Printing Information Modeling (PIM) for Additive Manufacturing of Concrete Structures

Abstract

:1. Introduction

2. System and Process Analysis

- Common types of printing systems and software applications currently used for concrete printing;

- Work areas, actors, and tasks along the digital workflow of concrete printing;

- Information exchanged among the actors (e.g., inputs and outputs) and material–process interactions observed or relevant for each work area.

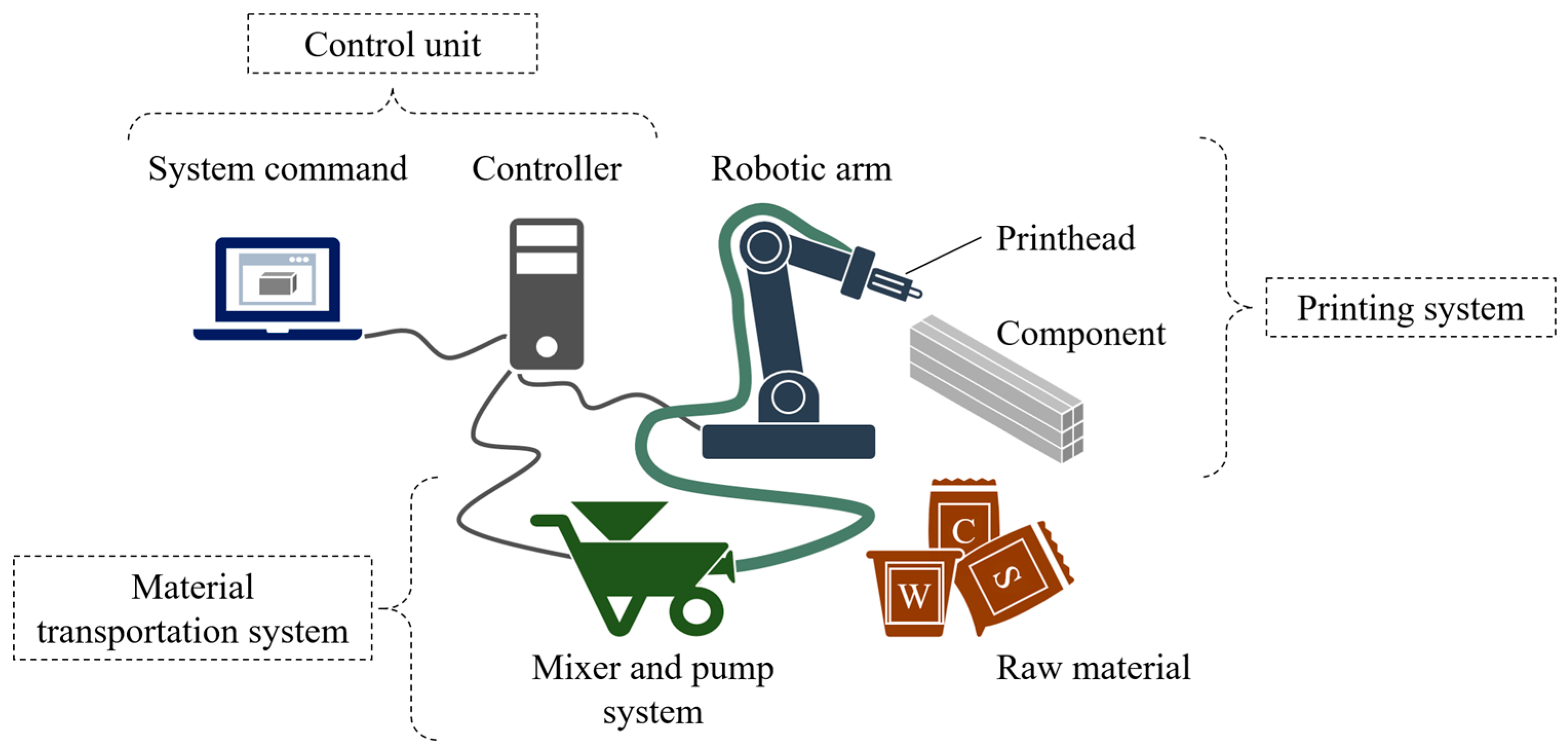

2.1. Concrete Printing System

- Control unit: In the control unit, the system command prepares the data necessary for printing, such as user-defined inputs and generating machine instructions. The system command communicates with the controller via human–machine interfaces. The controller handles the kinematics and electromechanical aspects of the robotic arm and printhead. The controller also processes the machine instructions that define toolpaths and process parameters, controls the multiple axes executing motions of the robotic arm and the printhead, and monitors the performance of the concrete printer using sensing technologies. Depending on the complexity of the printing system, the controller may also handle the material transportation system.

- Printing system: In the printing system, the robotic arm facilitates the deposition of concrete at desired locations with desired speeds under desired angles. The printhead, as the end effector of the robotic arm, is an element used to extrude concrete, and it consists of an extruding mechanism and a nozzle. The extruding mechanism is a series of parts of the printhead that pushes the concrete through the nozzle. The nozzle, the end part of the printhead, is a hollow element that gives shape to the concrete layer as it is deposited in place to build up a component.

- Material transportation system: In the material transportation system, the mixer mixes the raw materials to obtain concrete, and the pump transports the concrete from the mixing unit to the printhead, avoiding segregation and bleeding.

2.2. Concrete Printing Process

2.3. Information Exchange Requirements

3. Printing Information Model for Additive Manufacturing of Concrete Structures

3.1. Conceptual Modeling of the Printing Information Model

3.2. Formal Modeling of the Printing Information

| Listing 1. Description logic rules for the AMComponent class. |

3.3. Verification of the Printing Information

3.3.1. Model Checking

3.3.2. Competency Questions

| Listing 2. Example SPARQL query Q1 for competency question CQ1. |

| SELECT ?componentType WHERE { ?componentType rdfs:subClassOf pimo:AMComponent } |

| Listing 3. Example SPARQL query Q2 for competency question CQ2. |

| SELECT ?componentType WHERE { ?wall rdf:type pimo:AMWallComponent. ?wall pimo:hasMaterial ?material . ?material rdf:type pimo:Concrete . ?material pimo:hasRole ?role . ?role rdf:type pimo:Main_Material . } |

| Listing 4. Example SPARQL query Q3 for competency question CQ3. |

| SELECT ?process WHERE { ?wall pimo:isOutput ?process . ?process rdf:type pimo:AMProcess . ?wall rdf:type pimo:AMComponentWall } |

| Listing 5. Example SPARQL query Q4 for competency question CQ4. |

| SELECT ?wall WHERE { ?wall pimo:hasProperty ?property . ?wall rdf:type pimo:AMWallComponent . ?property rdf:type pimo:Density . ?property pimo:hasValue ?denistyValue . FILTER (?denistyValue >= 2050 && ?denistyValue <= 2080) } |

| Listing 6. Example SPARQL query Q5 for competency question CQ5. |

| SELECT ?freshStateProperty ?materialTestData WHERE { ?freshStateProperty pimo:isIdentifiedBy ?materialTestData } |

3.4. Validation of the Printing Information Model

4. Discussion of the Results

5. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

| Class Name | Axioms |

|---|---|

| AMComponent | |

| AMProcess | |

| AMTask | |

| AMMachine | |

| ToolpathData | |

| Material | |

| MaterialProperty | |

| Geometry | ) |

| FeatureParameter |

Appendix C

| Rules | |

|---|---|

| R1 | |

| R2 | |

| R3 | |

| R4 | |

References

- ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. International Organization for Standardization: Geneva, Switzerland, 2021.

- Labonnote, N.; Rønnquist, A.; Manum, B.; Rüther, P. Additive construction: State-of-the-art, challenges and opportunities. Autom. Constr. 2016, 72, 347–366. [Google Scholar] [CrossRef]

- Buswell, R.A.; Leal de Silva, W.R.; Bos, F.P.; Schipper, H.R.; Lowke, D.; Hack, N.; Kloft, H.; Mechtcherine, V.; Wangler, T.; Roussel, N. A process classification framework for defining and describing digital fabrication with concrete. Cem. Concr. Res. 2020, 134, 106068. [Google Scholar] [CrossRef]

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Yuan, X.; Zahiri, B.; Zhang, J.; Xia, B. Construction by Contour Crafting using sulfur concrete with planetary applications. Rapid Prototyp. J. 2016, 22, 848–856. [Google Scholar] [CrossRef]

- Dini, E. D-Shape. 2017. Available online: https://d-shape.com/ (accessed on 15 October 2019).

- Lachmayer, L.; Recker, T.; Raatz, A. Contour tracking control for mobile robots applicable to large-scale assembly and additive manufacturing in construction. In Proceedings of the 9th CIRP Conference on Assembly Technology and Systems, Leuven, Belgium, 6 April 2022. [Google Scholar]

- Dielemans, G.; Dörfler, K. Mobile Additive Manufacturing: A robotic system for cooperative on-site construction. In Proceedings of the IROS 2021 Workshop Robotic Fabrication: Sensing in Additive Construction, Prague, Czech Republic, 27 September 2021. [Google Scholar]

- Kruger, J.; Cho, S.; Zeranka, S.; Viljoen, C.; van Zijl, G. 3D concrete printer parameter optimization for high rate digital construction avoiding plastic collapse. Compos. Part B Eng. 2020, 183, 107660. [Google Scholar] [CrossRef]

- Markin, V.; Krause, M.; Otto, J.; Schröfl, C.; Mechtcherine, V. 3D-printing with foam concrete: From material design and testing to application and sustainability. J. Build. Eng. 2021, 43, 102870. [Google Scholar] [CrossRef]

- Roussel, N.; Buswell, R.; Ducoulombier, N.; Ivanova, I.; Kolawole, J.T.; Lowke, D.; Mechtcherine, V.; Mesnil, R.; Perrot, A.; Pott, U.; et al. Assessing the fresh properties of printable cement-based materials: High potential tests for quality control. Cem. Concr. Res. 2022, 158, 106836. [Google Scholar]

- Martens, P.; Mathot, M.; Bos, F.; Coenders, J. Optimising 3D printed concrete structures using topology optimisation. In Proceedings of the 2017 Fib Symposium—High Tech Concrete: Where Technology and Engineering Meet, Maastricht, The Netherlands, 12 June 2017. [Google Scholar]

- Perrot, A.; Pierre, A.; Nerella, V.N.; Wolfs, R.J.M.; Keita, E.; Nair, S.A.O.; Neithalath, N.; Roussel, N.; Mechtcherine, V. From analytical methods to numerical simulations: A process engineering toolbox for 3D concrete printing. Cem. Concr. Compos. 2021, 122, 104164. [Google Scholar] [CrossRef]

- Asprone, D.; Menna, C.; Bos, F.P.; Salet, T.A.; Mata-Falcón, J.; Kaufmann, W. Rethinking reinforcement for digital fabrication with concrete. Cem. Concr. Res. 2018, 112, 111–121. [Google Scholar] [CrossRef]

- Buswell, R.A.; Leal de Silva, W.R.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Bos, F.P.; Perrot, A.; Leal da Silva, W.R.; Nerella, V.N.; Fataei, S.; Wolfs, R.J.M.; Sonebi, M.; Roussel, N. Extrusion-based additive manufacturing with cement-based materials–Production steps, processes, and their underlying physics: A review. Cem. Concr. Res. 2020, 132, 106037. [Google Scholar] [CrossRef]

- ISO/ASTM 52950:2021; Additive Manufacturing—General Principles—Overview of Data Processing. International Organization for Standardization: Geneva, Switzerland, 2021.

- Bonnard, R.; Hascoët, J.-Y.; Mognol, P.; Stroud, I. STEP-NC digital thread for additive manufacturing: Data model, implementation and validation. Int. J. Comput. Integr. Manuf. 2018, 31, 1141–1160. [Google Scholar] [CrossRef]

- Kim, S.; Rosen, D.W.; Witherell, P.; Ko, H. A design for additive manufacturing ontology to support manufacturability analysis. In Proceedings of the ASME 2018 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Quebec City, QC, Canada, 26 August 2018. [Google Scholar]

- Sanfilippo, E.M.; Belkadi, F.; Bernard, A. Ontology-based knowledge representation for additive manufacturing. Comput. Ind. 2019, 109, 182–194. [Google Scholar] [CrossRef]

- Lu, Y.; Choi, S.; Witherell, P. Towards an integrated data schema design for additive manufacturing: Conceptual modeling. In Proceedings of the ASME 2015 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2 August 2015. [Google Scholar]

- Kim, D.B.; Witherell, P.; Lu, Y.; Feng, S. Toward a digital thread and data package for metals additive manufacturing. Smart Sustain. Manuf. Syst. 2017, 1, 75–99. [Google Scholar] [CrossRef]

- Slepicka, M.; Vilgertshofer, S.; Borrmann, A. Fabrication information modeling: Interfacing building information modeling with digital fabrication. Constr. Robot. 2022, 6, 87–99. [Google Scholar] [CrossRef]

- Li, C.; Zahedi, A.; Petzold, F. Pragmatic design decision support for additive construction using formal knowledge and its prospects for synergy with a feedback mechanism. Buildings 2022, 12, 2072. [Google Scholar] [CrossRef]

- Placzek, G.; Brohmann, L.; Mawas, K.; Schwerdtner, P.; Hack, N.; Maboudi, M.; Gerke, M. A lean-based production approach for shotcrete 3D printed concrete components. In Proceedings of the 38th International Symposium on Automation and Robotics in Construction, Dubai, United Arab Emirates, 2 November 2021. [Google Scholar]

- Salet, T.A.; Bos, F.P.; Wolfs, R.J.; Ahmed, Z.Y. 3D concrete printing—A structural engineering perspective. In Proceedings of the 2017 fib Symposium—High Tech Concrete: Where Technology and Engineering Meet, Maastricht, The Netherlands, 12 June 2017. [Google Scholar]

- Smarsly, K.; Peralta, P.; Luckey, D.; Heine, S.; Ludwig, H.-M. BIM-based concrete printing. In Proceedings of the International ICCCBE and CIB W78 Joint Conference on Computing in Civil and Building Engineering 2020, Sao Paolo, Brazil, 18 August 2020. [Google Scholar]

- Peralta, P.; Smarsly, K. Requirements analysis of additive manufacturing for concrete printing—A systematic review. In Proceedings of the 39th International Symposium on Automation and Robotics in Construction, Bogota, Colombia, 13 July 2022. [Google Scholar]

- buildingSmart. Information Delivery Manual: Guide to Components and Development Methods. Available online: https://technical.buildingsmart.org/standards/information-delivery-manual/ (accessed on 9 August 2021).

- DIN SPEC 17071:2019-12; Additive Manufacturing-Requirements for Quality-Assured Processes at Additive Manufacturing Centers. Beuth Verlag GmbH: Berlin, Germany, 2019.

- Object Management Group. Business Process Model and Notation–Version 2.0. Available online: www.bpmn.org (accessed on 9 August 2021).

- Duro-Royo, J.; Oxman, N. Towards Fabrication Information Modeling (FIM): Four case models to derive designs informed by multi-scale trans-disciplinary data. MRS Online Proc. Libr. (OPL) 2015, 1800, mrss15-2138549. [Google Scholar] [CrossRef]

- Peralta, P.; Heine, S.; Ludwig, H.-M.; Smarsly, K. A BIM-based approach towards additive manufacturing of concrete structures. In Proceedings of the 27th International Workshop on Intelligent Computing in Engineering, Berlin, Germany, 1 July 2020. [Google Scholar]

- Peralta, P.; Smarsly, K. An algorithmic BIM approach to advance concrete printing. In Proceedings of the 28th International Workshop on Intelligent Computing in Engineering, Berlin, Germany, 30 June 2021. [Google Scholar]

- Theiler, M.; Legatiuk, D.; Ibanez, S.; Smarsly, K. Metaization concepts for monitoring-related information. Adv. Eng. Inform. 2020, 46, 1011158. [Google Scholar] [CrossRef]

- Object Management Group. Unified Modeling Language Version 2.5.1. Available online: https://www.omg.org/spec/UML/ (accessed on 15 October 2021).

- The World Wide Web Consortium. SPARQL 1.1 Overview. Available online: http://www.w3.org/TR/sparql11-overview/ (accessed on 15 January 2023).

- Mejhed Mkhinini, M.; Labbani-Narsis, O.; Nicolle, C. Combining UML and ontology: An exploratory survey. Comput. Sci. Rev. 2020, 35, 100223. [Google Scholar] [CrossRef]

- ISO/IEC 21838-2:2021; Information Technology–Top-Level Ontologies (TLO)–Part 2: Basic Formal Ontology (BFO). ISO: Geneva, Switzerland, 2021.

- BuildingSmart. IfcOWL Ontology. Available online: https://standards.buildingsmart.org/IFC/DEV/IFC4/ADD2_TC1/OWL/index.html (accessed on 15 January 2023).

- Tchouanguem, F.T.; Karray, M.H.; Foguem, B.K.; Magniont, C.; Abanda, F.H.; Smith, B. BFO-based ontology enhancement to promote interoperability in BIM. Appl. Ontol. 2021, 16, 453–479. [Google Scholar] [CrossRef]

- Sirin, E.; Parsia, B.; Grau, B.C.; Kalyanpur, A.; Katz, Y. Pellet: A practical OWL-DL reasoner. J. Web Semant. 2007, 5, 51–53. [Google Scholar] [CrossRef]

- Bezerra, C.; Freitas, F.; Santana, F. Evaluating ontologies with competency questions. In Proceedings of the 2013 IEEE/WIC/ACM International Joint Conferences on Web Intelligence and Intelligent Agent Technologies, Atlanta, GA, USA, 17 November 2013. [Google Scholar]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Early age mechanical behavior of 3D printed concrete: Numerical modelling and experimental testing. Cem. Concr. Res. 2018, 106, 103–116. [Google Scholar] [CrossRef]

| Information Unit | Attributes | Rqd. | Opt. |

|---|---|---|---|

| Process data | The process data will have been specified prior to developing the additive manufacturing model. The process data include printing strategy (e.g., layer-by-layer strategy, infill pattern, and nozzle height), boundary conditions (e.g., process constraints and machine constraints), and machine parameters (e.g., printing speed, acceleration, and pump pressure). | X | |

| Sliced model | The sliced model will have been generated prior to developing the additive manufacturing model. The sliced model includes slicing parameters (i.e., scale factor, layer height, extrusion width, and build orientation) and support structure parameters (i.e., support pattern and support spacing). | X | |

| Material specifications | The material specifications will have been defined prior to developing the additive manufacturing model. The material specifications include design parameters for the main material (e.g., concrete type, design strength, design moduli, maximum aggregate size, slump, and open time), support material (e.g., material type and design strength), and reinforcement material (e.g., material type and design strength). | X | |

| Project properties | General properties of the additive manufacturing project: | ||

| • Project name; | X | ||

| • Engineer. | X | ||

| Toolpath | Path for the printhead to follow: | ||

| • Path (printing and axes); | X | ||

| • Process parameter profile; | X | ||

| • Material parameter profile. | X | ||

| Results of material models | Results of numerical modeling of the material behavior according to the material specifications. | X | |

| Results of manufacturing process simulations | Results of the simulation of the additive manufacturing process according to the process data, the sliced model, and the material behavior. | X | |

| Feedback | Feedback from the printing process (Post-process). | X |

| Test | Description | Result |

|---|---|---|

| Ontology consistency checking | The PIM-O has no inconsistencies, answering the question “is there at least one model of the PIM-O?” | ✓ |

| Concept satisfiability checking | ?” | ✓ |

| Concept subsumption checking | with respect to PIM-O. | ✓ |

| Competency Question | Answer | Result |

|---|---|---|

| CQ1: What kind of components can be 3D-printed? | AMWallComponent AMBeamComponent AMColumnComponent AMSupportComponent AMReinfComponent | ✓ |

| CQ2: Identify walls that are designed using concrete as main material | Instance: wall_1OG | ✓ |

| CQ3: Identify AM processes that have walls as output | Instance: cp_Process1 | ✓ |

| CQ4: Retrieve walls that have a bulk density between 2050 and 2080 kg/m3 | Instance: wall_1OG | ✓ |

| CQ5: Which fresh state material property are identified by material test data? | Instance: property_GreenStrength | ✓ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peralta Abadia, P.; Ahmad, M.E.; Smarsly, K. Printing Information Modeling (PIM) for Additive Manufacturing of Concrete Structures. Appl. Sci. 2023, 13, 12664. https://doi.org/10.3390/app132312664

Peralta Abadia P, Ahmad ME, Smarsly K. Printing Information Modeling (PIM) for Additive Manufacturing of Concrete Structures. Applied Sciences. 2023; 13(23):12664. https://doi.org/10.3390/app132312664

Chicago/Turabian StylePeralta Abadia, Patricia, Muhammad E. Ahmad, and Kay Smarsly. 2023. "Printing Information Modeling (PIM) for Additive Manufacturing of Concrete Structures" Applied Sciences 13, no. 23: 12664. https://doi.org/10.3390/app132312664

APA StylePeralta Abadia, P., Ahmad, M. E., & Smarsly, K. (2023). Printing Information Modeling (PIM) for Additive Manufacturing of Concrete Structures. Applied Sciences, 13(23), 12664. https://doi.org/10.3390/app132312664