Developing a Static Kinematic Model for Continuum Robots Using Dual Quaternions for Efficient Attitude and Trajectory Planning

Abstract

:1. Introduction

2. Materials and Methods

2.1. Dual Quaternion Rule

2.2. Dual Quaternion Representation of Rigid Body Motion

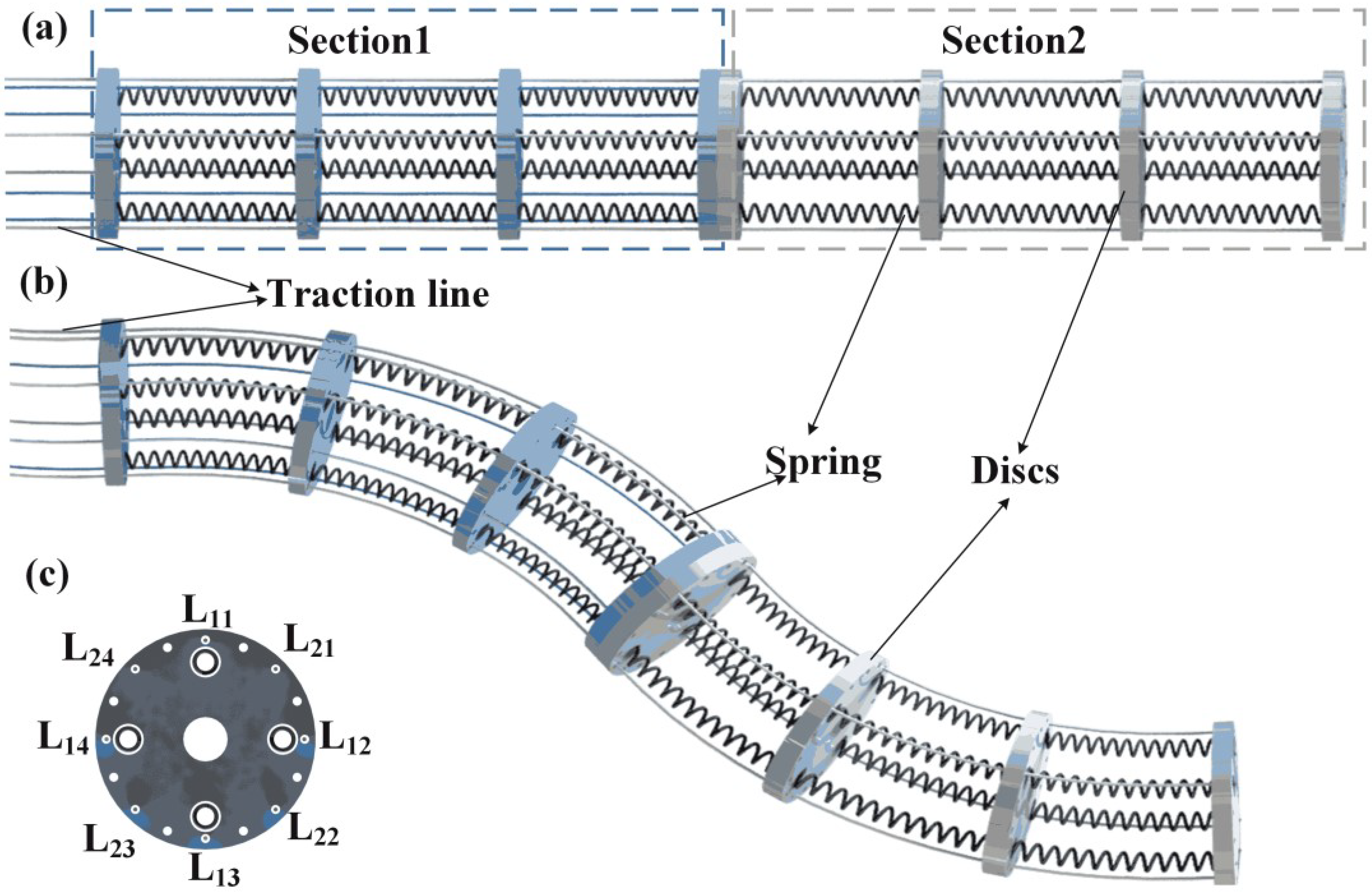

2.3. Physical Model of Continuum Robot

3. Kinematic Model of Continuum Robotics

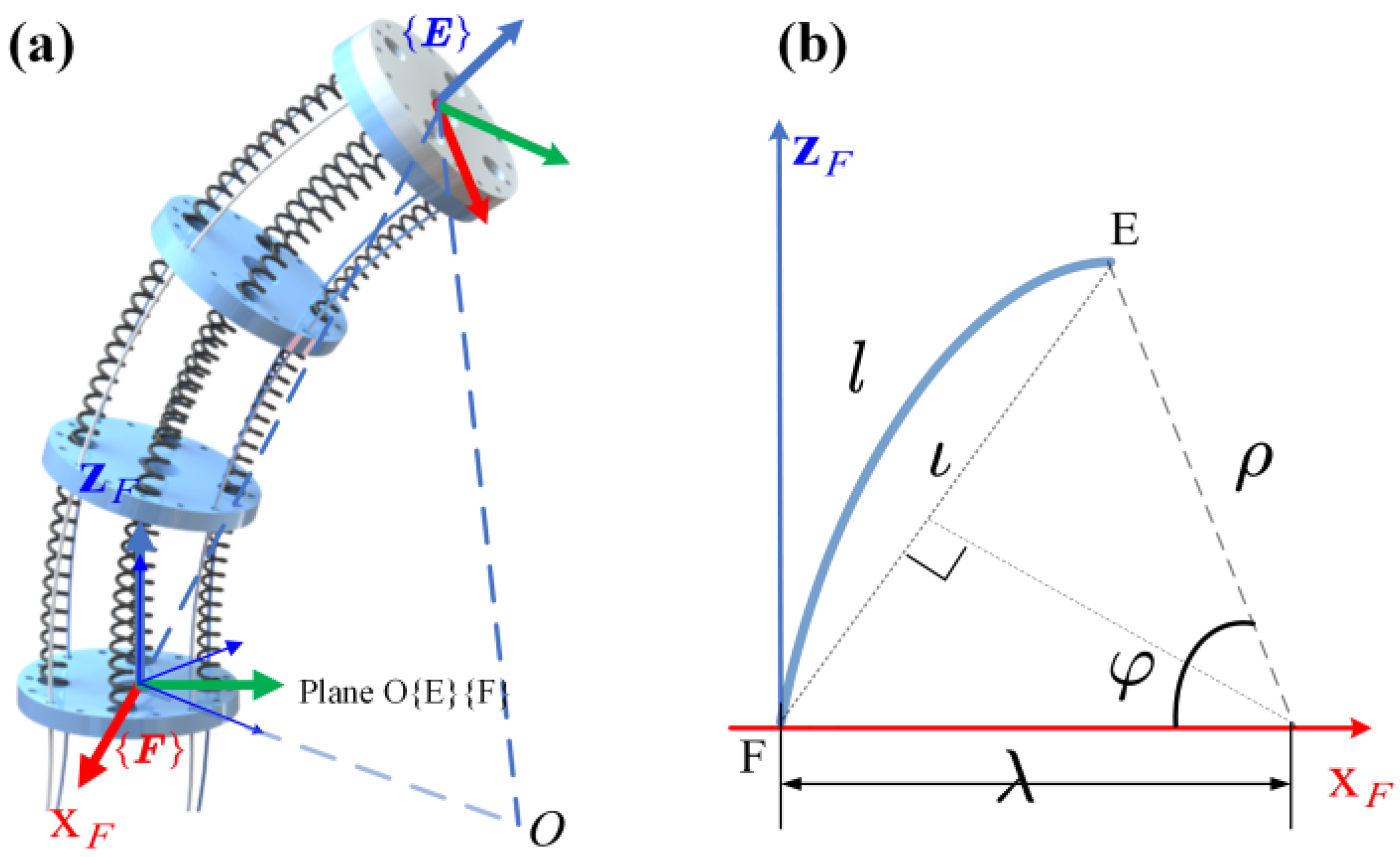

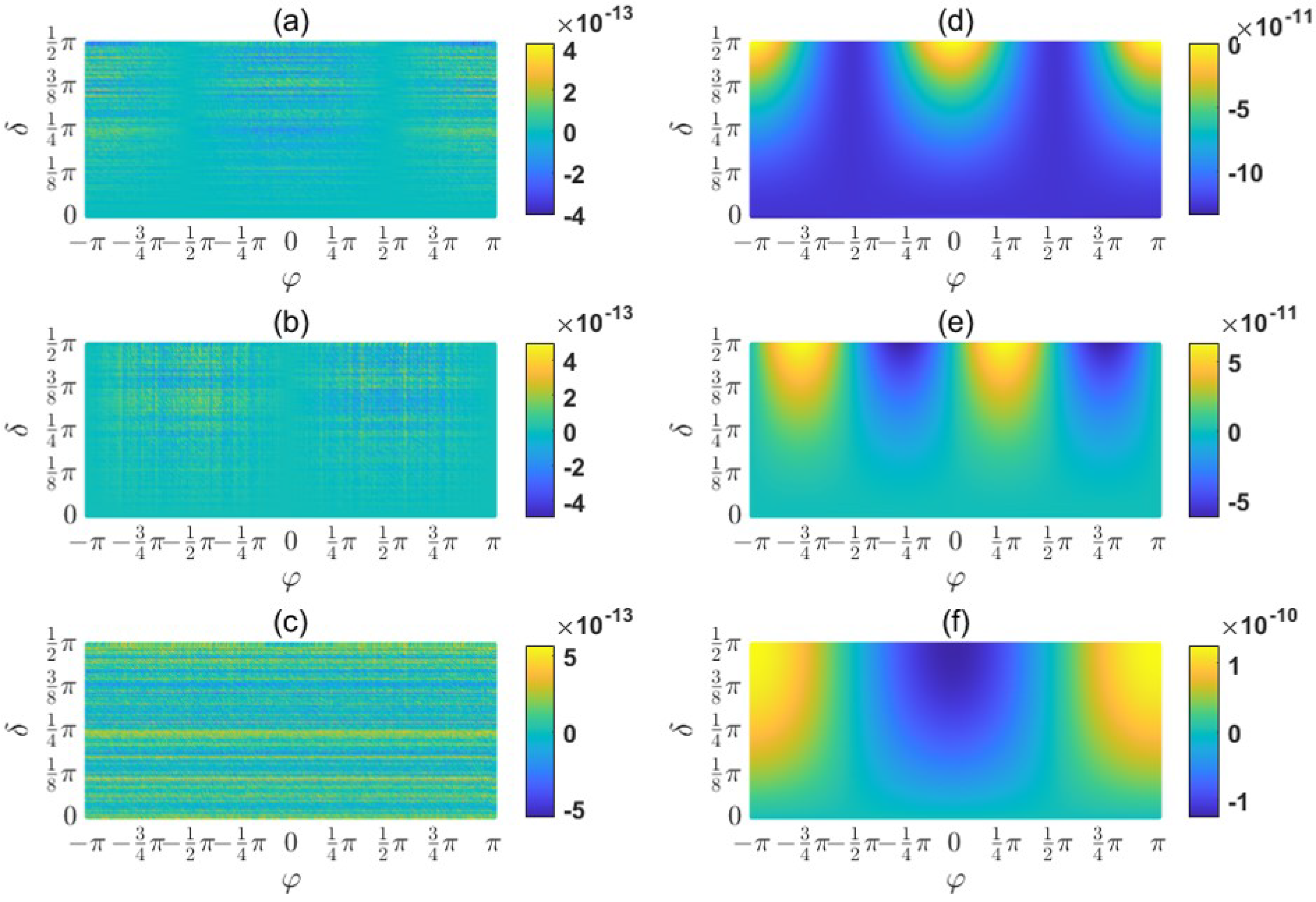

3.1. Center Axis Curve Parameters

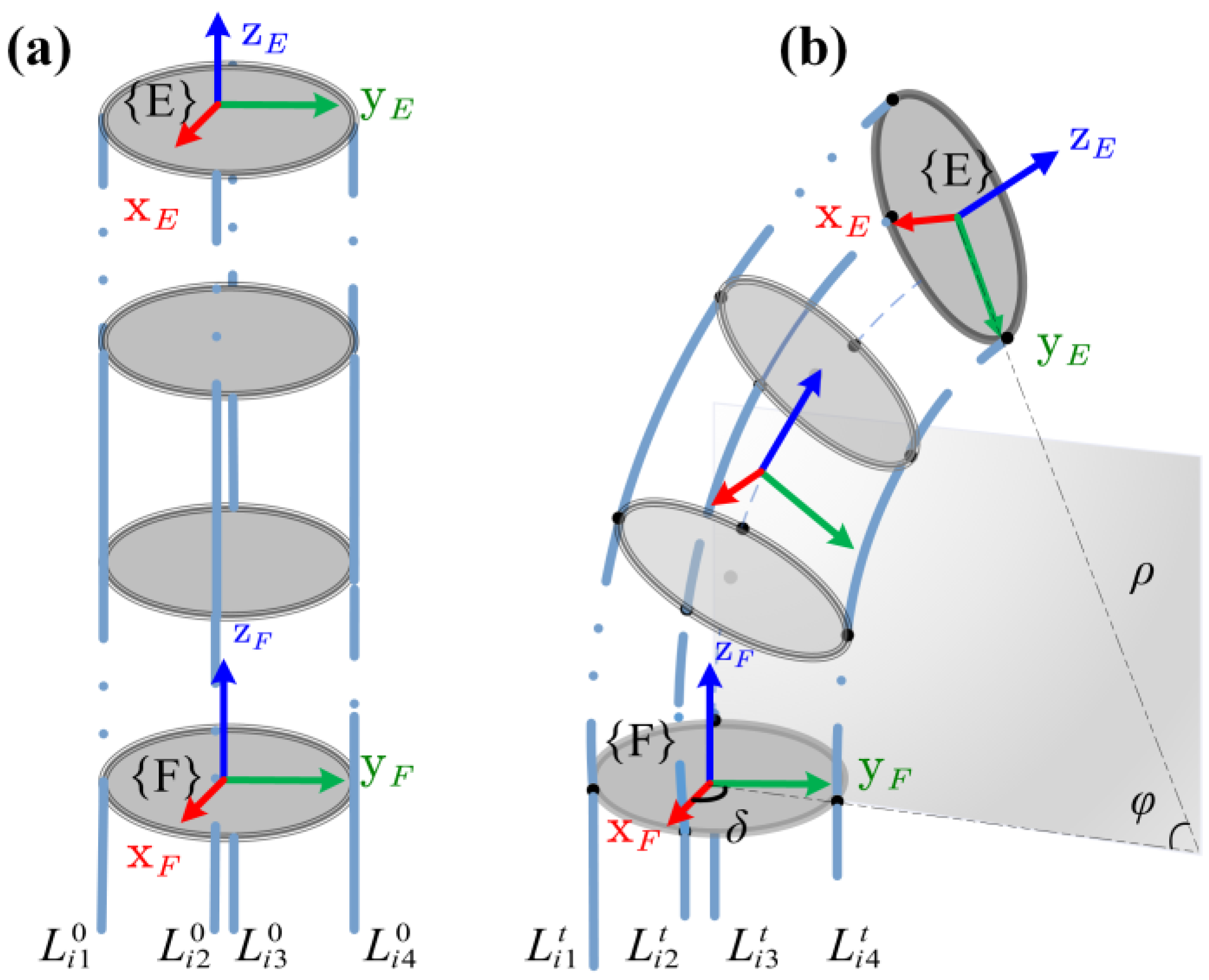

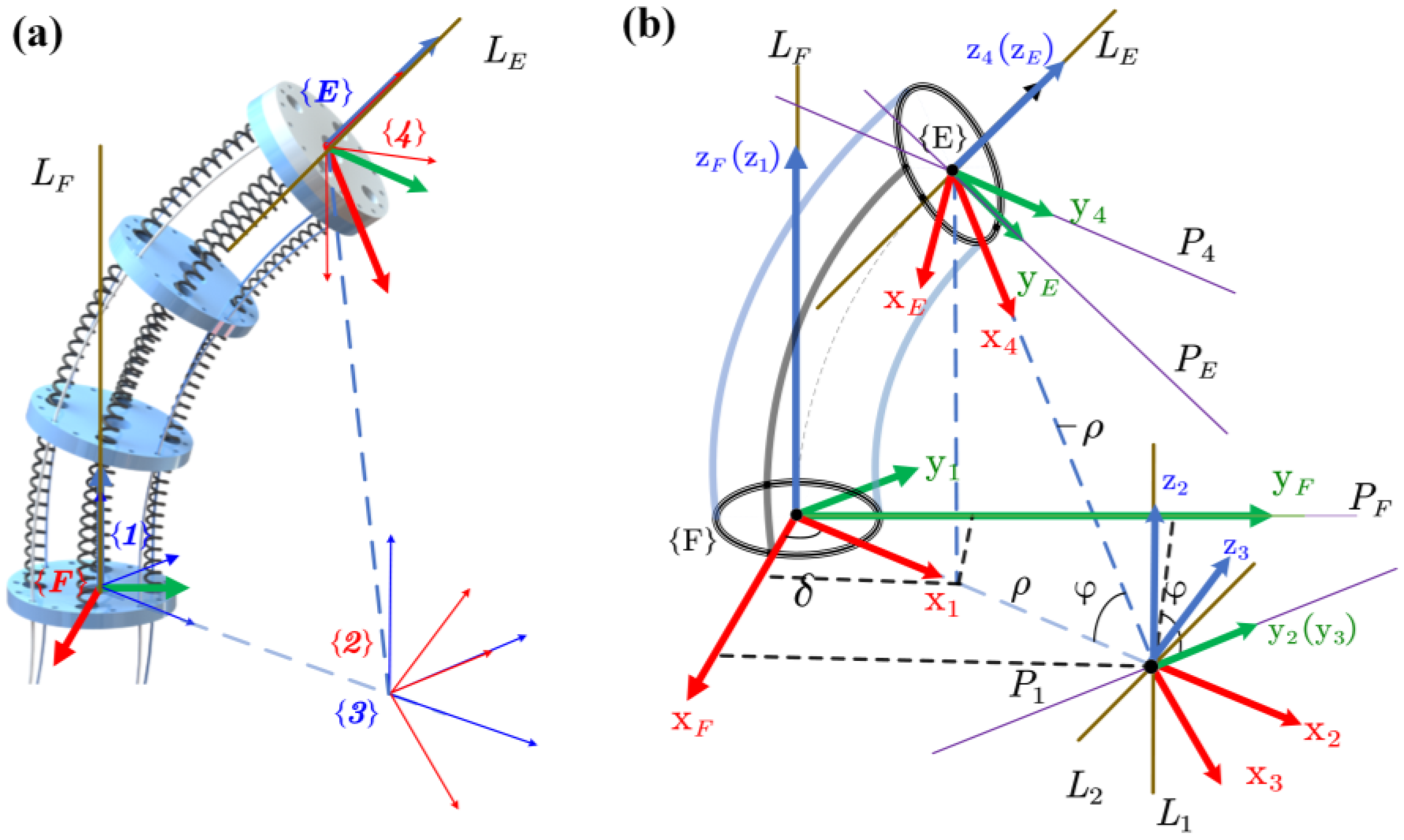

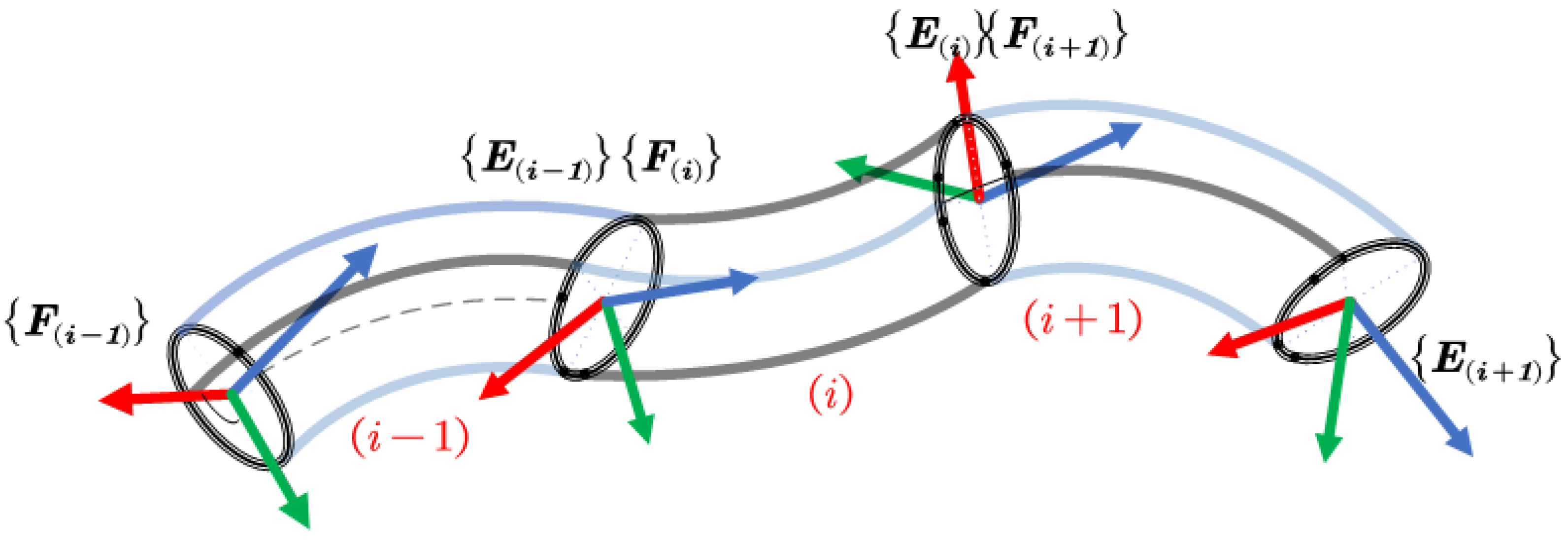

3.2. Coordinate Systems and Dual Quaternion Transformations of Points and Lines

3.3. Kinematic Equations of Continuum Manipulator

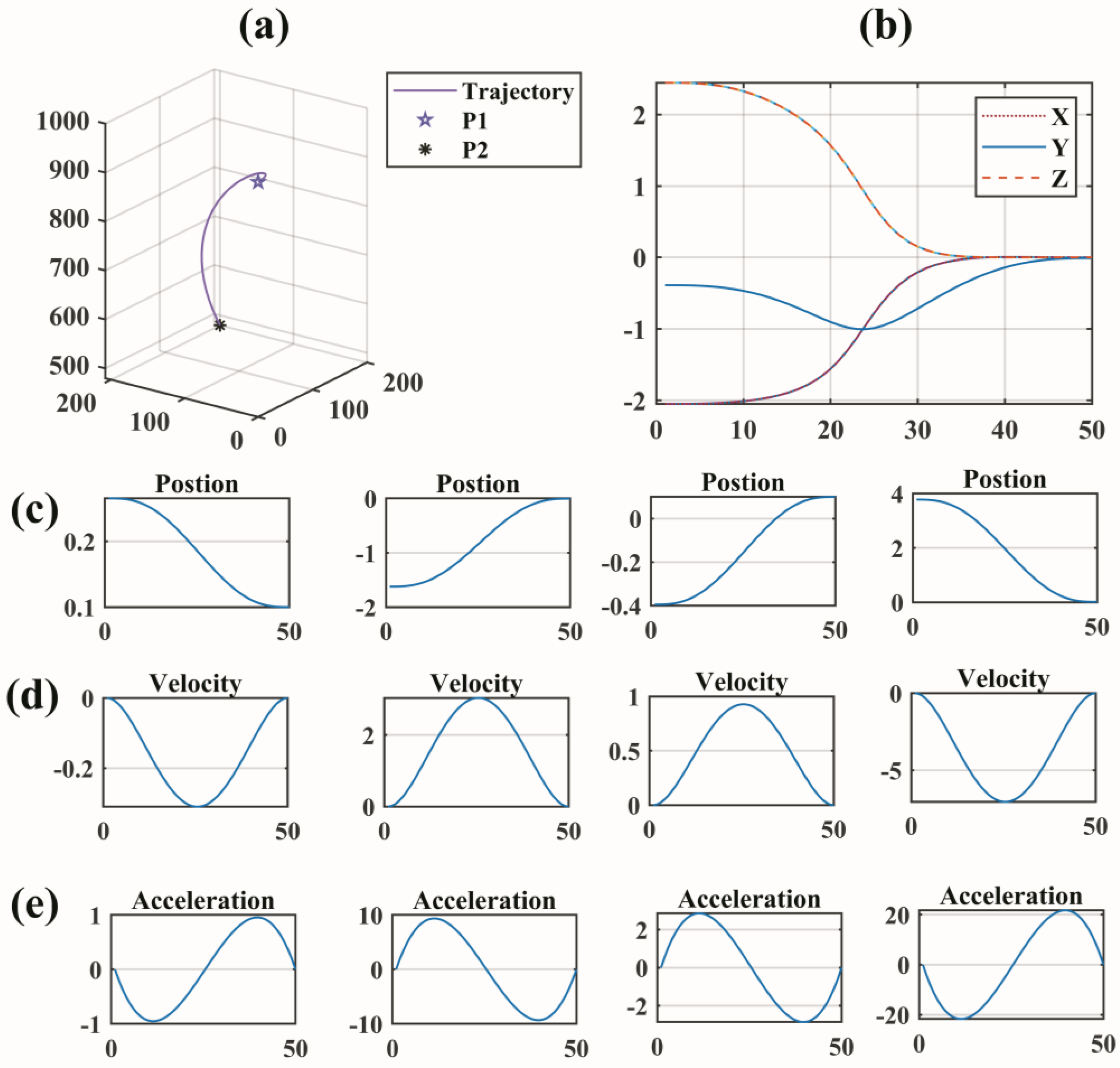

3.4. Control the Motion of the Robotic Arm through the End Position

4. Simulation Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

Appendix C

References

- Dou, W.; Zhong, G.; Cao, J.; Shi, Z.; Peng, B.; Jiang, L. Soft Robotic Manipulators: Designs, Actuation, Stiffness Tuning, and Sensing. Adv. Mater. Technol. 2021, 6, 2100018. [Google Scholar] [CrossRef]

- Xu, K.; Zhao, J.; Fu, M. Development of the SJTU Unfoldable Robotic System (SURS) for Single Port Laparoscopy. IEEE/ASME Trans. Mechatron. 2015, 20, 2133–2145. [Google Scholar] [CrossRef]

- Su, H.; Qi, W.; Schmirander, Y.; Ovur, S.E.; Cai, S.; Xiong, X. A Human Activity-Aware Shared Control Solution for Medical Human–Robot Interaction. Assem. Autom. 2022, 42, 388–394. [Google Scholar] [CrossRef]

- Jin, S.; Lee, S.K.; Lee, J.; Han, S. Kinematic Model and Real-Time Path Generator for a Wire-Driven Surgical Robot Arm with Articulated Joint Structure. Appl. Sci. 2019, 9, 4114. [Google Scholar] [CrossRef]

- Liu, T.; Mu, Z.; Xu, W.; Yang, T.; You, K.; Fu, H.; Li, Y. Improved Mechanical Design and Simplified Motion Planning of Hybrid Active and Passive Cable-Driven Segmented Manipulator with Coupled Motion. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; pp. 5978–5983. [Google Scholar]

- Wang, M.; Dong, X.; Ba, W.; Mohammad, A.; Axinte, D.; Norton, A. Design, Modelling and Validation of a Novel Extra Slender Continuum Robot for in-Situ Inspection and Repair in Aeroengine. Robot. Comput.-Integr. Manuf. 2021, 67, 102054. [Google Scholar] [CrossRef]

- Yeshmukhametov, A.; Koganezawa, K.; Yamamoto, Y.; Buribayev, Z.; Mukhtar, Z.; Amirgaliyev, Y. Development of Continuum Robot Arm and Gripper for Harvesting Cherry Tomatoes. Appl. Sci. 2022, 12, 6922. [Google Scholar] [CrossRef]

- Xu, F.; Wang, H.; Wang, J.; Au, K.W.S.; Chen, W. Underwater Dynamic Visual Servoing for a Soft Robot Arm with Online Distortion Correction. IEEE/ASME Trans. Mechatron. 2019, 24, 979–989. [Google Scholar] [CrossRef]

- Liu, Y.; Ge, Z.; Yang, S.; Walker, I.D.; Ju, Z. Elephant’s Trunk Robot: An Extremely Versatile Under-Actuated Continuum Robot Driven by a Single Motor. J. Mech. Robot. 2019, 11, 051008. [Google Scholar] [CrossRef]

- Qin, G.; Ji, A.; Cheng, Y.; Zhao, W.; Pan, H.; Shi, S.; Song, Y. A Snake-Inspired Layer-Driven Continuum Robot. Soft Robot. 2022, 9, 788–797. [Google Scholar] [CrossRef]

- Walker, I.D.; Dawson, D.M.; Flash, T.; Grasso, F.W.; Hanlon, R.T.; Hochner, B.; Kier, W.M.; Pagano, C.C.; Rahn, C.D.; Zhang, Q.M. Continuum Robot Arms Inspired by Cephalopods. In Unmanned Ground Vehicle Technology VII; Gerhart, G.R., Shoemaker, C.M., Gage, D.W., Eds.; SPIE: Orlando, FL, USA, 2005; p. 303. [Google Scholar]

- Webster, R.J.; Jones, B.A. Design and Kinematic Modeling of Constant Curvature Continuum Robots: A Review. Int. J. Robot. Res. 2010, 29, 1661–1683. [Google Scholar] [CrossRef]

- Rucker, D.C.; Webster, R.J., III. Statics and Dynamics of Continuum Robots with General Tendon Routing and External Loading. IEEE Trans. Robot. 2011, 27, 1033–1044. [Google Scholar] [CrossRef]

- Till, J.; Aloi, V.; Riojas, K.E.; Anderson, P.L.; Webster Iii, R.J.; Rucker, C. A Dynamic Model for Concentric Tube Robots. IEEE Trans. Robot. 2020, 36, 1704–1718. [Google Scholar] [CrossRef]

- Lafmejani, A.S.; Doroudchi, A.; Farivarnejad, H.; He, X.; Aukes, D.; Peet, M.M.; Marvi, H.; Fisher, R.E.; Berman, S. Kinematic Modeling and Trajectory Tracking Control of an Octopus-Inspired Hyper-Redundant Robot. IEEE Robot. Autom. Lett. 2020, 5, 3460–3467. [Google Scholar] [CrossRef]

- Amanov, E.; Nguyen, T.D.; Burgner-Kahrs, J. Tendon-Driven Continuum Robots with Extensible Sections—A Model-Based Evaluation of Path-Following Motions. Int. J. Robot. Res. 2019, 40, 027836491988604. [Google Scholar] [CrossRef]

- Chitalia, Y.; Deaton, N.J.; Jeong, S.; Rahman, N.; Desai, J.P. Towards FBG-Based Shape Sensing for Micro-Scale and Meso-Scale Continuum Robots with Large Deflection. IEEE Robot. Autom. Lett. 2020, 5, 1712–1719. [Google Scholar] [CrossRef]

- Walker, I.D. Continuous Backbone “Continuum” Robot Manipulators. ISRN Robot. 2013, 2013, 726506. [Google Scholar] [CrossRef]

- Samadikhoshkho, Z.; Ghorbani, S.; Janabi-Sharifi, F. Coupled Dynamic Modeling and Control of Aerial Continuum Manipulation Systems. Appl. Sci. 2021, 11, 9108. [Google Scholar] [CrossRef]

- Sedal, A.; Bruder, D.; Bishop-Moser, J.; Vasudevan, R.; Kota, S. A Continuum Model for Fiber-Reinforced Soft Robot Actuators. J. Mech. Robot. 2018, 10, 024501. [Google Scholar] [CrossRef]

- Singh, I.; Amara, Y.; Melingui, A.; Mani Pathak, P.; Merzouki, R. Modeling of Continuum Manipulators Using Pythagorean Hodograph Curves. Soft Robot. 2018, 5, 425–442. [Google Scholar] [CrossRef]

- Ma, X.; Chiu, P.W.-Y.; Li, Z. Shape Sensing of Flexible Manipulators with Visual Occlusion Based on Bezier Curve. IEEE Sens. J. 2018, 18, 8133–8142. [Google Scholar] [CrossRef]

- Kołota, J.; Kargin, T.C. Comparison of Various Reinforcement Learning Environments in the Context of Continuum Robot Control. Appl. Sci. 2023, 13, 9153. [Google Scholar] [CrossRef]

- Godage, I.S.; Walker, I.D. Dual Quaternion Based Modal Kinematics for Multisection Continuum Arms. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 1416–1422. [Google Scholar]

- Araújo, A.L. SMART 2015 7th ECCOMAS Thematic Conference on Smart Structures and Materials, Azores, Portugal, 3–6 June 2015; IDMEC: Lisboa, Portugal, 2015; ISBN 978-989-96276-8-0. [Google Scholar]

- Seleem, I.A.; El-Hussieny, H.; Assal, S.F.M.; Ishii, H. Development and Stability Analysis of an Imitation Learning-Based Pose Planning Approach for Multi-Section Continuum Robot. IEEE Access 2020, 8, 99366–99379. [Google Scholar] [CrossRef]

| Model | Optimization Algorithm | Actual Position | Iterations | Time(s) |

|---|---|---|---|---|

| DH | Genetic algorithm | [369.8147, 345.8322, 702.9025] | 25 | 3.43 |

| Simulated annealing algorithm | [369.8150, 345.8317, 702.9021] | 5500 | 62.15 | |

| Numerical solution Algorithm | [369.8143, 345.8315, 702.9017] | 32 | 1.15 | |

| Particle Swarm Optimization | [369.8125, 345.8306, 702.9003] | 225 | 3.36 | |

| DH Taylor expansion | Genetic algorithm | [372.2827, 347.7579, 706.3873] | 400 | 4.50 |

| Simulated annealing algorithm | [369.8165, 345.8329, 702.9044] | 7700 | 52.30 | |

| Numerical solution Algorithm | [369.8146, 345.8319, 702.9018] | 31 | 0.41 | |

| Particle Swarm Optimization | [369.8101, 345.8311, 702.8985] | 380 | 4.60 | |

| dual quaternions | Genetic algorithm | [369.8161, 345.8352, 702.9070] | 350 | 2.39 |

| Simulated annealing algorithm | [369.8118, 345.8293, 702.8986] | 3900 | 28.50 | |

| Numerical solution Algorithm | [369.8146, 345.8319, 702.9018] | 32 | 0.45 | |

| Particle Swarm Optimization | [366.5362, 345.7464, 701.7661] | 85 | 1.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Wang, Q.; Liu, Q. Developing a Static Kinematic Model for Continuum Robots Using Dual Quaternions for Efficient Attitude and Trajectory Planning. Appl. Sci. 2023, 13, 11289. https://doi.org/10.3390/app132011289

Li Y, Wang Q, Liu Q. Developing a Static Kinematic Model for Continuum Robots Using Dual Quaternions for Efficient Attitude and Trajectory Planning. Applied Sciences. 2023; 13(20):11289. https://doi.org/10.3390/app132011289

Chicago/Turabian StyleLi, Yunfei, Qiuhao Wang, and Qian Liu. 2023. "Developing a Static Kinematic Model for Continuum Robots Using Dual Quaternions for Efficient Attitude and Trajectory Planning" Applied Sciences 13, no. 20: 11289. https://doi.org/10.3390/app132011289