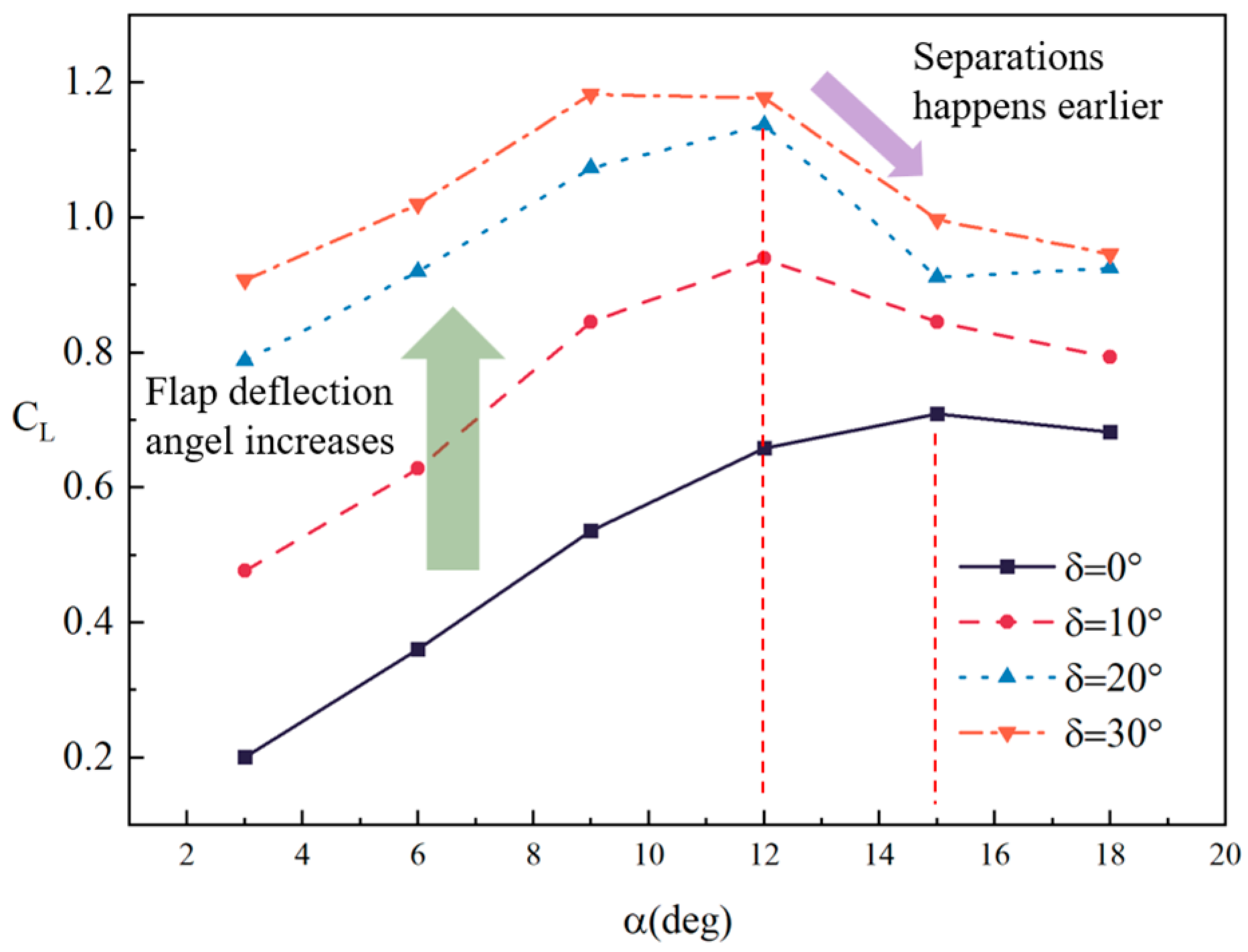

3.2. Aerodynamic Characteristics of the NASA SC(2)-0410 2D Straight-Wing Model without Flow Control

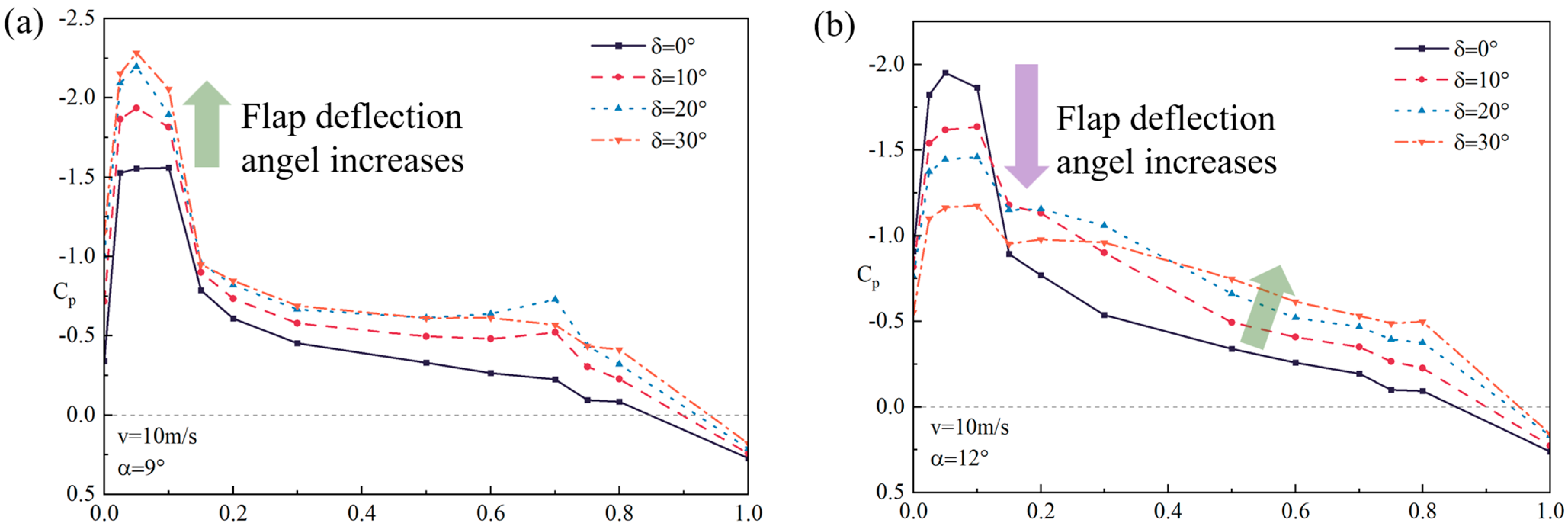

3.3. Analysis of Aerodynamic Characteristics of the Wing Model with Sweeping Jet Control

4. Conclusions

- A large angular deflection of a simple flap causes flow separation on the upper surface of the wing and flap, which limits further improvement in the wing lift coefficient using only flap deflection during the takeoff stage.

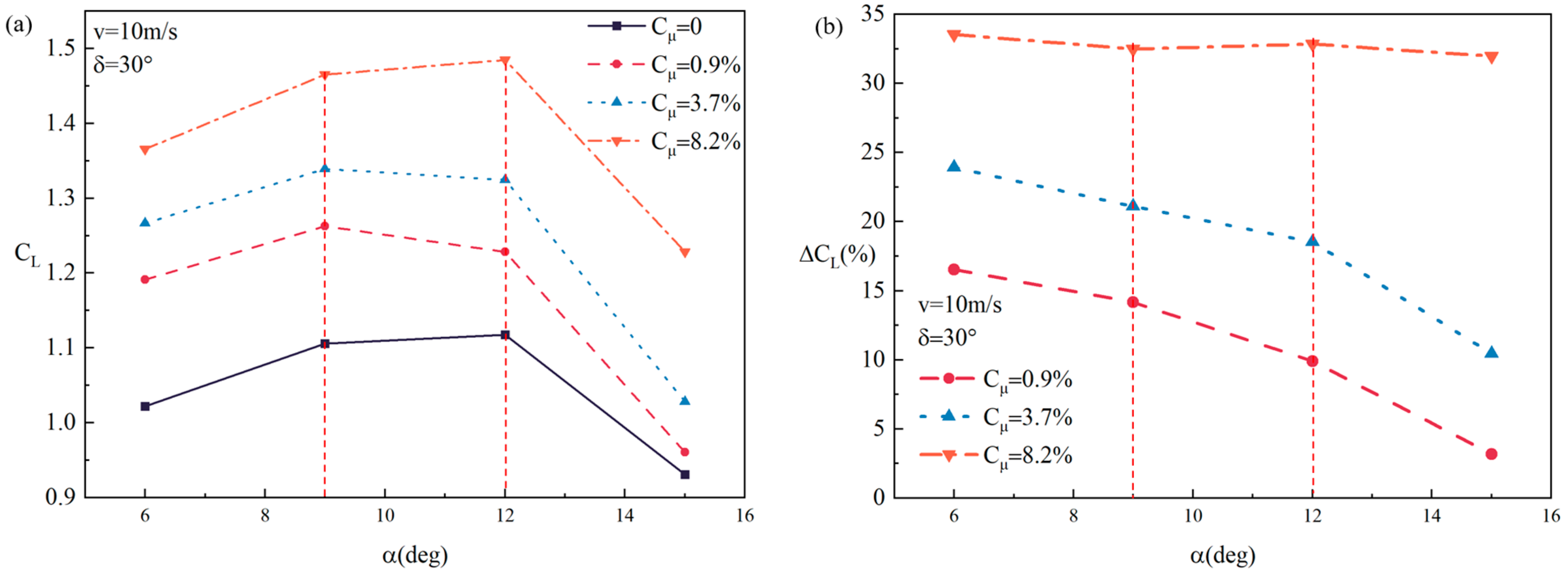

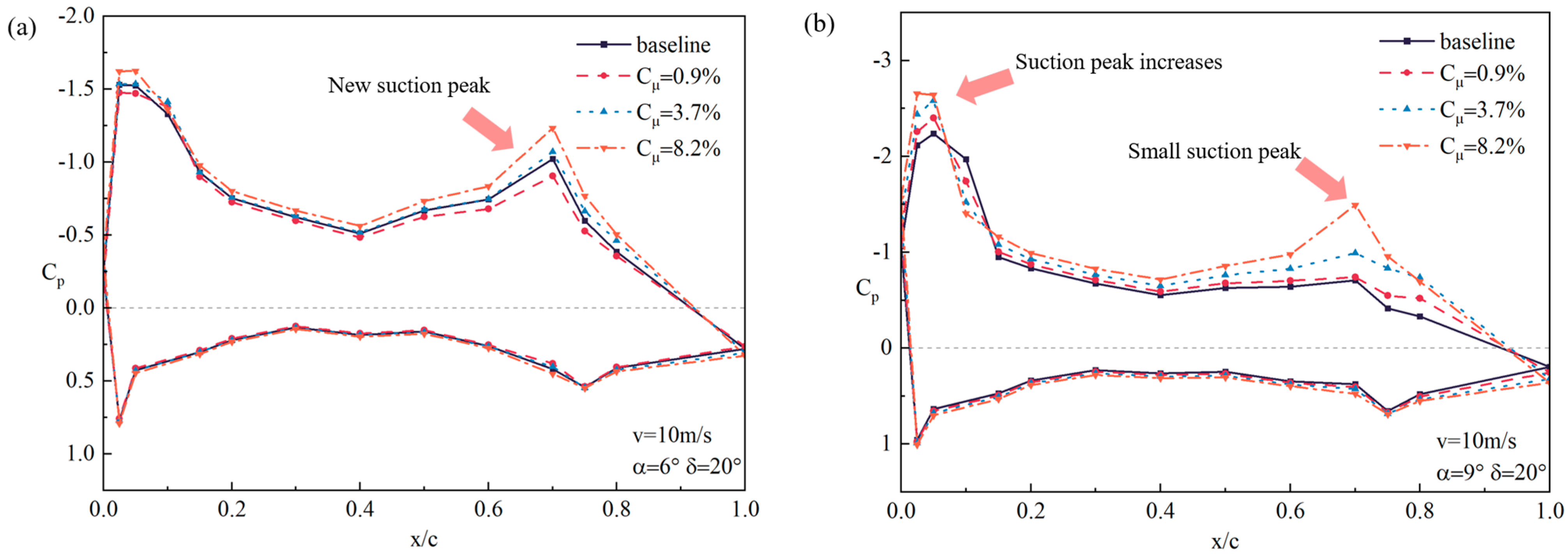

- The lifting effect of the sweeping jet flow control is enhanced with the increase in the jet momentum coefficient of the sweeping jet. In this study, the flow control based on the sweeping jet actuator can generate a maximum increase of approximately 33% in the lift coefficient of the wing model with Cμ = 8.2%.

- The use of a sweeping jet at the front of the flap can effectively improve the lift coefficient of the whole wing, which comes from the extra lift generated by the jet at the flap and from the greater negative pressure near the leading edge on the upper wing surface owing to the induced flow caused by the sweeping jet.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| The area of the section at the throat of the actuator. | |

| c | Wing chord length. |

| CL | The lift coefficient of the model. |

| Cp | The surface pressure coefficient of the model. |

| Cμ | The momentum coefficient of the sweeping jet. |

| d | Spanwise spacing distance of the actuators. |

| fjet | The frequency of the sweeping jet. |

| l | Wing span. |

| L | The lift of the wing model. |

| The mass flow rate of the sweeping jet. | |

| The static pressure of the incoming flow. | |

| The dynamic pressure of the incoming flow. | |

| Re | Reynold number. |

| S | The reference area of the wing model. |

| V | The velocity of incoming flow. |

| Vjet | The velocity of the jet at the throat of the actuator. |

| α | Angle of attack. |

| δ | Flap deflection angle. |

| The density of the incoming flow. | |

| The density of airflow at the throat of the actuator. |

References

- Batikh, A.; Baldas, L.; Colin, S. Application of active flow control on aircrafts—State of the art. In Proceedings of the International Workshop on Aircraft System Technologies, Hamburg, Germany, 21–22 February 2017. [Google Scholar]

- Van Dam, C.P. The aerodynamic design of multi-element high-lift systems for transport airplanes. Prog. Aerosp. Sci. 2002, 38, 101–144. [Google Scholar] [CrossRef]

- Loftin, K.L. Quest for Performance: The Evolution of Modern Aircraft; NASA-SP-468; Scientific and Technical Information Branch, National Aeronautics and Space Administration: Newport News, VA, USA, 1985. [Google Scholar]

- McLean, J.; Crouch, J.; Stoner, R.; Sakurai, S.; Seidel, G.E.; Feifel, W.M.; Rush, H.M. Study of the Application of Separation Control by Unsteady Excitation to Civil Transport Aircraft; NASA/CR-1999-209338; National Aeronautics and Space Administration: Hampton, VA, USA, 1999. [Google Scholar]

- Kiedaisch, J.; Nagib, H.; Demanett, B. Active flow control applied to high-lift airfoils utilizing simple flaps. In Proceedings of the 3rd AIAA Flow Control Conference, San Francisco, CA, USA, 5–8 June 2006. [Google Scholar]

- Pack Melton, L.G.; Koklu, M. Active flow control using sweeping jet actuators on a semi-span wing model. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016. [Google Scholar] [CrossRef]

- Cao, X.; Dong, H.; Gu, Y.; Cheng, K.; Zhang, F. Experimental Study of Vertical Tail Model Flow Control Based on Oscillating Jet. Appl. Sci. 2023, 13, 786. [Google Scholar] [CrossRef]

- Raman, G.; Raghu, S. Cavity resonance suppression using miniature fluidic oscillators. AIAA J. 2004, 42, 2608–2612. [Google Scholar] [CrossRef]

- DeSalvo, M.; Whalen, E.; Glezer, A. High-Lift Performance Enhancement Using Active Flow Control. AIAA J. 2020, 58, 4228–4242. [Google Scholar] [CrossRef]

- Tomac, M.N.; Hossain, M.A. Flow and Frequency Characterization of the Synchronized Stacked Sweeping Jets. AIAA J. 2021, 59, 118–130. [Google Scholar] [CrossRef]

- Serrar, A.; Khlifi, M.; Kourta, A. Characterisation and comparison of unsteady actuators: A fluidic oscillator and a sweeping jet. Int. J. Numer. Methods Heat Fluid Flow 2022, 32, 1237–1254. [Google Scholar] [CrossRef]

- Mohammadshahi, S.; Samsam-Khayani, H.; Deng, Z. Experimental investigation of flow dynamics of oscillating jet emitted in confined and non-confined backward-facing step geometries. Eur. J. Mech.-B/Fluids 2021, 88, 89–102. [Google Scholar] [CrossRef]

- Song, J.; Wang, S.; Wen, X.; Li, Z.; Lu, H.; Kong, X.; Liu, Y. Active flow control in an S-shaped duct at Mach 0.4 using sweeping jet actuators. Exp. Therm. Fluid Sci. 2022, 138, 110699. [Google Scholar] [CrossRef]

- Alexander, M.G.; Harris, F.K.; Spoor, M.; Boyland, S.R.; Farrell, T.; Raines, D. Active Flow Control (AFC) and Insect Accretion and Mitigation (IAM) system design and integration on the Boeing 757 ecoDemonstrator. In Proceedings of the 16th AIAA Aviation Technology, Integration, and Operations Conference, Washington, DC, USA, 13–17 June 2016. [Google Scholar] [CrossRef][Green Version]

- Greenblatt, D.; Wygnanski, I. The control of flow separation by periodic excitation. Prog. Aerosp. Sci. 2000, 36, 487–545. [Google Scholar] [CrossRef]

- Hartwich, P.M.; Camacho, P.; El-Gohary, K.; Gonzales, A.B.; Lawson, E.L.; Shmilovich, A. System-level trade studies for transonic transports with Active Flow Control (AFC) enhanced high-lift systems. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar]

- Shmilovich, A.; Yadlin, Y.; Dickey, E.D.; Hartwich, P.M.; Khodadoust, A. Development of an active flow control technique for an airplane high-lift configuration. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar]

- Jones, G.S.; Milholen, W.E.; Chan, D.T.; Goodliff, S.L. A sweeping jet application on a high Reynolds number semi-span supercritical wing configuration. In Proceedings of the 35th AIAA Applied Aerodynamics Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar]

- Melton, L.P.; Koklu, M.; Andino, M.; Lin, J.C. Active flow control via discrete sweeping and steady jets on a simple-hinged flap. AIAA J. 2018, 56, 2961–2973. [Google Scholar] [CrossRef]

- Vatsa, V.N.; Duda, B.M.; Lin, J.C.; Pack Melton, L.G.; O’Connell, M. Numerical simulation of a simplified high-lift CRM configuration embedded with fluidic actuators. In Proceedings of the 2018 Applied Aerodynamics Conference, Atlanta, GA, USA, 25–29 June 2018. [Google Scholar]

- Koklu, M.; Pack Melton, L.G.; Lin, J.C.; Hannon, J.; Andino, M.; Paschal, K.; Vatsa, V.N. Surface flow visualization of the high lift common research model. In Proceedings of the AIAA Aviation 2019 Forum, Dallas, TX, USA, 17–21 June 2019. [Google Scholar]

- Pack Melton, L.G.; Lin, J.C.; Hannon, J.; Koklu, M.; Andino, M.; Paschal, K.B. Sweeping jet flow control on the simplified high-lift version of the common research mode. In Proceedings of the AIAA Aviation 2019 Forum, Dallas, TX, USA, 17–21 June 2019. [Google Scholar]

- Vatsa, V.N.; Duda, B.M.; Lin, J.C.; Pack Melton, L.G.; Lockard, D.P.; O’Connell, M.; Hannon, J. Comparative study of active flow control strategies for lift enhancement of a simplified high-lift configuration. In Proceedings of the AIAA Aviation 2019 Forum, Dallas, TX, USA, 17–21 June 2019. [Google Scholar]

- Lin, J.C.; Pack Melton, L.G.; Hannon, J.; Andino, M.Y.; Koklu, M.; Paschal, K.C.; Vatsa, V.N. Wind tunnel testing of High Efficiency Low Power (HELP) actuation for active flow control. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar]

- Lin, J.C.; Melton, L.P.; Hannon, J.A.; Andino, M.Y.; Koklu, M.; Paschal, K.B.; Vatsa, V.N. Testing of high-lift common research model with integrated active flow control. J. Aircr. 2020, 57, 1121–1133. [Google Scholar] [CrossRef]

- Baghaei, M.; Bergada, J.M. Fluidic Oscillators, the Effect of Some Design Modifications. Appl. Sci. 2020, 10, 2105. [Google Scholar] [CrossRef]

- Samsam-Khayani, H.; Mohammadshahi, S.; Kim, K.C. Experimental Study on Physical Behavior of Fluidic Oscillator in a Confined Cavity with Sudden Expansion. Appl. Sci. 2020, 10, 8668. [Google Scholar] [CrossRef]

- Awate, V.G.; Ansell, P.J. Characterization of Inclined Oscillating Jet and Crossflow Interaction for Use in Active Flow Control. In Proceedings of the AIAA SciTech Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar] [CrossRef]

- Ostermann, F.; Woszidlo, R.; Nayeri, C.; Paschereit, C.O. Interaction Between a Crossflow and a Spatially Oscillating Jet at Various Angles. AIAA J. 2020, 58, 2450–2461. [Google Scholar] [CrossRef]

- Fromm, M.; Kim, J.; Seifert, A.; Kriegseis, J.; Grundmann, S. Flow Patterns of Self-Sustained Oscillations in Fluidic Diverters. AIAA J. 2022, 60, 4207–4214. [Google Scholar] [CrossRef]

- Koklu, M. The effects of sweeping jet actuator parameters on flow separation control. In Proceedings of the 45th AIAA Fluid Dynamics Conference, Dallas, TX, USA, 22–26 June 2015. [Google Scholar]

| Fx | Fy | Fz | Mx | My | Mz | |

|---|---|---|---|---|---|---|

| Range | 165 N | 165 N | 495 N | 15 N·m | 15 N·m | 15 N·m |

| Precision (FS) | 1.00% | 1.00% | 1.00% | 1.00% | 1.00% | 1.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, S.; Li, L.; Cheng, K.; Gu, Y.; Fang, R.; Wang, W. Active Flow Control of a Supercritical Airfoil and Flap with Sweeping Jets. Appl. Sci. 2023, 13, 10166. https://doi.org/10.3390/app131810166

Luo S, Li L, Cheng K, Gu Y, Fang R, Wang W. Active Flow Control of a Supercritical Airfoil and Flap with Sweeping Jets. Applied Sciences. 2023; 13(18):10166. https://doi.org/10.3390/app131810166

Chicago/Turabian StyleLuo, Shuai, Linkai Li, Keming Cheng, Yunsong Gu, Ruishan Fang, and Wanbo Wang. 2023. "Active Flow Control of a Supercritical Airfoil and Flap with Sweeping Jets" Applied Sciences 13, no. 18: 10166. https://doi.org/10.3390/app131810166

APA StyleLuo, S., Li, L., Cheng, K., Gu, Y., Fang, R., & Wang, W. (2023). Active Flow Control of a Supercritical Airfoil and Flap with Sweeping Jets. Applied Sciences, 13(18), 10166. https://doi.org/10.3390/app131810166