Damping Ratio of Sand Containing Fine Particles in Cyclic Triaxial Liquefaction Tests

Abstract

1. Introduction

2. Materials and Methods

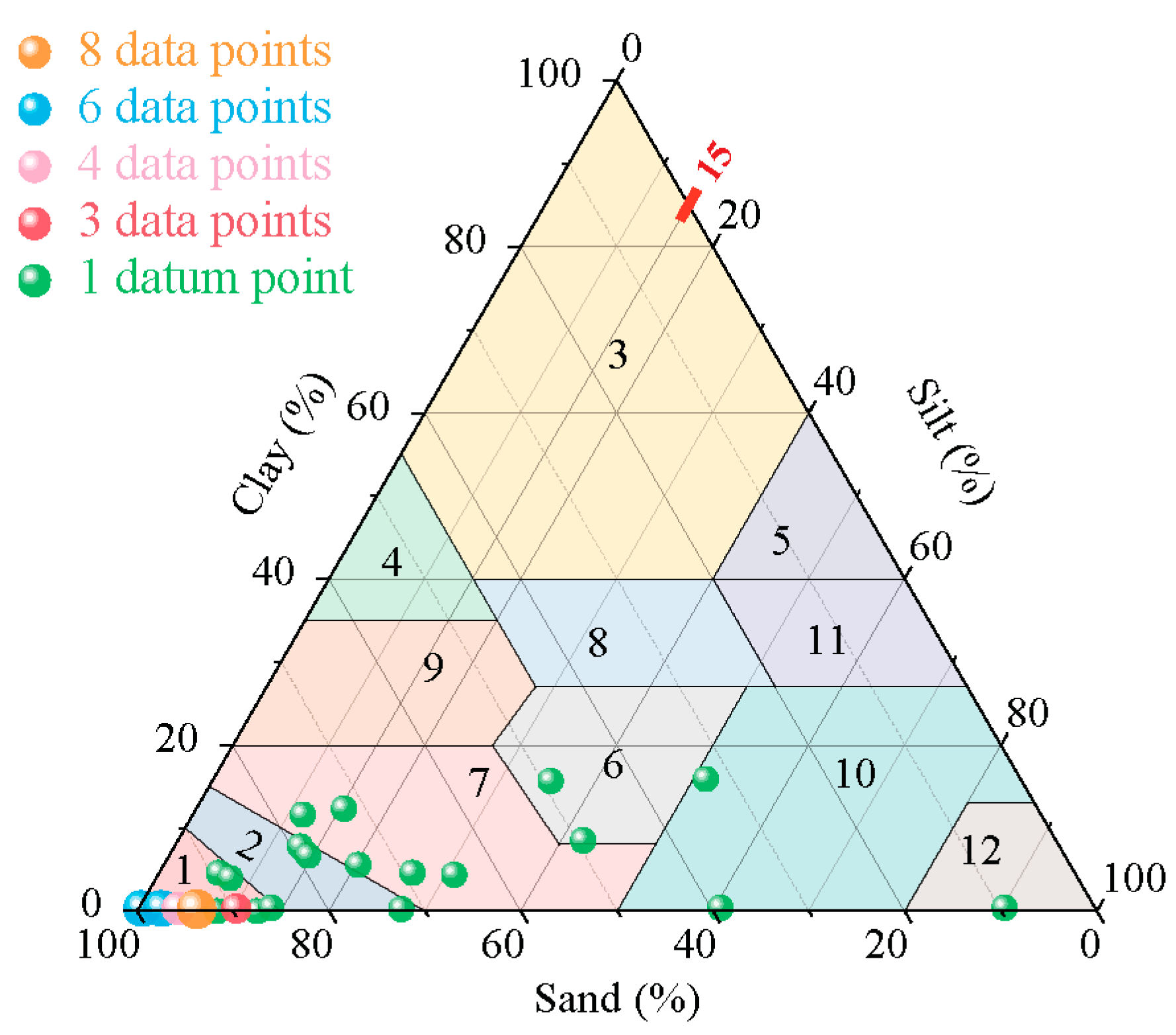

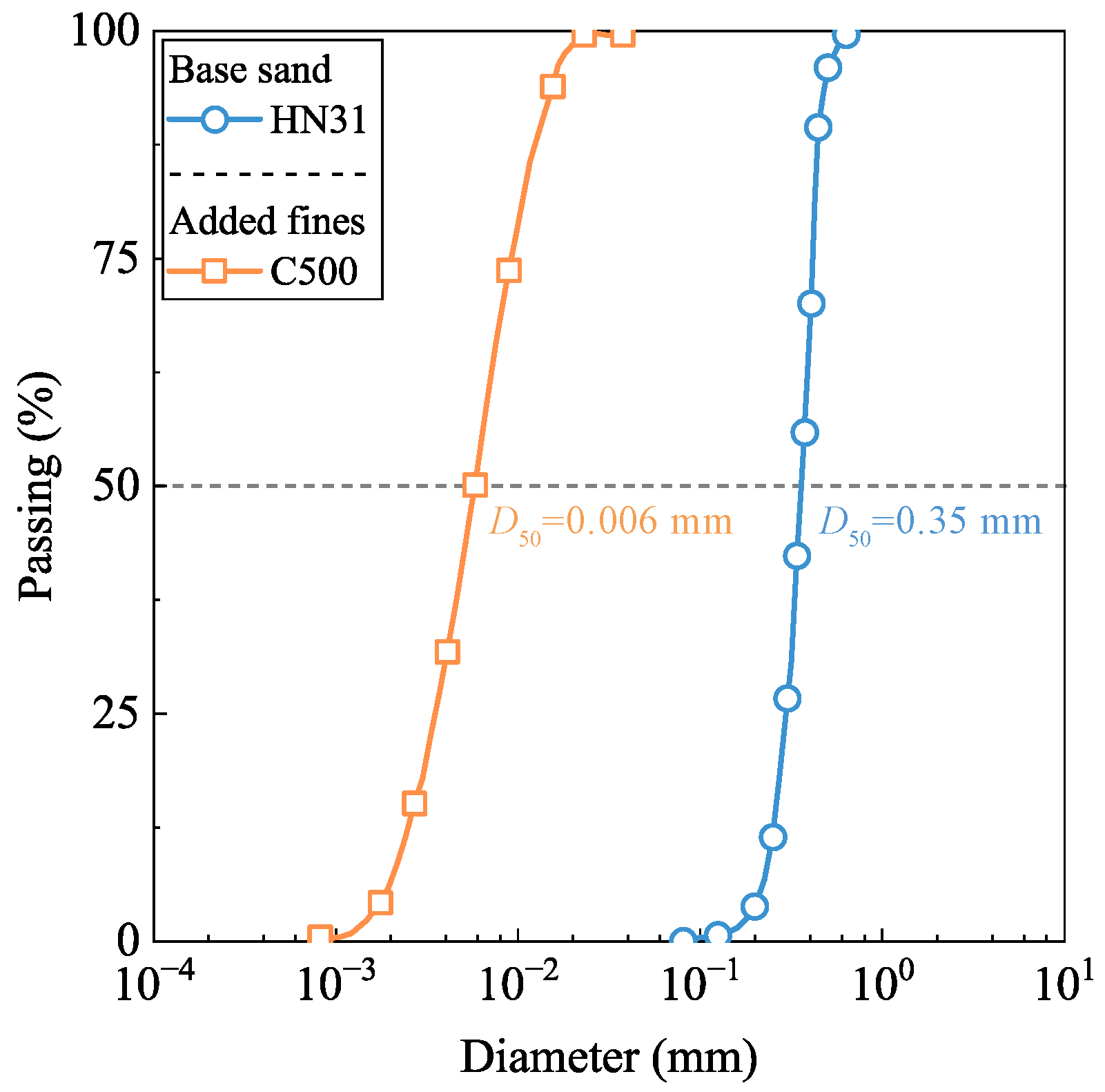

2.1. Physical Properties of Test Materials

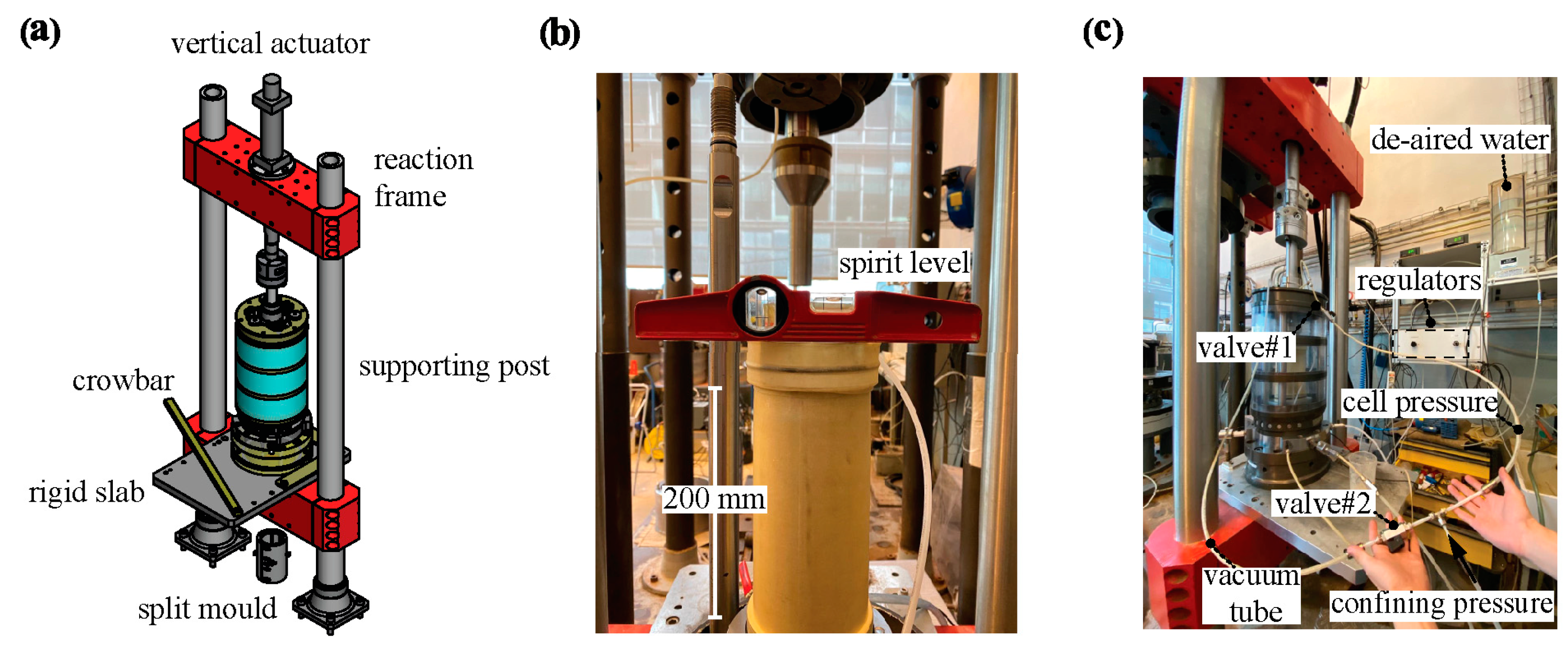

2.2. Experimental Programme

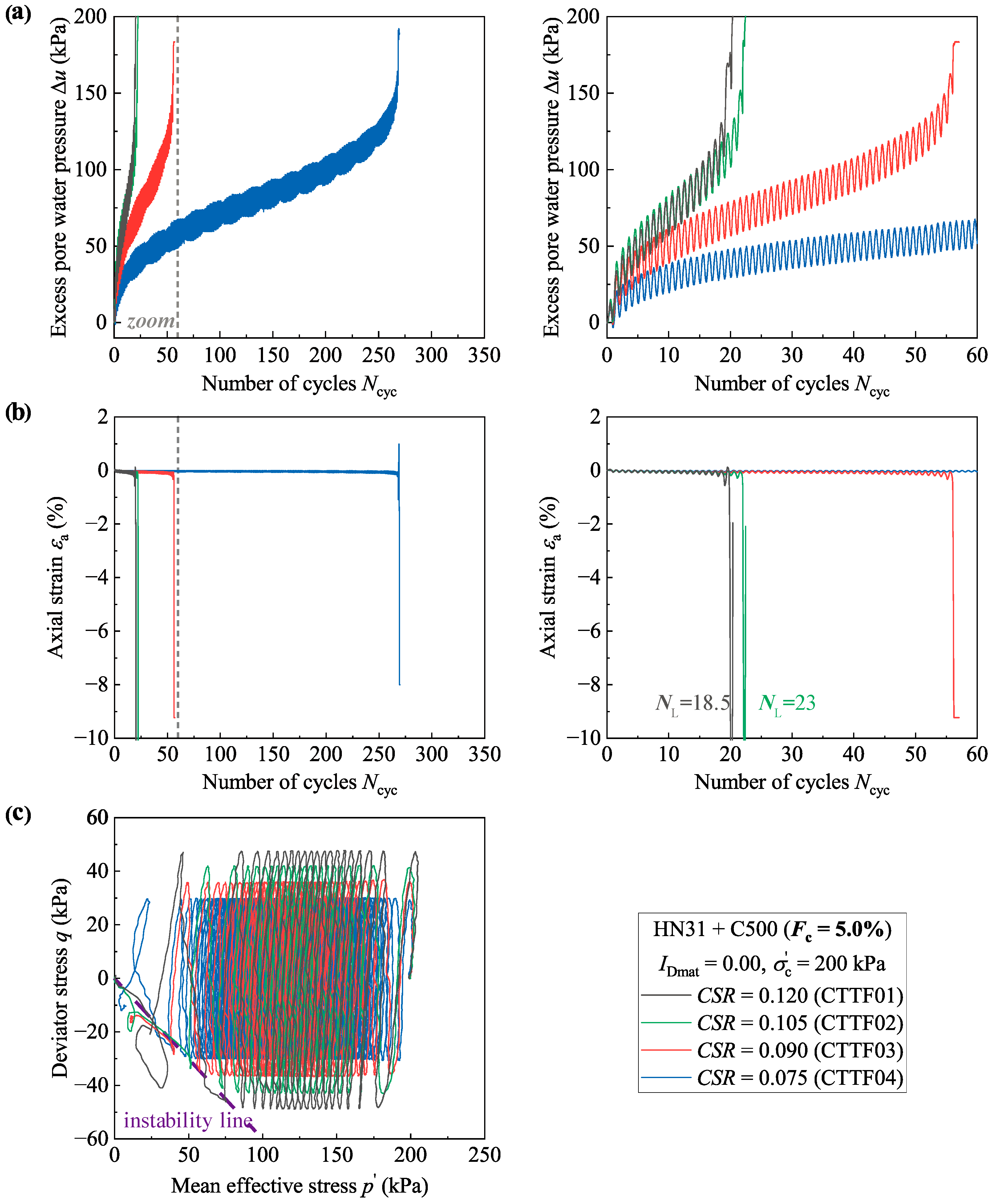

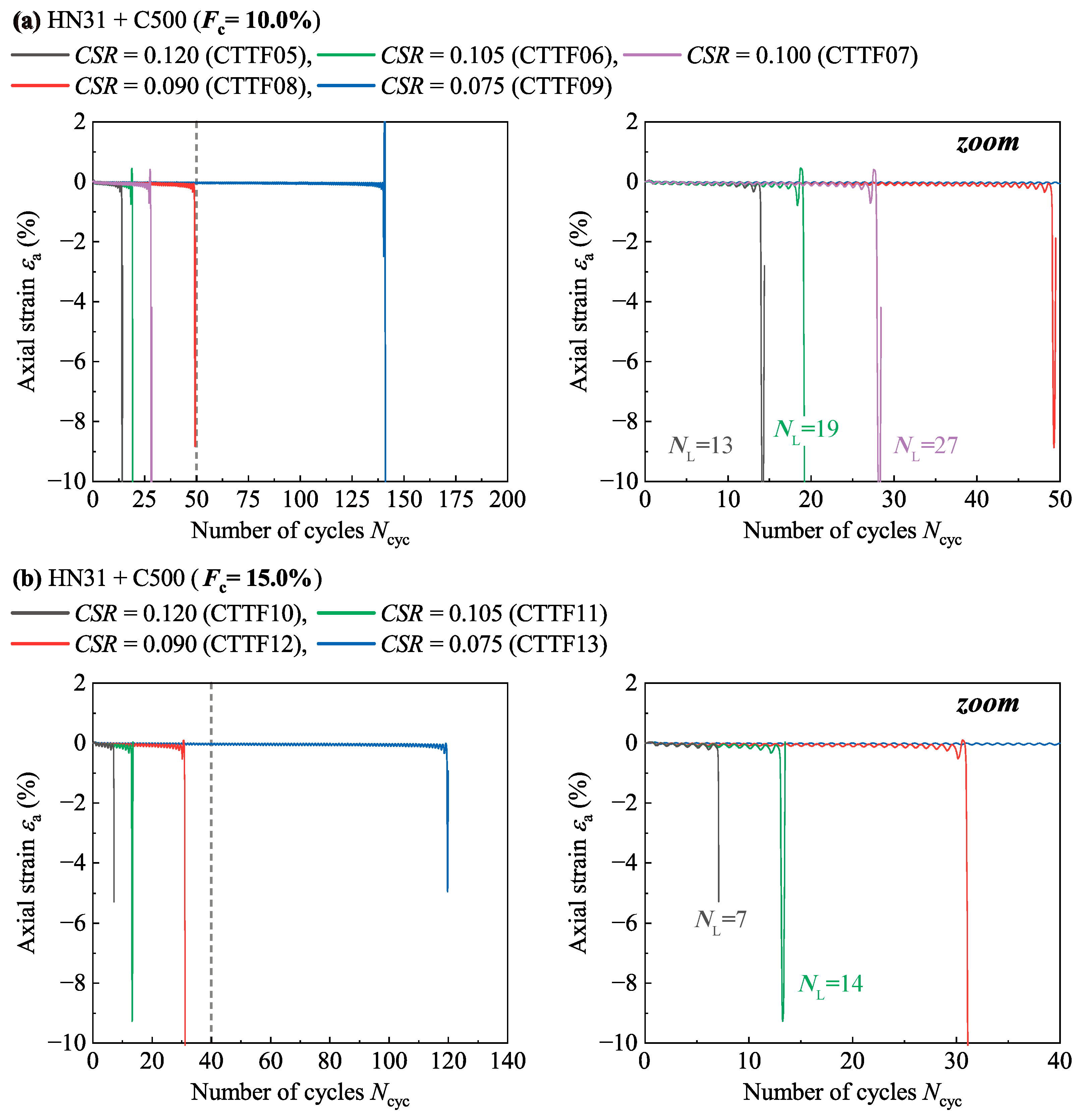

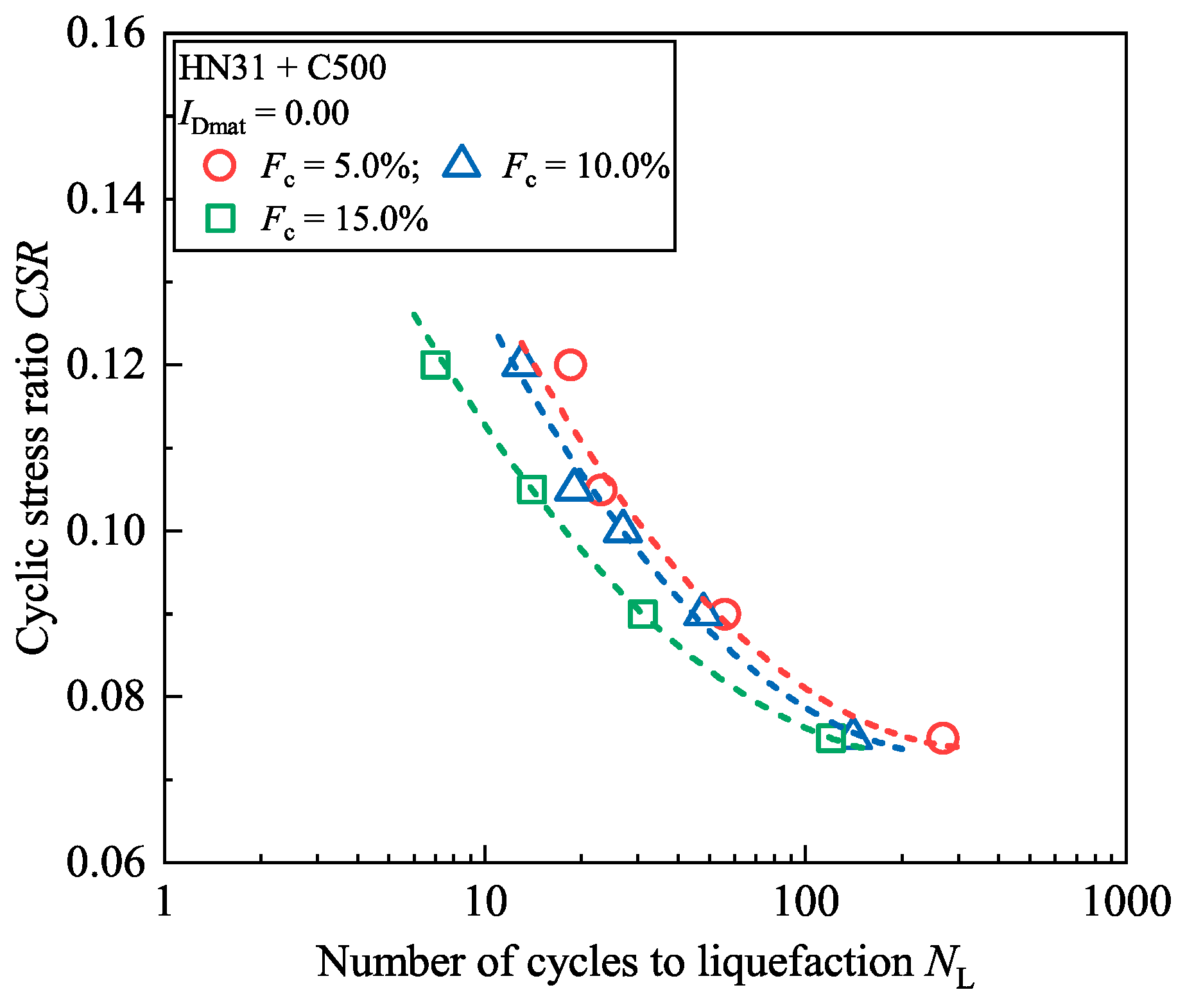

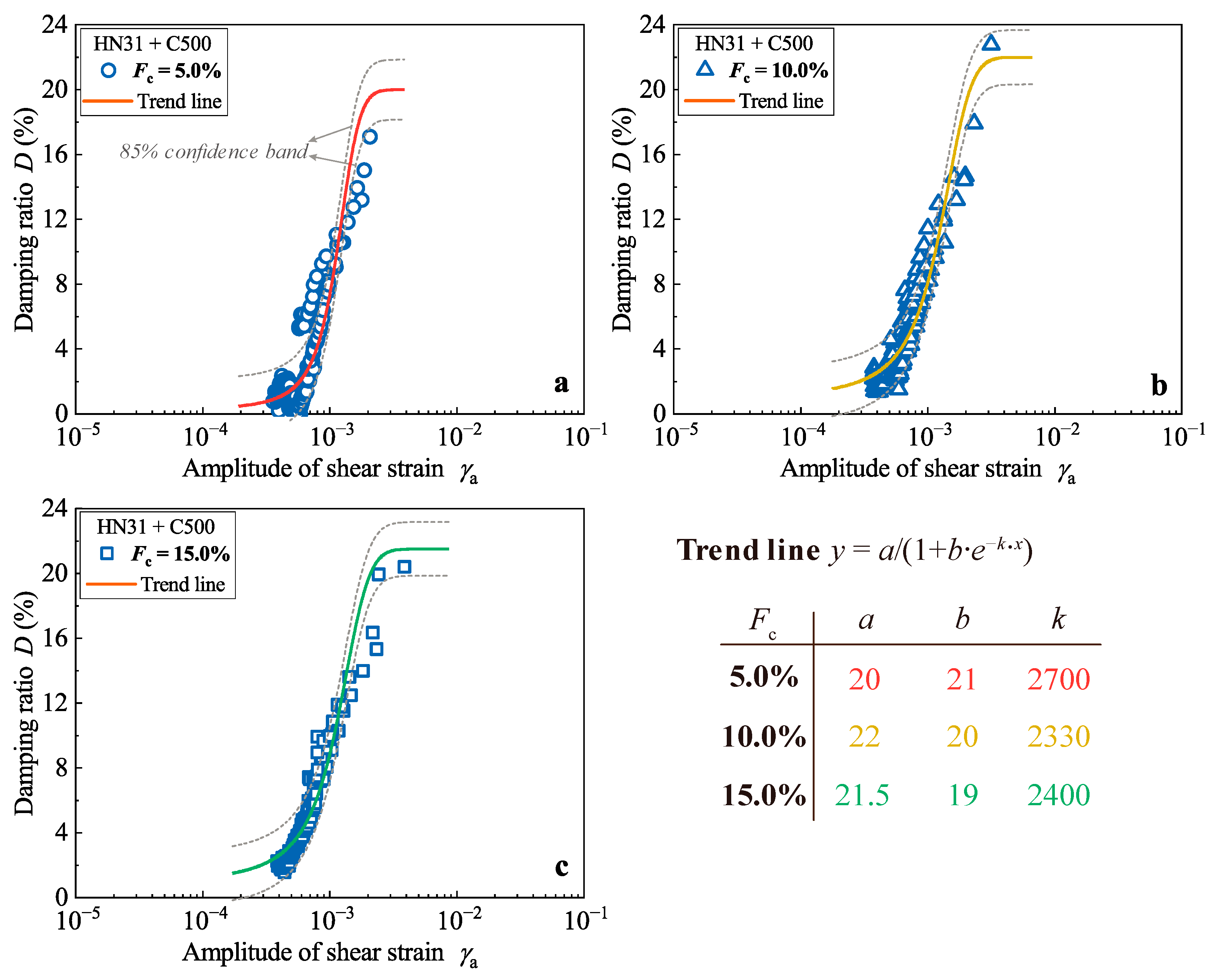

3. Results

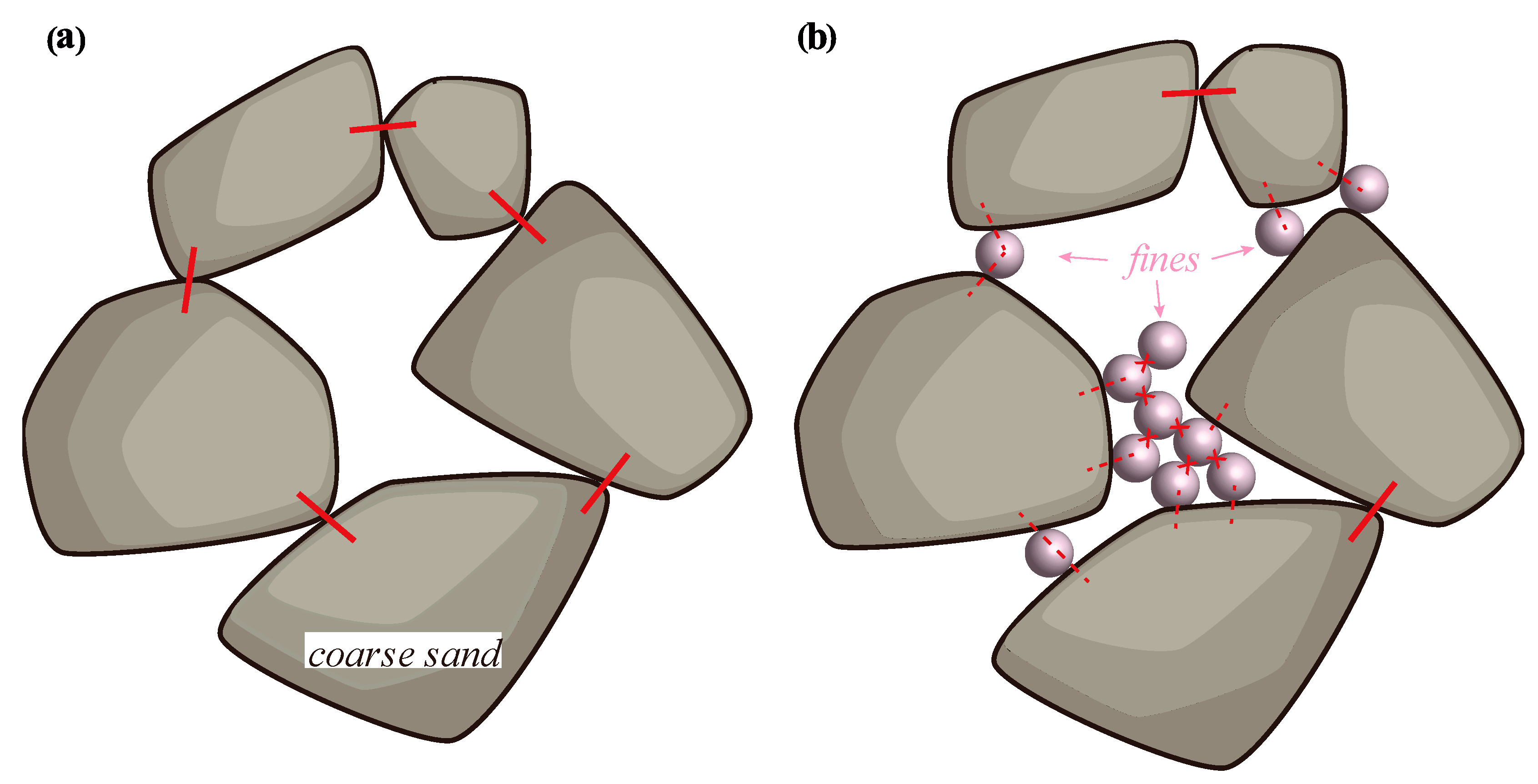

4. Discussion

5. Conclusions

- For test specimens containing fine particles reconstituted with the dry tamping method, the addition of fines provides a negative contribution to the global soil structure; consequently, the liquefaction potential rises significantly. From the microscopic viewpoint, this weakening effect can be attributed to the fact that the presence of fine particles can possibly break a part of strong force chains which bear the main external loading.

- Although the liquefaction potential is indeed affected by the presence of fine particles, the evolution of the damping ratio remains shear strain-dependent, regardless of the fines contents. This is due to the similar positive influence of fine particles on the relative sliding between coarse sand grains during both the loading and unloading stages. Thus, the damping ratio manifests itself invariant on the macroscopic scale in triaxial tests.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kameda, J.; Kamiya, H.; Masumoto, H.; Morisaki, T.; Hiratsuka, T.; Inaoi, C. Fluidized Landslides Triggered by the Liquefaction of Subsurface Volcanic Deposits during the 2018 Iburi–Tobu Earthquake, Hokkaido. Sci. Rep. 2019, 9, 13119. [Google Scholar] [CrossRef]

- Hong, Y.; Ling, X.; He, K. Effects of Sliding Liquefaction on Homogeneous Loess Landslides in Western China. Sci. Rep. 2021, 11, 11941. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Tian, Z.; Bo, J.; Zhu, S.; Li, Y. Study on Sand Liquefaction Induced by Songyuan Earthquake with a Magnitude of M5.7 in China. Sci. Rep. 2022, 12, 9588. [Google Scholar] [CrossRef] [PubMed]

- Tsukamoto, Y.; Ishihara, K. Advances in Soil Liquefaction Engineering; Springer: Berlin, Germany, 2022. [Google Scholar]

- Ohsaki, Y. Effects of Sand Compaction on Liquefaction during the Tokachioki Earthquake. Soils Found. 1970, 10, 112–128. [Google Scholar] [CrossRef]

- Tokimatsu, K.; Yoshimi, Y. Empirical Correlation of Soil Liquefaction Based on SPT N-Value and Fines Content. Soils Found. 1983, 23, 56–74. [Google Scholar] [CrossRef] [PubMed]

- Jradi, L.; El Dine, B.S.; Dupla, J.C.; Canou, J. Influence of Low Fines Content on the Liquefaction Resistance of Sands. Eur. J. Environ. Civ. Eng. 2022, 26, 6012–6031. [Google Scholar] [CrossRef]

- Yang, J.; Wei, L.M. Collapse of Loose Sand with the Addition of Fines: The Role of Particle Shape. Geotechnique 2012, 62, 1111–1125. [Google Scholar] [CrossRef]

- Monkul, M.M.; Etminan, E.; Şenol, A. Influence of Coefficient of Uniformity and Base Sand Gradation on Static Liquefaction of Loose Sands with Silt. Soil Dyn. Earthq. Eng. 2016, 89, 185–197. [Google Scholar] [CrossRef]

- Xenaki, V.C.; Athanasopoulos, G.A. Liquefaction Resistance of Sand-Silt Mixtures: An Experimental Investigation of the Effect of Fines. Soil Dyn. Earthq. Eng. 2003, 23, 1–12. [Google Scholar] [CrossRef]

- Jain, A.; Mittal, S.; Shukla, S.K. Liquefaction Proneness of Stratified Sand-Silt Layers Based on Cyclic Triaxial Tests. J. Rock Mech. Geotech. Eng. 2022. [Google Scholar] [CrossRef]

- Benahmed, N.; Canou, J.; Dupla, J.C. Initial Structure and Static Liquefaction Properties of Sand. C. R. Mec. 2004, 332, 887–894. [Google Scholar] [CrossRef]

- Monkul, M.M.; Etminan, E.; Şenol, A. Coupled Influence of Content, Gradation and Shape Characteristics of Silts on Static Liquefaction of Loose Silty Sands. Soil Dyn. Earthq. Eng. 2017, 101, 12–26. [Google Scholar] [CrossRef]

- Kramer, S.L. Geotechnical Earthquake Engineering; Pearson Education: Chennai, India, 1996; ISBN 8131707180. [Google Scholar]

- Ishihara, K. Soil Behaviour in Earthquake Geotechnics; Clarendon Press: Oxford, UK, 1996. [Google Scholar]

- Sitharam, T.G.; Govindaraju, L.; Srinivasa Murthy, B.R. Evaluation of Liquefaction Potential and Dynamic Properties of Silty Sand Using Cyclic Triaxial Testing. Geotech. Test. J. 2004, 27, 423–429. [Google Scholar]

- Zhu, Z.; Zhang, F.; Dupla, J.C.; Canou, J.; Foerster, E. Investigation on the Undrained Shear Strength of Loose Sand with Added Materials at Various Mean Diameter Ratios. Soil Dyn. Earthq. Eng. 2020, 137, 106276. [Google Scholar] [CrossRef]

- Shengcong, F.; Tatsuoka, F. Soil Liquefaction during Haicheng and Tangshan Earthquake in China: A Review. Soils Found. 1984, 24, 11–29. [Google Scholar] [CrossRef]

- Benahmed, N.; Nguyen, T.K.; Hicher, P.Y.; Nicolas, M. An Experimental Investigation into the Effects of Low Plastic Fines Content on the Behaviour of Sand/Silt Mixtures. Eur. J. Environ. Civ. Eng. 2015, 19, 109–128. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, F.; Peng, Q.; Dupla, J.C.; Canou, J.; Cumunel, G.; Foerster, E. Assessment of the Loading Waveform on the Cyclic Liquefaction Resistance with Hostun 31 Sand. Soil Dyn. Earthq. Eng. 2021, 150, 106919. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, F.; Peng, Q.; Chabot, B.; Dupla, J.C.; Canou, J.; Cumunel, G.; Foerster, E. Development of an Auto Compensation System in Cyclic Triaxial Apparatus for Liquefaction Analysis. Soil Dyn. Earthq. Eng. 2021, 144, 106707. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, F.; Dupla, J.C.; Canou, J.; Foerster, E.; Peng, Q. Assessment of Tamping-Based Specimen Preparation Methods on Static Liquefaction of Loose Silty Sand. Soil Dyn. Earthq. Eng. 2021, 143, 106592. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, F.; Peng, Q.; Dupla, J.C.; Canou, J.; Cumunel, G.; Foerster, E. Effect of the Loading Frequency on the Sand Liquefaction Behaviour in Cyclic Triaxial Tests. Soil Dyn. Earthq. Eng. 2021, 147, 106779. [Google Scholar] [CrossRef]

- Nong, Z.; Park, S.S.; Jeong, S.W.; Lee, D.E. Effect of Cyclic Loading Frequency on Liquefaction Prediction of Sand. Appl. Sci. 2020, 10, 4502. [Google Scholar] [CrossRef]

- Lade, P.V. Static Instability and Liquefaction of Loose Fine Sandy Slopes. J. Geotech. Eng. 1992, 118, 51–71. [Google Scholar] [CrossRef]

- Zhu, Z. Influence of Fine Particles on the Liquefaction Properties of a Reference Sand Application to the Seismic Response of a Sand Column on a Vibrating Table; Springer Nature: Berlin, Germany, 2023. [Google Scholar]

- Polito, C. The Effects of Non-Plastic and Plastic Fines on the Liquefaction Of Sandy Soils; Verginia Polytechnic Institute and State University: Berlin, Germany, 1999. [Google Scholar]

- Belkhatir, M.; Arab, A.; Della, N.; Missoum, H.; Schanz, T. Liquefaction Resistance of Chlef River Silty Sand: Effect of Low Plastic Fines and Other Parameters. Acta Polytech. Hung. 2010, 7, 119–137. [Google Scholar]

- Stamatopoulos, C.A. An Experimental Study of the Liquefaction Strength of Silty Sands in Terms of the State Parameter. Soil Dyn. Earthq. Eng. 2010, 30, 662–678. [Google Scholar] [CrossRef]

- Oda, M. Initial Fabrics and Their Relations to Mechanical Properties of Granular Material. Soils Found. 1972, 12, 17–36. [Google Scholar] [CrossRef]

- Yang, Z.X.; Li, X.S.; Yang, J. Quantifying and Modelling Fabric Anisotropy of Granular Soils. Geotechnique 2008, 58, 237–248. [Google Scholar] [CrossRef]

- Kokusho, T. Cyclic Triaxial Test of Dynamic Soil Properties for Wide Strain Range. Soils Found. 1980, 20, 45–60. [Google Scholar] [CrossRef]

- Ye, B.; Lu, J.; Ye, G. Pre-Shear Effect on Liquefaction Resistance of a Fujian Sand. Soil Dyn. Earthq. Eng. 2015, 77, 15–23. [Google Scholar] [CrossRef]

- Ni, X.; Ye, B.; Zhang, F.; Feng, X. Influence of Specimen Preparation on the Liquefaction Behaviors of Sand and Its Mesoscopic Explanation. J. Geotech. Geoenviron. Eng. 2021, 147, 1–14. [Google Scholar] [CrossRef]

- Ni, X.; Zhang, Z.; Ye, B.; Zhang, S. Influence of Anisotropy on Liquefaction / Reliquefaction Resistance of Granular Materials and Its Quantitative Evaluation. Soil Dyn. Earthq. Eng. 2022, 161, 107415. [Google Scholar] [CrossRef]

- Ni, X.; Ye, B.; Zhang, Z.; Zhang, S.; Zhang, F. An Investigation of the Influence of Reconsolidation Properties on the Reliquefaction Resistance of Sand by Element Tests. J. Geotech. Geoenviron. Eng. 2022, 148, 1–11. [Google Scholar] [CrossRef]

- Wang, H.; Cui, Y.J.; Zhang, F.; Liu, J. Effect of Grain Breakage on the Compressibility of Soils. Acta Geotech. 2022, 17, 769–778. [Google Scholar] [CrossRef]

- Yang, J.; Wei, L.M.; Dai, B.B. State Variables for Silty Sands: Global Void Ratio or Skeleton Void Ratio? Soils Found. 2015, 55, 99–111. [Google Scholar] [CrossRef]

- Cheng, K.; Zhang, J.; Miao, Y.; Ruan, B.; Peng, T. The Effect of Plastic Fines on the Shear Modulus and Damping Ratio of Silty Sands. Bull. Eng. Geol. Environ. 2019, 78, 5865–5876. [Google Scholar] [CrossRef]

| Material | Mineral Composition | D50 (1) (mm) | emin (2) | emax (3) | Gs (4) | Ip (5) |

|---|---|---|---|---|---|---|

| HN31 | Sand | 0.35 | 0.656 | 1 | 2.65 | NP |

| C500 | Silica | 0.006 | - | - |

| Ref. | Fc (%) | CSR (1) | f (Hz) | σ′c (kPa) |

|---|---|---|---|---|

| CTT01 | 5.0 | 0.120 | 0.10 | 200 |

| CTT02 | 5.0 | 0.105 | ||

| CTT03 | 5.0 | 0.090 | ||

| CTT04 | 5.0 | 0.075 | ||

| CTT05 | 10.0 | 0.120 | ||

| CTT06 | 10.0 | 0.105 | ||

| CTT07 | 10.0 | 0.100 | ||

| CTT08 | 10.0 | 0.090 | ||

| CTT09 | 10.0 | 0.075 | ||

| CTT10 | 15.0 | 0.120 | ||

| CTT11 | 15.0 | 0.105 | ||

| CTT12 | 15.0 | 0.090 | ||

| CTT13 | 15.0 | 0.075 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Zhu, Z.; Liu, J.; Zhong, H. Damping Ratio of Sand Containing Fine Particles in Cyclic Triaxial Liquefaction Tests. Appl. Sci. 2023, 13, 4833. https://doi.org/10.3390/app13084833

Zhao J, Zhu Z, Liu J, Zhong H. Damping Ratio of Sand Containing Fine Particles in Cyclic Triaxial Liquefaction Tests. Applied Sciences. 2023; 13(8):4833. https://doi.org/10.3390/app13084833

Chicago/Turabian StyleZhao, Jiajing, Zhehao Zhu, Jiaquan Liu, and Huaqiao Zhong. 2023. "Damping Ratio of Sand Containing Fine Particles in Cyclic Triaxial Liquefaction Tests" Applied Sciences 13, no. 8: 4833. https://doi.org/10.3390/app13084833

APA StyleZhao, J., Zhu, Z., Liu, J., & Zhong, H. (2023). Damping Ratio of Sand Containing Fine Particles in Cyclic Triaxial Liquefaction Tests. Applied Sciences, 13(8), 4833. https://doi.org/10.3390/app13084833