A Hybrid Architectural Model for Monitoring Production Performance in the Plastic Injection Molding Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Application Field: Injection Molding Production Line

- Injection molding machine;

- Picking robot;

- Station for control–assembly operations.

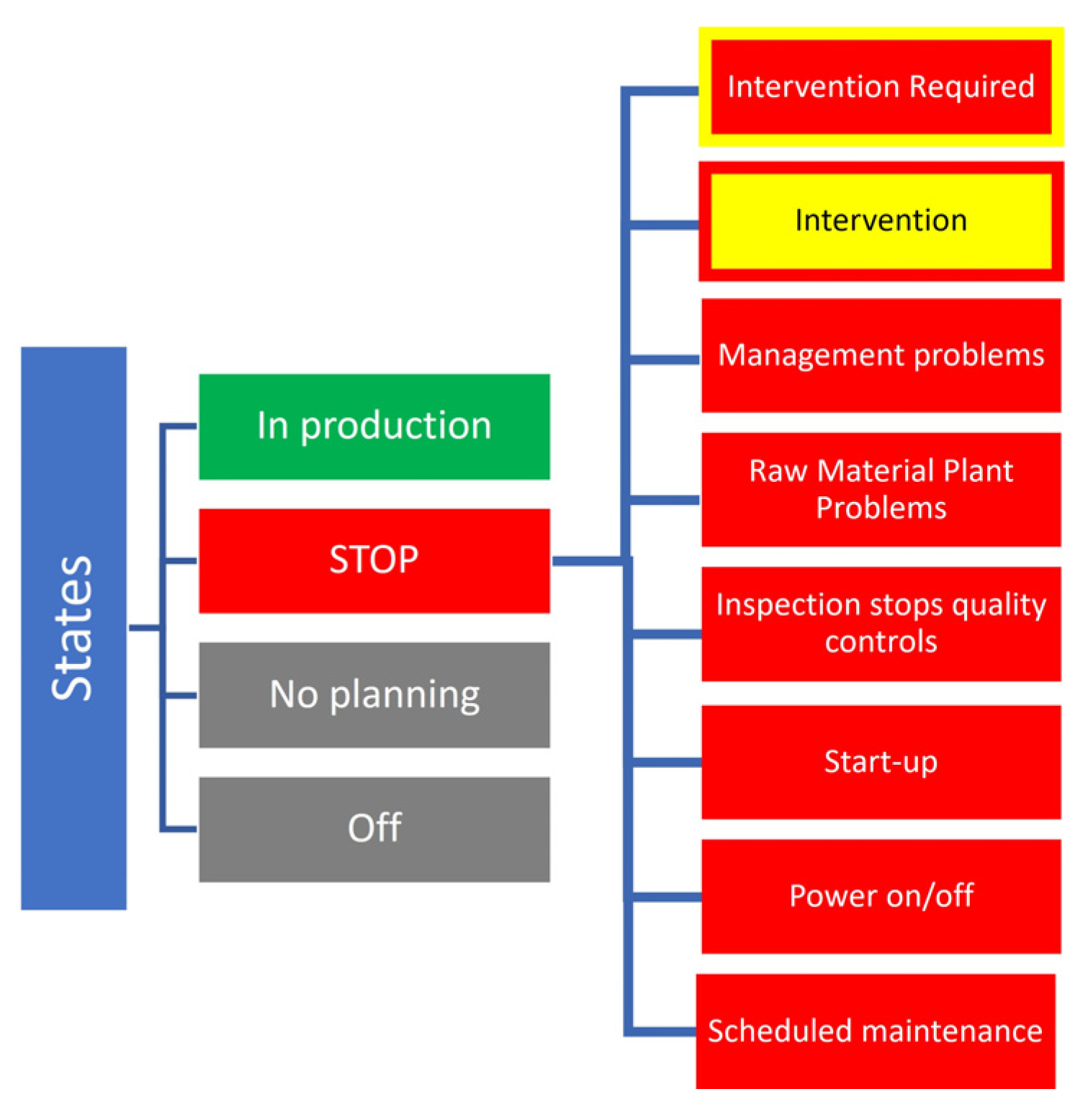

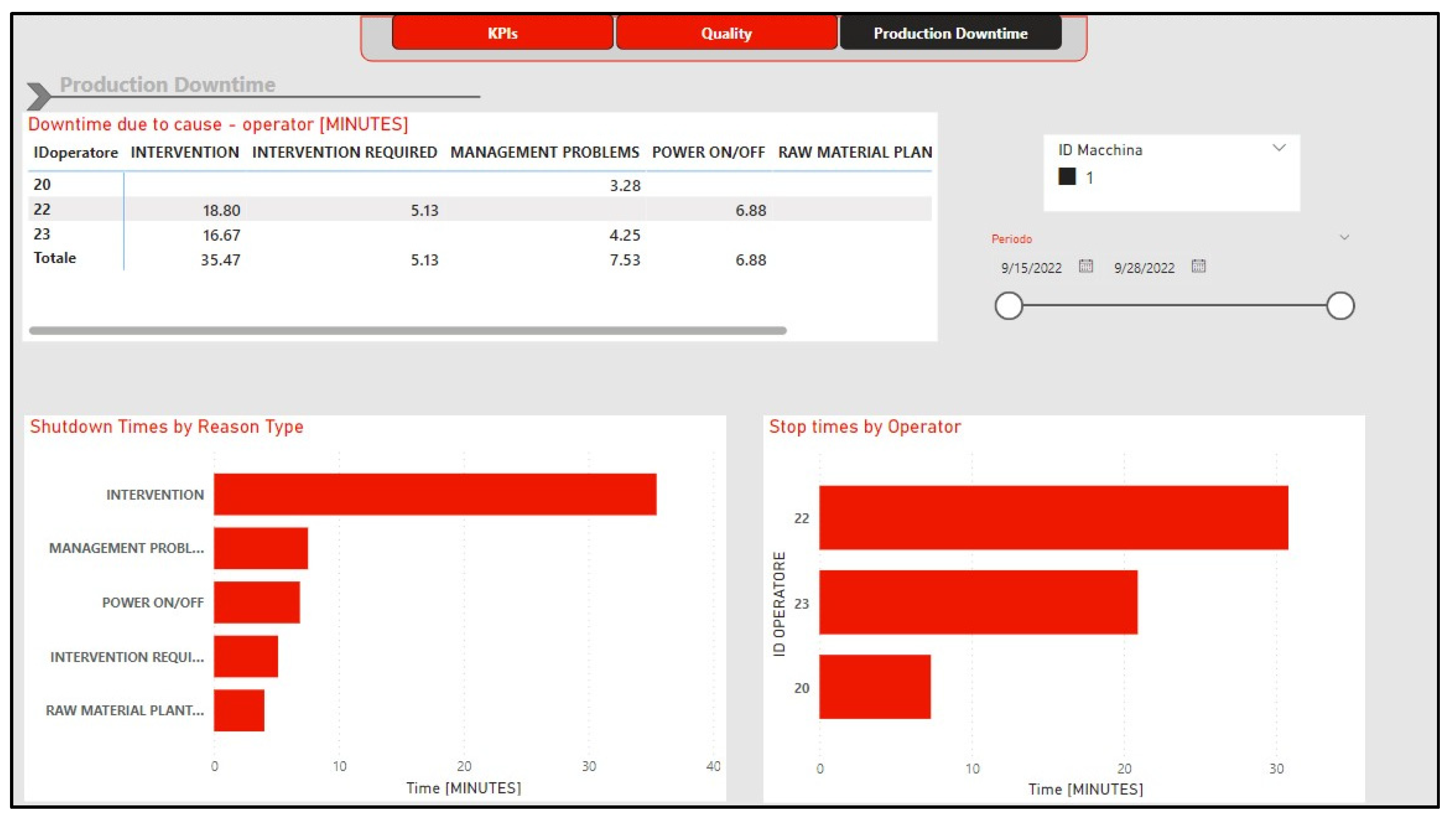

- Intervention required: the intervention of a specific professional figure is required;

- Intervention: an operator is intervening on the production unit;

- Management problems: the unit is stopped due to non-technical problems (e.g., lack of a line operator);

- Raw material plant problems: the unit is stopped due to problems related to the quality or availability of plastic granules;

- Inspection stops quality control: the unit is stopped due to quality problems on the molded products;

- Start-up: the unit is in the start-up phase of production;

- Power on/off: for an injection molding machine, both switching on and off takes some time;

- Scheduled maintenance: for maintenance activities already foreseen in the maintenance calendar.

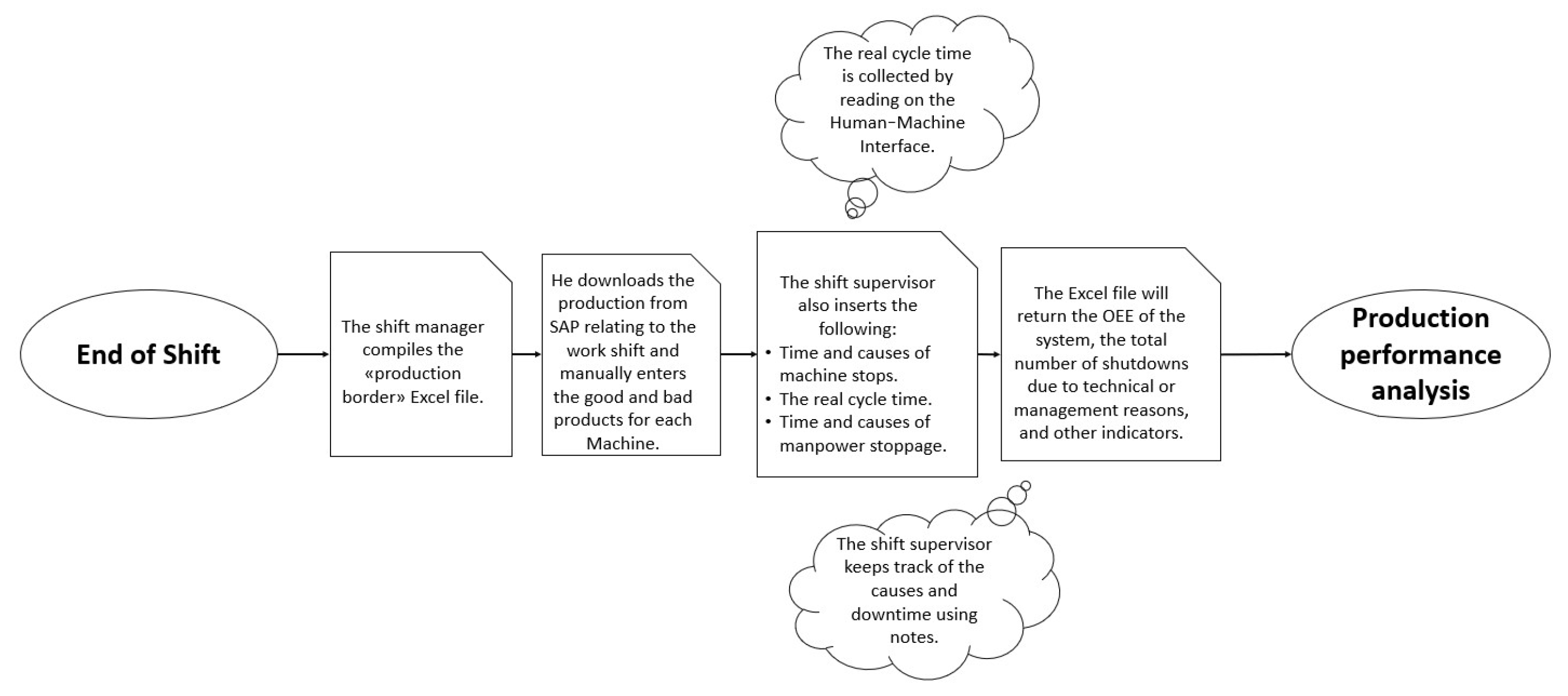

2.2. Case Study: AS-IS Downtime Management Process

2.3. BPMN for Representation of TO-BE Processes

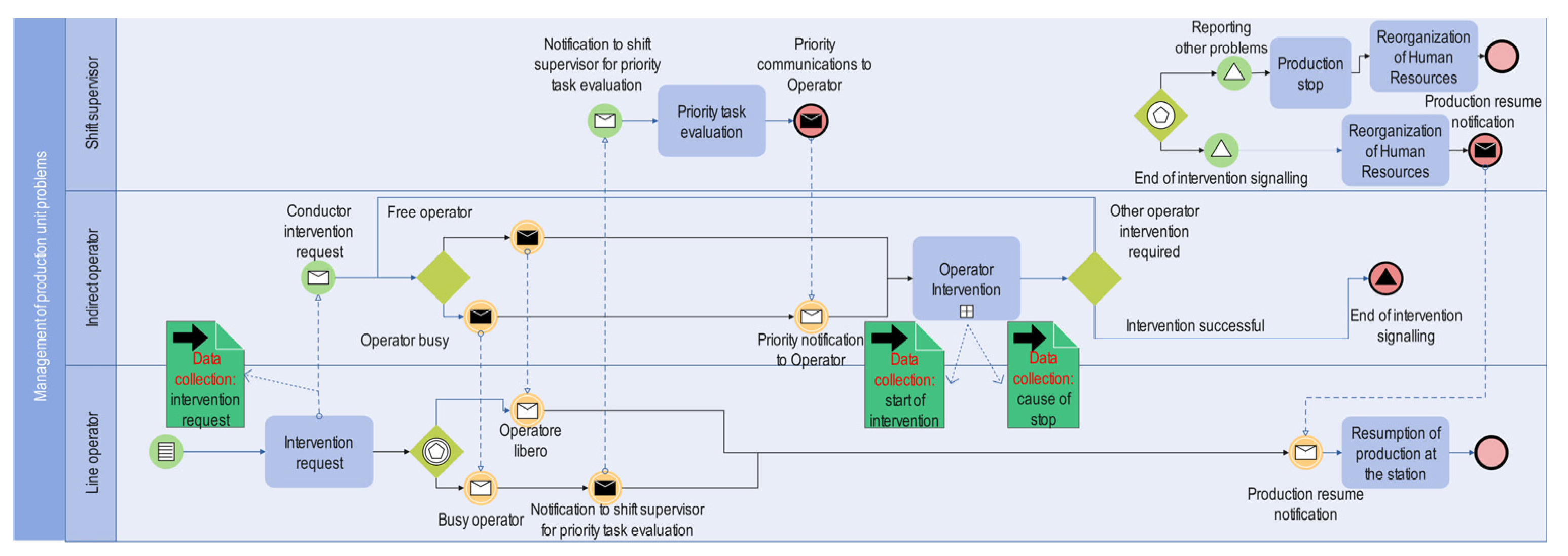

2.4. TO-BE Downtime Management Process to Improve the Quality of Manually Collected Data

- Intervention request;

- Intervention start;

- Cause of unit shutdown.

3. Architectural Model

3.1. Solutions for Monitoring a Plastic Injection Molding Production Line

- Telemetry of the injection molding machine: data collected automatically by the injection molding machine’s programmable logic controller (PLC).

- Intervention request system: for collecting data relating to an operator’s intervention request.

- Intervention tracking system: for the digital tracking of the interventions carried out by the operators.

- Human–system interface: to speed up the manual data collection phase.

- Real-Time Monitoring Dashboard: allows one to analyze the monitoring information managed by the digital platform in an easy and intuitive way.

3.1.1. Telemetry of the Injection Molding Machine

3.1.2. Intervention Request System

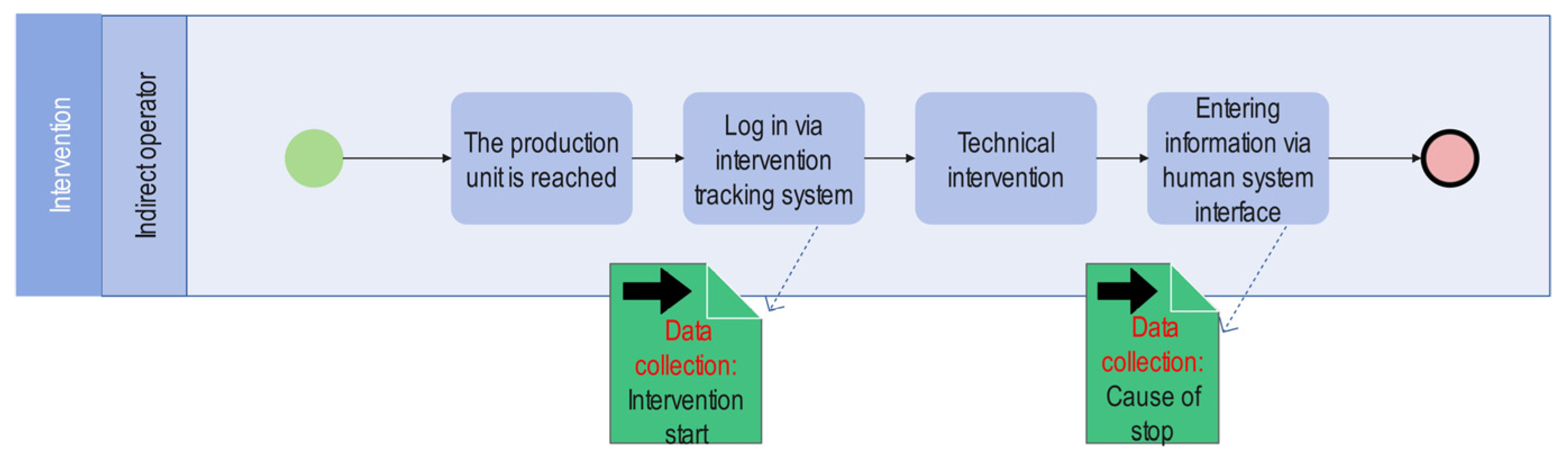

3.1.3. Intervention Tracking System

3.1.4. Human–System Interface

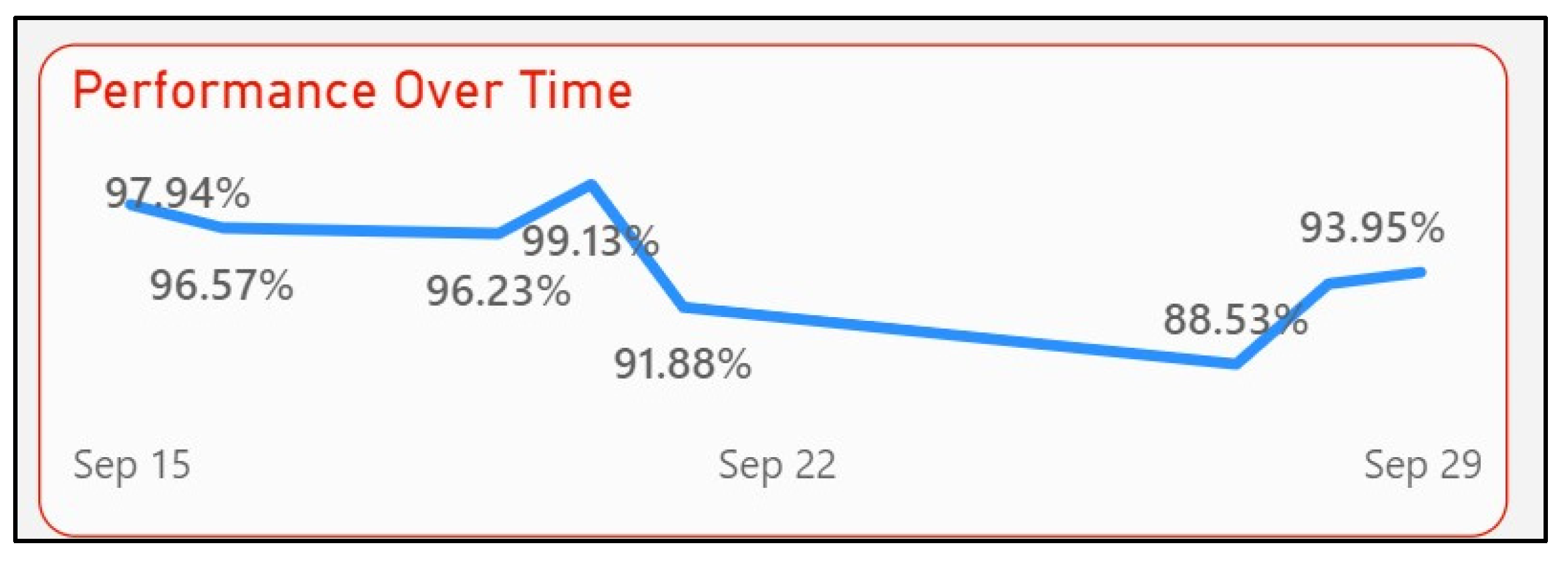

3.2. The Dashboard for Performance Analysis

4. Discussions and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Santos, C.; Mehrsai, A.; Barros, A.; Araújo, M.; Ares, E. Towards Industry 4.0: An overview of European strategic roadmaps. Procedia Manuf. 2017, 13, 972–979. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Reddy, K.S.P.; Roopa, Y.M.; Kovvada Rajeev, L.N.; Nandan, N.S. IoT based smart agriculture using machine learning. In Proceedings of the 2nd International Conference on Inventive Research in Computing Applications (ICIRCA 2020), Coimbatore, India, 15–17 July 2020. [Google Scholar]

- Massaro, A.; Mastandrea, G.; D’Oriano, L.; Rana, G.R.; Savino, N.; Galiano, A. Systems for an intelligent application of Automated Processes in industry: A case study from ‘PMI IoT Industry 4.0’project. In Proceedings of the 2020 IEEE International Workshop on Metrology for Industry 4.0 & IoT, Roma, Italy, 3–5 June 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar]

- Chakravarthi, V.S. Internet of Things and M2M Communication Technologies: Architecture and Practical Design Approach to IoT in Industry 4.0; Springer International Publishing: Midtown Manhattan, NY, USA, 2021. [Google Scholar] [CrossRef]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2017, 6, 6505–6519. [Google Scholar] [CrossRef]

- Bu, L.; Zhang, Y.; Liu, H.; Yuan, X.; Guo, J.; Han, S. An IIoT-driven and AI-enabled framework for smart manufacturing system based on three-terminal collaborative platform. Adv. Eng. Inform. 2021, 50, 101370. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Pivoto, D.G.S.; de Almeida, L.F.F.; Da Rosa Righi, R.; Rodrigues, J.J.P.C.; Lugli, A.B.; Alberti, A.M. Cyber-physical systems architectures for industrial internet of things applications in Industry 4.0: A literature review. J. Manuf. Syst. 2021, 58, 176–192. [Google Scholar] [CrossRef]

- Laghari, R.A.; Mekid, S. Comprehensive approach toward IIoT based condition monitoring of machining processes. Measurement 2023, 217, 113004. [Google Scholar] [CrossRef]

- Corrales, L.d.C.N.; Lambán, M.P.; Korner, M.E.H.; Royo, J. Overall Equipment Effectiveness: Systematic Literature Review and Overview of Different Approaches. Appl. Sci. 2020, 10, 6469. [Google Scholar] [CrossRef]

- Iannone, R.; Elena, M. Managing OEE to Optimize Factory Performance. In Operations Management; InTech: Pulau Pinang, Malaysia, 2013. [Google Scholar] [CrossRef]

- Li, X.; Liu, G.; Hao, X. Research on Improved OEE Measurement Method Based on the Multiproduct Production System. Appl. Sci. 2021, 11, 490. [Google Scholar] [CrossRef]

- Schiraldi, M.M.; Varisco, M. Overall Equipment Effectiveness: Consistency of ISO standard with literature. Comput. Ind. Eng. 2020, 145, 106518. [Google Scholar] [CrossRef]

- Cheah, C.K.; Prakash, J.; Ong, K.S. Overall equipment effectiveness: A review and development of an integrated improvement framework. Int. J. Prod. Qual. Manag. 2020, 30, 46. [Google Scholar] [CrossRef]

- Singh, S.; Khamba, J.S.; Singh, D. Analyzing the Role of Six Big Losses in OEE to Enhance the Performance: Literature Review and Directions. In Lecture Notes in Mechanical Engineering; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2021; pp. 411–421. [Google Scholar] [CrossRef]

- Breiter, S.; Arlinghaus, J.C. Disruption data collection in low-volume, complex product assembly. IFAC-PapersOnLine 2021, 54, 80–85. [Google Scholar] [CrossRef]

- Kaya, O.; Bergsjö, D.; Kaya, O.; Bergsjö, D. Learning from digital disturbance management in an integrated product development and production flow. Int. J. Prod. Lifecycle Manag. 2018, 11, 295–325. [Google Scholar] [CrossRef]

- Li, Y.H.; Inoue, L.C.G.V.; Sinha, R. Real-time OEE visualisation for downtime detection. In Proceedings of the IEEE International Conference on Industrial Informatics (INDIN), Perth, Australia, 25–28 July 2022; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2022; pp. 729–734. [Google Scholar] [CrossRef]

- Breiter, S.; Gottwald, J.; Arlinghaus, J.C. Recording Data on Production Disruptions: Usability and Data Quality. IFAC-PapersOnLine 2022, 55, 964–969. [Google Scholar] [CrossRef]

- Breiter, S.; Gottwald, J.; Arlinghaus, J.C. Manual Collection of Data on Disruptions: Determinants to Increase the Intention to Use. IFAC-PapersOnLine 2022, 55, 952–957. [Google Scholar] [CrossRef]

- Tortora, A.M.R.; Di Pasquale, V.; Franciosi, C.; Miranda, S.; Iannone, R. The Role of Maintenance Operator in Industrial Manufacturing Systems: Research Topics and Trends. Appl. Sci. 2021, 11, 3193. [Google Scholar] [CrossRef]

- Rosato, D.V.; Rosato, M.G. Injection Molding Handbook; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Nwanya, S.; Udofia, J.; Ajayi, O. Optimization of machine downtime in the plastic manufacturing. Cogent Eng. 2017, 4, 1335444. [Google Scholar] [CrossRef]

- BPMN 2.0. Available online: https://www.omg.org/spec/BPMN/2.0 (accessed on 1 August 2023).

- Abouzid, I.; Saidi, R. Proposal of BPMN extensions for modelling manufacturing processes. In Proceedings of the 2019 5th International Conference on Optimization and Applications (ICOA), Kenitra, Morocco, 25–26 April 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Djatna, T.; Munichputranto, F. An Analysis and Design of Mobile Business Intelligence System for Productivity Measurement and Evaluation in Tire Curing Production Line. Procedia Manuf. 2015, 4, 438–444. [Google Scholar] [CrossRef][Green Version]

- EUROMAP 67. Electrical Interface between Injection Moulding Machine and Handling Device/Robot This Recommendation was Prepared by the Technical Commission of EUROMAP. Available online: www.euromap.org/technical-issues/technical-recommendations (accessed on 20 July 2023).

- OPC Foundation. Unified Architecture. Available online: https://opcfoundation.org/about/opc-technologies/opc-ua/ (accessed on 24 July 2023).

- Hermundsdottir, F.; Aspelund, A. Competitive sustainable manufacturing—Sustainability strategies, environmental and social innovations, and their effects on firm performance. J. Clean. Prod. 2022, 370, 133474. [Google Scholar] [CrossRef]

| Name | Variable | Description |

|---|---|---|

| Date and Time stamp | The variable is reported for each row when the value of any variable changes. | |

| Machine ID | An ID is associated with each machine. | |

| Status | Machine status can be either in production or stop. | |

| Count outputs | The variable is a counter that is incremented by one unit for each print cycle. | |

| Defect | The variable is a Boolean that is 0 if the unit is good and 1 if it is defective. |

| Name | Variable | Description |

|---|---|---|

| Date and Time request | The variable reports when the request is effected. | |

| Machine ID | ID of the machine where intervention is effected | |

| Request ID | An ID is associated with each request. | |

| Intervention required | The types of intervention can be conductor, maintenance, or technologist. |

| Name | Variable | Description |

|---|---|---|

| Date and Time intervention start | The variable reports when the intervention starts. | |

| Date and Time intervention end | The variable reports when the intervention ends. | |

| Machine ID | Machine’s ID where intervention is effected. | |

| Operator ID | This variable identifies the operator. | |

| Intervention ID | An ID is associated with each intervention tracked by the system. | |

| Request ID | If the intervention is associated with a request. |

| Name | Variable | Description |

|---|---|---|

| Date and Time inserting cause of downtime | The variable reports when the request is effected. | |

| Machine ID | Machine’s ID where intervention is effected | |

| Operator ID | The variable identifies the operator. | |

| Intervention ID | The variable identifies the intervention. | |

| Reason for type of stoppage | The cause of stoppage is one of those shown in Figure 1. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luisi, G.; Di Pasquale, V.; Pietronudo, M.C.; Riemma, S.; Ferretti, M. A Hybrid Architectural Model for Monitoring Production Performance in the Plastic Injection Molding Process. Appl. Sci. 2023, 13, 12145. https://doi.org/10.3390/app132212145

Luisi G, Di Pasquale V, Pietronudo MC, Riemma S, Ferretti M. A Hybrid Architectural Model for Monitoring Production Performance in the Plastic Injection Molding Process. Applied Sciences. 2023; 13(22):12145. https://doi.org/10.3390/app132212145

Chicago/Turabian StyleLuisi, Gerardo, Valentina Di Pasquale, Maria Cristina Pietronudo, Stefano Riemma, and Marco Ferretti. 2023. "A Hybrid Architectural Model for Monitoring Production Performance in the Plastic Injection Molding Process" Applied Sciences 13, no. 22: 12145. https://doi.org/10.3390/app132212145

APA StyleLuisi, G., Di Pasquale, V., Pietronudo, M. C., Riemma, S., & Ferretti, M. (2023). A Hybrid Architectural Model for Monitoring Production Performance in the Plastic Injection Molding Process. Applied Sciences, 13(22), 12145. https://doi.org/10.3390/app132212145