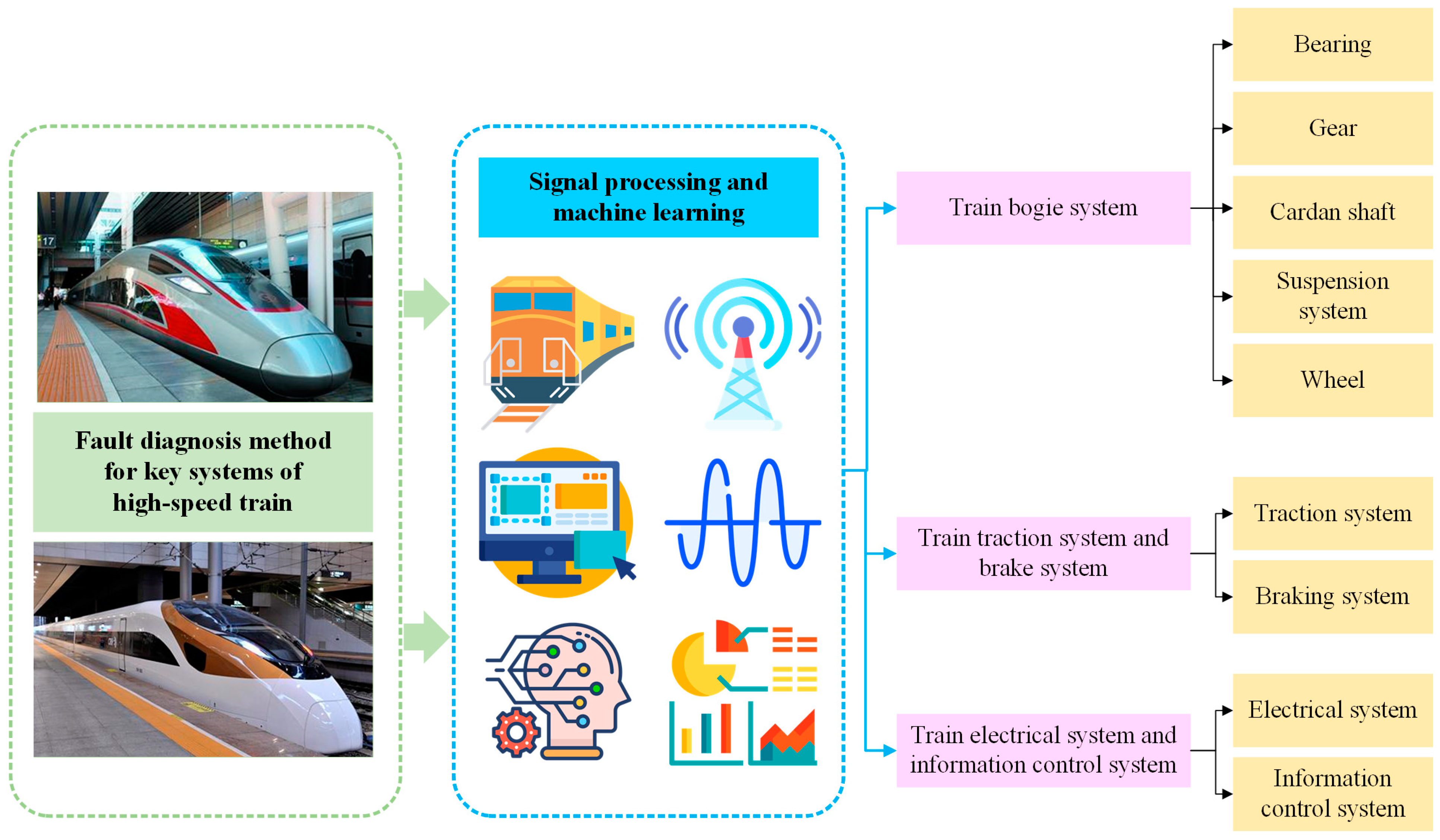

A Review of Fault Diagnosis Methods for Key Systems of the High-Speed Train

Abstract

1. Introduction

- (1)

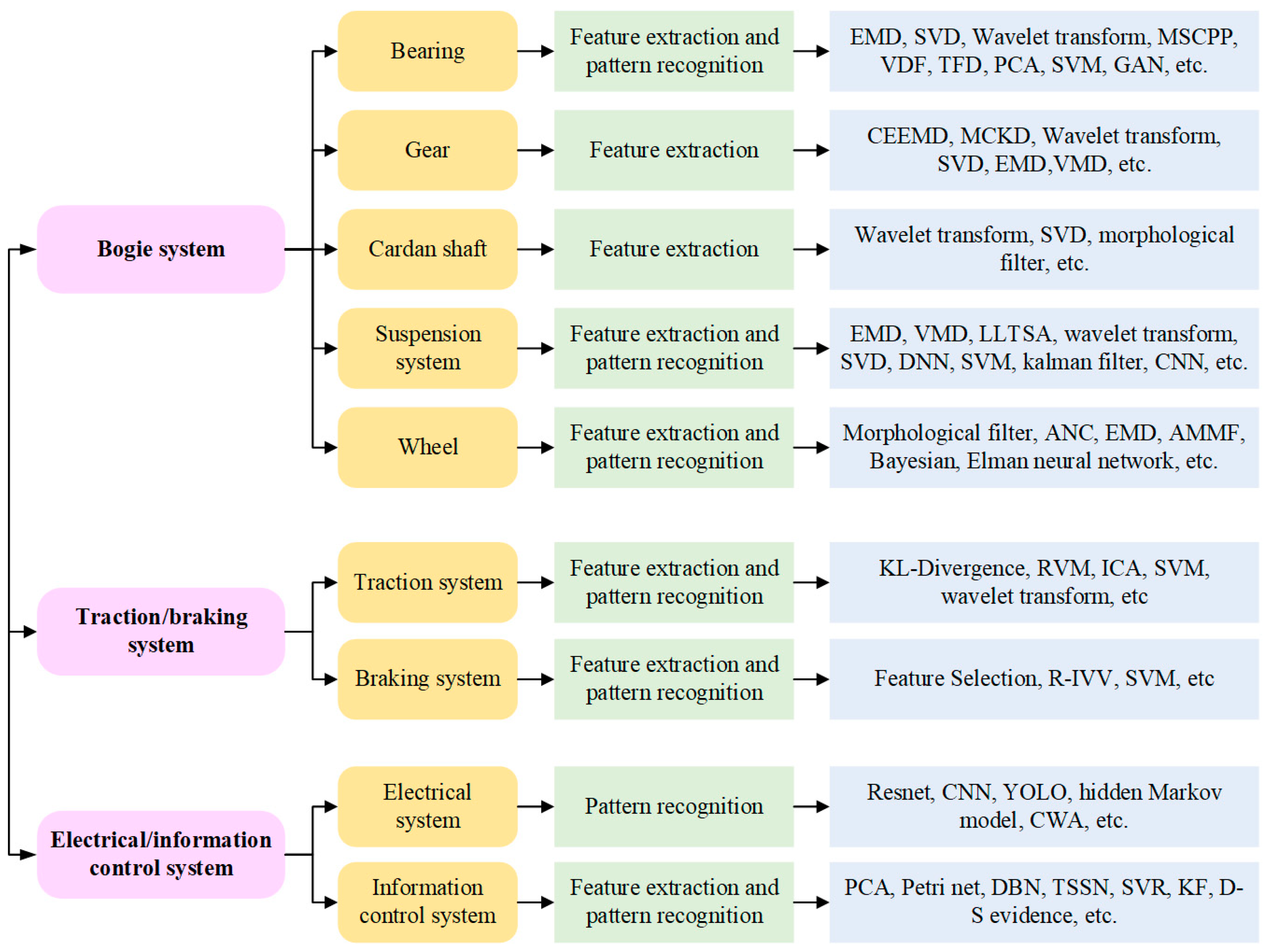

- The fault diagnosis methods of the bogie system of the high-speed train are presented.

- (2)

- The fault diagnosis methods of the traction system and brake system of the high-speed train are summarized.

- (3)

- The fault diagnosis methods of electric systems and information control systems of the high-speed train are overview.

- (4)

- The applicability of main fault diagnosis methods for high-speed trains is discussed.

2. Fault Diagnosis of High-Speed Train Bogie System

2.1. Fault Diagnosis of Train Bearing

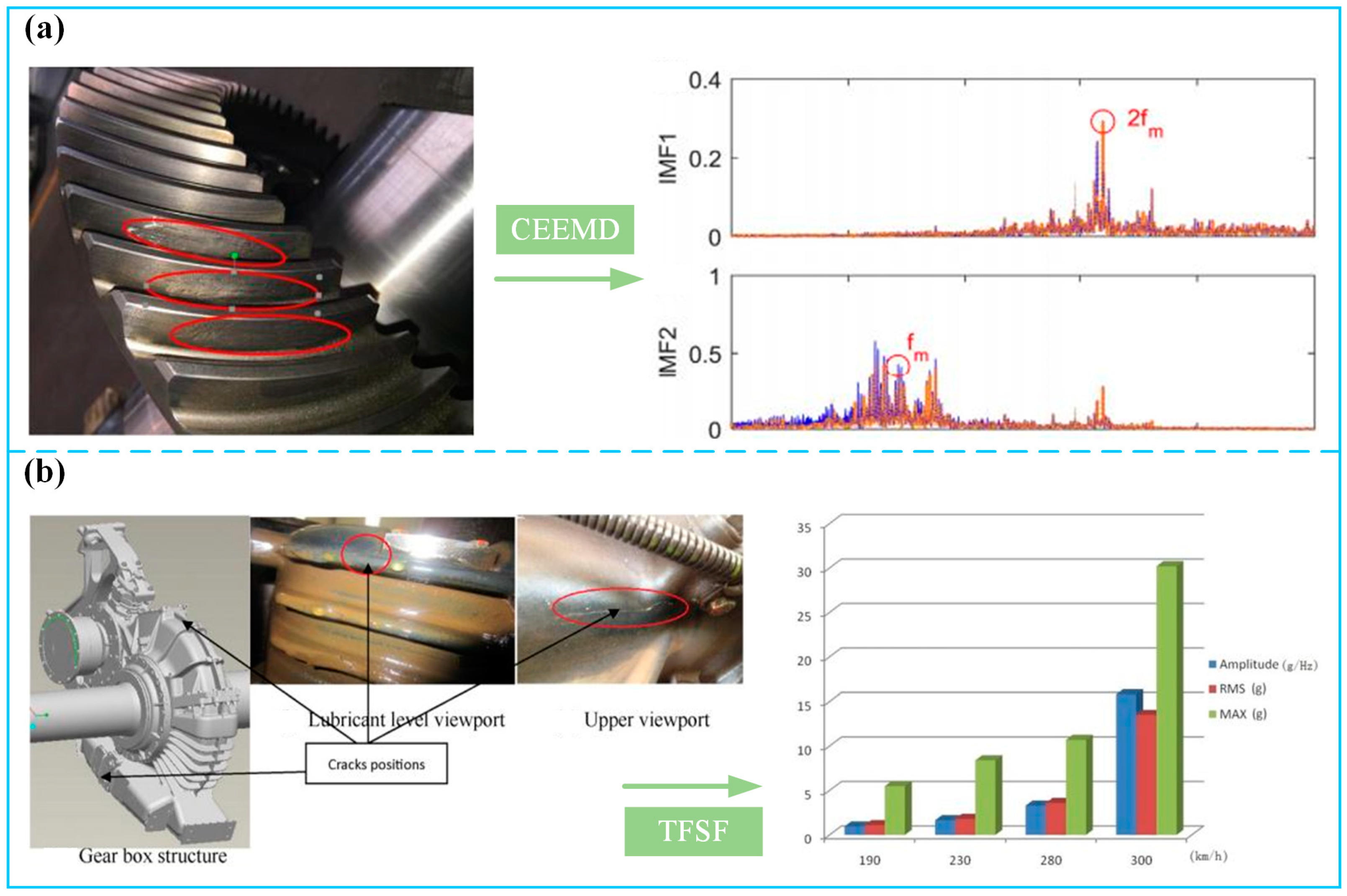

2.2. Fault Diagnosis of Train Gear

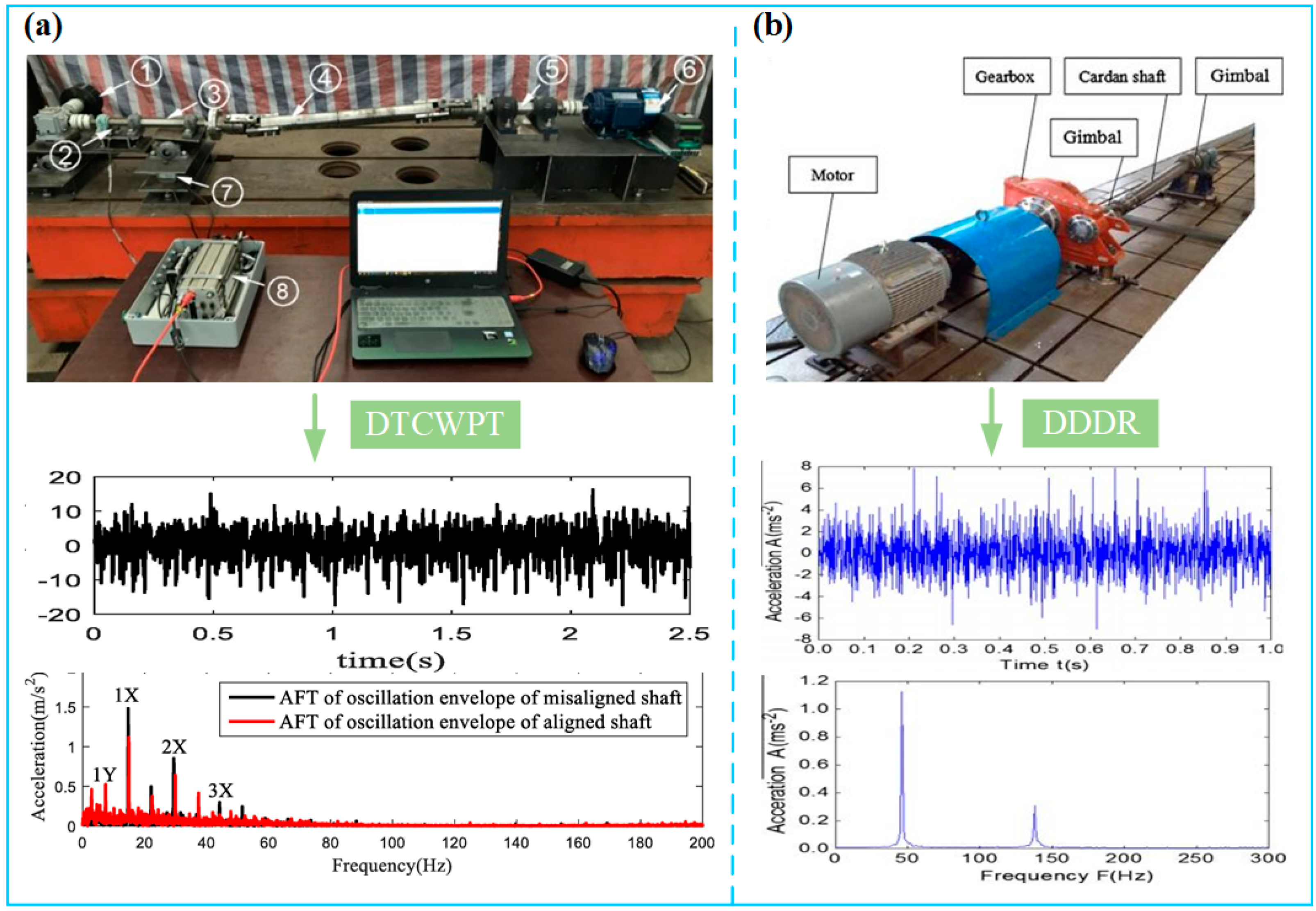

2.3. Fault Diagnosis of Train Cardan Shaft

2.4. Fault Diagnosis of Train Suspension System

2.5. Fault Diagnosis of Train Wheels

3. Fault Diagnosis of the High-Speed Train Traction System and Brake System

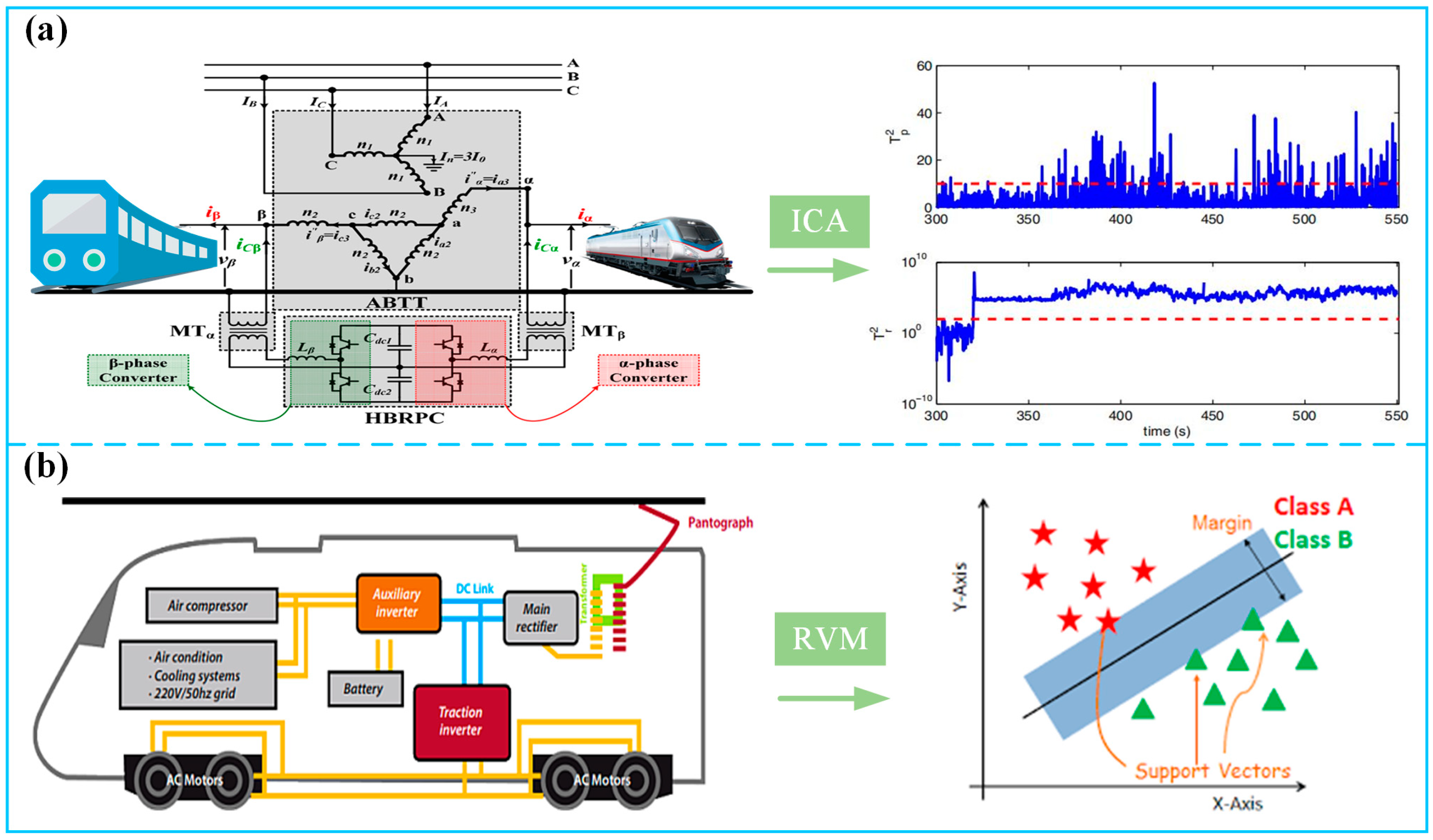

3.1. Fault Diagnosis of Train Traction System

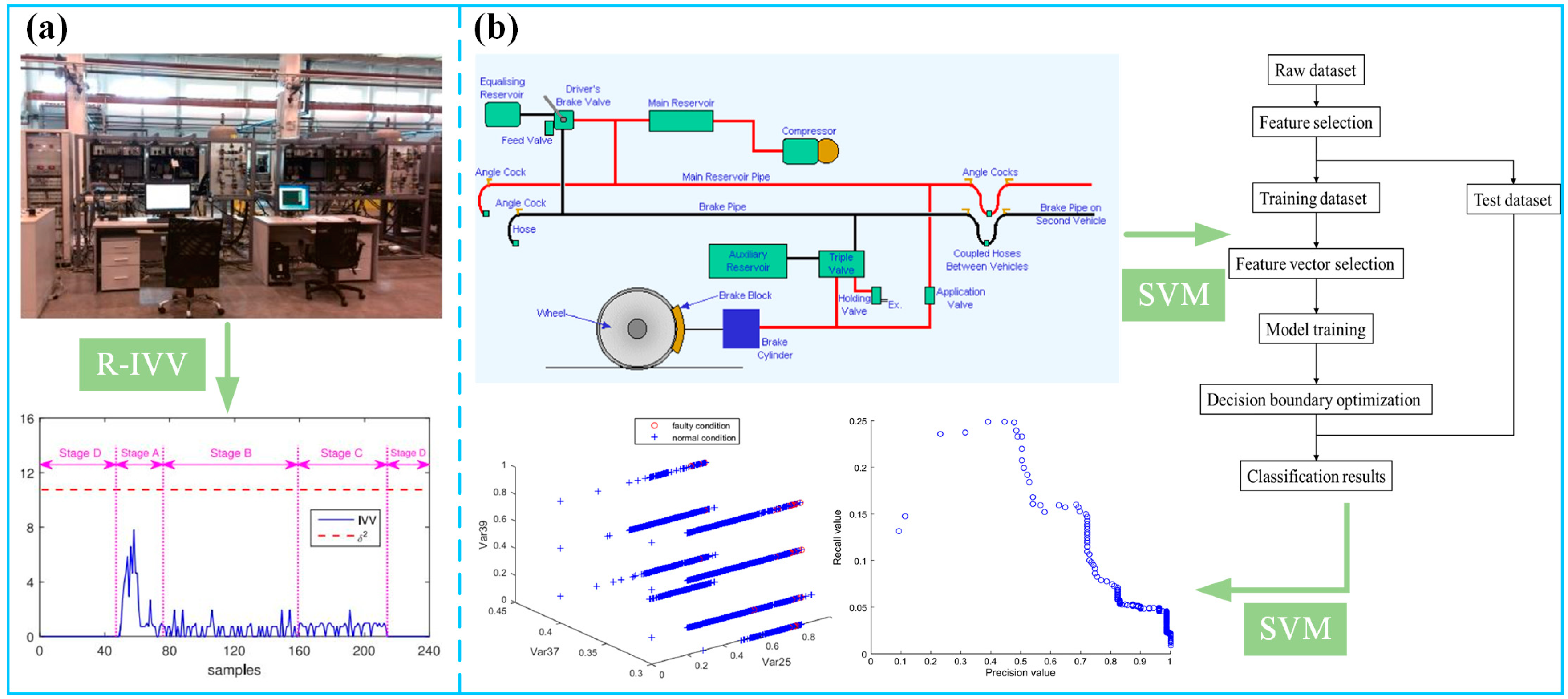

3.2. Fault Diagnosis of Train Braking System

4. Fault Diagnosis of the High-Speed Train Electrical System and Information Control System

4.1. Fault Diagnosis of Train Electrical System

4.2. Fault Diagnosis of the Train Information Control System

5. Applicability of Fault Diagnosis Methods for the High-Speed Train

6. Discussion and Conclusions

- (1)

- Developing online monitoring technology can ensure the reliability and safety of high-speed trains. This can not only quickly identify early failures of key systems but also predict performance degradation, thus establishing a long-term warning mechanism.

- (2)

- By installing various sensors (voltage, current, vibration acceleration, displacement, and pressure) in the key system of the train, a large number of real train operation data and corresponding historical data can be obtained, which provides data support for train fault diagnosis based on the combination of big data and experience knowledge.

- (3)

- With the advantages of machine learning and deep learning, a big data-driven condition monitoring and fault diagnosis platform for key systems of high-speed trains is being developed. This can shift from traditional planned repairs to condition repairs and forecast repairs, thereby reducing annual maintenance costs and preventing potential safety accidents.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, K.; Huang, W.; Hou, X.; Xu, J.; Su, R.; Xu, H. A Fault Diagnosis and Visualization Method for High-Speed Train Based on Edge and Cloud Collaboration. Appl. Sci. 2021, 11, 1251. [Google Scholar] [CrossRef]

- Tan, H.; Xie, S.; Ma, W.; Yang, C.; Zheng, S. Correlation feature distribution matching for fault diagnosis of machines. Reliab. Eng. Syst. Saf. 2023, 231, 108981. [Google Scholar] [CrossRef]

- Hamadache, M.; Dutta, S.; Olaby, O.; Ambur, R.; Stewart, E.; Dixon, R. On the Fault Detection and Diagnosis of Railway Switch and Crossing Systems: An Overview. Appl. Sci. 2019, 9, 5129. [Google Scholar] [CrossRef]

- Zhao, M.; Fu, X.; Zhang, Y.; Meng, L.; Tang, B. Highly imbalanced fault diagnosis of mechanical systems based on wavelet packet distortion and convolutional neural networks. Adv. Eng. Inform. 2022, 51, 101535. [Google Scholar] [CrossRef]

- Garramiola, F.; Poza, J.; Madina, P.; del Olmo, J.; Almandoz, G. A Review in Fault Diagnosis and Health Assessment for Railway Traction Drives. Appl. Sci. 2018, 8, 2475. [Google Scholar] [CrossRef]

- Tan, H.; Xie, S.; Liu, R.; Ma, W. Bearing fault identification based on stacking modified composite multiscale dispersion entropy and optimised support vector machine. Measurement 2021, 186, 110180. [Google Scholar] [CrossRef]

- Liu, Q.; Kong, D.; Qin, S.J.; Xu, Q. Map-Reduce Decentralized PCA for Big Data Monitoring and Diagnosis of Faults in High-Speed Train Bearings. IFAC-PapersOnLine 2018, 51, 144–149. [Google Scholar] [CrossRef]

- Cao, H.; Fan, F.; Zhou, K.; He, Z. Wheel-bearing fault diagnosis of trains using empirical wavelet transform. Measurement 2016, 82, 439–449. [Google Scholar] [CrossRef]

- Zhang, D.; Entezami, M.; Stewart, E.; Roberts, C.; Yu, D. A novel Doppler Effect reduction method for wayside acoustic train bearing fault detection systems. Appl. Acoust. 2019, 145, 112–124. [Google Scholar] [CrossRef]

- Ding, J. Fault detection of a wheelset bearing in a high-speed train using the shock-response convolutional sparse-coding technique. Measurement 2018, 117, 108–124. [Google Scholar] [CrossRef]

- Zhang, D.; Entezami, M.; Stewart, E.; Roberts, C.; Yu, D. Adaptive fault feature extraction from wayside acoustic signals from train bearings. J. Sound Vibr. 2018, 425, 221–238. [Google Scholar] [CrossRef]

- Li, Y.; Liang, X.; Lin, J.; Chen, Y.; Liu, J. Train axle bearing fault detection using a feature selection scheme based multi-scale morphological filter. Mech. Syst. Signal Proc. 2018, 101, 435–448. [Google Scholar] [CrossRef]

- Zhang, D.; Entezami, M.; Stewart, E.; Roberts, C.; Yu, D.; Lei, Y. Wayside acoustic detection of train bearings based on an enhanced spline-kernelled chirplet transform. J. Sound Vibr. 2020, 480, 115401. [Google Scholar] [CrossRef]

- Ding, J.; Zhao, W.; Miao, B.; Lin, J. Adaptive sparse representation based on circular-structure dictionary learning and its application in wheelset-bearing fault detection. Mech. Syst. Signal Proc. 2018, 111, 399–422. [Google Scholar] [CrossRef]

- Zhao, M.; Lin, J.; Miao, Y.; Xu, X. Detection and recovery of fault impulses via improved harmonic product spectrum and its application in defect size estimation of train bearings. Measurement 2016, 91, 421–439. [Google Scholar] [CrossRef]

- Huang, Y.; Lin, J.; Liu, Z.; Wu, W. A modified scale-space guiding variational mode decomposition for high-speed railway bearing fault diagnosis. J. Sound Vibr. 2019, 444, 216–234. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, S.; He, Q.; Kong, F. The Doppler Effect based acoustic source separation for a wayside train bearing monitoring system. J. Sound Vibr. 2016, 361, 307–329. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhou, N.; Zhang, W.; Wang, Z. Application of an improved minimum entropy deconvolution method for railway rolling element bearing fault diagnosis. J. Sound Vibr. 2018, 425, 53–69. [Google Scholar] [CrossRef]

- Huang, Y.; Huang, C.; Ding, J.; Liu, Z. Fault diagnosis on railway vehicle bearing based on fast extended singular value decomposition packet. Measurement 2020, 152, 107277. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, B.; Sun, Q. Fault Diagnosis of High-speed Train Rolling Bearings Based on EWT-SVD Method. Electr. Drive Locomot. 2020, 1, 102–107. [Google Scholar]

- Yang, H.; Wu, C.; He, L.; Long, Y. Application of an Impact Feature Extracting Method Based on WATV in Fault Diagnosis of High-speed Train Bearing. Electr. Drive Locomot. 2020, 1, 108–111. [Google Scholar]

- Li, J.; Song, D.; Zhang, W.; Wang, Z.; Chen, B. Failure Diagnosis Method for Axle Box Bearing of High-speed Train Based on Morphological Component Analysis. Railw. Locomot. Car 2020, 40, 20–24. [Google Scholar]

- Liu, Q.; Zhan, Z.; Wang, S.; Liu, Y.; Fang, T. Data-driven multimodal operation monitoring and fault diagnosis of high-speed train bearings. Sci. China (Inf. Sci.) 2020, 50, 527–539. [Google Scholar]

- Huang, C.; Lin, J.; Yi, C.; Huang, Y.; Jin, H. Extended SVD packet and its application in wheelset bearing fault diagnosis of high-speed train. J. Vib. Shock. 2020, 39, 45–56. [Google Scholar]

- Zhang, K.; Luo, Y.; Zou, Y.; Wang, C.; Song, X. Sample Correlation Improvement Based High Speed Train Fault Diagnosis Method. China Mech. Eng. 2018, 29, 151–157. [Google Scholar]

- Jin, H.; Lin, J.; Wu, C.; Deng, T.; Huang, C. Diagnostic Method for High-Speed Train Bearing Fault Based on EEMD-TEO Entropy. J. Southwest Jiaotong Univ. 2018, 53, 359–366. [Google Scholar]

- Feng, B. Fault Diagnosis of Rolling Bearing of High Speed Train Based on SVD-PE. Modul. Mach. Tool Autom. Manuf. Tech. 2018, 108–110. [Google Scholar] [CrossRef]

- Shen, C.; Wang, X.; Wang, D.; Que, H.; Shi, J.; Zhu, Z. Multi-scale convolution intra-class transfer learning for train bearing fault diagnosis. J. Traffic Transp. Eng. 2020, 20, 151–164. [Google Scholar]

- Zhang, X.; Liu, Z.; Wang, L.; Zhang, J.; Han, W. Bearing fault diagnosis based on sparse representations using an improved OMP with adaptive Gabor sub-dictionaries. ISA Trans. 2020, 106, 355–366. [Google Scholar] [CrossRef]

- Li, X.; Jiang, H.; Niu, M.; Wang, R. An enhanced selective ensemble deep learning method for rolling bearing fault diagnosis with beetle antennae search algorithm. Mech. Syst. Signal Proc. 2020, 142, 106752. [Google Scholar] [CrossRef]

- Liu, S.; Jiang, H.; Wu, Z.; Li, X. Rolling bearing fault diagnosis using variational autoencoding generative adversarial networks with deep regret analysis. Measurement 2021, 168, 108371. [Google Scholar] [CrossRef]

- Xu, G.; Hou, D.; Qi, H.; Bo, L. High-speed train wheel set bearing fault diagnosis and prognostics: A new prognostic model based on extendable useful life. Mech. Syst. Signal Proc. 2021, 146, 107050. [Google Scholar] [CrossRef]

- Chen, D.; Lin, J.; Li, Y. Modified complementary ensemble empirical mode decomposition and intrinsic mode functions evaluation index for high-speed train gearbox fault diagnosis. J. Sound Vibr. 2018, 424, 192–207. [Google Scholar] [CrossRef]

- Zhang, B.; Tan, A.C.C.; Lin, J. Gearbox fault diagnosis of high-speed railway train. Eng. Fail. Anal. 2016, 66, 407–420. [Google Scholar] [CrossRef]

- Zhu, D.; Su, Y.; Sun, Q.; Long, Y. Application of BSO-MCKD in Incipient Fault Diagnosis of Gearbox Bearings of High-speed Train. Railw. Locomot. Car 2020, 40, 14–19. [Google Scholar]

- Wang, T.; Zhang, B. Application of Improved Empirical Wavelet Transform in Fault Feature Extraction of Rolling Bearings. Railw. Locomot. Car 2019, 39, 53–58. [Google Scholar]

- Long, Y.; Su, Y.; Gao, Y.; Li, Y.; He, L. Fault diagnosis of gearbox bearings of high-speed train applying adaptive TQWT. China Meas. Test. Technol. 2019, 45, 108–113. [Google Scholar]

- Zhu, D.; Su, Y.; Yan, C. Fault Diagnosis of Gearbox Bearings of High-speed Train Based on the SVD-MOMEDA. Electr. Drive Locomot. 2020, 144–148. [Google Scholar] [CrossRef]

- Peng, D.; Liu, Z.; Jin, Y.; Qin, Y. Improved EMD with a Soft Sifting Stopping Criterion and Its Application to Fault Diagnosis of Rotating Machinery. J. Mech. Eng. 2019, 55, 122–132. [Google Scholar] [CrossRef]

- Li, C.; Lin, J.; Hu, Y. Application of Optimization Parameters VMD and MED in Fault Diagnosis of Train Gearbox Rolling Bearings. Electr. Drive Locomot. 2020, 142–147. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, B.; Tan, A.C. Acceleration signal with DTCWPT and novel optimize SNR index for diagnosis of misaligned cardan shaft in high-speed train. Mech. Syst. Signal Proc. 2020, 140, 106723. [Google Scholar] [CrossRef]

- Ding, J.; Lin, J.; Yu, S. Dynamic unbalance detection of Cardan shaft in high-speed train applying double decomposition and double reconstruction method. Measurement 2015, 73, 111–120. [Google Scholar] [CrossRef]

- Li, Y.; Liu, W.; Lin, J. A morphology filter method for high speed train cardan shaft unbalance fault detection. J. Vib. Eng. 2018, 31, 176–182. [Google Scholar]

- Zhang, Y.; Qin, N.; Huang, D.; Liang, K. Fault Diagnosis of High-speed Train Bogie Based on Deep Neural Network. IFAC-PapersOnLine 2019, 52, 135–139. [Google Scholar] [CrossRef]

- Dumitriu, M.; Gheţi, M.A. Cross-Correlation Analysis of the Vertical Accelerations of Railway Vehicle Bogie. Procedia Manuf. 2019, 32, 114–120. [Google Scholar] [CrossRef]

- Gou, X.; Li, C.; Jin, W. Fault Diagnosis Method for High-Speed Train Lateral Damper Based on Variational Mode Decomposition and Multiscale Entropy. J. Vib. Meas. Diagn. 2019, 39, 292–297. [Google Scholar]

- Qin, N.; Wang, K.; Jin, W.; Huang, J.; Sun, Y. Fault feature analysis of high-speed train bogie based on empirical mode decomposition entropy. J. Traffic Transp. Eng. 2014, 14, 57–64. [Google Scholar]

- Qin, N.; Jin, W.; Huang, J.; Gou, X.; Jiang, P. Wavelet entropy used in feature analysis of high speed train bogie fault signal. Appl. Res. Comput. 2013, 30, 3657–3659. [Google Scholar]

- Guo, C.; Yang, Y.; Jin, W. Fault Analysis of High Speed Train Based on EDBN-SVM. Comput. Sci. 2016, 43, 281–286. [Google Scholar]

- Qin, N.; Jiang, P.; Sun, Y.; Jin, W. Fault Diagnosis of High Speed Train Bogie Based on EEMD and Permutation Entropy. J. Vib. Meas. Diagn. 2015, 35, 885–891. [Google Scholar]

- He, D.; Chen, E.; Li, X.; Liu, Q. Research on fault diagnosis method of high-speed train running gear rolling bearing based on RS and LSSVM. J. Guangxi Univ. (Nat. Sci. Ed.) 2017, 42, 403–408. [Google Scholar]

- Shi, G.; Li, X.; Jin, W.; Gou, X. Fault analysis of high-speed train bogie based on permutation entropy. Appl. Res. Comput. 2014, 31, 3625–3627. [Google Scholar]

- Li, H.; Jin, W. Lateral damper fault diagnosis of high-speed train based on statistical characteristics of white noise and EEMD. Appl. Res. Comput. 2016, 33, 2648–2651. [Google Scholar]

- Wu, Y.; Jin, W.; Huang, Y. Fault Diagnosis of High Speed Train Bogie Based on Multi-domain Fusion CNN. J. Syst. Simul. 2018, 30, 4492–4497. [Google Scholar]

- Zhu, Z.; Wu, S.; Fu, K. Characteristic Analysis of High-Speed Train Vibration Based on Entropy Feature. J. Vib. Meas. Diagn. 2015, 35, 381–387. [Google Scholar]

- Liu, H.; Meng, Q.; Zhao, Y.; Luo, J. Dual Tree Complex Wavelet Based Fault Characteristic Analysis for High-speed Trains. Control Eng. China 2018, 25, 1386–1392. [Google Scholar]

- Zhao, Y.; Tan, X. Applications of Feature Matrix Construction Method in Fault Diagnoise of High-speed Train. Comput. Eng. 2017, 43, 21–25. [Google Scholar]

- Ye, Y.; Zhang, Y.; Wang, Q.; Wang, Z.; Teng, Z.; Zhang, H. Fault diagnosis of high-speed train suspension systems using multiscale permutation entropy and linear local tangent space alignment. Mech. Syst. Signal Proc. 2020, 138, 106565. [Google Scholar] [CrossRef]

- Wu, Y.; Jiang, B.; Lu, N.; Zhou, D. ToMFIR-based incipient fault detection and estimation for high-speed rail vehicle suspension system. J. Frankl. Inst. 2015, 352, 1672–1692. [Google Scholar] [CrossRef]

- Kaiser, I.; Strano, S.; Terzo, M.; Tordela, C. Anti-yaw damping monitoring of railway secondary suspension through a nonlinear constrained approach integrated with a randomly variable wheel-rail interaction. Mech. Syst. Signal Proc. 2021, 146, 107040. [Google Scholar] [CrossRef]

- Zoljic-Beglerovic, S.; Stettinger, G.; Luber, B.; Horn, M. Railway Suspension System Fault Diagnosis using Cubature Kalman Filter Techniques. IFAC-PapersOnLine 2018, 51, 1330–1335. [Google Scholar] [CrossRef]

- Aravanis, T.C.I.; Sakellariou, J.S.; Fassois, S.D. A stochastic Functional Model based method for random vibration based robust fault detection under variable non–measurable operating conditions with application to railway vehicle suspensions. J. Sound Vibr. 2020, 466, 115006. [Google Scholar] [CrossRef]

- Skarlatos, D.; Karakasis, K.; Trochidis, A. Railway wheel fault diagnosis using a fuzzy-logic method. Appl. Acoust. 2004, 65, 951–966. [Google Scholar] [CrossRef]

- Wang, Y.W.; Ni, Y.Q.; Wang, X. Real-time defect detection of high-speed train wheels by using Bayesian forecasting and dynamic model. Mech. Syst. Signal Proc. 2020, 139, 106654. [Google Scholar] [CrossRef]

- Chi, Z.; Lin, J.; Chen, R.; Huang, S. Data-driven approach to study the polygonization of high-speed railway train wheel-sets using field data of China’s HSR train. Measurement 2020, 149, 107022. [Google Scholar] [CrossRef]

- Li, Y.; Zuo, M.J.; Lin, J.; Liu, J. Fault detection method for railway wheel flat using an adaptive multiscale morphological filter. Mech. Syst. Signal Proc. 2017, 84, 642–658. [Google Scholar] [CrossRef]

- Zeng, Y.; Song, D.; Zhang, W.; Zhou, B.; Xie, M.; Tang, X. A new physics-based data-driven guideline for wear modelling and prediction of train wheels. Wear 2020, 456–457, 203355. [Google Scholar] [CrossRef]

- Chellaswamy, C.; Krishnasamy, M.; Balaji, L.; Dhanalakshmi, A.; Ramesh, R. Optimized railway track health monitoring system based on dynamic differential evolution algorithm. Measurement 2020, 152, 107332. [Google Scholar] [CrossRef]

- Liang, B.; Iwnicki, S.; Ball, A.; Young, A.E. Adaptive noise cancelling and time–frequency techniques for rail surface defect detection. Mech. Syst. Signal Proc. 2015, 54–55, 41–51. [Google Scholar] [CrossRef]

- Ward, C.P.; Goodall, R.M.; Dixon, R. Contact Force Estimation in the Railway Vehicle Wheel-Rail Interface. IFAC Proc. Vol. 2011, 44, 4398–4403. [Google Scholar] [CrossRef]

- Lingamanaik, S.N.; Thompson, C.; Nadarajah, N.; Ravitharan, R.; Widyastuti, H.; Chiu, W.K. Using Instrumented Revenue Vehicles to Inspect Track Integrity and Rolling Stock Performance in a Passenger Network during Peak Times. Procedia Eng. 2017, 188, 424–431. [Google Scholar] [CrossRef]

- Zhou, Y.; Lin, L.; Wang, D.; He, M.; He, D. A new method to classify railway vehicle axle fatigue crack AE signal. Appl. Acoust. 2018, 131, 174–185. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, B.; Lu, N.; Chen, W. Real-time incipient fault detection for electrical traction systems of CRH2. Neurocomputing 2018, 306, 119–129. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, B.; Lu, N.; Cocquempot, V. Accurate Prediction of RUL under Uncertainty Conditions: Application to the Traction System of a High-speed Train. IFAC-PapersOnLine 2018, 51, 401–406. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, K.; Jiang, B.; Yan, X. Interval observer and unknown input observer-based sensor fault estimation for high-speed railway traction motor. J. Frankl. Inst. 2020, 357, 1137–1154. [Google Scholar] [CrossRef]

- Wu, Y.; Jiang, B.; Lu, N.; Yang, H.; Zhou, Y. Multiple incipient sensor faults diagnosis with application to high-speed railway traction devices. ISA Trans. 2017, 67, 183–192. [Google Scholar] [CrossRef]

- Fei, M.; Ning, L.; Huiyu, M.; Yi, P.; Haoyuan, S.; Jianyong, Z. On-line fault diagnosis model for locomotive traction inverter based on wavelet transform and support vector machine. Microelectron. Reliab. 2018, 88–90, 1274–1280. [Google Scholar] [CrossRef]

- Yang, C.; Peng, T.; Yang, C.; Chen, Z.; Gui, W. Fault Testing and Validation Simulation Platform for Traction Drive System of High-speed Trains. Acta Autom. Sin. 2019, 45, 2218–2232. [Google Scholar]

- Jiang, B.; Chen, H.; Yi, H.; Lu, N. Data-driven fault diagnosis for dynamic traction systems in high-speed trains. Sci. China (Inf. Sci.) 2020, 50, 496–510. [Google Scholar]

- Zhang, K.; Jiang, B.; Chen, F.; An, C.; Ren, F. Time-varying model identified based coupled fault diagnosis for high speed trains. Control Decis. 2019, 34, 274–278. [Google Scholar]

- Tao, T.; Xu, H. Immersion and invariance fault-tolerant control for a class high-speed trains. J. Jilin Univ. (Eng. Technol. Ed.) 2015, 45, 554–561. [Google Scholar]

- Ji, H.; Zhou, D. Incipient fault detection of the high-speed train air brake system with a combined index. Control Eng. Pract. 2020, 100, 104425. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Zio, E. A SVM framework for fault detection of the braking system in a high speed train. Mech. Syst. Signal Proc. 2017, 87, 401–409. [Google Scholar] [CrossRef]

- Sang, J.; Zhang, J.; Guo, T.; Zhou, D.; Chen, M.; Tai, X. Detection of incipient faults in EMU braking system based on data domain description and variable control limit. Neurocomputing 2020, 383, 348–358. [Google Scholar] [CrossRef]

- Guo, T.; Tai, X.; Chen, M.; Zhou, D. A Convex Hull Vertices-Based Fault Diagnosis Algorithm for EMU Braking System. Control Eng. China 2019, 26, 1011–1014. [Google Scholar]

- Wu, Y.; Jiang, B.; Wang, Y. Incipient winding fault detection and diagnosis for squirrel-cage induction motors equipped on CRH trains. ISA Trans. 2020, 99, 488–495. [Google Scholar] [CrossRef]

- Bai, W.; Dong, H.; Yao, X.; Ning, B. Robust fault detection for the dynamics of high-speed train with multi-source finite frequency interference. ISA Trans. 2018, 75, 76–87. [Google Scholar] [CrossRef]

- Yang, C.; Liu, Z.; Liu, K.; Zhong, J.; Han, Z. A Loose Default Diagnosis Method for Oblique Bracing Wire in High-Speed Railway. IFAC-PapersOnLine 2019, 52, 18–23. [Google Scholar] [CrossRef]

- Yao, Z.; He, D.; Chen, Y.; Liu, B.; Miao, J.; Deng, J.; Shan, S. Inspection of exterior substance on high-speed train bottom based on improved deep learning method. Measurement 2020, 163, 108013. [Google Scholar] [CrossRef]

- Han, Y.; Liu, Z.; Lyu, Y.; Liu, K.; Li, C.; Zhang, W. Deep learning-based visual ensemble method for high-speed railway catenary clevis fracture detection. Neurocomputing 2020, 396, 556–568. [Google Scholar] [CrossRef]

- Liu, C.; Yang, S.; Cui, Y.; Yang, Y. An improved risk assessment method based on a comprehensive weighting algorithm in railway signaling safety analysis. Saf. Sci. 2020, 128, 104768. [Google Scholar] [CrossRef]

- Oukhellou, L.; Debiolles, A.; Denœux, T.; Aknin, P. Fault diagnosis in railway track circuits using Dempster–Shafer classifier fusion. Eng. Appl. Artif. Intell. 2010, 23, 117–128. [Google Scholar] [CrossRef]

- Liu, J.; Li, Q.; Chen, W.; Cao, T. A discrete hidden Markov model fault diagnosis strategy based on K-means clustering dedicated to PEM fuel cell systems of tramways. Int. J. Hydrogen Energy 2018, 43, 12428–12441. [Google Scholar] [CrossRef]

- Xu, Q.; Zhang, P.; Liu, W.; Liu, Q.; Liu, C.; Wang, L.; Toprac, A.; Joe Qin, S. A Platform for Fault Diagnosis of High-Speed Train based on Big Data. IFAC-PapersOnLine 2018, 51, 309–314. [Google Scholar] [CrossRef]

- Niu, G.; Xiong, L.; Qin, X.; Pecht, M. Fault detection isolation and diagnosis of multi-axle speed sensors for high-speed trains. Mech. Syst. Signal Proc. 2019, 131, 183–198. [Google Scholar] [CrossRef]

- Cai, G.; Zhao, J.; Song, Q.; Zhou, M. System architecture of a train sensor network for automatic train safety monitoring. Comput. Ind. Eng. 2019, 127, 1183–1192. [Google Scholar] [CrossRef]

- Huang, P.; Wen, C.; Fu, L.; Peng, Q.; Li, Z. A hybrid model to improve the train running time prediction ability during high-speed railway disruptions. Saf. Sci. 2020, 122, 104510. [Google Scholar] [CrossRef]

- Yin, J.; Zhao, W. Fault diagnosis network design for vehicle on-board equipments of high-speed railway: A deep learning approach. Eng. Appl. Artif. Intell. 2016, 56, 250–259. [Google Scholar] [CrossRef]

- Liu, P.; Yang, L.; Gao, Z.; Li, S.; Gao, Y. Fault tree analysis combined with quantitative analysis for high-speed railway accidents. Saf. Sci. 2015, 79, 344–357. [Google Scholar] [CrossRef]

- Huang, W.; Liu, Y.; Zhang, Y.; Zhang, R.; Xu, M.; De Dieu, G.J.; Antwi, E.; Shuai, B. Fault Tree and Fuzzy D-S Evidential Reasoning combined approach: An application in railway dangerous goods transportation system accident analysis. Inf. Sci. 2020, 520, 117–129. [Google Scholar] [CrossRef]

- Zhou, Y.; Tao, X.; Yu, Z.; Fujita, H. Train-movement situation recognition for safety justification using moving-horizon TBM-based multisensor data fusion. Knowl. Based Syst. 2019, 177, 117–126. [Google Scholar] [CrossRef]

| Methods | Key Systems |

|---|---|

| Empirical modal decomposition | Bogie system (bearing, gear, suspension system, wheel), etc. |

| Variational modal decomposition | Bogie system (bearing, gear, suspension system), etc. |

| Wavelet transform | Bogie system (bearing, gear, cardan shaft), traction system, etc. |

| Singular value decomposition | Bogie system (bearing, gear, cardan shaft, suspension system), etc. |

| Kalman filter | Bogie system (suspension system), information control system, etc. |

| Support vector machine | Bogie system (bearing, suspension system, wheel), traction system, braking system, etc. |

| Principal component analysis | Bogie system (bearing, wheel), information control system, etc. |

| Morphological filter | Bogie system (bearing, cardan shaft, wheel), |

| Convolutional neural network | information control system, etc. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, S.; Tan, H.; Yang, C.; Yan, H. A Review of Fault Diagnosis Methods for Key Systems of the High-Speed Train. Appl. Sci. 2023, 13, 4790. https://doi.org/10.3390/app13084790

Xie S, Tan H, Yang C, Yan H. A Review of Fault Diagnosis Methods for Key Systems of the High-Speed Train. Applied Sciences. 2023; 13(8):4790. https://doi.org/10.3390/app13084790

Chicago/Turabian StyleXie, Suchao, Hongchuang Tan, Chengxing Yang, and Hongyu Yan. 2023. "A Review of Fault Diagnosis Methods for Key Systems of the High-Speed Train" Applied Sciences 13, no. 8: 4790. https://doi.org/10.3390/app13084790

APA StyleXie, S., Tan, H., Yang, C., & Yan, H. (2023). A Review of Fault Diagnosis Methods for Key Systems of the High-Speed Train. Applied Sciences, 13(8), 4790. https://doi.org/10.3390/app13084790