Dynamic Balance Simulation and Optimization of Electric Vehicle Scroll Compressor Rotor System

Abstract

:1. Introduction

2. Dynamic Balance Principle of Rotor System

3. Force Model

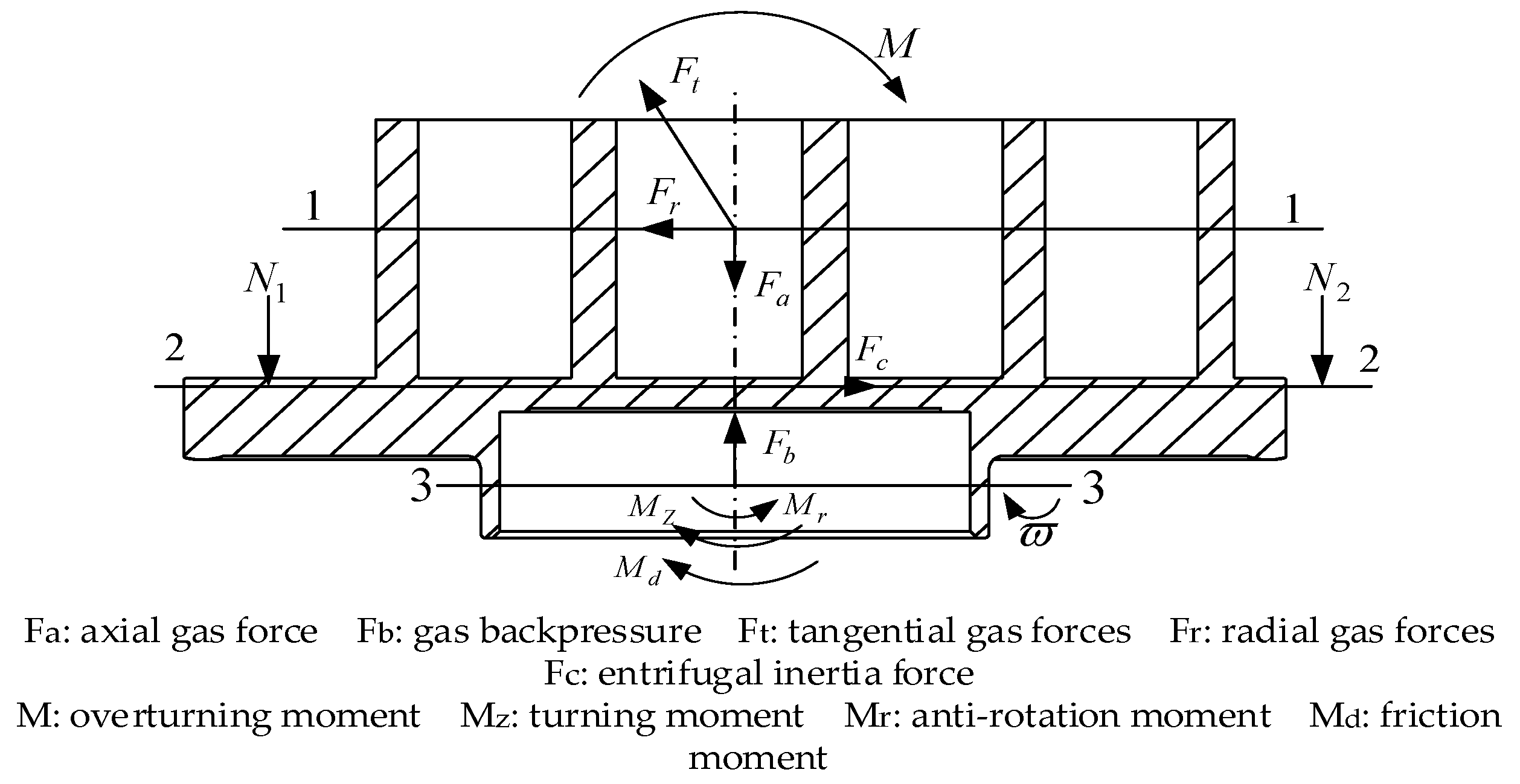

3.1. Force Model of Orbiting Scroll

3.2. Force Model of Drive Bearing

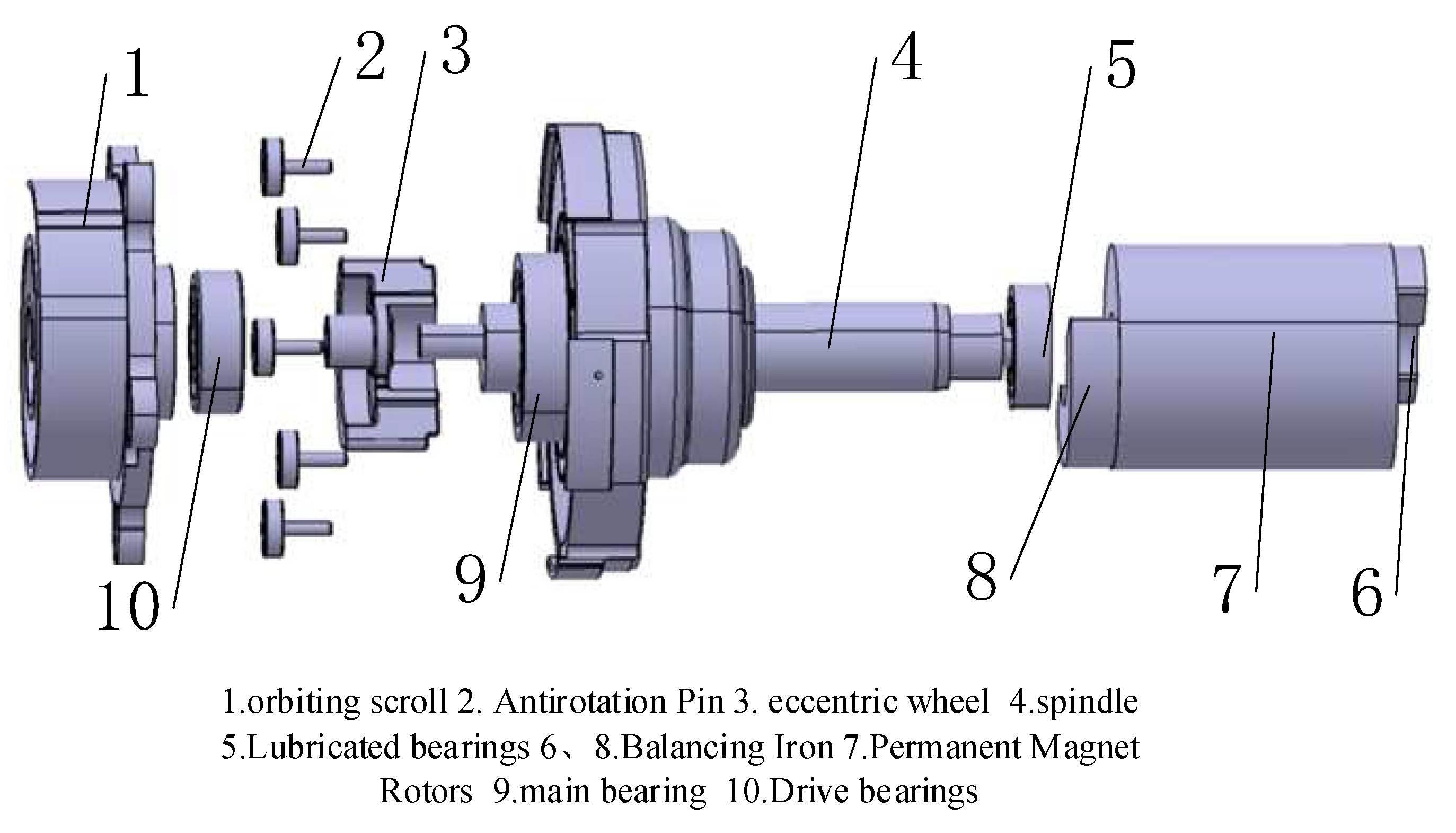

4. Scroll Compressor Rotor System Model

4.1. Defining Material Properties

4.2. Creating Constraints, Drivers and Measurements

4.3. Loading Gas Forces

5. Simulation Results and Analysis of the Driveline

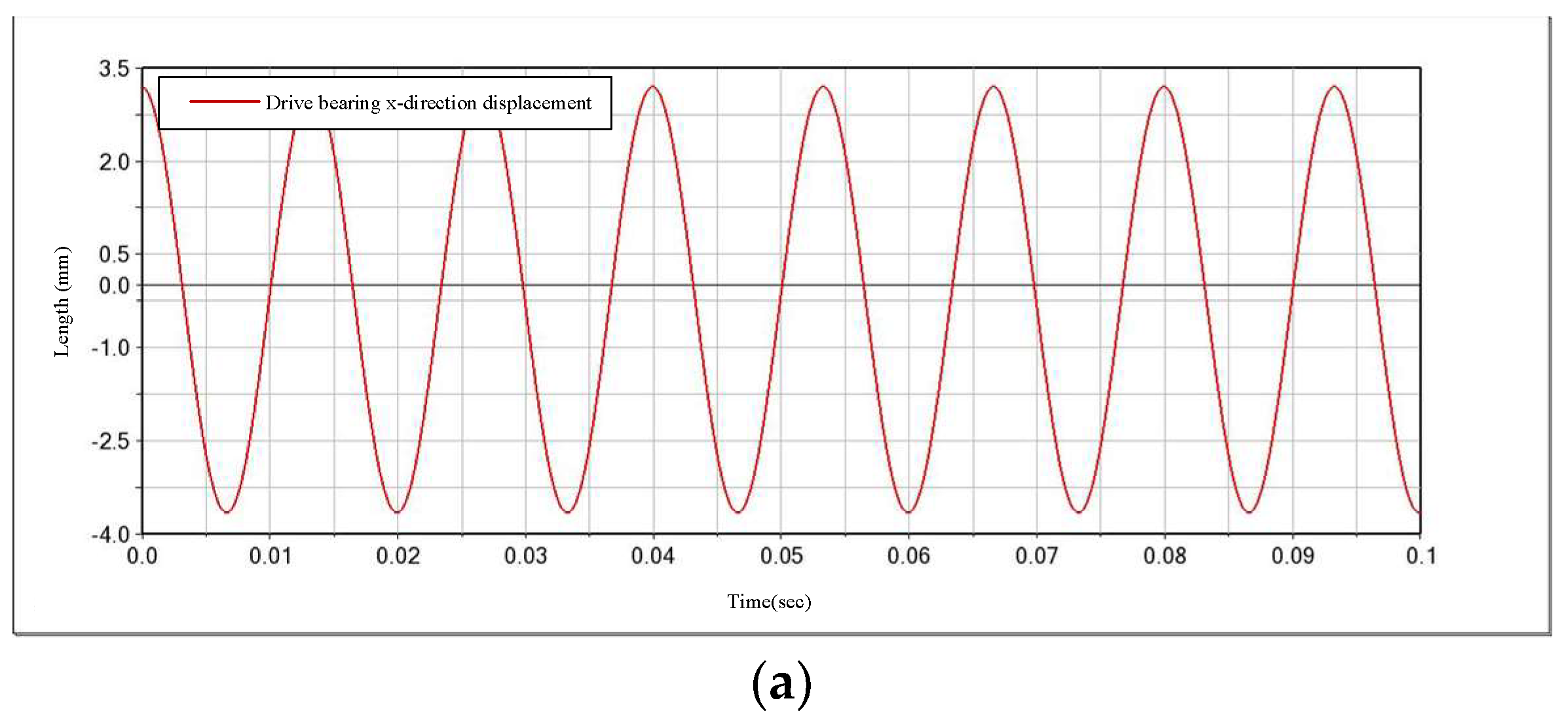

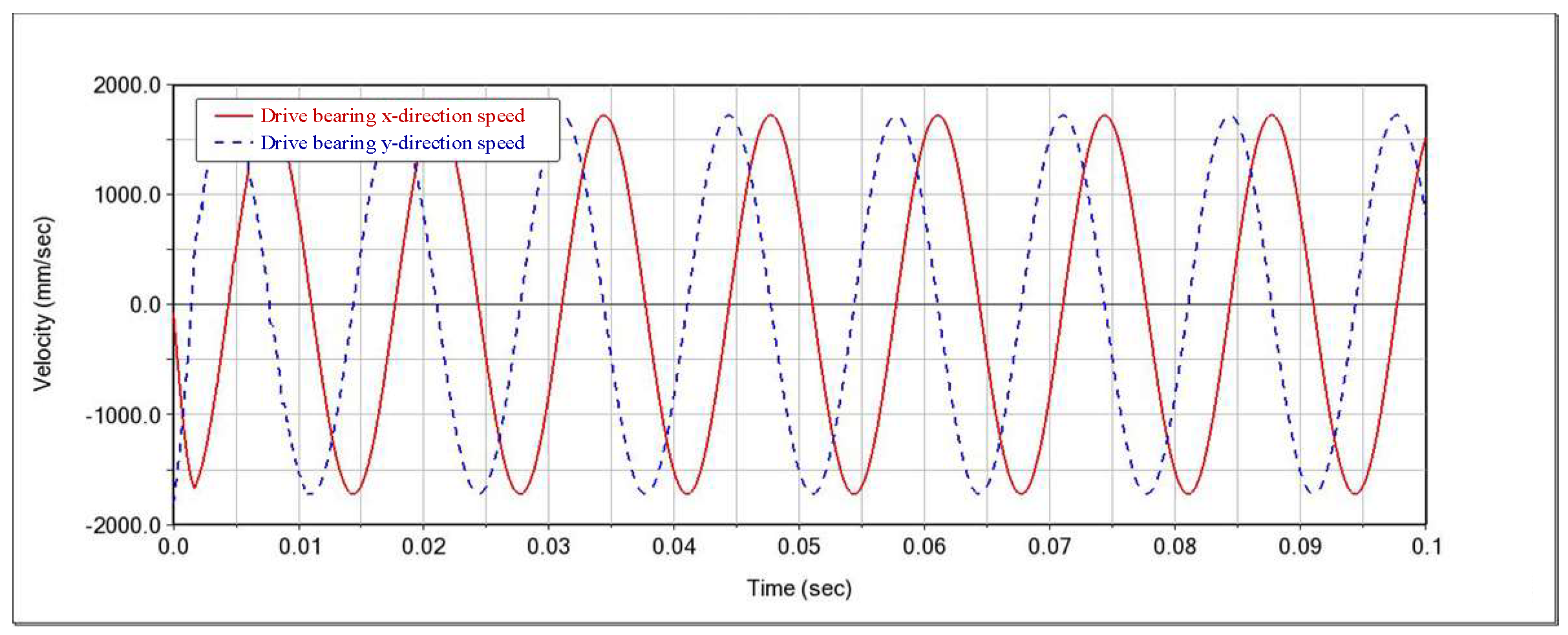

5.1. Model Motion Analysis

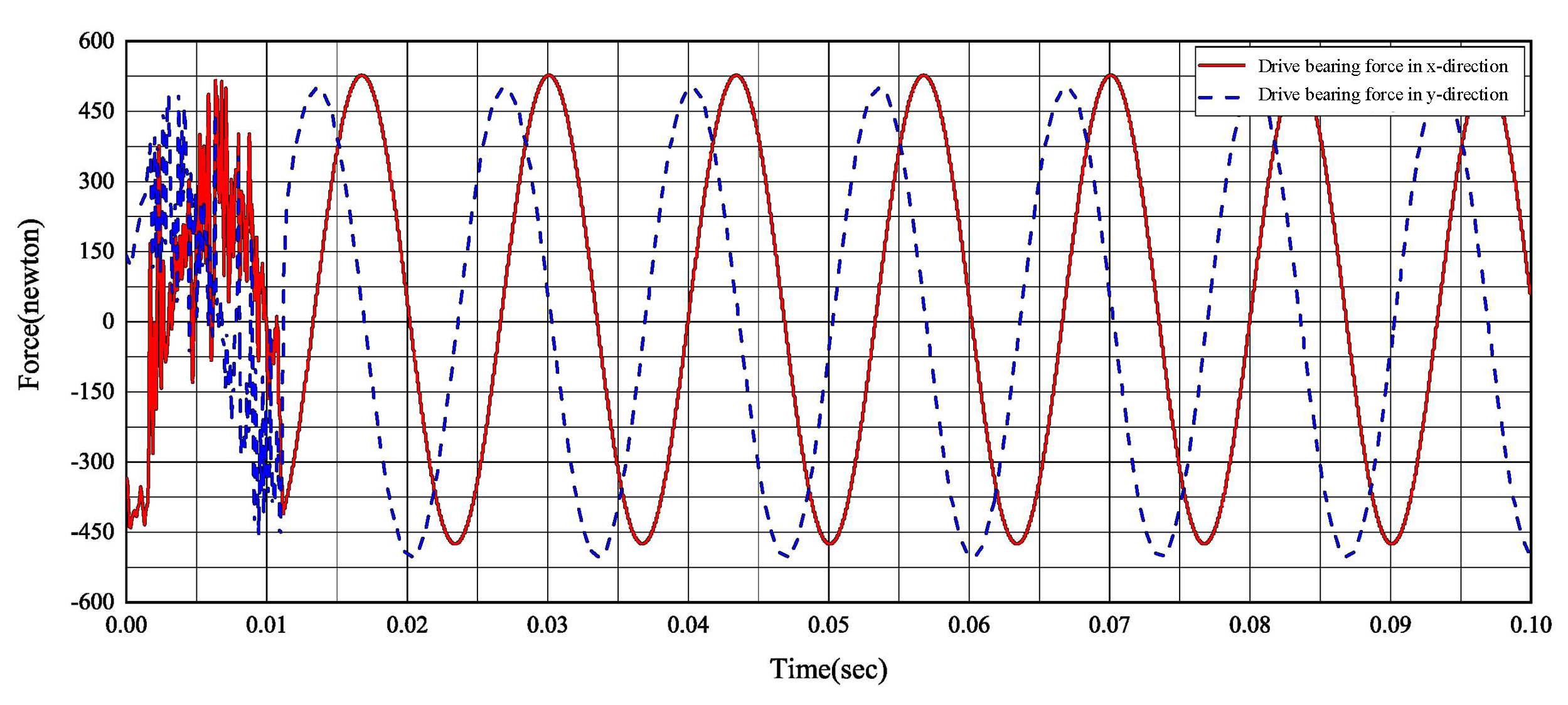

5.2. Dynamic Simulation Analysis

6. Optimization of Drivetrain Dynamic Balance Model

6.1. Model Parameterization

6.2. Determination of the Objective Function

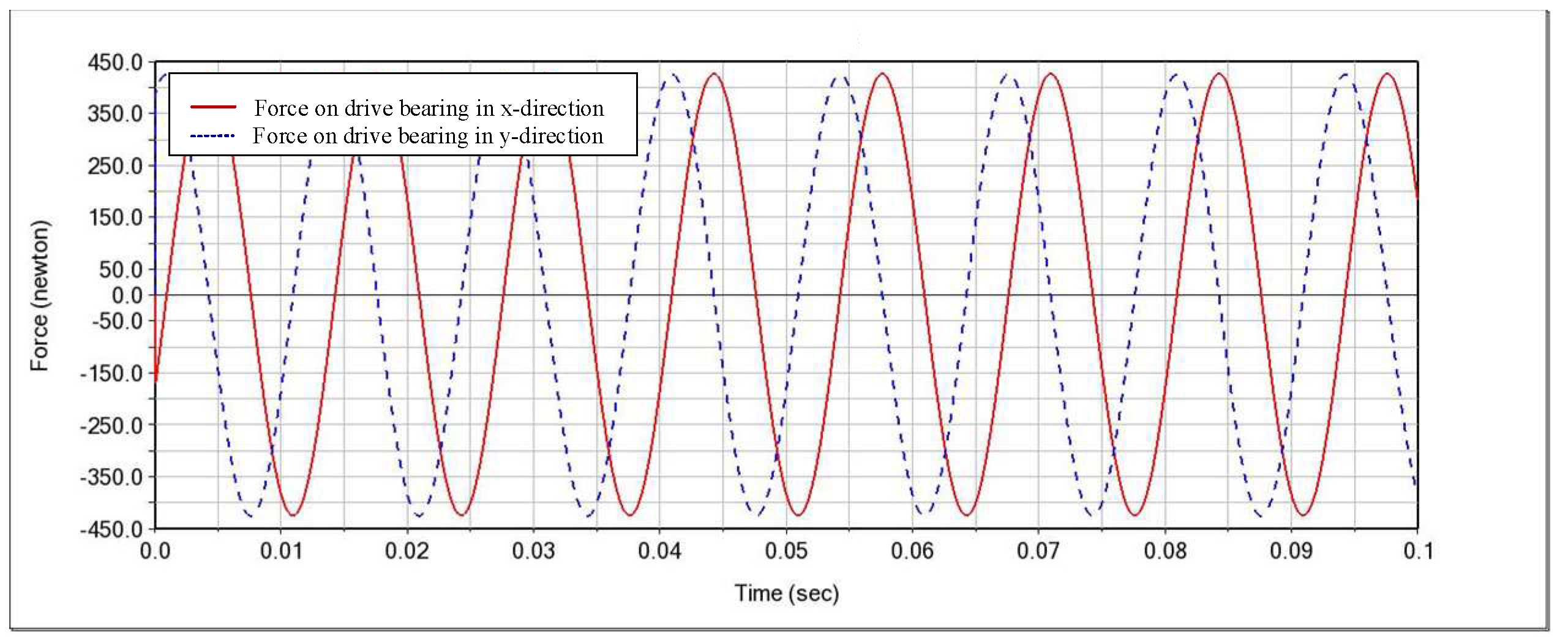

6.3. Optimization Analysis

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| total radial force (N) | the suction pressure (Mpa) | ||

| axial gas force (N) | the pitch of the scroll teeth (mm) | ||

| radial gas force (N) | |||

| tangential gas force (N) | the included angles of the line of action of the total radial force with respect to the direction of the principal coordinates (rad) | ||

| the compression chamber pressure (Mpa) | |||

| the compression chamber volume ( | |||

| the radius of the base circle (mm) | |||

| the equivalent effect of the centrifugal inertial force of the moving vortex disk transformed to the 1-1 action surface (N) | the included angles of the line of action of the total radial force with respect to the direction of the radial gas force (rad) | ||

| the displacement of the centre of mass turned in the x-direction (mm) | the tooth height (mm) | ||

| the crankshaft angle (rad) | |||

| the displacement of the centre of mass turned in the y-direction (mm) | the angular velocity of rotation of the drive system (rad/s) | ||

| the drive-bearing center-of-mass velocity in the x-direction (mm/s) | the compression chamber number | ||

| the drive-bearing center-of-mass velocity in the y-direction (mm/s) | |||

References

- Yang, W.Z.; Feng, Z.G.; Su, Y.F. Simulation and analysis of dynamic balance of scroll compressor’s transmission system. Mach. Des. Manuf. 2023, 80–83. [Google Scholar] [CrossRef]

- Pu, J.; Zhang, X.H.; Su, Y.F.; Yao, H. Dynamic characteristics analysis of rotor system of a new high speed scroll compressor. J. Guizhou Univ. (Nat. Sci.) 2020, 37, 23–27. [Google Scholar]

- Zhang, Y.B.; Peng, B.; Zhang, P.C.; Sun, J.; Liao, Z.X. Key technologies and application of electric scroll compressors: A Review. Energies 2024, 17, 179. [Google Scholar] [CrossRef]

- Li, C.; Wang, H.H.; Zhang, X.D.; Liu, J.Z. Study on the dynamic characteristics of scroll compressor rotor system considering the influence of clearance. Fluid Mach. 2021, 49, 43–50. [Google Scholar] [CrossRef]

- Dang, J.W. Study on Dynamic characteristics of rotor system of radial flexible mechanism of scroll compressor. J. Lanzhou Univ. Technol. 2023. [CrossRef]

- Zhao, M.; Zhang, Q.; Yan, P.J. Dynamics simulation analysis of drive bearing in scroll compressor with joint clearance. Compress. Technol. 2019, 4, 7–12. [Google Scholar]

- Zhao, M.; Li, X.Q. Simulation and rigid-flexible coupling analysis of orbiting scroll overturning of scroll compressor based on ADAMS. J. Lanzhou Univ. Technol. 2021, 47, 61–65. [Google Scholar]

- Li, C.; Cui, D.C.; Wang, X.L.; Liu, H.Y. Study on the stability of scroll compressor rotor system considering the influence of gas force. Fluid Mach. 2019, 47, 15–20. [Google Scholar]

- Cheng, J.G.; Li, C.; Zhang, Y. Research on Lubrication Characteristics of Scroll Compressor Thrust Bearing. Fluid Mach. 2023, 51, 66–75. [Google Scholar]

- Li, Y. Research on Multi-Body Dynamics Characteristics of Scroll Compressor Rotor System. Master’s thesis, Lanzhou University of Technology, Lanzhou, China, 2022. [Google Scholar]

- Tiwari, M.; Gupta, K. Dynamic response of an unbalanced rotor supported on ball bearings. J. Sound Vib. 2000, 238, 757–779. [Google Scholar] [CrossRef]

- Wang, A.M.; Cheng, X.H.; Meng, G.Y.; Xia, Y.; Wo, L.; Wang, Z.Y. Dynamic analysis and numerical experiments for balancing of the continuous single-disc and single-span rotor-bearing system. Mech. Syst. Signal Process. 2017, 86, 151–176. [Google Scholar] [CrossRef]

- Yu, Y.; Li, C.; Zhao, M.; Zheng, S.S. Analysis of bearing loads for scroll compressor considering phase-angled counterweights. Appl. Mech. Mater. 2012, 226–228, 483–486. [Google Scholar] [CrossRef]

- Ahn, S.; Choi, S.; Lee, B.; Rhim, Y.C. Analysis of thrust bearing in high-side shell type scroll compressor. Int. J. Refrig. 2016, 69, 251–260. [Google Scholar] [CrossRef]

- Kim, M.S.; Shim, J.; Kim, J.; Jang, D.G.; Park, S.S. Multiphysics simulation and experiment of a thrust bearing in scroll compressors. Tribol. Int. 2020, 142, 105969. [Google Scholar] [CrossRef]

- Makino, M.; Ogawa, N.; Abe, Y.; Fujiwara, Y. Automotive Air-Conditioning Electrically Driven Compressor; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Yu, Y.; Wang, X.M. Transient flow analysis for multi-state automotive scroll compressors. J. Phys. Conf. Ser. 2020, 1601, 042006. [Google Scholar] [CrossRef]

- Ma, L.Y. Compressor bearing dynamics analysis and life prediction. China Sci. Technol. Inf. 2023, 113–116. [Google Scholar] [CrossRef]

- Qian, W.X.; Gao, Q.H.; Li, X.Y.; Li, Y.N. Simulation study of dynamic characteristics of axial piston pump based on virtual prototype. Chin. Hydraul. Pneum. 2017, 61–67. [Google Scholar] [CrossRef]

- Sun, Y.; Jiang, J.H.; Cheng, M.Z.; Wang, Y.C. Research and application of virtual prototype technology base on dynamic simulation and analysis of axial piston pump. Chin. Hydraul. Pneum. 2010, 25–27. [Google Scholar] [CrossRef]

| Serial Number | Parts | Movement Subtypes |

|---|---|---|

| 1 | Spindle, Permanent Magnet Rotors | Fixing |

| 2 | Main Bearing, Spindle | Hinge connection |

| 3 | Secondary Bearing, Spindle | Hinge connection |

| 4 | Balancing Iron, Permanent Magnet Rotors | Fixing |

| 5 | Biasing Wheel, Spindle | Fixing |

| 6 | Biasing Wheel, Drive Bearings | Fixing |

| 7 | Drive Bearings, Orbiting Scroll | Hinge connection |

| 8 | Secondary Bearing | Relative geodesic fixation |

| Title | Notation | Numerical Value |

|---|---|---|

| Base circle radius | 1.65 mm | |

| Involute start angle | 51.6° | |

| Turning radius | 3.77 mm | |

| Pitch of vortex ring | 10.3 mm | |

| Vortex ring wall thickness | 2.8 mm | |

| Vortex ring height | 19 mm | |

| Number of swirl rings | 2.5 | |

| Maximum spread angle | 5.5 |

| Design Variable | Starting Value | Minimum Value | Maximum Value |

|---|---|---|---|

| DV_1 | −10.9 | −20 | 15 |

| DV_2 | 2.3 | −15 | 20 |

| DV_3 | −94.0 | −150 | 50 |

| Design Variable | Variable Initial Value | Initial Value Sensitivity |

|---|---|---|

| DV_1 | −10.9 | 20.5 |

| DV_2 | 2.3 | −1.96 |

| DV_3 | −94.0 | 0.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, M.; Yang, B.; Li, X.; Li, A.; Gao, F.; Ge, M. Dynamic Balance Simulation and Optimization of Electric Vehicle Scroll Compressor Rotor System. Appl. Sci. 2024, 14, 5024. https://doi.org/10.3390/app14125024

Yuan M, Yang B, Li X, Li A, Gao F, Ge M. Dynamic Balance Simulation and Optimization of Electric Vehicle Scroll Compressor Rotor System. Applied Sciences. 2024; 14(12):5024. https://doi.org/10.3390/app14125024

Chicago/Turabian StyleYuan, Mengli, Bin Yang, Xin Li, Annan Li, Feng Gao, and Mengqi Ge. 2024. "Dynamic Balance Simulation and Optimization of Electric Vehicle Scroll Compressor Rotor System" Applied Sciences 14, no. 12: 5024. https://doi.org/10.3390/app14125024

APA StyleYuan, M., Yang, B., Li, X., Li, A., Gao, F., & Ge, M. (2024). Dynamic Balance Simulation and Optimization of Electric Vehicle Scroll Compressor Rotor System. Applied Sciences, 14(12), 5024. https://doi.org/10.3390/app14125024