4D Printing: Bridging the Gap between Fundamental Research and Real-World Applications

Abstract

:1. Introduction

- The relationship between energy stimulation and material behavior, governed by Fick’s and/or Fourier’s laws, often leads to response times exceeding a minute for centimeter-sized objects;

- Limited mechanical performance, such as Young’s modulus.

- Reassessing manufacturing strategies, moving from continuous to discrete approaches;

- Ensuring the printability of voxels with different materials using local and global methods;

- Refining the design of the AM process.

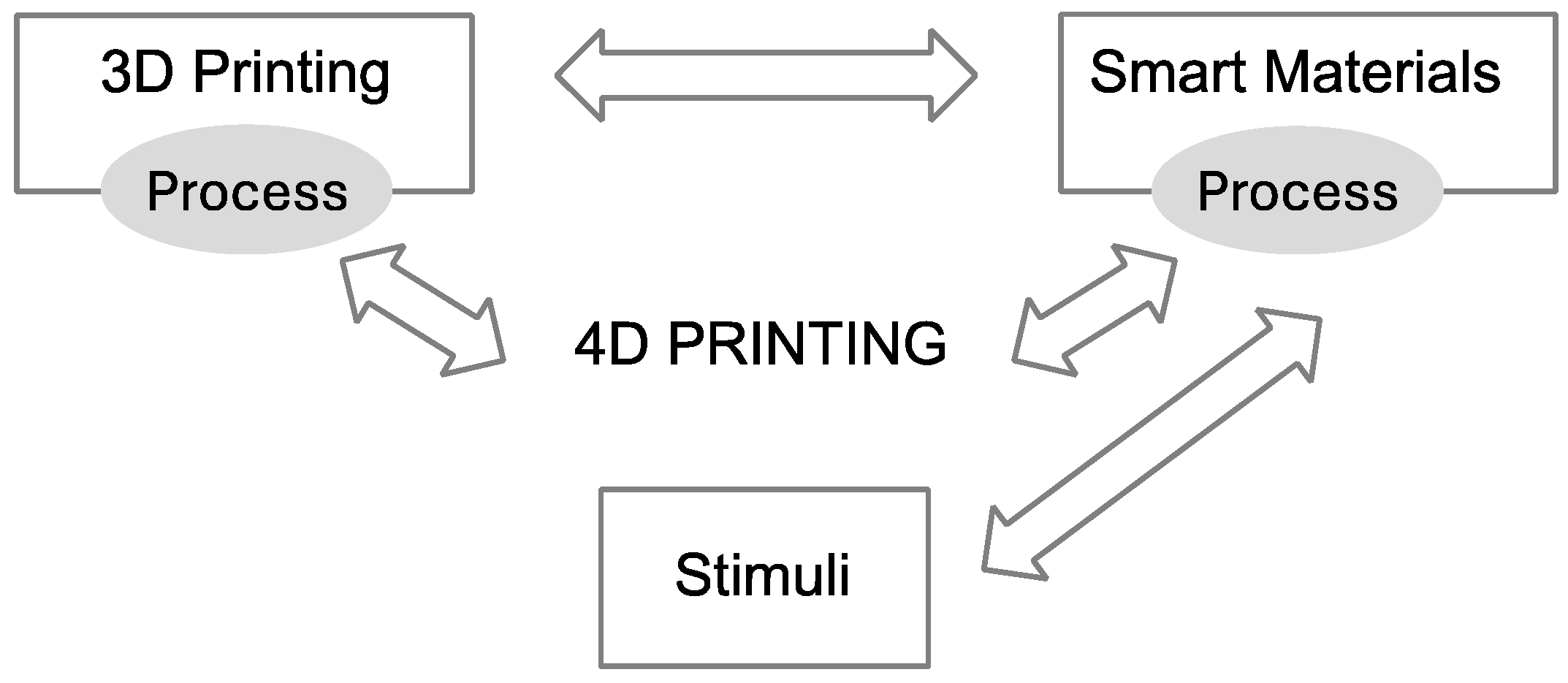

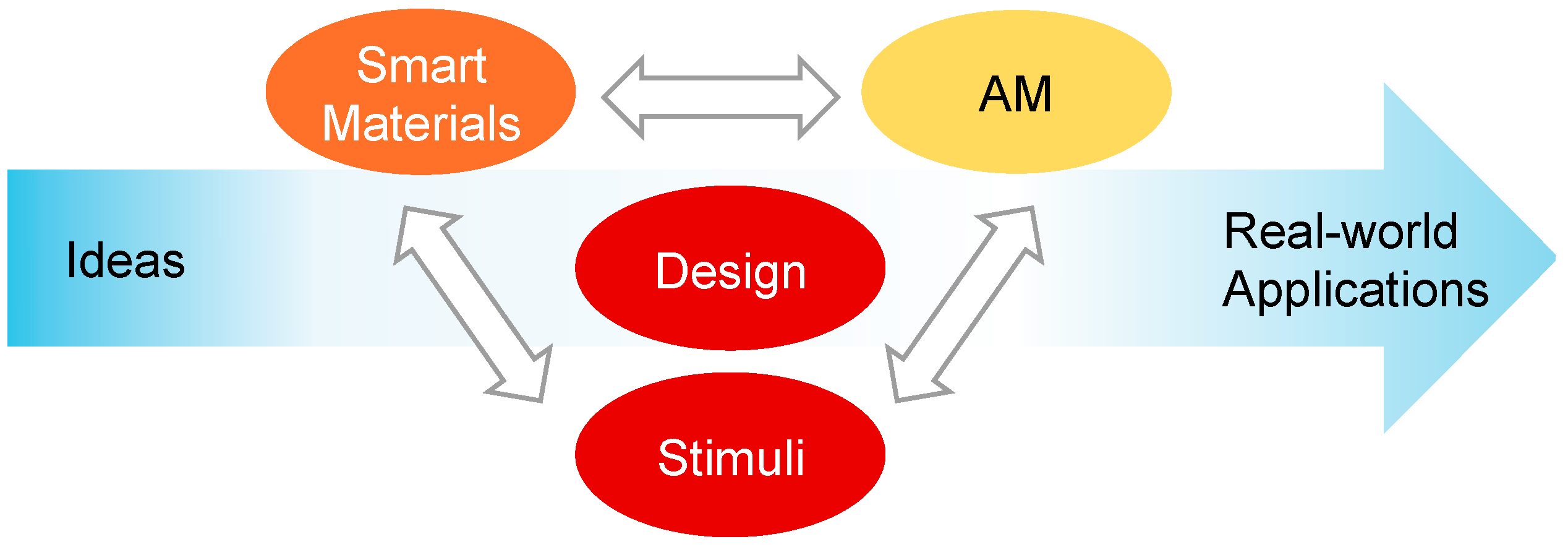

2. A Review of the Design of Complex Systems

2.1. Current Context

2.2. A Transition towards Engineering Sciences and Design

2.3. Systems and Their Representations

2.4. A Modest Strategy

- Collaborative project breakdown, with decisions made by project management;

- The simultaneous consideration of technical, usage, and management dimensions in their socio-spatial implications;

- Organized consultation process involving decision makers, actors, and users;

- Production of a programmatic document, iteratively constructed, that presents admissible solutions without being normative;

- Approach to design through transaction spaces, identifying actors based on usage and management.

3. The Sciences of “Admissible” Things

3.1. The Sciences of the Artificial

- Bounded rationality, which differs from “pure” rationality;

- Satisficing solutions, which are practical rather than optimal;

- Design without a final purpose, allowing for evolving decision criteria;

- Quasi-decomposability, modeling complex phenomena, starting from manageable subsystems;

- The distinction between state and process description, valuable in delineating the realization and usage of an object.

- Initial idea: originates from nature and framed by scientific and technical knowledge;

- Proof-of-concept (POC): requires design practices, leveraging existing knowledge or conducting specific inquiries;

- Complex phenomena: addressed within the design process using heuristic and interdisciplinary expertise;

- Subsystem design: can be independent but not uniquely decomposed, focusing on aggregative properties and ignoring weak relations [43];

- Satisficing solutions: proposed to validate POC usability;

- Technical validation: further evaluation transforms technical knowledge into innovation, considering societal criteria and feedback [35].

- Functionality: each module offers conceptually linked functions;

- Hierarchy: modules can be decomposed into submodules with hidden internal structures;

- Separation of concerns: modules are weakly coupled;

- Interoperability: modules interact easily;

- Reusability: modules can be reused in various systems.

- Analysis phase: identifying the idea’s applicable interest;

- Information gathering: clarifying the initial ideas for engineering;

- Proposal of solution: convincing stakeholders for support;

- Design: specifying initial objectives for creating the artifact;

- Analysis of barriers: reviewing the literature and consulting relevant sciences;

- Requirements: specifying the POC and artifact realization;

- PoC design: technical improvements and economic/societal considerations;

- Artifact design: representing the artifact in its final state;

- Evaluation: conducting feedback at each stage;

- Dissemination: preparing the artifact for dissemination upon success.

- Identification and definition: relevance and trajectory of the idea;

- Selective encoding: searching for relevant information;

- Search for similarities: exploring analogies, metaphors, and comparisons;

- Motivation and risk-taking: personal drive and willingness to take risks;

- Selective combination: grouping information to evolve the idea using heuristic expertise;

- Divergent thinking: generating possibilities;

- Self-evaluation: assessing the progress;

- Collaboration: trust in colleagues and support from the hierarchy.

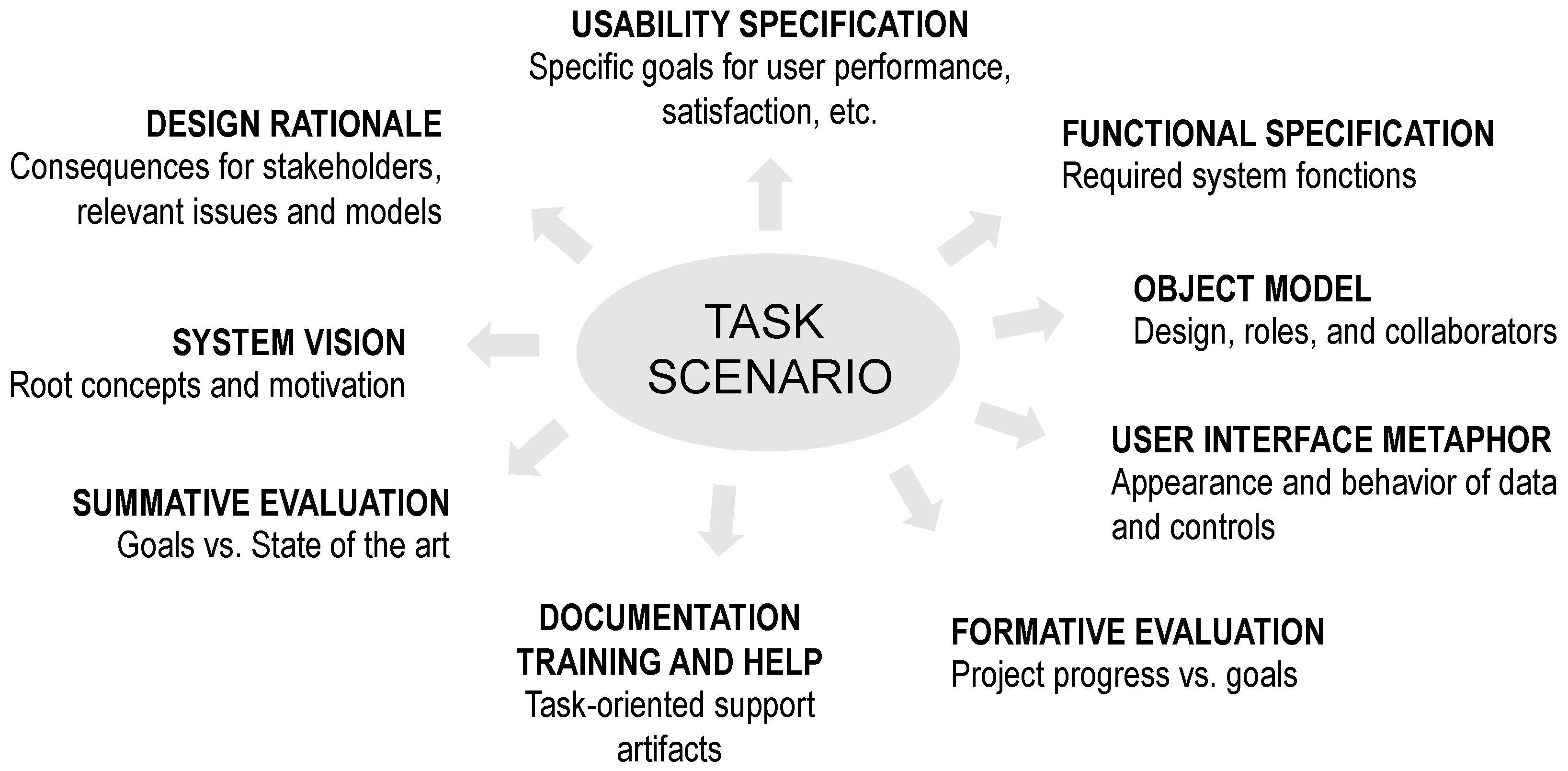

3.2. The Design Process

- Clarification of needs and functional specifications;

- Preliminary design;

- Embodiment design;

- Detail design and prototyping;

- Mass production.

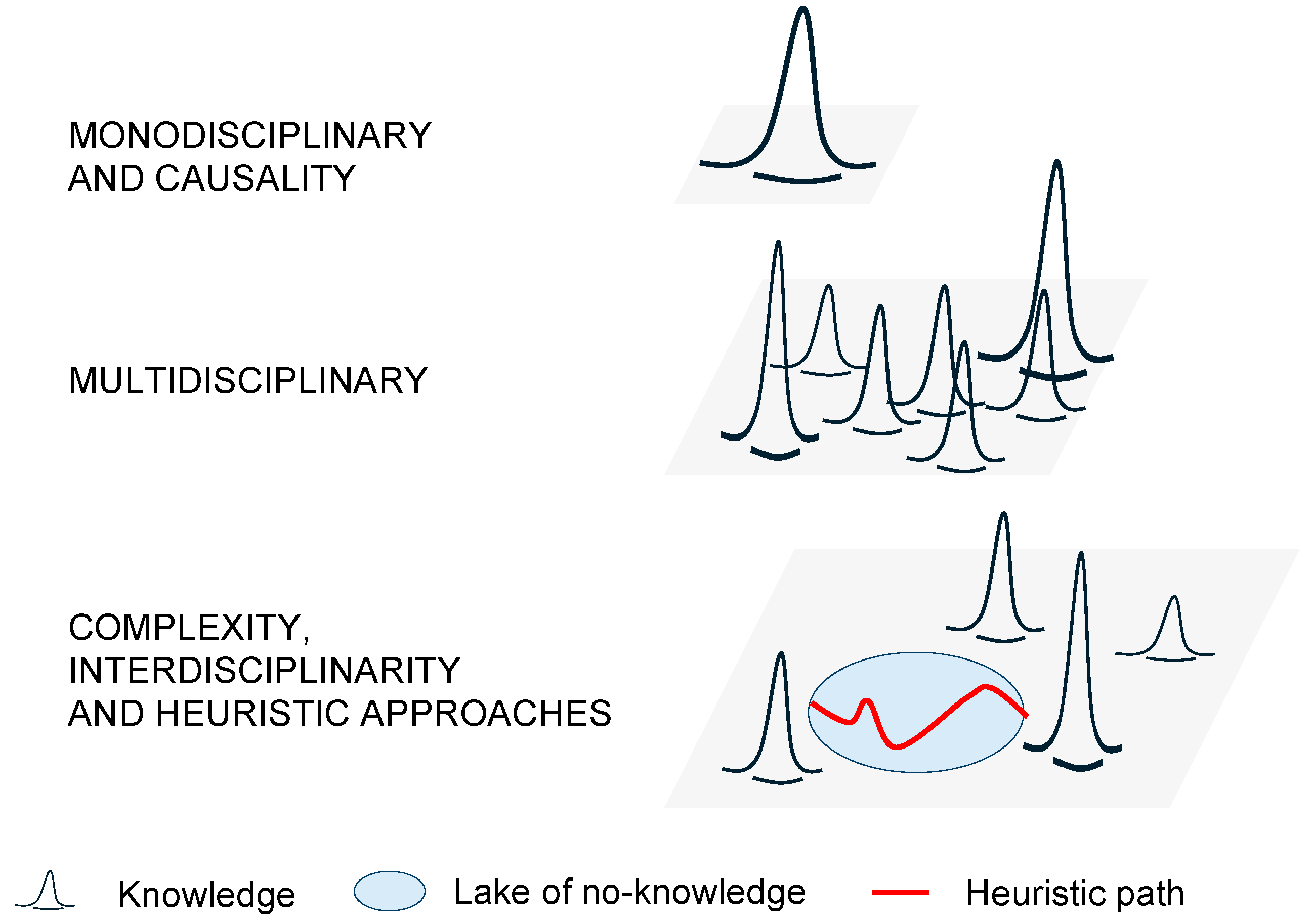

3.3. Heuristic Approaches

- Disciplinary considerations: focus on new knowledge, innovation, wealth creation, technical progress, healthcare, well-being, risk management, and resource sustainability;

- Ethical and moral considerations: emphasize prevention, ethics of life sciences, life preservation, intergenerational solidarity, sustainable development, and long-term effects;

- Daily living environment: address issues like community well-being, pollution, hygiene, safety, health, stress, living conditions, and comfort;

- Political and social framework: prioritize employment, social decision-making, civic engagement, democracy, community solidarity, policing, and security against terrorism;

- Hierarchical considerations: can lead to silencing dissenting voices due to difficulties in verifying statements, fear of incompetence, or submission to authority.

- Empirical knowledge about object design;

- Specific concepts posing challenges in natural sciences related to function, intention, and creativity;

- Tools supporting designers’ activities, such as computer-aided design and creativity methods.

3.4. Modeling and Design

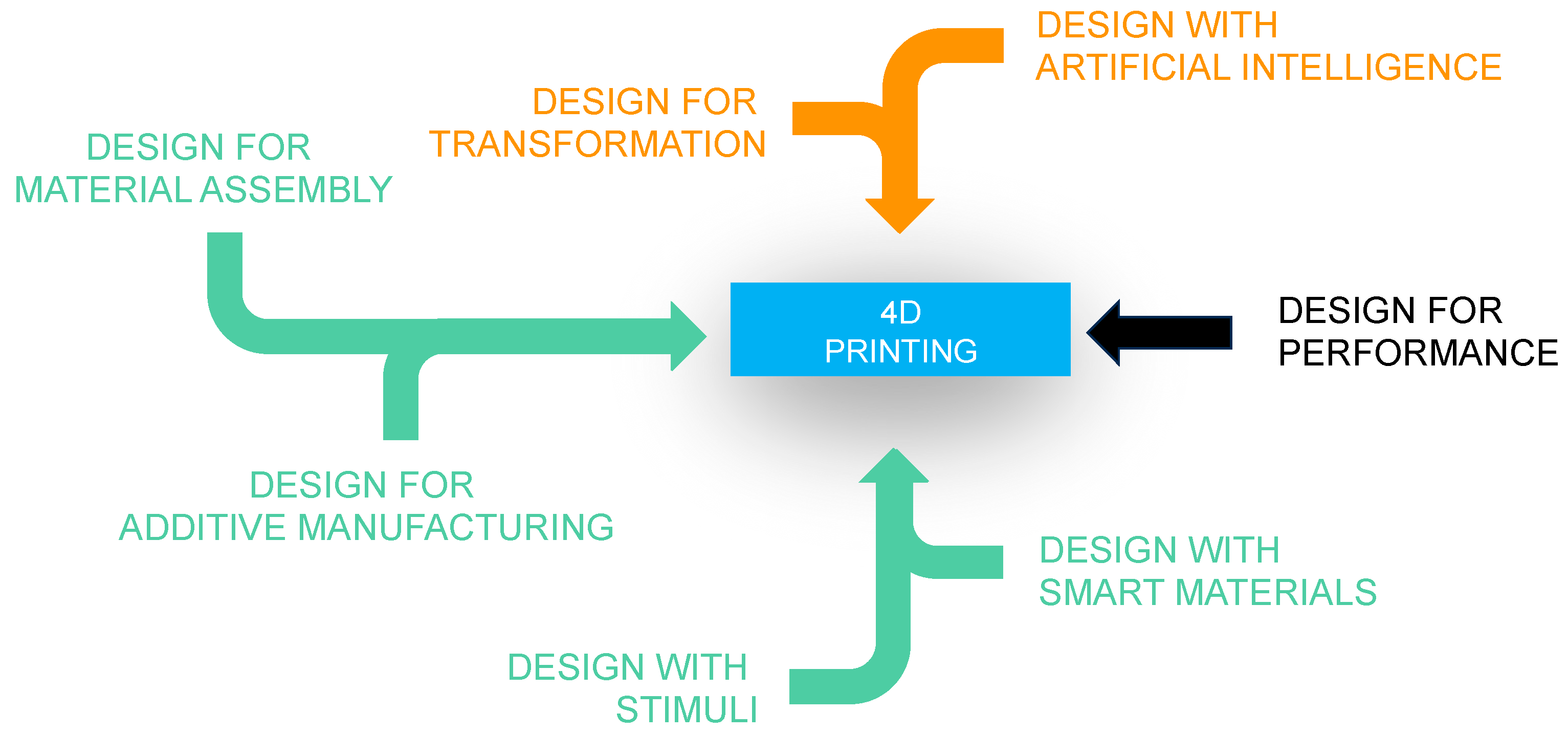

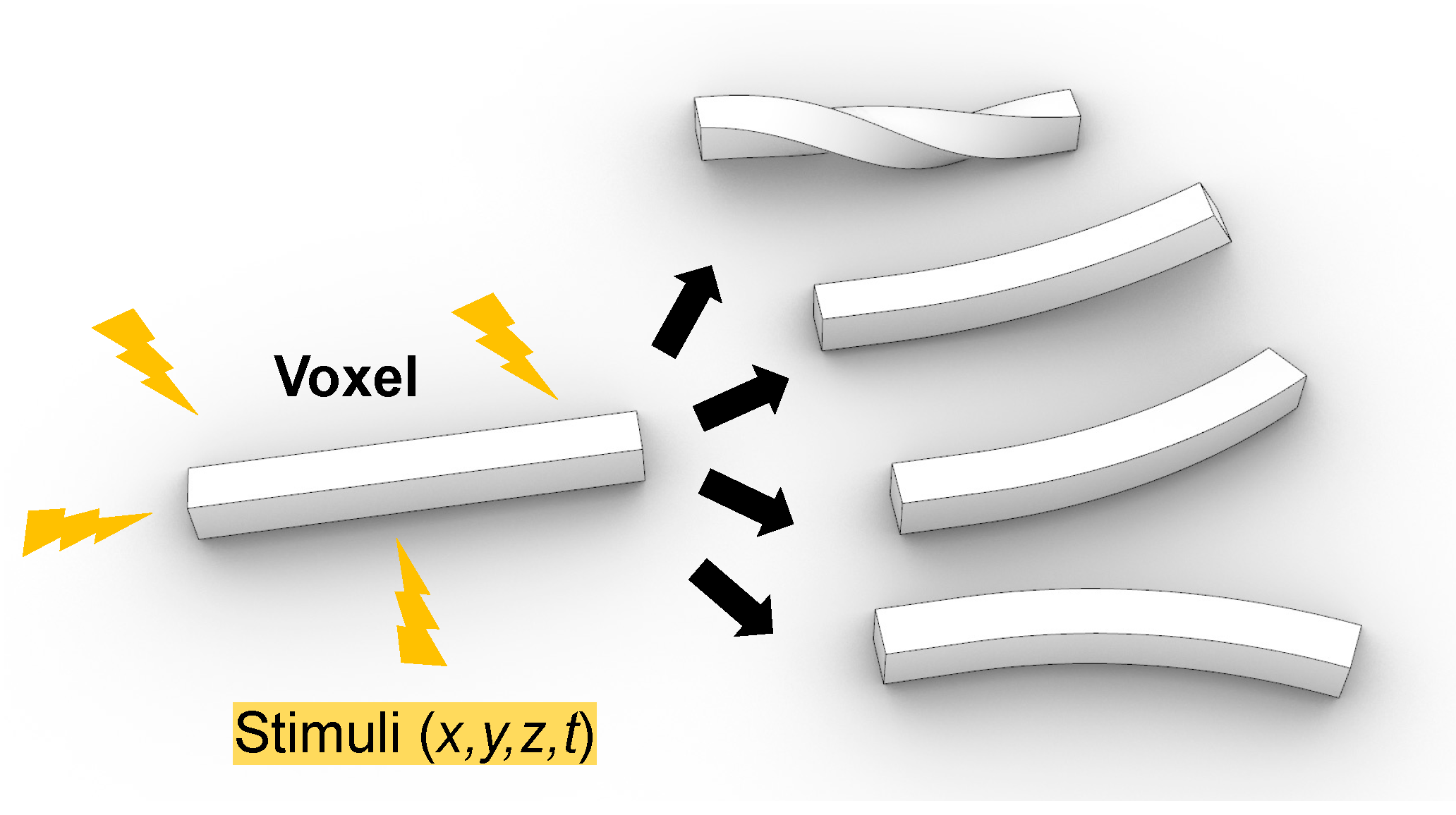

3.4.1. Isolated Voxels

- Developing standardized kinetic components in smart materials that exhibit transformation primitives, such as bending and twisting, to be used as active components for mechanical assemblies with rigid parts;

- Introducing an open kinetic library, accessible for downloading data on kinetic components to incorporate into designs, as well as enabling users to upload and share their own data;

- Running simulations based on empirical methods using kinetic components within assemblies.

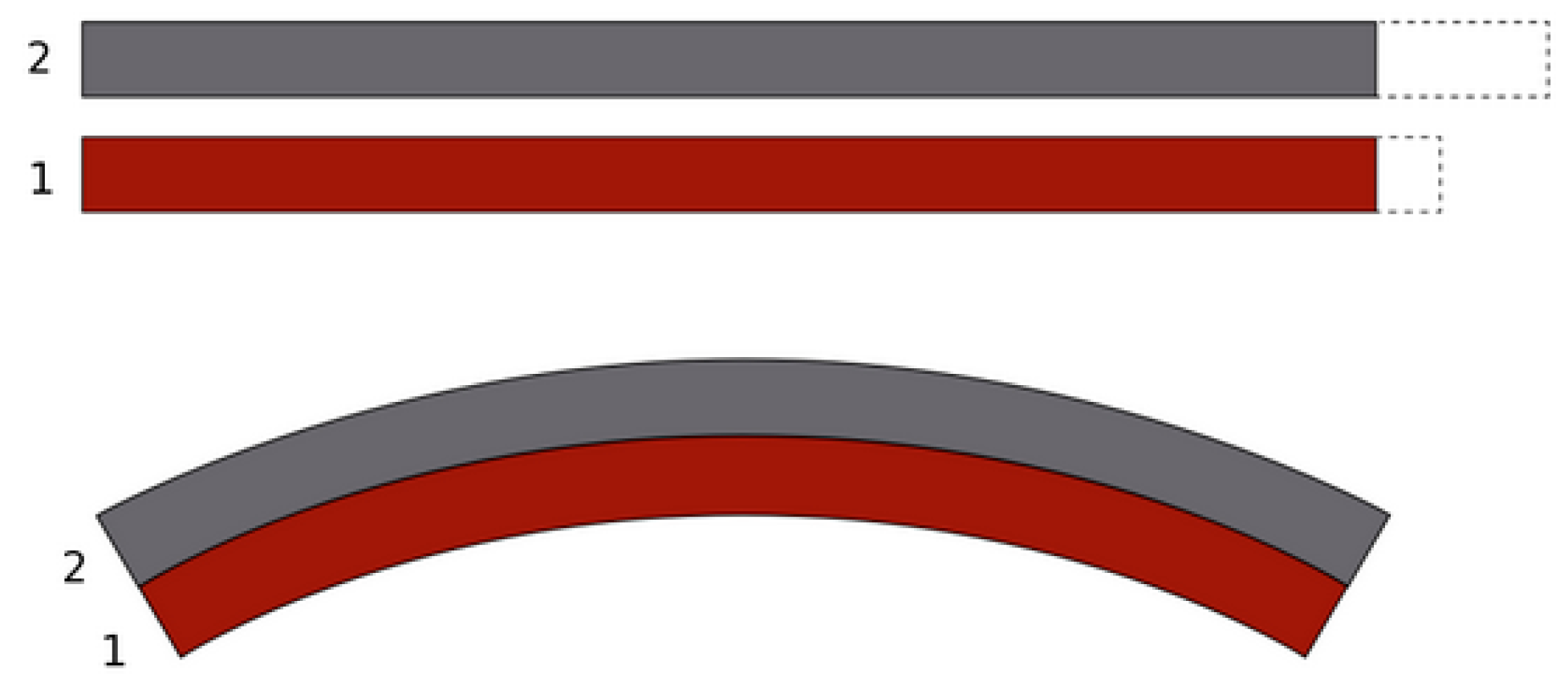

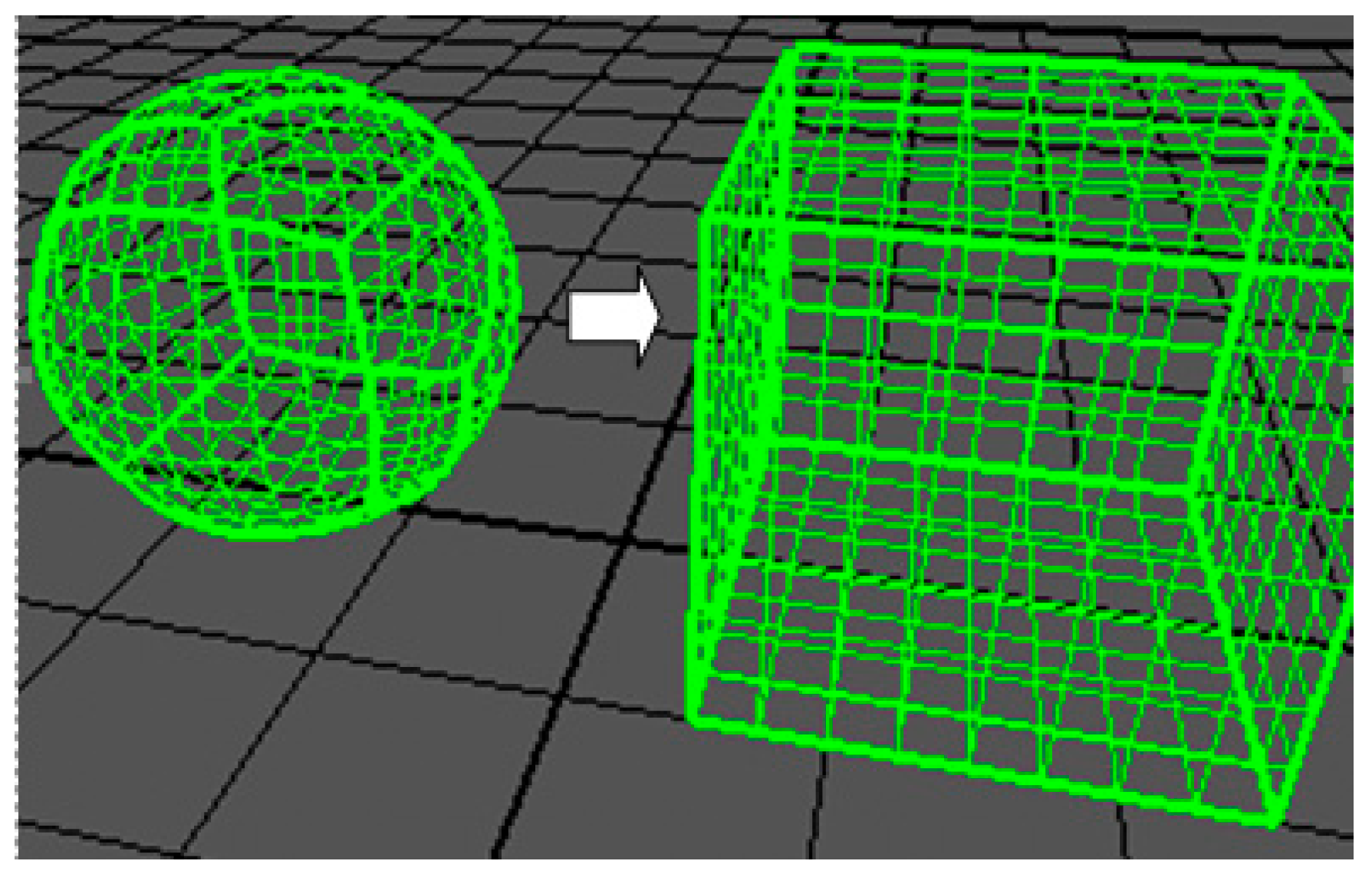

3.4.2. Voxel Assembly

3.4.3. Wire-Like Structures

3.4.4. Toward More Complex Models

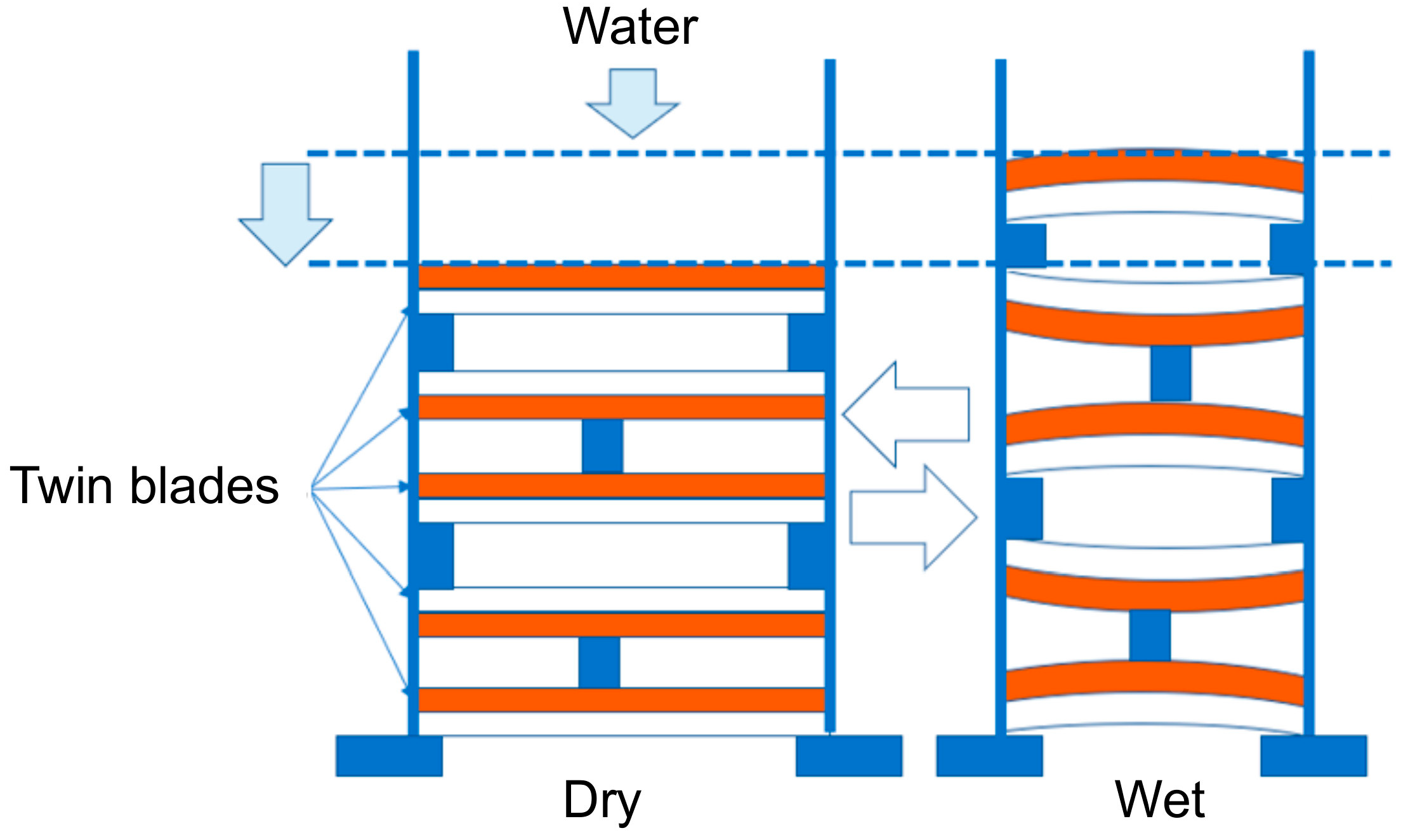

- General modeling principles stating that proportional expansion is a common self-morphing behavior for several materials;

- The four physical characteristics of mass diffusion, thermal expansion, molecular change, and organic development are differentiating elements;

- Most 4D-printed structures consist of an active layer/component and a passive layer/component.

- Development of a multi-scale interlocking block generation algorithm to enhance the structural performance and control of multi-material distribution, considering voxel relationships and the homogeneous nature of each voxel before and during energy stimulation;

- Optimization of geometric deviations to address AM inaccuracies;

- Integration of mechanical behaviors at the interfaces of interlocking blocks to improve the modeling accuracy and predict functional fatigue;

- Calculation of shadow effects during stimulations induced by voxels located between the one of interest and its primary and secondary sources of stimulation;

- Enhancement of calculation procedures for determining interlocking blocks using artificial intelligence-based techniques;

- Consideration of additional conditions in the calculation of the assembly of interlocking blocks;

- Development of a robotic platform for the manipulation and assembly of blocks at different scales for physical demonstrations;

- Expansion of experiments to include various shape-changing configurations and other active materials activated by stimuli;

- Examination of the use of solid multi-active materials responding to various stimuli.

3.4.5. Synthesis

3.5. Invention

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tibbits, S. The Emergence of 4D Printing. 2013. Available online: https://www.ted.com/talks/skylar_tibbits_the_emergence_of_4d_printing (accessed on 6 March 2024).

- Tibbits, S. 4D printing: Multi-material shape change. Archit. Des. 2014, 84, 116–121. [Google Scholar] [CrossRef]

- Demoly, F.; André, J.C. 4D Printing—Volume 1: Between Disruptive Research and Industrial Application–Volume 2: Between Science and Technology; ISTE/Wiley: London, UK, 2022. [Google Scholar]

- Ge, Q.; Sakhaei, A.H.; Lee, H.; Dunn, C.K.; Fang, N.X.; Dunn, M.L. Multi-material 4D printing with tailorable shape memory polymers. Sci. Rep. 2016, 6, 31110. [Google Scholar] [CrossRef]

- Boucher, M.P.; Helmreich, S.; Kinney, L.W.; Tibbits, S.; Uchill, R.; Ziporyn, E. Being Material; The MIT Press: Cambridge, MA, USA, 2022. [Google Scholar]

- Laruelle, F. En Tant Qu’Un; Aubier: Paris, France, 1991. [Google Scholar]

- André, J.C. From Additive Manufacturing to 3D/4D Printing—Volume 1: From the First Concept to the Present Applications; Volume 2: Improvement of the Present Technologies and Constraints; Volume 3: Breakdown Innovations: Programmable Matter; 4D Printing and Bio-Printing; ISTE/Wiley: London, UK, 2018. [Google Scholar]

- Bellit, S.; Charlet, V. L’Innovation de Rupture, Terrain de Jeu Exclusif Des Start-Up? Les Notes de La Fabrique—Presses des Mines: Paris, France, 2023. [Google Scholar]

- Schumpeter, J.A. Théorie de L’Evolution Economique; Dalloz: Paris, France, 1999. [Google Scholar]

- Morton, T. Hyper-Objects: Philosophy and Ecology after the End of the World; University of Minnesota Press: Minneapolis, MN, USA, 2013. [Google Scholar]

- Leleu-Merviel, S.; Boulekbache, H. Recherches en Design—Processus de Conception, Ecriture et Représentations; ISTE: London, UK, 2014. [Google Scholar]

- Silberzahn, P. Innovation: Les Technologies de Rupture, Ça N’Existe Pas. 2023. Available online: https://www.contrepoints.org/2023/12/05/468233-innovation-les-technologies-de-rupture-ca-nexiste-pas (accessed on 6 March 2024).

- Silberzahn, P. La Complexité N’est Pas Synonyme D’Impuissance. 2023. Available online: https://www.contrepoints.org/2023/10/24/465919-la-complexite-nest-pas-synonyme-dimpuissance (accessed on 6 March 2024).

- Silberzahn, P.; Rousset, B. Cracker Votre Code Pour Libérer les Possibles. 2019. Available online: https://www.youtube.com/watch?v=ZGxOpaSdFQk (accessed on 6 March 2024).

- Bertalanffy, L. The history and status of general systems theory. Acad. Manag. J. 1972, 15, 407–426. [Google Scholar] [CrossRef]

- Bertalanffy, L. Théorie Générale des Systèmes; Dunod: Paris, France, 1973. [Google Scholar]

- Guespin-Michel, J. La Révolution du Complexe: Science, Dialectique et Rationalité. 2016. Available online: http://www.revolutionducomplexe.fr/images/downloads/revolutionducomplexeguespin.pdf (accessed on 6 March 2024).

- Brown, T. Change by Design: How Design Thinking Transforms Organizations and Inspires Innovation; Harper Business: New York, NY, USA, 2009. [Google Scholar]

- Cross, N. Design Thinking: Understanding How Designers Think and Work; Berg Publishers: Oxford, UK, 2011. [Google Scholar]

- Findeli, A. La recherche-projet en design et la question de la question de recherche: Essai de clarification conceptuelle. Sci. Du Des. 2015, 1, 45–57. [Google Scholar] [CrossRef]

- Vial, S. Le Design Que Sais-je; PUF: Paris, France, 2015. [Google Scholar]

- Raîche-Savoie, G.; Déméné, C. La pluralité de la recherche en design: Tentative de clarification et de modélisation de la recherche-action, de la recherche-création et de la recherche-projet. Sci. Du Des. 2022, 16, 10–29. [Google Scholar] [CrossRef]

- Chaiken, S. Heuristic versus systematic processing and the use of source versus message cues in persuasion. J. Personal. Soc. Psychol. 1980, 39, 752–766. [Google Scholar] [CrossRef]

- Chaiken, S. The heuristic model of persuasion. In Social Influence: The Ontario Symposium; Zanna, M.P., Olson, J.M., Herman, C.P., Eds.; Erlbaum: Hillsdale, MI, USA, 1987; Volume 5, pp. 33–39. [Google Scholar]

- Moscovici, S. Fécondités, limites et échecs de la pratique interdisciplinaire. Genre Hum. 1998, 33, 15–29. [Google Scholar] [CrossRef]

- Latour, B.; Yaneva, A. Le point de vue de la théorie de l’acteur-réseau sur l’architecture. In Explorations in Architecture: Teaching, Design, Research; Geiser, R., Ed.; Birkhauser: Basel, Switzerland, 2009; pp. 80–89. [Google Scholar]

- Latour, B. Changer de Société—Refaire de la Sociologie; La Découverte: Paris, France, 2006. [Google Scholar]

- Chabard, P. Intermède. Ouvrir la croisée. Clara 2015, 3, 85–86. [Google Scholar] [CrossRef]

- Conan, M. Concevoir un Projet D’Architecture; L’Harmattan: Paris, France, 1990. [Google Scholar]

- Pena, W.; Parshall, S. Problem Seeking—An Architectural Programming Primer; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Zetlaoui-Léger, J. Invention et réinvention de la «programmation générative» des projets: Une opportunité de collaboration entre architecture et sciences humaines et sociales pour des modes d’habiter durables. Clara 2015, 3, 101–113. [Google Scholar] [CrossRef]

- Doucet, I. Intermède. Les artefacts architecturaux: Faites entrer les acteurs! Clara 2025, 3, 143–144. [Google Scholar] [CrossRef]

- Asimow, M. Introduction to Design; Prentice-Hall: New York, NY, USA, 1962. [Google Scholar]

- Fayemi, P.E. Innovation Par la Conception Bio-Inspirée: Proposition D’un Modèle Structurant les Méthodes Biomimétiques et Formalisation D’un Outil de Transfert de Connaissances. Ph.D. Thesis, ENSAM-ParisTech, Paris, France, 2016. [Google Scholar]

- André, J.C. Knowledge Production Modes between Science and Applications; ISTE/Wiley: London, UK, 2023. [Google Scholar]

- André, J.C. What means a “good” convergent expertise? 2024; to be published. [Google Scholar]

- Winnicott, D.W. Jeu et Réalité—L’Espace Potentiel; Gallimard NRF: Paris, France, 1975. [Google Scholar]

- Berten, A. Dispositif, Médiation, Créativité: Petite Généalogie; Hermès-La revue, 25; CNRS: Paris, France, 1999; pp. 31–47. [Google Scholar]

- Lévi-Strauss, C. La Pensée Sauvage; Pocket: Paris, France, 1990. [Google Scholar]

- Simon, H.A. The Sciences of the Artificial, 3rd ed.; MIT Press: Cambridge, MA, USA, 1996. [Google Scholar]

- Léchot Hirt, L. Recherche-Création en Design, Modèles Pour Une Pratique Expérimentale; Métis Presses: Genève, Switzerland, 2010. [Google Scholar]

- Avenier, M.J. Les Sciences de l’artificiel: Une conceptualisation révolutionnaire de sciences fondamentales à parachever. Proj./Proyéctica/Proj. 2019, 24, 43–56. [Google Scholar] [CrossRef]

- Séris, J.P. L’artificiel et la connaissance de l’artificiel. In Philosophies de la Nature; Editions de la Sorbonne: Paris, France, 2000. [Google Scholar]

- Hodgkinson, G.P.; Starkey, K. Extending the foundations and reach of design science: Further reflections on the role of critical realism. Br. J. Manag. 2012, 23, 605–610. [Google Scholar] [CrossRef]

- Messerschmitt, D. Understanding Networked Applications: A First Course; Morgan Kaufmann Publishers: San Francisco, CA, USA, 2000. [Google Scholar]

- Meyer, A.M.; Helfert, M.; Donnellan, B.; Kenneallypplying, J. Design science research for enterprise architecture business value assessments. In Design Science Research in Information Systems—Advances in Theory and Practice, Proceedings of the 7th International Conference, DESRIST 2012, Las Vegas, NV, USA, 14–15 May 2012; Peffers, K., Rothenberger, M., Kuechler, B., Eds.; Springer: New York, NY, USA, 2021; pp. 108–121. [Google Scholar]

- Lubart, T. Psychologie de la Créativité; A. Colin: Paris, France, 2005. [Google Scholar]

- UVED. Le Design Industriel. 2023. Available online: https://web.archive.org/web/20240106134447/http://stockage.univ-valenciennes.fr/EcoPEM/BoiteK/co/IV.html (accessed on 6 January 2024).

- Pahl, G.; Beitz, W. Engineering Design—A Systematic Approach, 3rd ed.; Wallace, K., Ed.; Wallace, K.; Blessing, L.; Bauert, F., Translators; Springer: London, UK, 1996. [Google Scholar]

- Suh, N.P. Axiomatic Design: Advances and Applications; Oxford University Press: Oxford, UK, 2001. [Google Scholar]

- Kannan, T. Design for Additive Manufacturing. 2013. Available online: http://geometricglobal.com/wp-content/uploads/2013/11/Geometric_Whitepaper-Additive-Manufacturing_July-2013 (accessed on 6 March 2024).

- Walden, D.D.; Roeder, G.J.; Forsberg, K.; Hamelin, R.D.; Shortell, T.M. Systems Engineering Handbook—A Guide for System Life Cycle Processes and Activities; Wiley: New York, NY, USA, 2015. [Google Scholar]

- Blessing, L. What is this thing called design research? In Proceedings of the ICED 03, the 14th International Conference on Engineering Design, Stockholm, Sweden, 19–21 August 2003. [Google Scholar]

- Blessing, L. Future issues in design research. In Human Behavior in Design: Individuals, Teams, Tools; Lindemann, U., Ed.; Springer: Heidelberg, Germany, 2003; pp. 298–303. [Google Scholar]

- Blessing, L.T.; Chakrabarti, A. DRM, A Design Research Methodology; Springer Science & Business Media: New York, NY, USA, 2009. [Google Scholar]

- Cohen, Y.H.; Reich, Y.; Greenberg, S. Biomimetics: Structure-function patterns approach. J. Mech. Des. 2014, 136, 111108. [Google Scholar] [CrossRef]

- MTC—Mind Tools Content Team TRIZ. 2023. Available online: https://www.mindtools.com/amtcc5f/triz (accessed on 6 March 2024).

- Ekmekci, I.; Nebati, E.E. TRIZ Methodology and Applications. Proc. Comput. Sci. 2019, 158, 303–315. [Google Scholar] [CrossRef]

- Hatchuel, A.; Le Masson, P.; Weil, B. Teaching innovative design reasoning: How concept–knowledge theory can help overcome fixation effects. Artificial Intelligence for Engineering Design. Anal. Manuf. 2011, 25, 77–92. [Google Scholar]

- Hatchuel, A.; Weil, B.; Le Masson, P. Towards an ontology of design: Lessons from C–K design theory and Forcing. Res. Eng. Des. 2012, 24, 147–163. [Google Scholar] [CrossRef]

- Shai, O.; Reich, Y.; Hatchuel, A.; Subrahmanian, E. Creativity and scientific discovery with infused design and its analysis with C–K theory. Res. Eng. Des. 2013, 24, 201–214. [Google Scholar] [CrossRef]

- Wöhr, F.; Uhri, E.; Königs, S.; Trauer, J.; Stanglmeier, M.; Zimmermann, M. Coordination and complexity: An experiment on the effect of integration and verification in distributed design processes. Des. Sci. 2023, 9, e1. [Google Scholar] [CrossRef]

- Bhasin, D.; Behmer, S.T.; McAdams, D.A. Fostering function-sharing using bioinspired product architecture. J. Mech. Des. 2021, 143, 061401. [Google Scholar] [CrossRef]

- Bhasin, D.; McAdams, D.A.; Layton, A. A product architecture-bassed tool for bioinspired function-sharing. J. Mech. Des. 2021, 143, 081401. [Google Scholar] [CrossRef]

- Bhasin, D.; McAdams, D.A. Current state of the art: Problem-driven multi-functional bio-inspired designs. In Proceedings of the ASME 2019 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference, Anaheim, CA, USA, 18–21 August 2019. [Google Scholar]

- Doran, J.; Ryan, G. The role of stimulating employees’ creativity and idea generation in encouraging innovation behavior in irish firms. Ir. J. Manag. 2017, 36, 32–48. [Google Scholar]

- Kin, V.; Rollet, A.; Senkel, M.P.; Jan, F. Génération et sélection d’idées dans le processus d’innovation: Cas de la méthodologie Delphi dans la logistique 4.0. Innovations 2021, 66, 109–138. [Google Scholar] [CrossRef]

- Parmentier, G.; Paris, T.; Gandia, R. De la créativité à l’innovation: Paradoxes, articulation et enjeux. Innovations 2021, 66, 5–16. [Google Scholar] [CrossRef]

- Jacob, E. La Professionnalité Emergente des Ingénieurs Généralistes en France au Prisme de L’Apprentissage de la Gestion de Projet: Le cas de la Formation des Elèves à L’Ecole Centrale de Marseille. Ph.D. Thesis, Aix-Marseille Université, Marseille, France, 2022. [Google Scholar]

- Dosi, G. Technological paradigms and technological trajectories: A suggested interpretation of the determinants and directions of technical change. Res. Policy 1982, 11, 147–162. [Google Scholar] [CrossRef]

- Dubois, M.J.F.; Brault, N. Manuel D’Epistémologie Pour L’Ingénieur; Editions Matériologiques: Paris, France, 2021. [Google Scholar]

- Reynaud, J.D. Les Règles du Jeu; Armand Colin: Paris, France, 1989. [Google Scholar]

- Jollivet, M.; Legay, J.M. Canevas pour une réflexion sur une interdisciplinarité entre sciences de la nature et sciences sociales. Nat. Sci. Sociétés 2005, 13, 184–188. [Google Scholar] [CrossRef]

- Jollivet, M. Eléments de théorie pour une recherche interdisciplinaire sur les interfaces nature/sociétés. In Modélisation de L’Environnement: Entre Natures et Sociétés; Laloë, F., Hervé, D., Eds.; Quaë: Versailles, France, 2009. [Google Scholar]

- Fabiani, J.L. A quoi sert la notion de discipline? In Qu’Est-ce Qu’une Discipline; Boutier, J., Passeron, J.C., Revel, J., Eds.; Editions de l’EHESS: Paris, France, 2006. [Google Scholar]

- Legay, J.M. Quelques réflexions à propos de l’écologie—Défense de l’indisciplinarité. Acta Acol. 1986, 7, 391–398. [Google Scholar]

- Sevtsuk, A.; Chancey, B.; Basu, R.; Mazzarello, M. Spatial structure of workplace and communication between colleagues: A study of E-mail exchange and spatial relatedness on the MIT campus. Soc. Netw. 2022, 70, 295–305. [Google Scholar] [CrossRef]

- Malmiry, R.B. Managing Complexity and Uncertainty by a Modelling Approach for Decision Making in Integrated Product/Process Design. Ph.D. Thesis, ParisTech, Paris, France, 2016. [Google Scholar]

- Orme, M.; Madera, I.; Gschweitl, M.; Ferrari, M. Topology optimization for additive manufacturing as an enabler for light weight flight hardware. In Design and Applications of Additive Manufacturing and 3D Printing; Salmi, M., Ed.; MDPI: Basel, Switzerland, 2022; pp. 70–92. [Google Scholar]

- Hooshmand-Ahoor, Z.; Tarantino, M.G.; Danas, K. Mechanically-grown morphogenesis of Voronoi-type materials: Computer design, 3D-printing and experiments. Mech. Mater. 2022, 173, 104432. [Google Scholar] [CrossRef]

- Jian, B.; Li, H.; He, X.; Wang, R.; Yang, H.Y.; Ge, Q. Two-photon polymerization-based 4D printing and its applications. Int. J. Ext. Manuf. 2024, 6, 012001. [Google Scholar] [CrossRef]

- Doualle, T.; Gallais, L.; André, J.C. 3D-printing of silica glass through multiphoton polymerization process. Opt. Lett. 2021, 46, 364–367. [Google Scholar] [CrossRef]

- Boyard, N. Méthodologie de Conception Pour la Réalisation de Pièces en Fabrication Additive. Ph.D. Thesis, ParisTech, Paris, France, 2015. [Google Scholar]

- Salmi, M. Design and Applications of Additive Manufacturing and 3D Printing; MDPI: Basel, Switzerland, 2022. [Google Scholar]

- Go, K.; Carroll, J.M. The blind men and the elephant: Views of scenario-based system design. Interactions 2004, 11, 44–53. [Google Scholar] [CrossRef]

- Bessant, J.; von Stamm, B.; Moeslein, K.M.; Neyer, A.K. Backing outsiders: Selection strategies for discontinuous innovation. RD Manag. 2010, 40, 345–356. [Google Scholar] [CrossRef]

- Gregor, S.; Hevner, A.R. Positioning and Presenting Design Science Research for Maximum Impact. MIS Q. 2013, 37, 337–356. [Google Scholar] [CrossRef]

- Maggi, B. L’Interprétation de L’Agir. In Interpreter L’Agir: Un Défi Théorique; Maggi, B., Ed.; PUF: Paris, France, 2011; pp. 1–14. [Google Scholar]

- Zolfagharian, A.; Bodaghi, M. 4D printing mechanics, modeling, and advanced engineering applications. In Smart Materials in Additive Manufacturing—Volume 2: 4D Printing Mechanics, Modeling, and Advanced Engineering Applications-Additive Manufacturing Materials and Technologies; Elsevier: Amsterdam, The Netherlands, 2022; pp. 1–17. [Google Scholar]

- Dimassi, S. Knowledge Formalization and Recommendation in Computational Design Synthesis for 4D Printing. Ph.D. Thesis, Université Bourgogne Franche-Comté (UBFC), Sévenans, France, 2022. [Google Scholar]

- Dimassi, S.; Demoly, F.; Cruz, C.; Gomes, S. From dispersed knowledge to ontology: A proposal for formalizing and integrating 4D printing in design. In Product Lifecycle Management. Green and Blue Technologies to Support Smart and Sustainable Organizations; Springer: Berlin/Heidelberg, Germany, 2022; Volume 2, pp. 80–95. [Google Scholar]

- Dimassi, S.; Demoly, F.; Cruz, C.; Qi, H.J.; Kim, K.Y.; André, J.C.; Gomes, S. An ontology-based framework to formalize and represent 4D printing knowledge in design. Comput. Ind. 2021, 126, 103374. [Google Scholar] [CrossRef]

- Dimassi, S.; Demoly, F.; Belkebir, H.; Cruz, C.; Kim, K.Y.; Gomes, S.; Qi, H.J.; André, J.C. A knowledge recommendation approach in design for multi-material 4D printing based on semantic similarity vector space model and case-based reasoning. Comput. Ind. 2023, 145, 103824. [Google Scholar] [CrossRef]

- Zhang, W.; Ge, Z.; Li, D. Evolution and emerging trends of 4D printing based on literature—Visualization analysis. Manuf. Rev. 2022, 9, 30. [Google Scholar]

- Bhattacharyya, A.; Kim, J.Y.; Alacoque, L.R.; James, K.A. Bio-inspired 4D-printed mechanisms with programmable morphology. arXiv 2023, arXiv:2306.00233. [Google Scholar]

- Zolfagharian, A.; Durran, L.; Sangtarash, K.; Ghasemi, S.E.; Kaynak, A.; Bodaghi, M. 4D printing modeling via machine learning. In Smart Materials in Additive Manufacturing—Volume 2: 4D Printing Mechanics, Modeling, and Advanced Engineering Applications-Additive Manufacturing Materials and Technologies; Elsevier: Amsterdam, The Netherlands, 2022; pp. 73–102. [Google Scholar]

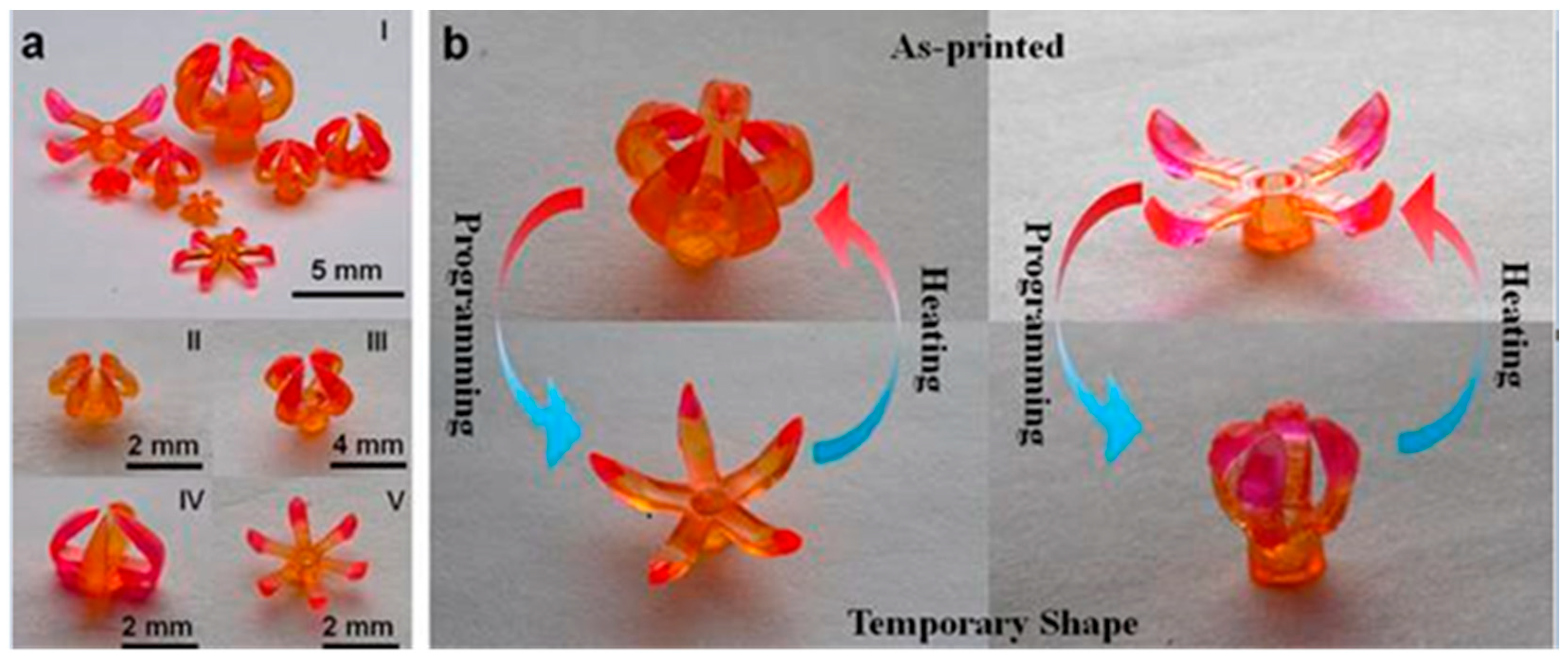

- Yue, L.; Sun, X.; Yu, L.; Li, M.; Montgomery, S.M.; Song, Y.; Nomura, T.; Tanaka, M.; Qi, H.Q. Cold-programmed shape-morphing structures based on grayscale digital light processing 4D printing. Nat. Commun. 2023, 14, 5519. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Jarrah, H.R.; Xavier, M.S.; Rolfe, B.; Bodaghi, M. Multi-material 4D printing with a tunable bending model. Smart Mater. Struct. 2023, 32, 065001. [Google Scholar] [CrossRef]

- Goo, B.; Hong, C.H.; Park, K. 4D printing using anisotropic thermal deformation of 3D-printed thermoplastic parts. Mater. Des. 2020, 188, 108485. [Google Scholar] [CrossRef]

- Choi, W.; Kim, D.; Lee, S.; Lee, Y.G. New modeling approach for 4D printing by using kinetic components. J. Comput. Des. Eng. 2021, 8, 1013–1022. [Google Scholar] [CrossRef]

- Lambert, P.; Renaud, P.; Szewczyk, J. Actionneurs Non-Conventionnels Pour La Robotique. 2016. Available online: https://hal.science/hal-02145907/file/Szewczyk%20TECH%20ING%202016.pdf (accessed on 6 March 2024).

- Lee, A.Y.; An, J.; Chua, C.K.; Zhang, Y. Preliminary Investigation of the Reversible 4D Printing of a Dual-Layer Component. Engineering 2019, 5, 1159–1170. [Google Scholar] [CrossRef]

- Baran, I.; Cinar, K.; Ersoy, N.; Akkerman, R.; Hattel, J.H. A review on the mechanical modeling of composite manufacturing processes. Arch. Comput. Meth. Eng. 2017, 24, 365–395. [Google Scholar] [CrossRef]

- Jian, B.; Demoly, F.; Zhang, Y.; Qi, H.J.; André, J.C.; Gomes, S. Origami-based design for 4D printing of 3D support-free hollow structures. Engineering 2022, 12, 70–82. [Google Scholar] [CrossRef]

- Chareyron, D.; Horsin-Molinaro, H. Physique et Ingenierie Des Objets: Le Bilame. 2020. Available online: https://culturesciencesphysique.ens-lyon.fr/ressource/bilame.xml (accessed on 6 March 2024).

- Weeger, O.; Boddeti, N.; Yeung, S.K.; Kaijima, S.; Dunn, M.L. Digital design and nonlinear simulation for additive manufacturing of soft lattice structures. Addit. Manuf. 2019, 25, 39–49. [Google Scholar] [CrossRef]

- Weeger, O. Inelastic finite deformation beam modelling and simulation of additively manufactured lattice structures. In Proceedings of the 4D Materials Design and Additive Manufacturing Conference 2022, Online, 1–2 September 2022. [Google Scholar]

- He, L.; Wang, P.; Yang, J.; Fan, K.; Zhang, H.; Zhang, L.; Jiang, M.; Chen, Z.; Chen, M.; Liu, H.; et al. Smart lattice structures with self-sensing functionalities via hybrid additive manufacturing technology. Micromachines 2024, 15, 2. [Google Scholar] [CrossRef]

- Ferro, C.G.; Varetti, S.; De Pasquale, G.; Maggiore, P. Lattice structured impact absorber with embedded anti-icing system for aircraft wings fabricated with additive SLM process. Mater. Today Commun. 2018, 15, 185–189. [Google Scholar] [CrossRef]

- Zhu, J.; Yang, J.; Zhang, W.; Gu, X.; Zhou, H. Design and applications of morphing aircraft and their structures. Front. Mech. Eng. 2023, 18, 34. [Google Scholar] [CrossRef]

- Ding, H.; Zhang, X.; Liu, Y.; Ramakrishna, S. Review of mechanisms and deformation behaviors in 4D printing. Int. J. Adv. Manuf. Tech. 2019, 105, 4633–4649. [Google Scholar] [CrossRef]

- Yang, Y.; Song, X.; Li, X.; Chen, Z.; Zhou, C.; Zhou, Q.; Chen, Y. Recent progress in biomimetic additive manufacturing technology: From materials to functional structures. Adv. Mater. 2018, 30, 1706539. [Google Scholar] [CrossRef]

- Weeger, O.; Kang, Y.S.B.; Yeung, S.K.; Dunn, M.L. Optimal design and manufacture of active rod structures with spatially variable materials. 3D Print. Addit. Manuf. 2016, 3, 204–215. [Google Scholar] [CrossRef]

- Weeger, O. Numerical homogenization of second gradient, linear elastic constitutive models for cubic 3D beam-lattice metamaterials. Int. J. Solids Struct. 2021, 224, 111037. [Google Scholar] [CrossRef]

- Liu, T.; Liu, L.; Zeng, C.; Liu, Y.; Leng, J. 4D printed anisotropic structures with tailored mechanical behaviors and shape memory effects. Compos. Sci. Technol. 2020, 186, 107935. [Google Scholar] [CrossRef]

- Momeni, F.; Ni, J. Laws of 4D Printing. Engineering 2020, 6, 1035–1055. [Google Scholar] [CrossRef]

- Biswas, M.C.; Chakraborty, S.; Bhattacharjee, A.; Mohammed, Z. 4D Printing of Shape Memory Materials for Textiles: Mechanism, Mathematical Modeling, and Challenges. Adv. Funct. Mater. 2021, 31, 2100257. [Google Scholar] [CrossRef]

- Aldawood, F.K. A comprehensive review of 4D printing: State of the art, opportunities, and challenges. Actuators 2023, 12, 101. [Google Scholar] [CrossRef]

- Sossou, G.; Demoly, F.; Belkebir, H.; Qi, H.J.; Gomes, S.; Montavon, G. Design for 4D printing: Modeling and Computation of Smart Materials Distribution. Mater. Des. 2019, 181, 108074. [Google Scholar] [CrossRef]

- Sossou, G.; Demoly, F.; Belkebir, H.; Qi, H.J.; Gomes, S.; Montavon, G. Design for 4D printing: A voxel-based modeling and simulation of smart materials. Mater. Des. 2019, 175, 107798. [Google Scholar] [CrossRef]

- Benyahia, K.; Seriket, H.; Prod’hon, R.; Gomes, S.; André, J.C.; Qi, H.J.; Demoly, F. A computational design approach for multi-material 4D printing based on interlocking blocks assembly. Add. Manuf. 2022, 58, 102993. [Google Scholar] [CrossRef]

- Nam, S.; Pei, E. A taxonomy of shape-changing behavior for 4D printed parts using shape-memory polymers. Prog. Addit. Manuf. 2019, 4, 167–184. [Google Scholar] [CrossRef]

- Jacobson, A.; Baran, I.; Popovic, J.; Sorkine-Hornung, O. Bounded Biharmonic Weights for Real-Time Deformation. Commun. ACM 2014, 57, 99–106. [Google Scholar] [CrossRef]

- Jacobson, A.; Panozzo, D.; Glauser, O.; Pradalier, C.; Hilliges, O.; Sorkine-Hornung, O. Tangible and modular input device for character articulation. ACM Trans. Graph. 2014, 33, 1–12. [Google Scholar] [CrossRef]

- Benyahia, K.; Gomes, S.; André, J.C.; Qi, H.J.; Demoly, F. Influence of interlocking blocks assembly on the actuation time, shape change, and reversibility of voxel-based multi-material 4D structures. Smart Mater. Struct. 2023, 32, 065011. [Google Scholar] [CrossRef]

- Peng, X.; Wu, S.; Sun, X.; Yue, L.; Montgomery, S.M.; Demoly, F.; Zhou, K.; Zhao, R.R.; Qi, H.J. 4D Printing of Freestanding Liquid Crystal Elastomers via Hybrid Additive Manufacturing. Adv. Mater. 2022, 34, 2204890. [Google Scholar] [CrossRef]

- Athinarayanarao, D.; Prod’hon, R.; Chamoret, D.; Qi, H.J.; Bodaghi, M.; André, J.C.; Demoly, F. Computational design for 4D printing of topology optimized multi-material active composites. NPJ Comput. Mater. 2023, 9, 1. [Google Scholar] [CrossRef]

- Benyahia, K. Hybrid Voxels 4D Printing Based on Topologically Interlocked Multi-Material Assembly. Ph.D. Thesis, Université Bourgogne Franche-Comté (UBFC), Sevenans, France, 21 December 2023. [Google Scholar]

- Lai, J.; Li, J.; Wang, M. 3D printed porous tissue engineering scaffolds with the self-folding ability and controlled release of growth factor. MRS Commun. 2020, 10, 579–586. [Google Scholar] [CrossRef]

- Cui, C.; Kim, D.O.; Pack, M.Y.; Han, B.; Han, L.; Sun, Y.; Han, L.H. 4D printing of self-folding and cell-encapsulating 3D microstructures as scaffolds for tissue-engineering applications. Biofabrication 2020, 12, 045018. [Google Scholar] [CrossRef]

- Roato, I.; Masante, B.; Putame, G.; Massai, D.; Mussano, F. Challenges of periodontal tissue engineering: Increasing biomimicry through 3D printing and controlled dynamic environment. Nanomaterials 2022, 12, 3878. [Google Scholar] [CrossRef]

- Morin, S.A.; Shevchenko, Y.; Lessing, J.; Kwok, S.W.; Shepherd, R.F.; Stokes, A.A.; Whitesides, G.M. Using ‘Click-e-Bricks’ to make 3D elastomeric structures. Adv. Mater. 2014, 26, 5991–5999. [Google Scholar] [CrossRef]

- Young, L.J.; Eom, J.; Choi, W.Y.; Cho, K.J. Soft LEGO: Bottom-up design platform for soft robotics. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Madrid, Spain, 1–5 October 2018; pp. 7513–7520. [Google Scholar] [CrossRef]

- Young, L.J.; Kim, W.B.; Eom, J.; Choi, W.Y.; Cho, K.J. Soft robotic blocks: Introducing SoBL, a fast-build modularized design block. IEEE Robot. Autom. Mag. 2016, 23, 30–41. [Google Scholar]

- Mishima, Y. Neige de Printemps; Gallimard: Paris, France, 1989. [Google Scholar]

- Horenstein, M.N. Design Concepts for Engineers; Prentice Hall: Upper Saddle River, NJ, USA, 2002. [Google Scholar]

- Millier, P. L’ingénieur, le bricoleur et l’innovateur. Entrep. Innover 2016, 28, 48–62. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Demoly, F.; André, J.-C. 4D Printing: Bridging the Gap between Fundamental Research and Real-World Applications. Appl. Sci. 2024, 14, 5669. https://doi.org/10.3390/app14135669

Demoly F, André J-C. 4D Printing: Bridging the Gap between Fundamental Research and Real-World Applications. Applied Sciences. 2024; 14(13):5669. https://doi.org/10.3390/app14135669

Chicago/Turabian StyleDemoly, Frédéric, and Jean-Claude André. 2024. "4D Printing: Bridging the Gap between Fundamental Research and Real-World Applications" Applied Sciences 14, no. 13: 5669. https://doi.org/10.3390/app14135669