Verification of Industrial Worker Walking Efficiency with Wearable Hip Exoskeleton

Abstract

:Featured Application

Abstract

1. Introduction

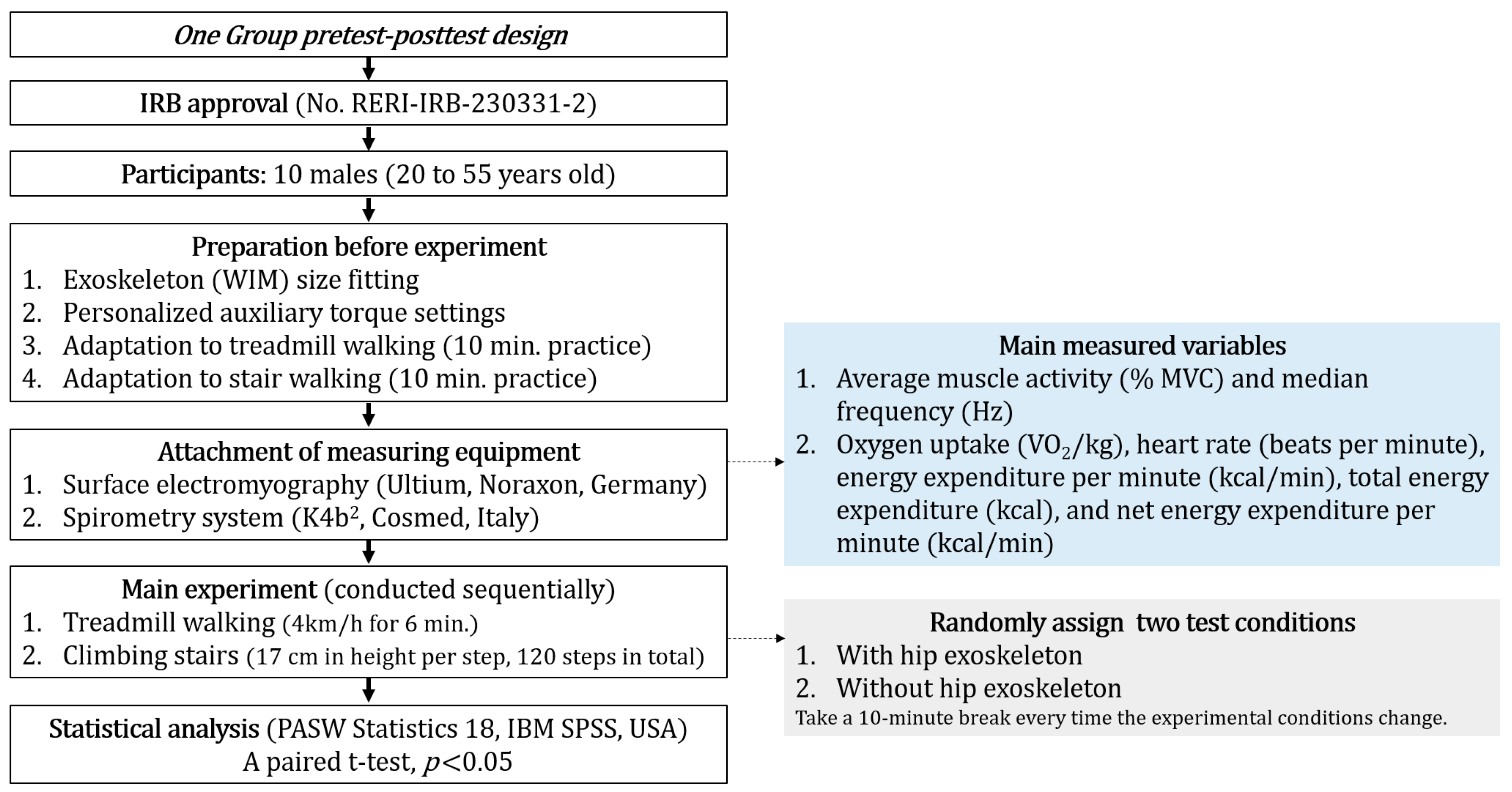

2. Materials and Methods

2.1. Participants

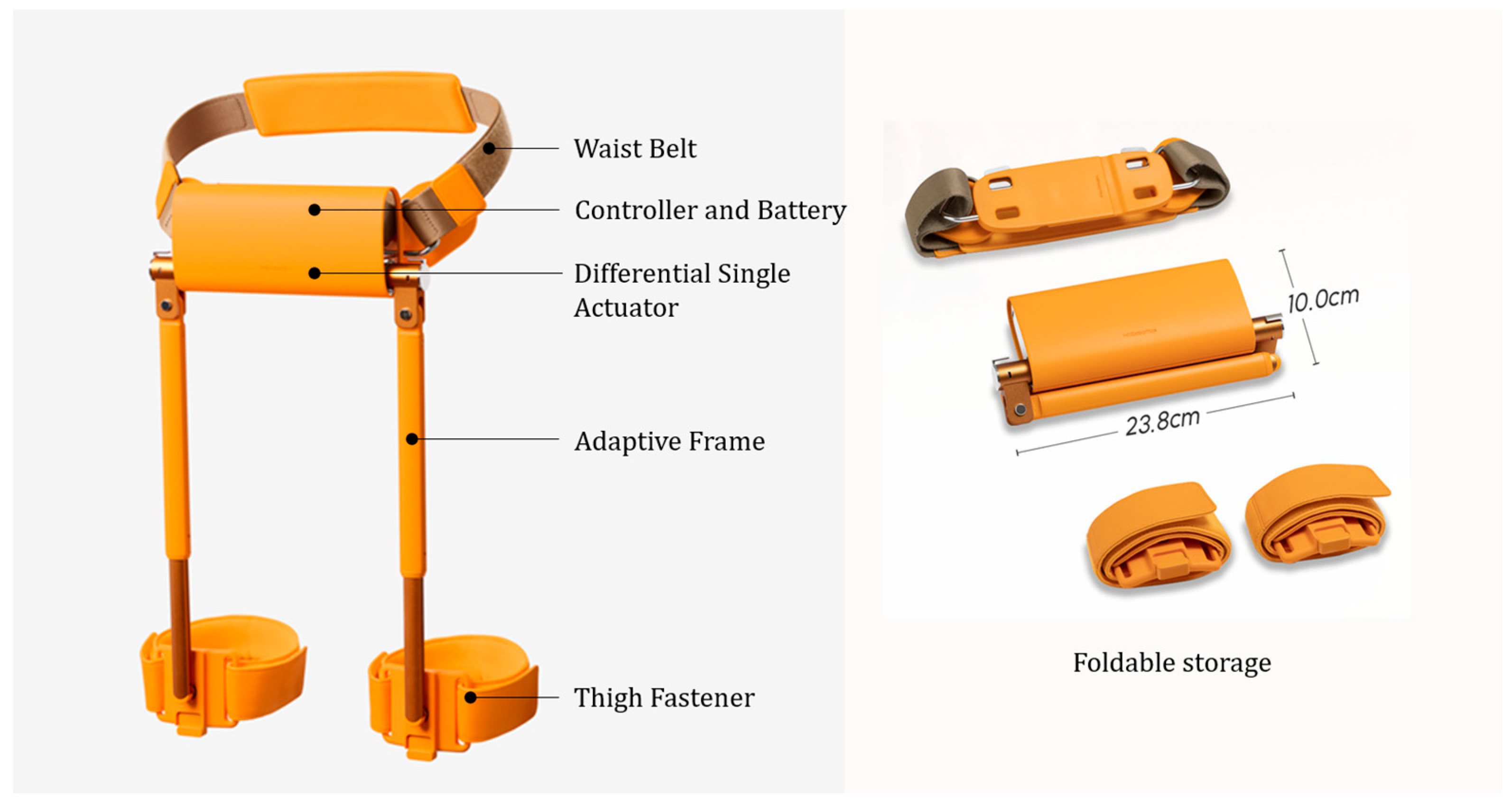

2.2. Ultralight Wearable Hip Exoskeleton Device

2.3. Measurement

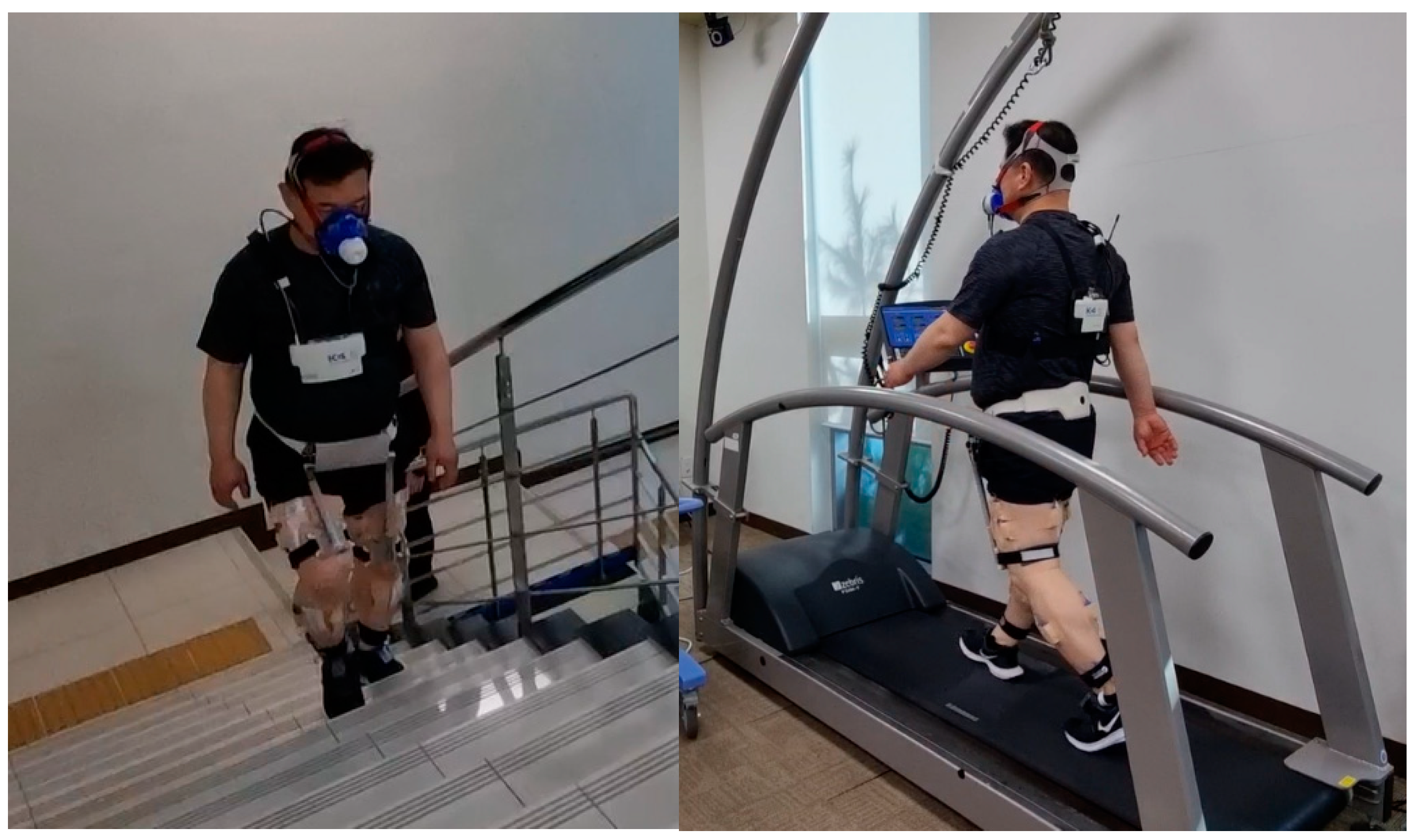

2.4. Experimental Procedure

2.5. Data Analysis

3. Results

3.1. Treadmill Walking

3.1.1. Muscle Activity and Fatigue

3.1.2. Energy Expenditure

3.2. Climbing Stairs

3.2.1. Muscle Activity and Fatigue

3.2.2. Energy Expenditure

4. Discussion

4.1. Treadmill Walking

4.2. Ascending Stairways

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bogue, R. Exoskeletons—A review of industrial applications. Ind. Robot. Int. J. 2018, 45, 585–590. [Google Scholar] [CrossRef]

- Baltrusch, S.J.; van Dieën, J.H.; Bruijn, S.M.; Koopman, A.S.; van Bennekom, C.A.M.; Houdijk, H. The effect of a passive trunk exoskeleton on metabolic costs during lifting and walking. Ergonomics 2019, 62, 903–916. [Google Scholar] [CrossRef]

- Zelik, K.E.; Nurse, C.A.; Schall, M.C.; Sesek, R.F.; Marino, M.C.; Gallagher, S. An ergonomic assessment tool for evaluating the effect of back exoskeletons on injury risk. Appl. Ergon. 2022, 99, 103619. [Google Scholar] [CrossRef]

- Kuschan, J.; Krüger, J. Fatigue recognition in overhead assembly based on a soft robotic exosuit for worker assistance. CIRP Ann. 2021, 70, 9–12. [Google Scholar] [CrossRef]

- Shi, Y.; Dong, W.; Lin, W.; Gao, Y. Soft wearable exoskeleton: Development status and technical challenges. Sensors 2022, 22, 7584. [Google Scholar] [CrossRef]

- John, S.W.; Murakami, K.; Komatsu, M.; Adachi, S. Cross-wire assist suit concept, for mobile and lightweight multiple degree of freedom hip assistance. In Proceedings of the 2017 International Conference on Rehabilitation Robotics (ICORR), London, UK, 17–20 July 2017; Volume 2017, pp. 387–393. [Google Scholar] [CrossRef]

- Jin, S.; Iwamoto, N.; Hashimoto, K.; Yamamoto, M. Experimental evaluation of energy efficiency for a soft wearable robotic suit. IEEE Trans. Neural Syst. Rehabil. Eng. 2017, 25, 1192–1201. [Google Scholar] [CrossRef]

- Chen, L.; Chen, C.; Wang, Z.; Ye, X.; Liu, Y.; Wu, X. A novel lightweight wearable soft exosuit for reducing the metabolic rate and muscle fatigue. Biosensors 2021, 11, 215. [Google Scholar] [CrossRef]

- Kim, J.; Quinlivan, B.T.; Deprey, L.A.; Arumukhom Revi, D.; Eckert-Erdheim, A.; Murphy, P.; Orzel, D.; Walsh, C.J. Reducing the energy cost of walking with low assistance levels through optimized hip flexion assistance from a soft exosuit. Sci. Rep. 2022, 12, 11004. [Google Scholar] [CrossRef]

- Tricomi, E.; Lotti, N.; Missiroli, F.; Zhang, X.; Xiloyannis, M.; Muller, T.; Crea, S.; Papp, E.; Krzywinski, J.; Vitiello, N.; et al. Underactuated soft hip exosuit based on adaptive oscillators to assist human locomotion. IEEE Robot. Autom. Lett. 2022, 7, 936–943. [Google Scholar] [CrossRef]

- Haufe, F.L.; Wolf, P.; Riener, R.; Grimmer, M. Biomechanical effects of passive hip springs during walking. J. Biomech. 2020, 98, 109432. [Google Scholar] [CrossRef]

- Yang, J.; Park, J.; Kim, J.; Park, S.; Lee, G. Reducing the energy cost of running using a lightweight, low-profile elastic exosuit. J. NeuroEngineering Rehabil. 2021, 18, 129. [Google Scholar] [CrossRef]

- Lee, H.J.; Lee, S.; Chang, W.H.; Seo, K.; Shim, Y.; Choi, B.O.; Ryu, G.H.; Kim, Y.H. A wearable hip assist robot can improve gait function and cardiopulmonary metabolic efficiency in elderly adults. IEEE Trans. Neural Syst. Rehabil. Eng. 2017, 25, 1549–1557. [Google Scholar] [CrossRef]

- Kim, D.S.; Lee, H.J.; Lee, S.H.; Chang, W.H.; Jang, J.; Choi, B.O.; Ryu, G.H.; Kim, Y.H. A wearable hip-assist robot reduces the cardiopulmonary metabolic energy expenditure during stair ascent in elderly adults: A pilot cross-sectional study. BMC Geriatr. 2018, 18, 230. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, J.; Lim, B.; Lee, H.J.; Kim, Y.H. Exercise with a wearable hip-assist robot improved physical function and walking efficiency in older adults. Sci. Rep. 2023, 13, 7269. [Google Scholar] [CrossRef]

- Xiloyannis, M.; Alicea, R.; Geogarakis, A.; Haufe, F.; Wolf, P.; Masia, L.; Riener, R. Soft robotic suits: State of the art, core technologies, and open challenges. IEEE Trans. Robot. 2021, 38, 1343–1362. [Google Scholar] [CrossRef]

- van Dijk, W.; van der Kooij, H.; Hekman, E. A passive exoskeleton with artificial tendons: Design and experimental evaluation. In Proceedings of the 2011 IEEE International Conference on Rehabilitation Robotics, Zurich, Switzerland, 29 June–1 July 2011; pp. 1–6. [Google Scholar] [CrossRef]

- Jarrassé, N.; Morel, G. Connecting a human limb to an exoskeleton. IEEE Trans. Robot. 2011, 28, 697–709. [Google Scholar] [CrossRef]

- Pesenti, M.; Antonietti, A.; Gandolla, M.; Pedrocchi, A. Towards a functional performance validation standard for industrial low-back exoskeletons: State of the art review. Sensors 2021, 21, 808. [Google Scholar] [CrossRef]

- Zhao, G.; Grimmer, M.; Seyfarth, A. The mechanisms and mechanical energy of human gait initiation from the lower-limb joint level perspective. Sci. Rep. 2021, 11, 22473. [Google Scholar] [CrossRef]

- Lim, B.; Choi, B.; Roh, C.; Hyung, S.; Kim, Y.; Lee, Y. Parametric delayed output feedback control for versatile human-exoskeleton interactions during walking and running. IEEE Robot. Autom. Lett. 2023, 8, 4497–4504. [Google Scholar] [CrossRef]

- Kang, H.; Dingwell, J. Effects of walking speed, strength and range of motion on gait stability in healthy older adults. J. Biomech. 2008, 41, 2899–2905. [Google Scholar] [CrossRef]

- Allison, G.T.; Fujiwara, T. The relationship between EMG median frequency and low frequency band amplitude changes at different levels of muscle capacity. Clin. Biomech. 2002, 17, 464–469. [Google Scholar] [CrossRef]

- Mitchell, J.H.; Blomqvist, G. Maximal oxygen uptake. N. Engl. J. Med. 1971, 284, 1018–1022. [Google Scholar] [CrossRef]

- Mtaweh, H.; Tuira, L.; Floh, A.A.; Parshuram, C.S. Indirect calorimetry: History, technology, and application. Front. Pediatr. 2018, 6, 257. [Google Scholar] [CrossRef]

- Giroux, M.; Moissenet, F.; Dumas, R. EMG-based validation of musculo-skeletal models for gait analysis. Comput. Methods Biomech. Biomed. Eng. 2013, 16, 152–154. [Google Scholar] [CrossRef]

- Merletti, R.; Conte, L.; Orizio, C. Indices of muscle fatigue. J. Electromyogr. Kinesiol. 1991, 1, 20–33. [Google Scholar] [CrossRef]

- Brehm, M.; Becher, J.; Harlaar, J. Reproducibility evaluation of gross and net walking efficiency in children with cerebral palsy. Dev. Med. Child Neurol. 2007, 49, 45–48. [Google Scholar] [CrossRef]

- Zuntz, N. Ueber die Bedeutung der verschiedenen Nährstoffe als Erzeuger der Muskelkraft. Arch. Für Die Gesamte Physiol. Des Menschen Und Der Tiere 1901, 83, 557–571. [Google Scholar] [CrossRef]

- Wert, D.; Brach, J.; Perera, S.; VanSwearingen, J. Gait biomechanics, spatial and temporal characteristics, and the energy cost of walking in older adults with impaired mobility. Phys. Ther. 2010, 90, 977–985. [Google Scholar] [CrossRef]

- Bigland-Ritchie, B.; Donovan, E.F.; Roussos, C.S. Conduction velocity and EMG power spectrum changes in fatigue of sustained maximal efforts. J. Appl. Physiol. 1981, 51, 1300–1305. [Google Scholar] [CrossRef]

- Lowery, M.M.; O’Malley, M.J. Analysis and simulation of changes in EMG amplitude during high-level fatiguing contractions. IEEE Trans. Biomed. Eng. 2003, 50, 1052–1062. [Google Scholar] [CrossRef]

- Hunter, G.R.; McCarthy, J.P.; Bamman, M.M. Effects of resistance training on older adults. Sports Med. 2004, 34, 329–348. [Google Scholar] [CrossRef]

- Zhang, J.; Fiers, P.; Witte, K.A.; Jackson, R.W.; Poggensee, K.L.; Atkeson, C.G.; Collins, S.H. Human-in-the-loop optimization of exoskeleton assistance during walking. Science 2017, 356, 1280–1284. [Google Scholar] [CrossRef]

- Ding, Y.; Galiana, I.; Asbeck, A.T.; De Rossi, S.M.; Bae, J.; Santos, T.R.; de Araujo, V.L.; Lee, S.; Holt, K.G.; Walsh, C. Biomechanical and physiological evaluation of multi-joint assistance with soft exosuits. IEEE Trans. Neural Syst. Rehabil. Eng. 2017, 25, 119–130. [Google Scholar] [CrossRef]

- Young, A.J.; Foss, J.; Gannon, H.; Ferris, D.P. Influence of power delivery timing on the energetics and biomechanics of humans wearing a hip exoskeleton. Front. Bioeng. Biotechnol. 2017, 5, 4. [Google Scholar] [CrossRef]

- Harper, N.G.; Wilken, J.M.; Neptune, R.R. Muscle function and coordination of stair ascent. J. Biomech. Eng. 2018, 140, 011001. [Google Scholar] [CrossRef]

- Lee, H.D.; Park, H.; Seongho, B.; Kang, T.H. Development of a soft exosuit system for walking assistance during stair ascent and descent. Int. J. Control Autom. Syst. 2020, 18, 2678–2686. [Google Scholar] [CrossRef]

- Knaggs, J.D.; Larkin, K.A.; Manini, T.M. Metabolic cost of daily activities and effect of mobility impairment in older adults. J. Am. Geriatr. Soc. 2011, 59, 2118–2123. [Google Scholar] [CrossRef]

- Cho, K.H.; Song, W.; Kim, J.; Jung, E.J.; Jang, J.; Im, S.H.; Kim, M. Energy expenditures for activities of daily living in Korean young adults: A preliminary study. Ann. Rehabil. Med. 2016, 40, 725–733. [Google Scholar] [CrossRef]

| Overall size | |

| Weight | 1.4 kg (including battery, fastener) |

| Operating time per charge | Approximately 2 h (assist mode) |

| Battery | Lithium-ion battery, 14.4 Vd.c., 3.35 Ah |

| Applicable body size | Main body—one size |

| Waist or thigh fastener—two sizes (waist 26′~36′) | |

| Adaptive thigh frame stroke | 160~350 mm |

| No WIM | WIM | % Difference | t-Value | ||

|---|---|---|---|---|---|

| RF | Muscle activity (%MVC) | 18.42 ± 9.34 § | 16.91 ± 8.95 | −8.20% | 0.591 |

| Muscle fatigue (Hz) | −0.005 ± 0.020 | −0.001 ± 0.020 | −84.62% | −0.838 | |

| ST | Muscle activity (%MVC) | 30.60 ± 12.06 | 29.02 ± 15.16 | −5.16% | 0.334 |

| Muscle fatigue (Hz) | −0.037 ± 0.053 | −0.009 ± 0.018 | −76.82% | −1.654 | |

| TA | Muscle activity (%MVC) | 11.05 ± 2.82 | 11.58 ± 3.12 | 4.80% | −0.708 |

| Muscle fatigue (Hz) | −0.007 ± 0.008 | −0.008 ± 0.008 | 18.31% | 0.407 | |

| GCM | Muscle activity (%MVC) | 17.29 ± 2.64 | 17.42 ± 4.83 | 0.74% | −0.106 |

| Muscle fatigue (Hz) | −0.015 ± 0.013 | −0.003 ± 0.013 | −79.45% | −4.244 ** |

| No WIM | WIM | % Difference | t-Value | |

|---|---|---|---|---|

| Oxygen uptake (VO2/Kg) | 9.28 ± 1.22 § | 8.55 ± 1.55 | −7.93% | 5.447 *** |

| Heart rate (bpm) | 88.93 ± 12.05 | 86.78 ± 14.74 | −2.42% | 1.647 |

| EEM (kcal/min) | 3.47 ± 0.40 | 3.21 ± 0.48 | −7.39% | 5.102 *** |

| Total EE (kcal) | 10.41 ± 1.22 | 9.66 ± 1.43 | −7.26% | 5.636 *** |

| Net EEM | 2.42 ± 0.33 | 2.16 ± 0.42 | −10.59% | 5.102 *** |

| No WIM | WIM | % Difference | t-Value | ||

|---|---|---|---|---|---|

| RF | Muscle activity (%MVC) | 19.90 ± 11.63 § | 16.56 ± 9.87 | −16.78% | 3.404 ** |

| Muscle fatigue (Hz) | 0.005 ± 0.050 | −0.040 ± 0.057 | −873.08% | 1.923 | |

| ST | Muscle activity (%MVC) | 14.06 ± 7.99 | 12.47 ± 7.69 | −11.32% | 3.234 ** |

| Muscle fatigue (Hz) | −0.024 ± 0.074 | 0.026 ± 0.069 | −206.15% | −2.014 | |

| TA | Muscle activity (%MVC) | 15.73 ± 5.05 | 14.75 ± 4.90 | −6.23% | 1.382 |

| Muscle fatigue (Hz) | −0.113 ± 0.082 | −0.019 ± 0.024 | −83.51% | −2.754 * | |

| GCM | Muscle activity (%MVC) | 22.95 ± 9.00 | 19.85 ± 8.23 | −13.49% | 2.529 * |

| Muscle fatigue (Hz) | −0.105 ± 0.084 | −0.025 ± 0.119 | −76.08% | −2.197 |

| No WIM | WIM | % Difference | t-Value | |

|---|---|---|---|---|

| Performance time (sec) | 98.00 ± 16.21 § | 109.10 ± 19.43 | 11.33% | −1.941 |

| Oxygen uptake (VO2/Kg) | 15.73 ± 2.74 | 13.53 ± 1.86 | −13.99% | 3.116 * |

| Heart rate (bpm) | 114.62 ± 15.01 | 105.60 ± 12.98 | −7.87% | 3.329 ** |

| Energy expenditure per minute (kcal/min) | 5.94 ± 0.89 | 5.17 ± 0.89 | −12.91% | 3.369 ** |

| Total energy expenditure (kcal) | 9.59 ± 1.50 | 9.43 ± 2.09 | −1.59% | 0.320 |

| Net EEM | 4.89 ± 0.88 | 4.12 ± 0.87 | −15.65% | 3.369 ** |

| Type | Weight | Test Environment | Metabolic Reduction | |

|---|---|---|---|---|

| Kim et al. (2022) [9] | Soft | 2.31 kg | Level ground | 7.2% |

| Lee et al. (2017) [13] | Rigid | 2.8 kg | Level ground | 6.6% |

| Kim et al. (2018) [14] | Rigid | 2.8 kg | Up stairs | 10.16% |

| WIM in this study | Soft and rigid | 1.4 kg | Level ground | 7.4% |

| WIM in this study | Soft and rigid | 1.4 kg | Up stairs | 12.9% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, Y.; Kang, J.; Jeong, B.; Kim, G.; Lim, B.; Choi, B.; Lee, Y. Verification of Industrial Worker Walking Efficiency with Wearable Hip Exoskeleton. Appl. Sci. 2023, 13, 12609. https://doi.org/10.3390/app132312609

Chang Y, Kang J, Jeong B, Kim G, Lim B, Choi B, Lee Y. Verification of Industrial Worker Walking Efficiency with Wearable Hip Exoskeleton. Applied Sciences. 2023; 13(23):12609. https://doi.org/10.3390/app132312609

Chicago/Turabian StyleChang, Yunhee, Jungsun Kang, Bora Jeong, Gyoosuk Kim, Bokman Lim, Byungjune Choi, and Younbaek Lee. 2023. "Verification of Industrial Worker Walking Efficiency with Wearable Hip Exoskeleton" Applied Sciences 13, no. 23: 12609. https://doi.org/10.3390/app132312609