Effect of Air Inlet Spacing on Air Distribution and Ventilation Performance of Stratum Ventilation Using Multiple Parallel Jets

Abstract

:1. Introduction

2. Methodology

2.1. Experimental Method

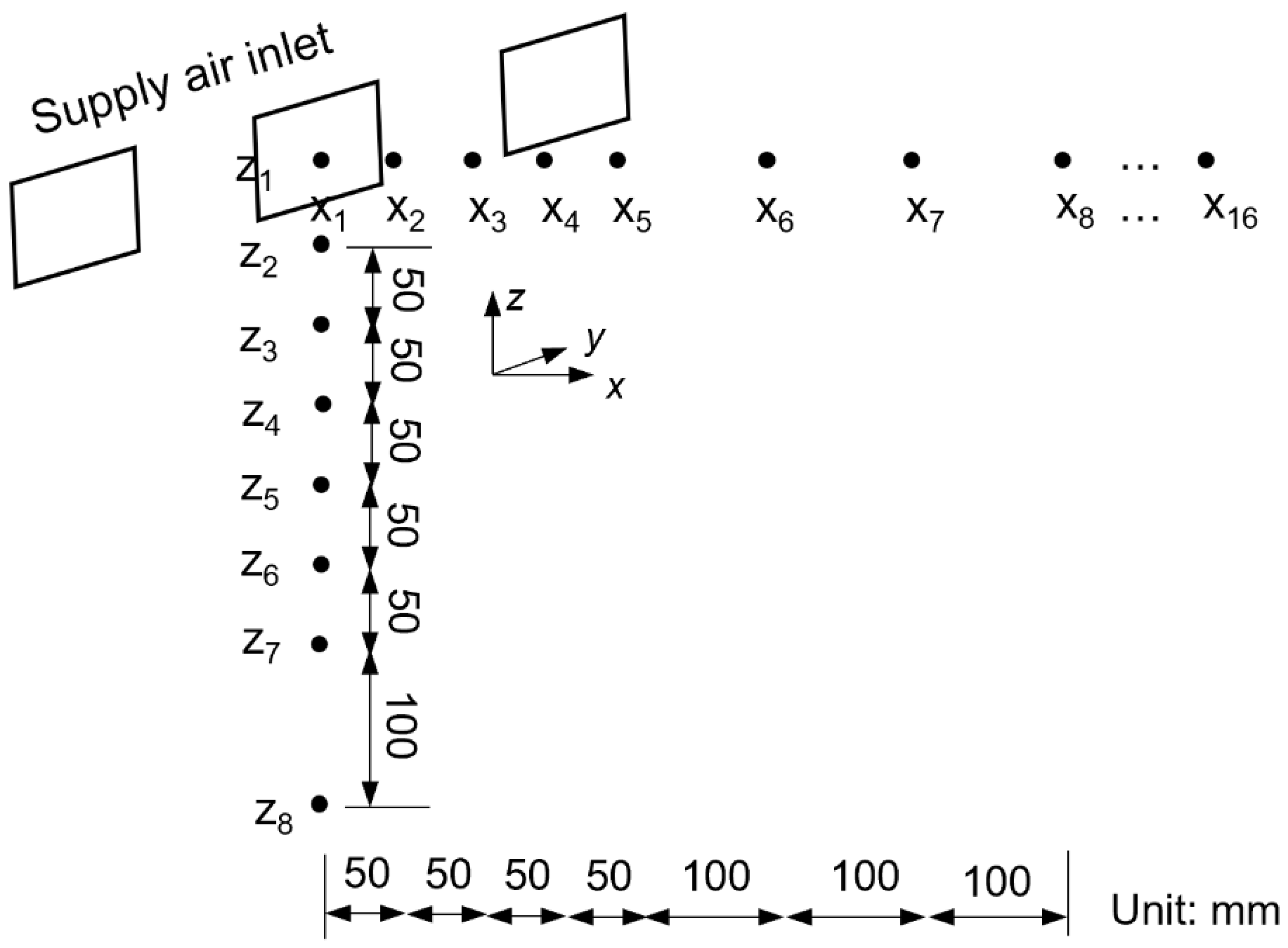

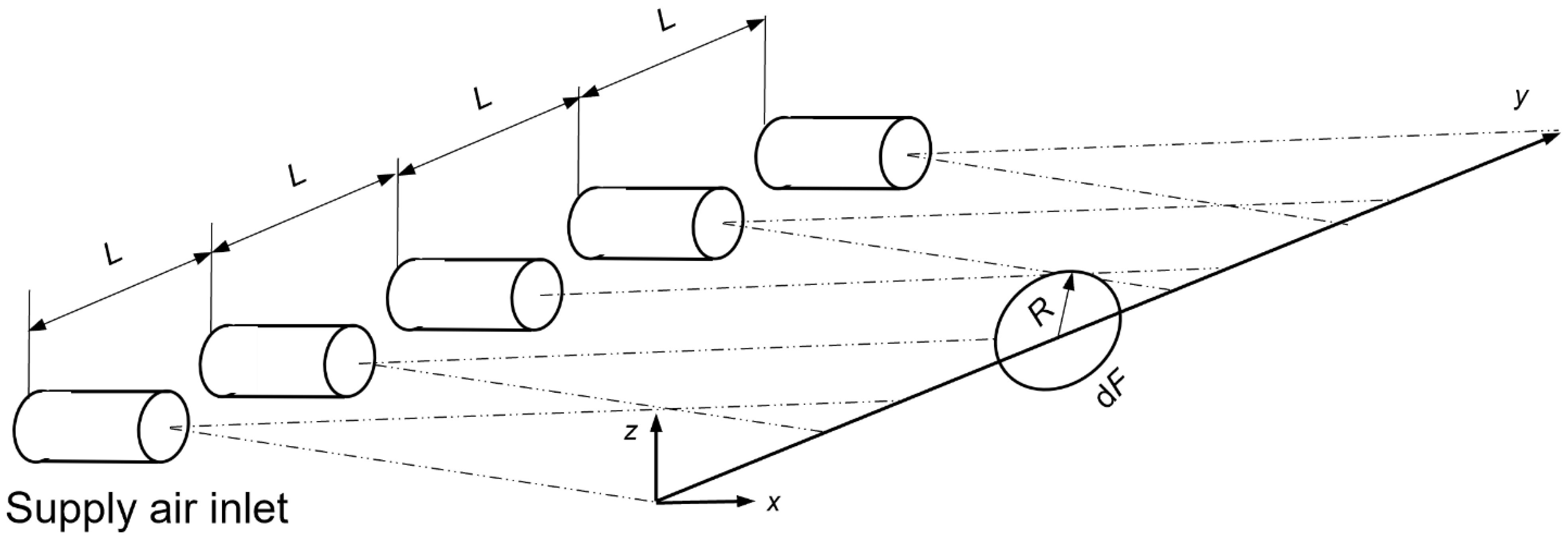

2.1.1. Experimental Platform

2.1.2. Experimental Cases

2.1.3. Experimental Measurements

2.2. Theory of Multiple Parallel Jets

2.3. Numerical Simulation

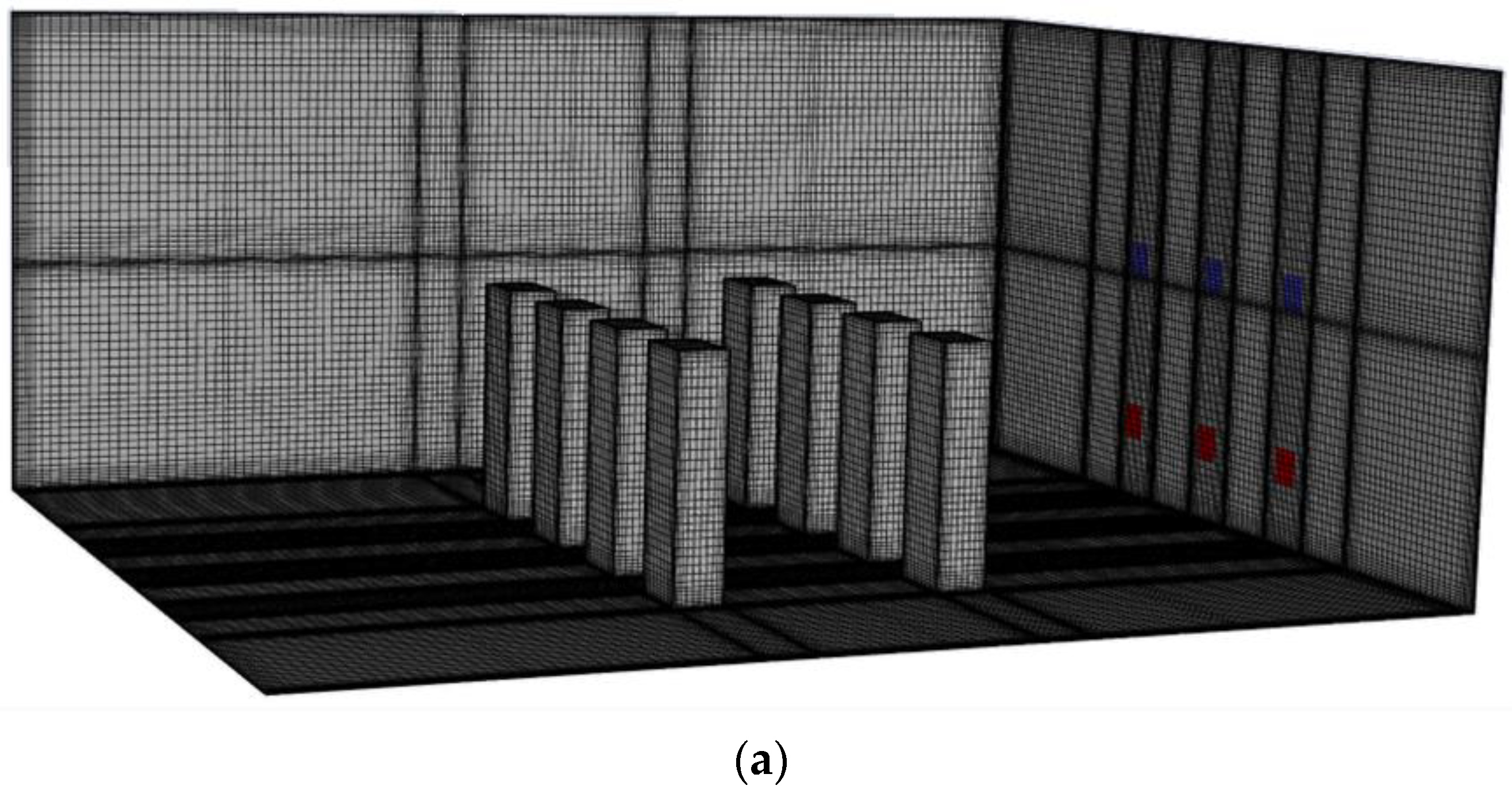

2.3.1. CFD Model

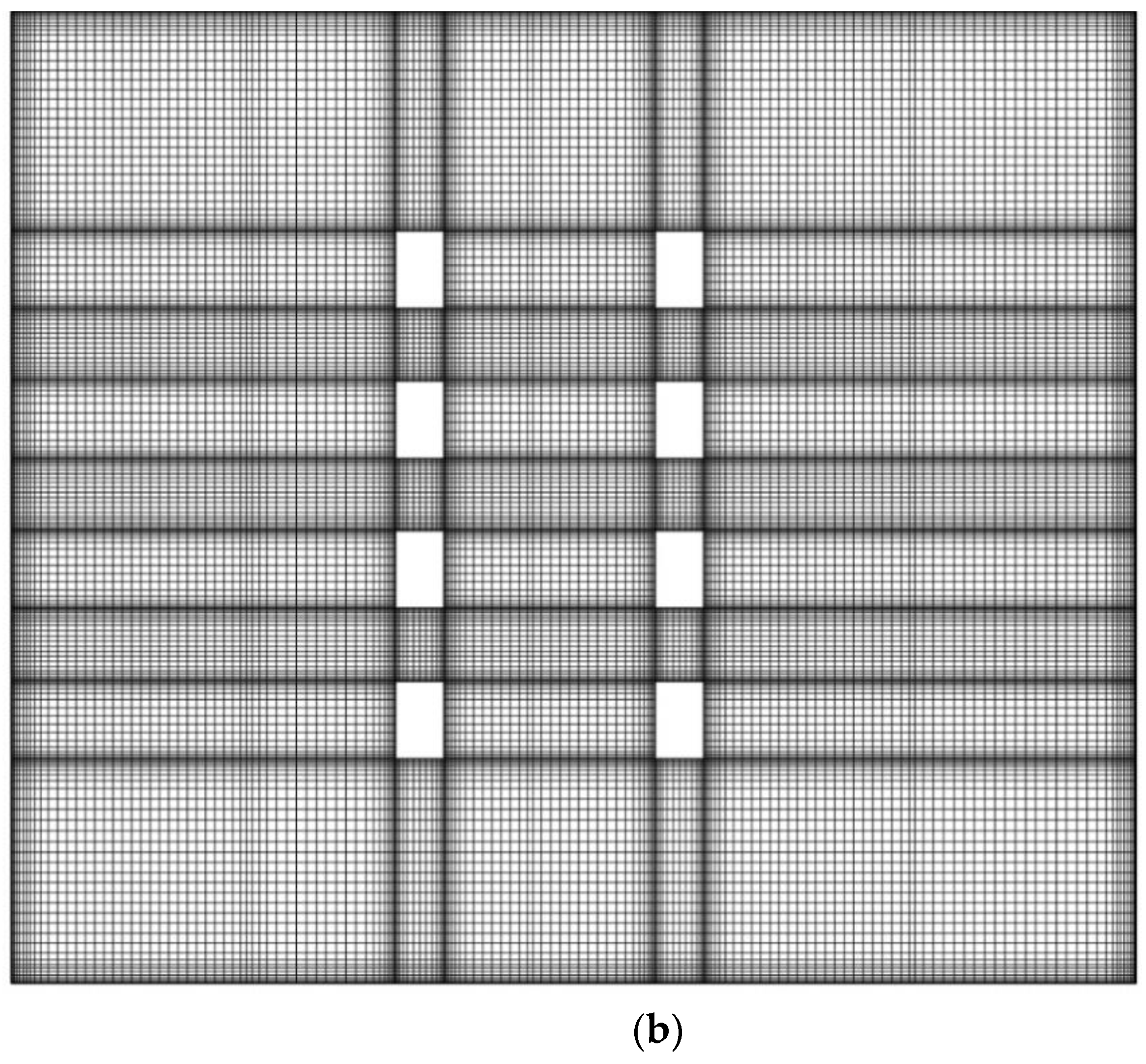

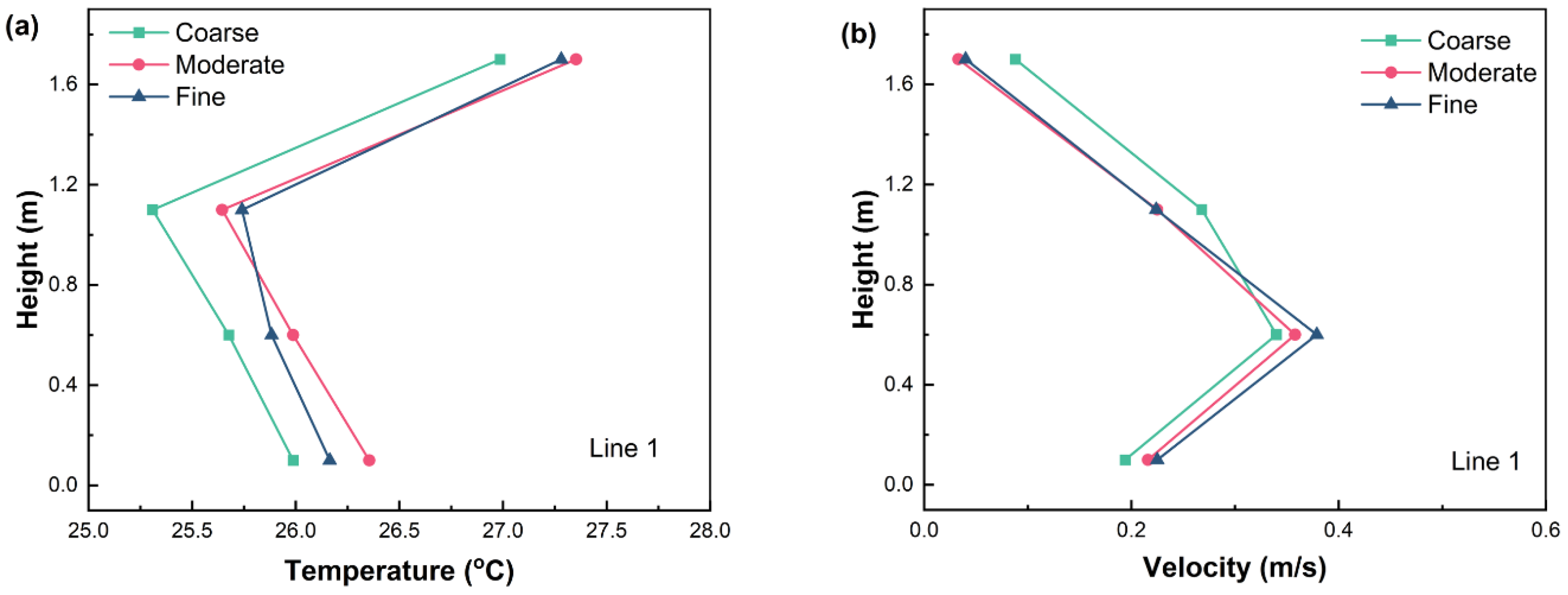

2.3.2. Grid Independence Tests

2.3.3. Studied Cases

2.3.4. Evaluation Indices

- Effective draft temperature for SV (EDTS);

- Air diffusion performance index (ADPI);

- Local mean age of air (LMAA);

- Energy utilization coefficient (EUC).

3. Results and Discussion

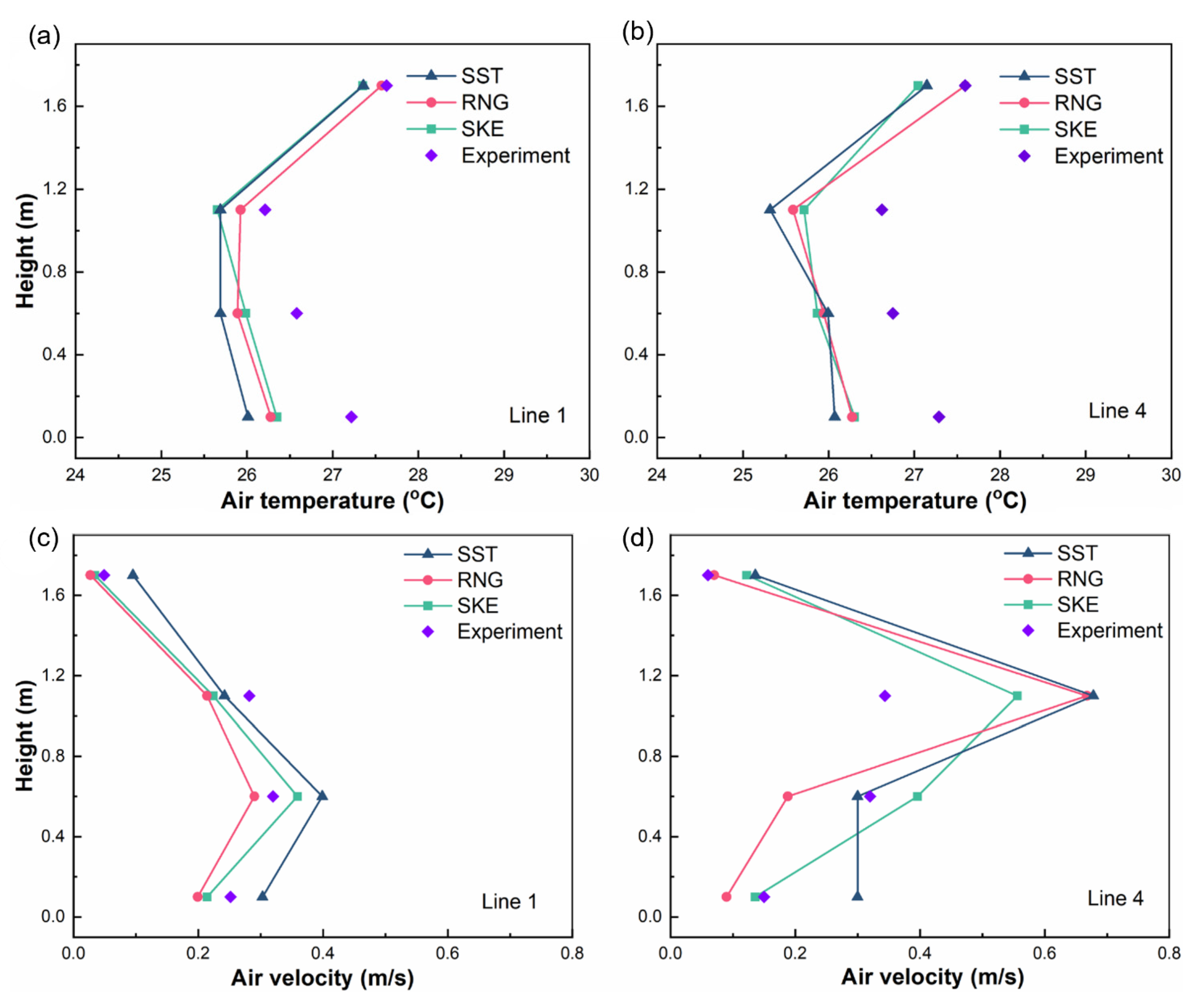

3.1. Validation of Numerical Model

3.2. Experimental Results

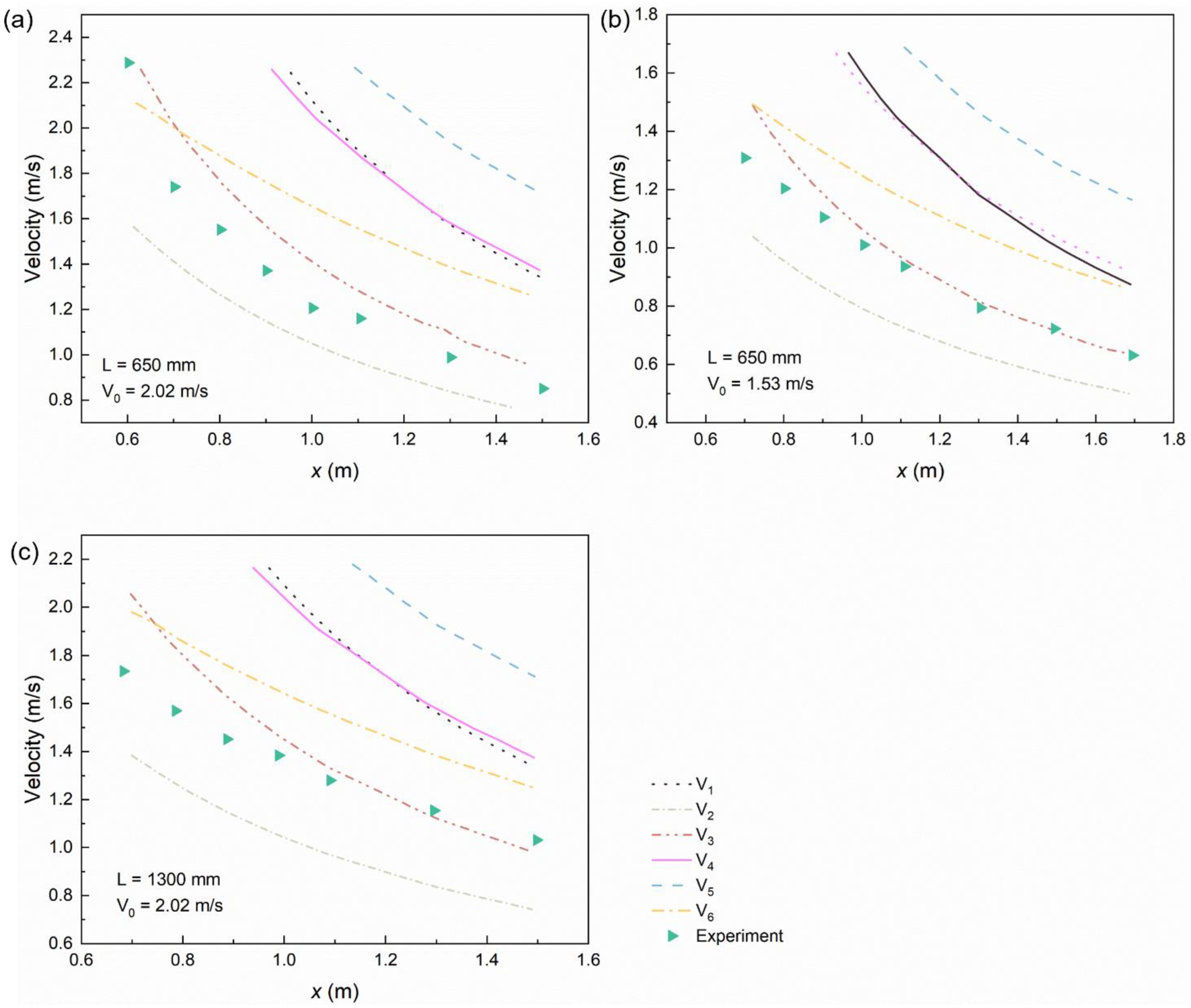

3.2.1. Verification of Theoretical Models of Multiple Parallel Jets

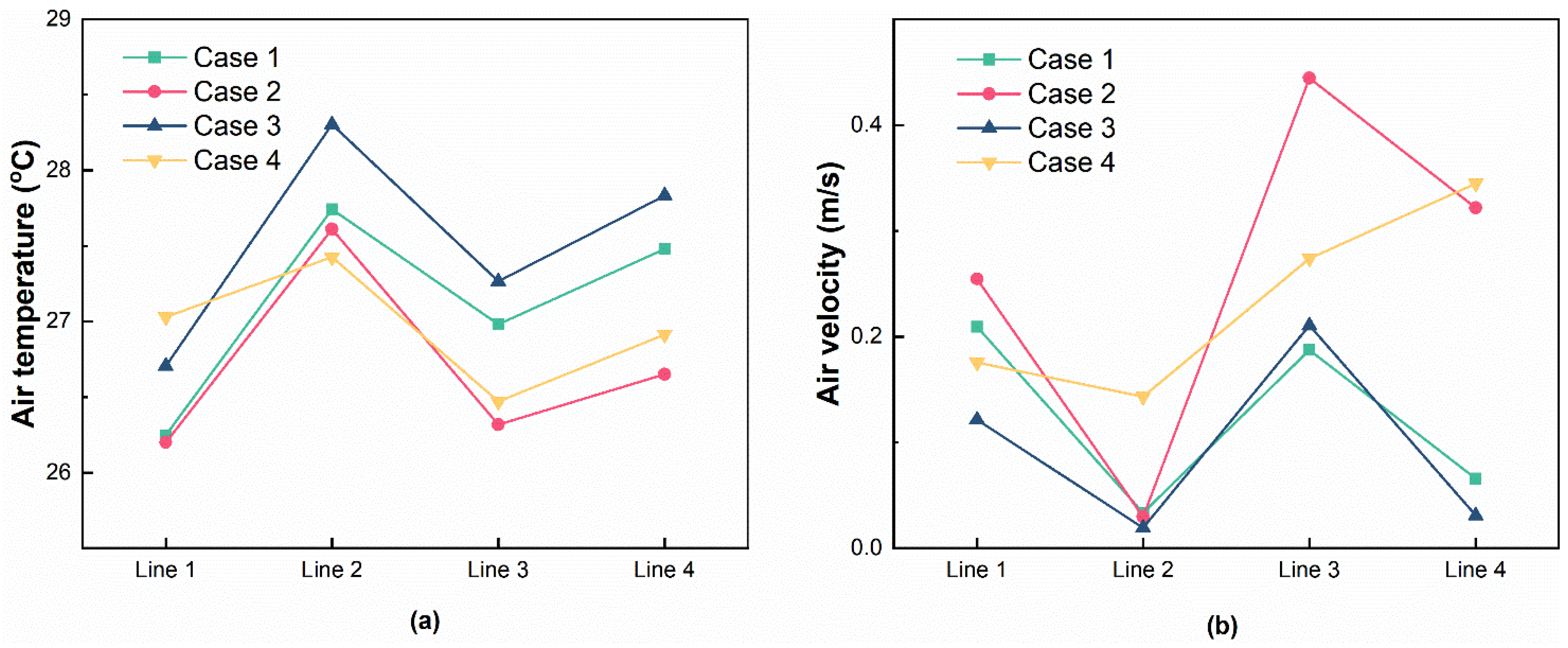

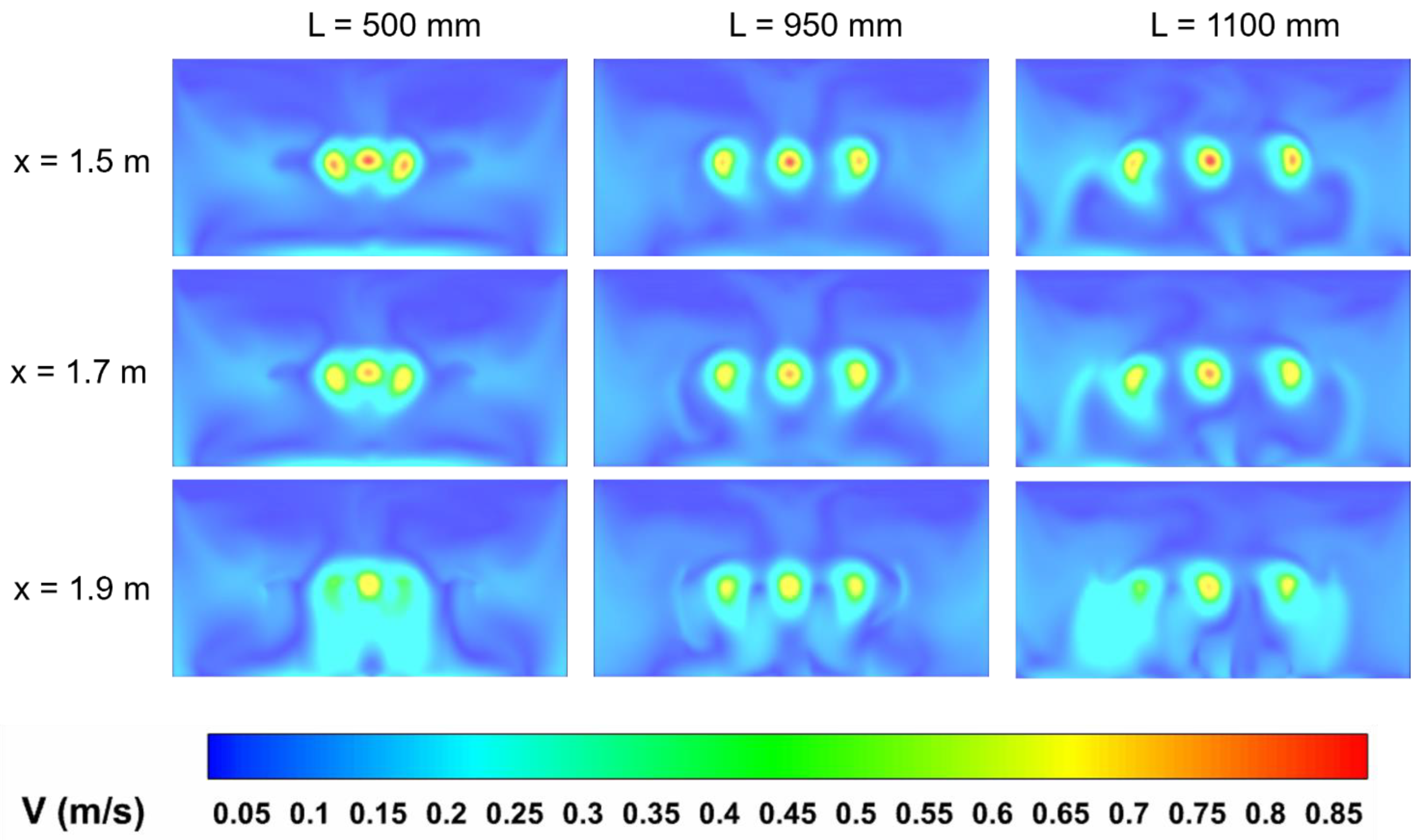

3.2.2. Influence of Air Inlet Spacing on Airflow Pattern

3.3. Simulation Results

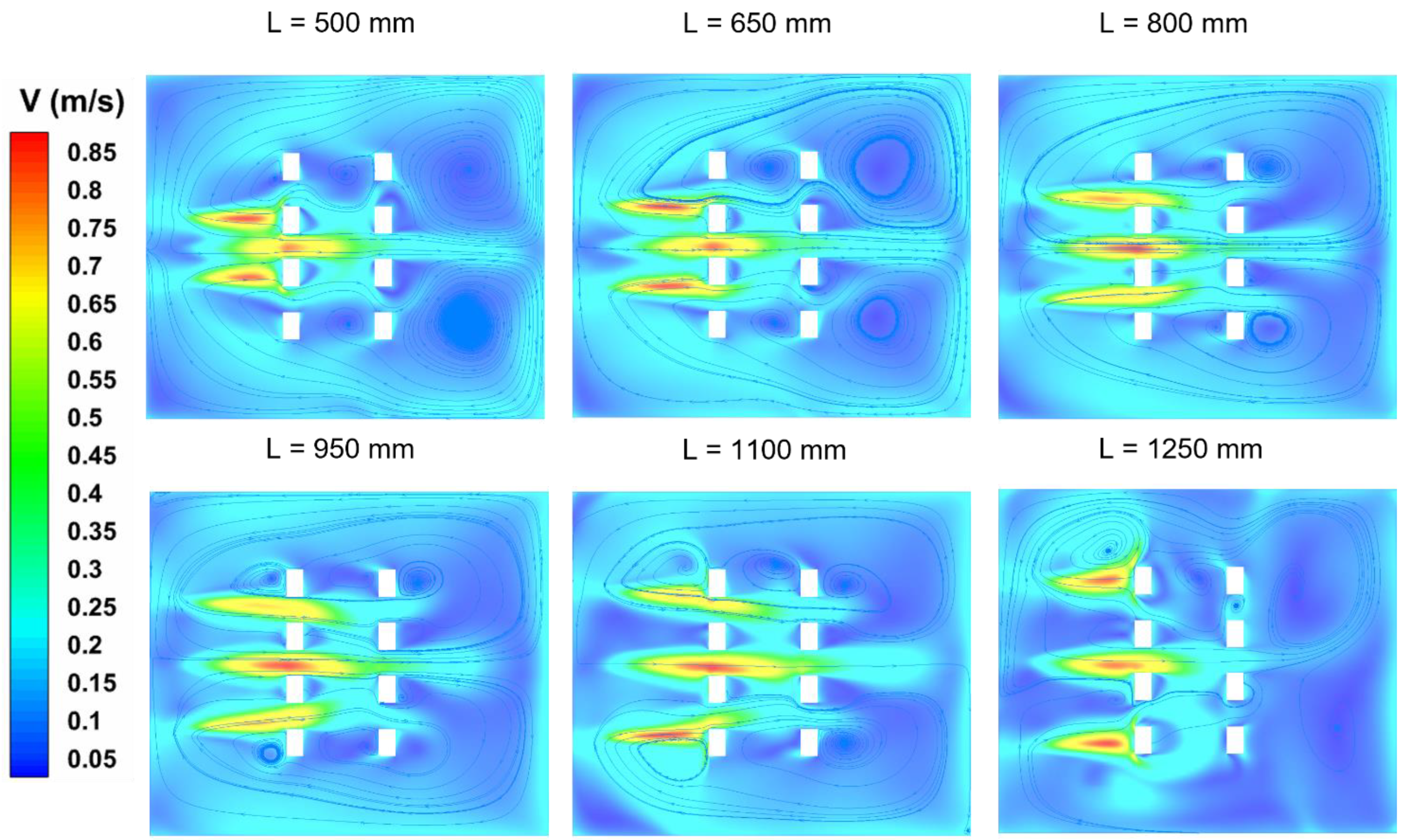

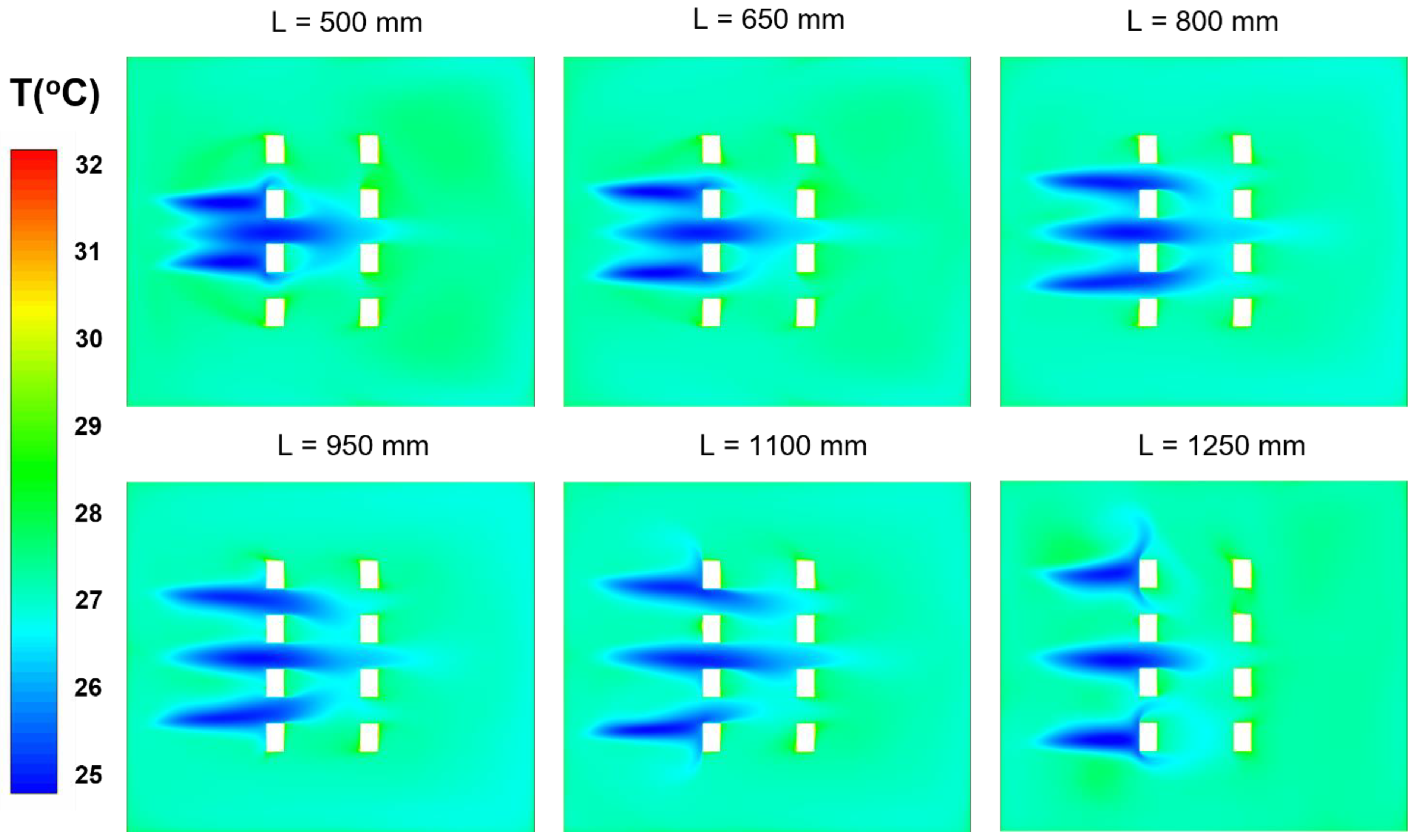

3.3.1. Airflow Characteristics

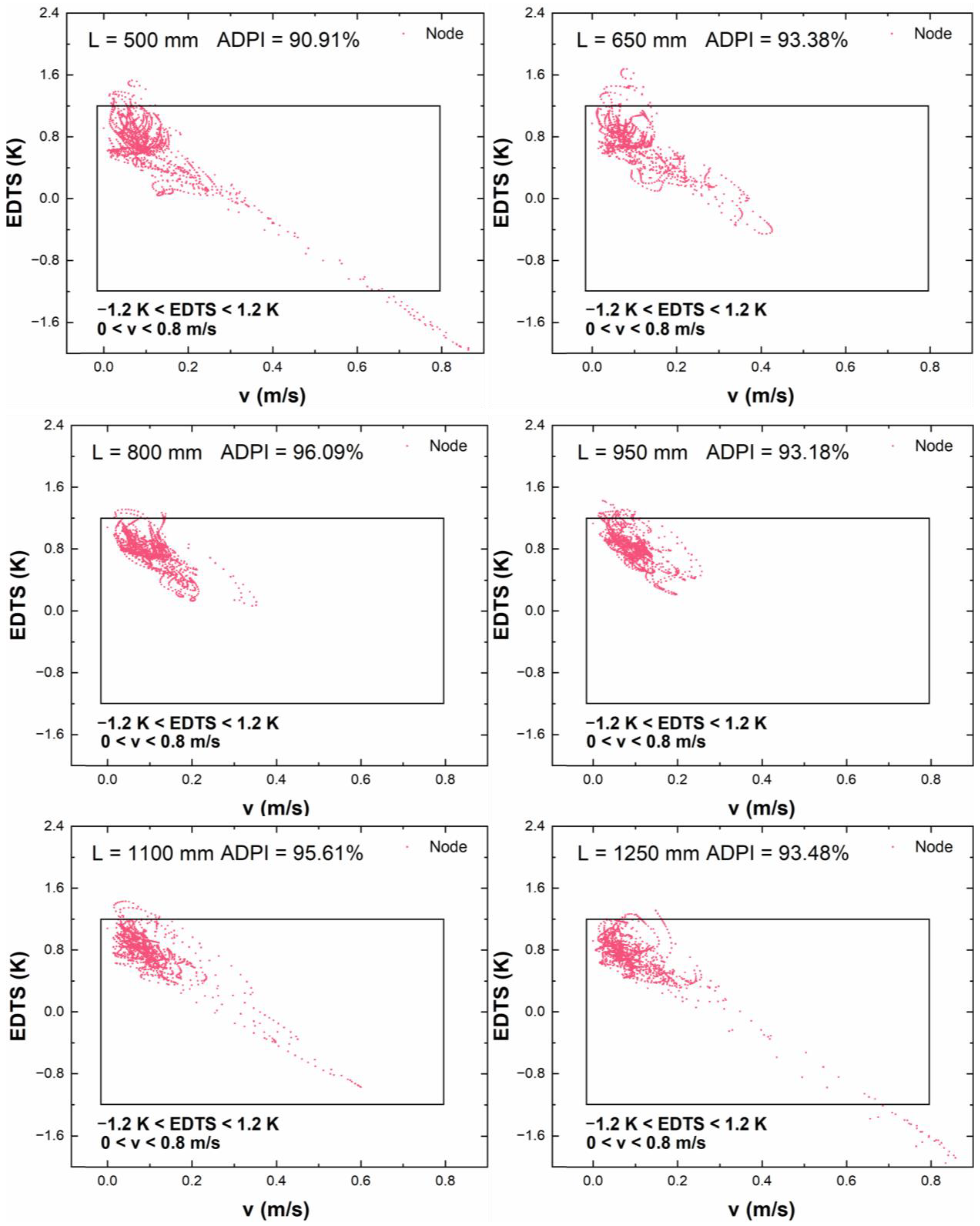

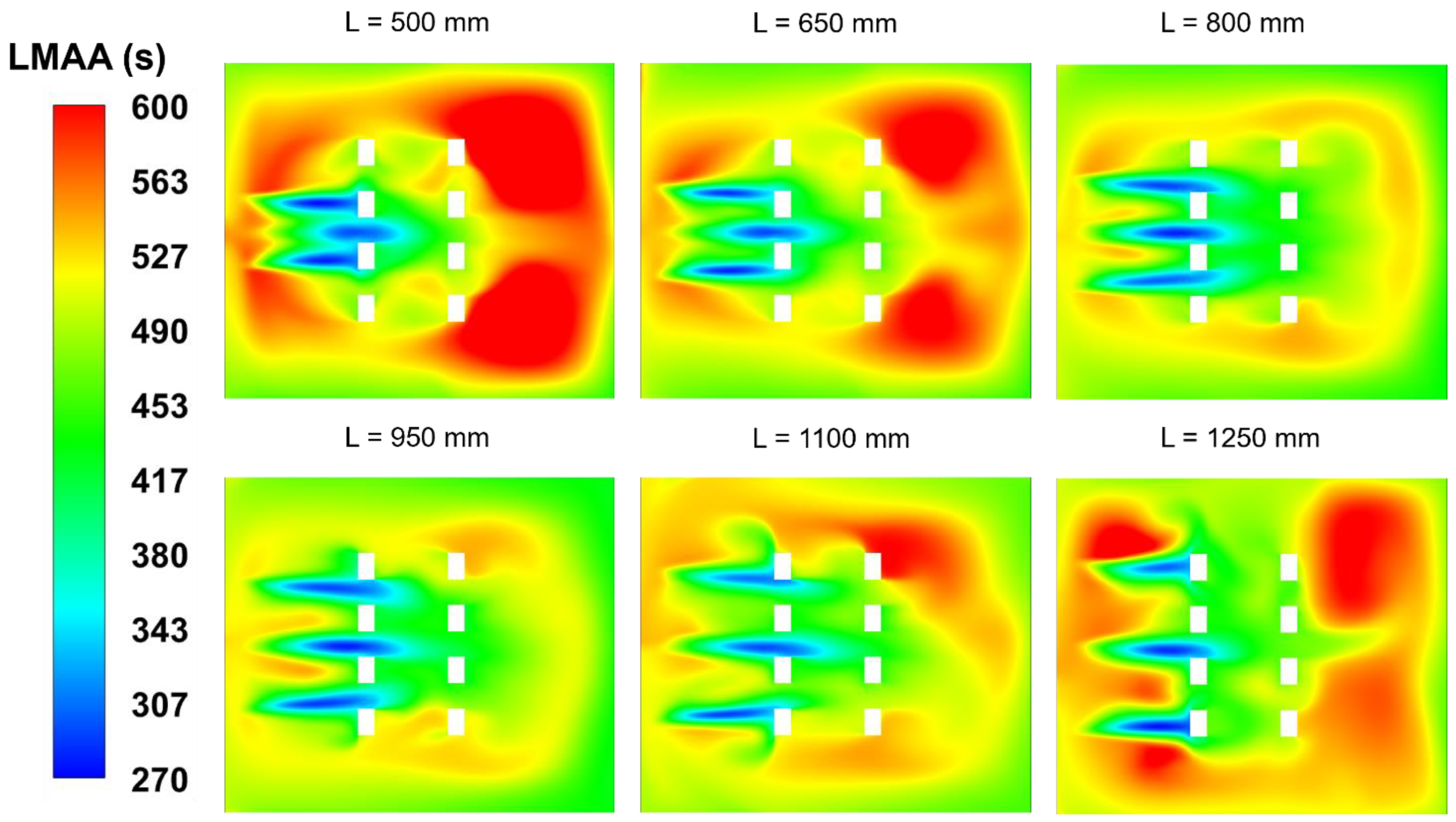

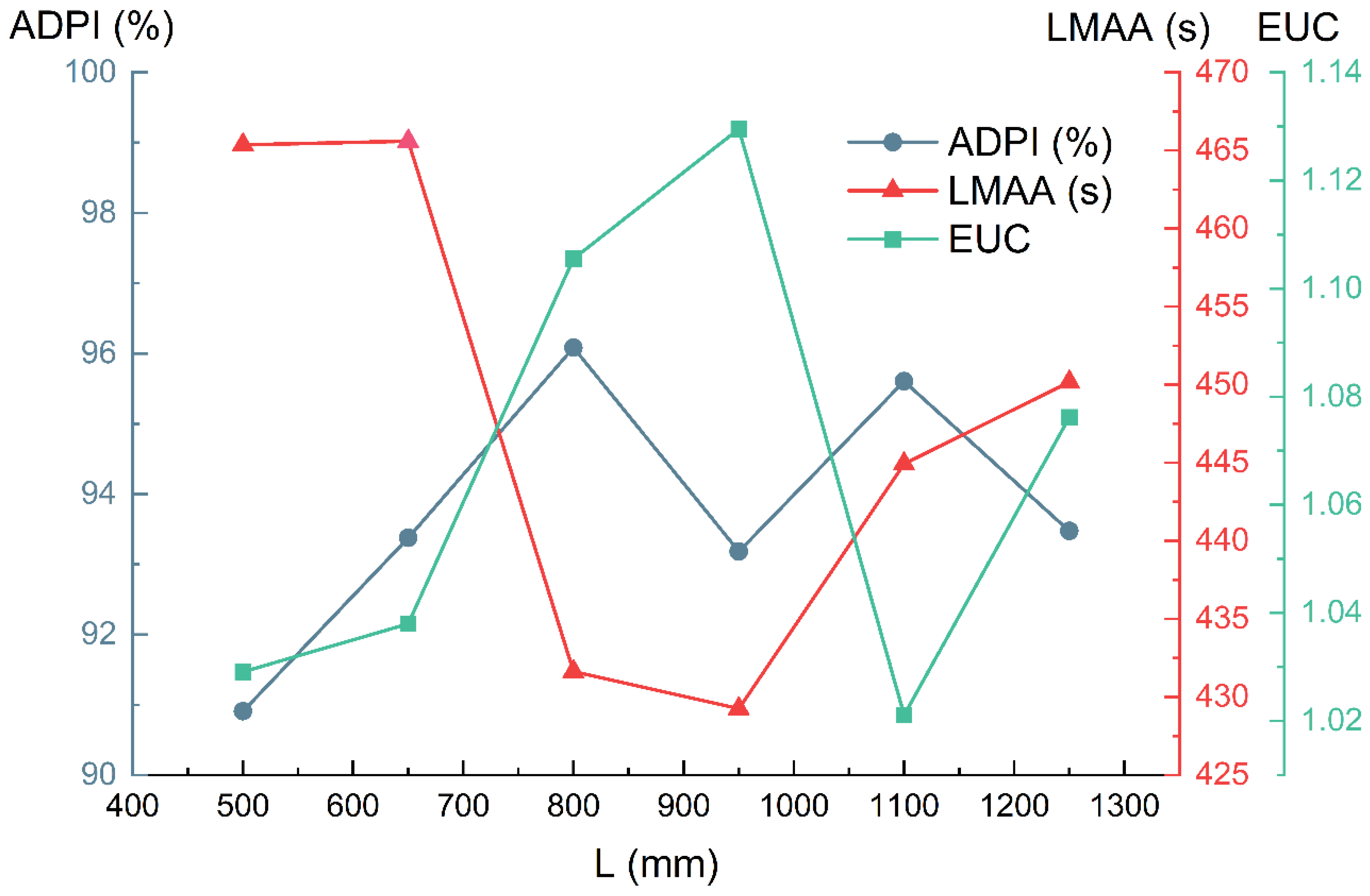

3.3.2. Analysis of Evaluation Indices

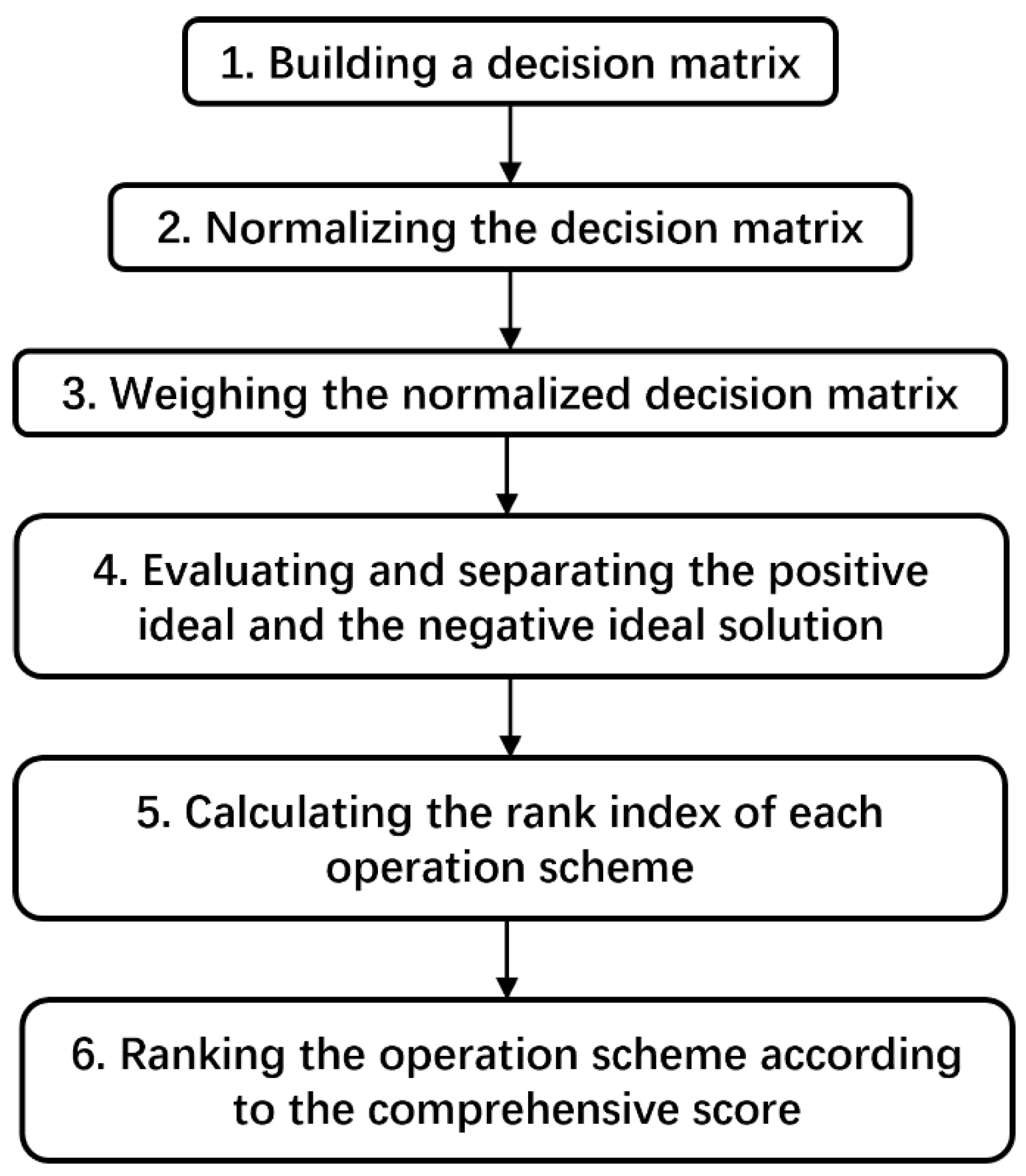

3.4. Optimization of Air Inlet Spacing

4. Conclusions

- Analysis of the experimental results showed that the flow characteristics in the occupied zone of the room were significantly different with different spacings of the supply air inlets, and the thermal comfort may be different at the same location. The position close to the air inlet was directly affected by the air inlet spacing. For locations away from the air inlets, the change in air temperature with spacing was more obvious than that of air velocity owing to the blocking effect of personnel.

- The attenuation formula for the jet axial velocity was verified using the measured data. The RMSE between the measured data and the predicted values for the three cases were 0.23 m/s, 0.09 m/s, and 0.18 m/s, respectively. Thus, the modified Abramovich formula is the most suitable for attenuation of the axial velocity of multiple parallel jets in SV rooms.

- Numerical simulation results showed that inappropriate air inlet spacing was not conducive to the performance of indoor air distribution. The distance between the merge point of the parallel jet and the air inlet depended on the spacing between the adjacent air inlets. A small air inlet spacing led to a concentration of the conditioned supply air in the middle of the room, and the indoor thermal environment on both sides could not be guaranteed. A large spacing resulted in areas that could not be covered by the supply air. The velocity profile showed strong asymmetry in its center downstream of the horizontal non-isothermal jet, mainly caused by the strong mixing of the lower part of the jet.

- By analyzing the influence of air inlet spacing on the three evaluation indices, it was found that the optimal value of ADPI corresponded to an air inlet spacing of 800 mm; the optimal LMAA and EUC corresponded to an air inlet spacing of 950 mm. The multi-objective optimization method TOPSIS was used to optimize the air inlet spacing. The optimal spacing was 800 mm.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Orosa, J.A.; Kameni Nematchoua, M.; Reiter, S. Air Changes for Healthy Indoor Ambiences under Pandemic Conditions and Its Energetic Implications: A Galician Case Study. Appl. Sci. 2020, 10, 7169. [Google Scholar] [CrossRef]

- Krzaczek, M.; Florczuk, J.; Tejchman, J. Improved energy management technique in pipe-embedded wall heating/cooling system in residential buildings. Appl. Energy 2019, 254, 113711. [Google Scholar] [CrossRef]

- Jung, W.; Jazizadeh, F. Human-in-the-loop HVAC operations: A quantitative review on occupancy, comfort, and energy-efficiency dimensions. Appl. Energy 2019, 239, 1471–1508. [Google Scholar] [CrossRef]

- Yang, B.; Melikov, A.K.; Kabanshi, A.; Zhang, C.; Bauman, F.S.; Cao, G.; Awbi, H.; Wigö, H.; Niu, J.; Cheong, K.W.D.; et al. A review of advanced air distribution methods-theory, practice, limitations and solutions. Energy Build. 2019, 202, 109359. [Google Scholar] [CrossRef] [Green Version]

- Nie, X.; Chen, Z.; Zhu, Z. Assessment of Low-Reynolds Number k-ε Models in Prediction of a Transitional Flow with Coanda Effect. Appl. Sci. 2023, 13, 1783. [Google Scholar]

- Segala, G.; Doriguzzi-Corin, R.; Peroni, C.; Gazzini, T.; Siracusa, D. A Practical and Adaptive Approach to Predicting Indoor CO2. Appl. Sci. 2021, 11, 10771. [Google Scholar] [CrossRef]

- Park, S.; Park, H.; Seo, J. Analysis on the Exhaust Air Recirculation of the Ventilation System in Multi-Story Building. Appl. Sci. 2021, 11, 4441. [Google Scholar] [CrossRef]

- Zhang, S.; Niu, D.; Lin, Z. Occupancy-aided ventilation for airborne infection risk control: Continuously or intermittently reduced occupancies? Build. Simul. 2022. [Google Scholar] [CrossRef]

- Zhang, S.; Lu, Y.L.; Niu, D.; Lin, Z. Energy performance index of air distribution: Thermal utilization effectiveness. Appl. Energy 2022, 307, 118122. [Google Scholar] [CrossRef]

- Olstrup, H.; Hagenbjork, A.; Orru, H. Ventilation Systems and Their Impact on Nanoparticle Concentrations in Office Buildings. Appl. Sci. Basel 2021, 11, 8930. [Google Scholar] [CrossRef]

- Danca, P.; Coşoiu, C.I.; Nastase, I.; Bode, F.; Georgescu, M.R. Personalized Ventilation as a Possible Strategy for Reducing Airborne Infectious Disease Transmission on Commercial Aircraft. Appl. Sci. 2022, 12, 2088. [Google Scholar] [CrossRef]

- Lin, Z.; Chow, T.T.; Tsang, C.F. Stratum ventilation-A conceptual introduction. In Proceedings of the 10th International Conference on Indoor Air Quality and Climate, Beijing, China, 4–9 September 2005; Volume 1–5, pp. 3260–3264. [Google Scholar]

- Lin, Z.; Yao, T.; Chow, T.T.; Fong, K.F.; Chan, L.S. Performance evaluation and design guidelines for stratum ventilation. Build. Environ. 2011, 46, 2267–2279. [Google Scholar] [CrossRef]

- Lin, Z.; Chow, T.T.; Tsang, C.F.; Fong, K.F.; Chan, L.S. Stratum ventilation—A potential solution to elevated indoor temperatures. Build. Environ. 2009, 44, 2256–2269. [Google Scholar] [CrossRef]

- Fong, M.L.; Lin, Z.; Fong, K.F.; Chow, T.T.; Yao, T. Evaluation of thermal comfort conditions in a classroom with three ventilation methods. Indoor Air 2011, 21, 231–239. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.; Lee, C.K.; Fong, S.; Chow, T.T.; Yao, T.; Chan, A.L.S. Comparison of annual energy performances with different ventilation methods for cooling. Energy Build. 2011, 43, 130–136. [Google Scholar] [CrossRef]

- Cheng, Y.; Lin, Z.; Fong, A.M.L. Effects of temperature and supply airflow rate on thermal comfort in a stratum-ventilated room. Build. Environ. 2015, 92, 269–277. [Google Scholar] [CrossRef]

- Lin, Z. Stratum ventilation-a low-carbon way to thermal comfort and indoor air quality. Int. J. Low Carbon Technol. 2017, 12, 323–329. [Google Scholar] [CrossRef] [Green Version]

- Tian, L.; Lin, Z.; Wang, Q. Comparison of gaseous contaminant diffusion under stratum ventilation and under displacement ventilation. Build. Environ. 2010, 45, 2035–2046. [Google Scholar] [CrossRef]

- Zhang, S.; Cheng, Y.; Oladoku, M.O.; Lin, Z. Subzone control method of stratum ventilation for thermal comfort improvement. Build. Environ. 2019, 149, 39–47. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Cheng, Y.; Lin, Z. Robust evaluation method of thermal deviation of air distribution. Build. Environ. 2019, 158, 217–225. [Google Scholar] [CrossRef]

- Cheng, Y.; Lin, Z. Technical feasibility of a stratum-ventilated room for multiple rows of occupants. Build. Environ. 2015, 94, 580–592. [Google Scholar] [CrossRef]

- Wu, W.Q.; Lin, Z. An experimental study of the influence of a walking occupant on three air distribution methods. Build. Environ. 2015, 85, 211–219. [Google Scholar] [CrossRef]

- Yao, T.; Lin, Z. An experimental and numerical study on the effect of air terminal layout on the performance of stratum ventilation. Build. Environ. 2014, 82, 75–86. [Google Scholar] [CrossRef]

- Fong, M.L.; Hanby, V.; Greenough, R.; Lin, Z.; Cheng, Y. Acceptance of thermal conditions and energy use of three ventilation strategies with six exhaust configurations for the classroom. Build. Environ. 2015, 94, 606–619. [Google Scholar] [CrossRef]

- Zheng, X.; Jian, X.; Wei, J.; Wenzheng, D. Numerical and Experimental Investigation of Near-Field Mixing in Parallel Dual Round Jets. Int. J. Aerosp. Eng. 2016, 2016, 7935101. [Google Scholar] [CrossRef] [Green Version]

- Yin, Z.; Zhang, H.; Lin, J. Experimental Study on the Flow Field Characteristics in the Mixing Region of Twin Jets. J. Hydrodyn. 2007, 19, 309–313. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, T.; Shi, E. Study of the aerodynamical characteristics of mutiple parallel jets. J. Xian Jiaotong Univ. 1989, 4, 73–81. [Google Scholar]

- Wang, X.K.; Tan, S.K. Experimental investigation of the interaction between a plane wall jet and a parallel offset jet. Exp. Fluids 2007, 42, 551–562. [Google Scholar] [CrossRef]

- Mondal, T.; Das, M.K.; Guha, A. Periodic vortex shedding phenomenon for various separation distances between two plane turbulent parallel jets. Int. J. Heat Mass Transf. 2016, 99, 576–588. [Google Scholar] [CrossRef]

- Liu, P.Y.; Zhang, H.; Wu, Y.X.; Zhang, M.; Lu, J.F. Experimental study on the flow interaction of two parallel rectangular jets through exits with sudden contraction. Exp. Therm. Fluid Sci. 2017, 88, 622–631. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, S.; Huan, C.; Oladokun, M.O.; Lin, Z. Optimization on fresh outdoor air ratio of air conditioning system with stratum ventilation for both targeted indoor air quality and maximal energy saving. Build. Environ. 2019, 147, 11–22. [Google Scholar] [CrossRef] [Green Version]

- Cheng, F.H.; Zhang, S.; Gao, S.S.; Tian, X.; Liao, C.H.; Cheng, Y. Experimental investigation of airflow pattern and turbulence characteristics of stratum ventilation in heating mode. Build. Environ. 2020, 186, 107339. [Google Scholar] [CrossRef]

- Xu, D.; Chen, J. Experimental study of stratified jet by simultaneous measurements of velocity and density fields. Exp. Fluids 2012, 53, 145–162. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, X.; Yang, Y. Study on Jet Coincidence Characteristics of Air Supply Outlet in Large Space. Build. Energy Environ. 1997, 3, 1–5. [Google Scholar]

- Zhou, Y.; Wang, S.; Peng, R.; Hua, C. Study on the calculation method of air distribution in stratified air conditioning. J. HVAC 1983, 2, 1–6+19. [Google Scholar]

- Zhao, J. Theoretical and Experimental Study on the Coincidence Characteristics of Multi-Stream Air Supply Jet in Large Space; Tongji University: Shanghai, China, 2000. [Google Scholar]

- ASHRAE. ASHRAE Handbook Fundamentals; ASHRAE Inc.: Atlanta, GA, USA, 2005. [Google Scholar]

- Li, A. Unity of air jet buoyant plume and buoyant jet. J. HVAC 1998, 28, 8–10. [Google Scholar]

- Chen, Q.Y. Ventilation performance prediction for buildings: A method overview and recent applications. Build. Environ. 2009, 44, 848–858. [Google Scholar] [CrossRef]

- Mao, N.; Song, M.J.; Chan, M.Y.; Pan, D.M.; Deng, S.M. Computational fluid dynamics (CFD) modelling of air flow field, mean age of air and CO2 distributions inside a bedroom with different heights of conditioned air supply outlet. Appl. Energy 2016, 164, 906–915. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhai, Z.Q.; Zhang, W.; Chen, Q.Y. Evaluation of various turbulence models in predicting airflow and turbulence in enclosed environments by CFD: Part 2-comparison with experimental data from literature. HvacR Res. 2007, 13, 871–886. [Google Scholar] [CrossRef]

- ANSYS Inc. ANSYS Fluent Theory Guide; ANSYS Inc.: Canonsburg, PA, USA, 2013. [Google Scholar]

- Heiselberg, P. Draught risk from cold vertical surfaces. Build. Environ. 1994, 29, 297–301. [Google Scholar] [CrossRef] [Green Version]

- Awbi, H.B. Calculation of convective heat transfer coefficients of room surfaces for natural convection. Energy Build. 1998, 28, 219–227. [Google Scholar] [CrossRef]

- Pereira, P.F.d.C.; Broday, E.E.; Xavier, A.A.d.P. Thermal Comfort Applied in Hospital Environments: A Literature Review. Appl. Sci. 2020, 10, 7030. [Google Scholar] [CrossRef]

- Lin, Z. Effective draft temperature for evaluating the performance of stratum ventilation. Build. Environ. 2011, 46, 1843–1850. [Google Scholar] [CrossRef]

- Liu, J.; Lin, Z. Energy and Exergy Performances of Floor, Ceiling, Wall Radiator and Stratum Ventilation Heating Systems for Residential Buildings. Energy Build. 2020, 220, 110046. [Google Scholar] [CrossRef]

- Tian, L.; Lin, Z.; Liu, J.; Yao, T.; Wang, Q.W. The impact of temperature on mean local air age and thermal comfort in a stratum ventilated office. Build. Environ. 2011, 46, 501–510. [Google Scholar] [CrossRef]

- Buratti, C.; Palladino, D. Mean Age of Air in Natural Ventilated Buildings: Experimental Evaluation and CO2 Prediction by Artificial Neural Networks. Appl. Sci. 2020, 10, 1730. [Google Scholar] [CrossRef] [Green Version]

- Chen, F.J.; Chen, H.X.; Xie, J.L.; Shu, Z.H.; Mao, J.N. Air distribution in room ventilated by fabric air dispersion system. Build. Environ. 2011, 46, 2121–2129. [Google Scholar] [CrossRef]

- Cheng, Y.; Lin, Z.; Yao, T.; Wu, W. Numerical comparison of indoor air quality and local thermal comfort in a classroom with three ventilation methods. In Proceedings of the 13th International Conference on Indoor Air Quality and Climate, Indoor Air 2014, Hong Kong, China, 7–12 July 2014; pp. 68–75. [Google Scholar]

- Ghaisas, N.S.; Shetty, D.A.; Frankel, S.H. Large eddy simulation of turbulent horizontal buoyant jets. J. Turbul. 2015, 16, 772–808. [Google Scholar] [CrossRef]

- ANSI/ASHRAE Standard 113-2013; Method of Testing for Room Air Diffusion. ANSI: Washington, DC, USA, 2013.

- Behzadian, M.; Khanmohammadi Otaghsara, S.; Yazdani, M.; Ignatius, J. A state-of the-art survey of TOPSIS applications. Expert Syst. Appl. 2012, 39, 13051–13069. [Google Scholar] [CrossRef]

- Fan, Y. A TOPSIS optimization for the indoor thermal environment through oscillating airflow generated from a cassette split type air conditioner. Indoor Built Environ. 2021, 30, 1200–1210. [Google Scholar] [CrossRef]

- Mao, N.; Song, M.; Deng, S. Application of TOPSIS method in evaluating the effects of supply vane angle of a task/ambient air conditioning system on energy utilization and thermal comfort. Appl. Energy 2016, 180, 536–545. [Google Scholar] [CrossRef]

| Test Series | Case | V0 (m/s) | L (mm) |

|---|---|---|---|

| 1 | 1.21 | 650 | |

| Series 1 | 2 | 1.62 | |

| 3 | 1.21 | 1300 | |

| 4 | 1.62 | ||

| 5 | 1.53 | 650 | |

| Series 2 | 6 | 2.02 | 650 |

| 7 | 2.02 | 1300 |

| Instrument | Measuring Location | Parameter | Range | Accuracy | Sampling Frequency | |

|---|---|---|---|---|---|---|

| WZY-1 |  | Room air | Temperature | −20–80 °C | ±0.3 °C | 0.2 Hz |

| Envelope | Temperature | 0.003 Hz | ||||

| Swema 03+ |  | Supply air and all the measurement points in the occupied zone and jet area | Velocity | 0.05–10 m/s | ±0.03 m/s ± 3% | 8 Hz |

| Temperature | 10–40 °C | ±0.2 °C | ||||

| Governing Equations | |||

|---|---|---|---|

| Mass equation | 1 | 0 | 0 |

| Momentum equation | |||

| Energy equation | T | ||

| Turbulent kinetic energy equation | k | ||

| Turbulent dissipation equation |

| Boundary | Boundary Condition |

|---|---|

| Supply air inlet | Velocity inlet |

| Exhaust outlet | Outflow |

| Window, walls, and ceiling | Constant wall temperature, 28.4 °C |

| Floor | Constant wall temperature, 27.2 °C |

| Occupant | Constant heat flux, 60.24 W/m2 |

| Light | Constant heat flux, 638.89 W/m2 |

| Case | T0 (°C) | V0 (m/s) | L (mm) |

|---|---|---|---|

| 1 | 23.5 | 1.5 | 500 |

| 2 | 650 | ||

| 3 | 800 | ||

| 4 | 950 | ||

| 5 | 1100 | ||

| 6 | 1250 |

| Turbulence Model | RMSE for Temperature | RMSE for Velocity |

|---|---|---|

| SKE | 0.72 | 0.107 |

| RNG | 0.81 | 0.142 |

| SST | 0.86 | 0.326 |

| Spacing of Air Inlet | Relative Fit Degree | Ranking |

|---|---|---|

| 500 | 0.0476 | 6 |

| 650 | 0.1001 | 5 |

| 800 | 0.8560 | 1 |

| 950 | 0.9010 | 2 |

| 1100 | 0.4019 | 4 |

| 1250 | 0.5283 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Ma, J.; Cheng, Y. Effect of Air Inlet Spacing on Air Distribution and Ventilation Performance of Stratum Ventilation Using Multiple Parallel Jets. Appl. Sci. 2023, 13, 4143. https://doi.org/10.3390/app13074143

Jiang Y, Ma J, Cheng Y. Effect of Air Inlet Spacing on Air Distribution and Ventilation Performance of Stratum Ventilation Using Multiple Parallel Jets. Applied Sciences. 2023; 13(7):4143. https://doi.org/10.3390/app13074143

Chicago/Turabian StyleJiang, Yaohong, Jiangze Ma, and Yong Cheng. 2023. "Effect of Air Inlet Spacing on Air Distribution and Ventilation Performance of Stratum Ventilation Using Multiple Parallel Jets" Applied Sciences 13, no. 7: 4143. https://doi.org/10.3390/app13074143