1. Introduction

The interaction between the drill bit and rock is a complex dynamic problem in the process of drilling and breaking rock. During the process of rotary drilling, the drill bit engages in a sequence of actions involving compression, cutting, and friction against the rock. These actions transition the rock from its initial elastic deformation phase into a more pronounced state of plastic deformation. This ultimately facilitates the accomplishment of cutting and fragmentation. Most scholars use static or quasi-static equilibrium analysis methods to conduct research, which cause large errors between the monitoring data and theoretical analysis results during the drilling process. Therefore, they cannot accurately explain the complex physical and mechanical changes in the rock drilling process.

As technology advances, sensors and automation equipment are becoming widely used in mining. Sensors are used to monitor equipment status, environmental conditions and work processes. This provides critical data for maintaining equipment, ensuring safety and optimizing production. Self-driving trucks, drones and automated drilling equipment are used in the drilling process, which can help increase production efficiency and reduce risks [

1,

2,

3,

4]. With the rapid advancement of computer technology, individuals have harnessed numerical simulation techniques to engage in diverse forms of simulated research on the process of rock-drilling-induced damage. This approach has provided a clearer exposition of the patterns of rock fragmentation and a more comprehensive understanding of the mechanics underpinning rock drilling. Consequently, this has paved the way for the proposition of more efficient drilling methods aimed at achieving higher levels of rock-fracturing efficacy. With the rapid development of computer technology, people have carried out various simulation research on the rock drilling failure process with the help of numerical simulation technology. This shows the breaking law of rock more clearly, understands the mechanism of drilling and breaking rock more comprehensively, and then proposes a drilling method with higher rock-breaking efficiency. The stereoscopic crushing effect of rocks refers to the process of crushing hard rock materials into smaller particles or fragments. Wang et al. [

5] used numerical simulation to study the rock-breaking process and mechanism of compound impact drilling. The research results show that under the action of compound impact, the rock will produce a stereoscopic crushing effect. Saksala [

6] utilized a finite-element-based modeling approach to simulate the dynamic interaction between a drilling bit and rock. This simulation involved a numerical investigation into the impact of static hydrostatic pressure and confining pressure on the process of impact drilling in hard rock. Shi [

7] employed the ABAQUS finite element software to establish a finite element model of a drilling system encompassing drill rods, borehole walls, drill bits, and coal rock. In the coal seam gas drainage operation, the gradual change in the interior of the coal rock after being damaged by cutting and the movement and force of the drill bit and drill pipe were simulated and analyzed. The results clarified the failure law of the coal rock and the force and movement law of the drill bit. Yan et al. [

8] undertook a numerical simulation to investigate the cutting process of individual abrasive particles. The outcomes indicate that when the cutting depth reaches a certain critical value, both radial and tangential cutting forces experience a sudden surge. Furthermore, during low-speed cutting, this increase is more pronounced compared to the increase observed during high-speed cutting. Aiming at the influence of factors such as bit cutting angle and drilling speed during the drilling process, Xu et al. [

9] and Luo [

10] used LS-DYNA software to establish the finite element models of the twist drill bit and the polycrystalline diamond compact. The simulation analysis obtained the relationship between the change in cutting angle and the drilling efficiency, and analyzed the influence of cutting speed and drilling speed on the drilling process. A large number of scholars [

5,

11,

12,

13] have conducted numerical simulations on rock drilling, and the research results show that impact energy, impact speed, and impact angle have a significant impact on rock fragmentation. As the impact energy increases, the rock fragmentation effect increases. Both the impact angle and impact speed have an optimal value, which can maximize the rock-crushing effect. Cyclic loading will gradually weaken the strength of the rock through multiple loading and unloading processes, leading to fatigue failure, thus affecting the rock-crushing effect.

Many scholars have conducted a lot of research on the rock-breaking efficiency of different bit shapes, bit structures and drilling methods [

14,

15,

16,

17,

18,

19]. For instance, Pryhorovska et al. [

14] established a finite element model of the cutting process for PDC drill bits, conducting numerical simulations on the cutting processes of PDC drill bits with varying shapes. The simulation results show that there is no essential difference between cross cutting and straight cutting, the cutting force relationship is oscillatory and non-uniform for all types of tools, and the increase in cutting depth leads to an increase in vibration amplitude. Yang et al. [

15] combined experimental investigations with numerical simulations and delved into the rock-fracturing mechanisms of PDC drill bits. They established nonlinear dynamic models for rock units and analyzed stress states within rock units, sliding fracture characteristics, plastic energy dissipation, and stress distribution along cutting edges. In comparison to unidirectional cutting, lateral cutting generates greater tensile stress within rock units. It exhibits lower plastic energy dissipation, and the average stress on the cutting edge is significantly lower than that observed in unidirectional cutting. During the lateral cutting process, rocks undergo not only shear deformation but also brittle fracture. This dual mode of failure contributes to an enhancement in the rock’s fracturing efficiency. Li et al. [

16] utilized the ABAQUS finite element method to construct a nonlinear dynamic simulation model for the dynamic rock fracturing of both PDC drill bits and roller-cone compound drill bits. Their study delved into the cutting and fracturing mechanisms of these two types of drill bits. It was discovered that, in hard formations, PDC drill bits experience more severe torsional vibration than roller-cone bits, resulting in relatively lower rock-fracturing efficiency. This discrepancy can be attributed to the fact that PDC drill bits rely on a combination of compression and tension for rock fracturing, while roller-cone bits primarily utilize tensile stress for fracturing. Friction and vibration phenomena are present during the drilling process, consequently leading to wear and tear of the drill bit. Therefore, Wang et al. [

17] closely integrated the friction between the drill string and the wellbore. They introduced a model to compute the drill string’s surface swing response, simulating the redistribution of friction during stick-slip motion caused by swinging and friction. Tkalich et al. [

18] constructed a representative 3D finite element model resembling the microstructure of hard metals. They employed macroscopic devices to conduct macroscopic finite element simulations on the normal and oblique frictional impact of elastic rocks using hard metal spherical tips. Through microstructure analysis, they elucidated that the tensile failure of hard alloy particles on the drill bit is the primary cause of drill bit wear. Peng [

19] conducted a comparative study on numerical simulation finite element models, constitutive models, and the accuracy of simulation results for single-tooth and full-bit rock fracturing. They found that the Mohr–Coulomb model introduces slightly larger errors in results compared to the Drucker–Prager model. Furthermore, they employed finite element numerical simulations to analyze the force distribution on the main cutting teeth during drill bit rock cutting, allowing them to predict the wear trend of the drill bit’s cutting teeth. When drilling into rock using a drill bit, friction is generated that wears away the rock as the drilling reaches a steady state [

20]. The contact stress acting on the rock drill bit and the inclination angle of the drill bit are important indicators that reflect the degree of drill bit wear [

21]. Wang et al. [

22] conducted laboratory drilling experiments to study drill bit wear during the drilling process. At present, the rock-breaking mechanism and theoretical research on the drilling process are not yet complete. Most of the previous studies used static or quasi-static equilibrium analysis methods [

23,

24,

25,

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36], which resulted in large errors between the data monitored during the drilling process and the theoretical analysis results. The complex physical and mechanical changes in the rock-drilling process cannot be accurately explained [

37,

38,

39,

40,

41,

42]. The process of drilling and breaking rock is carried out by controlling the drilling speed and rotation speed of the drill bit. Changes in the drilling speed, rotation speed and rock properties will cause changes in the force on the drill bit. ABAQUS is a powerful finite element analysis software that can be used to simulate a variety of engineering and scientific problems, including the techniques used to drill bits into rock. Using ABAQUS to simulate drilling into rock with a drill bit can help engineers optimize the drilling process, reduce costs and risks, and ensure the successful completion of the project. Therefore, it is necessary to use ABAQUS to study the changing rules of drill bit stress during drilling under different drilling speeds, rotational speeds, confining pressures and rock structure conditions.

In this paper, the dynamic process of drilling and breaking rock is analyzed using the ABAQUS software. According to the stress–strain state of the rock and the force of the drill bit, the rock-breaking mechanism of drilling is revealed. The effect of the size of the drill bit, and the characteristics of the rock mass on the drilling parameters is studied during the drilling process.

4. Discussion: Analysis of Factors Affecting Drilling Forces

This chapter analyzes the effects of drill bit size, rock mass structural characteristics, and confining pressure on thrust and torque.

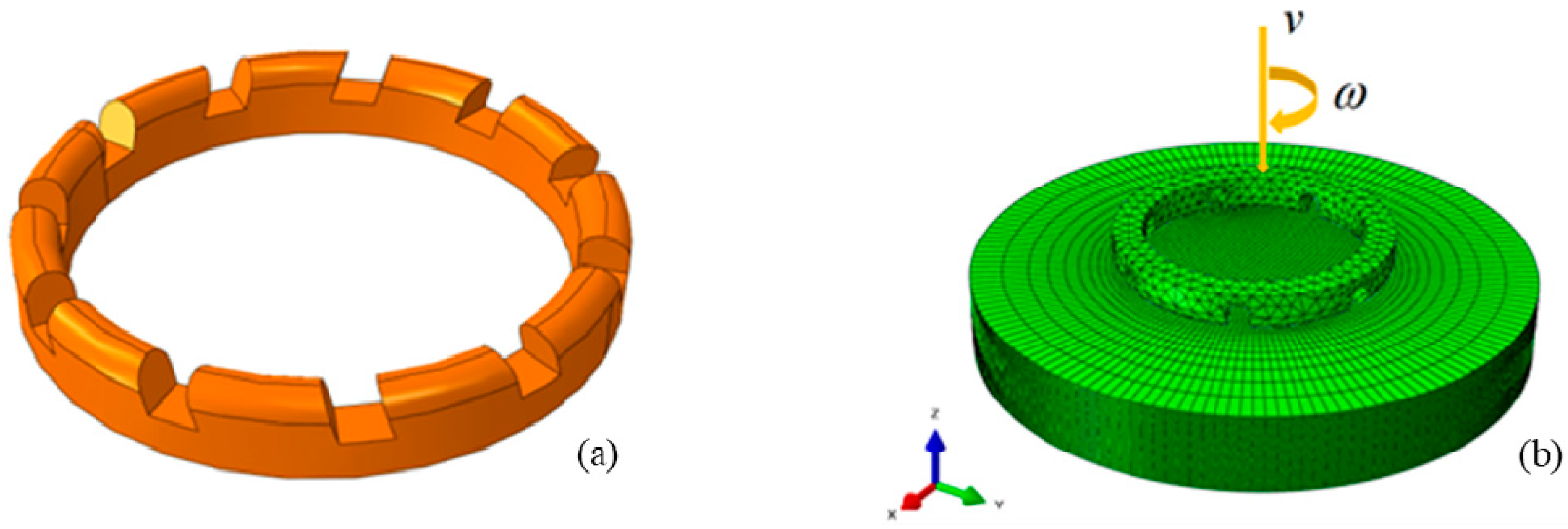

4.1. Analysis of Drill Bit Size on Drilling Force

During the drilling process, the variation in drill bit dimensions can have different effects on drill bit forces. In this study, we selected these drill bit sizes because they are relatively common on the market and can meet most practical drilling conditions. These drill bit models are denoted as 59#, 75#, and 110#. Their corresponding outer diameters are 59 mm, 75 mm, and 110 mm, while their inner diameters are 43 mm, 59 mm, and 91 mm, respectively. Additionally, the number of water outlets for these drill bits is 6, 7, and 10, respectively. Finite element mesh models for these three drill bit models interacting with the rock are depicted in

Figure 10.

By setting drilling speed and rotational speed, we control the drilling and rock-breaking process. We will separately discuss the variations in thrust force and torque with drilling speed for different-sized drill bits when the rotational speed is set at 200 rpm. Additionally, we will examine the changes in thrust force and torque with rotational speed for different-sized drill bits when the drilling speed is set at 2 mm/s.

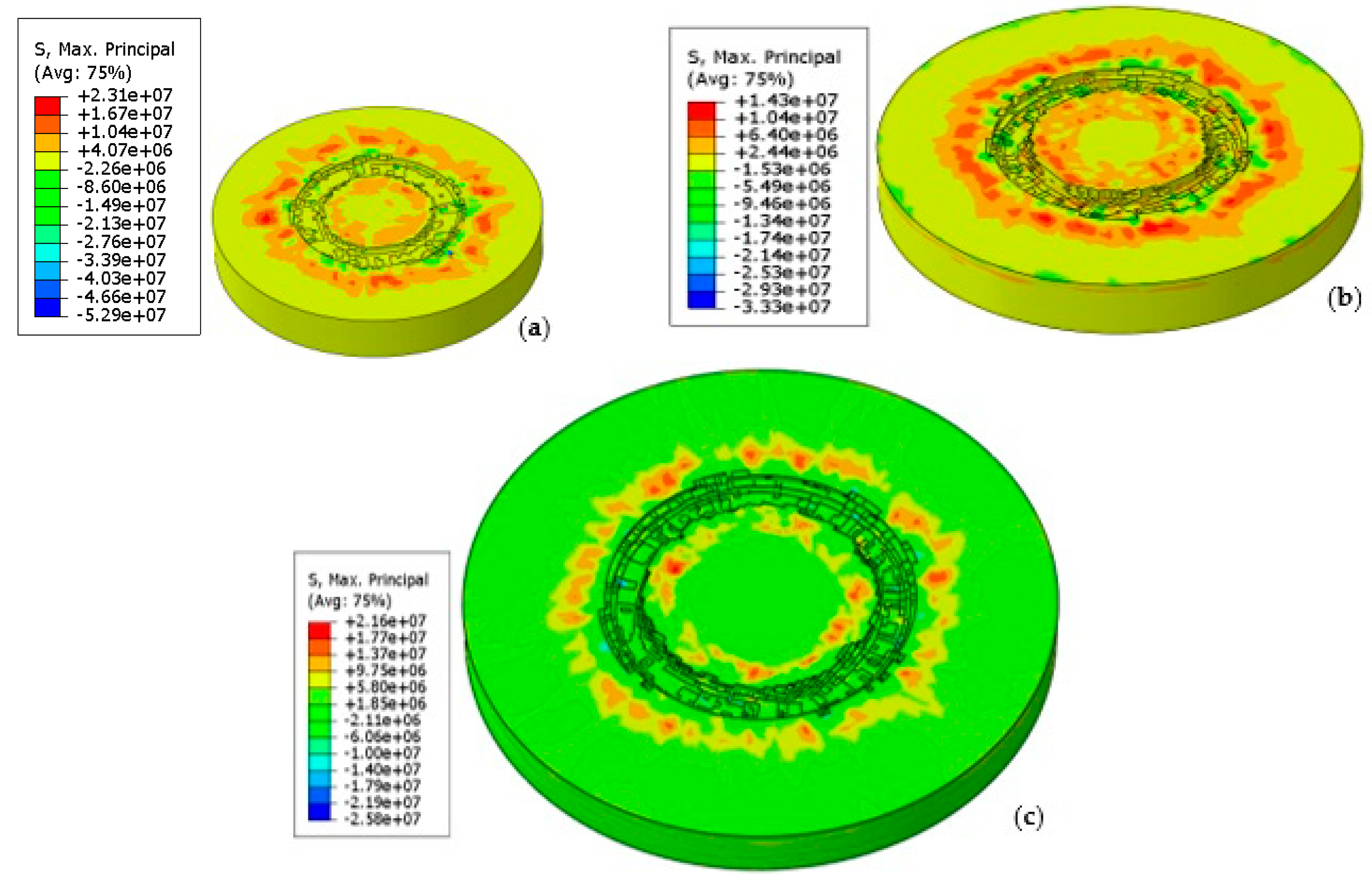

When the drilling speed is 2 mm/s, the rotation speed is 200 rpm, and the drilling time is 2.5 s. The large principal stress cloud diagrams of drilling with three sizes of drill bits are shown in

Figure 11. The diameter of the drill bit in

Figure 11a is 59, the diameter of the drill bit in

Figure 11b is 75, and the diameter of the drill bit in

Figure 11c is 110. There is a small difference in the stress values of the three sizes of drill bits. The maximum stress values appear at the contact point between the drill bit and the rock, mainly distributed at the bottom of the well and around the wellbore. Notably, the stress distribution region for the larger-sized drill bit extends over a wider range along the wellbore compared to the smaller-sized drill bits.

Figure 12 illustrates the relationship curves between thrust force, torque, and drilling speed for the three drill bit sizes, 59#, 75#, and 110#, all at the same rotational speed of 200 rpm. It is evident that both thrust force and torque exhibit a linear increase with the augmentation of drilling speed. Under the same drilling speed conditions, larger drill bit sizes result in higher thrust force and torque. However, the slope of the relationship curve between thrust force, torque, and drilling speed remains largely unaffected by drill bit size. The increase in drill bit size enlarges the effective contact area between the drill bit and the rock during drilling, consequently leading to increased thrust force and torque. Therefore, it is possible to calculate the required thrust force and torque for a given drill bit size by considering the effective contact area between the drill bit and the rock. For various drill bit sizes, the following relationship expressions between thrust force, torque, and drilling speed, taking into account the drill bit size effect, can be established:

where

F is thrust force,

T is torque,

v is drilling speed,

is the slope of the relationship curve between thrust force and drilling speed,

is the slope of the relationship curve between torque and drilling speed,

is the thrust force constant,

is the torque constant,

represents the drill bit size influence factor,

A0 represents the effective contact area between the current drill bit and the rock, and

An represents the effective contact area between the required drill bit size and the rock.

Figure 13 depicts the relationship curves between thrust force, torque, and rotational speed for the three drill bit sizes—59 #, 75 #, and 110 #—all at the same drilling speed of 2 mm/s. It can be observed that both thrust force and torque decrease in a power law manner with the increase in rotational speed. Under the same rotational speed conditions, larger drill bit sizes result in higher thrust force and torque. However, the correlation coefficient of the relationship curve between thrust force, torque, and rotational speed remains largely unaffected by drill bit size. The increase in drill bit size leads to an increase in thrust force and torque mainly due to the enlarged effective contact area between the drill bit and the rock during drilling. Therefore, it is possible to calculate the required thrust force and torque for a given drill bit size by considering the effective contact area between the drill bit and the rock. For various drill bit sizes, the following relationship expressions between thrust force, torque, and rotational speed, taking into account the drill bit size effect, can be established:

where

F is thrust force,

T is torque,

ω is rotational speed,

is the slope of the relationship between the thrust force and the rotation speed,

is the slope of the relationship between the torque and the rotation speed,

is thrust force constant,

is the torque constant, and

is the drill bit size influence factor.

Figure 14 illustrates the relationship between torque and thrust force during the drilling process for different-sized drill bits. From the graph, it is evident that regardless of the drill bit size, the torque during the drilling process exhibits a linear increase with thrust force. Additionally, larger drill bit sizes correspond to steeper slopes in the torque–pressure curve. Similarly, both Equations (15) and (17) yield the relationship expression between torque and thrust force, taking into account the drill bit size effect as follows:

From Equation (18), it is evident that the two expressions are identical in form. Therefore, the relationship expression between torque and thrust force, considering the drill bit size effect, can be simplified to:

where

F is thrust force,

T is torque,

is the slope of the relationship curve between thrust force and drilling speed,

is the torque constant, and

represents the drill bit size influence factor.

The changes in the relationships between thrust force, torque, drilling speed, and rotational speed, as well as the alteration in the torque–thrust force relationship during the drilling process with different-sized drill bits, primarily stem from variations in the effective contact area between the drill bit and the rock. Therefore, by introducing the drill bit size influence factor through the conversion relationship between different-sized drill bits and the effective contact area with the rock, we obtain the relationship expressions that consider the drill bit size effect for thrust force and torque concerning drilling speed and rotational speed. Additionally, we acquire the expression for the torque–thrust force relationship while considering the drill bit size effect.

4.2. Influence of Rock Mass Structural Characteristics on Drill Bit Forces

The structural characteristics of rock masses play a crucial role in controlling the deformation and failure of rock engineering, ultimately determining the overall stability of the rock mass. Therefore, investigating the impact of these structural characteristics on drill bit forces holds significant importance. In this section, the author primarily considers three influencing factors related to rock mass structure: the dip angle of structural planes, their thickness, and the presence of soft–hard interlayers between rock strata. Each of these factors will be separately discussed in terms of their influence on thrust force and torque during the rock drilling process.

The finite element mesh model containing the rock mass structural surface is shown in

Figure 15. Among them, the inclination angle of the rock mass structural plane is 45° and 90°, respectively, and the thicknesses of the rock mass structural plane are 1 mm, 3 mm and 5 mm, respectively. The 75# drill bit is also used for drilling. The process of drilling and rock breaking is controlled by setting the drilling speed and rotation speed. The drilling speed and rotation speed are set to 2 mm/s and 200 rpm, respectively. The drilling time is 2.5 s. The physical and mechanical parameters of the rock mass whose basic quality level is Level II in

Table 1 are selected, the structural plane is replaced by solid units with a lower rock mass quality level, and the physical and mechanical parameters of the Level IV rock mass are selected.

The inclination angles of the rock mass structural planes are 45° and 90°, respectively, and the large principal stress cloud diagrams with a structural plane thickness of 3 mm are shown in

Figure 16. The maximum stress values appear at the contact point between the drill bit and the rock, mainly distributed at the bottom of the well and around the wellbore; the minimum stress values appear at the structural surface and around the boundary. The stress values in the two areas of the 90° structural plane are symmetrically distributed, and the stress values in the lower area of the 45° structural plane are slightly larger than those in the upper area. This is due to the extrusion of the upper rock mass on the lower rock mass on the structural plane during the drilling process.

Figure 17 displays the relationship curves between drill pressure and torque and the thickness of structural planes, with structural plane inclinations of 45° and 90°. A thickness of 0 mm indicates rock mass without structural planes. As observed from the graph, both drill pressure and torque decrease significantly as the thickness of the structural planes increases, indicating that the presence of structural planes in the rock mass has a substantial impact on drill pressure and torque. As shown in

Figure 17a, for structural planes inclined at 45°, drill pressure and torque initially experience a sharp reduction as the thickness of the structural planes increases. This behavior can be attributed to the tilted orientation of the structural planes, causing a relatively larger contact area with the drill bit when the structural planes are initially encountered. However, as the drilling depth increases, the contact point between the drill bit and the structural planes gradually shifts away from the center until the drill completely penetrates the structural planes, resulting in a less pronounced reduction. As shown in

Figure 17b, when the inclination angle of the structural surface is 90°, the thrust force and torque decrease in a relatively stable manner as the thickness of the structural surface increases. Since the structural plane separates the rock mass symmetrically, as the drilling depth increases, the drill bit and the structural plane are always in contact at the middle part, and thrust force and torque decrease by basically the same extent. Clearly, the presence of structural planes significantly influences the mechanical properties of the rock mass. Therefore, utilizing real-time drilling monitoring methods can effectively identify the existence of rock structural planes and provide insights into characteristics such as structural plane inclination and thickness.

The finite element mesh model for the rock mass with soft–hard interlayers is depicted in

Figure 18. In this model, the upper rock layer has a thickness of 3 mm, while the lower rock layer has a thickness of 17 mm. The drilling process involves initial contact with the upper rock layer, followed by penetration through it and then contacting the lower rock layer. The distribution of soft and hard layers is considered in two scenarios: upper soft/lower hard rock layers and upper hard/lower soft rock layers. The same 75# drill bit is used, with drilling and rotation speeds set at 2 mm/s and 200 rpm, respectively. The drilling duration is set at 2.5 s. For the physical mechanical parameters, values are selected based on

Table 1, with the physical parameters for the hard rock layer taken from rock mass quality Level II and those for the soft rock layer from rock mass quality Levels III and IV.

Figure 19 shows the thrust force and torque curves of soft and hard interbedded rock mass. Drilling analysis of the upper soft/lower hard rock layer and upper hard/lower soft rock layer were carried out, respectively. The hard rock layer is assigned properties corresponding to rock mass quality Level II, while the soft rock layer properties are selected from rock mass quality Levels III and IV. Regardless of the upper soft/lower hard rock layer distribution or the upper hard/lower soft rock layer distribution, the thrust force and torque values will change suddenly at the interface of the two rock layers, and there is an obvious boundary. During the drilling process, owing to the recurrent cycle of adhesion, slippage, and re-adhesion between the drill bit and the rock, the thrust force and torque consistently oscillate within a specific range during the stable phase.

As depicted in

Figure 19a,b, when drilling in a rock formation with an upper layer of soft rock and a lower layer of hard rock, the drill bit initially comes into contact with the soft rock layer. After penetrating the upper soft rock layer, it reaches the lower hard rock layer, and drilling continues within the hard rock until completion. Upon the initial contact between the drill bit and the soft rock surface, significant impact pressure and torque are generated. Likewise, when the drill bit encounters the interface between the soft and hard rock layers, there is a notable increase in impact pressure and torque. This phenomenon is a result of the continuous action of drilling speed and rotational velocity during the transition from the soft rock surface to the hard rock layer. Once drilling stabilizes, both thrust force and torque remain within a certain range. During the stable drilling phase, the thrust force and torque in the soft rock layer are noticeably lower than those in the hard rock layer. When drilling through the soft rock layer, the thrust force and torque for the Level IV rock layer are notably lower than those for the Level III rock layer. Furthermore, it is worth noting that variations in the upper soft rock layer’s rock quality have a relatively minor impact on the thrust force and torque when drilling the lower hard rock layer.

As illustrated in

Figure 19c,d, when drilling in a rock formation with an upper layer of hard rock and a lower layer of soft rock, the drill bit initially comes into contact with the hard rock layer. After penetrating the upper hard rock layer, it reaches the lower soft rock layer, and drilling continues within the soft rock until completion. Upon the initial contact between the drill bit and the hard rock surface, significant impact pressure and torque are generated. Subsequently, when the drill bit encounters the interface between the hard and soft rock layers, there is a slight reduction in pressure and torque. This phenomenon is a result of the continuous action of drilling speed and rotational velocity during the transition from the hard rock surface to the soft rock layer. Once drilling stabilizes, both thrust force and torque remain within a certain range. During the stable drilling phase, the thrust force and torque in the hard rock layer are noticeably higher than those in the soft rock layer. The variations in rock quality within the lower soft rock layer have a relatively minor impact on the thrust force and torque when drilling through the upper hard rock layer. When drilling through the soft rock layer, the thrust force and torque for the Level IV rock layer are slightly lower than those for the Level III rock layer.

The drilling results in the soft–hard interlayered rock formation clearly demonstrate significant differences in thrust force and torque during the drilling process in different rock layers. Whether transitioning from a soft rock layer to a hard rock layer or from a hard rock layer to a soft rock layer, whenever there is a change in rock quality, the thrust force and torque relationship curves are distinctly reflected. Therefore, it is possible to deduce the distribution pattern of rock layers by observing changes in thrust force and torque during the drilling process, which serve as indicators of specific variations in rock quality within the formation.

4.3. Effect of Rock Mass Confining Pressure on Drill Bit Stress

Due to limitations in model size and computational capacity, it is not possible to directly simulate the entire drilling process. Therefore, it is necessary to apply confining pressure at the model boundaries to simulate the in situ stress field in the rock mass. The study considers the variations in thrust force and torque when the drill bit penetrates under different Levels of static hydrostatic pressure and deviatoric stress. Consider the changes in the bit pressure and torque of the rock mass when drilling under different hydrostatic pressures and partial confining pressures. The effect of lateral confining pressure considers two different ways of drilling—vertical and horizontal.

The finite element grid model with applied rock confinement pressure is shown in

Figure 20. Normal confinement pressure is applied to the upper part of the rock, and radial confinement pressure is applied at the lateral boundaries. The bottom of the rock is subjected to fixed constraints. A 75# drill bit is used for drilling, and the drilling process is controlled by setting the drilling speed and rotation speed to 2 mm/s and 200 rpm, respectively, with a drilling duration of 2.5 s. In the case where the normal confinement pressure (

) equals the radial confinement pressure (

), the rock is in a state of hydrostatic pressure. Different static water pressures of 0 MPa, 2 MPa, 10 MPa, and 20 MPa are applied to the rock.

Figure 21 depicts the thrust force and torque for the rock under various static water pressures. When drilling vertically, the normal confining pressure is equal to the vertical stress, and the radial confining pressure is equal to the horizontal stress. The rock is subjected to normal pressures of 0 MPa, 2 MPa, 10 MPa, and 20 MPa in the vertical direction and radial pressures of 0 MPa, 0.6 MPa, 2.9 MPa, and 5.8 MPa in the radial direction.

When performing horizontal drilling, the normal pressure is equal to the horizontal stress , and the radial pressure is equal to the vertical stress . The rock is subjected to normal pressures of 0 MPa, 0.6 MPa, 2.9 MPa, and 5.8 MPa in the vertical direction and radial pressures of 0 MPa, 2 MPa, 10 MPa, and 20 MPa in the radial direction. With the increase in confining pressure, the thrust force and torque during the drilling process also increase accordingly.

The wear experienced by tools and equipment in the course of technological processes within geotechnology and mining carries substantial economic repercussions. On one hand, there are material costs stemming from the replacement of worn-out tools and equipment. On the other hand, there are expenses related to work process downtime [

45]. Abrasivity is intricately linked to tool wear, rendering it imperative to ascertain the abrasivity rate specific to individual geological materials, contingent upon the nature of their interaction with the tools [

46,

47]. Numerous abrasivity tests have been meticulously developed within laboratory settings, establishing abrasivity as one of the most widely recognized index methods for evaluating the abrasive nature of rocks [

45,

46,

47]. Abrasivity describes the ability of rocks to wear the surface of solid materials, primarily, but not limited to, metal. Such interactions transpire during various activities, including rock mining, drilling holes, loading, and both short and long-distance transportation. Abrasivity is responsible for how much the element in contact with it wears out. Crucially, it exerts a notable impact on the wear experienced by drill bits and contributes to increased forces acting upon the drill bit. Future research endeavors should aim to scrutinize the relationships between abrasivity and rock properties such as drilling properties, uniaxial compressive strength, point load strength, Brazilian tensile strength, Schmidt rebound hardness, and equivalent quartz content.

5. Conclusions

This paper uses ABAQUS software to simulate and analyze the rock-breaking process of diamond-impregnated drill bits and study the changing rules of rotation speed, drilling speed, drill bit size and confining pressure on thrust force and torque.

Considering the influence of drilling speed and rotation speed on thrust force and torque during drilling, the changing rules of drilling parameters on thrust and torque are obtained. This can reduce unnecessary energy consumption, improve drilling efficiency and reduce costs. When the rotational speed is fixed, the thrust and torque are linearly positively related to the drilling speed. As the rotation speed decreases, the slope of the relationship curve between thrust force and torque and drilling speed increases. When the drilling speed is constant, as the rotational speed increases, the thrust force and torque decrease as a power function.

When the drilling speed is constant, the larger the drill bit size, the greater the thrust force and torque. When the rotational speed is constant, the larger the drill bit size, the greater the thrust force and torque.

When the inclination angle of the structural surface is 45° and 90°, the thrust force and torque both decrease with the increase in the thickness of the structural surface. The thrust force and torque decrease sharply during the drilling process from not containing the structural surface to including the structural surface. The drilling results of soft and hard interbedded rock masses show that whether it is a transition from soft rock layer to hard rock layer, or from hard rock layer to soft rock layer, the relationship curve of thrust and torque can identify the transition process.

Thrust force and torque increase with increasing confining pressure. The thrust force and torque under the action of hydrostatic pressure increase with the confining pressure to a greater extent than those under the bias pressure. This paper uses numerical simulation software to simulate the dynamic process of the drill bit drilling into the rock, which can reduce the cost of actual testing and drilling.