Digging Performance and Stress Characteristic of the Excavator Bucket

Abstract

:1. Introduction

2. ADAMS-EDEM-ANSYS Coupling Simulation Method

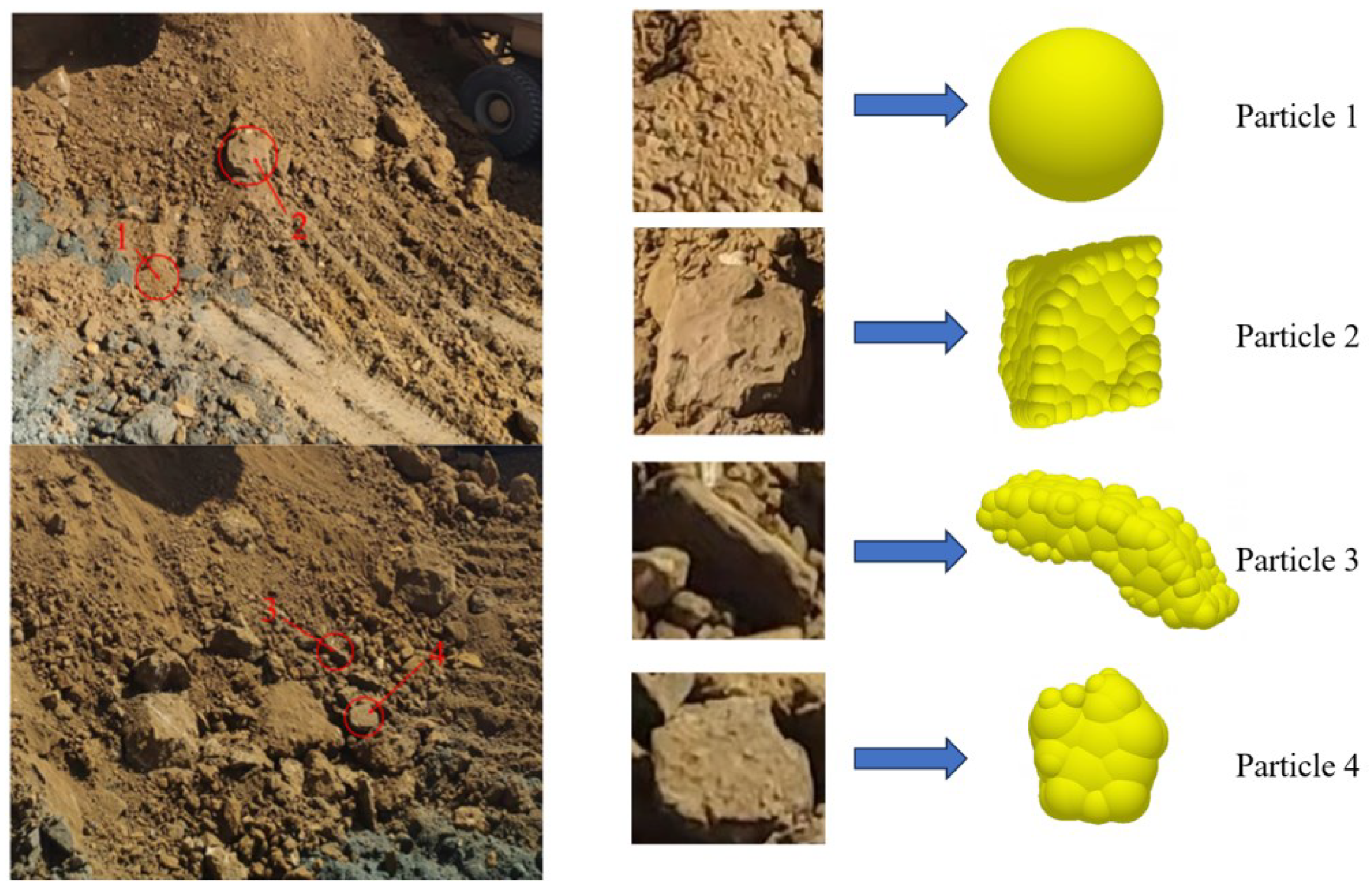

2.1. Construction of Discrete Element Model of Loess Material Pile

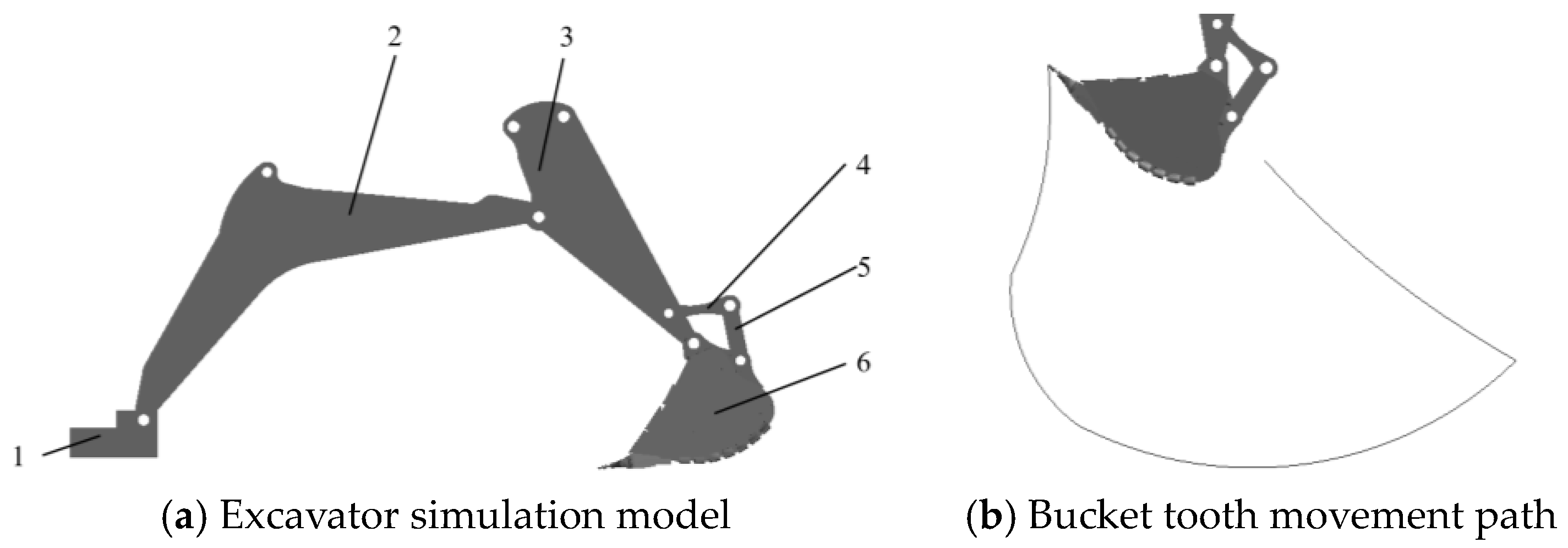

2.2. Construction of Excavator Dynamics Model

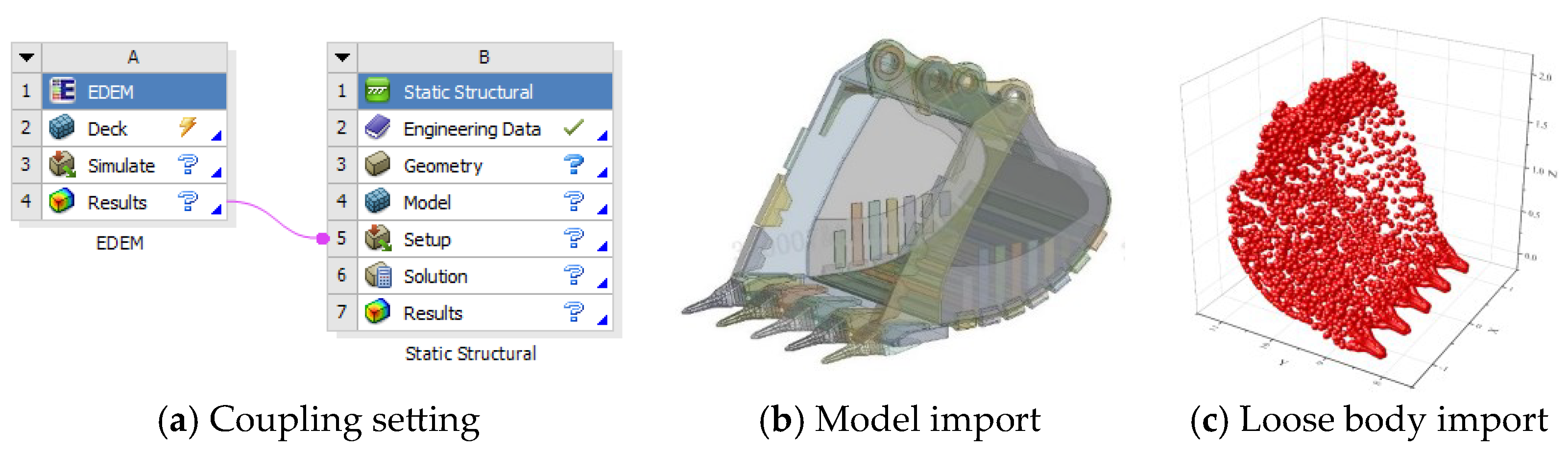

2.3. Construction of ADAMS-EDEM Coupling Simulation Model

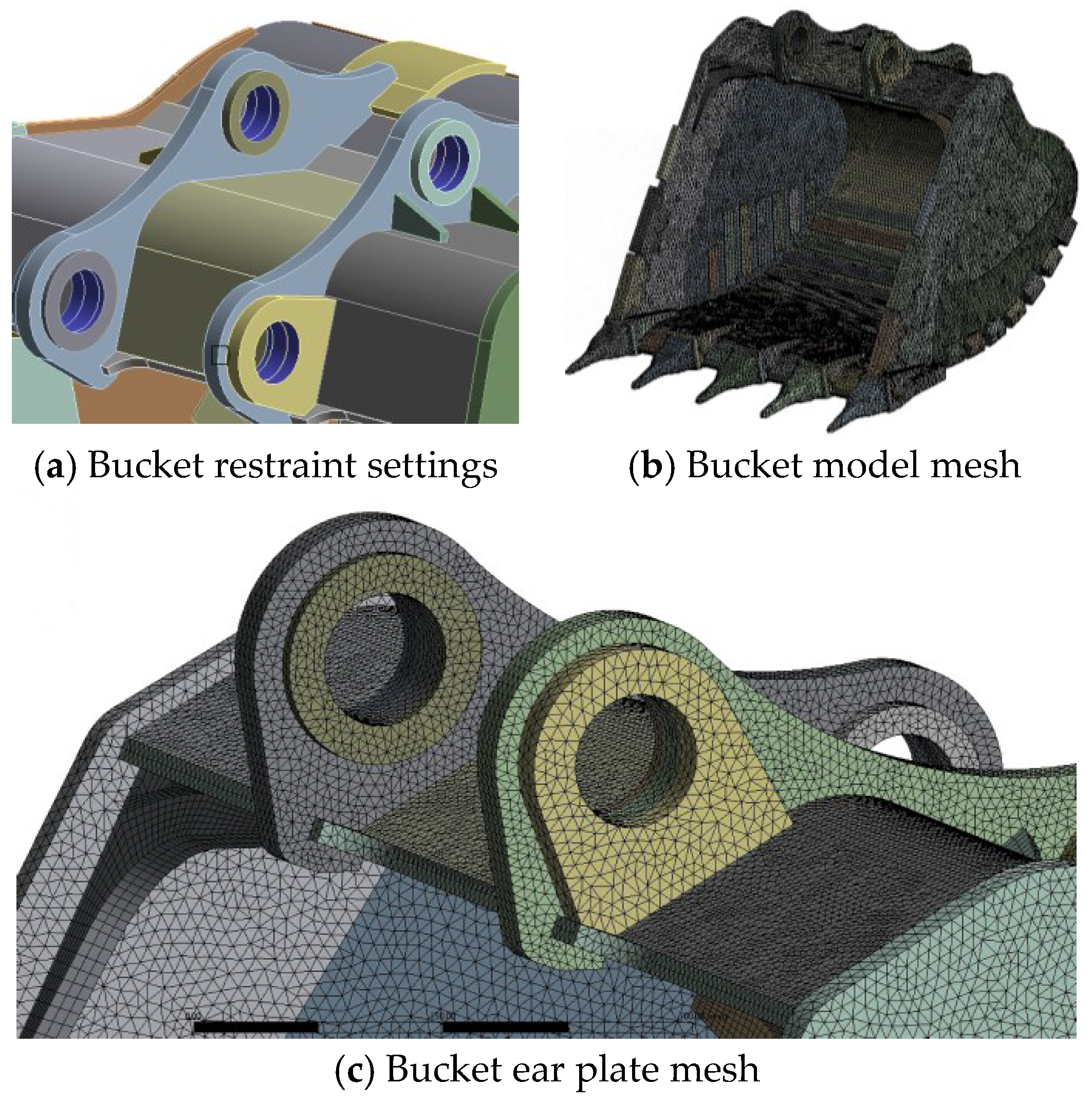

2.4. Construction of ADAMS-EDEM-ANSYS Coupling Simulation Model

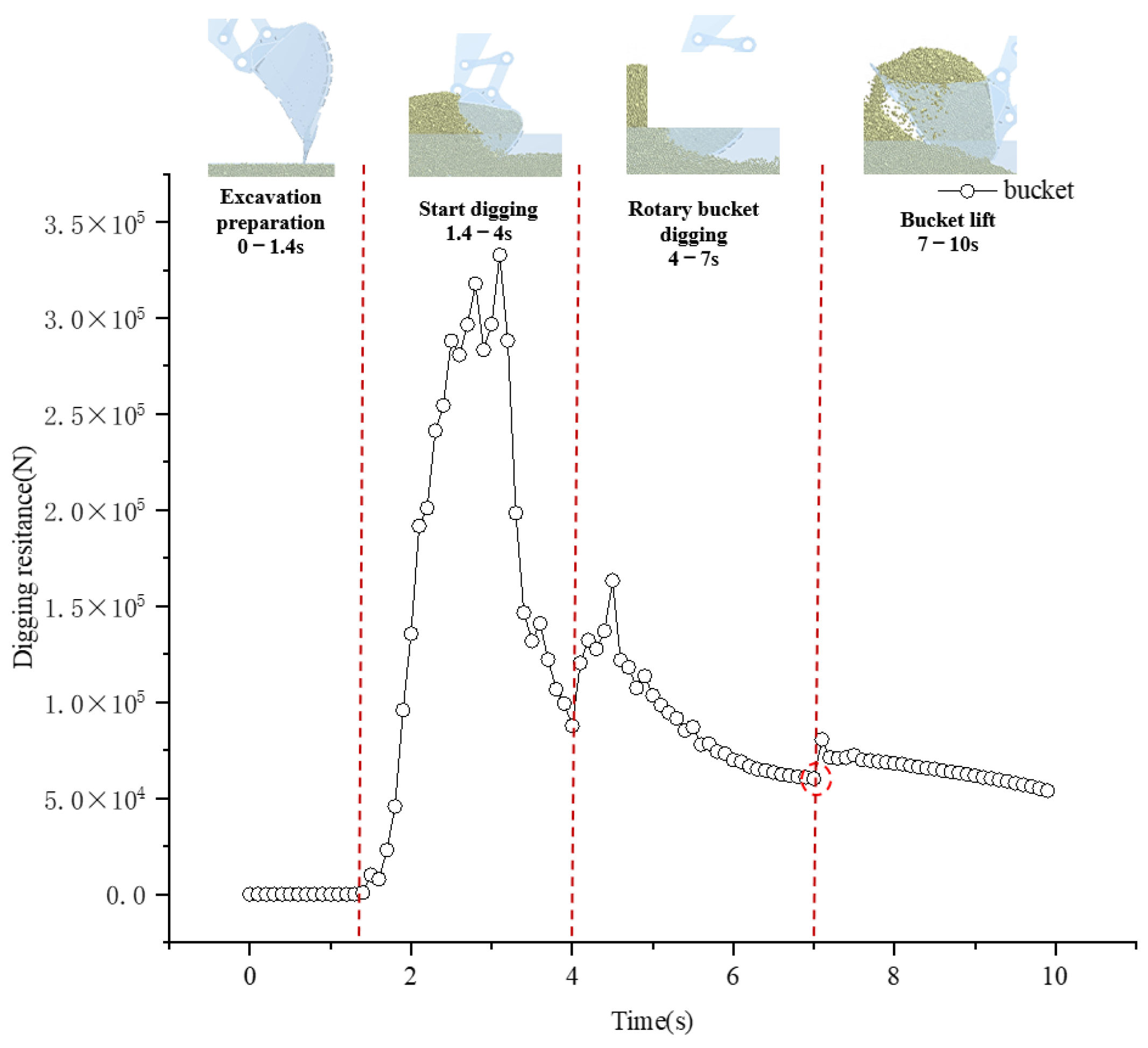

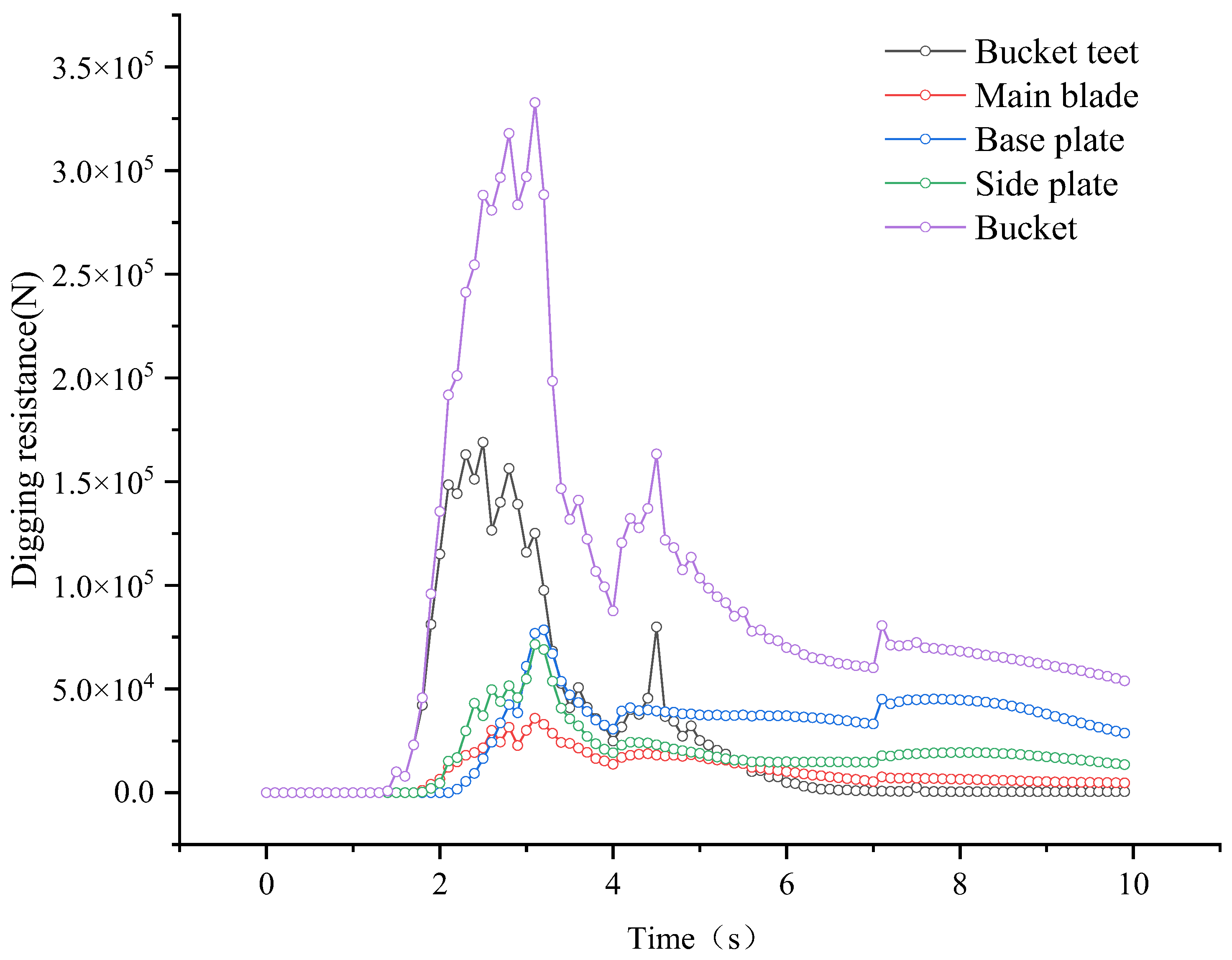

3. Analysis of ADAMS-EDEM Coupling Simulation Results

3.1. ADAMS-EDEM Co-Simulation of Mining Process

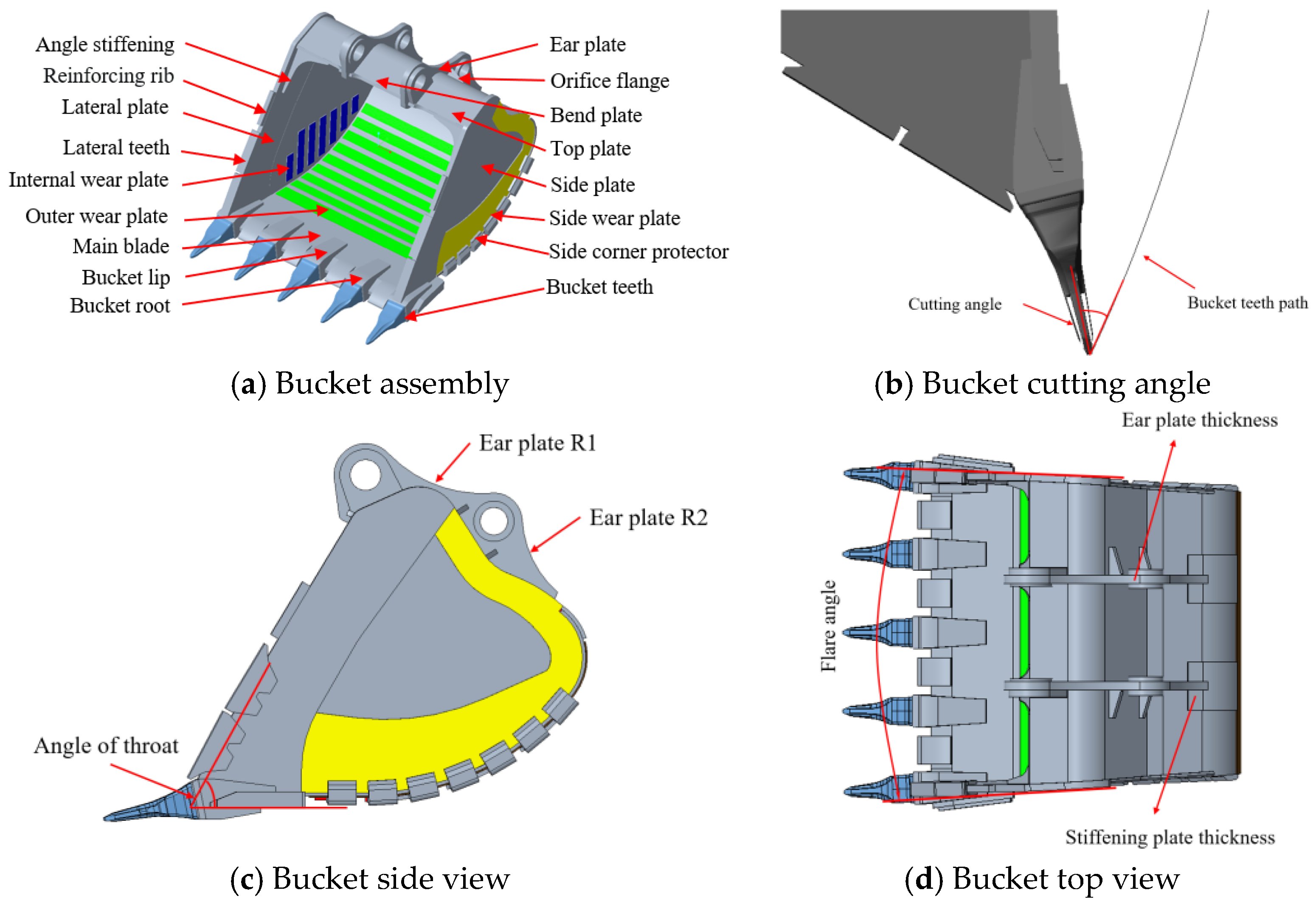

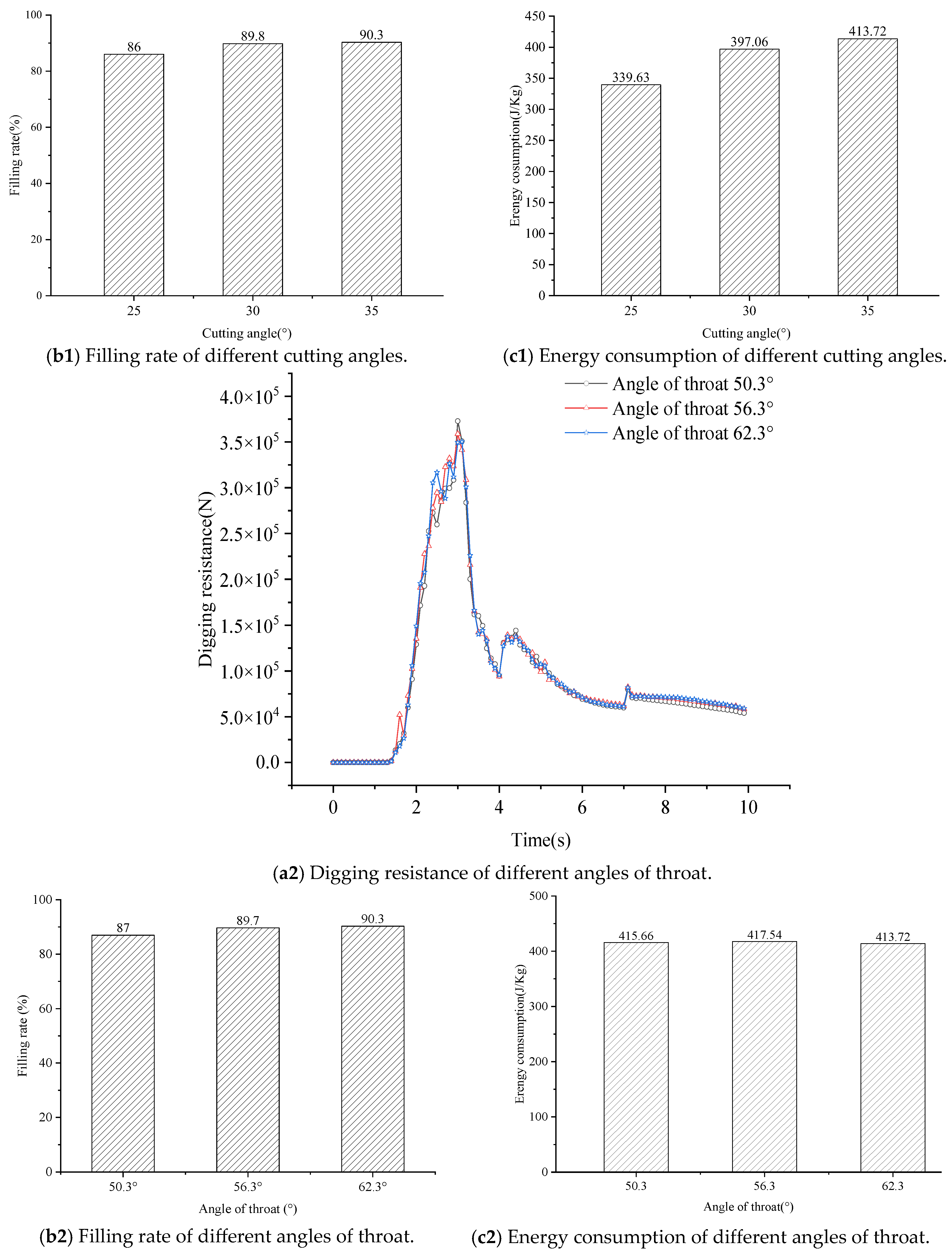

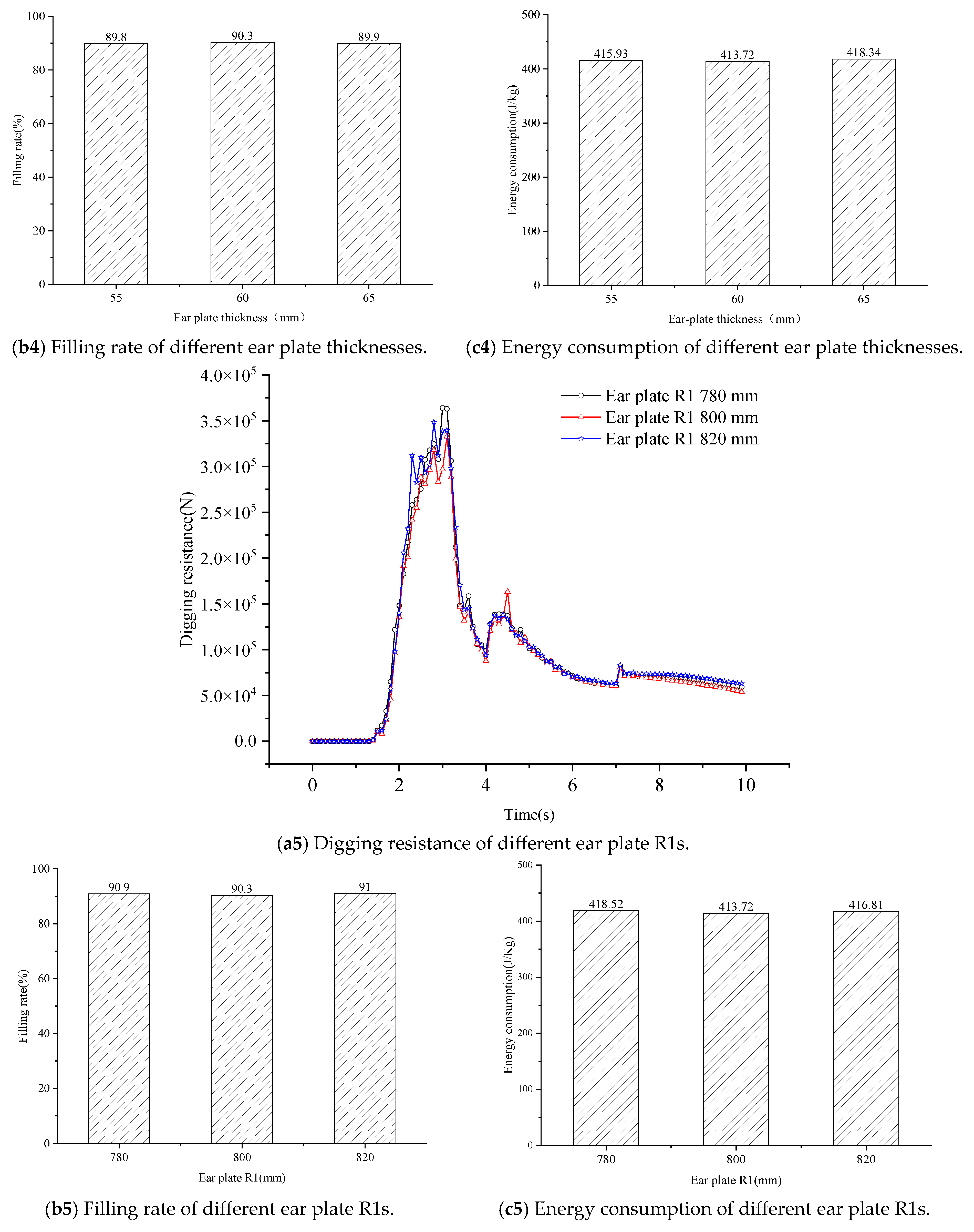

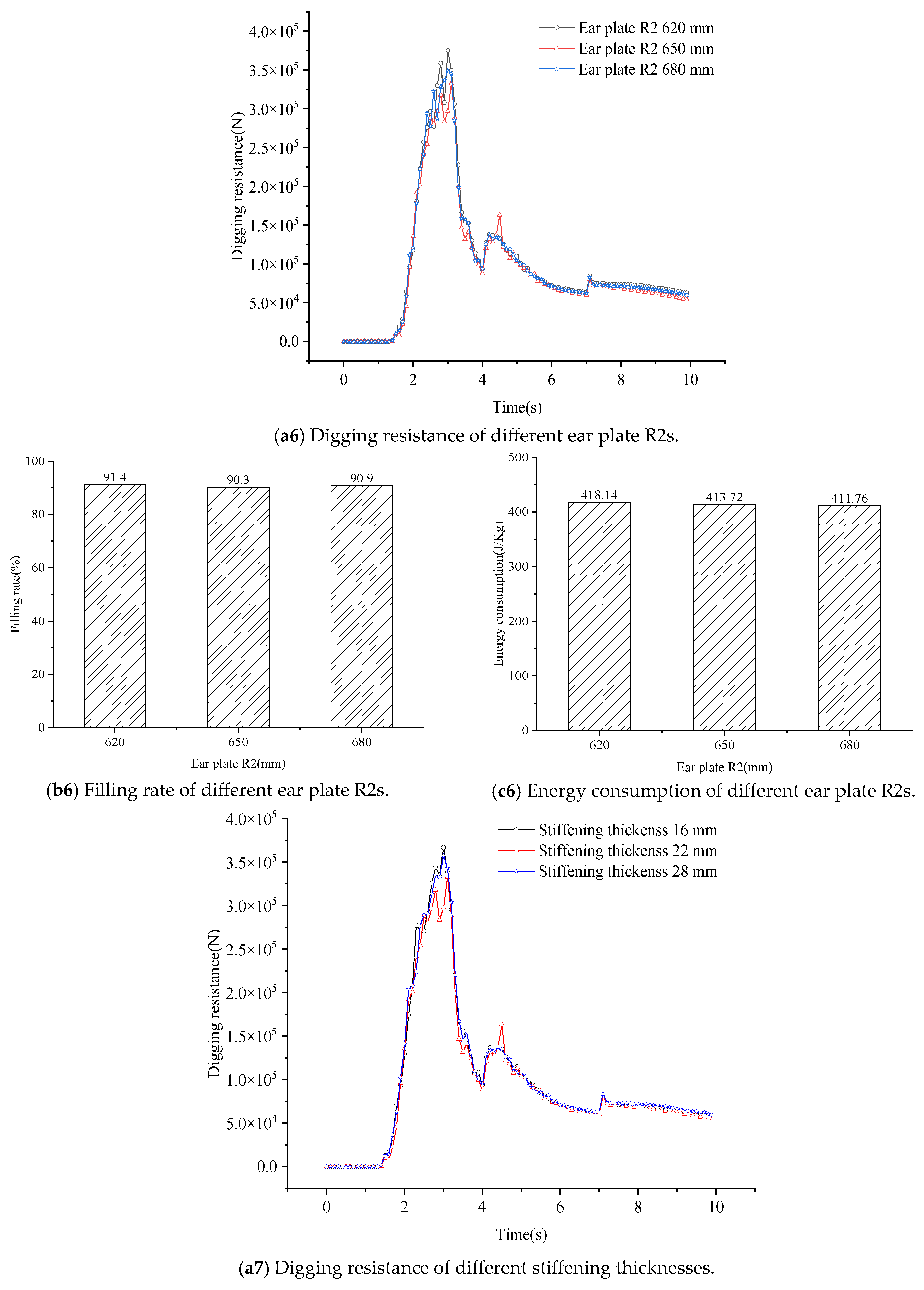

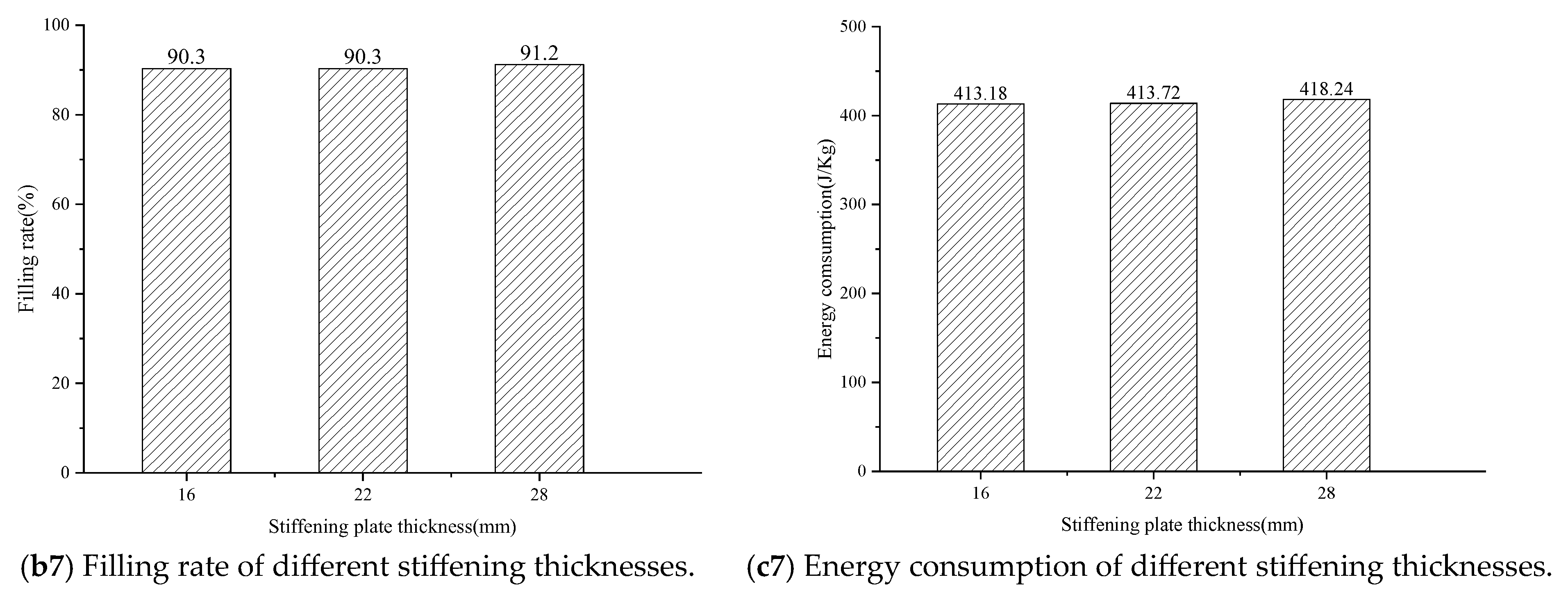

3.2. Influence of Bucket Structure Parameters on Excavation Characteristics

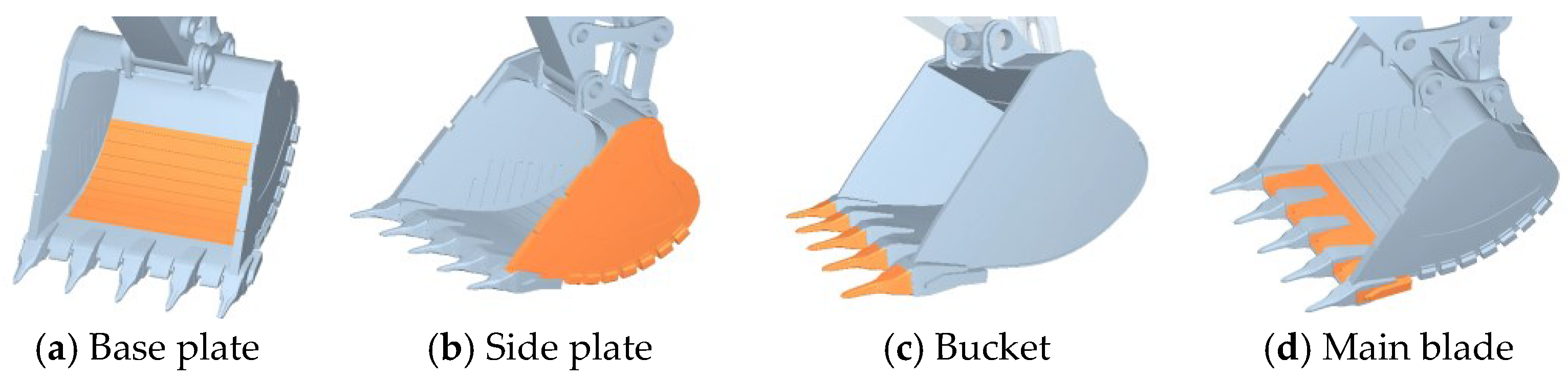

4. Analysis of EDEM-ANSYS Coupling Simulation Results

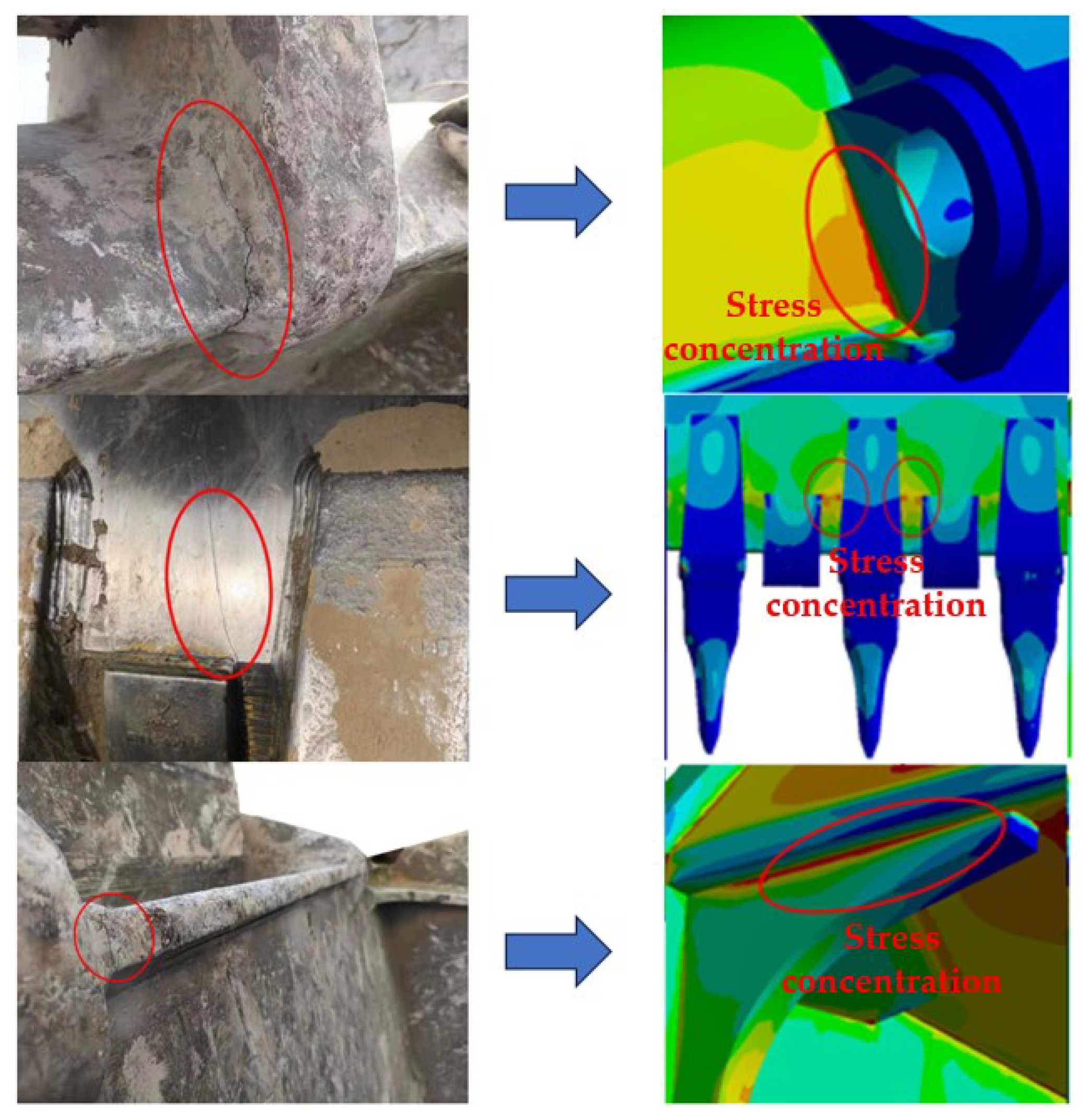

4.1. Finite Element Model Verification

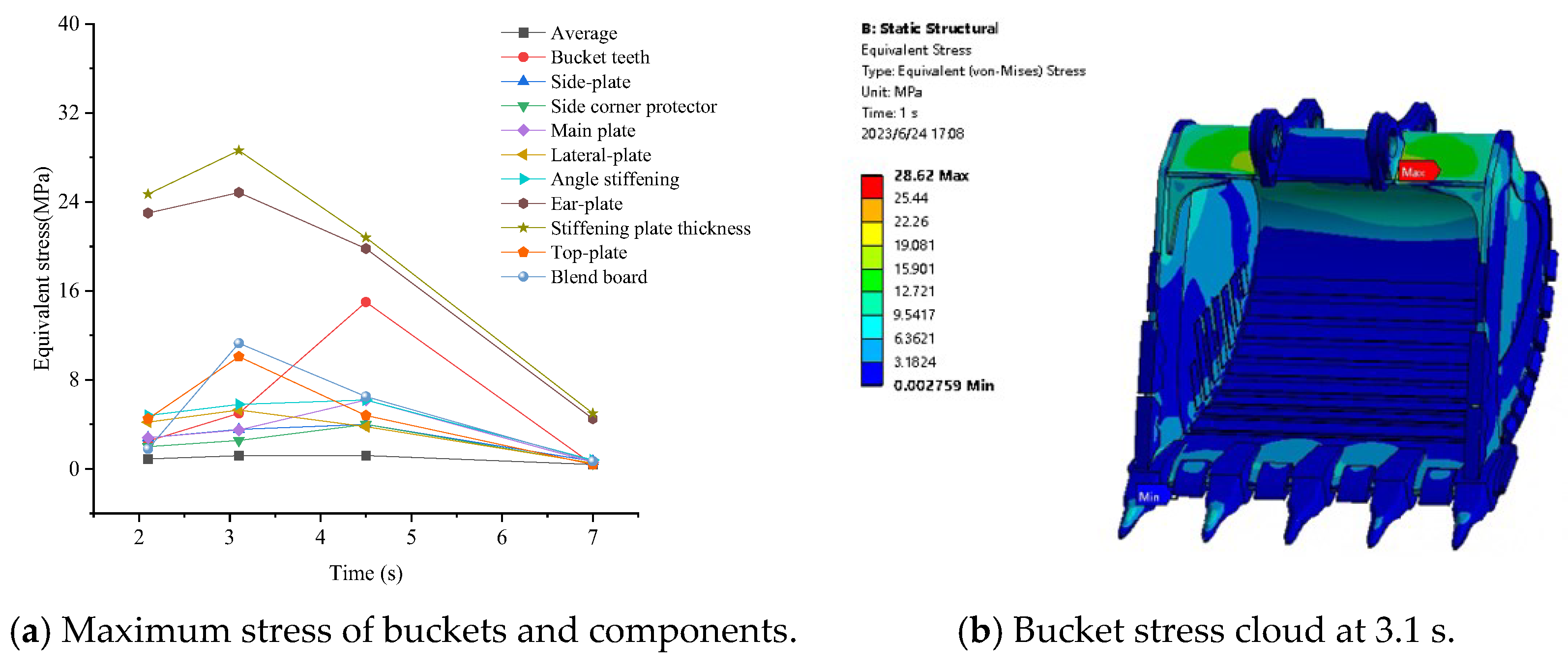

4.2. Stress and Deformation Characteristics of Bucket during Excavation

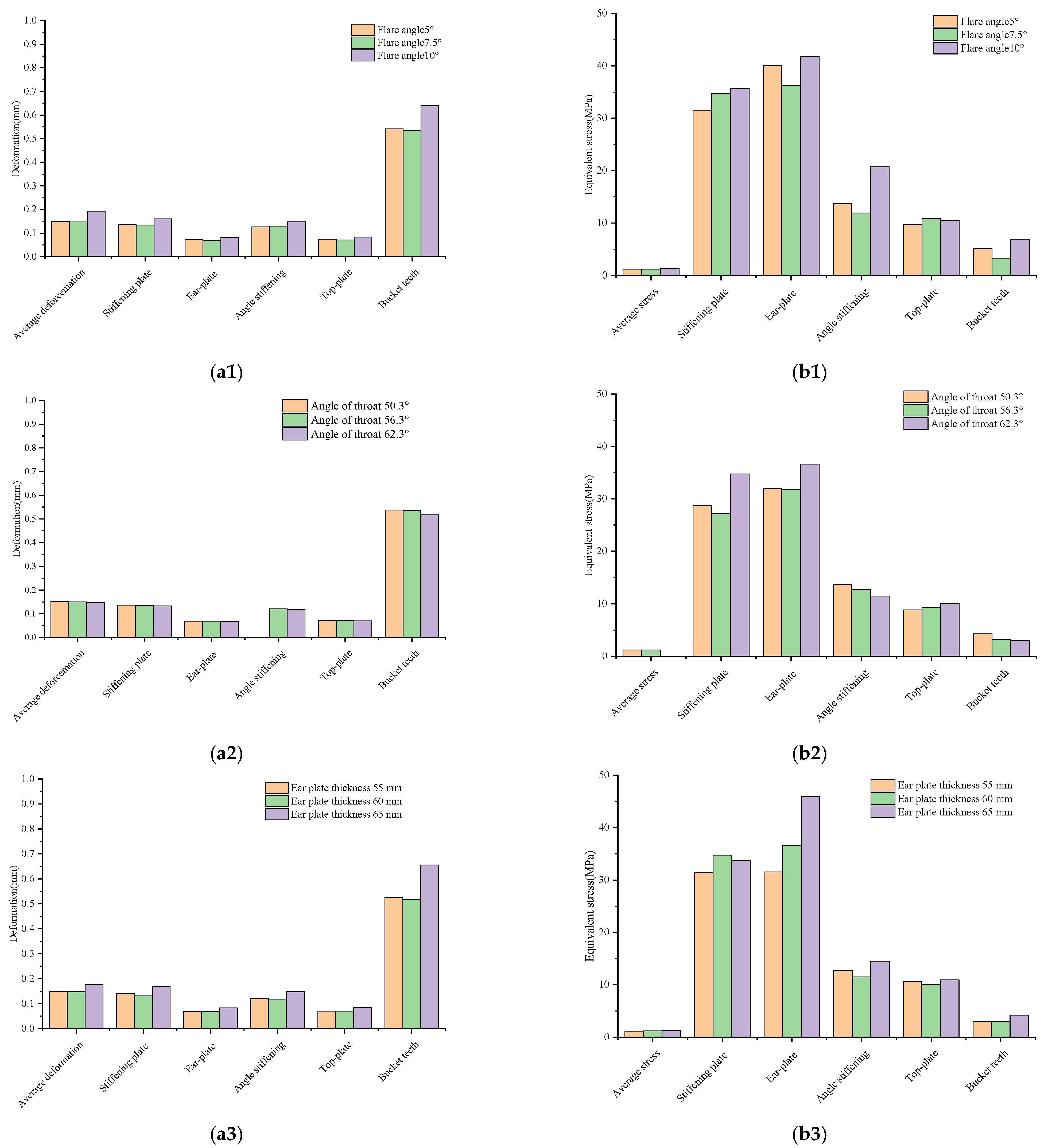

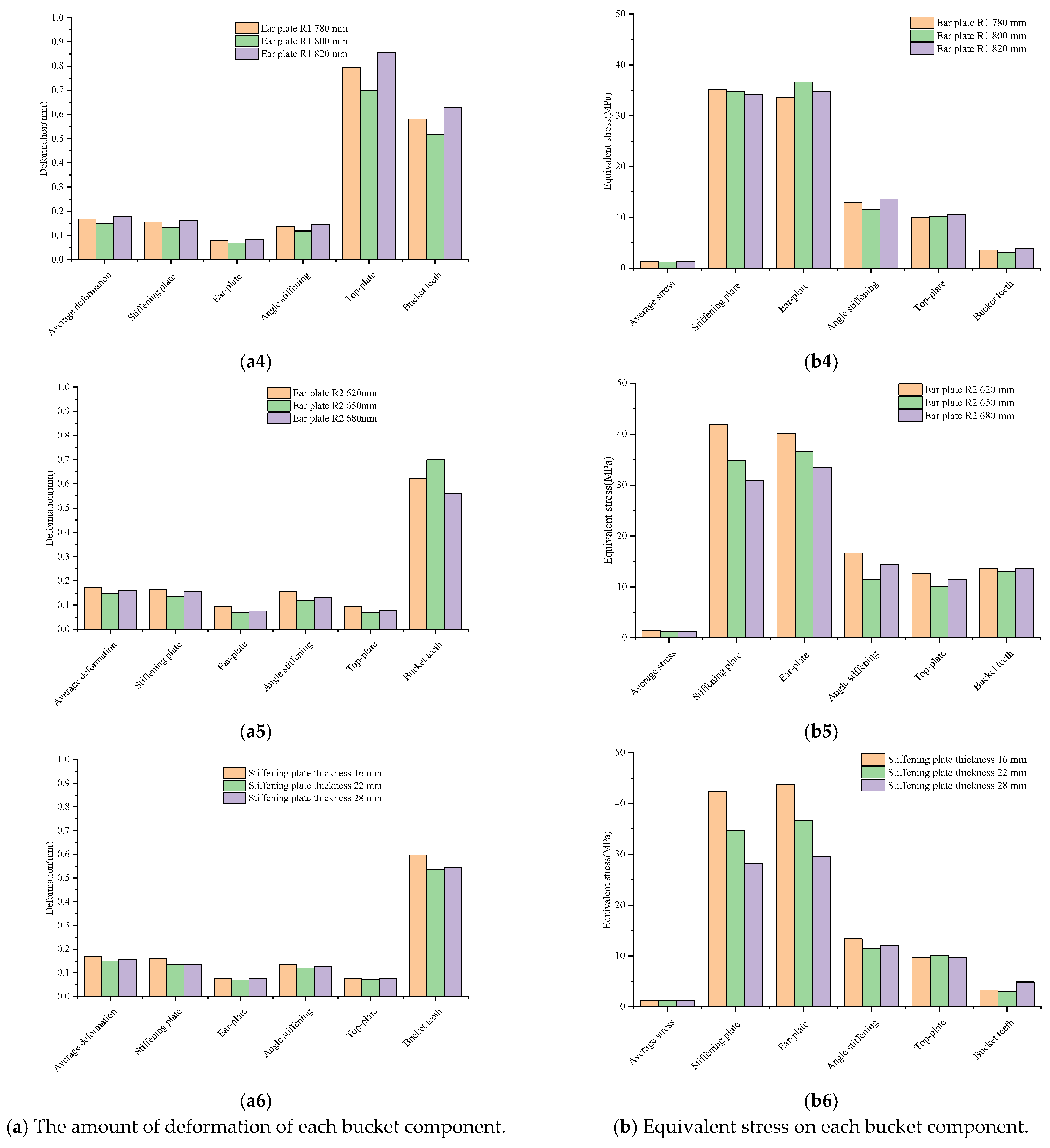

4.3. Influence of Bucket Structure Parameters on Stress and Deformation

5. Conclusions

- (1)

- Through EDEM-ADAMS coupling simulation and analysis of the mechanical characteristics of the bucket, a bucket designer can increase the angle of the throat of the bucket to obtain a higher filling rate and minimize the energy consumption per unit mass of materials excavated by the bucket. To some extent, the deformation of and equivalent stress on the whole bucket can be reduced by appropriately reducing the thickness of the ear plate and increasing the thickness of the reinforced plate.

- (2)

- From the EDEM-ANSYS coupling simulation results, it was found that the finite element model can truly reflect the stress deformation and damage of the bucket. This entails that researchers only need to carry out a finite element analysis of the loose force at the moment of the maximum excavation resistance, which can reveal the influence law of the bucket structural parameters on the bucket strain and stress.

- (3)

- By reducing the thickness of the ear plate or increasing the thickness of the stiffening plate, one can reduce the digging resistance of the bucket and the energy consumption required for digging, improve the digging efficiency of the bucket, and extend the working life of the bucket.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Velikanov, V.S.; Kozyr, A.V.; Dyorina, N.V. Engineering Implementation of View Objectives in Mine Excavator Design. Procedia Eng. 2017, 206, 1592–1596. [Google Scholar] [CrossRef]

- Wen, L.; Kim, D.; Liu, M.; Lee, S. 3D Excavator Pose Estimation Using Projection-Based Pose Optimization for Contact-Driven Hazard Monitoring. J. Comput. Civ. Eng. 2023, 37, 04022048. [Google Scholar] [CrossRef]

- Iwata, H.; Yu, S.; Mizushima, S.; Yamamura, S. Design of a Discrete Element Method Parameter Identification System for the Efficient Excavation of Mining Shovels Based on Digging resistance Analysis. Int. J. Mech. Eng. Robot. Res. 2022, 11, 304–310. [Google Scholar] [CrossRef]

- Ren, Z.; Li, J.; Pang, X.; Liu, J.; Li, T.; Yu, S. Research on the matching characteristics of the theoretical digging force of a backhoe hydraulic excavator. Sci. Rep. 2022, 12, 16181. [Google Scholar] [CrossRef] [PubMed]

- He, J.L.; Zheng, H.H.; Li, D. The Calculation for Digging-Resistance of Small-Scale Excavator Based on Torque Method. Appl. Mech. Mater. 2013, 456, 248–251. [Google Scholar] [CrossRef]

- Jiang, Y.Z.; Liao, G.W.; Zhu, S.S.; Hu, Y.F. Investigation on cutting resistance characteristic of bucket wheel excavator using DEM and DOE methods. Simul. Model. Pract. Theory 2021, 111, 102339. [Google Scholar] [CrossRef]

- Brînaș, I.; Andraș, A.; Radu, S.M.; Popescu, F.D.; Andraș, I.; Marc, B.I.; Cioclu, A.R. Determination of the Bucket Wheel Drive Power by Computer Modeling Based on Specific Energy Consumption and Cutting Geometry. Energies 2021, 14, 3892. [Google Scholar] [CrossRef]

- Tomatsu, T.; Nonaka, K.; Sekiguchi, K.; Suzuki, K. Digging Soil Experiments for Micro Hydraulic Excavators based on Model Predictive Tracking Control. J. Phys. Conf. Ser. 2016, 744, 012067. [Google Scholar] [CrossRef]

- Sarkar, M.; Ghosh, S.K.; Mukherjee, P. Analysis of wear generation in mine excavator bucket. Ind. Lubr. Tribol. 2015, 67, 52–58. [Google Scholar] [CrossRef]

- Gan, J.; Zhou, Z.; Yu, A.; Ellis, D.; Attwood, R.; Chen, W. Co-simulation of multibody dynamics and discrete element method for hydraulic excavators. Powder Technol. 2023, 414, 118001. [Google Scholar] [CrossRef]

- Sun, H.; Ren, Z.; Wang, J.; Wei, W.; Liang, Y.; Feng, M. Integrated expression and general optimisation method of bucket shapeline of backhoe hydraulic excavator. J. Mech. Sci. Technol. 2021, 35, 2543–2550. [Google Scholar] [CrossRef]

- Yu, X.; Pang, X.; Zou, Z.; Zhang, G.; Hu, Y.; Dong, J.; Song, H. Lightweight and High-Strength Design of an Excavator Bucket under Uncertain Loading. Math. Probl. Eng. 2019, 2019, 3190819. [Google Scholar] [CrossRef]

- Wang, C.H.; Gao, Y.; Zhang, Y.Y.; Li, C.L. Dynamic Characteristics of the Backhoe Excavator Bucket Based on Pro/E and ANSYS. Adv. Mater. Res. 2012, 619, 30–33. [Google Scholar] [CrossRef]

- Long, Y.; Yang, L.; Li, Y. Load Law Analysis and Fatigue Life Prediction for Bucket Teeth of Excavator Working Device. In Proceedings of the 2022 IEEE 17th Conference on Industrial Electronics and Applications (ICIEA), Chengdu, China, 16–19 December 2022; pp. 1322–1327. [Google Scholar] [CrossRef]

- Nezami, E.G.; Hashash, Y.M.A.; Zhao, D.; Ghaboussi, J. Simulation of front end loader bucket–soil interaction using discrete element method. Int. J. Numer. Anal. Methods Geomech. 2007, 31, 1147–1162. [Google Scholar] [CrossRef]

- Coetzee, C.J.; Els, D.N.J. The numerical modelling of excavator bucket filling using DEM. J. Terramech. 2009, 46, 217–227. [Google Scholar] [CrossRef]

- Coetzee, C.J.; Els, D.N.J. Calibration of granular material parameters for DEM modelling and numerical verification by blade–granular material interaction. J. Terramech. 2009, 46, 15–26. [Google Scholar] [CrossRef]

- She, Y.N.; Ning, X.B.; Lin, Q. Kinematics Performance Simulation and Optimization of Large Face-Shovel Hydraulic Excavator Working Device Based on ADAMS. Appl. Mech. Mater. 2013, 271–272, 996–1000. [Google Scholar] [CrossRef]

- Ji, S.; Liang, S. DEM-FEM-MBD coupling analysis of landing process of lunar lander considering landing mode and buffering mechanism. Adv. Space Res. 2021, 68, 1627–1643. [Google Scholar] [CrossRef]

| Material Properties | Loess | Bucket |

|---|---|---|

| Poisson’s ratio | 0.41 | 0.28 |

| Shear modulus (MPa) | 10 | 206,000 |

| Density (kg/m3) | 1680 | 7850 |

| Contact parameters | loess-loess | loess-bucket |

| Coefficient of restitution | 0.6 | 0.5 |

| Coefficient of static friction | 0.39 | 0.5 |

| Coefficient of rolling friction | 0.11 | 0.05 |

| Particle Type | Particle 1 | Particle 2 | Particle 3 | Particle 4 |

|---|---|---|---|---|

| Particle size/mm | <50 | 50–100 | 100–200 | >200 |

| Mass distribution | 70% | 15% | 10% | 5% |

| Type | Constraint | Motion |

|---|---|---|

| Fixed pair | console-ground | |

| Revolute pair | arm-console | rotation driving |

| Revolute pair | bucket rod-arm | rotation driving |

| Revolute pair | rocker rod-bucket rod | rotation driving |

| Revolute pair | link rod-rocker rod | |

| Revolute pair | bucket-link rod | |

| Revolute pair | bucket-bucket rod |

| Type of Revolute Pair | Driving Function |

|---|---|

| arm-console | STEP (time, 0, 0, 1, −25 d) + STEP (time, 7, 0, 10, −30 d) |

| bucket rod-arm | STEP (time, 0, 0, 1, 26 d) + STEP (time, 1, 0, 4, −72 d) |

| rocker rod-bucket rod | STEP (time, 0, 0, 1, 57 d) + STEP (time, 4, 0, 7, −48 d) + STEP (time, 7, 0, 10, −17 d) |

| Parameter | Elasticity Modulus (N/m2) | Poisson’s Ratio | Density (kg/m3) | Yield Strength (MPa) |

|---|---|---|---|---|

| Value | 2.06 × 1011 | 0.28 | 7.85 × 103 | 355 |

| Bucket Structure | Cutting Angle (°) | Angle of Throat (°) | Flare Angle (°) | Ear Plate Thickness (mm) | Ear Plate R1 (mm) | Ear Plate R2 (mm) | Stiffening Plate Thickness (mm) |

|---|---|---|---|---|---|---|---|

| Original parameter | 30 | 56.3 | 7.5 | 60 | 650 | 800 | 22 |

| Variation parameter | 25 | 50.3 | 5 | 55 | 620 | 780 | 16 |

| 35 | 62.3 | 10 | 65 | 680 | 820 | 28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Wang, Y.; Wang, L.; Li, C.; Tang, L.; Wang, D.; Ma, R.; Xue, Z.; Wei, X.; Cui, M.; et al. Digging Performance and Stress Characteristic of the Excavator Bucket. Appl. Sci. 2023, 13, 11507. https://doi.org/10.3390/app132011507

Sun Y, Wang Y, Wang L, Li C, Tang L, Wang D, Ma R, Xue Z, Wei X, Cui M, et al. Digging Performance and Stress Characteristic of the Excavator Bucket. Applied Sciences. 2023; 13(20):11507. https://doi.org/10.3390/app132011507

Chicago/Turabian StyleSun, Yuan, Yong Wang, Linlin Wang, Chenchen Li, Liang Tang, Dagang Wang, Ruiyong Ma, Ziao Xue, Xuefeng Wei, Muchun Cui, and et al. 2023. "Digging Performance and Stress Characteristic of the Excavator Bucket" Applied Sciences 13, no. 20: 11507. https://doi.org/10.3390/app132011507

APA StyleSun, Y., Wang, Y., Wang, L., Li, C., Tang, L., Wang, D., Ma, R., Xue, Z., Wei, X., Cui, M., Chong, H., & Xu, W. (2023). Digging Performance and Stress Characteristic of the Excavator Bucket. Applied Sciences, 13(20), 11507. https://doi.org/10.3390/app132011507