The Dual-Parameter Control of Synchronization in Steel Box Girder Incremental Launching Construction

Abstract

:1. Introduction

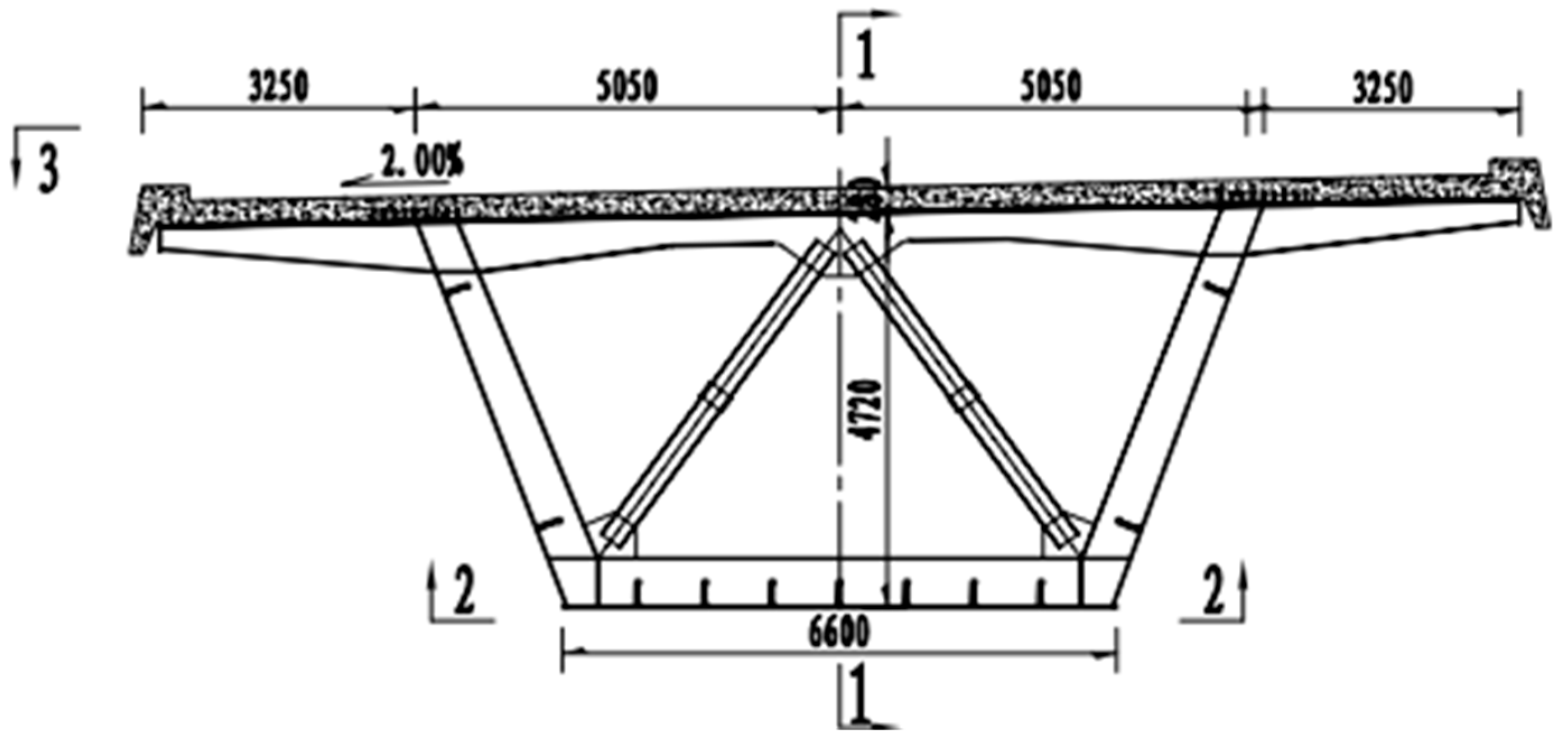

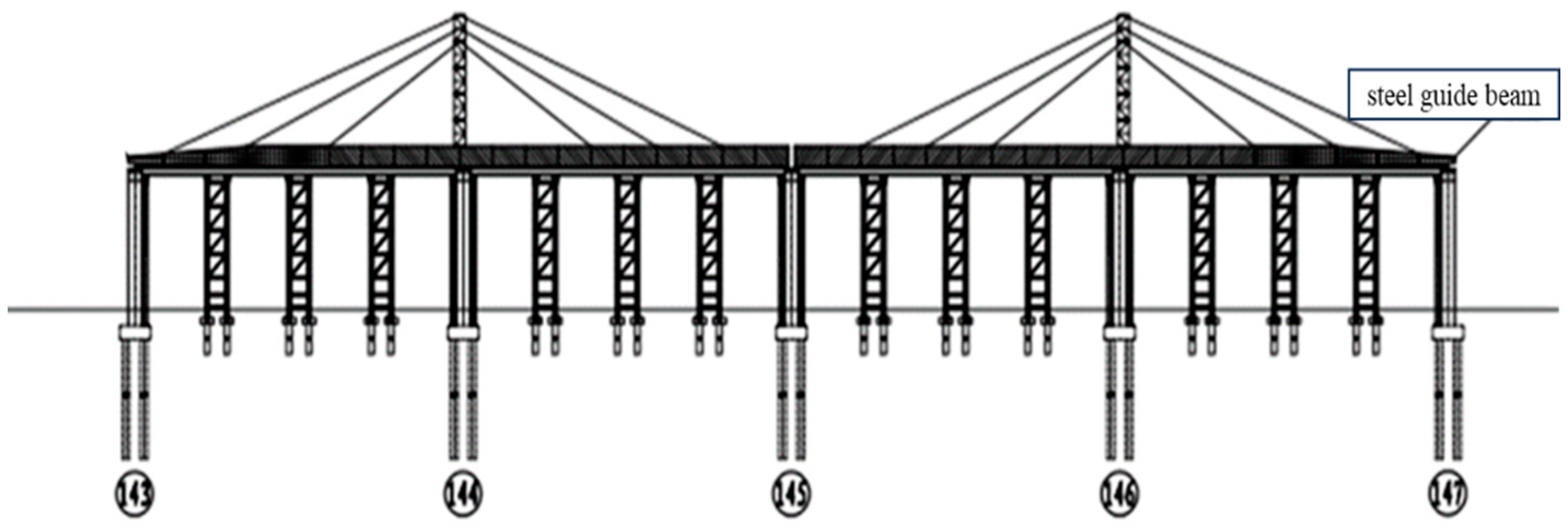

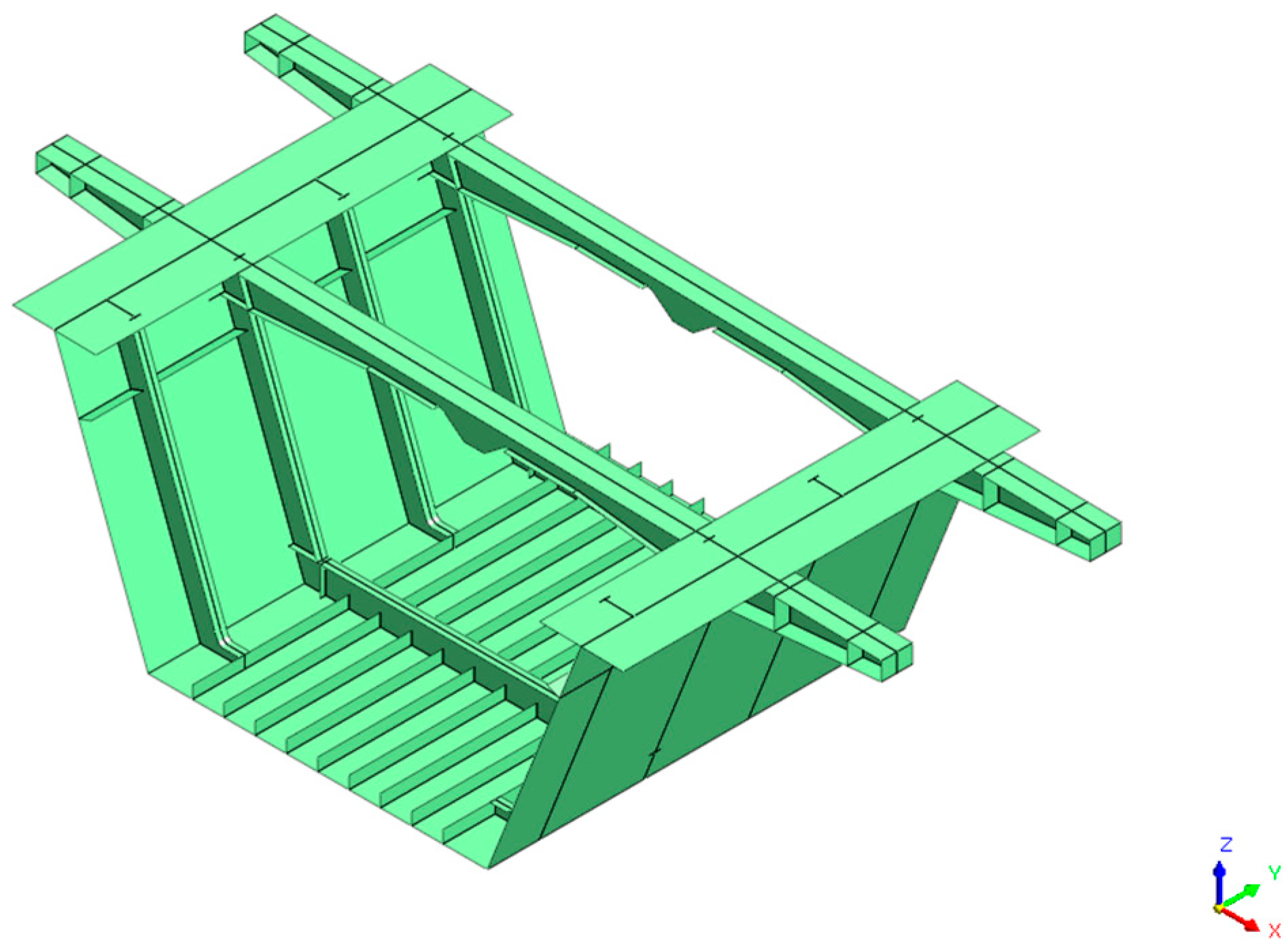

2. Bridge Structural Parameters

3. Finite Element Modeling

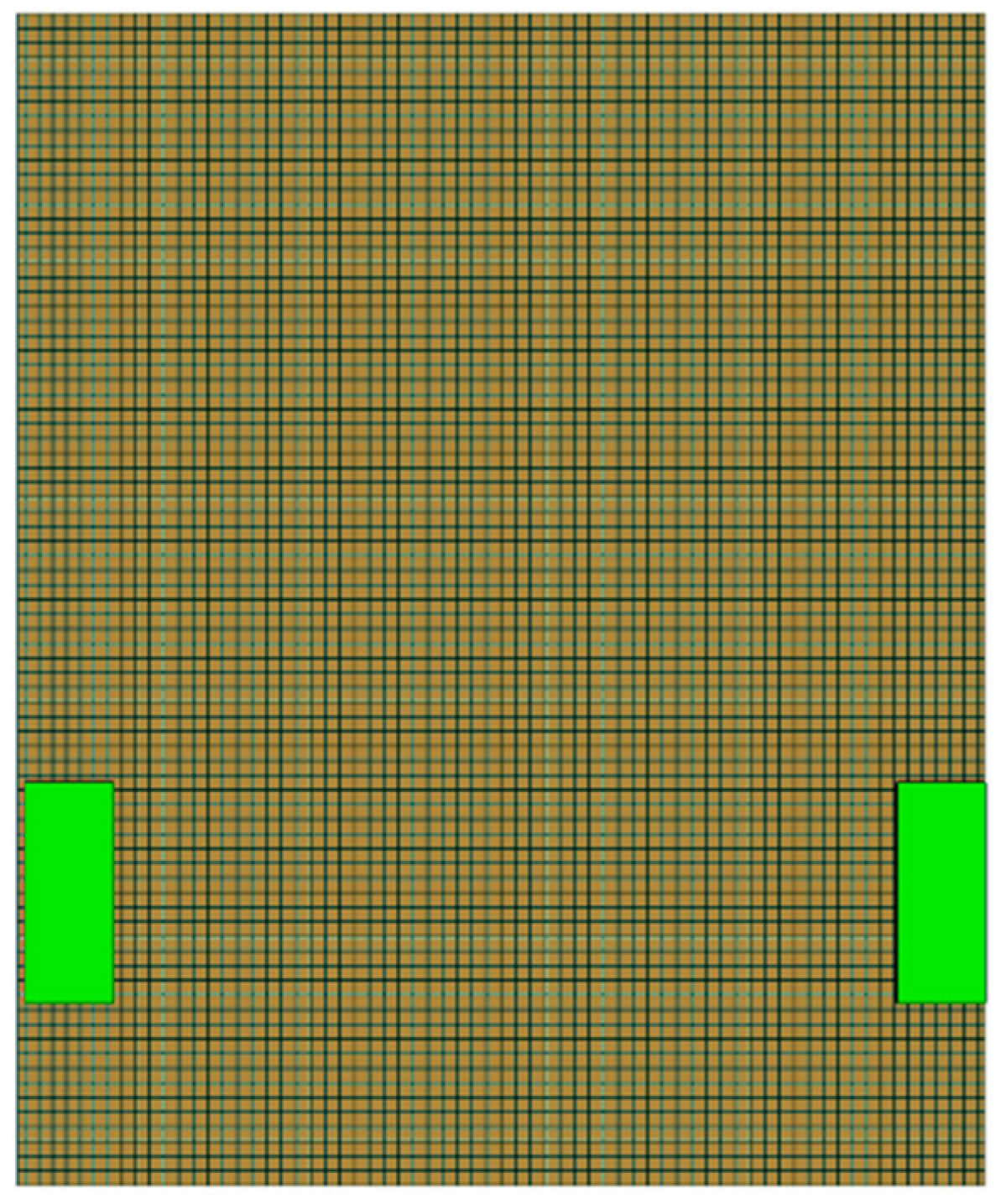

3.1. Module Selection and Meshing

3.2. Boundary Condition Simulation

3.3. Load Simulation

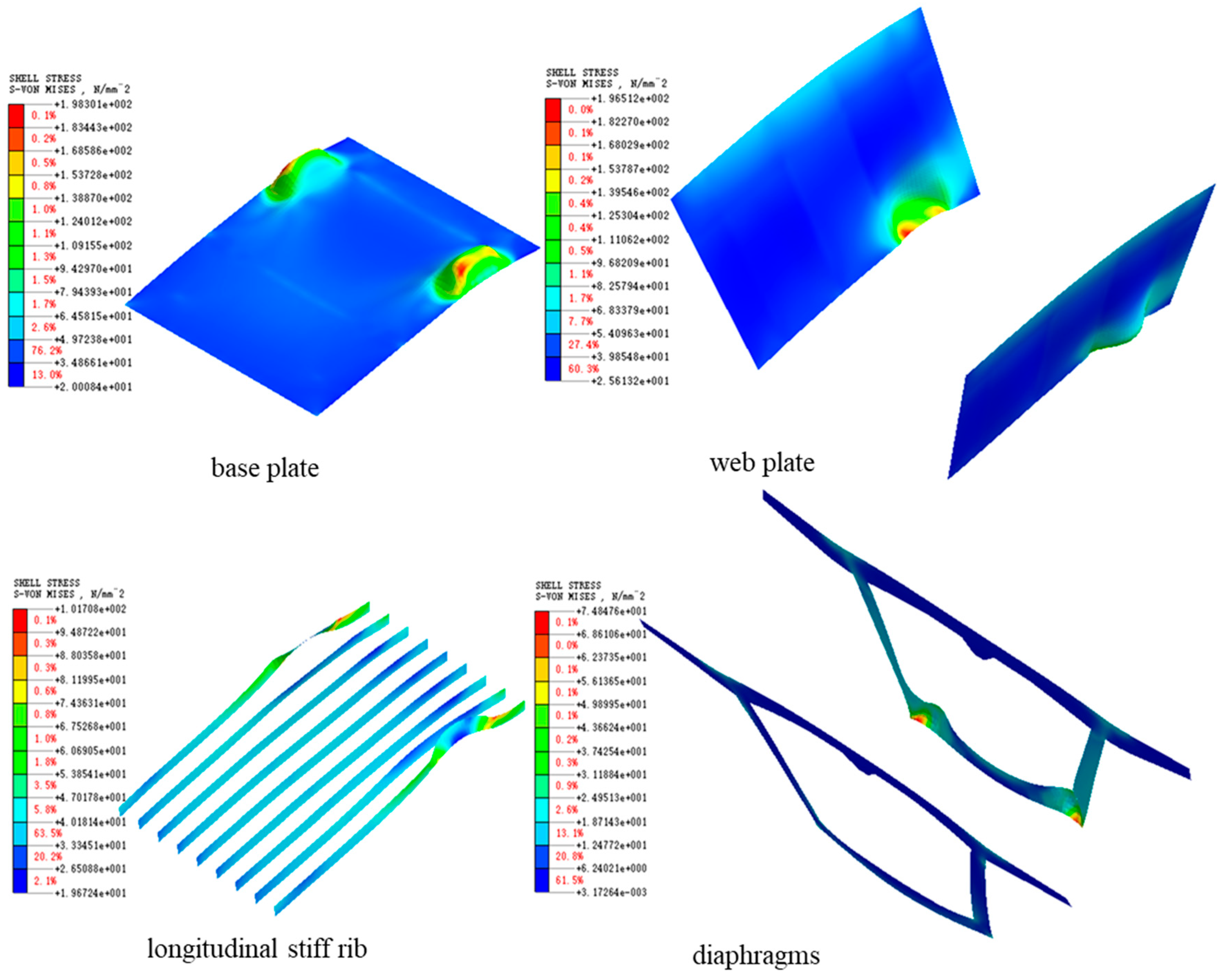

4. Local Stress Analysis

5. Study on Single-Parameter Control of Synchronization in Incremental Launching Construction

5.1. Stress Changes Due to Unsynchronized Vertical Jacking

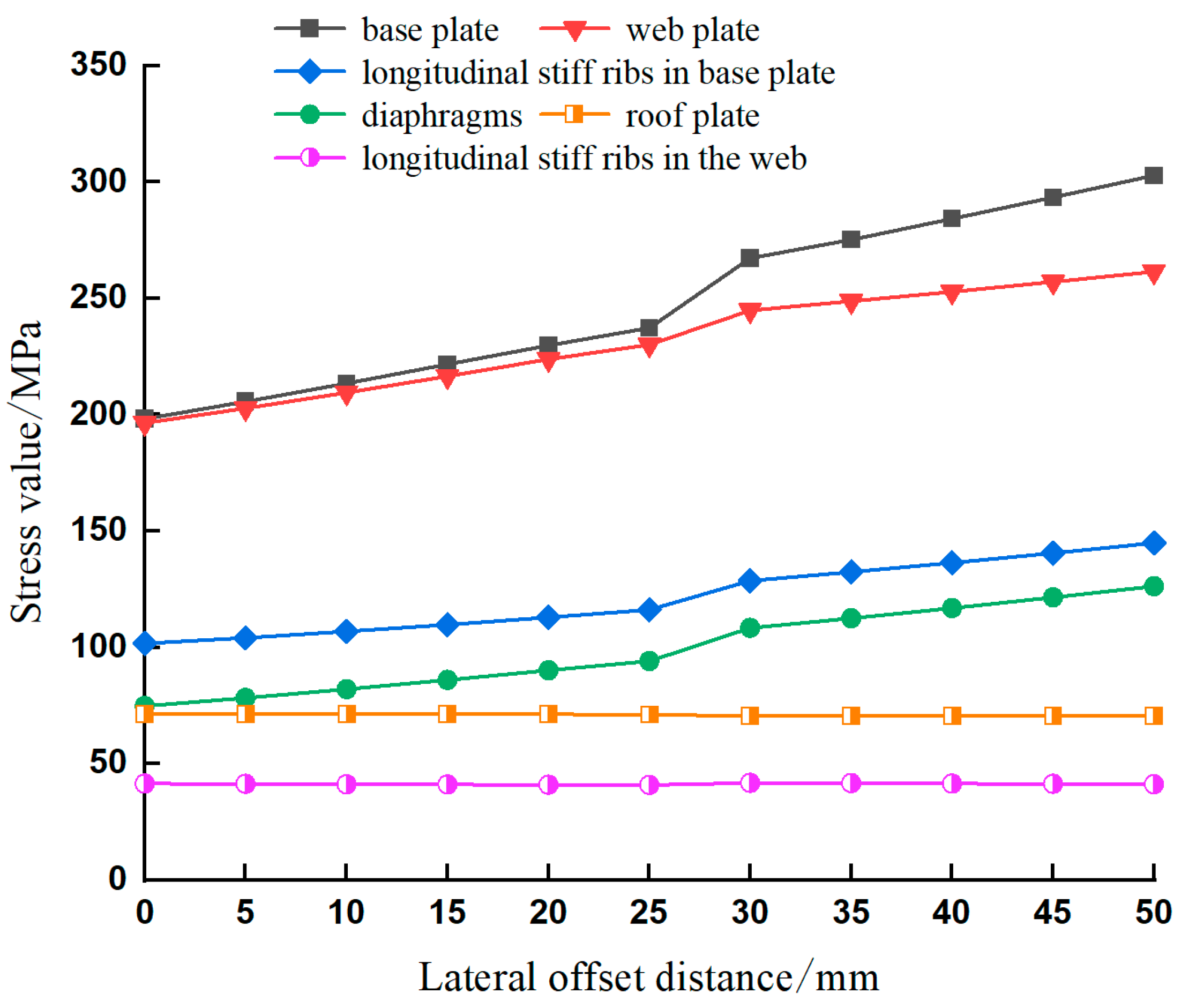

5.2. Stress Changes Due to Lateral Offset

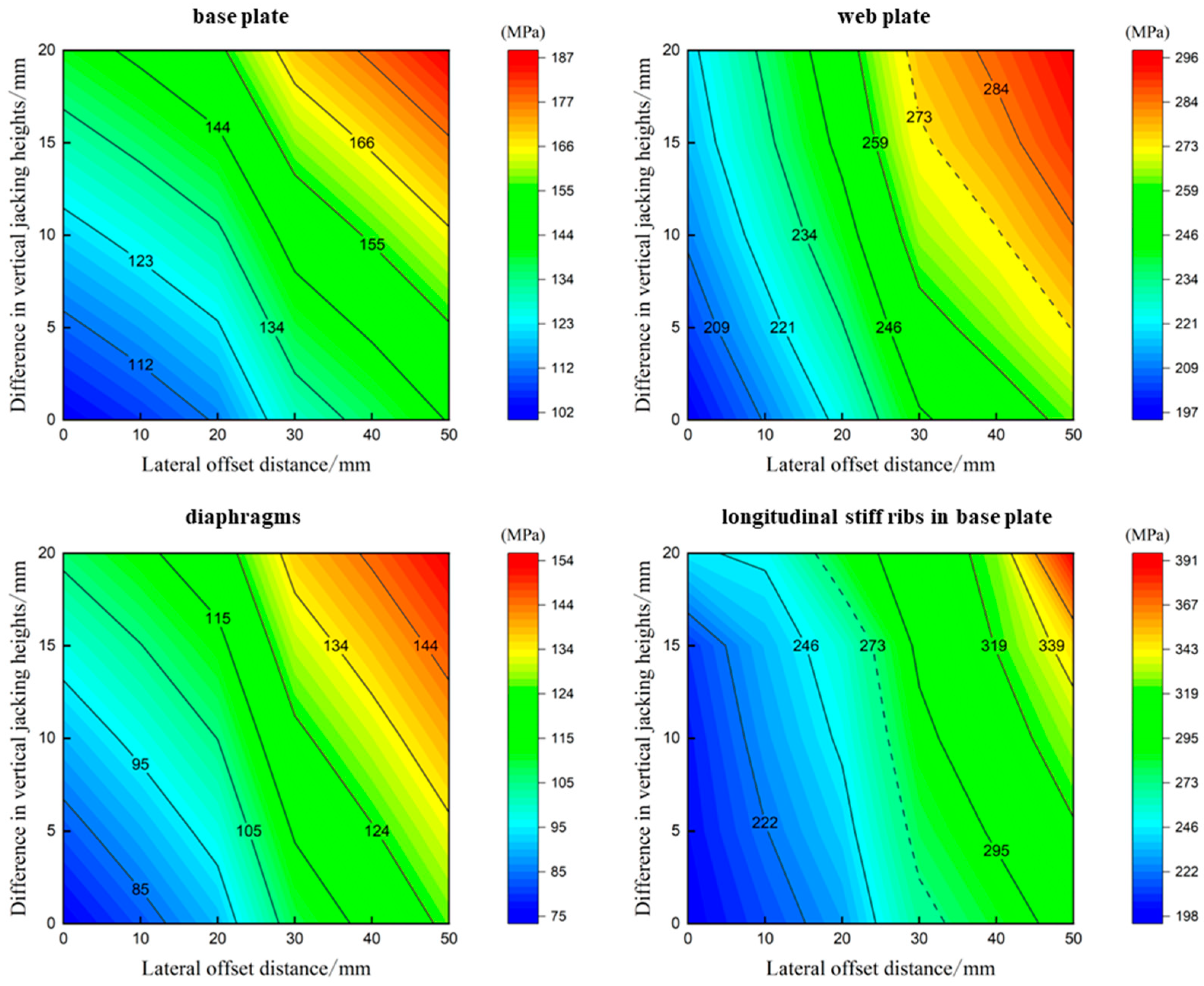

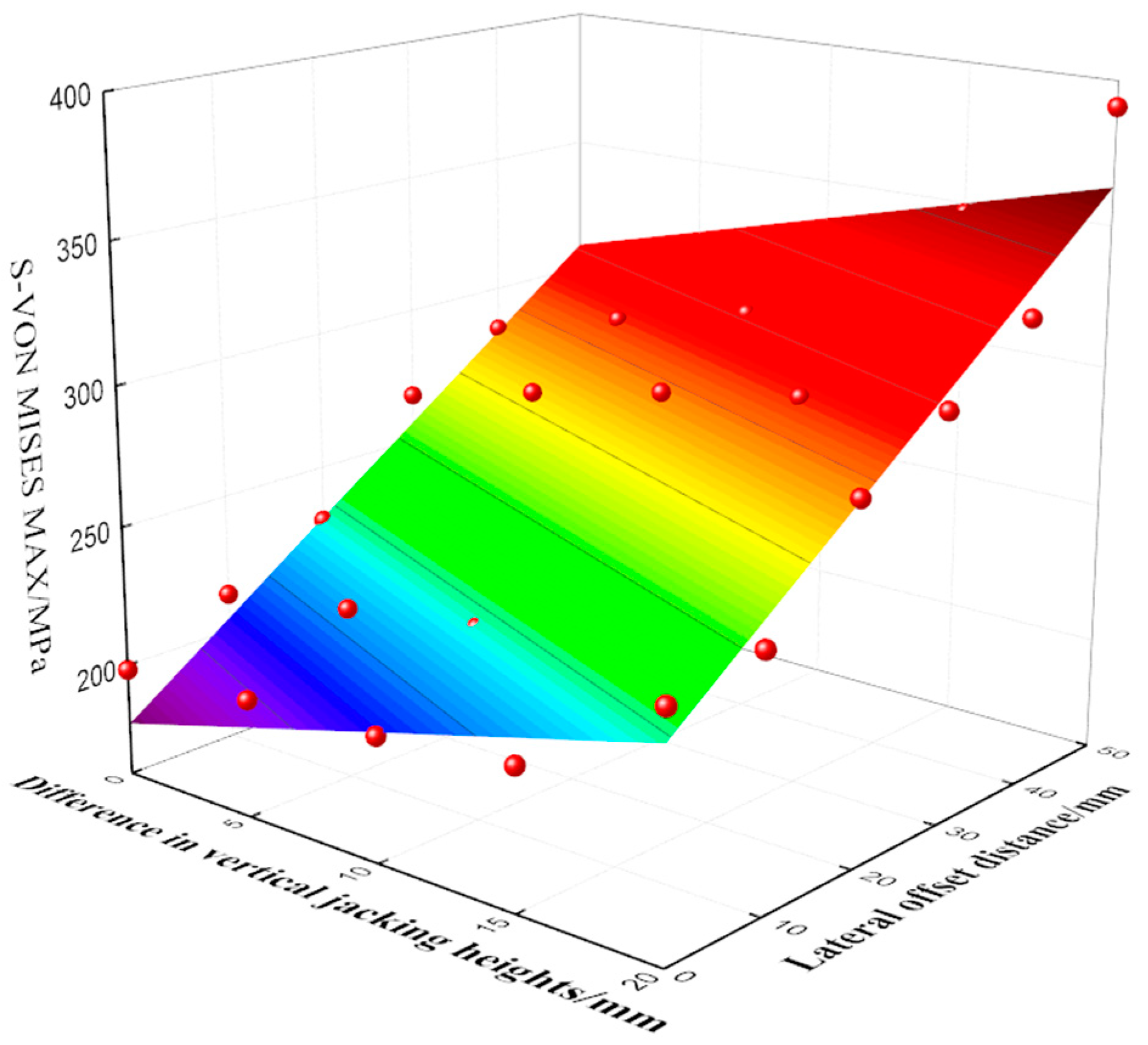

6. Study on Two-Parameter Control of Synchronization in Incremental Launching Construction

7. Conclusions

- (1)

- In this paper, the local stresses on the girder segments supported on the top of the piers in the maximum cantilever state were analyzed by establishing a finite element model of the steel box girder in the maximum cantilever state during incremental launching construction. The analysis results indicated that the local force of the steel box girders met the requirements, and the jacking could be carried out smoothly.

- (2)

- By simulating the unsynchronized vertical jacking and lateral offset occurring during incremental launching construction in the above model, the local stress changes in the girder segments under the separate effects of unsynchronized vertical jacking and lateral offset were analyzed. When unsynchronized vertical jacking occurred, the beam generated a bias load (the side with the smaller jacking height was subjected to a larger reaction force) and the local maximum equivalent force became larger with an increase in the difference in the jacking height. The sensitivities of different stress components to unsynchronized vertical jacking were different, and the diaphragms and longitudinal stiff ribs of the base plate were more sensitive to unsynchronized vertical jacking. When lateral offset occurred, the local maximum equivalent stress occurred in the contact area between the base plate and the pad, and increased with an increase in the lateral offset distance, even approaching the yield stress of the steel and seriously affecting the structural safety. Therefore, thresholds for the synchronization control of incremental launching shall be established and strictly monitored and corrected in a timely manner.

- (3)

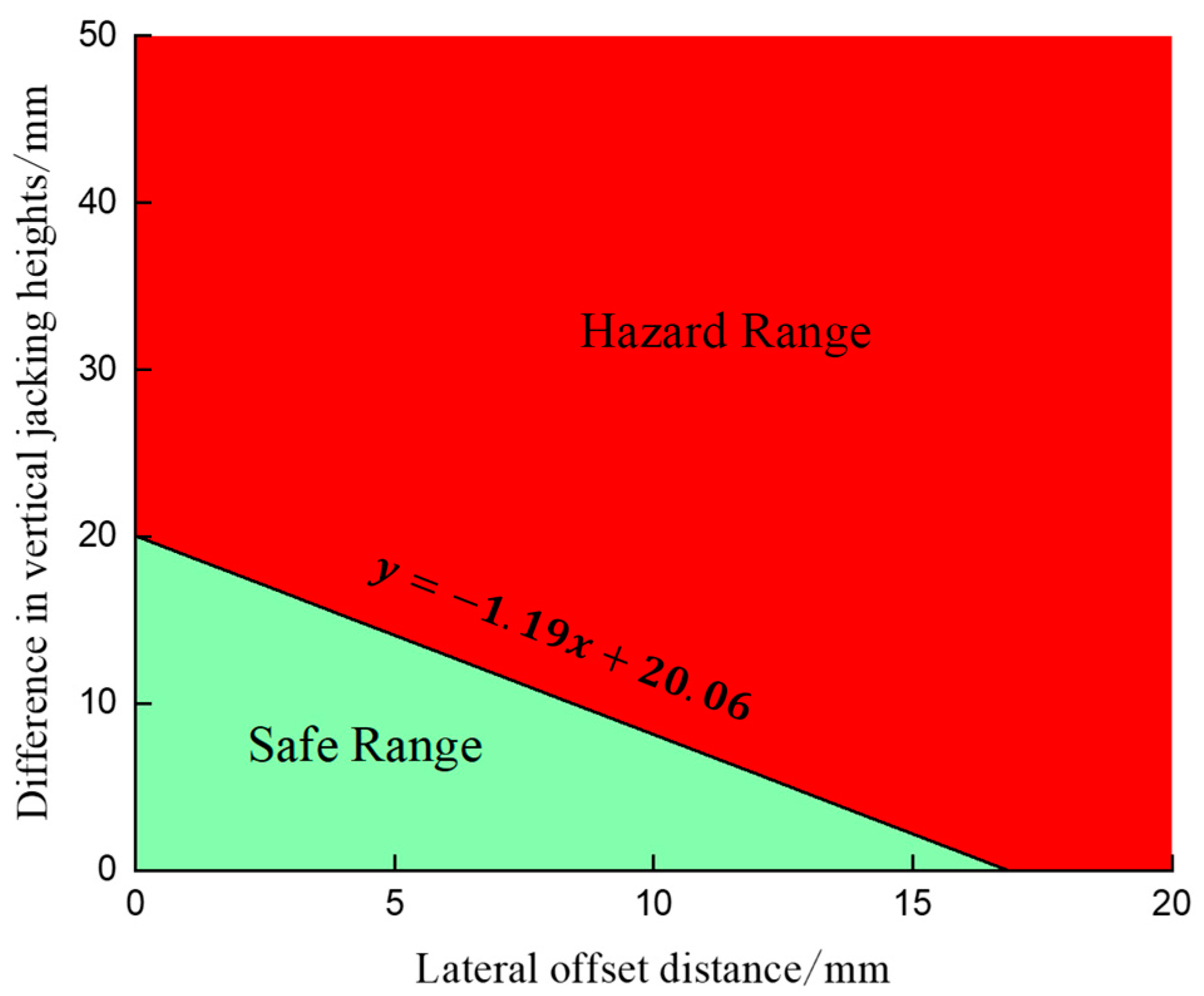

- By calculating the local stresses in the beam when unsynchronized vertical jacking and lateral deflection occurred simultaneously in the beam, it could be found that the beam met the control requirements when the vertical jacking was unsynchronized vertical jacking or when the lateral deflections individually reached a certain value; however, when the two acted together, the local stresses in the beam may still have exceeded the safe range. Against the problem that the single-parameter control of synchronicity misses unfavorable states, this paper proposed the two-parameter control of top thrust synchronization, fitting the maximum equivalent stress under two-parameter co-action, and the permissible stress of Q345qD steel was used as the limit value to obtain the two-parameter control equation of jacking synchronization, determine the control threshold of unsynchronized vertical jacking as 15 mm, and calculate the corresponding control threshold of lateral deflection according to the control equation to realize the dynamic control of lateral deflection.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, R.; Zhang, S. Research status and development trend of bridge jacking method construction. China J. Highw. Transp. 2016, 29, 32–43. [Google Scholar]

- Gong, Z. Top thrust weight 9000t continuous steel box girder bridge in Chiapas, Mexico. World Bridges 2004, 3, 27. [Google Scholar]

- Shao, H.; Zhou, Y.; Luo, X. Construction of Dijiahe Bridge by Overhead Pushing Method. J. China Railw. Soc. 1979, 2, 63–78. [Google Scholar]

- Hua, X.; Cao, L.; Wang, Y. Transient Dynamic Effect Analysis of Incremental Launching Start-Up of Steel Truss Grider Bridge Under Long Cantilever State. Bridge Constr. 2019, 49, 18–22. [Google Scholar]

- Zhang, M.; Xin, Y.; Hu, T. Intelligent Monitoring and Analysis of Incremental Launching Construction of Precast Frame Bridge. Ind. Constr. 2022, 52, 106–110. [Google Scholar]

- Xiong, B.; Yu, Z.; Ma, M. Application of BIM technology in the jacking construction of steel box girder bridge. Build. Struct. 2022, 52, 1968–1972. [Google Scholar]

- Zhou, J.; Li, X.; Wu, Y. Incremental Launching Construction Method for Long-Span Light Rail Bridge with Main Grider Composed of Steel Boxes and Concrete Slabs. World Bridges 2021, 49, 64–71. [Google Scholar]

- Chen, W. Monitoring on Incremental Launching Construction of Prestressed Concrete Continuous Box Girder. Railw. Eng. 2018, 58, 53–57. [Google Scholar]

- Yang, W.; Que, S.; Chu, M. Rotation Adaptive Control Method for Incremental Launching Construction of Main Girder in Bridge with Complex Vertical Curves. Bridge Constr. 2022, 52, 53–59. [Google Scholar]

- Li, C.; Zhou, Q.; Dong, C. Fabrication Configuration and Unstressed Geometry Achievement of Beam Segment of Incrementally Launched Steel Box Girder. J. Highw. Transp. Res. Dev. 2018, 35, 40–48. [Google Scholar]

- Chen, X.; Li, J.; Yang, H. Steel Truss Girder Linear and Stress Control Based on Improved Equipment Pushing Constructio. J. Civ. Eng. Manag. 2018, 35, 43–47. [Google Scholar]

- Dong, C.; Li, C.; Zhang, Y. Single-step modulus search and composition method for determining the scheme of support elevation adjustment during girder launching with vertically varied curvatures. China Civ. Eng. J. 2015, 48, 101–111. [Google Scholar]

- Cui, M. Research on Control Technology of Steel Box Girder Incremental Launching Construction; North China University of Water Resources and Electric Power: Zhengzhou, China, 2020. [Google Scholar]

- Wang, D.; Zhang, Z.; Huang, W. Local force analysis and control in incremental launching process of wide steel box beams. J. Zhejiang Univ. Technol. 2023, 51, 248–254. [Google Scholar]

- Xu, W.; He, P.; Lu, H. Prediction of Local Maximum Stress of Ultra Wide Steel Box Girder during Incremental Launching Construction Process Based on GSA-SVR. J. Highw. Transp. Res. Dev. 2021, 38, 41–47. [Google Scholar]

- Tian, Z.; Chen, Y.; Zhao, L. Local contact analysis and improvement measures of continuous steel girder incremental launchin. J. Chang. Univ. 2012, 32, 44–50. [Google Scholar]

- Wang, H.-J.; Liu, H.-Z.; Wang, Z.-S.; Zou, Y.; Wei, H. Incremental launching construction method for open steel box girder. J. Shenyang Univ. Technol. 2016, 38, 337–343. [Google Scholar]

- Markovic, N.; Kovacevic, S. Influence of patch load length on plate girders. Part I: Experimental research. J. Constr. Steel Res. 2019, 157, 207–228. [Google Scholar] [CrossRef]

- Viet-Hung, T.; Papazafeiropoulos, G.; Quang-Viet, V.; Pham, V.-T.; Kong, Z. Predicting the patch load resistance of stiffened plate girders using machine learning algorithms. Ocean. Eng. 2021, 240, 109886. [Google Scholar]

- Yu, H. Stress and Lateral Displacement Test of Highway Box Girder During Incremental Pushing Process. Highw. Eng. 2019, 44, 198–202. [Google Scholar]

- Li, X.; Zhao, R.; Xu, T. Testing and statistical analysis of lateral offsets in box girder step launching construction. Tunn. Rail Transit 2015, 2, 33–35+44+66. [Google Scholar]

- Li, L.; Liu, Y.; Wang, S. Research on Construction Limit and Deviation Correction Technology of Concrete Continuous Box Girder Jacking. Build. Technol. Dev. 2018, 45, 44–45. [Google Scholar]

- Xu, S. A New Method Using Two—Point Limit for Jacking Construction of Curved Concrete Box Girder. J. Railw. Eng. Soc. 2014, 5, 53–58. [Google Scholar]

- Li, C.; Chen, Z.; Dong, C. Analysis on Local Stress of Wide Steel Box Beam Constructed by Transverse Four—slide Walking—type Incremental Launching Method. J. Highw. Transp. Res. Dev. 2019, 36, 72–79. [Google Scholar]

- Zhu, L.; Tang, J.; Xing, S. Effect of Lateral offset on Force State of Prestressed Concrete Trough Girders with Asymmetric Cross-Section. J. Southwest Jiaotong Univ. 2019, 54, 1155–1161. [Google Scholar]

- Wang, J.; Chen, S.; Chen, S. Analysis of the Influence of Axis Deviation on the Stress of Multi-span Steel Truss Girder during Pushing Construction. Railw. Stand. Des. 2020, 64, 86–90. [Google Scholar]

- Kuang, S. Risk evaluation and analysis of continuous steel box girder jacking construction. Build. Struct. 2023, 53, 2310–2313. [Google Scholar]

- Zhu, L.; Chen, Q.; Wu, B. Research on two parameters control and local stress of walking-type incremental launching wide steel box girder. Build. Struct. 2021, 51, 934–939. [Google Scholar]

- He, Y. Structural Behavior of Continuous Steel Box Girder Bridges during Stepwise Incremental Launching Construction. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2017. [Google Scholar]

- Xie, Q. An Analytical Study of Local Stresses on Steel Box Girders by Walk-Behind Incremental Launching Construction Process. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2015. [Google Scholar]

- Wang, B. Research on the Causes of Lateral Deviation of Steel-Hybrid Girder Incremental Launching and Countermeasures for Deviation Correction. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2015. [Google Scholar]

| Difference in Vertical Jacking Heights/mm | 0 | 5 | 10 | 15 | 20 | 25 |

|---|---|---|---|---|---|---|

| Reaction force/KN | 1368.12 | 1434.25 | 1492.39 | 1537.88 | 1563.82 | 1570.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Guo, H.; Guo, B. The Dual-Parameter Control of Synchronization in Steel Box Girder Incremental Launching Construction. Appl. Sci. 2023, 13, 12074. https://doi.org/10.3390/app132112074

Li Q, Guo H, Guo B. The Dual-Parameter Control of Synchronization in Steel Box Girder Incremental Launching Construction. Applied Sciences. 2023; 13(21):12074. https://doi.org/10.3390/app132112074

Chicago/Turabian StyleLi, Qingfu, Hao Guo, and Biao Guo. 2023. "The Dual-Parameter Control of Synchronization in Steel Box Girder Incremental Launching Construction" Applied Sciences 13, no. 21: 12074. https://doi.org/10.3390/app132112074

APA StyleLi, Q., Guo, H., & Guo, B. (2023). The Dual-Parameter Control of Synchronization in Steel Box Girder Incremental Launching Construction. Applied Sciences, 13(21), 12074. https://doi.org/10.3390/app132112074