Abstract

In this study, the chassis design target setting for a high-performance car was performed using a virtual prototype to solve the problem of increasing complexity of vehicle development. To achieve efficient handling performance of Hyundai Avante N, a high-performance vehicle, the kinematic and compliance (K&C) characteristics of the chassis corresponding to the design target were set prior to the design process using virtual simulation, thereby facilitating the efficient and systematic development of the actual vehicle. In order to overcome the limitations of existing research and apply it to the actual development of mass-production vehicles, the following major tasks were performed. The first is setting quantitative factors that match the sensibility evaluation. The second is building a virtual model to ensure consistency in performance predictions. The third is optimizing the chassis characteristics to achieve the vehicle performance goal. When all optimization results were applied, the average of the performance items increased by 0.5 points and the standard deviation improved by 0.4 points compared to the existing Civic Type-R, which was the best. In the case of the final specification considering design constraints, the average of performance items increased by 0.1 point and the standard deviation improved by 0.5 point compared to the existing Civic Type-R. Therefore, the design target of the chassis systems that could achieve the vehicle handling performance goal could be established prior to the design. Using this virtual development, it is possible to eliminate the trial and error process that the first and second test cars needed. This could save more than 500,000 USD (per unit trim) of the first and second test vehicles.

1. Introduction

The complexity of vehicles and their development process has significantly increased owing to the increase in electronic control systems installed in vehicles, shortening of the product life cycle, diversification of markets, and the application of various power sources. In addition, the pressure to reduce costs has increased because of the need for resources for the development of eco-friendly and autonomous driving technologies and the increase in material costs for the application of related parts.

Chassis specifications have a considerable influence on the vehicle’s platform; therefore, it is necessary to consider the changes in chassis specifications in the early stages of development. This requires the chassis specification to be set in an appropriate direction before commencing the design process. In particular, if a goal for the design direction can be set in advance before the design, inefficiency owing to future design changes can be minimized. In the past, the chassis characteristics of vehicles with good chassis system-related vehicle performance were measured and set as a target, but this method is not suitable because of the following reasons.

- -

- To satisfy future development goals such as fuel efficiency, crashes, and cost, different power sources, specifications, and tires from competitors are considered.

- -

- When transitioning from a ‘Fast Follower’ to a ‘First Mover’, there cannot be a competitor to follow blindly.

- -

- The performance goals to be pursued are different because of the differences in the situations faced by different companies.

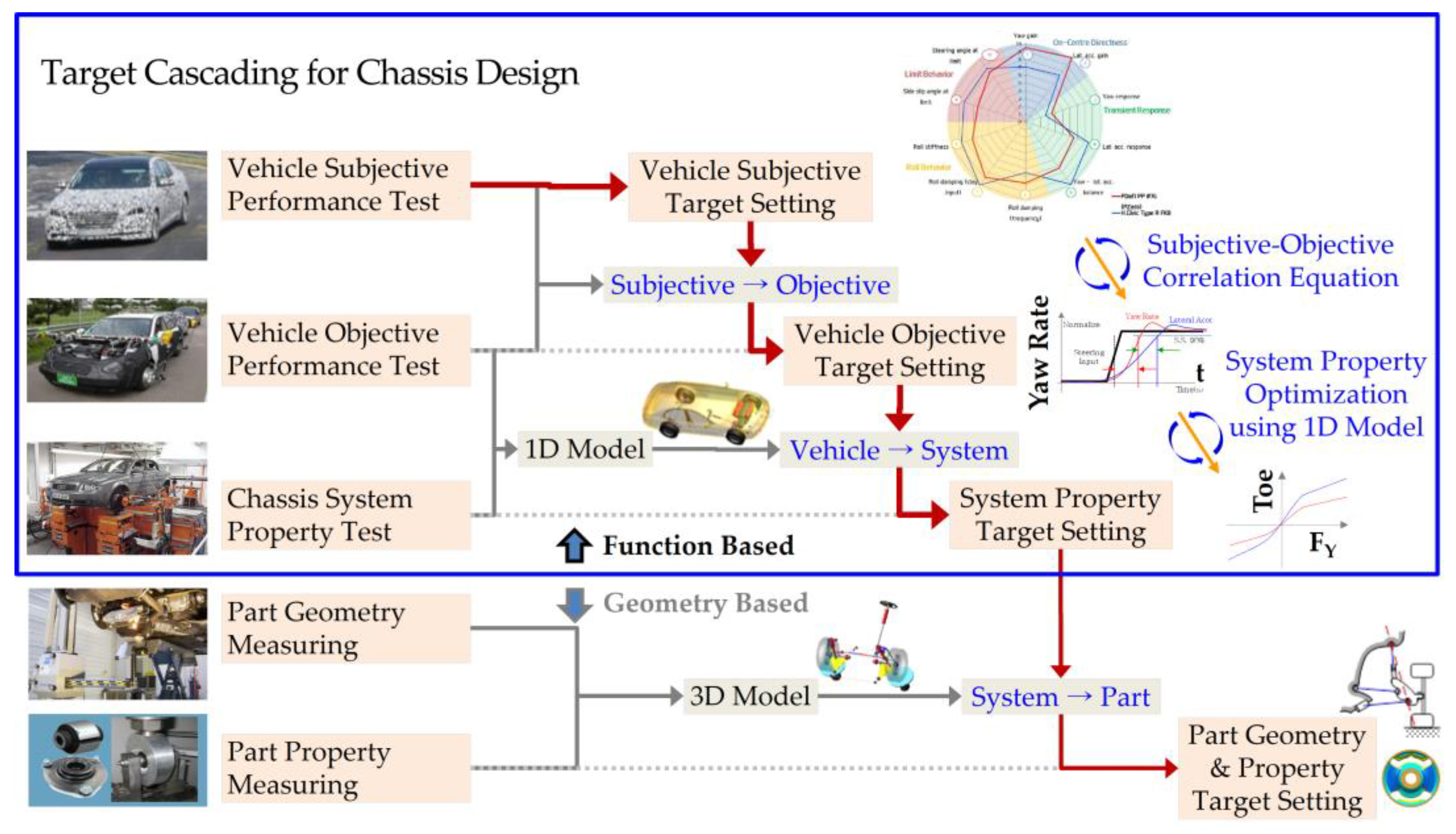

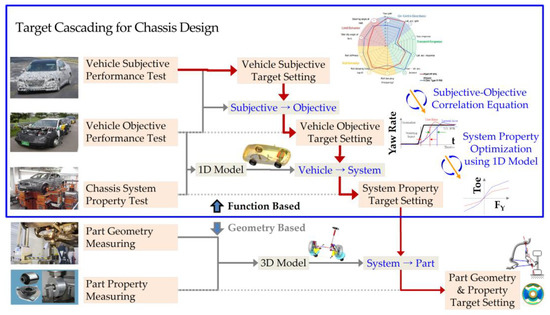

Ultimately, it is necessary to set the chassis system characteristics to achieve the desired vehicle handling performance based on the correlation between the vehicle’s handling performance and the chassis system characteristics. A simulation model can be used to check in advance whether the vehicle handling performance target can be achieved by changing the chassis-related characteristic values. However, as the multi-body-based model (ADAMS, etc.), which has been widely used in chassis system simulation, requires design data such as hard point and bush characteristics, these characteristics should be verified after the design is completed. However, after the design is completed, the process for manufacturing and evaluating the actual vehicle would be well established, making it difficult to effectively validate the proposal by design verification simulation. Therefore, in this study, the design goals are set in advance by using a function-based model (1 Dimensional model) that can use the kinematic and compliance (K&C) characteristics corresponding to the design goals as model input factors before designing (Figure 1).

Figure 1.

Optimal setting of model-based design factors before design.

Some previous studies have attempted to perform sensitivity analysis to determine the key design factors in the chassis design target establishment stage and to perform optimization based on this from various perspectives. A. Afkar et al. (2012) optimized geometric parameters of suspension systems using genetic algorithms (GAs) to improve the ride comfort, handling, and stability of vehicles. By optimizing the geometric parameters of the suspension system, it is observed that the vehicle can follow the target path with minimum deviation, along with maintaining stability and improving ride comfort conditions [1]. That is, since a model consisting of hard points, which are component-related characteristics that can be given after chassis platform design, is used, it can be reviewed only for the purpose of improving the existing design. Therefore, in order to set the design goal before chassis platform design, a model composed of K&C characteristics, which are characteristics related to the suspension system, is required. Sh. Lajqi et al. (2012) replaced the suspension model with a simplified mathematical model with adequate accuracy to effectively optimize the stiffness and damping coefficient of the passenger car’s suspension [2]. However, parts-related characteristics such as spring stiffness and shock absorber damping are tuning factors and can be tuned even after the test vehicle is released. J. Tey et al. (2014) proposed an efficient approach to identify the unknown parameters through optimization based on experimental results, where the covariance matrix adaptation–evolutionary strategy (CMA-es) is utilized to improve the simulation and experimental results against the kinematic and compliance tests. Once accurate representation of the vehicle suspension model is achieved, further analysis, such as ride and handling performances, can be implemented for further optimization [3]. However, since it used a model that can be made only by testing a real vehicle, it is difficult to use it for developing a new platform where a test vehicle does not exist. Park et al. (2015) analyzed the sensitivity of chassis design factors to cross winds using simulation and driving simulator equipment [4]. That is, since a model consisting of hard points and joint stiffness, which are component-related characteristics that can be given after chassis platform design, is used, it can be reviewed only for the purpose of improving the existing design. Therefore, in order to set the design goal before chassis platform design, a model composed of K&C characteristics, which are characteristics related to the suspension system, is required. J. Tey et al. (2016) proposed a new method to simplify and reduce the conventional approach in vehicle suspension optimization for ride comfort, and the handling performance design objectives are formulated into a multi-objective optimization problem together with the suspension packaging dimensions as the design constraints. These objectives are minimized using a multi-objective optimization workflow, which involves a sampling technique and a regularity-model-based multi-objective estimation of the distribution algorithm to solve greater than 100-dimensional spaces of the design parameters by the optimization process [5]. However, optimization to achieve the goals required for vehicle development is difficult because it is not a model capable of predicting an emotionally developed ride and handling performance. Karimi Eskandary et al. (2016) optimized the air suspension system to independently control the stiffness and ride height [6]. The stiffness and ride height of the air spring are tuning parameters of the controller, and it is a general vehicle development process to tune mainly after the test vehicle is released. On the other hand, in order to set the design goal before designing the chassis platform, a model consisting of system-level parameters that reflect the geometry characteristics of the suspension system, such as K&C characteristics, is required. Y. Liu et al. (2018) established a geometric design and a virtual prototype model of the suspension system. Through Adams simulation analysis, the hardness of the suspension frame was used as a variable, and changes in a series of positioning parameters such as the toe value, camber angle, and roll rigidity of the suspension were compared and refined. This provided certain references for actual vehicle manufacturing [7]. Because a model consisting of characteristics that can be given after designing the platform, it can be reviewed only for the purpose of improving the existing design, and it is not suitable for the stage of setting goals for the chassis design. Choi et al. (2018) proposed an optimal design to determine the optimal spring setting position to minimize the side load acting on the damper of the McPherson strut suspension to improve ride comfort. Flexible multi-body dynamics (FMBD) was used for sophisticated simulation, and a sequential approximate optimal design was performed by repeating sequential sampling and meta-modeling to increase the optimization efficiency [8]. As a result, it is limited to improving the existing design because it uses a model consisting of hard points and joint stiffness, which are part-level factors that can be given after designing the platform. Therefore, in order to set design goals before platform design, a model composed of K&C characteristics, which are suspension system level factors, is required. Qi Gao et al. (2019) constructed a parameterized vehicle dynamic model using the vehicle’s measurement data and performed sensitivity analysis and optimization for McPherson strut suspension to improve seven normal/abnormal handling and stability performance indicators. A generalized multi-dimension adaptive learning particle swarm optimization technique was applied to increase the convergence speed of optimization [9]. Since it also used a model that can be made only by testing a real vehicle, it is difficult to use it for developing a new platform where a test vehicle does not exist. On the other hand, G. Papaioannou et al. (2021) conducted a study on the optimization of parameters for passenger comfort and improved vehicle handling while minimizing tire wear. In addition to finding the optimal parameters, optimization is also used as a tool to identify and emphasize the potential balance between the objectives and the various design parameters [10]. However, it is difficult to optimize to achieve the objectives required in vehicle development because it is not a model that can predict ride and handling performance that is actually being developed emotionally. In order to improve the overall performance of the chassis system, T. Cui et al. (2020) proposed a hierarchical dynamic constraint analytical target cascading (DCATC) optimization method for the integrated system. Based on the dynamic model of the steering and suspension-integrated system, the evaluation indexes of the integrated system were proposed and deduced, which involved steering energy consumption, steering feel, steering sensitivity, ride comfort, and steering stability. Then, the optimization mathematical model of the integrated system was established. The simulation results showed that the proposed DCATC can improve the overall performance of the integrated system [11]. It is also difficult to optimize to achieve a goal required during vehicle development, as it is not a model capable of predicting ride comfort and steering performance, which are actually developed on an emotional basis. Yoon et al. (2021) proposed an optimal design to improve the ride comfort of a commercial vehicle. As the efficiency of the cabin suspension model needs to be increased to handle numerous design variables, a 3-Degrees of freedom (DOF) tabular-based cabin equivalent model with bound, roll, and pitch modes was developed [12]. However, component-level factors such as the stiffness of the spring mounted in the cabin and the damping of the shock absorber are tuning factors and can be tuned even after the test vehicle is released. On the other hand, in order to set design goals prior to platform design, a model composed of system-level factors that reflect suspension geometry characteristics, such as K&C characteristics, is required. Chenyu Wang et al. (2021) proposed an integrated multi-field optimal design with a collaborative optimization and approximation technique to improve ride comfort, reducing the fluctuating range of the front wheel and improving the steering experience, using a mathematical model of a 7-degrees of freedom electric power steering (EPS) system and a simulation model of the front wheel suspension [13]. However, since it is not a model capable of predicting ride comfort and steering performance, which are actually developed on an emotional basis, it is difficult to optimize to achieve the goal required during vehicle development.

As can be seen from the results of previous research, vehicle manufacturers do not rely solely on simulation to establish a chassis platform design goal to satisfy ride and handling performances. For this reason, most vehicle manufacturers perform ride and handling performance tests by manufacturing test vehicles with chassis parts designed using various methods. In order to improve the performance lacking in the test results, a test vehicle is manufactured with redesigned chassis parts, and a ride and handling performance test is performed. Vehicle manufacturers repeat these processes (design, manufacture, and test) at least three times in order to achieve the performance target of a vehicle to which a new chassis is applied. As the number of repetitions of this process increases, the cost of manufacturing a test vehicle and the number of work hours required for development increase, but a test vehicle is a prototype made in small quantities. As for the manufacturing cost, the first test vehicle costs more than about $300,000, the second test vehicle costs more than about $200,000, and the third test vehicle costs more than about $100,000. However, since it is necessary to manufacture a test car for each trim and sales region, it generally costs several million dollars. Therefore, many manufacturers, including Hyundai Motor Company, are trying to introduce a virtual development process to minimize the number of iterations of the development process dependent on the real object.

The tasks to be solved to increase the accuracy of setting design goals using virtual models are summarized as follows.

- -

- With a simulation model that predicts quantitative values, it is difficult to predict ride and handling performances, which are emotional evaluation items.

- -

- Insufficient analysis of the predictive consistency of the simulation model for quantitative measurement items related to ride and handling performance.

- -

- Lack of consideration for direct application to actual design.

In this study, to efficiently achieve the handling performance goal of Hyundai Avante N, a high-performance vehicle, the following steps were followed for setting the K&C characteristics of the chassis corresponding to the design target before the design process.

- -

- Establish a quantitative measurement item that matches the handling rating, which is an emotional evaluation item, and develop a relationship between them.

- -

- Build a virtual model with predictive consistency for quantitative measurement items related to handling performance.

- -

- Optimize the chassis characteristics to achieve the vehicle performance goal: Optimize step-by-step using a factor sequence with a smaller impact on other fields.

- -

- The cause of performance improvement is analyzed when applying the design factors obtained by optimization to clarify the direction of improvement.

- -

- Provide priority information that needs to be applied through analysis of the performance impact by a factor that changes as a result of optimization.

2. Quantitative Measurement Item That Matches Well with the Handling Rating

The target of developing the handling performance of the actual vehicle is determined by emotional evaluation, whereas the values predicted by the simulation model are quantitative physical values; therefore, it is difficult to accurately express the handling performance of the actual vehicle using the simulation results. Therefore, in this study, a relational expression between the related quantitative measurement items and emotional evaluation rating was established so that the handling development performance, which is dependent on emotional evaluation, could be expressed quantitatively. This could quantitatively set the handling performance development goal for the actual vehicle.

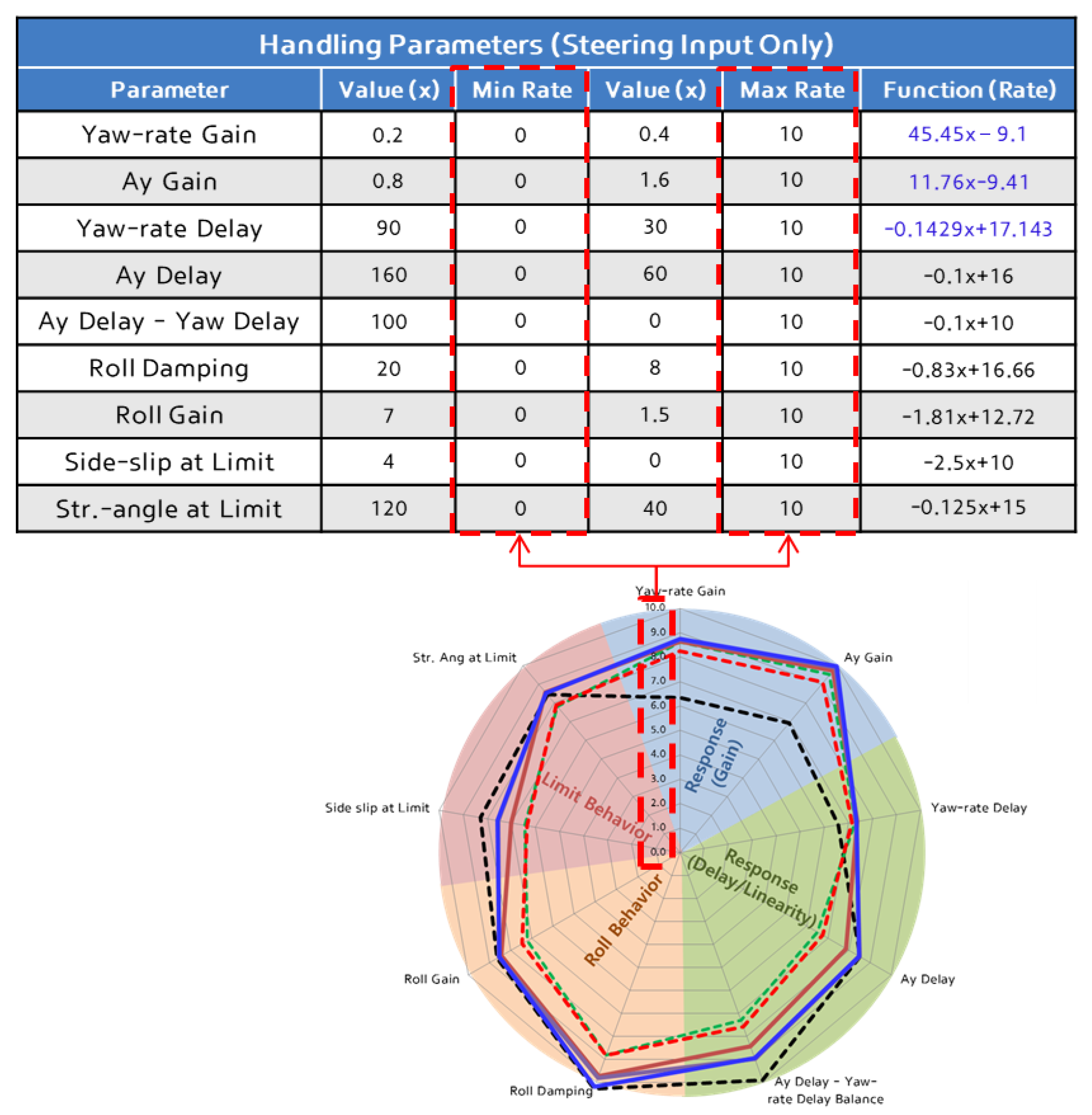

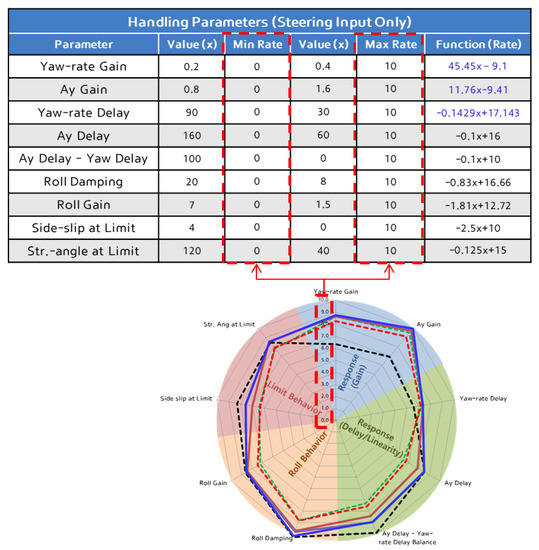

To establish a target for developing quantitative handling performances suitable for high-performance vehicles, a relational expression was derived through linear regression by statistically analyzing subjective evaluation results and measurement result data for high-performance reference vehicles. In general, the scores used by manufacturers for vehicle development are given by trained professional drivers by performing emotional evaluation in a prescribed manner, and they have a 10-point system. In order to convert this emotional evaluation into a measurement evaluation, after conducting an emotional evaluation and measurement test on dozens of vehicles, the correlation between the emotional evaluation score of each item and the measurement result data of the corresponding item was established as a mathematical model. To secure consistent data for statistical analysis, a relational expression was derived based on data accumulated in the same place by the same driver with the same procedure (Figure 2). In the table, the Min Rate and Max Rate columns are the minimum and maximum values of the emotional evaluation rate for each item. The column on the left of the Min Rate and Max Rate columns is the minimum and maximum values of measurement data for each item.

Figure 2.

Relational expression between the handling subjective test items and objective test factors.

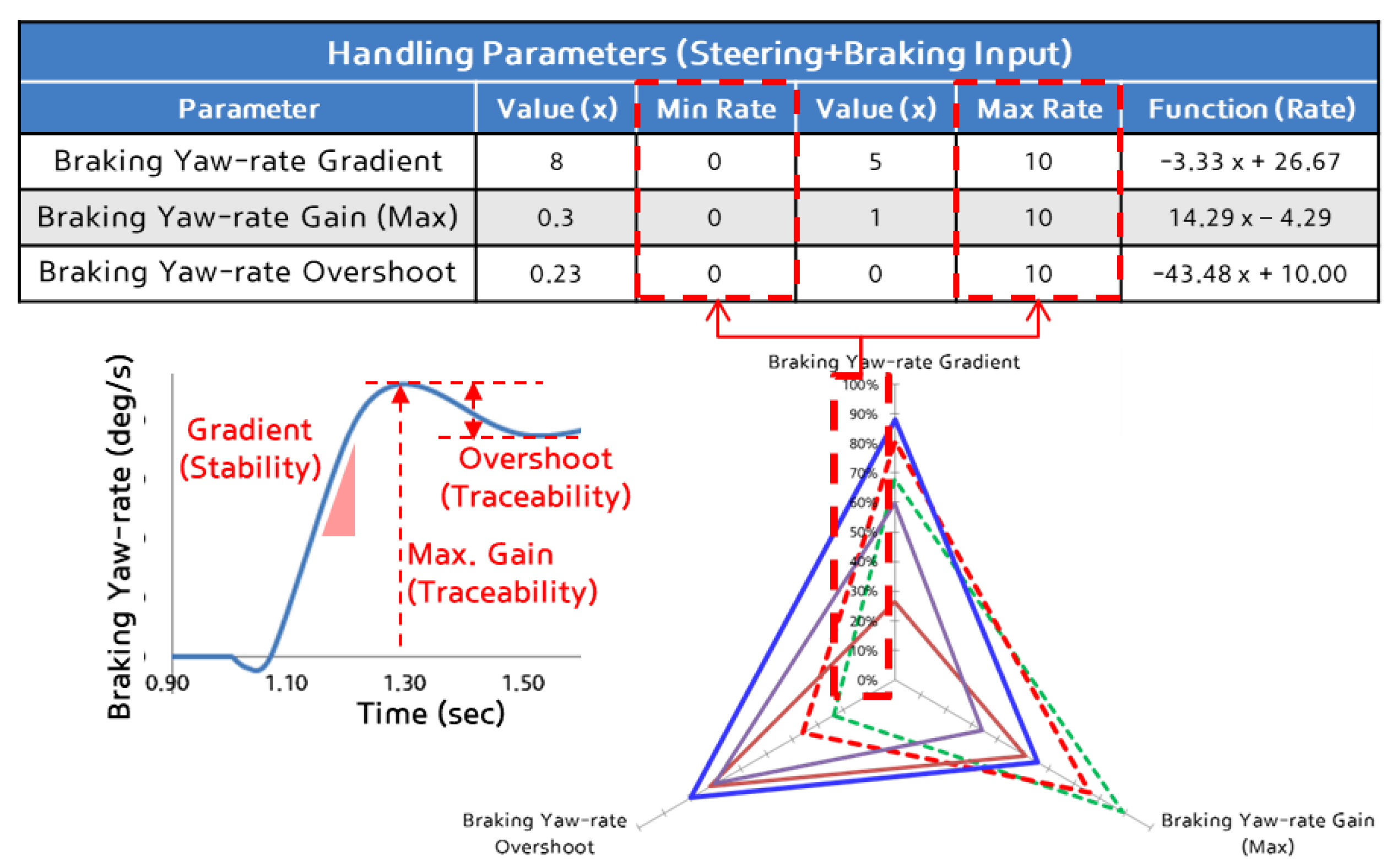

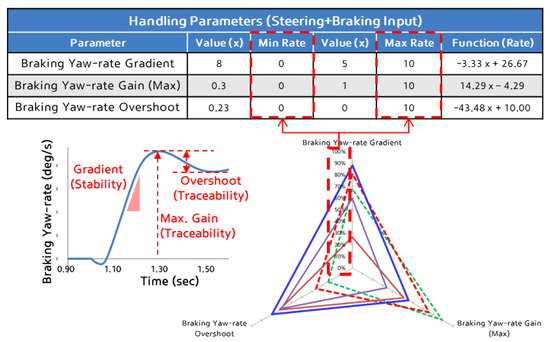

In the case of high-performance cars, the performance of braking-in-turn is important when entering a corner to improve the racing track-limit driving performance. Entering the corner as fast as possible to shorten the lap time causes understeer to be pushed out of the corner by the inertia of the vehicle; therefore, the vehicle speed must be reduced in advance only to the extent that it does not leave the course. Therefore, in high-performance cars, when braking and turning simultaneously occur in the corner entry section (trail braking), it is advantageous to improve the course traceability and lap time when developing in the direction of increasing the yaw motion gain by reducing the understeer. That is, the driver performs additional steering using braking, and it is advantageous for the driver to exercise complete control when the increase in yaw motion gain by braking occurs gradually without being too urgent. This is because, in race-track driving, abrupt steering input is avoided to maintain the tire grip characteristics. Moreover, when the increase in braking force occurs, the increase in yaw movement must also occur in proportion. Therefore, it is advantageous to suppress any additional over-shoot or vibration as much as possible.

Therefore, a relational expression was additionally set up to express the development factors for the race-track-driving of high-performance cars as quantitative measurement factors in this study (Figure 3).

Figure 3.

Additional settings for race-track-driving performance indicators.

3. A Framework for the Optimization Tool and Simulation Tool

This chapter describes how to change variables in a virtual vehicle model using an optimization tool. In this paper, we use this method for two purposes:

- -

- Virtual vehicle modeling with predictive consistency;

- -

- Optimizing chassis characteristics for the development goal.

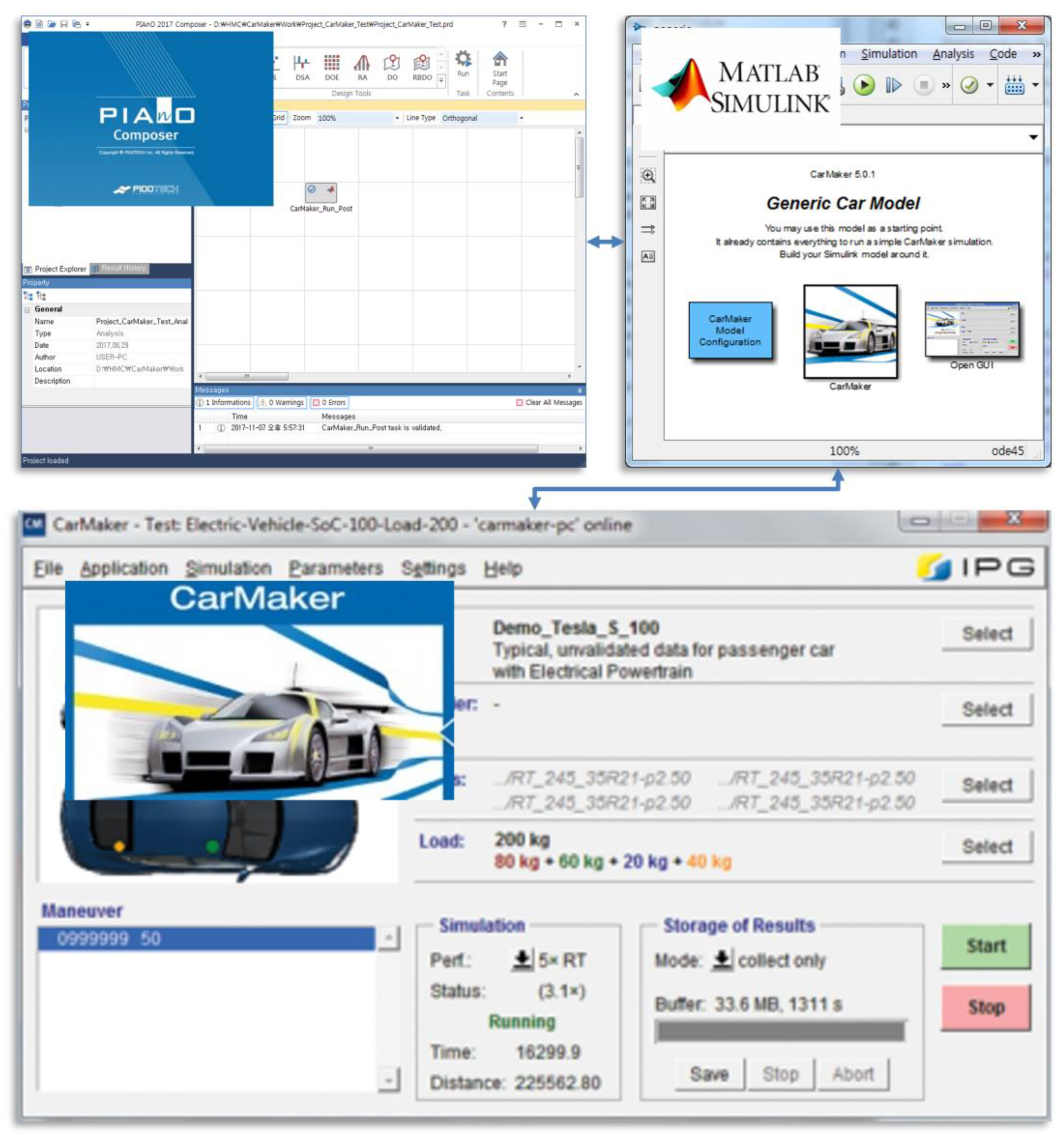

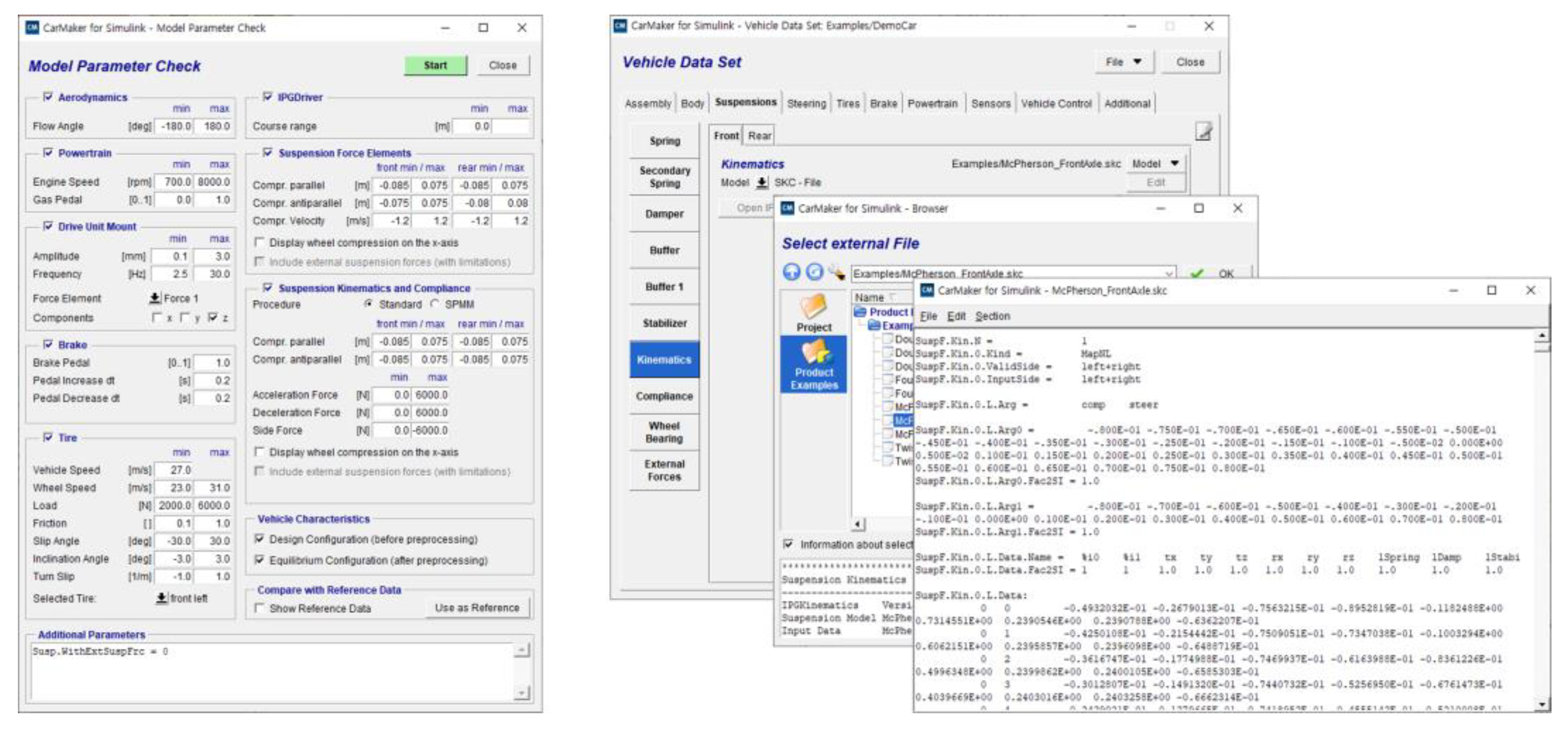

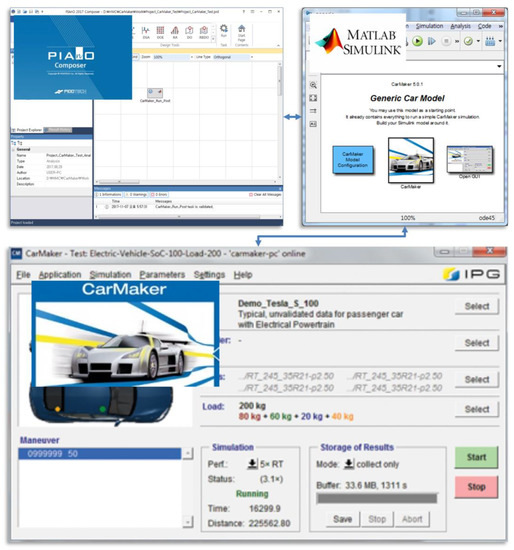

Adjustment of model parameters using the optimization tool was performed using three simulation tools: PiAnO, Matlab/Simulink, and IPG CarMaker (Figure 4)

Figure 4.

Adjustment of model parameters using optimization tools.

PIAnO (Process integration, automation, and optimization) is software for process integration and design optimization, which can derive optimized designs based on engineering data obtained through simulation [14]. IPG Carmaker is simulation software for virtual test driving of vehicles [15]. In this paper, IPG Carmaker was used to construct the vehicle model. This software can test vehicles modeled with user-set parameters and easily test driving simulations for test conditions to understand the dynamic characteristics of the vehicle.

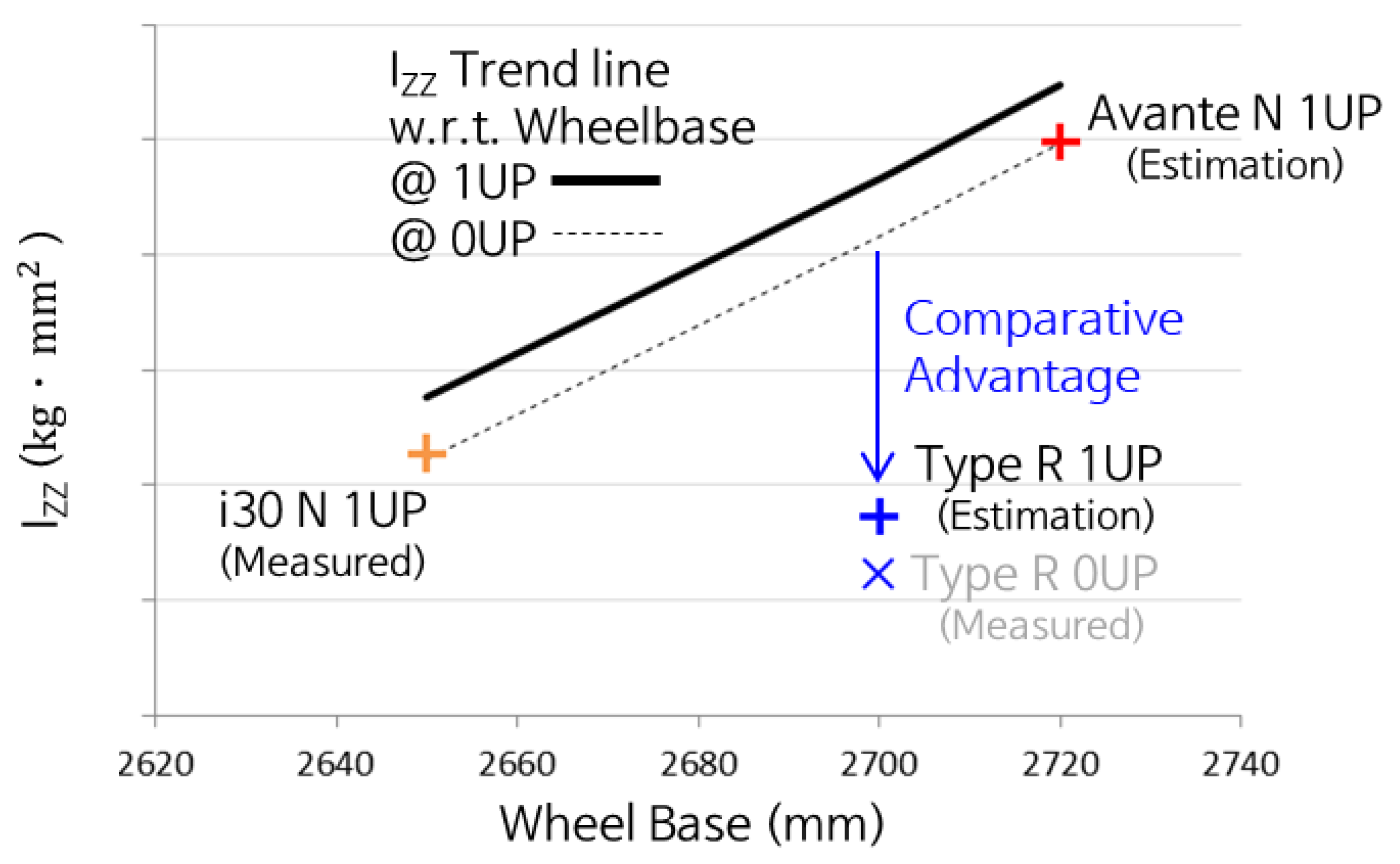

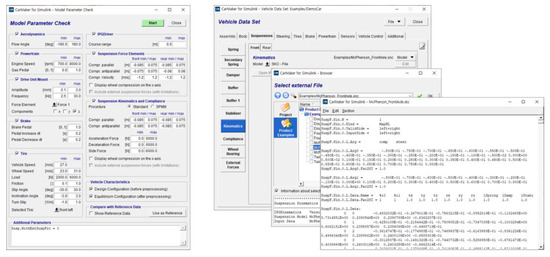

Adjustment of model parameters using optimization tools is performed through a process defined in PIAnO. The process is divided into a pretreatment step, a CarMaker simulation step, and a post-treatment step. First, in the preprocessing step of PIAnO, the carmaker model file is updated to change the K&C curve of the vehicle model or to change the vehicle specifications by inputting the design variable. Through the preprocessing step, the parameters of the CarMaker vehicle model are applied according to the design variables, as shown in Figure 5. Thereafter, in the CarMaker simulation step with PIAnO, the test items determined sequentially are simulated. CarMaker simulation is performed by executing Matlab’s simulation code running the Simulink model linked to CarMaker in PIAnO. The driving simulation of the vehicle model is performed as shown in Figure 6. Finally, in the post-processing step of PIAnO, the performance index is calculated from the Ascii-type CarMaker driving simulation result data file. The performance index is then used for optimization, and the design variables of the first step can be obtained through optimization. This process runs repeatedly to finally set the model parameters.

Figure 5.

IPG CarMaker Software Vehicle Model Parameter setting.

Figure 6.

IPG CarMaker Software Simulation.

In this paper, progressive quadratic response surface approximation (RQRSA) was used as an optimization method for the objective function [10]. This optimization method was proposed by Hong et al. (2021). This approximation uses only 2n + 1 design points for one approximation optimization and uniquely determines main effect terms such as linear and quadratic regression coefficients. We then gradually updated the two interaction terms using the main effect terms between successive iterations. Thus, PQRSA is an efficient approximation method for constructing a quadratic reaction surface model.

4. Virtual Model with Predictive Consistency

In virtual development, the construction of a vehicle model with consistency in performance prediction should be considered. In this study, to develop a coherent model, the mother car model and the measurement data of the mother car are utilized. That is, the calibration factor of the model is set using the measurement data. Then, by reflecting the specifications of the vehicle to be developed, it is used as a base model to change the chassis characteristic factor to satisfy the performance target.

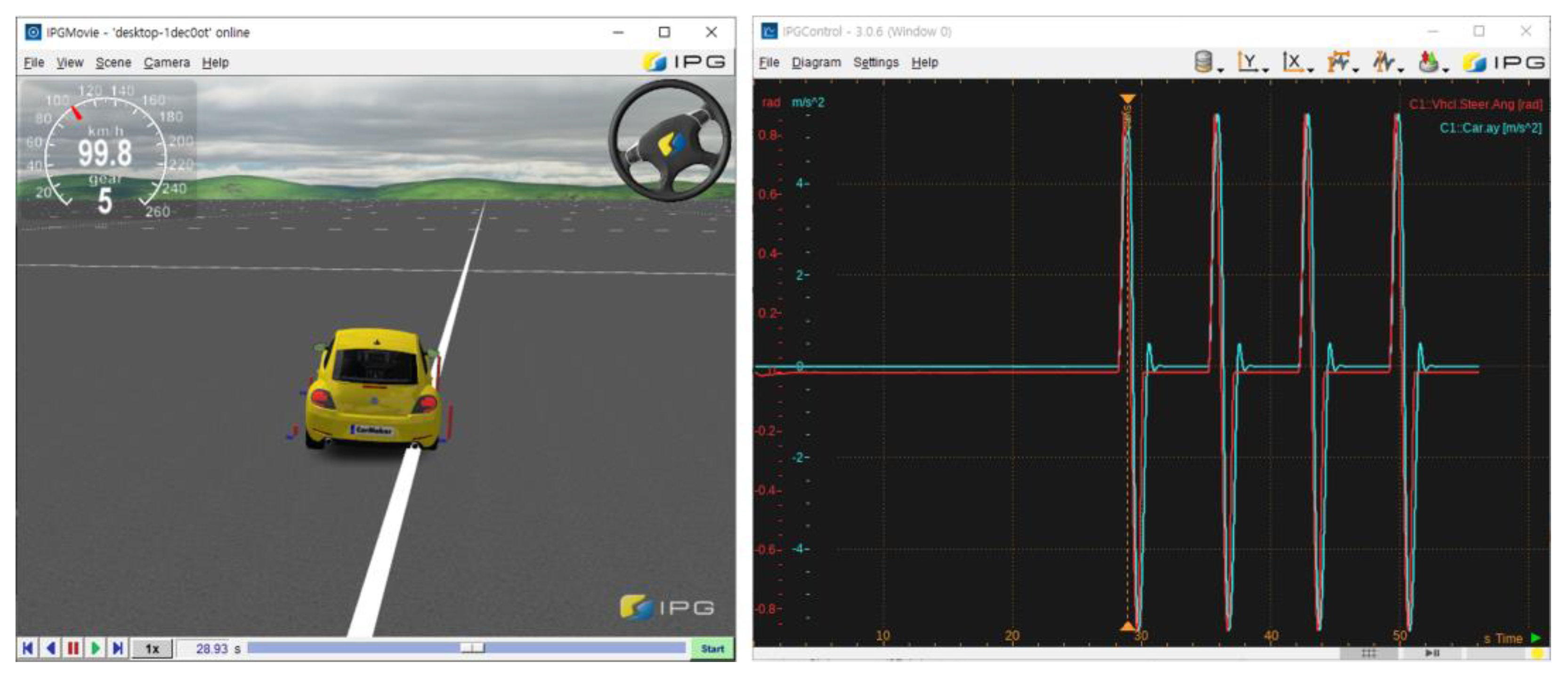

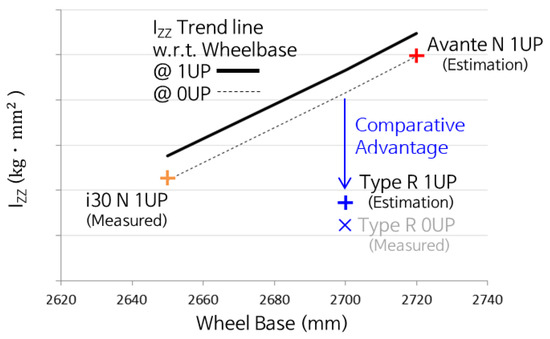

First, moment of inertia information, which is important for realizing the dynamic characteristics of the vehicle, was estimated. Moment of inertia information is important in realizing the dynamic characteristics of a vehicle. If there is no measured value, the regression model result is used. For an existing vehicle, measurement data were available and were used. However, as the moment of inertia of the existing vehicle was measured to be smaller than that of the regression model, the moment of inertia of the vehicle to be developed in the same class was also corrected and used by the same ratio. However, while the moment of inertia data of the existing and developed vehicles were managed based on 1 UP, only the data measured in the 0 UP state existed in the case of the competitive car. Therefore, in the trend model, the difference between the 0 UP and 1 UP states was corrected and compared with the vehicle to be developed. Therefore, it can be confirmed that the moment of inertia of the existing model is smaller than that of the vehicle to be developed, which is advantageous for handling performance (Figure 7). In this study, the chassis characteristics are optimized to secure the same or better handling performance even under conditions such as an unfavorable moment of inertia compared to competitors owing to the high development targets for collision safety and space utilization of the vehicle.

Figure 7.

Izz (moment of inertia about the z-axis) Estimation: Trend Model + Measured Data.

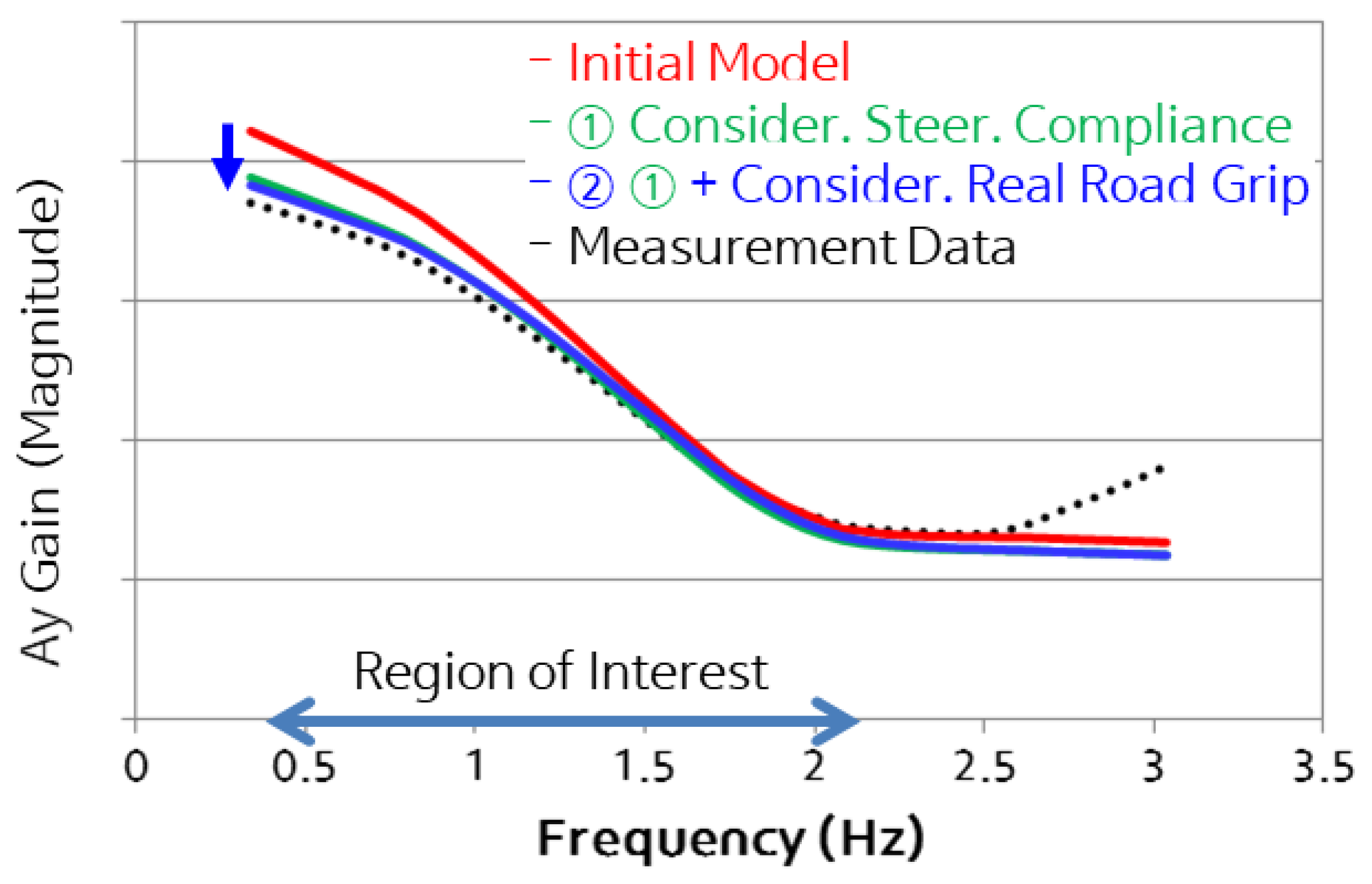

To check the consistency of the model for each steering input speed, the lateral acceleration response according to the increase in the steering input frequency was compared with the measurement results. For reference, the frequency corresponding to the turn-in input during normal turns is approximately 0.5 Hz, and when changing lanes very quickly, it can reach the level of 2 Hz; therefore, 0.5–2 Hz was considered as the necessary guaranteed range. It can be observed that the response gain of the initial model is similar to the measurement result near 2 Hz, but it becomes larger than the measurement result as the frequency decreases. The main reason is that the actual car has a larger understeer value than the model. Analyzing the related phenomenon, the model is used for concept setting in the early stage of development, and therefore, the EPS logic that is tuned later for each vehicle was not reflected. However, the toe compliance characteristic of the lateral force of the front wheel that affects the understeer of the vehicle is proportional to the deformation of the torque sensor’s torsion bar in the EPS. Here, the torsion bar torsion is inversely proportional to the motor assist torque, and the motor assist torque varies according to the vehicle or vehicle speed. Therefore, the level of understeer by EPS is different for each vehicle or each vehicle speed. Therefore, this paper proposes a method of estimating the toe compliance characteristics due to the lateral force of the front wheel when the motor assist torque is applied using the handling measurement results of the preceding vehicle (Figure 8). For estimating the toe compliance characteristics to meet the understeer level of real car, we utilized the method introduced in Section 2.

Figure 8.

Estimation results of the toe compliance characteristics.

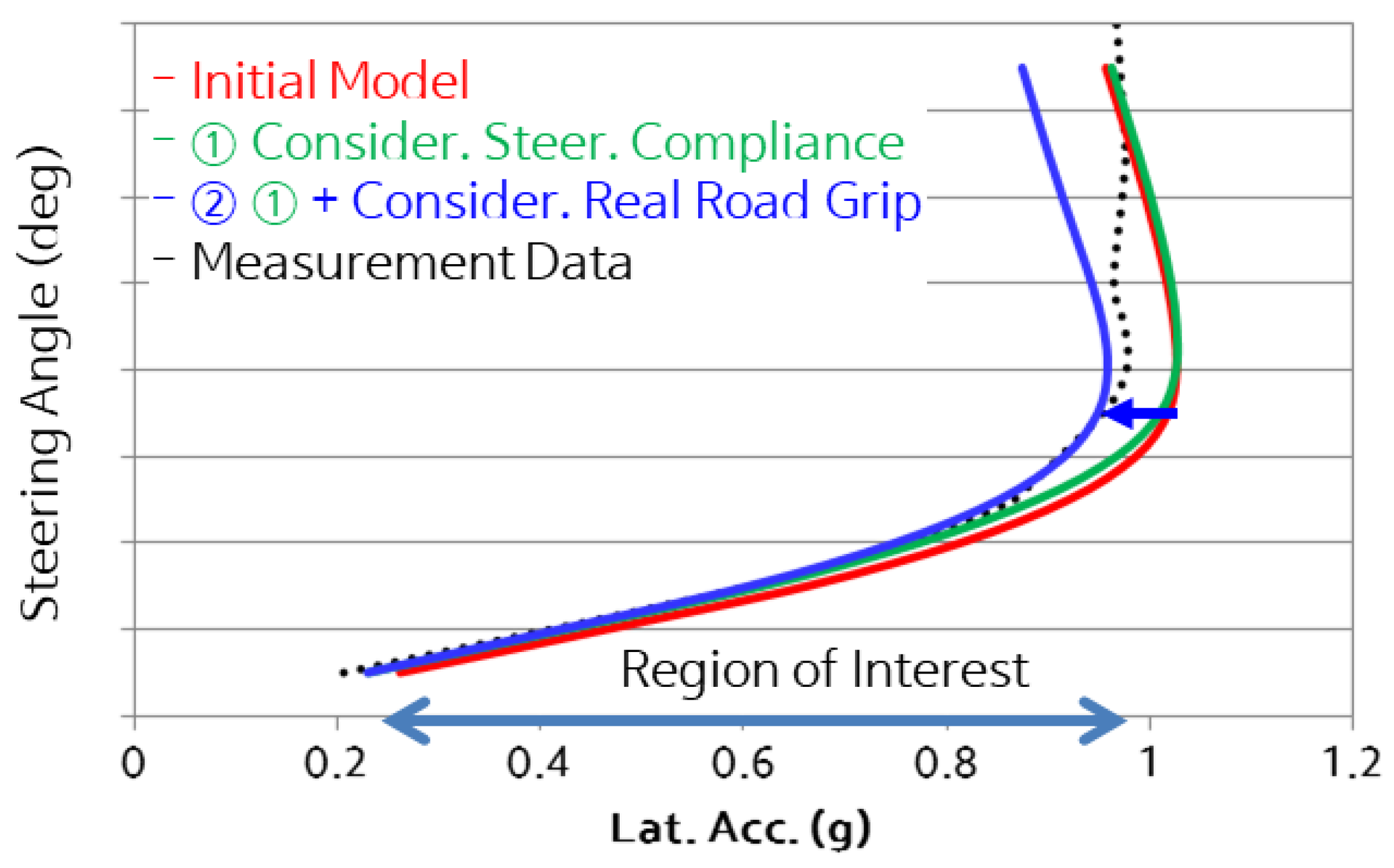

Next, the lateral acceleration response according to the increase in the steering angle was compared with the measurement results to check the consistency of the model for each steering input size. In the case of the initial model, it can be observed that the lateral acceleration at the same steering angle is larger than the measurement result. However, it can be confirmed that the value of the model becomes similar to the measurement result when the correction of the steering system deformation characteristics is considered according to the driving conditions performed earlier. However, it can still be observed that the maximum lateral acceleration is larger than the measurement result in the limit region. The tire model applied to this vehicle model is constructed by measuring the characteristics of tire from the tire flat track. In general, the friction coefficient of the external asphalt road surface including the general test proving ground tends to be smaller than the flat track belt road surface. Therefore, in this paper, we propose a method to estimate the tire lateral friction force characteristics using the method introduced in Chapter 2, so that the maximum lateral acceleration characteristics of the vehicle can be reproduced using the handling measurement results of the preceding vehicle (Figure 9).

Figure 9.

Estimation results of the tire lateral frictional force characteristics.

When there are two or more factors to be adjusted using the optimization tool, there is a tendency to preferentially adjust the factor of high sensitivity to achieve the purpose. In other words, the tire lateral force characteristics may have a significant influence on the model characteristics similar to the result of the frequency response measurement, and in this case, the tire lateral force characteristics could be changed more than necessary to ensure consistency in the frequency response characteristics. In that case, the toe compliance characteristics due to the lateral force of the front wheel are changed less significantly, and the probability that the model implemented in this manner, configured in a different combination from the actual vehicle, increases. As the lateral acceleration of the vehicle in the frequency response characteristic test is less than 0.4 g and the tire lateral force characteristic is a linear range, it can be considered that the tire model is reliable to some extent. However, the toe compliance characteristic of the lateral force of the front wheel is affected by the EPS motor torque, and therefore, this factor needs to be adjusted anyway. Therefore, to reproduce the frequency response characteristic of the linear section, the optimization process of adjusting only the toe compliance characteristic by the lateral force of the front wheel was performed first. Subsequently, the second optimization was performed so that the maximum lateral acceleration characteristics realized in the nonlinear region of the tire characteristics were reproduced by adjusting the tire lateral force characteristics. However, if the tire lateral force characteristics are adjusted, the frequency response characteristics, which are in a linear range, may be partially changed. Therefore, it may be necessary to partially adjust the toe compliance value by the lateral force to compensate for this. Therefore, for the second optimization, not only the maximum lateral acceleration but also the frequency response characteristics were used to define multiple objective functions, and factors requiring adjustment included not only the tire lateral force characteristics but also the toe compliance characteristics by the front wheel. However, in the second optimization process, even though the final optimization is performed by including all factors and objective functions, the first optimization is performed to adjust the toe compliance characteristic that needs adjustment in the linear response section close to an appropriate value. When performing the second integrated optimization, the toe compliance characteristic already starts from an appropriate value, and therefore, it is possible to fundamentally avoid the problem that the tire lateral force characteristic may considerably change to reproduce the linear-response region-response characteristic. In the end, fine tuning of the remaining factors is performed only to the extent of compensating for the changed tire lateral force characteristics to reproduce the maximum lateral acceleration characteristics.

5. Optimizing Chassis Characteristics

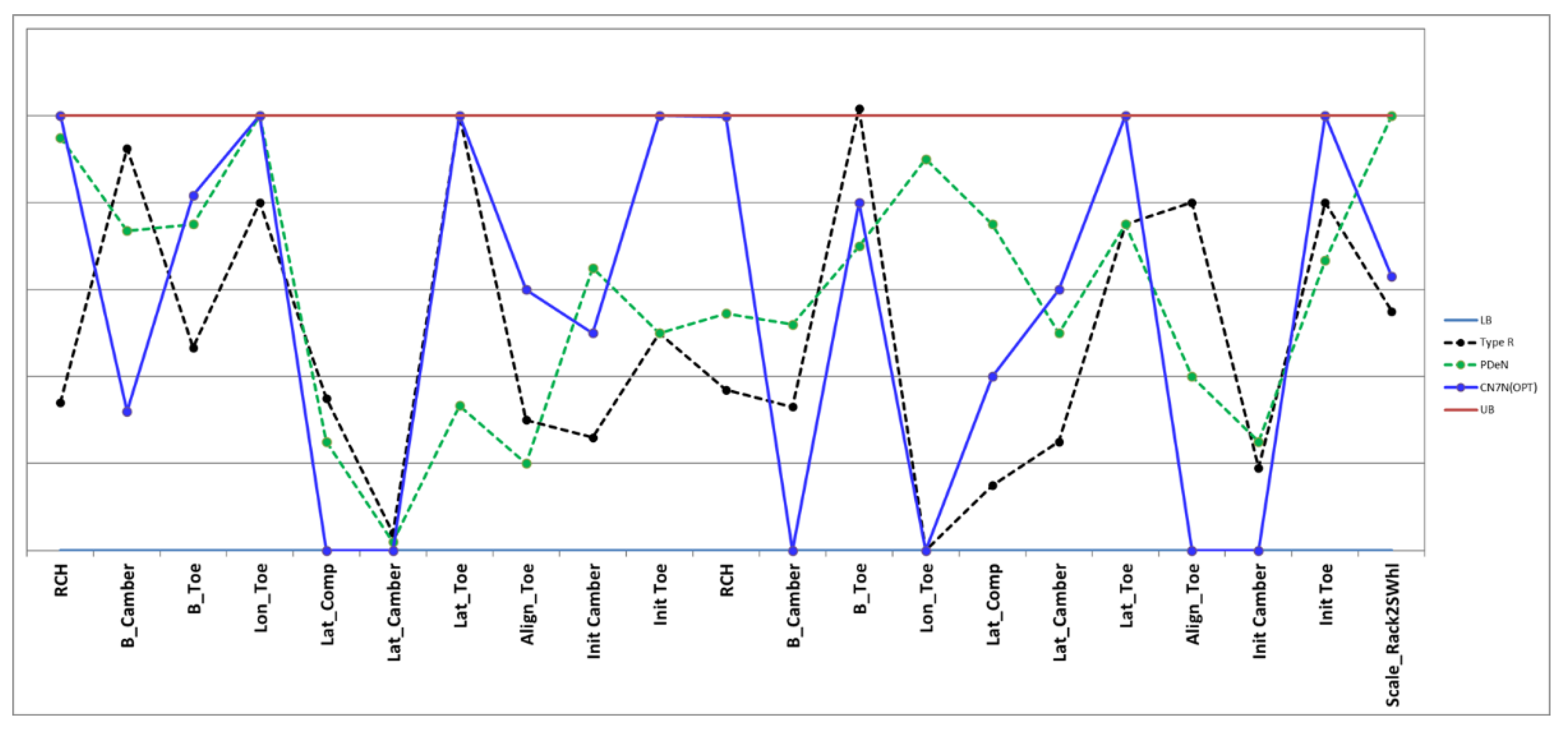

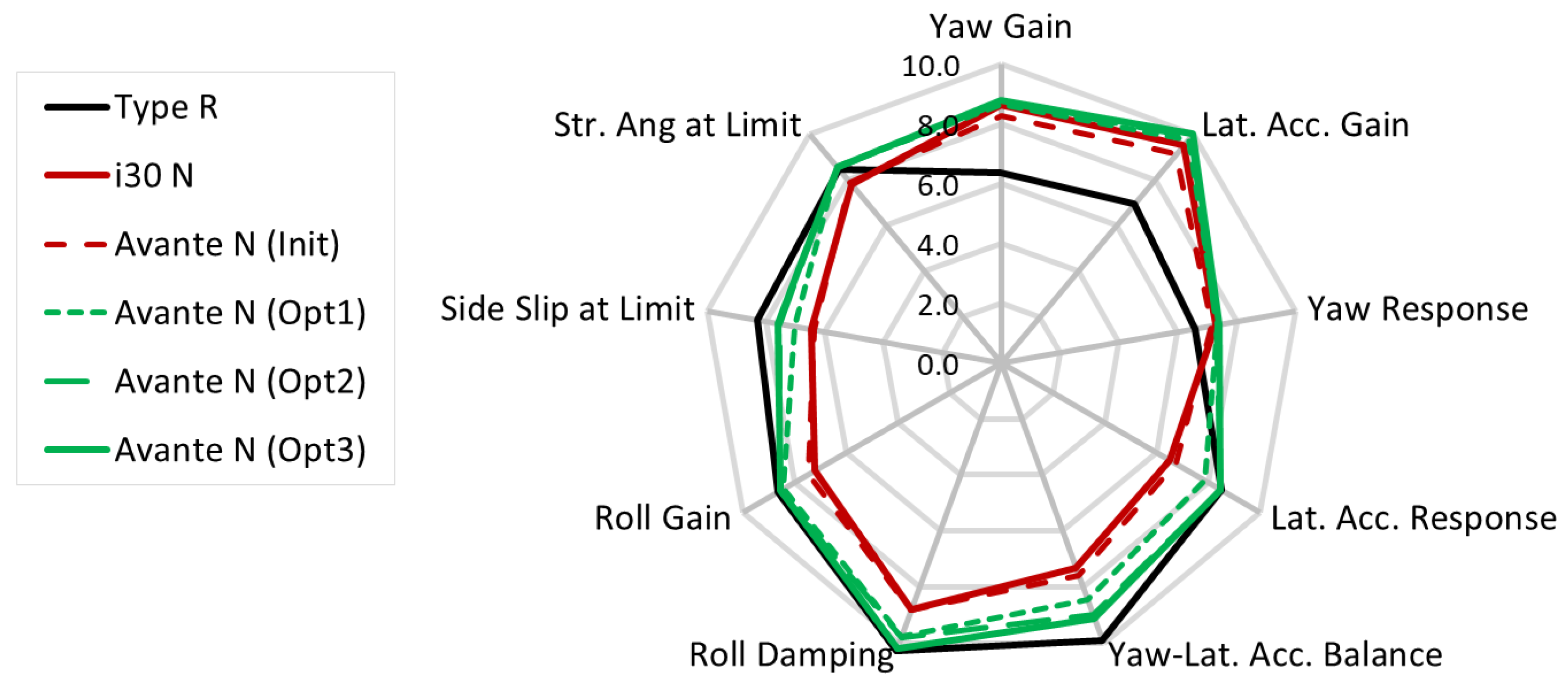

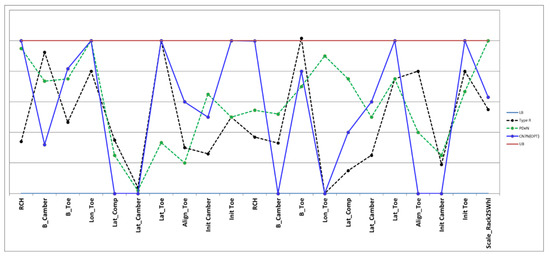

Avante N’s handling performance development goal was set as Best-In-Class. Therefore, we conducted a measurement related to the handling performance of Civic Type-R and i30 N, which were well evaluated in terms of the handling performance at that time. Civic Type-R was excellent in most items because of its smaller weight and excellent tire friction characteristics. However, i30 N was excellent in items of response gain for cornering in the racing track (Figure 8). Setting the best goal for all items at the same time can be a challenging task, but to verify the potential of virtual model-based optimization technology, the goal function is set so that the best handling performance can be achieved for all items. The scope of the factors to be changed was set to the scope of the K&C design guide (Figure 10). The changeable range of high-performance vehicles is limited considering the investment costs. Therefore it has to be selectively applied among the optimization results. However the fundamental solution was found to help not only other development vehicles but also current development vehicles. Instead, a vehicle performance impact analysis was also performed to help selectively apply the changes according to this optimization result.

Figure 10.

Optimizing within the K&C design guide.

There are several chassis system factors that need to be set to achieve the vehicle handling performance goal, and as there are interactions between them, it takes many work hours to find a set that meets the vehicle handling performance goal while changing those factors. Multiple optimization theories may be used to automatically find numerous factors to satisfy several items of the vehicle handling performance simultaneously. However, when performing multiple optimizations, the vehicle’s handling performance target is usually determined by changing the sensitive chassis factors first. Mainly, there was a tendency to passively change the remaining factors accordingly with the initial toe/camber and bump toe set to the maximum value. However, when the initial toe/camber has a large value, performance in terms of tire wear and fuel efficiency becomes disadvantageous, and the toe change due to the bump stroke considerably affects the turning braking performance. Therefore, to reduce the dependence on initial toe/camber and toe changes due to bump stroke that significantly affect its performance in other parameters, the first optimization is performed without the corresponding factor, and the remaining factors are actively changed to achieve the goal. After that, the initial toe/camber is added to perform secondary optimization so that it is fine-tuned. The third optimization was performed by adding the purpose function of the turning braking performance, the toe compliance factor due to the bump stroke, and the toe compliance factor due to the braking force (Figure 11).

Figure 11.

Optimizing handling performance (steering input).

6. Analyzing the Cause of Performance Improvement

No matter how good a tool makes the optimal factor change to improve performance, there is a high risk to apply it to the actual design unconditionally without knowing the principle. Therefore, in this study, the actual application was proposed only after analyzing the change direction for each factor found in the optimization tool in principle.

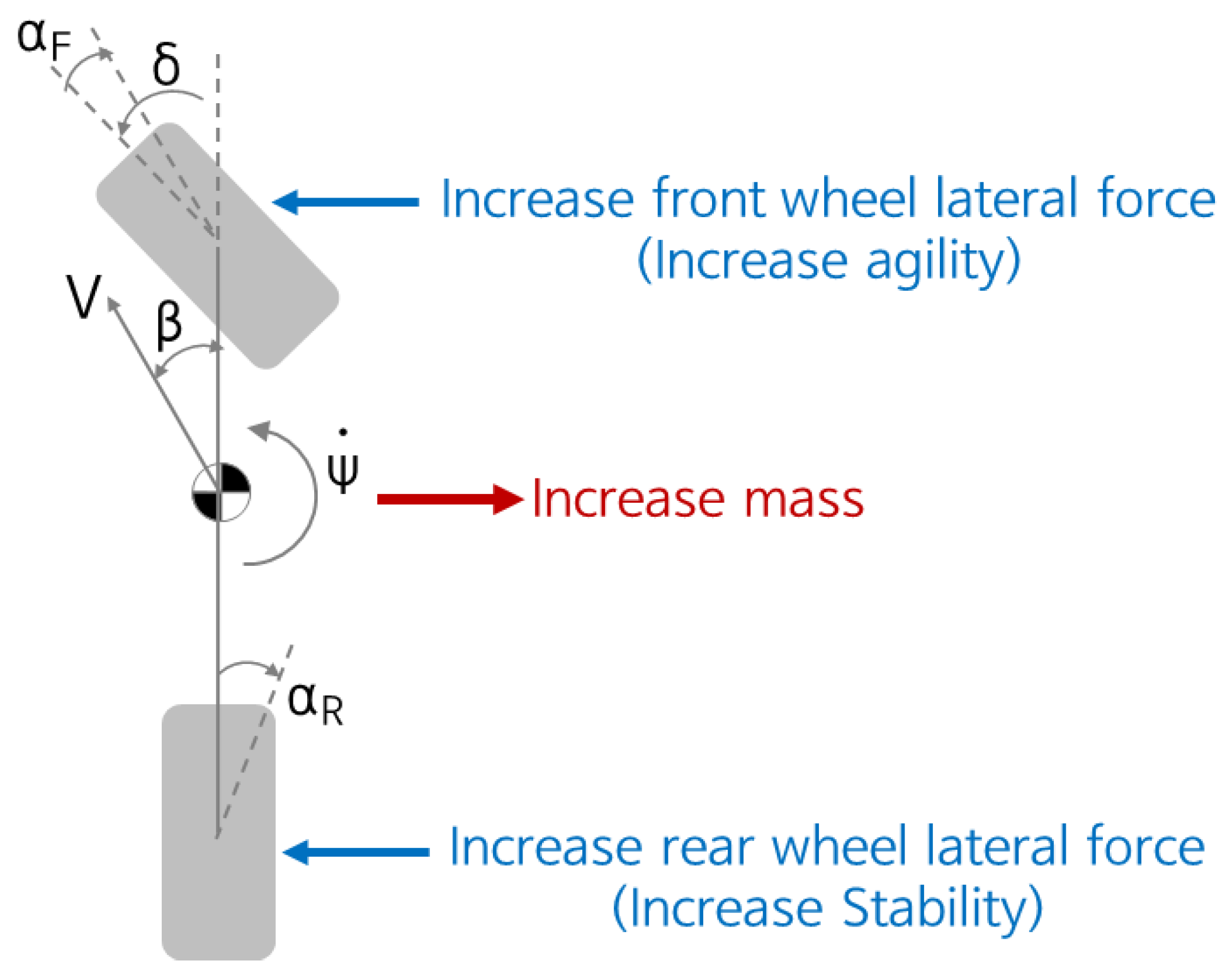

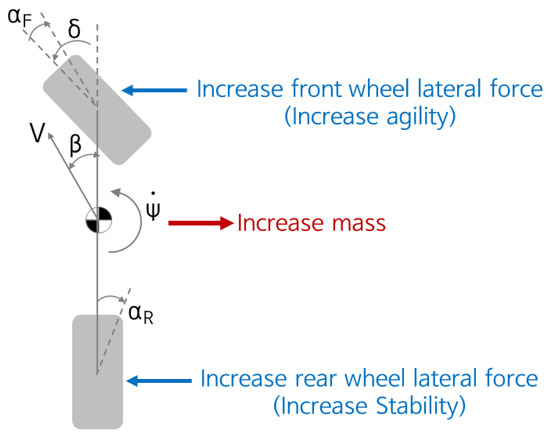

First, Avante N has the larger weight of the two vehicles considered, and in particular, Civic Type-R is equipped with a tire with excellent lateral force characteristics. For Avante N to achieve the best handling performance, it is important to secure a centripetal force (tire lateral force) corresponding to the centrifugal force (weight) (Figure 12).

Figure 12.

Centripetal force increase setting to cope with increased centrifugal force.

Therefore, it was confirmed that the chassis characteristic was set in the following manner to actively generate the lateral force of the tire.

- -

- Increase the negative camber properties;

- -

- Increase the roll center height;

- -

- Increase the positive toe properties.

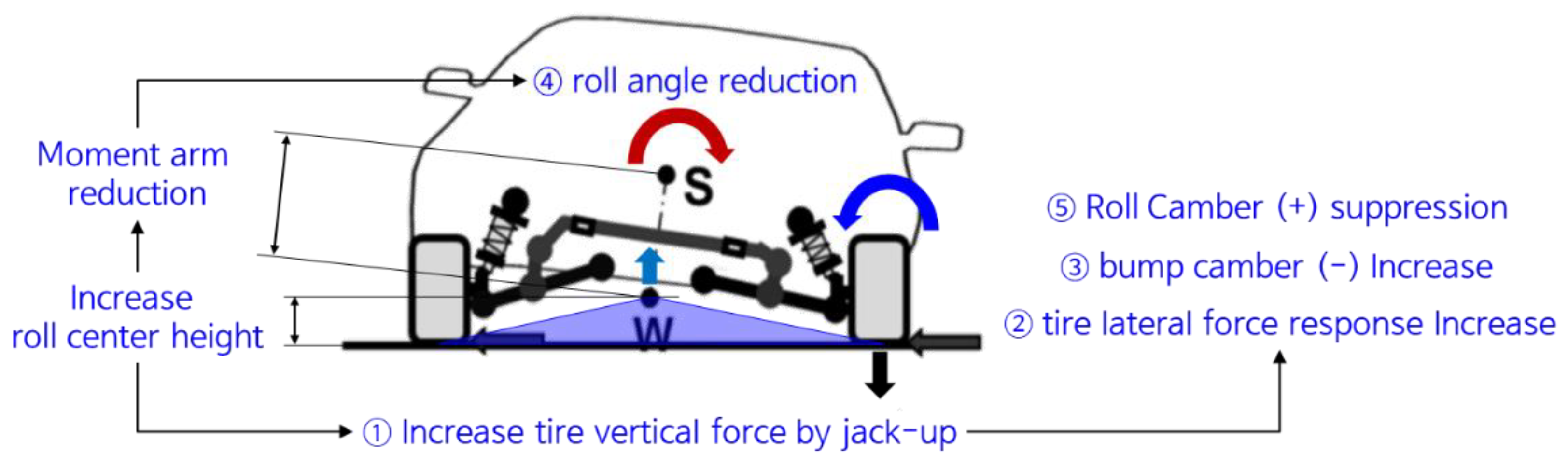

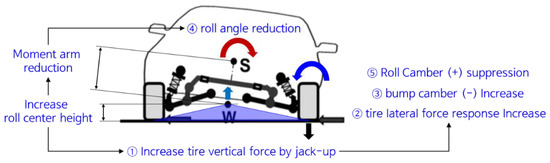

In particular, Figure 13 shows the principle by which the handling performance is advantageous according to the increase in the height of the roll center.

Figure 13.

Principle of the lateral force increase when the roll center is raised.

7. Priority Information Required for Application

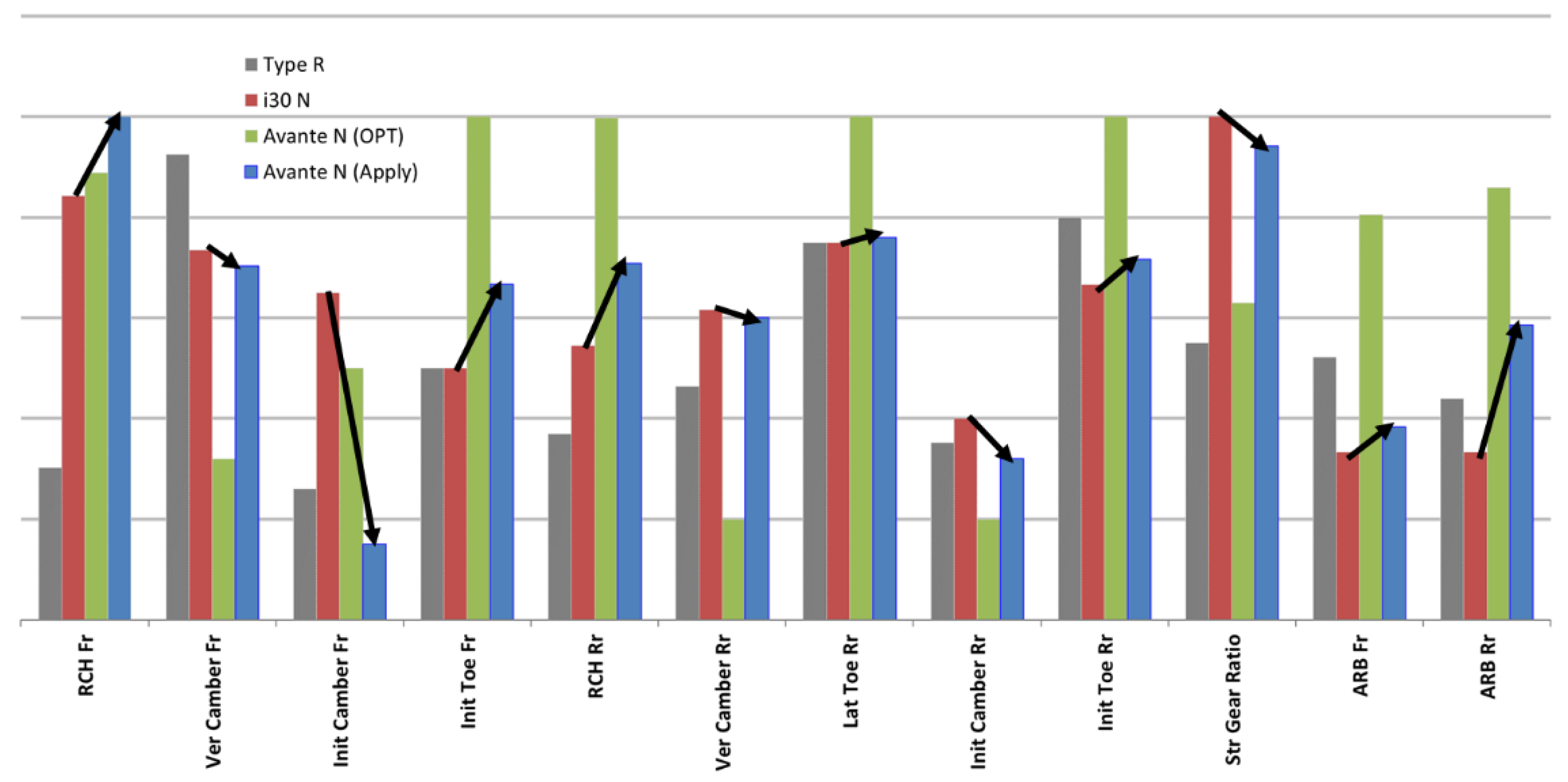

As high-performance cars are basically derivatives of basic cars, the range that can be changed is limited considering the sharing and investment costs. Moreover, during development, modifications may occur compared to the initial development goals for various reasons. Therefore, there are many reasons why the optimization results cannot be unconditionally applied in the design. Therefore, we analyze the contribution of vehicle handling performance for each factor that changes as a result of optimization and provide a solution to help developers make judgments regarding which factors and how to change them. Accordingly, the results of the final specifications developed by the development officials are shown in Figure 14.

Figure 14.

Performance impact factor recommendation and application results.

Among the factors changed as a result of optimization, 12 factors with high overall contribution were applied in the recommended direction. Among them, 10 factors had to be changed in smaller amounts than the optimization result due to common use with existing vehicles. Instead, the two factors with a high degree of freedom of change were applied in a more active way to make up for the insufficient amount of change in the above 10 factors.

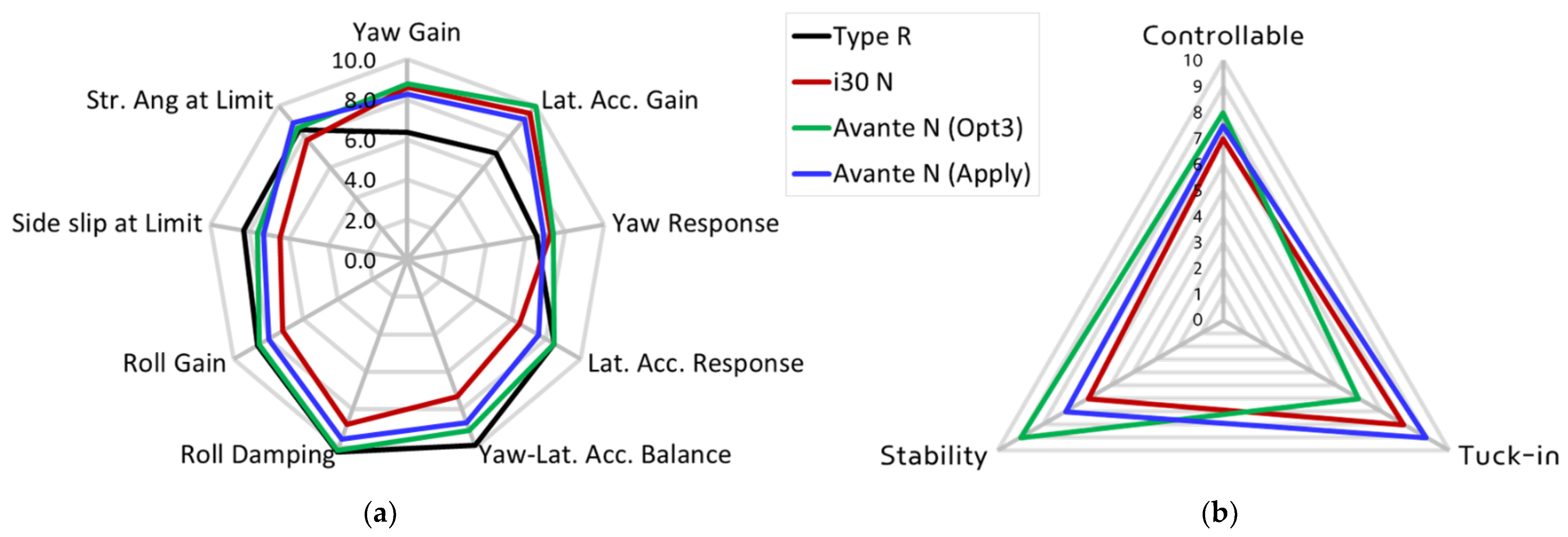

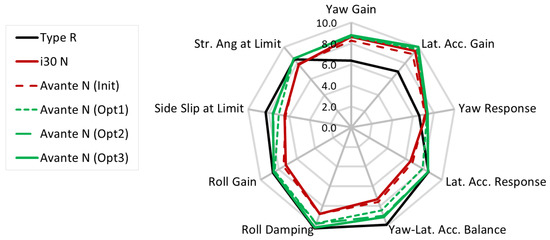

Despite unfavorable conditions such as the wheel base increase, weight increase, investment cost minimization, and common use with existing vehicles, Avante N achieved high scores evenly in all handling performance items (Figure 15).

Figure 15.

Avante N handling performance: (a) Handling performance (steering input); (b) Composite handling performance (steering/breaking).

In order to confirm the overall handling performance, the scores for each item were statistically analyzed (Table 1). As a result, the average score was excellent in the order of Avante N (Opt3), Avante N (Apply), Civic Type-R, and i30 N, and the standard deviation was excellent in the order of Avante N (Apply), Avante N (Opt3), i30 N, and Civic Type-R. The optimization result, Avante N (Opt3), improved by 0.5 points in the average and 0.4 points in the standard deviation compared to Civic Type-R, which was previously the best. Avante N (Apply), which can be applied to the design, also improved by 0.1 point in the average and by 0.5 points in the standard deviation compared to Civic Type-R, which was the best. Therefore, the design target of the chassis systems that could achieve the vehicle handling performance goal could be established prior to the design.

Table 1.

Average and standard variation of scores by handling performance item.

8. Conclusions and Discussion

In this study, to solve the recently increased complexity of vehicle development, we developed a high-performance car chassis concept before the design process using the virtual prototype.

To efficiently achieve the handling performance goal of Avante N, a high-performance vehicle, the following tasks were performed in setting the K&C characteristics of the chassis corresponding to the design goal before the design process.

- -

- Set quantitative factors that match the emotional evaluation.

- -

- Build a virtual model to ensure consistency in performance predictions.

- -

- Optimize the chassis characteristics to achieve the vehicle performance goal: Optimize step-by-step by factor sequence with a smaller impact on other performance goals.

- -

- The cause of performance improvement is analyzed when applying the design factors obtained by optimization to clarify the direction of improvement.

- -

- Provide priority information that needs to be applied through analysis of the performance impact by a factor that changes as a result of optimization.

When all optimization results were applied, the average of the performance items increased by 0.5 points and the standard deviation improved by 0.4 points compared to the existing Civic Type-R, which was the best. In the case of the final specification considering design constraints, the average of performance items increased by 0.1 points and the standard deviation improved by 0.5 points compared to the existing Civic Type-R. As a result, despite unfavorable conditions such as the wheel base increase, weight increase, investment cost minimization, and common use with existing vehicles, Avante N achieved high scores evenly in all handling performance items. Therefore, the design target of the chassis systems that could achieve the vehicle handling performance goal could be established prior to the design. Using this virtual development, it is possible to eliminate the trial and error process that the first and second test cars needed. This could save more than 500,000 USD (per unit trim) of the first and second test vehicles. Considering the combination of three types by region and two types by trim, 3,000,000 USD can be saved.

The future plan is to ensure that these model-based pre-concept setup tasks continue to be carried out in an efficient and consistent manner so that most vehicle development tasks can be carried out more systematically and efficiently. In other words, to establish a framework that provides consistent and reliable data and simulation results that are needed to effectively make decisions based on data or models from the beginning of the development process. The following steps should be followed in this regard.

- -

- Analysis of required data and outputs by development task.

- -

- Life-cycle management for modeling and simulation result data.

- -

- Standardization and automation of data, modeling, and simulation-related tasks.

Author Contributions

Conceptualization, S.W. and D.S.; Methodology, S.W.; Software, S.W.; Validation, S.W. and D.S.; Formal analysis, Y.H.; Investigation, S.W.; Resources, J.Y.; Data curation, E.J.; Writing—original draft preparation, S.W.; Writing—review and editing, Y.H.; Visualization, S.W.; Supervision, S.W.; Project administration, S.W.; Funding acquisition, J.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the Korea Agency for Infrastructure Technology Advancement (KAIA) grant funded by the Ministry of Land, Infrastructure and Transport (Grant 22AMDP-C162182-02).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Afkar, A.; Mahmoodi-Kaleibar, M.; Paykani, A. Geometry optimization of double wishbone suspension system via genetic algorithm for handling improvement. J. Vibroengineering 2012, 14, 827–837. [Google Scholar]

- Lajqi, S.; Gugler, J.; Lajqi, N.; Shala, A.; Likaj, R. Possible experimental method to determine the suspension parameters in a simplified model of a passenger car. Int. J. Automot. Technol. 2012, 13, 615–621. [Google Scholar] [CrossRef]

- Tey, J.; Ramli, R.; Kheng, C.; Chong, S.; Abidin, M. Identification of vehicle suspension parameters by design optimization. Eng. Optim. 2014, 46, 669–686. [Google Scholar] [CrossRef]

- Park, J.; Park, J.; Lee, J.; Yi, Y.S.; Park, T. Analysis of sensitivity and optimization for chassis design parameters on the X-wind stability. In Proceedings of the 18th Asia Pacific Automotive Engineering Conference, Melbourne, Australia, 10–12 March 2015. [Google Scholar]

- Tey, J.; Ramli, R.; Abdullah, A. A new multi-objective optimization method for full-vehicle suspension systems. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2016, 230, 1443–1458. [Google Scholar] [CrossRef]

- Karimi Eskandary, P.; Khajepour, A.; Wong, A.; Ansari, M. Analysis and optimization of air suspension system with independent height and stiffness tuning. Int. J. Automot. Technol. 2016, 17, 807–816. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, B.; Shi, W. Suspension Optimization Design and Virtual Prototype Simulation Analysis of FSAE Racing Car. In Proceedings of the 2018 IEEE 4th Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 14–16 December 2018. [Google Scholar]

- Choi, B.C.; Cho, S.; Kim, C.W. Sequential approximate optimization of Macpherson strut suspension for minimizing side load by using progressive meta-model method. Int. J. Automot. Technol. 2018, 19, 455–461. [Google Scholar] [CrossRef]

- Gao, Q.; Feng, J.; Zheng, S. Optimization design of the key parameters of McPherson suspension systems using generalized multi-dimension adaptive learning particle swarm optimization. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2019, 233, 3403–3423. [Google Scholar] [CrossRef]

- Papaioannou, G.; Jerrelind, J.; Drugge, L. Multi-Objective Optimisation of Tyre and Suspension Parameters during Cornering for Different Road Roughness Profiles. Appl. Sci. 2021, 11, 5934. [Google Scholar] [CrossRef]

- Cui, T.; Zhao, W.; Wang, C.; Guo, Y.; Zheng, H. Design optimization of a steering and suspension integrated system based on dynamic constraint analytical target cascading method. Struct. Multidiscip. Optim. 2020, 62, 419–437. [Google Scholar] [CrossRef]

- Yoon, J.; Hyun, M.; Heo, S.; Park, J.; Kang, D. Development of a Commercial Vehicle Ride Comfort Performance Optimization Design Process Using the 3-Dof Equivalent Cabin Suspension Model. Trans. Publ. Korean Soc. Automot. Eng. 2021, 29, 515–522. [Google Scholar] [CrossRef]

- Wang, C.; Chen, X.; Shi, G.; Yang, Z. Collaborative optimization of vehicle chassis integration system. In Proceedings of the IEEE 12th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 13–15 May 2021. [Google Scholar]

- PIDOTECH Inc. Process Intergration, Automation, and Optimization. In PIAnO User’s Manual; PIDOTECH Inc.: Seoul, Korea, 2021. [Google Scholar]

- IPG Automotive GmbH. IPG CarMaker. Reference Manual Version 9.0.1; IPG Automotive GmbH: Karlsruhe, Germany, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).