1. Introduction

With the continuous and accelerating development of social modernization, conventional modes of tunnel design and construction are often unable to meet requirements due to various factors. In particular, the design of tunnels must take into account the influence of many boundary conditions. The advent of bifurcated tunnels has alleviated many problems faced in tunnel design and has also helped in subsequent design and construction [

1,

2].

A bifurcated tunnel refers to the intersection of one tunnel with another, including the intersection of auxiliary tunnel inclined shafts, vertical shafts, or transverse tunnels with the main tunnel, as well as the intersection of hydropower tunnels and working tunnels. With the combination of a large span tunnel and a small clear distance tunnel, the bifurcated tunnel presents higher requirements for design and construction technology [

3,

4].

Scholars have conducted extensive and effective research on bifurcated tunnels. Lu et al. [

5] studied the maximum ceiling temperature and longitudinal temperature distribution of bifurcated tunnels with different bifurcated angles under longitudinal ventilation conditions. Chen et al. [

6] used numerical simulation methods to study the critical wind speed in fire scenarios where the fire source is located before and after the fork of the bifurcated tunnel. Wang et al. [

7] conducted numerical simulations of bifurcated tunnels to determine the ventilation distribution ratio. Zhang et al. [

8] analyzed the deformation characteristics and control measures of the surrounding rock in the large arch section of the bifurcated tunnel of the Miaoya tunnel on the Huurongxi Expressway by monitoring the surrounding rock deformation. Tan et al. [

9], for the Liantang tunnel with a maximum span of 30.1 m and a minimum spacing of 1.05 m, proposed the reverse expansion excavation method and the sectional controlled blasting excavation method. Peng et al. [

10] proposed a new nonlinear reinforcement analysis method for the design of reinforced concrete lining and anchor reinforcement systems for the fork of a long-span tailwater tunnel with complex three-dimensional geometry. Cao et al. [

11] studied the stability criterion of the surrounding rock in a multiarch section with a small clear distance using theoretical analysis and calculated the internal stress and corresponding ultimate strength of the middle rock pillar under different burial depths and widths according to the stability criterion. Li et al. [

12], relying on the Xiamen Haicang Evacuate Channel project, monitored and analyzed the blasting vibration velocity and surrounding rock acoustic velocity of the middle rock pillar by employing blasting vibration measurement and acoustic testing on-site, optimized the original blasting scheme, and explored the vibration propagation and damage evolution law of the middle rock pillar under cyclic blasting. Qing et al. [

1] used numerical simulation methods to compare and analyze the deformation of the surrounding rock of small clear distance tunnels using the beach cut method, CD method, and double side heading method. Wang et al. [

13] conducted a 1:10 scale physical shaking table test model for a tunnel with a small clear distance and shallow deviation to study the type, direction, and peak acceleration of seismic waves that greatly influence the dynamic response characteristics of the tunnel.

As one of the three pillars of the new Austrian tunnel construction concept, monitoring and measurement play crucial roles in ensuring tunnel construction safety. Careful on-site monitoring and measurement enable construction teams to understand the response dynamics of the ground and tunnel and make necessary adjustments to design parameters and construction sequences based on feedback data to ensure safe and smooth construction. Monitoring technology and information management are directly related to the safety and quality of tunnel construction [

14]. Over the years, both theoretical systems and equipment technology have made significant progress. For instance, Wu et al. [

15] developed an automatic tunnel monitoring and early warning system based on geostationary technology satellites, enabling information management and the early warning and forecasting of tunnel monitoring and measurement data. Lin et al. [

16] conducted tunnel monitoring at the Qiyueshan tunnel site, analyzed the deformation characteristics and development trends of the tunnel surrounding rock by processing and evaluating the measurement data of tunnel section arch settlement and surrounding displacement, and revised and optimized tunnel design and construction accordingly. Wei et al. [

17] described the construction process of the tunnel opening excavation monitoring and measurement system in a mountainous area based on the actual situation of the tunnel opening excavation monitoring and measurement in a mountainous area of Chongqing. The portal stability analysis method and monitoring information feedback process based on multisource data were analyzed. Xiong et al. [

18] analyzed the deformation and mechanical characteristics of the surrounding rock and initial support of the plateau wetland tunnel in the construction process of the Bodhisattva Hill wetland tunnel and introduced monitoring and measurement projects and methods in the construction process of the new Austrian method. Furthermore, Xiong et al. [

19] presented a tunnel monitoring method based on distributed fiber sensing, which provides hundreds of strain and temperature sensing points within the structure, offering new information about the tunnel lining behavior. Chen et al. [

20] evaluated the applicability of two noncontact measurement methods for monitoring a series of small model tunnels, while Shi et al. [

21] introduced BOTDR, a newly developed strain measurement and monitoring technology, and analyzed its feasibility in TST strain monitoring through the BOTDR monitoring results of a tunnel in Nanjing. Luo et al. [

22] conducted a comparative test of three-dimensional coordinate measurement, RDM, and traditional measurement at the tunnel construction site, while Sakai et al. [

23] proposed a prediction method based on monitoring the roadway crown dip angle along the roadway axis and applied it in field tests. Additionally, Du et al. [

24] developed and proposed the CNU-TS-1 mobile tunnel monitoring system based on an in-depth study of tunnel monitoring methods. This method can effectively obtain the cross-section of the tunnel and eliminate the control measurement that depends on design data.

Zhang et al. [

25] conducted finite element calculation and analysis on the stability of surrounding rock at the overpass of the upper and lower reaches of the Fengze Street tunnel and emphasized the importance of mastering the mechanical dynamics of surrounding rock and support, timely feedback adjustment of construction methods and supporting parameters, and on-site monitoring projects. Wu et al. [

26] introduced the field measurement results of deformation at the fork of the Y-shaped fork of the mainline tunnel and branch tunnel of Guangzhou Rail transit line 3 during construction. Bai et al. [

27] provided a detailed description of the on-site monitoring and measurement method of deformation in the bifurcation section of the Shanghai Metro Line 2 tunnel and Metro Line 1 tunnel during the construction process of shield tunneling. Finally, Yang et al. [

28] carried out on-site monitoring and measurement during the construction of the Nanjing Xuanwuhu tunnel and subway bifurcation section.

In recent years, research on the monitoring and measurement of bifurcated tunnels has mainly focused on subway and shallow buried bifurcated tunnel engineering. However, for large section bifurcated tunnel engineering, the requirement of monitoring and measurement technology is high, which is mainly reflected in how to use the geological and deformation data to predict the stability of the new tunnel and its control standard in advance. However, at present, monitoring and measurement research on complex bifurcated tunnels still lacks systematic research results, so it is necessary to carry out in-depth research on the monitoring and control of bifurcated tunnel construction with small clear distances. Taking the large section bifurcated small clear distance tunnel of the Xiamen Haicang Evacuate Channel project as the background, the tunnel monitoring and the layout scheme of monitoring points were introduced. The monitoring data were analyzed, and the excavation and support measures were optimized. An automatic monitoring and control method of the middle rock pillar was also developed. The results can be referred to by the construction of a large section bifurcated small clear distance tunnel.

2. Engineering Background

The Xiamen Haicang Evacuate Channel project is located in Haicang District, Xiamen City, as shown in

Figure 1a. A Lushu interchange is set up in the Xiamen Haicang Evacuate Channel project, and a total of four ramps are laid at the interchange, which is a semi-interworking form. The research section is the bifurcated small clear distance section between the Lushu left mainline tunnel and the ramp, as shown in

Figure 1b,c. The maximum span of the Lushu main line tunnel is 16.17 m, the height is 11.32 m, and the maximum excavation area of the section is 361.43 m

2. The maximum span of ramp A is 12.62 m, the height is 10.40 m, and the limit span is 11.10 m. The maximum excavation area of the section is 370.76 m

2. In the research section, the maximum clear distance of the bifurcated small clear distance section and the maximum excavation width reach 28.0 m and 30.52 m, respectively. The clear distance of the ultrasmall clear distance section of the bifurcated tunnel is 1.2 to 8.0 m, as shown in

Figure 1d. The pile numbers of the research section are ZK4 + 090~ZK4 + 490, among which ZK4 + 090~ZK4 + 150 are large sections and ZK4 + 150~ZK4 + 490 are small clear distance sections.

The Xiamen Haicang Evacuate Channel tunnel runs through a granite stratum and is covered with Quaternary residual and slope deposits. The tunnel site is located in the Damaoshan-Shifengyan fault zone and is characterized by developed tectonics and extensive jointing and cracking of the rock mass due to multiphase tectonic stress. The groundwater at the site is also relatively abundant, mainly stored in the alluvium and some structural water storage zones. It is shallowly buried, with depths generally ranging between 1.0 and 5.0 m, and is affected by seasonal precipitation. The research section of the tunnel passes through the second intrusion granite strata of late Yanshan, which is mainly medium weathered. The surrounding rock grading is III, which belongs to relatively intact rock. Surface water is abundant in the research section, but it has little influence on the tunnel construction activities. Groundwater is developed in the fault tectonic zone. To excavate the tunnel, the design scheme adopts the step method, short step method, CD method, and double side heading method, following the construction principle of the new Austrian method. The composite lining includes primary support using the first bolt–shotcrete steel net and the second bolt–shotcrete steel net, temporary support using an I-steel frame, and secondary lining using a concrete layer of the arch wall and the invert. The retaining structures’ parameters are shown in

Table 1. The tunnel in the research section has a large section and super small clear distance, complicated construction sequence, asynchronous excavation and support, and construction blasting disturbance, which require high-quality monitoring. Traditional monitoring methods cannot satisfy the requirements and cannot be used in real time. Therefore, there is a need to develop methods that can be monitored automatically and in real time.

4. Monitoring Analysis of Large Section Bifurcated Small Clear Distance Tunnel

The tunnel inclined shaft was constructed to shorten the construction period and increase the working face. The mileage number of the inclined well in the research section was ZK4 + 180. The section with mileage ZK4 + 180 was defined as the dividing line. It was specified that ZK4 + 090 to ZK4 + 180 was defined as the direction of small mileage, and ZK4 + 180 to ZK4 + 490 was defined as the direction of large mileage. In mileage ZK4 + 090~ZK4 + 490, a cross-section was selected every 30 m for monitoring. The vault settlement and peripheral convergence were analyzed using the monitoring data of one week in the research section, and the geological and supporting state observation and advanced geological prediction were analyzed.

4.1. Vault Settlement

Figure 5 illustrates the variation in vault settlement for each monitoring section during the monitoring period in the research section. The primary coordinate axis shows the cumulative value of vault settlement, the cumulative value of vault settlement since excavation, the rate of vault settlement, and the control value of the vault settlement rate. The secondary coordinate axis represents the cumulative control value of vault settlement. While the cumulative vault settlement and the cumulative vault settlement rate did not exceed the control value,

Table 3 indicates that monitoring should be strengthened when it exceeds one third of the control value. Therefore, it is necessary to enhance the monitoring of existing supporting sections within the range of ZK4 + 120~ZK4 + 400. The ZK4 + 150 and ZK4 + 120 sections, in the direction of small mileage, exceeded two thirds of the control value, so increasing the monitoring frequency and strengthening support means is essential to meet the requirements of information construction.

Based on the variation trend of vault settlement, the ZK4 + 090 section closest to the working face was excavated within a week, so its vault settlement was consistent with the cumulative settlement. However, ZK4 + 120 and ZK4 + 150, which were farther away from the working face, did not settle within this week. In the large mileage, the section closer to the excavation face was in the stage of continuous displacement development. The displacement velocity of the vault at both ends of the mileage was greater than 0.1 mm/d, and the surrounding rock deformation had not been stable, while the convergence velocity of the arch in the middle section was close to 0, and the surrounding rock deformation had been basically stable.

4.2. Peripheral Convergence

Figure 6 depicts the peripheral convergence of the three measurement lines in each mileage. The primary axes include peripheral convergence, peripheral convergence rate, cumulative peripheral convergence, and peripheral convergence rate control value. The secondary axes represent the cumulative peripheral convergence control values. The overall trend along the direction of large and small mileage was consistent, but the values were slightly different. None of the peripheral convergence values exceeded the peripheral convergence control value. However, due to the early excavation and support of the section near the boundary line, the cumulative peripheral convergence value exceeded the control value by one third to two thirds in the continuous deformation. For these early support sections, frequent monitoring should be performed to identify the trend of peripheral convergence and predict the risk earlier.

For peripheral convergence, when the convergence rate was 0.1–0.2 mm/d, the rapid deformation could be considered to be completed and entered a stable stage, according to the monitoring scheme. For ZK4 + 090 with a large cross-section, its peripheral convergence rate was between 0.88 and 1.58 mm/d, and the convergence displacement continued to occur. It was necessary to strengthen the monitoring and observe whether there was a large number of cracks in the shotcrete layer. At the same time, when the convergence rate varied suddenly and the displacement was too large, timely completion measures should have been taken, including increasing the thickness of shotcrete, applying the invert in advance, and increasing the number of bolts to share the excessive surrounding rock pressure.

4.3. Geological and Support Status Observation

In addition to monitoring the vault settlement and surrounding convergence, geological and supporting states were observed after each excavation, and a geological sketch of the excavation working face was drawn, including the development of joints and fissures, the stable state of the working face, and water gushing conditions.

Table 4 illustrates the geological and supporting states of ZK4 + 090 with a large section.

4.4. Advanced Geology Prediction

The SIR-3000 geological penetrating radar was used to predict the geological conditions of the surrounding rock ahead of the working face. Advanced geological exploration was conducted in the 30 m range in front of the working face at ZK4 + 090–ZK4 + 060 of the large section to provide a better understanding of the rock mass condition before excavation.

Figure 7 shows the situation of the surrounding rock at the working face.

5. Automatic Monitoring and Control Method for Middle Rock Pillars

The field monitoring method used in the past relied mainly upon manual monitoring activities, which involved coordinating the placement of measuring points and lines and conducting measurements at fixed intervals. However, this traditional method posed challenges in monitoring deformations in the middle rock pillar due to human error and the scattering of data. As a result, it was difficult to obtain an accurate and real-time reflection of the overall deformation of the structure. To address this issue, an automatic monitoring and control method was proposed to comprehensively and dimensionally reflect the application of real-time monitoring in the construction process of small clear distance tunnels. This method can identify engineering anomalies, carry out dynamic visual monitoring of the entire risk process, and achieve the purpose of early warning.

The proposed monitoring method uses data acquisition hardware that includes microwave radar, spherical cameras, automatic laser rangefinders, computers, and processors. The automatic monitoring system, which is formed by arranging the microwave radar, spherical camera, and automatic laser rangefinder, has advantages such as high penetration, long detection distance, high precision, strong resolution, and stable operation. The system can remotely monitor and control the deformation of the rock mass in a small clear distance tunnel in real time. After analyzing and processing the monitoring data, the deformation of the rock mass was obtained, and the existing stability criterion of the rock mass was used to alert the deformation of the rock mass and control it in real time. The overall layout of the automatic monitoring scheme is shown in

Figure 8. The proposed method can automatically monitor the position variation in measuring points, calculate the displacement of the surrounding rock, and judge the stable status of the middle rock pillar. The stable state of the middle rock pillar was fed back in real time at the construction site through the alarm indicator light.

5.1. Work Preparation

To facilitate cross work between site monitoring and construction, the monitoring work should not occupy the ground space inside the tunnel. Therefore, the tunnel lining steel frame was used as the carrier of the monitoring equipment. The microwave radar, spherical camera, and automatic laser rangefinder were fixed in the position flush with the central axis of the middle rock pillar, which is the two tunnel arches. A pulley guide rail was arranged at the lower part of the steel frame so that the monitoring equipment could advance along with the excavation face and maintain a certain distance.

5.2. Association between Devices

The displacement monitoring device consists of three parts: microwave radar, spherical camera, and automatic laser rangefinder. These three parts need to be connected to form a monitoring system.

First, the radar set up a defense area and warning line, and the influence range of the microwave radar was classified. The main function area of the radar was within the range of the defense area and warning line, and it was also the key area of monitoring. The microwave radar was then associated with the spherical camera to visualize the radar’s defense area in the camera. To facilitate remote monitoring using the spherical camera, the camera was connected to the remote computer through a wireless network connection. After sensing the displacement change in the measuring point in the defense area, the radar displayed the view in the spherical camera. To quantify the change in the displacement value, the radar was associated with the laser rangefinder, and the displacement change perceived by the radar was transmitted to the laser rangefinder to utilize the data. The correlation between the above devices enabled the realization of a real-time visual comprehensive monitoring system. The section layout of the test equipment is shown in

Figure 9.

5.3. Monitoring Point Calibration and Monitoring Scheme

5.3.1. Monitoring Point

To monitor the displacement of the middle rock pillar, it was necessary to arrange monitoring points on the surface of the middle rock pillar. In the monitoring system, the radar calibration tool was used to calibrate the monitoring points in the associated spherical camera for the positions of two section vaults and four section waists in the small clear distance tunnel. After the calibration of the measuring point, the laser range finder sent a long laser time to fix the initial position of the monitoring point.

5.3.2. Monitoring Scheme

The monitoring scheme was set up from two dimensions of vertical displacement and horizontal displacement. The stability of the tunnel vault and arch is normally weak, and monitoring should be strengthened [

30]. Therefore, the vertical displacement can be automatically monitored and controlled by two marked vault monitoring points. The horizontal displacement was automatically monitored and controlled by four monitoring points in the arches of the two tunnels. In addition, a turning-over punctuation belt was laid on each monitoring point to facilitate positioning and tracking. The specific measurement point layout is shown in

Figure 10.

5.4. Automatic Monitoring Process

The automatic monitoring process was composed of monitoring point tracking and displacement numerical processing.

5.4.1. Monitoring Point Tracking

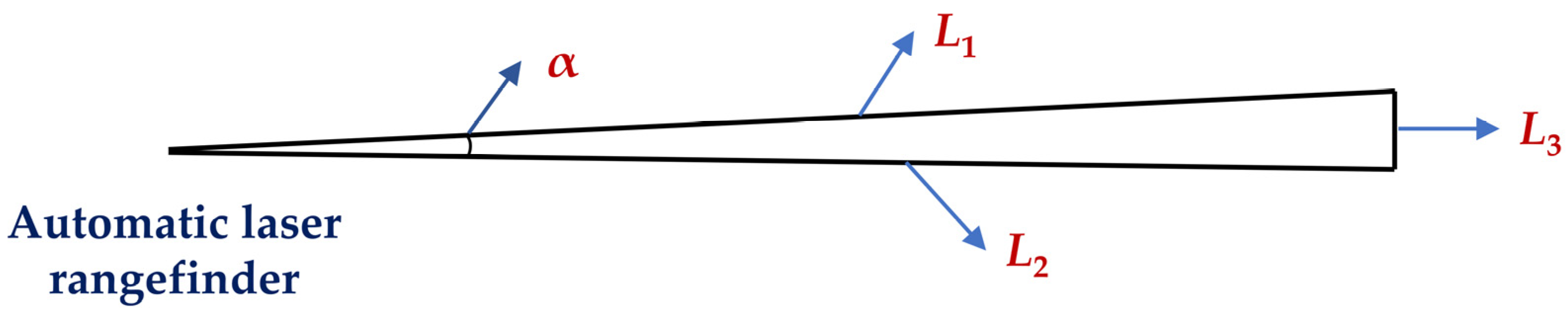

Through the association between the spherical camera and microwave radar, the monitoring points arranged on the section can be located, and the displacement generated during construction can be tracked by it and can be visualized in the images collected by the spherical camera. The laser rangefinder determines the initial position of the measuring point by sending a laser, and the radar transmits the sensed change in the position coordinates to the laser rangefinder. The laser rangefinder can track the laser rangefinder from the spherical camera and microwave radar to the tiny rotation angle α.

5.4.2. Displacement Numerical Processing

The initial positioning distance of the monitoring point by the laser rangefinder was

L1. The small rotation angle generated by tracking the displacement of the measuring point through the radar feedback input was

α. After moving, the laser rangefinder can obtain the distance

L2 from the new location of the measuring point. After the above parameters were obtained, they were remotely transmitted to the computer for data processing through the unlimited connection device set on site. The actual displacement of the monitoring point is calculated through the cosine theorem of the trigonometric function, as shown in Formula (1), where

L3 is the displacement of the monitoring point.

Figure 11 shows the above processing calculation.

The vertical displacement of the main tunnel vault V1, the ramp tunnel vault V2, the horizontal displacement of the main tunnel left arch waist H3, the horizontal displacement of the main tunnel right arch waist H4, the horizontal displacement of the ramp tunnel right arch waist H5, and the horizontal displacement of the ramp tunnel left arch waist H6 were calculated using Formula (1).

5.5. Determination of the Stability of the Middle Rock Pillar

The monitoring data of six monitoring points arranged on the vault and arches of the tunnel section were selected as independent variables. According to the calculation formula obtained in a previous study [

31], the displacement value of the upper and central regions of the middle rock pillar could be calculated. The calculated displacement was compared with the corresponding limit value to determine the stable state of the middle rock pillar.

In a previous study [

31], the relation between the horizontal displacement

H of the central region of the middle rock pillar and the convergence of the horizontal clearance

X2 of the ramp and horizontal clearance

X3 of the main line tunnel was Formula (2).

where

X2 is the difference between the horizontal displacement

H5 of the right arch waist of the ramp and the horizontal displacement

H6 of the left arch waist of the ramp.

X3 is the difference between the horizontal displacement

H4 of the right arch waist of the main tunnel and the

H3 of the right arch waist of the main tunnel.

According to a previous study [

31], the relationship between the vertical displacement of the upper region of the middle rock pillar

V and the ramp vault settlement

V2 and the arch settlement

V1 of the main tunnel is shown in Formula (3).

In a previous study [

31], the horizontal and vertical displacement criteria for the stability of the middle rock pillar were given, as shown in Formula (4).

When the horizontal displacement of the central region of the middle rock pillar H calculated by the convergence of the horizontal clearance of the ramp and the main line tunnel was ≤−1.21 mm, and the vertical displacement of the central region of the middle rock pillar V calculated by the settlement of the ramp and the arch of the main line tunnel was ≤−7.0 mm, the middle rock pillar was in a stable state.

The distance data measured by the laser rangefinder were entered into the computer remotely through the device interface to complete the calculation and the stability judgment of the middle rock pillar. If H and V were less than the limit values, it was considered that the middle rock pillar was stable. If either H or V was greater than the limit value, it was considered that the middle rock pillar may already be in an unstable state and needs to be strengthened by auxiliary measures.

5.6. Visual Monitoring

The spherical camera was remotely connected to the computer through wireless equipment, and the computer display screen could realize long-term monitoring of the surrounding rock state in the excavation and support of the tunnel face during the construction process. It can observe the development of dangerous cracks on the site and judge the possible falling of dangerous rocks in advance, so as to achieve the effect of real-time monitoring and visualization.

5.7. Alarm Feedback

The stability of the middle rock pillar must be monitored in real-time to avoid possible risks. It is necessary to display the monitored stable state of the middle rock pillar at the construction site through alarm indicator lights. After remote input, calculation and processing of the displacement data monitored on-site, the judgment conclusion was obtained. It is necessary to input the conclusion back to the site to increase the feedback of the stable state of the middle rock pillar. Alarm indicator lights were arranged on the working steel frame placed by the monitoring device, and the method in

Table 5 was used as the output indication information.

When V and H conformed to the above relationship, the corresponding COLOR information code color was fed back to the indicator remotely. When COLOR was −1, the field displacement value exceeded the limit value, and the red light was on and beeped. When COLOR was 0, the field displacement value was greater than the limit value of two thirds, and the alarm yellow light was always on. When COLOR was 1, the field displacement value was less than two thirds of the limit value and greater than one third of the limit value, and the alarm yellow light flashed. A COLOR of 2 indicated that the field displacement value was less than one third of the limit value, and the alarm green light was always on.

In general, the automatic monitoring and control method carried out three-dimensional dynamic deformation monitoring of dangerous parts such as the tunnel contour section and middle rock pillar during the construction process. The real-time monitoring data upload processor controlled the stability and fracture condition of the monitored parts through the criteria, and the dynamic observation of the change in the face over a long distance can also be realized through the camera. It can cope with the occurrence of unexpected adverse events to a certain extent, and its control process is shown in

Figure 12.