Novel Aluminum Alloy Tailored for Additive Manufacturing: Structural Characterization and Qualification Perspectives

Abstract

Featured Application

Abstract

1. Introduction

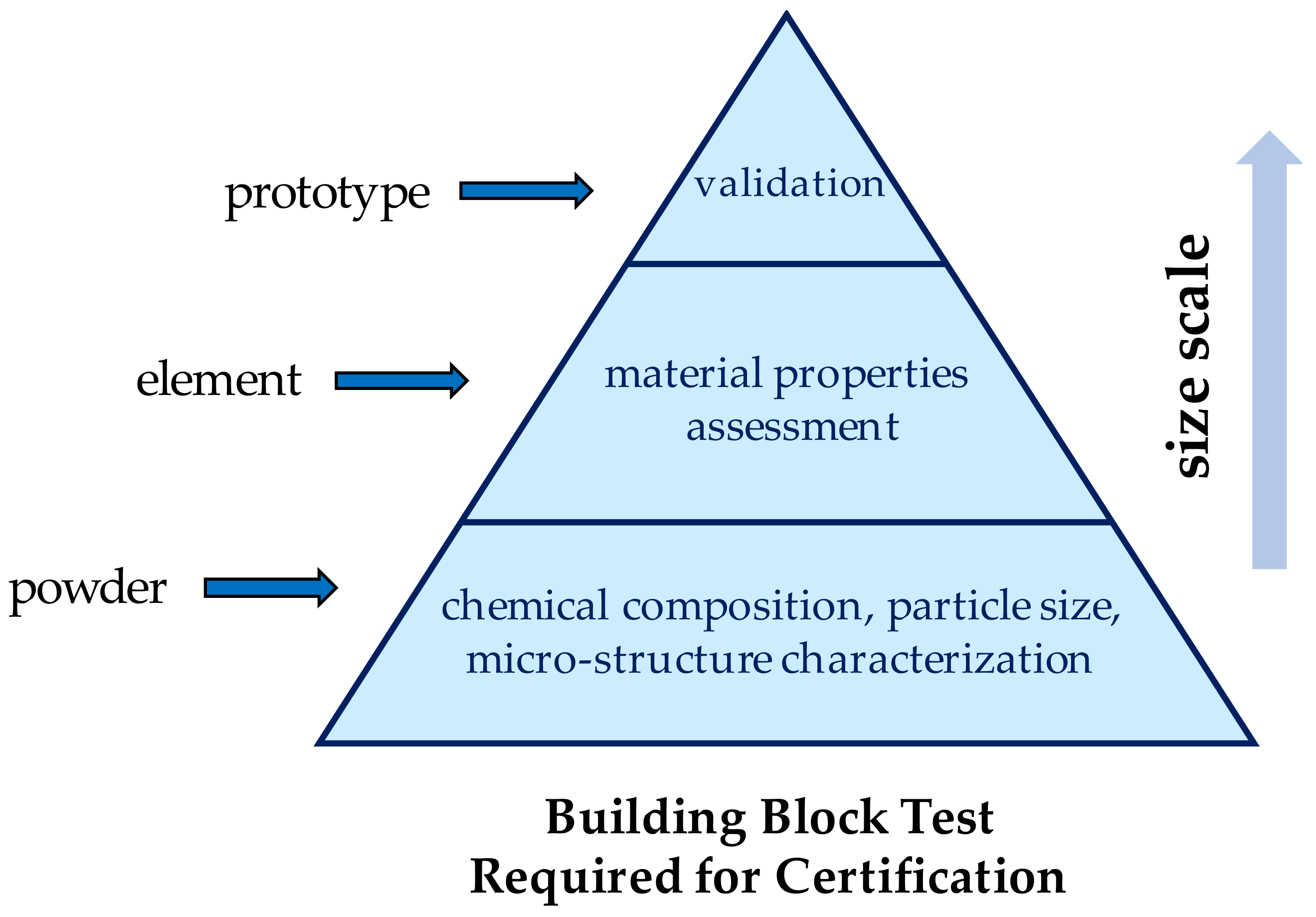

1.1. AM in the New Technological Scenario

1.2. Materials for Metal AM in Aerospace

1.3. Scope of the Study

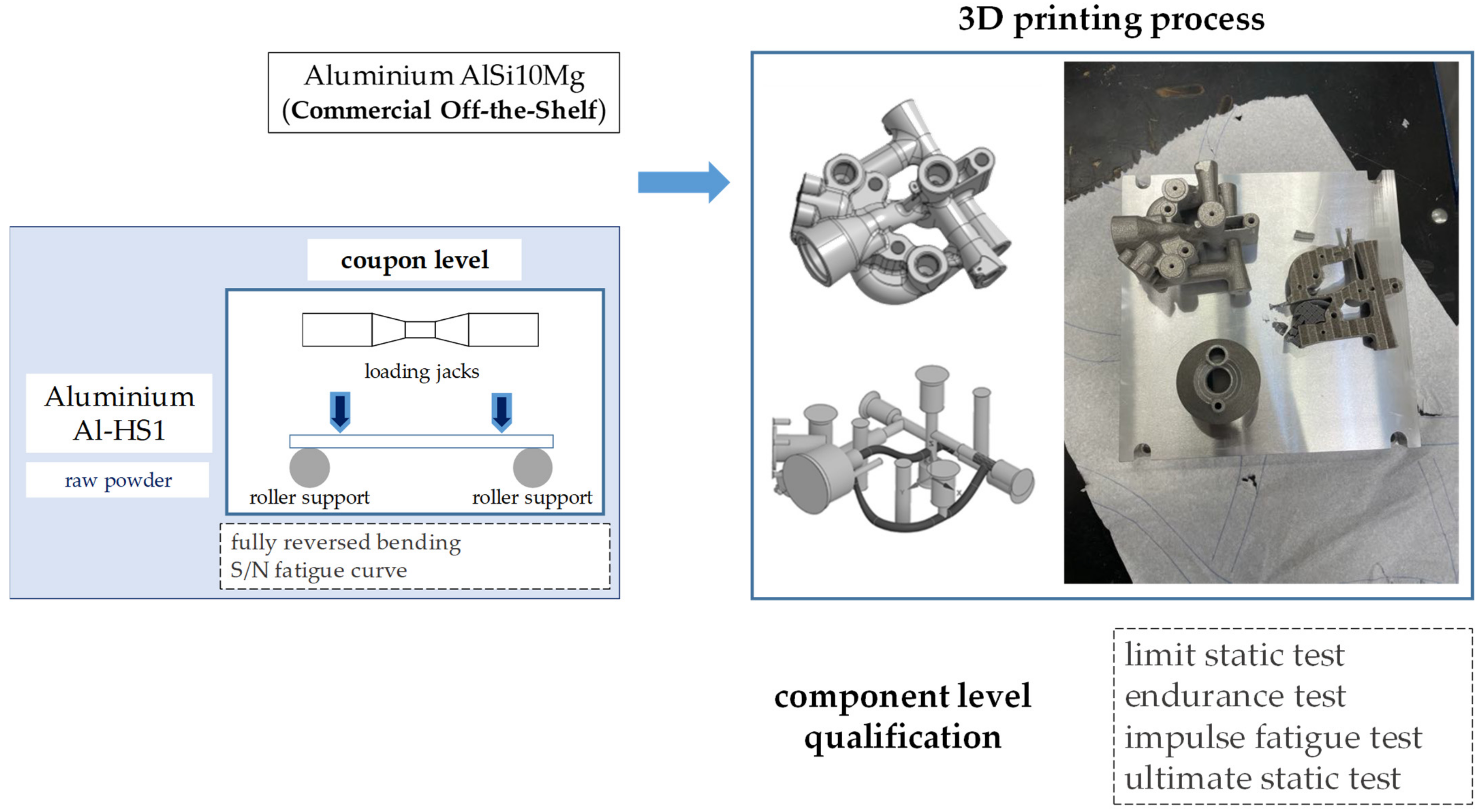

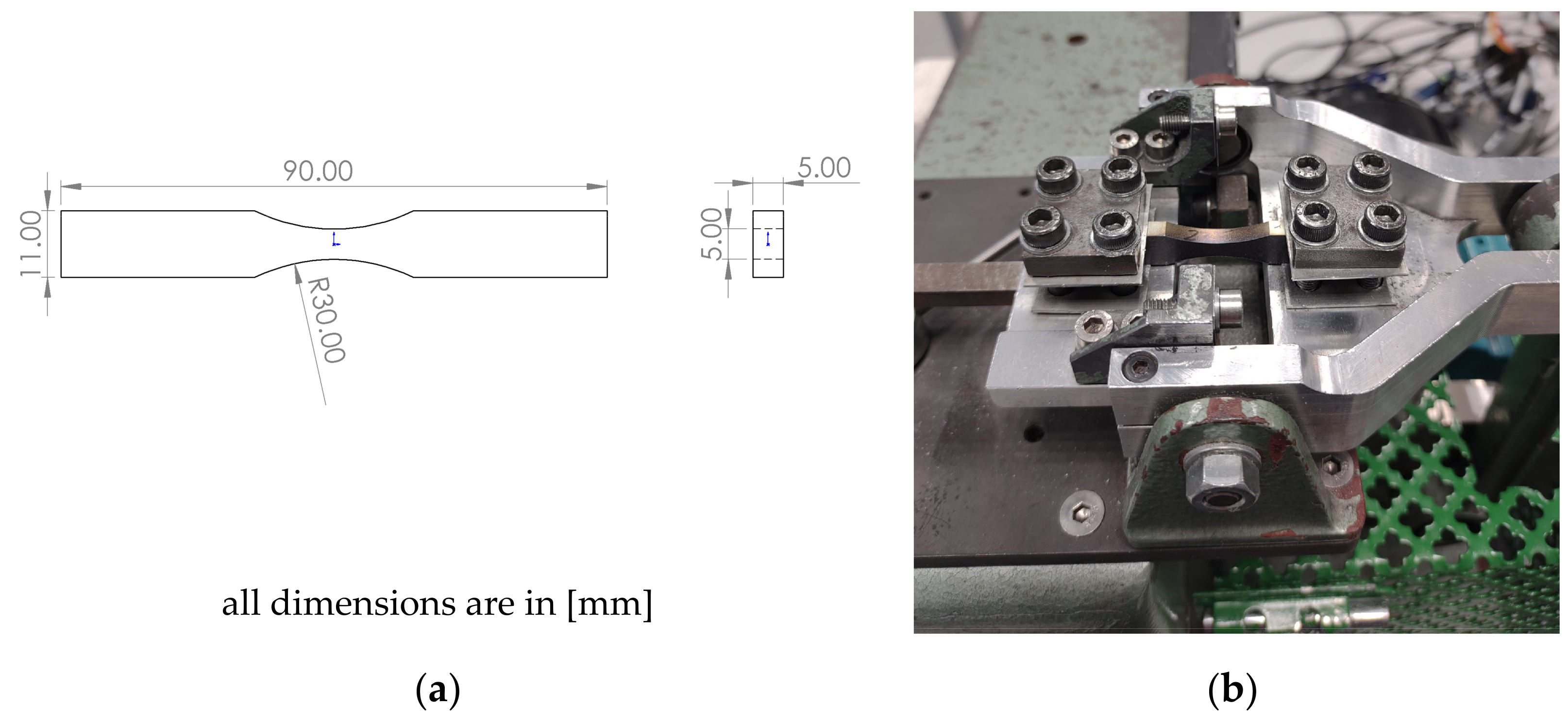

2. Materials and Methods

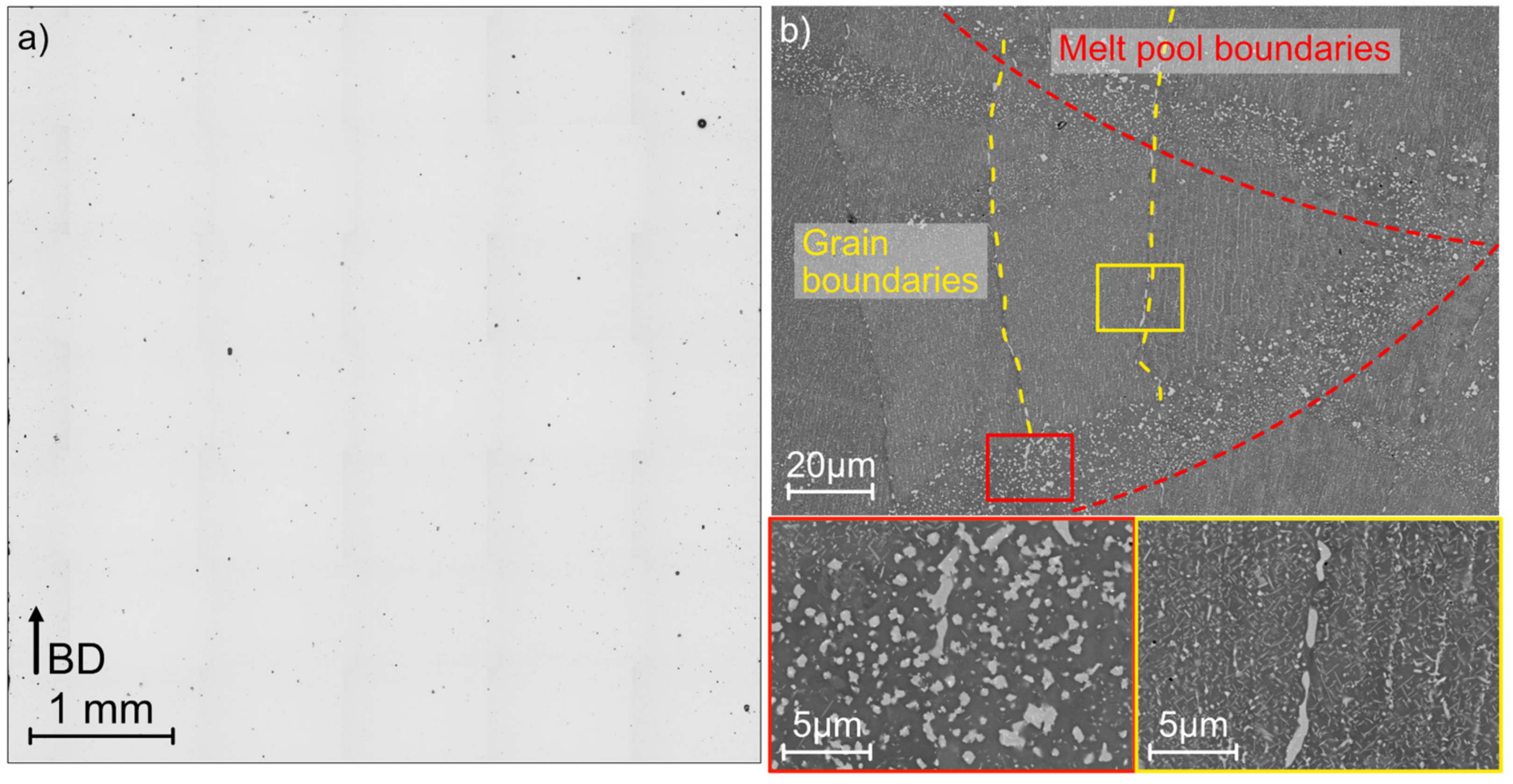

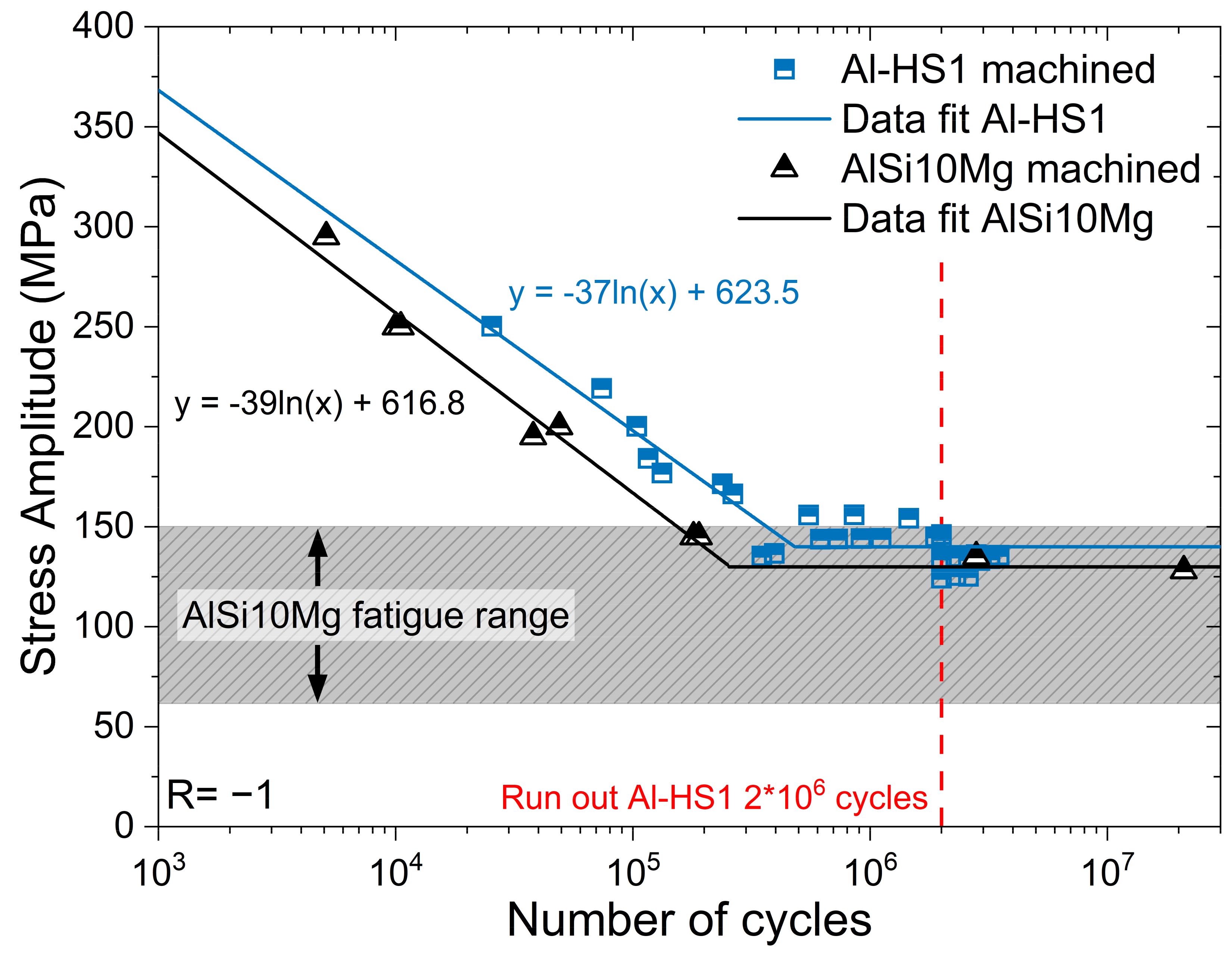

3. Microstructure and Mechanical Properties

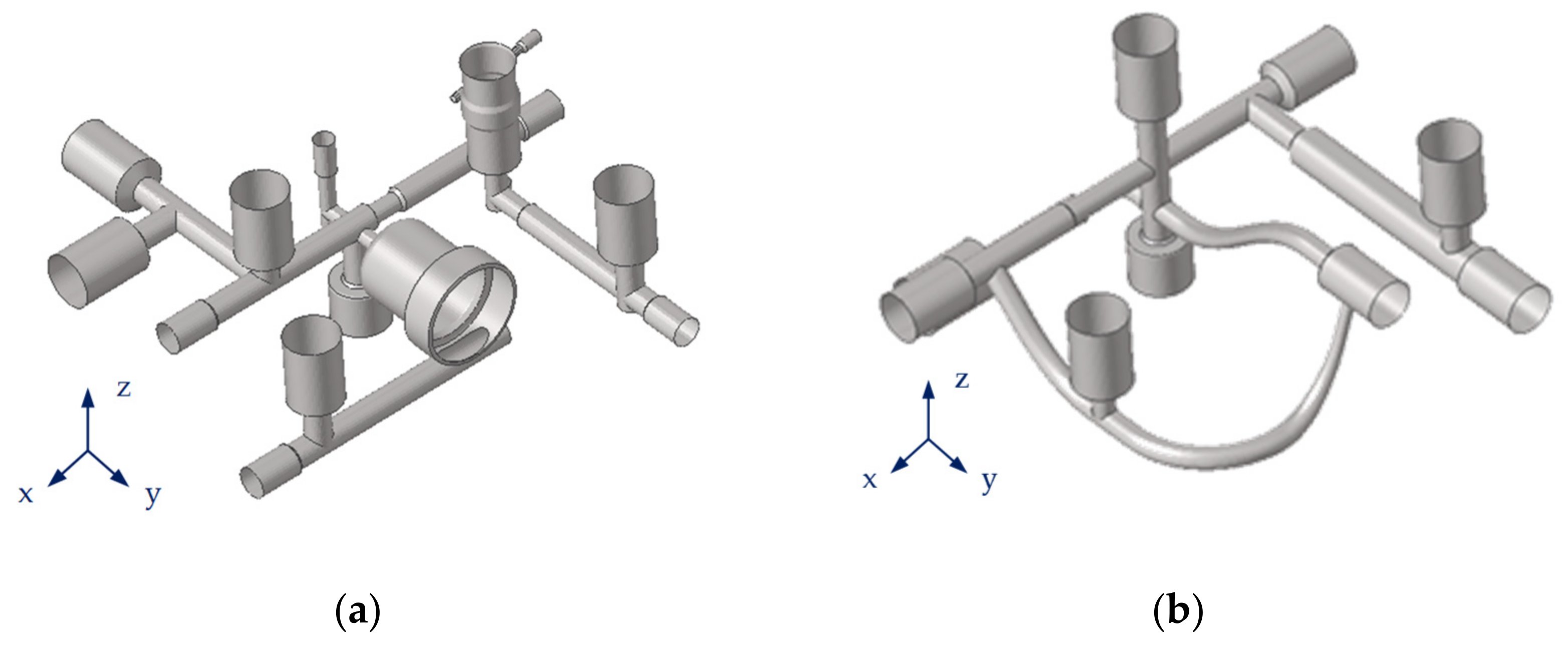

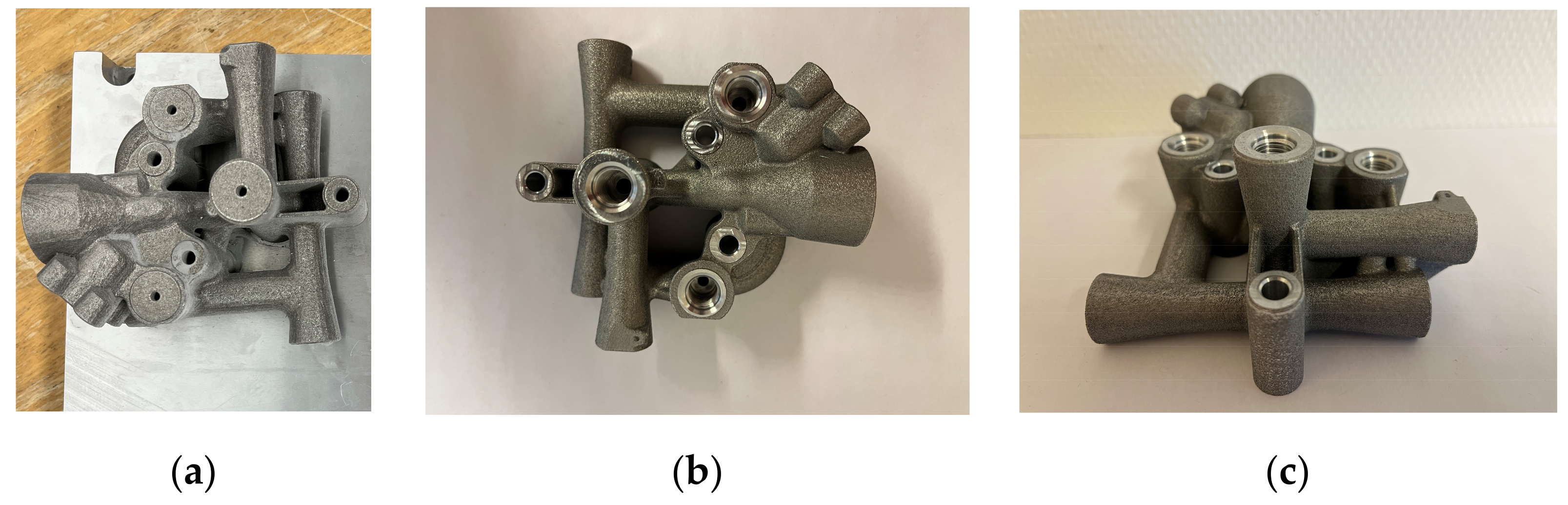

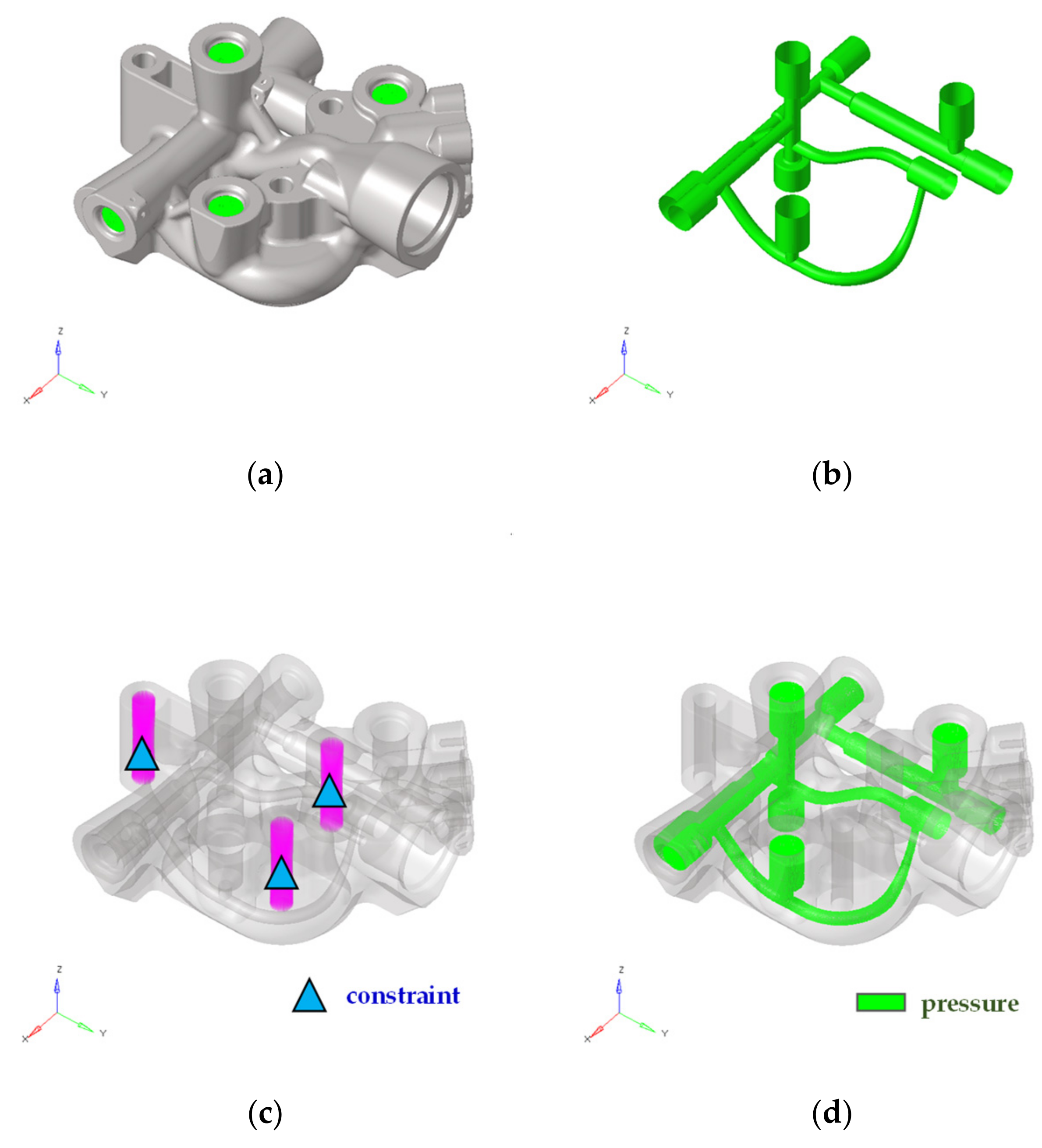

4. Hydraulic Manifold dfAM and Manufacturing

5. Numerical Analyses and Qualification

5.1. Hydraulic Sizing Conditions

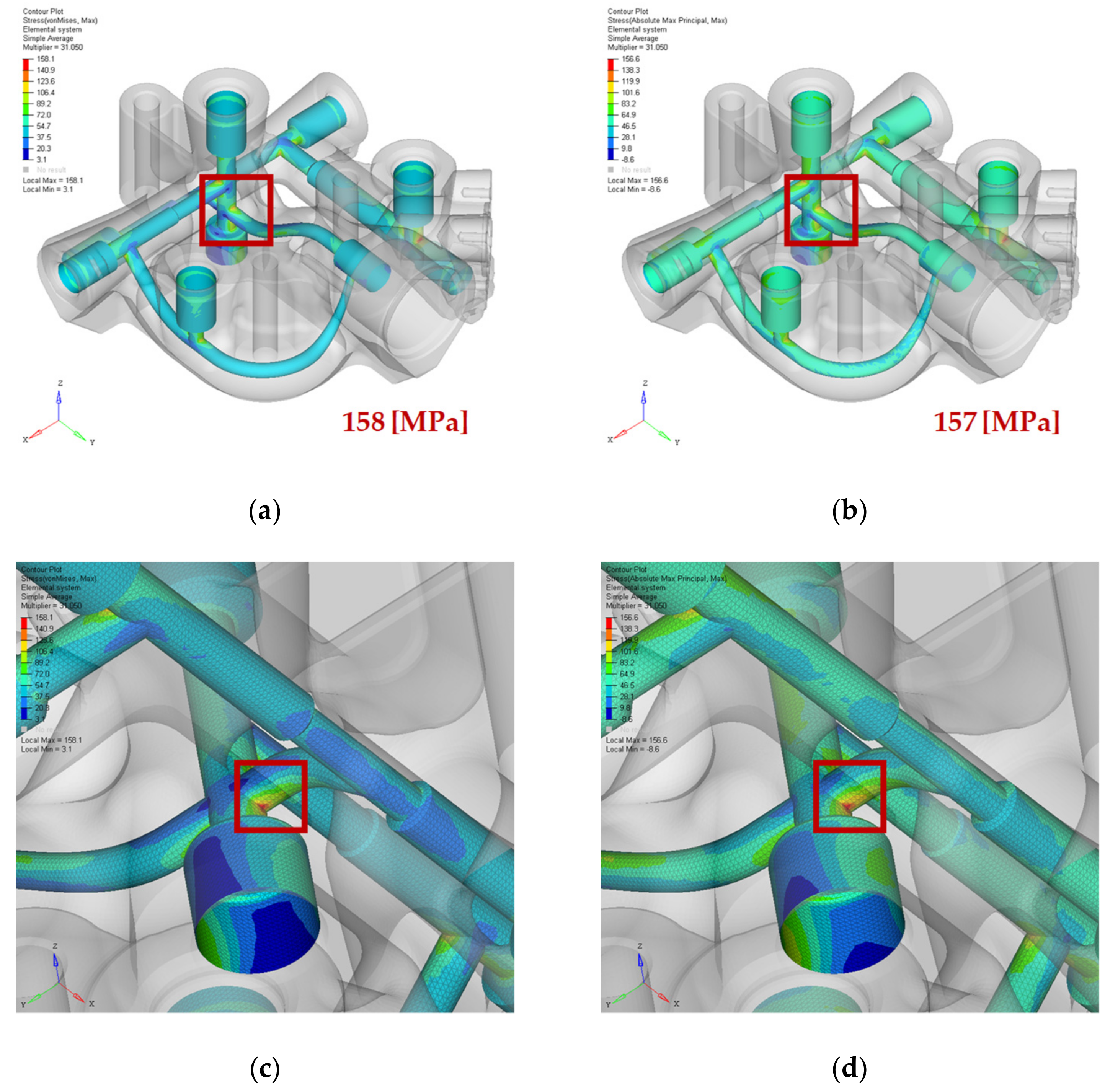

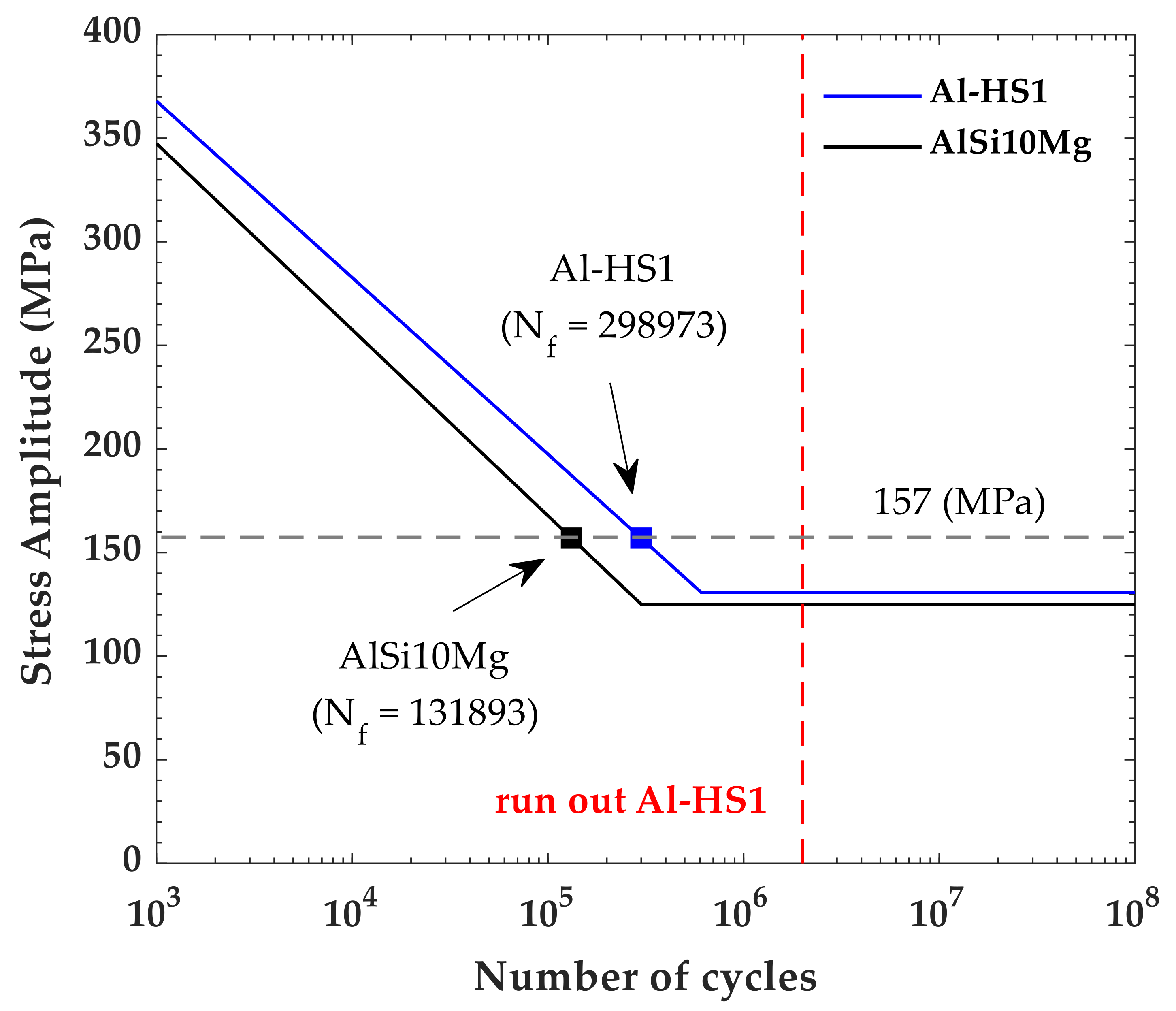

5.2. Finite Element Results

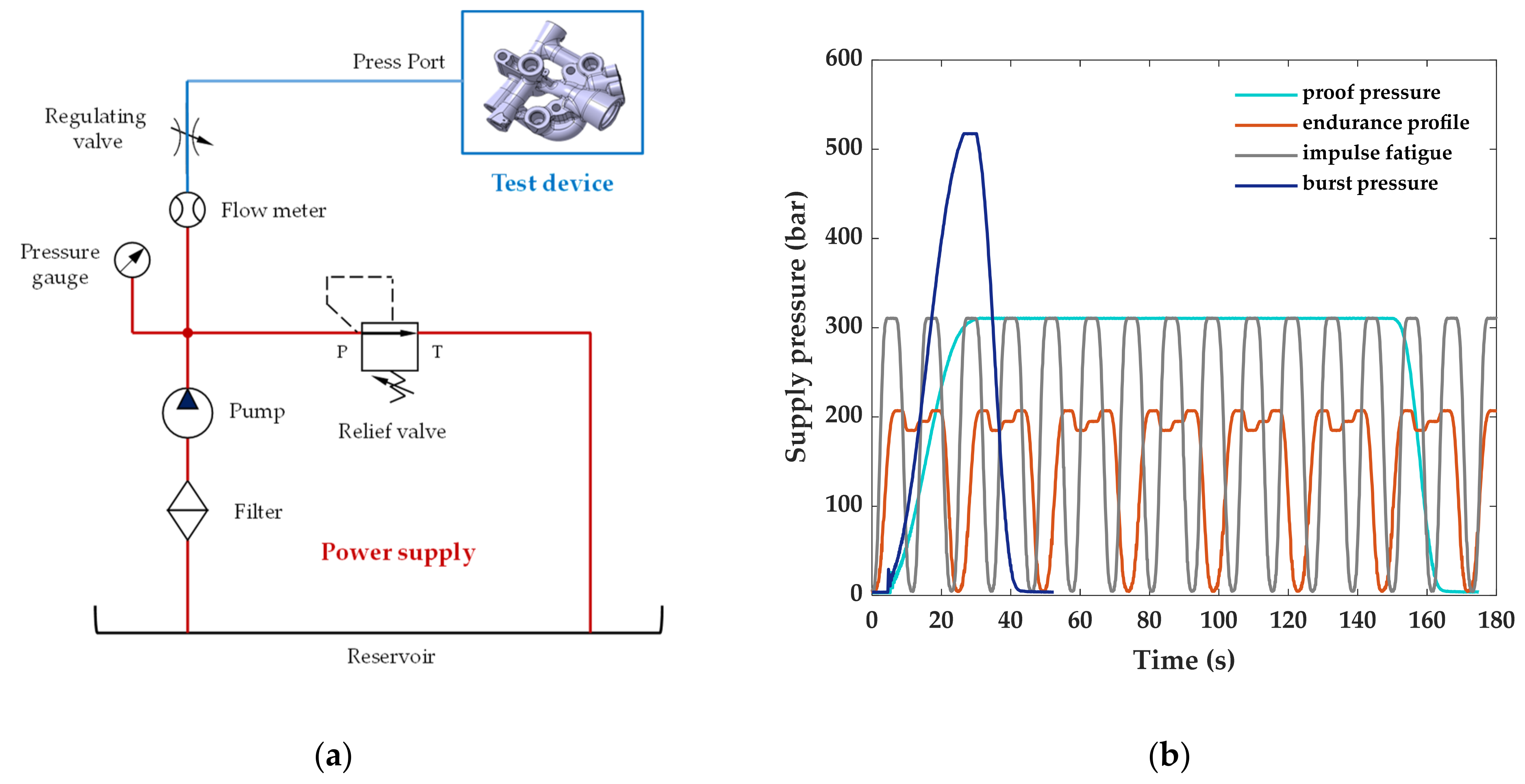

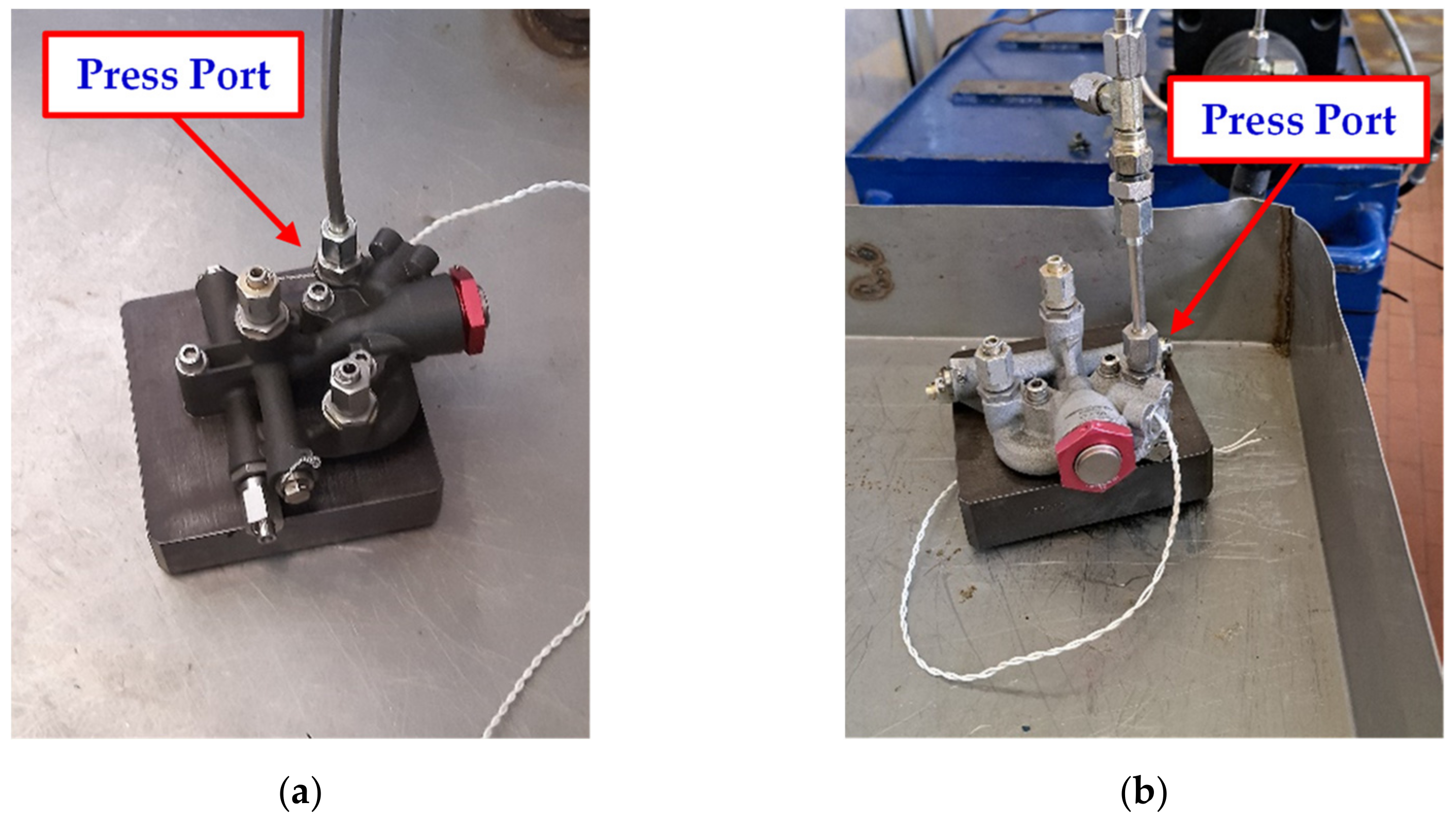

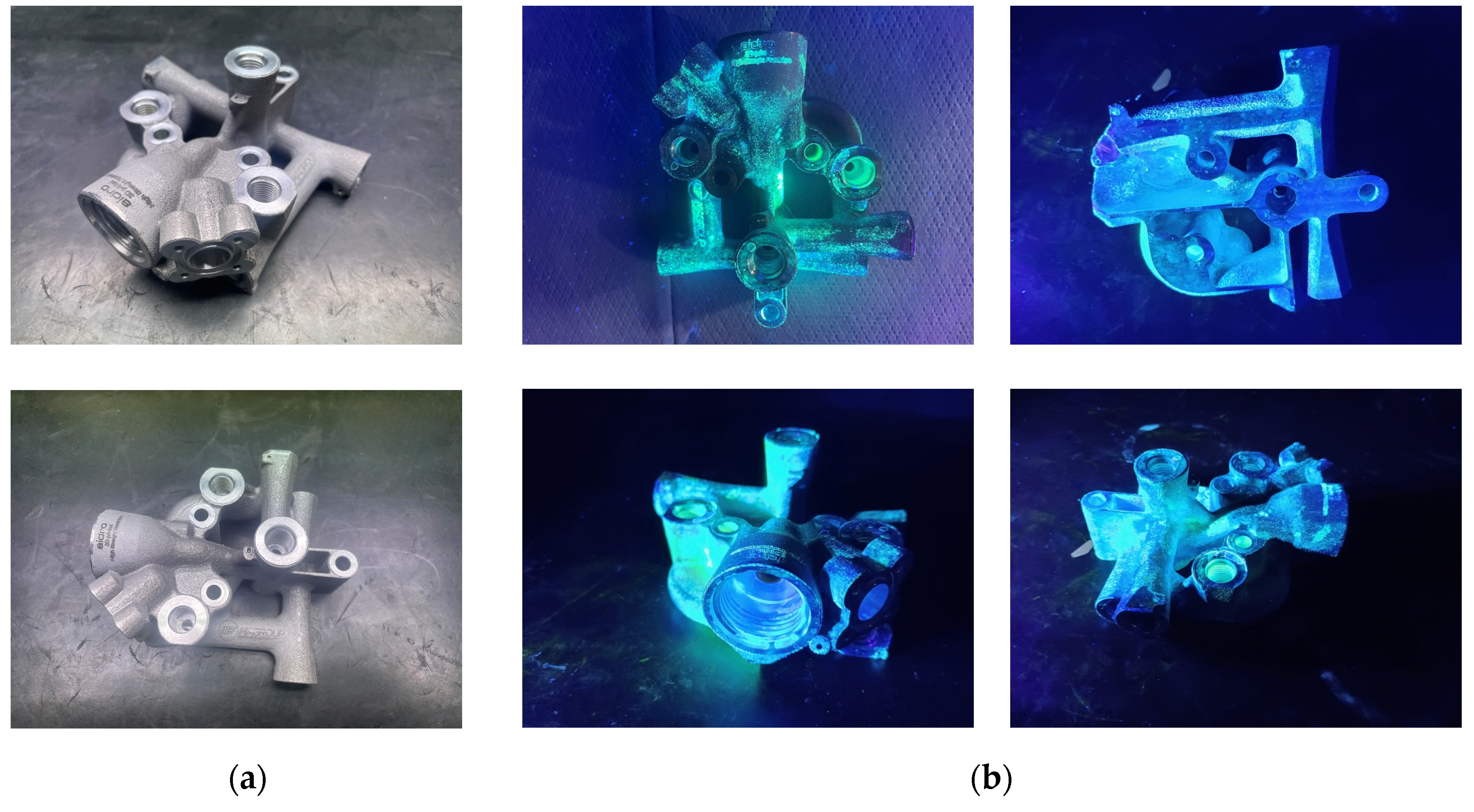

5.3. Qualification Tests Overview

- -

- Hydraulic fluid conforming to MIL-PRF-5606J (type II) for the supply pressure [75];

- -

- A hydraulic bench, including a pump source, controlled by the relief pressure valve;

- -

- Test temperature of about +30 ± 15 °C;

- -

- A contamination level of the hydraulic fluid of class 7 or better, as per NAS 1638;

- -

- Hydraulic fluid supplied to the press port, and a pressure value recorded by means of a pressure transducer (Figure 13a). All other ports were closed with actual plugs and hydraulic fittings;

- -

- Load pressure profiles as plotted in Figure 13b.

6. Discussion of the Results

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dass, A.; Moridi, A. State of the Art in Directed Energy Deposition: From Additive Manufacturing to Materials Design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef]

- Liu, R.; Wang, Z.; Sparks, T.; Liou, F.; Newkirk, J. Aerospace applications of laser additive manufacturing. In Laser Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2017; pp. 351–371. [Google Scholar]

- Selema, A.; Ibrahim, M.N.; Sergeant, P. Metal Additive Manufacturing for Electrical Machines: Technology Review and Latest Advancements. Energies 2022, 15, 1076. [Google Scholar] [CrossRef]

- Chatham, C.A.; Long, T.E.; Williams, C.B. A review of the process physics and material screening methods for polymer powder bed fusion additive manufacturing. Prog. Polym. Sci. 2019, 93, 68–95. [Google Scholar] [CrossRef]

- Mishra, A.K.; Kumar, A. Computational analysis of the thermo-hydrodynamic transport processes during substrate re-melting in laser powder bed fusion of AlSi10Mg. Therm. Sci. Eng. Prog. 2023, 39, 101698. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Easton, M. 2—Powder bed fusion processes: An overview. Laser Addit. Manuf. 2017, 55–77. [Google Scholar]

- Dejene, N.D.; Lemu, H.G. Current Status and Challenges of Powder Bed Fusion-Based Metal Additive Manufacturing: Literature Review. Metals 2023, 13, 424. [Google Scholar] [CrossRef]

- Gülcan, O.; Günaydın, K.; Tamer, A. The State of the Art of Material Jetting—A Critical Review. Polymers 2021, 13, 2829. [Google Scholar] [CrossRef]

- Li, M.; Du, W.; Elwany, A.; Pei, Z.; Ma, C. Metal Binder Jetting Additive Manufacturing: A Literature Review. J. Manuf. Sci. Eng. 2020, 142, 090801. [Google Scholar] [CrossRef]

- Suwanpreecha, C.; Manonukul, A. A Review on Material Extrusion Additive Manufacturing of Metal and How It Compares with Metal Injection Moulding. Metals 2022, 12, 429. [Google Scholar] [CrossRef]

- Riccio, C.; Civera, M.; Ruiz, O.G.; Pedullà, P.; Reinoso, M.R.; Tommasi, G.; Vollaro, M.; Burgio, V.; Surace, C. Effects of Curing on Photosensitive Resins in SLA Additive Manufacturing. Appl. Mech. 2021, 2, 942–955. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Sheet Lamination. In Additive Manufacturing Technologies; Springer International Publishing: Cham, Switzerland, 2021; pp. 253–283. [Google Scholar]

- Tan, L.J.; Zhu, W.; Zhou, K. Recent progress on polymer materials for additive manufacturing. Adv. Funct. Mater. 2020, 30, 2003062. [Google Scholar] [CrossRef]

- Jadhav, A.; Jadhav, V.S. A review on 3D printing: An additive manufacturing technology. Mater. Today Proc. 2022, 62, 2094–2099. [Google Scholar] [CrossRef]

- Praveena, B.A.; Lokesh, N.; Buradi, A.; Santhosh, N.; Praveena, B.L.; Vignesh, R. A comprehensive review of emerging additive manufacturing (3D printing technology): Methods, materials, applications, challenges, trends and future potential. Mater. Today Proc. 2022, 52, 1309–1313. [Google Scholar]

- Srinivasan, K.V.; Manimaran, A.; Arulprakasajothi, M.; Devante, M.; Arolkar, V.A. Design and development of porous regenerator for Stirling cryocooler using additive manufacturing. Therm. Sci. Eng. Prog. 2019, 11, 195–203. [Google Scholar] [CrossRef]

- McDonough, J.R. A perspective on the current and future roles of additive manufacturing in process engineering, with an emphasis on heat transfer. Therm. Sci. Eng. Prog. 2020, 19, 100594. [Google Scholar] [CrossRef]

- Favero, G.; Bonesso, M.; Rebesan, P.; Dima, R.; Pepato, A.; Mancin, S. Additive manufacturing for thermal management applications: From experimental results to numerical modeling. Int. J. Thermofluids 2021, 10, 100091. [Google Scholar] [CrossRef]

- Mollamahmutoglu, M.; Yilmaz, O. Volumetric heat source model for laser-based powder bed fusion process in additive manufacturing. Therm. Sci. Eng. Prog. 2021, 25, 101021. [Google Scholar] [CrossRef]

- Tucker, R.; Khatamifar, M.; Lin, W.; McDonald, K. Experimental investigation of orientation and geometry effect on additive manufactured aluminium LED heat sinks under natural convection. Therm. Sci. Eng. Prog. 2021, 23, 100918. [Google Scholar] [CrossRef]

- Froes, F.; Boyer, R.; Dutta, B. Introduction to Aerospace Materials Requirements and the Role of Additive Manufacturing; Elsevier Inc.: Amsterdam, The Netherlands, 2019. [Google Scholar]

- European Commission. European Aeronautics: A Vision for 2020; European Communities: Luxembourg, 2001. [Google Scholar]

- European Commission. Flightpath 2050; EU: Luxembourg, 2011. [Google Scholar]

- ISO/ASTM 52920:2023; Additive Manufacturing—Qualification Principles—Requirements for Industrial Additive Manufacturing Processes and Production Sites. International Organization for Standardization: Geneva, Switzerland, 2023.

- DNV-ST-B203; Additive Manufacturing of Metallic Parts, Edition 2022-10. Greater: Oslo, Norway, 2022.

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Alami, A.H.; Olabi, A.G.; Alashkar, A.; Alasad, S.; Aljaghoub, H.; Rezk, H.; Abdelkareem, M.A. Additive manufacturing in the aerospace and automotive industries: Recent trends and role in achieving sustainable development goals. Ain Shams Eng. J. 2023, 14, 102516. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, E. Metal additive manufacturing in aircraft: Current application, opportunities and challenges. IOP Conf. Ser. Mater. Sci. Eng. 2019, 493, 012032. [Google Scholar] [CrossRef]

- Titanium, N. Norsk Titanium to Deliver the World’s First FAA-Approved, 3DPrinted, Structural Titanium Components to Boeing|Additive Manufacturing (AM). Available online: https://additivemanufacturing.com/2017/04/10/norsk-titanium-to-deliver-the-worlds-first-faa-approved-3d-printed-structural-titanium-components-to-boeing/ (accessed on 4 January 2024).

- Lyons, B. Additive Manufacturing in Aerospace: Examples and Research Outlook, The Boeing Company, Frontiers of Engineering: Reports on Leading-Edge Engineering from the 2011 Symposium; National Academies Press: Washington, DC, USA, 2012. [Google Scholar]

- Boeing, S.A. Acess Door Latch. Available online: https://www.additivemanufacturing.media/articles/what-is-the-role-for-additive-manufacturing-in-aircraft-structural-components (accessed on 2 January 2024).

- Gerald, M.; Cross Robert, R. Filler, Additive Manufacturing (AM) of a Rotorcraft Gearbox Housing Independent Research & Development (IRAD) Project, Boeing Research and Technology; The Boeing Company: Arlington County, VA, USA, 2019. [Google Scholar]

- Romero, I.; Martin, J.M.; Marzal, M.; Gallego, J.; Calero, M.A.; Martin, J.C. Additive Manufacturing (AM). Status in Airbus Defence and Space (Spain). In Proceedings of the 8th European Conference for Aeronautics and Space Sciences (EUCASS), Madrid, Spain, 1–4 July 2019. [Google Scholar]

- Kumar, L.J.; Nair, C.G.K. Current trends of additive manufacturing in the aerospace industry. In Advances in 3D Printing & Additive Manufacturing Technologies; Springer Singapore: Singapore, 2017; pp. 39–54. [Google Scholar]

- Orme, M.E.; Gschweitl, M.; Ferrari, M.; Madera, I.; Mouriaux, F. Designing for additive manufacturing: Lightweighting through topology optimization enables lunar spacecraft. J. Mech. Des. Trans. ASME 2017, 139, 100905. [Google Scholar] [CrossRef]

- Caujolle, M. First Titanium 3D-Printed Part Installed into Serial Production Aircraft. 2017. Available online: https://www.airbus.com/en/newsroom/press-releases/2017-09-first-titanium-3d-printed-part-installed-into-serial-production (accessed on 2 January 2024).

- Tomlin, M.; Meyer, J. Topology optimization of an additive layer manufactured (ALM) aerospace part. In Proceedings of the 7th Altair CAE Technology Conference 2011, Gaydon, UK, 7–9 November 2011; pp. 1–9. [Google Scholar]

- Meng, L.; Zhang, W.; Quan, D.; Shi, G.; Tang, L.; Hou, Y.; Breitkopf, P.; Zhu, J.; Gao, T. From topology optimization design to additive manufacturing: Today’s success and tomorrow’s roadmap. Arch. Comput. Methods Eng. 2020, 27, 805–830. [Google Scholar] [CrossRef]

- Uhlmann, E.; Kersting, R.; Borsoi Klein, T.; Cruz, M.F.; Borille, A.V. Additive manufacturing of titanium alloy for aircraft components. In Proceedings of the 15th Machining Innovations Conference for Aerospace Industry, Hannover, Germany, 18–19 November 2015; Volume 35, pp. 55–60. [Google Scholar]

- General Electric— Additive, LEAP Engine Fuel Nozzle. Available online: https://www.geaerospace.com/news/articles/manufacturing/manufacturing-milestone-30000-additive-fuel-nozzles (accessed on 2 January 2024).

- General Electric—Additive, GE9X Engine Additive Parts. Available online: https://www.ge.com/additive/sites/default/files/2020-08/GE9X-Additive-Parts.pdf (accessed on 2 January 2024).

- Hoffmann, M.; Elwany, A. In-Space Additive Manufacturing: A Review. J. Manuf. Sci. Eng. 2023, 145, 020801. [Google Scholar] [CrossRef]

- Gradl, P.R.; Mireles, O.; Protz, C.S.; Garcia, C. Metal Additive Manufacturing for Propulsion Applications. In AIAA Progress in Astronautics and Aeronautics Book Series; American Institute of Aeronautics and Astronautics, Inc.: Reston, VA, USA, 2022. [Google Scholar]

- Gradl, P.R.; Protz, C.S. Technology advancements for channel wall nozzle manufacturing in liquid rocket engines. Acta Astronaut. 2020, 174, 148–158. [Google Scholar] [CrossRef]

- Kerstens, F.; Cervone, A.; Gradl, P. End to end process evaluation for additively manufactured liquid rocket engine thrust chambers. Acta Astronaut. 2021, 182, 454–465. [Google Scholar] [CrossRef]

- Thales Alenia Space and 3D Systems, Antenna Bracket. Available online: https://www.3dsystems.com/learning-center/case-studies/tipping-point (accessed on 2 January 2024).

- Clark, S. Astronauts Fly with SpaceX in Landmark Launch for Commercial Spaceflight. Available online: https://spaceflightnow.com/2020/11/16/astronauts-ride-spacex-crew-capsule-in-landmark-launch-for-commercial-spaceflight/ (accessed on 2 January 2024).

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Haghdadi, N.; Laleh, M.; Moyle, M.; Primig, S. Additive manufacturing of steels: A review of achievements and challenges. J. Mater. Sci. 2021, 56, 64–107. [Google Scholar] [CrossRef]

- Armstrong, M.; Mehrabi, H.; Naveed, N. An overview of modern metal additive manufacturing technology. J. Manuf. Process. 2022, 84, 1001–1029. [Google Scholar] [CrossRef]

- Narasimharaju, S.R.; Zeng, W.; See, T.L.; Zhu, Z.; Scott, P.; Jiang, X.; Lou, S. A comprehensive review on laser powder bed fusion of steels: Processing, microstructure, defects and control methods, mechanical properties, current challenges and future trends. J. Manuf. Process. 2022, 75, 375–414. [Google Scholar] [CrossRef]

- Tshephe, T.S.; Akinwamide, S.O.; Olevsky, E.; Olubambi, P.A. Additive manufacturing of titanium-based alloys—A review of methods, properties, challenges, and prospects. Heliyon 2022, 8, e09041. [Google Scholar] [CrossRef] [PubMed]

- Williams, J.C.; Boyer, R.R. Opportunities and issues in the application of titanium alloys for aerospace components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Mostafaei, A.; Ghiaasiaan, R.; Ho, I.-T.; Strayer, S.; Chang, K.-C.; Shamsaei, N.; Shao, S.; Paul, S.; Yeh, A.-C.; Tin, S.; et al. Additive manufacturing of nickel-based superalloys: A state-of-the-art review on process-structure-defect-property relationship. Prog. Mater. Sci. 2023, 136, 101108. [Google Scholar] [CrossRef]

- Höganäs, A.B. forAM(r) Al-HS1 Powder. Available online: https://www.hoganas.com/en/powder-technologies/products/foram/foram-al-hs1-20-63-ga/ (accessed on 4 January 2024).

- Mehta, B. Development of High Performance Aluminium Alloys Tailored for Powder Bed Fusion-Laser Beam. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2023. [Google Scholar]

- Arena, M.; Ambrogiani, P.; Raiola, V.; Bocchetto, F.; Tirelli, T.; Castaldo, M. Design and Qualification of an Additively Manufactured Manifold for Aircraft Landing Gears Applications. Aerospace 2023, 10, 69. [Google Scholar] [CrossRef]

- Biedermann, M.; Beutler, P.; Meboldt, M. Automated design of additive manufactured flow components with consideration of overhang constraint. Addit. Manuf. 2021, 46, 102119. [Google Scholar] [CrossRef]

- Diegel, O.; Schutte, J.; Ferreira, A.; Chan, Y.L. Design for additive manufacturing process for a lightweight hydraulic manifold. Addit. Manuf. 2020, 36, 101446. [Google Scholar] [CrossRef]

- Alshare, A.A.; Calzone, F.; Muzzupappa, M. Hydraulic manifold design via additive manufacturing optimized with CFD and fluid-structure interaction simulations. Rapid Prototyp. J. 2019, 25, 1516–1524. [Google Scholar] [CrossRef]

- Krailling/Munich, Germany. Available online: https://www.eos.info (accessed on 4 January 2024).

- Mehta, B.; Nyborg, L.; Frisk, K.; Hryha, E. Al–Mn–Cr–Zr-based alloys tailored for powder bed fusion-laser beam process: Alloy design, printability, resulting microstructure and alloy properties. J. Mater. Res. 2022, 3, 1–13. [Google Scholar] [CrossRef]

- Mehta, B.; Frisk, K.; Nyborg, L. Advancing Novel Al-Mn-Cr-Zr Based Family of Alloys Tailored for Powder Bed Fusion-Laser Beam Process. J. Alloys Compd. 2023, 967, 171685. [Google Scholar] [CrossRef]

- Mehta, B.; Frisk, K.; Nyborg, L. Effect of Precipitation Kinetics on Microstructure and Properties of Novel Al-Mn-Cr-Zr Based Alloys Developed for Powder Bed Fusion—Laser Beam Process. J. Alloys Compd. 2022, 920, 165870. [Google Scholar] [CrossRef]

- Knipling, K.E.; Dunand, D.C.; Seidman, D.N. Precipitation evolution in Al-Zr Al-Zr-Ti alloys during aging at 450–600 °C. Acta Mater. 2008, 56, 1182–1195. [Google Scholar] [CrossRef]

- Kaufman, J.G. Properties and Applications of Wrought Aluminum Alloys. Prop. Sel. Alum. Alloy 2019, 2, 202–275. [Google Scholar]

- Mackenzie, D.S. Metallurgy of Heat Treatable Aluminum Alloys; ASM International: Novelty, OH, USA, 2016; Volume 4. [Google Scholar]

- Bengtsson, S.; Mehta, B.; Frisk, K.; Nyborg, L. New Aluminium Alloy Tailored for Powder Bed Fusion—Laser Beam Process. In Proceedings of the WorldPM 2022 Congress & Exhibition: Conference Proceedings, Lyon, France, 9–13 October 2022. [Google Scholar]

- Uzan, N.E.; Shneck, R.; Yeheskel, O.; Frage, N. Fatigue of AlSi10Mg specimens fabricated by additive manufacturing selective laser melting (AM-SLM). Mater. Sci. Eng. A 2017, 704, 229–237. [Google Scholar] [CrossRef]

- Mower, T.M.; Long, M.J. Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Mater. Sci. Eng. A 2016, 651, 198–213. [Google Scholar] [CrossRef]

- Raja, A.; Cheethirala, S.R.; Gupta, P.; Vasa, N.J.; Jayaganthan, R. A review on the fatigue behaviour of AlSi10Mg alloy fabricated using laser powder bed fusion tech-nique. J. Mater. Res. Technol. 2022, 17, 1013–1029. [Google Scholar] [CrossRef]

- SAE-AS8775; Military Specification: Hydraulic System Components, Aircraft and Missiles, General Specification for AS8775. SAE International: Warrendale, PA, USA, 1998.

- SAE ARP1383; Aerospace—Impulse Testing of Hydraulic Components, rev. C. SAE International: Warrendale, PA, USA, 2013.

- MSC Nastran®. Quick Reference Guide 2021; MSC Software: Newport Beach, CA, USA, 2021. [Google Scholar]

- MIL-PRF-5606J; Performance Specification: Hydraulic Fluid, Petroleum Base; Aircraft, Missile, and Ordnance. U.S. Department of Defense Military Specifications and Standards: Arlington County, VA, USA, 2018.

| Alloy | Chemical Composition |

|---|---|

| Al-HS1 | Al 5 Mn 0.8 Cr 0.6 Zr 0.17 Fe 0.24 Si |

| AlSi10Mg | Al 9.8 Si 0.33 Mg 0.15 Fe |

| Alloy | Direction | Yield Strength, fty | Tensile Strength, ftu | Elongation to Failure | Density |

|---|---|---|---|---|---|

| (Z), (XY) | [MPa] | [MPa] | [%] | [g/cm3] | |

| Al-HS1 | Vertical (Z) | 343 | 430 | 4.8 | 2.99 |

| Horizontal (XY) | 356 | 441 | 10.4 | ||

| AlSi10Mg | Vertical (Z) | 220 | 468 | 10.7 | 2.645 |

| Horizontal (XY) | 261 | 449 | 15.7 |

| Test | Pressure | No. of Cycles | Reference |

|---|---|---|---|

| [bar] | [-] | [-] | |

| 0. Supply Pressure | DOP = 207 | - | - |

| 1. Proof Pressure | 1.5 × DOP = 310.5 | - | SAE AS8775 [72] |

| 2. Endurance Cycles | 5–207–185–195–207–5 | 5,000 | Legacy spectrum |

| 3. Hydraulic Fatigue | 0.5–310.5–0.5 | 100,000 | SAE ARP1383 Rev. C [73] |

| 4. Burst Pressure | 2.5 × DOP = 517.5 | - | SAE AS8775 [72] |

| Load Case | Description | Safety Margin/Fatigue Damage |

|---|---|---|

| Proof pressure | Static load (limit) | AlSi10Mg: MSlim = (220/158) − 1 = 0.39 |

| Al-HS1: MSlim = (343/158) − 1 = high | ||

| Burst pressure | Static load (ultimate) | AlSi10Mg: MSult = (449/263) − 1 = 0.71 |

| Al-HS1: MSult = (430/263) − 1 = 0.63 | ||

| Pulsating cycles | Fatigue | AlSi10Mg: D = 100,000/131,893 = 0.76 < 1.0 |

| Al-HS1: D = 100,000/298,973 = 0.33 < 1.0 |

| Load Case | Description | Success/Failure Criteria |

|---|---|---|

| Proof pressure | Static (2 min) | No permanent deformation, pressure drop, and external leakage |

| Endurance | Cyclic | No leakage or evidence of excessive wear or malfunctioning |

| Pulsating cycles | Cyclic | No failure or permanent deformation |

| Burst pressure | Static (3 s) | No rupture, pressure drop, or external leakage |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arena, M.; Mehta, B.; Tirelli, T.; Ambrogiani, P.; Castaldo, M.; Bengtsson, S.; Nyborg, L. Novel Aluminum Alloy Tailored for Additive Manufacturing: Structural Characterization and Qualification Perspectives. Appl. Sci. 2024, 14, 4647. https://doi.org/10.3390/app14114647

Arena M, Mehta B, Tirelli T, Ambrogiani P, Castaldo M, Bengtsson S, Nyborg L. Novel Aluminum Alloy Tailored for Additive Manufacturing: Structural Characterization and Qualification Perspectives. Applied Sciences. 2024; 14(11):4647. https://doi.org/10.3390/app14114647

Chicago/Turabian StyleArena, Maurizio, Bharat Mehta, Tommaso Tirelli, Paolo Ambrogiani, Martina Castaldo, Sven Bengtsson, and Lars Nyborg. 2024. "Novel Aluminum Alloy Tailored for Additive Manufacturing: Structural Characterization and Qualification Perspectives" Applied Sciences 14, no. 11: 4647. https://doi.org/10.3390/app14114647

APA StyleArena, M., Mehta, B., Tirelli, T., Ambrogiani, P., Castaldo, M., Bengtsson, S., & Nyborg, L. (2024). Novel Aluminum Alloy Tailored for Additive Manufacturing: Structural Characterization and Qualification Perspectives. Applied Sciences, 14(11), 4647. https://doi.org/10.3390/app14114647