Abstract

This study aimed to calculate the optimal thermal processing parameters for goose meat using CFD simulation. CFD provides a precise determination of heat treatment conditions by predicting protein denaturation and mass loss, leading to higher quality and improved sensory experience and, thus, acceptance of products. Accurate calculation of these conditions reduces energy losses and enhances process efficiency in the food industry. This study focused on the prediction of protein denaturation and cooking loss in goose breast meat during roasting. Specific CFD techniques, including conjugate heat transfer and phase change models, were utilized to ensure accuracy in protein denaturation prediction. These models accounted for variations in meat composition, such as fat and water content across different samples, which improved the accuracy of the predictions. Optimal conditions were determined using a mathematical model. These conditions were 164.65 °C, 63.58% humidity, and a fan rotation of 16.59 rpm for 2000 s. The myosin, collagen, and actin denaturation levels, as well as cooking loss, closely matched predicted values. The findings show that CFD is a valuable method for evaluating protein denaturation and cooking loss in goose breast meat, potentially improving product quality and consistency in gastronomy and the meat industry. This innovative optimization method enhances food production efficiency and elevates sensory characteristics, physicochemical properties, and nutritional value, contributing to consumer satisfaction and market competitiveness. The model proposed in this paper can be adapted to predict denaturation in other types of meat or food products with necessary modifications, offering broad applicability. Potential limitations of using CFD in protein denaturation prediction in complex food matrices include the need for detailed compositional data and computational resources, which can be addressed in future research.

1. Introduction

In today’s dynamic market and social environment, the quality of goose meat has become a crucial factor defining the success of the meat industry and gastronomy. Consumer awareness regarding the source and quality of consumed products has reached a new level, with expectations extending beyond basic nutrients to encompass sensory, ethical, and sustainable development aspects [1]. Goose meat without skin, characterized by its low-fat content and specific muscle structure, influences the protein denaturation process differently compared to other types of meat. The low-fat content and high water content in goose meat result in dynamic thermal transfer to the geometric interior of the sample. Additionally, the unique muscle structure of geese, which contains more dark muscles rich in myoglobin, can affect the rate and manner in which proteins denature. As a result, goose meat may require a longer cooking time compared to poultry or pork to achieve optimal texture and flavor. Goose meat, with its unique texture and flavor, is gaining popularity [2,3]. Meeting these consumer expectations requires not only excellent breeding and nutrition but also a precise understanding of the processes influencing the final product’s quality [4]. The quality of goose meat thus becomes a key competitive factor in the food market, affecting not only health but also overall consumer satisfaction [5,6,7].

A critical aspect of goose meat quality is the protein denaturation process, which is a complex phenomenon involving dynamic processes at the molecular level that largely determine the final structure and characteristics of meat products [8,9]. This is a key process in shaping the unique characteristics of goose meat, affecting its cohesion, juiciness, and durability [10,11]. Understanding the correlation between thermal process parameters and protein denaturation in goose meat can provide valuable insights into optimizing these parameters to achieve the desired balance between meat durability and preserving its taste, consistency, and nutritional value [12,13,14].

To meet the growing expectations of consumers and improve the energy efficiency of meat production, strict control and optimization of thermal process parameters are essential [15]. Parameters such as temperature, process duration, and heat flow velocity are crucial in minimizing energy and resource losses while aligning with sustainable development principles [16]. Furthermore, optimizing these thermal parameters directly impacts the sensory characteristics of goose meat, influencing the taste, aroma, and consistency of the meat. The interaction of various thermal processing parameters—temperature, humidity, and airflow—significantly influences the denaturation of proteins in goose meat. Higher temperatures accelerate the denaturation process, causing proteins such as myosin and actin to unfold and coagulate, leading to changes in texture and moisture retention. Increased humidity during cooking can help maintain meat juiciness by reducing water loss, thus affecting the extent and rate of protein denaturation. Conversely, low humidity might enhance surface dehydration and protein hardening. Airflow also plays a crucial role; consistent airflow ensures even heat distribution, preventing localized overheating and uneven protein denaturation. Therefore, optimizing these parameters is essential to achieve the desired texture, flavor, and moisture levels in cooked goose meat [4,17,18].

Previous studies on the phytochemical composition of goose breast meat have shown that it is essential to understand the diversity of phytochemicals in their different parts and their impact on physicochemical properties and thermal parameters. Goose meat, like other types of meat, contains complex mixtures of chemical compounds, including proteins, lipids, carbohydrates, vitamins, and minerals. The composition of these compounds can vary depending on the part of the meat, affecting its texture, flavor, and reactions to heat treatment. Phytochemical composition models enable precise mapping of these compounds, which is crucial for understanding the protein denaturation processes during cooking. Protein denaturation, a process of altering the tertiary structure of proteins under the influence of temperature, is a key factor affecting the texture and juiciness of the meat. Thermal parameters, i.e., heat capacity, thermal conductivity, and specific temperatures, are closely related to the phytochemical composition, influencing the efficiency of thermal processes in the food industry. Understanding these compounds and their interactions during heat treatment allows for the optimization of technological processes, potentially leading to improved quality of the final product [4,18,19].

Innovative approaches based on computational engineering methods, especially Computational Fluid Dynamics (CFD), are revolutionizing research on protein denaturation in food. CFD is an indispensable tool for modeling heat, mass flow, and chemical reactions during thermal processes [20,21]. This method allows precise simulation of conditions during the thermal processing of goose meat, providing crucial information on how environmental factors affect protein denaturation at the molecular level [22]. CFD enables the development of complex yet realistic heat flow models, which are essential for the analysis and optimization of thermal processes Conventional methods and computational fluid dynamics (CFD) differ significantly in predicting protein denaturation and cooking loss. Conventional methods typically rely on experimental measurements and empirical models, which can be time-consuming and expensive, often requiring simplifications and assumptions that may reduce accuracy. In contrast, CFD uses advanced algorithms and computer simulations to provide more detailed and comprehensive modeling of the thermal and chemical processes occurring in proteins. This allows CFD to offer more accurate predictions of protein denaturation and cooking loss, and it is more time-efficient as it enables rapid simulations of multiple scenarios without the need for numerous experiments. As a result, CFD can greatly enhance the precision and efficiency of the prediction process compared to traditional methods. The application of CFD to predict protein denaturation in complex food matrices faces several limitations and challenges. These include the inherent complexity and heterogeneity of food matrices, which can make it difficult to accurately model the physical and chemical environments. Additionally, the lack of precise kinetic data on protein denaturation processes under varying conditions complicates the simulation accuracy. To mitigate these challenges, future studies should focus on integrating more detailed and experimentally validated kinetic models of protein denaturation. Improved computational techniques that can handle the complexity and multi-scale nature of food matrices are also essential. Collaboration between computational scientists and food technologists can help in refining models to better reflect real-world conditions, thereby enhancing the predictive capabilities of CFD in food science [23,24,25]. Changes in consumer preferences and expectations, such as a growing demand for healthier, safer, and more sustainably produced meat, drive the need for advancements in meat processing technologies like CFD. Consumers are increasingly seeking meat products with improved texture, flavor, and nutritional value while also demanding transparency and minimal environmental impact. This necessitates more precise and efficient processing techniques. CFD helps optimize processes by predicting heat and mass transfer, improving quality control, and reducing waste. Anticipated future trends include the integration of artificial intelligence with CFD for real-time process optimization, enhanced texture and flavor profiles, and greater focus on energy-efficient and environmentally friendly processing methods. These advancements aim to meet consumer demands while ensuring high-quality and sustainable meat production. Consumers are increasingly looking for technologies and application solutions for preparing food at home. Undoubtedly, goose meat requires specialized thermal treatment. CFD will allow you to professionally program the process of thermal processing of goose meat in a home oven, thanks to which the high quality of the final product will be maintained. The innovative use of CFD modeling will encourage consumers to learn new culinary techniques that will guarantee satisfaction with the choice of expensive meat.

The object of the experiment was to calculate the optimal parameters of the thermal processing of goose meat based on CFD simulation. The solver parameters for the SST turbulence model were set with a convergence criterion of 10 × 10−4 and 600 iterations. The solver’s working type was specified as Double Precision. The selection of the SST turbulence model was made due to its versatility, efficient management of boundary layers, comparatively low computational complexity, and extensive application in the realm of CFD. Regarding the transient state solver definition, an adaptive time step was implemented with 2–5 iterations per step, a time step range of 0.1–10 s, and a process duration of 2000 s. Thanks to the use of CFD for predicting the protein denaturation level and mass decrease in goose meat, it is possible to precisely determine the optimal conditions for heat treatment. This will allow for the production of products with better and more consistent quality and, consequently, higher sensory acceptance among consumers. By accurately calculating the optimal conditions for thermal processing, the heat dose will be precisely adjusted, which will allow for the reduction of energy losses in the food industry. As a result, energy consumption during roasting will be reduced. Additionally, the reduced mass loss during the thermal processes of goose meat will lead to increased process efficiency in gastronomy and the meat processing sector.

2. Materials and Methods

2.1. Materials

In this study, a variety of reagents, consumables, and materials have been used. The following is a detailed list of these materials, including their sources, suppliers, and purities:

Geese samples: The goose breast fillets without skin (Pectoralis major) used for the experiment were taken from oat geese White Kołuda® and acquired from a commercial plant (ZD DROP SA, Ostrzeszów, Poland).

Temperature and humidity sensors: TrackSense Pro wireless temperature and humidity sensors were used for precise temperature measurement within the geese samples. These sensors were supplied by Ellab (TrackSense® Pro, Ellab, Hillerød, Denmark).

DSC materials: The geese muscle proteins denaturation level was evaluated using differential scanning calorimetry DSC 1 from Mettler Toledo (Schwerzenbach, Switzerland). For DSC analysis standard 40 μL aluminum pans (No.: ME-51119870) tightly sealed with aluminum lids (No.: ME-51119871) have been used. The instrument was calibrated using pure indium and zinc (Mettler Toledo).

Gases: Argon of purity 5.0 (99.999%) was used in the DSC analysis (ALPHAGAZTM 1 Ar; Air Liquide, Graz, Austria, 5.0).

Software: The CFD simulations were carried out using ANSYS Fluent software R19.0 (ANSYS, Inc., Canonsburg, PA, USA).

2.2. Experiment Design

Three design factors—temperature, humidity, and fan rotation speed—were used as quantitative autonomous variables to examine their impact on the degree of denaturation of myosin, collagen, actin, and cooking loss. These independent variables were assessed across the following ranges: 140–190 °C for temperature, 0–60% for humidity, and 0–1400 rpm for fan rotation speed The parameter ranges were determined based on the literature research and preliminary studies [2,14,26]. The software application Design Expert version 11 (Stat-Ease, Inc., USA) was employed to conduct 20 experiments (see Table 1). A quadratic equation was selected to illustrate the connections between the variables and responses. The model’s central point was duplicated six times for accuracy.

Table 1.

Experiment design.

2.3. The Heat Treatment Process Using CDF Simulation

2.3.1. CFD Description and Implementation

The Ansys software (version 19.0; the supplier of software: MEsco Ltd., Pune, India) was used to design a 3D model of the testing device, and it was also used for simulating heat treatment in the oven. The simulation process followed the procedure published by Szpicer et al. [24] with certain modifications.

The main elements that affect the thermal properties of food items include their primary constituents, which comprise quantities of basic composition. The conduction coefficient (λ) and specific heat (Cp) of the raw sample play a role in determining these components. The basic composition of goose breast meat can exhibit variation attributable to factors such as breeding method, age, developmental stage, or activity level [14,18,27,28]. Input data for simulation were derived from the basic composition of goose breast as determined by Damaziak et al.: 57.93% water, 22.16% fat, 17.55% proteins, 1.43% CTP (connective tissue protein), and 0.93% ash [1]. The work aimed to establish the thermal penetration coefficient for calculating the denaturation extent of individual proteins and the consequent cooking loss. The differential scanning calorimetry (DSC) technique was employed to collect temperature and specific heat information for each protein type: myosin at 56.65 °C, collagen at 63.03 °C, and actin at 80.46 °C, with specific heat values of 6.55 J/gK, 0.94 J/gK, and 5.29 J/gK, respectively [2].

To run the simulation, a three-dimensional model of a combination steamer (CPE 110, Convect-Air Professional Küppersbusch Germany) was prepared using the approach described by Szpicer et al. [22]. The setup comprised a heater, fan, steam generator, and GN container rack. A piece of goose breast meat measuring 35 × 35 × 35 mm was positioned on a GN ½ tray (530 × 325 × 20 mm) within the chamber. The roasting duration was simulated for 2000 s, assuming the meat had an anisotropic microstructure [29,30]. To account for the anisotropic properties of the meat, the thermal conductivity and mass diffusivity were defined as anisotropic in the simulation. The thermal conductivity along the muscle fibers (λ1) was set to 0.7 W/m⋅K, and across the fibers (λt), it was set to 0.3 W/m⋅K. The mass diffusivity for water along the muscle fibers (D1) was set to 1.2 × 10−9 m2/s, and across the fibers (Dt) to 0.7 × 10−9 m2/s [31,32]. The forced convection was characterized by the overall heat transfer coefficient, while water diffusion was modeled using Fick’s law of diffusion with a global diffusion coefficient [33,34].

2.3.2. Numerical Model

The Analyzed Space

The model consisted of three separate regions. The first area covered the fluid surrounding the sleeve-shaped rotor, which rotated at a predetermined speed. This setup allowed for the simulation of the rotor’s movement within the chamber, with the blades depicted as surfaces. The second region represented the chamber space where air circulation was generated by the rotating rotor. Finally, the third section comprised two solid elements: the sample insert and the supporting plate.

Mesh

A Hex structural mesh was applied to the rotor space, incorporating surface compaction for the rotor blades to enhance flow representation. For the chamber, a Tetra/Prism mesh was used, with prismatic elements strategically placed, such as along the meat and plate walls, for heat transfer analysis. Hexa mesh was chosen for the goose breast sample and plate. The model specifications were as follows: rotor space—152,880 hexes and 177,702 nodes; chamber—339,867 tetras, 100,385 prisms, and 120,714 nodes; meat and plate—54,528 hexes and 62,148 nodes.

Materials

In the computations, the materials used included a blend of air and water vapor, goose breast meat as the used material, and stainless steel (AISI 304). The initial temperature of the solids was set at 25 °C.

Material data:

Goose breast meat:

The determination of the conduction coefficient (λ) relied on Equation (1) following the description by Choi and Okos, considering the essential composition of the sample [35].

where:

x—mass fraction of the food ingredient,

indexes:

c—carbohydrates,

p—proteins,

f—fat,

a—ash,

w—water.

The computation of specific heat (Cp) was derived from Equation (2) following the explanation provided by Singh and Heldman, considering the fundamental composition of the samples [36].

where:

x—mass fraction of the food ingredient,

indexes:

c—carbohydrates,

p—proteins,

f—fat,

a—ash,

w—water.

Stainless Steel (AISI 304—properties at 300 K) [37]

Conduction coefficient (λ)—14.9 W/m⋅K

Specific heat (Cp)—477 J/kgK.

Air—Air Ideal Gas:

The ideal gas equation of state can be applied for the computation of different gas properties according to Equation (3).

where:

p—the absolute pressure of the gas,

V—the volume of the gas,

n—the amount of substance of gas (also known as number of moles),

R—the ideal, or universal, gas constant, equal to the product of the Boltzmann constant and the Avogadro constant,

T—the absolute temperature of the gas.

Water vapor—Redlich-Kwong Dry Steam:

Properties were determined using the Redlich-Kwong equation, as denoted by Equation (4) [38].

where:

- p—gas pressure,

- R—gas constant,

- T—temperature,

- Vm—molar volume (V/n),

- a—constant that corrects for attractive potential of molecules,

- b—constant that corrects for volume.

The measurement used a gas mixture comprising steam and air, with the composition of the blend determined by the mass fractions of its constituent components.

- Humidity

The Goff-Gratch equation (Equation (5)) [39] was applied to convert humidity into mass fractions of steam and air at a particular temperature.

where:

log refers to the logarithm in base 10

e*—the saturation water vapor pressure (hPa)

T—the absolute air temperature in Kelvins

Tst—the steam-point (i.e., boiling point at 1 atm.) temperature (373.15 K)

e*st—e* at the steam-point pressure (1 atm = 1013.25 hPa)

Using Equation (6), the mass fraction of water vapor in the mixture was established by considering the saturation pressure at the provided temperature and the designated humidity.

Stages of CFD Analysis

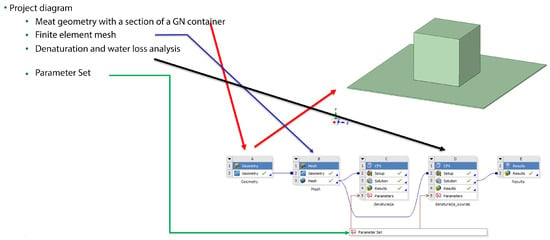

The CFD analysis was conducted in two phases, necessitated by the fluctuating output parameters during roasting and the model’s size (Figure 1). The 1st phase encompassed a steady-state analysis, yielding actual heat transfer coefficients on the surfaces of the goose fillet sample and the GN container. In the subsequent phase, the outcomes from the 1st stage were used in modeling the solids (goose sample and GN container), and transient simulations were executed to capture the temperature variations of the samples over time. The 1st stage focused on determining penetration coefficients, while the 2nd stage involved simulating protein denaturation and cooking loss.

Figure 1.

Project diagram.

For the first part of the analysis, a steady gas flow inside the chamber was obtained, forced by the rotation of the rotor. A constant temperature of the medium was assumed according to Table 1 and adiabatic flow (without temperature loss). Based on steady-state calculations, heat transfer coefficients on the surface of the meat and the plate are obtained. These data were used as boundary conditions for further unsteady-state analysis for solids. For the unsteady state analysis, the initial temperature was 25 °C and the process duration was 2000 s. The unsteady state thermal analysis was carried out only for the lump of meat and the supporting plate. The heat transfer coefficient and external temperature determining heat transfer were obtained from steady-state analysis.

Boundary Conditions and Initial Setup from Ansys

The simulation of protein denaturation and heat treatment optimization in goose breast meat was conducted using ANSYS software. The methodology comprised two stages: determination of penetration coefficients and simulation of denaturation and water extrusion.

- Determination of Penetration Coefficients

In the initial stage, the following boundary conditions were applied:

- Vapour density: 0.5163 kg/m3

- Volume fraction: 0.63828

- Air density (Rho air): 0.83419 kg/m3

- Absolute humidity: 0.75998

- Mass mixing ratio: 0.47672

- Steam density (Rho steam): 0.5163 kg/m3

- Volume mixing ratio: 0.63828

- Surface heat transfer coefficient: 31.071 W/(m2 × K)

The parameters for process temperature, humidity, and fan speed were set in accordance with Table 1 for each run.

- II.

- Simulation of Denaturation and Water Extrusion

In the second stage, the following initial conditions and parameters were used:

- Initial temperature of the meat: 298.15 K

- Temperature inside the oven: As specified in the first stage

- Fraction water: 57.93%

- Fraction ash: 0.93%

- Fraction fat: 22.16%

- Fraction CTP (connective tissue proteins): 1.43%

- Fraction protein: 17.55%

- Roasting time: 2000 s

- Roasting time steps: 10 s

- Transient results time step interval: 1 s

The denaturation temperatures for specific proteins were:

- Myosin: 56.65 °C

- Collagen: 63.03 °C

- Actin: 80.46 °C

The grid independence study in the CFD simulations was conducted by systematically varying the grid resolution while keeping other parameters constant. This involved running simulations with different grid sizes and analyzing the results to determine if changes in resolution significantly affected the outcomes. The results confirmed the accuracy of the simulations by demonstrating consistent convergence of key flow parameters across varying grid resolutions, indicating that the chosen grid resolution was adequate for reliable predictions.

2.4. Roasting Optimization Using RSM

The study concerns the influence of three different factors on the denaturation of myosin, collagen, actin, and mass loss, which was evaluated. The variables considered were the temperature within the furnace, air stream speed (fan speed), and humidity level. A quadratic equation was used to identify and characterize the correlation between these variables and the measured parameters. The central point was replicated six times in the model. Using Design Expert version 11 (Stat-Ease, Inc., Minneapolis, MN, USA), the thermal treatment was optimized concerning the denaturation of myosin, collagen, actin, and cooking loss based on the model. The final step involved optimizing heat treatment parameters according to the RSM production model and empirical validation of the evaluated response values.

2.5. Verification of the Predicted Results Using Laboratory Tests

2.5.1. Goose Breast Meat

Goose breast fillets without skin (Pectoralis major) for the experiment were taken from oat geese White Kołuda® acquired from a commercial plant (ZD DROP SA, Ostrzeszów, Poland). The geese’s welfare adhered to universally accepted standards for geese in Poland [40], and they were processed in a commercial slaughterhouse following standard procedures. The fillets (430 ± 30 g) were subjected to further processing. The fillets were transported to the laboratory in cooling boxes, maintaining cooled conditions at 4 ± 1 °C. Cube-shaped samples (35 × 35 × 35 mm) were cut from goose breasts without skin, according to Figure 2.

Figure 2.

Scheme of meat sample preparation for laboratory tests at the stage of verification of the prediction model.

2.5.2. The Proximate Composition Evaluation

The proximate composition of goose breast muscle was analyzed using the near-infrared (NIR) spectrometry method as outlined by Stelmasiak et al. [41]. The measurements were performed using a NIRFlex N-500 spectrometer with a solid’s module (Büchi Labortechnik AG, Flawil, Switzerland) operating in reflectance mode, spanning a spectral range of 12,500–4000 cm−1, and employing Büchi Art. No. N555-501. Homogenized goose breasts, each weighing 100 g, were put onto the Petri dish and subjected to measurements. The assessment of the basic composition, encompassing water, fat, proteins, CTP, and ash, was conducted in triplicate (three technical replications). Measurements were taken for each of the 3 independent biological replications (3 different batches) involving distinct raw goose breast samples.

2.5.3. Heat Treatment

The goose meat cubes were thermally processed in accordance with the optimized parameters based on RSM data in a Küppersbusch CPE-110 combi-steam oven (Küppersbusch Convect-Air Professional; Essen, Germany). Process parameters (temperature and humidity) were controlled using wireless TrackSense Pro recorders (Ellab, Hillerød, Denmark).

2.5.4. The Protein Denaturation Level

Protein denaturation levels were assessed through DSC (DSC 1 Mettler Toledo; Schwerzenbach, Switzerland) [24]. Before the measurement, the instrument was calibrated using pure standards (zinc and indium). Both untreated and heat-treated samples were analyzed. A BÜCHI B-400 homogenizer was used to uniformly mix each sample. Subsequently, 10.0 ± 0.1 mg of goose samples were placed into a standard 40 μL aluminum pan (No.: ME-51119870) and tightly closed with an aluminum lid (No.: ME-51119871) using a Mettler Toledo Crucible Sealing Press.

DSC analysis was performed at a heating rate of 10 °C/min (β) under an argon atmosphere (100 cm3/min) within the temperature range of 10 °C to 100 °C. The resultant curves were scrutinized using STARe software to identify the initial (Ton), maximum (Tmax), and final (Tend) temperatures, along with the enthalpy (ΔH). The level of denaturation for myosin, collagen, and actin was ascertained based on the curves, according to the methodology outlined by Agafonkina et al. (2019) [42]. The denaturation level for each protein was calculated by comparing the enthalpy of denaturation between the untreated and heat-treated samples using Equation (7). The DSC analyses were conducted thrice for each sample.

where:

Hraw—the proteins denaturation enthalpy of raw goose sample before the heat treatment (J/g)

Hroasted—the proteins denaturation enthalpy of roasted goose sample following heat treatment (J/g)

The evaluation of the denaturation degree was conducted thrice for each sample to ensure the precision and dependability of the outcomes (three technical replicates). Measurements were carried out across three independent biological replicates (three separate batches) using distinct raw materials for each.

During the assessment of protein denaturation using DSC, potential sources of error primarily include sample preparation variability, instrument calibration inaccuracies, and baseline drift. These were minimized by employing standardized protocols for sample handling, regular calibration checks, and meticulous data analysis techniques to correct baseline fluctuations, ensuring precise measurement of protein unfolding transitions.

2.5.5. Cooking Loss

For the assessment of cooking loss, the sample underwent weighing before entering the oven and promptly after extraction. The degree of cooking loss was computed by evaluating the disparity in cooking between the raw and roasted goose samples, using Equation (8). These cooking loss tests were conducted in three repetitions.

where:

Mraw—the raw goose sample mass before thermal treatment (g)

Mroasted—the roasted goose sample mass after thermal treatment (g)

The evaluation of cooking loss was conducted three times for each sample (3 technical replicates). Measurements were carried out across three independent biological replicates (3 distinct batches), using varied raw materials for each batch.

2.6. Statistics

The experimental design was executed using Design Expert v. 11 software (Stat-Ease, Inc., USA), outlined in Table 1. An examination of the impact of temperature, humidity, and convection intensity on individual responses was conducted following the programmed experimental model. The significant terms within this model were identified through analysis of variance (ANOVA) for each response, assessing lack of fit, coefficients of determination (R2), and coefficients of variation (CV) to ensure model accuracy. Based on the analysis results, 3D charts were generated, and quadratic equations describing the model were employed for subsequent investigations.

During the prediction analysis with RSM, the maximum desired level of myosin and collagen denaturation was established, while minimizing actin denaturation and mass loss were chosen as parameters.

The final stage of the experiment was optimizing and validating the thermal treatment process. Values of predicted response were then compared with empirically determined values. Laboratory tests were conducted using raw materials from various production batches in three independent biological replicates. Following optimization, Student’s t-test at p ≤ 0.05 was applied to ascertain differences between two sets of values: expected and empirically measured properties in laboratory tests. Statistical analyses were conducted using Design Expert software, and the findings were showcased as mean (X−) ± standard deviation (SD). A Student’s t-test with a significance level of p ≤ 0.05 was employed to identify differences between two sets of values: predicted and measured properties from laboratory experiments.

3. Results and Discussion

3.1. Assessing the Model’s Adequacy

Figure 3 presents the temperature distribution and degree of protein denaturation in goose breast meat samples at intervals of 0, 250, 500, 750, 1000, 1250, 1500, 1750, and 2000 s during the roasting process, and Figure 4 presents the mechanism of action of the heat transfer. Table 2 showcases the regression coefficients of the predicted quadratic polynomial models for the physical attributes of myosin, collagen, actin denaturation, and cooking loss. The adequacy of the prediction models has been thoroughly evaluated and confirmed, with all R2 values ranging from 0.758 to 0.997. The adequacy of these models was evaluated based on their R2 values and the P-values of lack of fit. The R2 values for the myosin, collagen, and actin denaturation were impressively high, at 0.922, 0.982, and 0.997, respectively, indicating strong model performance and accurate predictions for these proteins. In contrast, the R2 value for cooking loss was lower, at 0.758, suggesting a relatively weaker but still acceptable model fit. No cases of insufficient model fitting were detected, as evidenced by the p-values of lack of fit for myosin, collagen, actin denaturation, and cooking loss, which were 0.237, 0.228, 0.158, and 0.139, respectively.

Figure 3.

Temperature distribution and protein denaturation degree in the goose breast meat sample after 0, 250, 500, 750, 1000, 1250, 1500, 1750, and 2000 s of the heat treatment process.

Figure 4.

The mechanism of action of the heat transfer.

Table 2.

Regression coefficients of the predicted quadratic polynomial models for the physical properties of myosin, collagen, actin denaturation, and cooking loss.

Standard deviation values ranged from 1.14 to 2.32, with the lowest standard deviation values observed for myosin denaturation level and actin denaturation level at 1.14 and 1.78, respectively. Collagen denaturation and cooking loss were described as standard deviations of 2.32 and 2.13, respectively. In optimizing the heat treatment process parameters for goose breast meat, 3 independent variables were taken into account: temperature, humidity, and fan rotation speed, representing the airflow speed within the oven chamber. The interactions between these variables and the responses were displayed in linear, intercept, and quadratic terms.

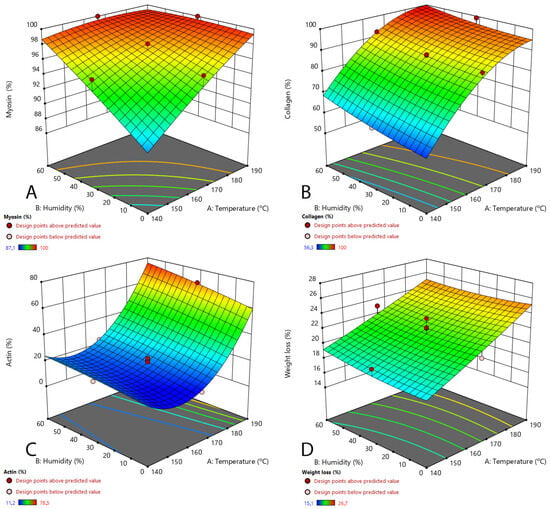

3.2. Thermal Treatment Parameters Optimization

RSM was used to assess the influence of temperature, humidity, and fan rotation on the heat treatment of goose breast fillets (Pectoralis major). This modeling technique enabled the observation of trends in the outcomes as the independent variables were altered. The regression coefficients outlined in Table 2, along with the 3D plots depicted in Figure 5, demonstrated that all three independent variables exerted a statistically significant effect on the denaturation levels of individual proteins, encompassing myosin, collagen, actin, and cooking loss in the goose samples. However, the extent of this impact varied depending on the specific response and the level of the independent variable.

Figure 5.

The 3D surface charts generated using the RSM model at fan rotation of 700 rpm illustrate the impact of factors and their interactions on output data: (A)—myoglobin denaturation [%], (B)—collagen denaturation [%], (C)—actin denaturation [%], and (D)—cooking loss [%].

The myosin denaturation level was notably impacted by temperature and humidity in linear terms (p ≤ 0.001). Similarly, a linear impact was observed for fan rotation speed (p ≤ 0.05) on myosin denaturation. Additionally, the interaction between temperature and humidity had a significant influence on myosin denaturation (p ≤ 0.001). Nevertheless, there were no significant effects of temperature, fan speed, and humidity in quadratic terms (p > 0.05). The interaction between fan speed × temperature and fan speed × humidity did not exert a significant influence on myosin denaturation (p ≤ 0.05). The study carried out by Vaskoska et al. [43] sheds light on the intricacies of myosin denaturation during thermal processing, particularly in masseter and cutaneous trunci muscles, which exhibit distinct characteristics. The research highlights significant differences in quality, chemical composition, and histological properties between the two muscle types. The masseter muscles exhibited elevated pH levels, as well as higher total and soluble collagen content, and shorter sarcomere length in comparison to the cutaneous trunci. Notably, myosin denaturation was found to occur at a lower temperature (54 °C) in cutaneous trunci compared to masseter (63 °C), where it coincided with collagen and sarcoplasmic protein denaturation. This lower transition temperature of myosin in cutaneous trunci was identified as a key factor contributing to a greater cooking loss and shrinkage in this muscle type compared to masseter at temperatures up to 65 °C. Additionally, the intense transverse shrinkage observed in the masseter at 60–70 °C coincided with the later onset of myosin denaturation in this muscle [43]. The study conducted by Zhang et al. [44] delves into the intricate effects of thermal processing on the conformational and digestive properties of myosin, a crucial protein in meat. The findings reveal that increasing heating temperatures lead to notable changes in the structural integrity of myosin. Specifically, higher temperatures result in the exposure of internal groups to a polar environment while simultaneously causing a decline in the sturdy α-helix structure of myosin. Tryptophan fluorescence analysis confirms that myosin’s tertiary structure appears to unfold at 70 °C. Furthermore, excessive heating, exemplified by treatment at 100 °C for 30 min, induces greater protein denaturation, evidenced by elevated sulfhydryl contents and turbidity, ultimately leading to the formation of irregular aggregates. Importantly, the study highlights the impact of heating temperature on myosin’s digestibility by pepsin, a key digestive enzyme. Mild heating at 70 °C enhances the exposure of active sites for pepsin, thereby improving digestibility. In contrast, overheating at 100 °C results in a decrease in pepsin sensitivity, as indicated by an increase in the Michaelis constant (Km value) during digestion. However, overheating also prompts the production of new peptides with longer sequences, possibly due to the formation of irregular myosin aggregates [44].

The investigation into collagen denaturation in goose breast fillets revealed analogous associations to those observed for myosin denaturation. The analysis underscored that temperature, humidity, and fan rotation speed significantly impacted collagen denaturation in linear terms (p ≤ 0.001, p ≤ 0.001, p ≤ 0.05, respectively). However, the interactions between temperature × fan rotation, temperature × humidity, and humidity × fan rotation speed did not yield statistically significant effects on collagen denaturation during the computer simulation (p > 0.05). In addition, temperature exhibited a significant effect on the extent of collagen denaturation in quadratic terms (p ≤ 0.001). Conversely, humidity and air movement speed in the oven chamber did not demonstrate statistically significant quadratic effects on collagen denaturation (p > 0.05). Research by Latorre and Velazquez [38] focuses on comprehending how the collagen attributes of intermuscular connective tissue (IMCT) contribute to hardness and elasticity in various parts of meat after the cooking process. This work proposes a laboratory test of changes in IMCT after thermal treatment. The study involving thermal treatment (1 h) at varying temperatures (25−65 °C) was aimed at examining the chemical, mechanical, and thermal characteristics of collagen within the isolated IMCT-perimysium. The degree of collagen degradation, solubility of collagen components and proteoglycans, thermal properties, and mechanical stress were investigated on IMCT-treated perimysium. The results showed that collagen degradation significantly increased at 65 °C. The soluble proteoglycan fraction showed no change between treatments. The thermal properties showed significant changes at 65 °C. Denaturation enthalpies (ΔH) increased, and denaturation peak temperature (Tp) decreased relative to lower thermal treatments. Finally, there were no significant differences in mechanical properties and loading stresses between treatments. Degradation at 65 °C may indicate chemical changes in total collagen; labile populations were dissolved, while the stable population remained in the IMCT-perimysium. The effects of thermal treatment at higher temperatures and the presence of meat enzymes should be investigated in the future [45]. Research by Purslow [46] focuses on understanding differences in the amount and thermal stability of collagen in IMCT, which play a role in the differential elasticity of heat-treated meat. This review focuses on the sources of variability, especially in perimysial IMCT, and challenges some accepted ideas about its behavior during denaturation, its effect on shrinkage during high cooking temperatures, and the concept of IMCT as an unchanging “hard background”. IMCT predominates in the shear strength of raw and lightly cooked muscle; however, at cooking temperatures ranging from 70 to 80 °C, its influence diminishes compared to the myofibrillar component. The thermal denaturation temperature of IMCT collagen, as indicated by differential scanning calorimetry under fast heating rates, typically falls within the range of 62–67 °C. Nevertheless, collagen denaturation is a complex, multistep process sensitive to heating rate, with denaturation occurring at temperatures as low as 55–60 °C under slow heating regimes such as slow roasting or sous-vide cooking. While it’s commonly believed that collagen shrinkage at temperatures above 65 °C leads to meat wastage, available evidence does not support this notion. Factors affecting growth rate can modify the amount and thermal stability of IMCT collagen, with recent models outlining these effects. The identification of thermally stable IMCT collagen as the primary determinant of connective tissue’s contribution to cooked meat elasticity underscores the importance of investigating mechanisms governing the degradation or regeneration of this specific fraction [46].

All analyzed factors exhibited statistically significant effects on the dynamics of actin process denaturation in linear terms, specifically temperature, humidity, and fan rotation speed (p ≤ 0.001). Furthermore, all interactions among these factors, such as temperature × humidity, temperature × fan rotation speed, and humidity × fan rotation speed, demonstrated statistically significant impacts on the process of actin denaturation (p ≤ 0.05, p ≤ 0.001, p ≤ 0.05; respectively). Nevertheless, quadratic terms for humidity and hot air movement speed did not demonstrate a significant influence (p > 0.05). Conversely, only temperature exhibited a significant influence on the extent of actin denaturation in quadratic terms (p ≤ 0.001). In the Liu et al.’s study [47], the process of protein thermal denaturation plays a crucial role in the texture and overall delicacy of Beijing roast duck. The study demonstrates that the equation correlating surface and center temperature can effectively predict the real-time center temperature of the roast duck, guiding parameter settings for industrialization and the development of new roasting equipment. This advancement contributes to the industrialization and intelligent transformation of the Beijing roast duck production process. Specifically, the denaturation of actin during thermal processing exerts a substantial influence on the texture properties changes compared to myosin denaturation level. The study highlights the significance of intermolecular forces in the denaturation of main myofibrillar proteins during the roasting process. Notably, myosin thermal degeneration occurs around the 20-min mark, while complete denaturation of main myofibrillar proteins is observed at approximately 40 min [47].

The investigation delved into how specific factors influenced cooking loss during the simulation of goose breast fillet roasting. Findings unveiled that temperature (p ≤ 0.001) significantly affected cooking loss in linear terms. Conversely, the humidity level inside the chamber and fan movement showed no significant impact on changes in goose meat weight during roasting (p > 0.05). Moreover, there were no significant interactions identified between temperature × fan speed, temperature × humidity, and humidity × fan speed (p > 0.05). Also, none of the factors, including temperature, humidity, and fan speed, demonstrated a significant influence on cooking loss after roasting in quadratic terms (p ≤ 0.05). Wołoszyn et al. [26] carried out a comparative analysis of the effects of various heat treatment methods, including water bath cooking, oven convection roasting, grilling, and pan frying, on selected physical properties of goose meat. The investigation encompassed measurements of cooking loss, texture, color parameters, and sensory properties. Results indicated that the type of heat treatment significantly influenced cooking loss, shear force, and rheological parameters. Particularly, water bath-cooked and pan-fried samples exhibited lower cooking loss compared to other methods across both types of meat. Additionally, goose samples with skin and subcutaneous fat demonstrated higher weight loss after cooking and lower values of shear force, hardness, gumminess, and chewiness than those without skin, irrespective of the cooking method. The examination of cooking and roasting losses during thermal treatment of goose samples from various Polish native breeds depicted significant disparities among genotypes and muscle types. Cooking losses, represented as percentages, exhibited substantial variation across genotypes. Kartuska and Suwalska geese displayed comparable cooking losses, whereas Lubelska and Kielecka geese showed significantly lower losses. Within each genotype, thigh muscles generally incurred lower cooking losses than breast muscles. Specifically, Kartuska and Suwalska geese exhibited higher cooking losses in breast muscles compared to Lubelska and Kielecka geese. Similarly, roasting losses displayed significant differences among genotypes and muscle types. Suwalska geese demonstrated the highest roasting losses in breast muscles, followed by Kartuska geese, while Lubelska and Kielecka geese exhibited lower losses. Conversely, in thigh muscles, Suwalska and Kartuska geese showed higher roasting losses compared to Lubelska and Kielecka geese [28]. The CFD approach has been instrumental in predicting the core temperature and cooking loss that occurs after the vacuum cooling process of meat samples. Through a series of numerical simulations, this study has facilitated the simultaneous prediction of unsteady heat and mass transfer phenomena, including temperature distribution, cooking loss, and water content of the samples under vacuum pressure conditions. Experimental verification was conducted by cooling samples with a cylindrical shape within a laboratory vacuum cooler, ensuring the accuracy and reliability of the CFD model. Further investigations explored several factors impacting the process, including anisotropy and thermal shrinkage of the food, vapor, and water transport within the food matrix, radiation effects on the surface, and the pressure history during the cooling process. By considering these factors, the study provides insights into the intricacies of weight loss mechanisms during thermal processing, aiding in the optimization of heat treatment processes for improved efficiency and product quality [48].

The current study on the use of CFD to predict protein denaturation and optimize heat treatment of goose breast meat builds on and contrasts with previous research on other meat and food products. In the study by Szpicer et al. (2023), CFD was used to predict protein denaturation and water loss in pork tenderloin (m. Longissimus Dorsi). This experiment simulated a large piece of pork. CFD has been shown to enable accurate modeling of thermal processes occurring during roasting of pork, showing the impact of heat distribution on protein denaturation and the resulting weight loss in a large piece of meat [22]. Moreover, Szpicer et al. (2024) used this method to examine the process of protein denaturation and docosahexaenoic acid (DHA) decomposition in a sample of Atlantic salmon (Salmo salar L.). Similarly, this study highlights the potential of hybrid CFD and RSM models. It focuses on the optimization of heat treatment processes, especially for salmon meat, which is characterized by unique thermal properties compared to other species. Additionally, it was possible to predict the quantitative breakdown of DHA acid, the consumption of which has a significant impact on human health [23]. Additionally, Szpicer et al. (2022) investigated the optimization of heat treatment of beef using CFD simulations, with an emphasis on modeling the level of protein denaturation depending on the basic composition of the sample. Our study simulated the roasting of 3 different pieces of beef with different basic compositions (i.e., the content of water, fat, protein, CTP, and ash). It has been proven that CFD simulations successfully predict the course of denaturation of beef proteins, and the basic composition significantly affects the course of this process [24].

These findings underscore the impact of genotype and muscle type on the extent of cooking and roasting losses during thermal processing, highlighting the need to consider these factors in optimizing heat treatment processes for goose breast meat. To adapt or extend the CFD model for optimizing thermal processing parameters for various meat or food products beyond its current scope, adjustments must be made to account for specific heat transfer properties, moisture content, and structural characteristics of the new materials. This may involve recalibrating simulation parameters, incorporating additional variables such as moisture evaporation rates, and validating the model against experimental data for each type of product. Additionally, the model might require refinement to accurately simulate complex interactions between different food matrices and heating environments [49].

The composition of goose breast meat, particularly its fat and water content, can significantly impact the accuracy of CFD simulations in predicting protein denaturation and optimizing heat treatment processes. Variations in meat composition alter the thermal properties of the meat, such as thermal conductivity, specific heat capacity, and density, which are critical parameters in CFD models. The meat’s thermal conductivity is influenced by its fat and water content. Water has a higher thermal conductivity compared to fat, meaning that higher water content can lead to faster heat transfer within the meat. Conversely, increased fat content, which has lower thermal conductivity, can slow down the heat transfer process. The specific heat capacity, which is the amount of energy required to raise the temperature of a unit mass of meat by one degree Celsius, also varies with the composition. Water has a higher specific heat capacity compared to fat, so meat with higher water content requires more energy for heating, affecting the rate and uniformity of temperature rise during heat treatment. The density of meat affects the overall mass and, thus, the heat distribution within the meat during cooking. Variations in fat and water content change the density of the meat, influencing the heat absorption and distribution patterns [50,51,52].

To enhance the reliability of the CFD model in predicting protein denaturation and cooking loss within intricate food matrices, several additional validation steps could be implemented. Firstly, conducting experimental validation studies by comparing the model predictions with actual measurements in real-world scenarios would provide crucial validation. This involves testing the model’s accuracy across a range of food matrices and cooking conditions to ensure its applicability and reliability in diverse contexts. Moreover, sensitivity analysis could be performed to assess the impact of various input parameters on the model’s outputs, helping to identify critical factors influencing prediction accuracy. Furthermore, cross-validation techniques, such as splitting the dataset into training and testing subsets, could be employed to assess the model’s robustness in terms of performance. Additionally, incorporating feedback from food industry experts and conducting peer reviews of the model’s methodology and results would offer valuable insights and validation perspectives [53,54,55,56].

In the context of analyzing the influence of temperature, fan rotation speed in a combi-steam oven, and humidity on the denaturation of myosin, collagen, and actin proteins, as well as mass loss in goose breast meat, it is essential to address the recent approaches. For instance, deep learning has been effectively applied to the analysis of medical data and the diagnosis and treatment of COVID-19, as described in the study described by Jamshidi et al., 2020. Deep learning algorithms could be used to analyze complex relationships between thermal process parameters and protein denaturation, potentially leading to more precise predictive models. By comparing our CFD approach with deep learning methods, it can be observed that CFD offers accurate modeling of the physical and chemical processes occurring during heat treatment, while deep learning could facilitate analysis and optimization based on large datasets [57,58]. The application of machine learning in health, as discussed in the work presented by Jamshidi et al., 2021, also provides interesting parallels. Machine learning models can be used to predict the effects of various thermal processing parameters on meat quality, similar to how they predict drug interactions in the context of COVID-19. The inclusion of these techniques could enhance the prediction and optimization capabilities of thermal processes in the food industry [57]. Large language models (LLMs) and generative artificial intelligence (Generative AI), as described in the recent literature, could also find applications in this study. LLMs could assist in processing and analyzing the scientific literature and generating research hypotheses, while Generative AI could be used to simulate different heat treatment scenarios, aiding in the identification of optimal processing conditions [59,60,61]. The integration of deep learning, machine learning, LLM, and Generative AI with our CFD approach could significantly enrich the study and provide a more holistic view of the optimization of thermal processes in the meat industry.

3.3. Verification of Heat Treatment Parameters

The final step of the study was validating the results of the production model by comparing them with laboratory analysis. The maximum acceptable denaturation levels for myosin, collagen, and sarcoplasmic proteins were established, with efforts made to minimize actin denaturation and cooking loss. According to the RSM optimization model, ideal processing conditions for goose breast meat are a temperature of 164.65 °C, a humidity of 63.58%, and a fan rotation set at 16.59 rpm.

The expected values for the output variables (X− ± SD) were as follows: myosin denaturation—99.42 ± 0.80%, collagen denaturation—88.69 ± 0.74%, actin denaturation—20.64 ± 0.31%, and weight loss during cooking—19.12 ± 0.10%. The outcomes of the optimization and verification steps are shown in Table 3, indicating that the empirical experiment outcomes were aligned with the predictions of the mathematical model. All measured parameters did not show statistically significant differences compared to laboratory analysis results (p > 0.05).

Table 3.

Verification of prediction model with empirical analyses (X− ± SD).

4. Conclusions

This study showcases the innovative application of the CFD method in predicting protein denaturation in goose breast meat and optimizing heat treatment procedures. Through the utilization of mathematical models, the study identified optimal thermal treatment parameters: 164.65 °C temperature, 63.58% air humidity, and a fan rotation speed of 16.59 rpm. The research assessed the denaturation of various proteins and losses during the roasting process. Upon laboratory result verification, it was observed that the denaturation levels of myosin, collagen, and actin, as well as the losses during cooking, closely aligned with the expectations derived from the developed RSM model based on simulation data. This investigation underscores the efficacy of the CFD method in forecasting protein denaturation and cooking losses in goose breast meat, offering potential enhancements in efficiency and product quality for the gastronomy and food industry.

Thanks to the use of CFD for predicting the protein denaturation degree and mass loss in goose meat, it is possible to precisely determine the optimal conditions for heat treatment. This will allow for the production of products with better and more consistent quality and, consequently, higher sensory acceptance among consumers. By accurately calculating the optimal conditions for thermal processing, the heat dose will be precisely adjusted, which will allow for the reduction of energy losses in the food industry. As a result, energy consumption during roasting will be reduced. Additionally, the reduced mass loss during the thermal processes of goose meat will lead to increased process efficiency in gastronomy and the food industry.

The findings of this study can potentially be generalized to other types of meat or food products by making appropriate modifications to the CFD model parameters specific to the new food matrix. This includes adjusting the thermal properties, moisture content, and structural characteristics of the target food product. Furthermore, extensive experimental validation would be necessary to ensure the accuracy and reliability of the CFD predictions in the new context. By doing so, the benefits observed in goose breast meat, such as optimized heat treatment conditions, improved product quality, and reduced energy consumption, could also be achieved in other meats or food products, enhancing their overall production efficiency and sensory acceptance.

However, there are potential practical challenges in implementing CFD-based optimization in commercial food production settings. These challenges include the need for high computational power and expertise in CFD modeling, which may not be readily available in all food production facilities. To overcome these challenges, it is essential to develop user-friendly software with pre-configured settings and provide training for food industry professionals. Collaboration between CFD experts and food technologists can also facilitate the integration of CFD tools into commercial processes. Additionally, investment in advanced computational infrastructure and ongoing research to refine and simplify CFD models will be crucial to making this technology accessible and effective for broader application in the meat industry.

Author Contributions

Conceptualization, A.S. (Arkadiusz Szpicer); methodology, A.S. (Arkadiusz Szpicer); software, A.S. (Arkadiusz Szpicer) and A.S. (Adrian Stelmasiak); validation, A.S. (Arkadiusz Szpicer) and K.P.; formal analysis, A.S. (Arkadiusz Szpicer) and W.B.; investigation, A.S. (Arkadiusz Szpicer); resources, A.S. (Adrian Stelmasiak); data curation, A.S. (Arkadiusz Szpicer); writing—original draft preparation, A.S. (Arkadiusz Szpicer), W.B. and. I.W.-K.; writing—review and editing, A.S. (Arkadiusz Szpicer), W.B., A.S. (Adrian Stelmasiak), K.P., I.W.-K. and M.Z.; visualization, A.S. (Arkadiusz Szpicer) and W.B.; supervision, A.S. (Arkadiusz Szpicer) and A.P.; project administration, A.S. (Arkadiusz Szpicer). All authors have read and agreed to the published version of the manuscript.

Funding

Research financed by the Polish Ministry of Science and Higher Education within funds of the Faculty of Human Nutrition and Consumer Sciences, Warsaw University of Life Sciences (WULS), for scientific research.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The authors declare the availability of data and material.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| Abbreviation | Full name |

| CFD | computational fluid dynamics |

| CTP | connective tissue protein |

| DSC | differential scanning calorimetry |

| GN | gastro norm |

| IMCT | intermuscular connective tissue |

| LLM | Large language models |

| NIR | near-infrared spectrometry |

| rpm | revolutions per minute |

| RSM | response surface methodology |

| Nomenclature | |

| λ | conduction coefficient (W/(m⋅K)) |

| Cp | specific heat (J/kgK) |

| β | heating rate (°C/min) |

| Ton | temperature at the start of the reaction (°C) |

| Tmax | maximum peak temperature (°C) |

| Tend | temperature at the end of the reaction (°C) |

| ΔH | enthalpy (J/g) |

| X− | mean |

| SD | standard deviation |

References

- Damaziak, K.; Stelmasiak, A.; Michalczuk, M.; Wyrwisz, J.; Moczkowska, M.; Marcinkowska-Lesiak, M.M.; Niemiec, J.; Wierzbicka, A. Analysis of Storage Possibility of Raw and Smoked Breast Meat of Oat-Fattened White Kołuda® Goose Based on Their Quality Characteristics. Poult. Sci. 2016, 95, 2186–2197. [Google Scholar] [CrossRef]

- Wojtasik-Kalinowska, I.; Marcinkowska-Lesiak, M.; Onopiuk, A.; Stelmasiak, A.; Szpicer, A.; Holc, D.; Wierzbicka, A.; Poltorak, A. Geese Fillets Flavor Stability and Quality Characteristics at Different Stages of Sous-Vide Cooking. Anim. Sci. Pap. Rep. 2021, 39, 419–435. [Google Scholar] [CrossRef]

- Zhang, H.; Tang, D.; Yang, H.; Liu, X.; Cheng, J.; Wang, X.; Zou, J.; Lin, Y. Effects of High Hydrostatic Pressure Assisted Enzymatic Tenderization on Goose Meat Texture and Myofibril Protein. LWT-Food Sci. Technol. 2023, 184, 114845. [Google Scholar] [CrossRef]

- Weng, K.; Huo, W.; Song, L.; Cao, Z.; Zhang, Y.; Zhang, Y.; Chen, G.; Xu, Q. Effect of Marketable Age on Nutritive Profile of Goose Meat Based on Widely Targeted Metabolomics. LWT-Food Sci. Technol. 2022, 170, 114071. [Google Scholar] [CrossRef]

- Geldenhuys, G.; Hoffman, L.C.; Muller, N. Aspects of the Nutritional Value of Cooked Egyptian Goose (Alopochen Aegyptiacus) Meat Compared with Other Well-Known Fowl Species. Poult. Sci. 2013, 92, 3050–3059. [Google Scholar] [CrossRef]

- Häfner, L.; Kalkhof, S.; Jira, W. Authentication of Nine Poultry Species Using High-Performance Liquid Chromatography–Tandem Mass Spectrometry. Food Control 2021, 122, 107803. [Google Scholar] [CrossRef]

- Wojtasik-Kalinowska, I.; Górska-Horczyczak, E.; Stelmasiak, A.; Marcinkowska-Lesiak, M.; Onopiuk, A.; Wierzbicka, A.; Półtorak, A. Effect of Temperature and Oxygen Dose During Rendering of Goose Fat to Promote Fatty Acid Profiles. Eur. J. Lipid Sci. Technol. 2021, 123, 2100085. [Google Scholar] [CrossRef]

- Nowicka, K.; Jaworska, D.; Przybylski, W.; Górska, E.; Tambor, K.; Półtorak, A. Determinants of the Sensory Quality of Półgȩsek in Relation to Volatile Compounds and Chemical Composition. Pol. J. Food Nutr. Sci. 2017, 67, 283–292. [Google Scholar] [CrossRef]

- Orkusz, A.; Michalczuk, M. Research Note: Effect of Packaging Atmosphere on the Fatty Acid Profile of Intramuscular, Subcutaneous Fat, and Odor of Goose Meat. Poult. Sci. 2020, 99, 647–652. [Google Scholar] [CrossRef]

- Wang, Y.; Li, W.; Zhang, C.; Li, F.; Yang, H.; Wang, Z. Metabolomic Comparison of Meat Quality and Metabolites of Geese Breast Muscle at Different Ages. Food Chem. X 2023, 19, 100775. [Google Scholar] [CrossRef]

- Orkusz, A. Effects of Packaging Conditions on Some Functional and Sensory Attributes of Goose Meat. Poult. Sci. 2018, 97, 2988–2993. [Google Scholar] [CrossRef] [PubMed]

- Shi, W.; Wang, Y.; Chen, X.; Hu, H.; Chen, X.; Mintah, B.K.; Dabbour, M.; Meng, X.; Zhang, Z.; He, R.; et al. Thawing of Goose Meat by Simultaneous Dual Frequency Ultrasound for Process Efficiency: Thawing Rate, Quality Attributes, Structural Characteristics. Innov. Food Sci. Emerg. Technol. 2024, 92, 103588. [Google Scholar] [CrossRef]

- Wereńska, M.; Okruszek, A. Impact of Frozen Storage on Some Functional Properties and Sensory Evaluation of Goose Meat. Poult. Sci. 2023, 102, 102894. [Google Scholar] [CrossRef] [PubMed]

- Goluch, Z.; Barbara, K.; Haraf, G.; Wołoszyn, J.; Okruszek, A.; Wereńska, M. Impact of Various Types of Heat Processing on the Energy and Nutritional Values of Goose Breast Meat. Poult. Sci. 2021, 100, 101473. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Shi, W.; Wang, Y.; Meng, X.; Dabbour, M.; Kumah Mintah, B.; Chen, X.; Chen, X.; He, R.; Ma, H. Mono-Frequency Ultrasonic-Assisted Thawing of Frozen Goose Meat: Influence on Thawing Efficiency, Product Quality and Microstructure. Ultrason. Sonochem. 2023, 98, 106489. [Google Scholar] [CrossRef] [PubMed]

- Wereńska, M. Comparative Study on the Effects of Sous-Vide, Microwave Cooking, and Stewing on Functional Properties and Sensory Quality of Goose Meat. Poult. Sci. 2023, 102, 103064. [Google Scholar] [CrossRef]

- Wereńska, M.; Haraf, G.; Wołoszyn, J.; Goluch, Z.; Okruszek, A.; Teleszko, M. Fatty Acid Profile and Health Lipid Indicies of Goose Meat in Relation to Various Types of Heat Treatment. Poult. Sci. 2021, 100, 102337. [Google Scholar] [CrossRef] [PubMed]

- Kozák, J. Goose Production and Goose Products. Worlds. Poult. Sci. J. 2021, 77, 403–414. [Google Scholar] [CrossRef]

- Lv, J.M.; Gouda, M.; Zhu, Y.Y.; Ye, X.Q.; Chen, J.C. Ultrasound-Assisted Extraction Optimization of Proanthocyanidins from Kiwi (Actinidia Chinensis) Leaves and Evaluation of Its Antioxidant Activity. Antioxidants 2021, 10, 1317. [Google Scholar] [CrossRef]

- Szpicer, A.; Bińkowska, W.; Wojtasik-Kalinowska, I.; Salih, S.M.; Półtorak, A. Application of Computational Fluid Dynamics Simulations in Food Industry. Eur. Food Res. Technol. 2023, 249, 1411–1430. [Google Scholar] [CrossRef]

- Szpicer, A.; Binkowska, W.; Stelmasiak, A.; Wojtasik-Kalinowska, I.; Wierzbicka, A.; Poltorak, A. Application of Computational Fluid Dynamics Simulation in Predicting Food Protein Denaturation: Numerical Studies on Selected Food Products—A Review. Anim. Sci. Pap. Rep. 2023, 41, 307–332. [Google Scholar] [CrossRef]

- Szpicer, A.; Binkowska, W.; Wojtasik-Kalinowska, I.; Poltorak, A. Prediction of Protein Denaturation and Weight Loss in Pork Loin (Muscle Longissimus Dorsi) Using Computational Fluid Dynamics. Eur. Food Res. Technol. 2023, 249, 3055–3068. [Google Scholar] [CrossRef]

- Szpicer, A.; Binkowska, W.; Wojtasik-Kalinowska, I.; Stelmasiak, A.; Poltorak, A. Hybrid Method for Predicting Protein Denaturation and Docosahexaenoic Acid Decomposition in Atlantic Salmon (Salmo salar L.) Using Computational Fluid Dynamics and Response Surface Methodology. Eur. Food Res. Technol. 2024, 250, 1163–1176. [Google Scholar] [CrossRef]

- Szpicer, A.; Wierzbicka, A.; Półtorak, A. Optimization of Beef Heat Treatment Using CFD Simulation: Modeling of Protein Denaturation Degree. J. Food Process Eng. 2022, 45, e14014. [Google Scholar] [CrossRef]

- Taler, D.; Taler, J.; Trojan, M. The CFD Based Method for Determining Heat Transfer Correlations on Individual Rows of Plate-Fin and Tube Heat Exchangers. In Heat Transfer—Design, Experimentation and Applications; Araiz, M., Ed.; Intechopen: London, UK, 2021; pp. 29–52. [Google Scholar]

- Wołoszyn, J.; Wereńska, M.; Goluch, Z.; Haraf, G.; Okruszek, A.; Teleszko, M.; Król, B. The Selected Goose Meat Quality Traits in Relation to Various Types of Heat Treatment. Poult. Sci. 2020, 99, 7214–7224. [Google Scholar] [CrossRef] [PubMed]

- Okruszek, A.; Wołoszyn, J.; Haraf, G.; Orkusz, A.; Wereńska, M. Chemical Composition and Amino Acid Profiles of Goose Muscles from Native Polish Breeds. Poult. Sci. 2013, 92, 1127–1133. [Google Scholar] [CrossRef]

- Haraf, G.; Wołoszyn, J.; Okruszek, A.; Wereńska, M. Technological Properties, Chemical Composition, Texture Profile, and Sensory Evaluation of Goose Muscles from Polish Native Breeds. Poult. Sci. 2023, 102, 102424. [Google Scholar] [CrossRef]

- Chhanwal, N.; Tank, A.; Raghavarao, K.S.M.S.; Anandharamakrishnan, C. Computational Fluid Dynamics (CFD) Modeling for Bread Baking Process-A Review. Food Bioprocess Technol. 2012, 5, 1157–1172. [Google Scholar] [CrossRef]

- Ishiwatari, N.; Fukuoka, M.; Sakai, N. Effect of Protein Denaturation Degree on Texture and Water State of Cooked Meat. J. Food Eng. 2013, 117, 361–369. [Google Scholar] [CrossRef]

- Alabi, K.P.; Zhu, Z.; Sun, D.W. Transport Phenomena and Their Effect on Microstructure of Frozen Fruits and Vegetables. Trends Food Sci. Technol. 2020, 101, 63–72. [Google Scholar] [CrossRef]

- Zorrilla, S.E.; Rubiolo, A.C. Mathematical Modeling for Immersion Chilling and Freezing of Foods. Part I: Model Development. J. Food Eng. 2005, 66, 329–338. [Google Scholar] [CrossRef]

- Li, R.; Kou, X.; Zhang, L.; Wang, S. Inactivation Kinetics of Food-Borne Pathogens Subjected to Thermal Treatments: A Review. Int. J. Hyperth. 2018, 34, 177–188. [Google Scholar] [CrossRef] [PubMed]

- Sakin, M.; Kaymak-Ertekin, F.; Ilicali, C. Simultaneous Heat and Mass Transfer Simulation Applied to Convective Oven Cup Cake Baking. J. Food Eng. 2007, 83, 463–474. [Google Scholar] [CrossRef]

- Sahin, S.; Servet, G.Ş. Physical Properties of Foods, 1st ed.; Heldman, D.R., Ed.; Springer: Berlin/Heidelberg, Germany, 2006; ISBN 9783642253874. [Google Scholar]

- Singh, R.P.; Heldman, D.R. Introduction to Food Engineering: Fifth Edition; Academic Press: Cambridge, MA, USA, 2014; ISBN 9780123985309. [Google Scholar]

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; DeWitt, D.P. Introduction to Heat Transfer, 6th ed.; Wiley: New York, NY, USA, 2011; ISBN 9780470501962. [Google Scholar]

- Markočič, E.; Knez, Ž. Redlich-Kwong Equation of State for Modelling the Solubility of Methane in Water over a Wide Range of Pressures and Temperatures. Fluid Phase Equilib. 2016, 408, 108–114. [Google Scholar] [CrossRef]

- Wagner, W.; Kretzschmar, H.-J. International Steam Tables—Properties of Water and Steam Based on the Industrial Formulation IAPWS-IF97, 2nd ed.; Wagner, W., Kretzschmar, H.-J., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 9783642253874. [Google Scholar]

- Mazanowski, A. Breeding and Farming Geese, 1st ed.; Adamski, M., Ed.; APRA: Osielsko, Poland, 2012. [Google Scholar]

- Stelmasiak, A.; Wyrwisz, J.; Wierzbicka, A. Effect of Packaging Methods on Salt-Reduced Smoked-Steamed Ham Using Herbal Extracts. CYTA-J. Food 2019, 17, 834–840. [Google Scholar] [CrossRef]

- Agafonkina, I.V.; Korolev, I.A.; Sarantsev, T.A. The Study of Thermal Denaturation of Beef, Pork, Chicken and Turkey Muscle Proteins Using Differential Scanning Calorimetry. Theory Pract. Meat Process. 2019, 4, 19–23. [Google Scholar] [CrossRef]

- Vaskoska, R.; Ha, M.; Ong, L.; Chen, G.; White, J.; Gras, S.; Warner, R. Myosin Sensitivity to Thermal Denaturation Explains Differences in Water Loss and Shrinkage during Cooking in Muscles of Distinct Fibre Types. Meat Sci. 2021, 179, 108521. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Zhu, S.; Li, Q.; Xue, D.; Jiang, S.; Han, Y.; Li, C. Effect of Thermal Processing on the Conformational and Digestive Properties of Myosin. Foods 2023, 12, 1249. [Google Scholar] [CrossRef] [PubMed]

- Latorre, M.E.; Velazquez, D.E. Effects of Thermal Treatment on Collagen Present in Bovine M. Semitendinosus Intramuscular Connective Tissue. Analysis of the Chemical, Thermal and Mechanical Properties. Food Struct. 2021, 27, 100165. [Google Scholar] [CrossRef]

- Purslow, P.P. Contribution of Collagen and Connective Tissue to Cooked Meat Toughness; Some Paradigms Reviewed. Meat Sci. 2018, 144, 127–134. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Z.; Zhang, D.; Pan, T.; Liu, H.; Shen, Q.; Hui, T. Effect of Protein Thermal Denaturation on the Texture Profile Evolution of Beijing Roast Duck. Foods 2022, 11, 664. [Google Scholar] [CrossRef]

- Sun, D.W.; Hu, Z. CFD Predicting the Effects of Various Parameters on Core Temperature and Weight Loss Profiles of Cooked Meat during Vacuum Cooling. Comput. Electron. Agric. 2002, 34, 111–127. [Google Scholar] [CrossRef]

- Ramachandran, R.P.; Akbarzadeh, M.; Paliwal, J.; Cenkowski, S. Computational Fluid Dynamics in Drying Process Modelling—A Technical Review. Food Bioprocess Technol. 2018, 11, 271–292. [Google Scholar] [CrossRef]

- Anandharamakrishnan, C. Computational Fluid Dynamics in Food Processing, 1st ed.; Hartel, R.W., Ed.; Springer: London, UK, 2007; ISBN 9781420009217. [Google Scholar]

- Varga, S.; Oliveira, J.C.; Oliveira, F.A.R. Influence of the Variability of Processing Factors on the F-Value Distribution in Batch Retorts. J. Food Eng. 2000, 44, 155–161. [Google Scholar] [CrossRef]

- Hartmann, C.; Delgado, A. The Influence of Transport Phenomena during High-Pressure Processing of Packed Food on the Uniformity of Enzyme Inactivation. Biotechnol. Bioeng. 2003, 82, 725–735. [Google Scholar] [CrossRef]

- Grijspeerdt, K.; Hazarika, B.; Vucinic, D. Application of Computational Fluid Dynamics to Model the Hydrodynamics of Plate Heat Exchangers for Milk Processing. J. Food Eng. 2003, 57, 237–242. [Google Scholar] [CrossRef]

- Chauhan, A.; Trembley, J.; Wrobel, L.C.; Jouhara, H. Experimental and CFD Validation of the Thermal Performance of a Cryogenic Batch Freezer with the Effect of Loading. Energy 2019, 171, 77–94. [Google Scholar] [CrossRef]

- Verboven, P.; Scheerlinck, N.; De Baerdemaeker, J.; Nicolaï, B.M. Computational Fluid Dynamics Modelling and Validation of the Temperature Distribution in a Forced Convection Oven. J. Food Eng. 2000, 43, 61–73. [Google Scholar] [CrossRef]

- Ramachandran, R.P.; Akbarzadeh, M.; Paliwal, J.; Cenkowski, S. Three-Dimensional CFD Modelling of Superheated Steam Drying of a Single Distillers’ Spent Grain Pellet. J. Food Eng. 2017, 212, 121–135. [Google Scholar] [CrossRef]

- Jamshidi, M.B.; Lalbakhsh, A.; Talla, J.; Peroutka, Z.; Roshani, S.; Matousek, V.; Roshani, S.; Mirmozafari, M.; Malek, Z.; La Spada, L.; et al. Deep Learning Techniques and COVID-19 Drug Discovery: Fundamentals, State-of-the-Art and Future Directions. Stud. Syst. Decis. Control 2021, 348, 9–31. [Google Scholar] [CrossRef]

- Jamshidi, M.; Lalbakhsh, A.; Talla, J.; Peroutka, Z.; Hadjilooei, F.; Lalbakhsh, P.; Jamshidi, M.; Spada, L.L.; Mirmozafari, M.; Dehghani, M.; et al. Artificial Intelligence and COVID-19: Deep Learning Approaches for Diagnosis and Treatment. IEEE Access 2020, 8, 109581–109595. [Google Scholar] [CrossRef]

- Gozalo-Brizuela, R.; Garrido-Merchán, E.C. A Survey of Generative AI Applications. J. Comput. Sci. 2024, 20, 801–818. [Google Scholar] [CrossRef]

- Thirunavukarasu, A.J.; Ting, D.S.J.; Elangovan, K.; Gutierrez, L.; Tan, T.F.; Ting, D.S.W. Large Language Models in Medicine. Nat. Med. 2023, 29, 1930–1940. [Google Scholar] [CrossRef]

- Naveed, H.; Khan, A.U.; Qiu, S.; Saqib, M.; Anwar, S.; Usman, M.; Akhtar, N.; Barnes, N.; Mian, A. A Comprehensive Overview of Large Language Models. arXiv 2023, arXiv:2307.06435. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).