Borehole Condition and Limit Pressure Differential Analysis in Carbonate Reservoirs

Abstract

1. Introduction

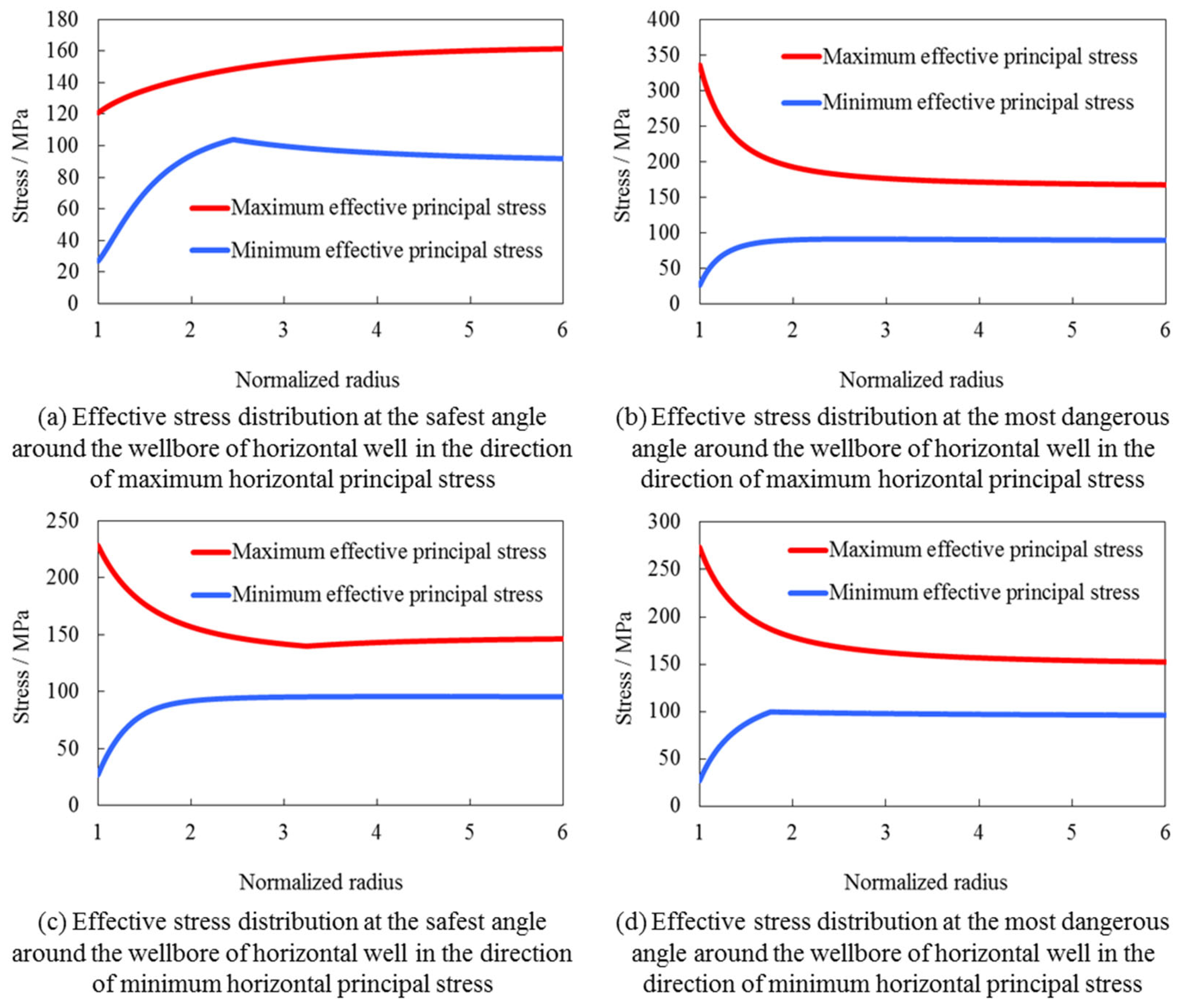

2. Stress Distribution around Borehole in Open-Hole Completion

3. Evaluation of Open-Hole Wellbore Condition in Carbonate Rock

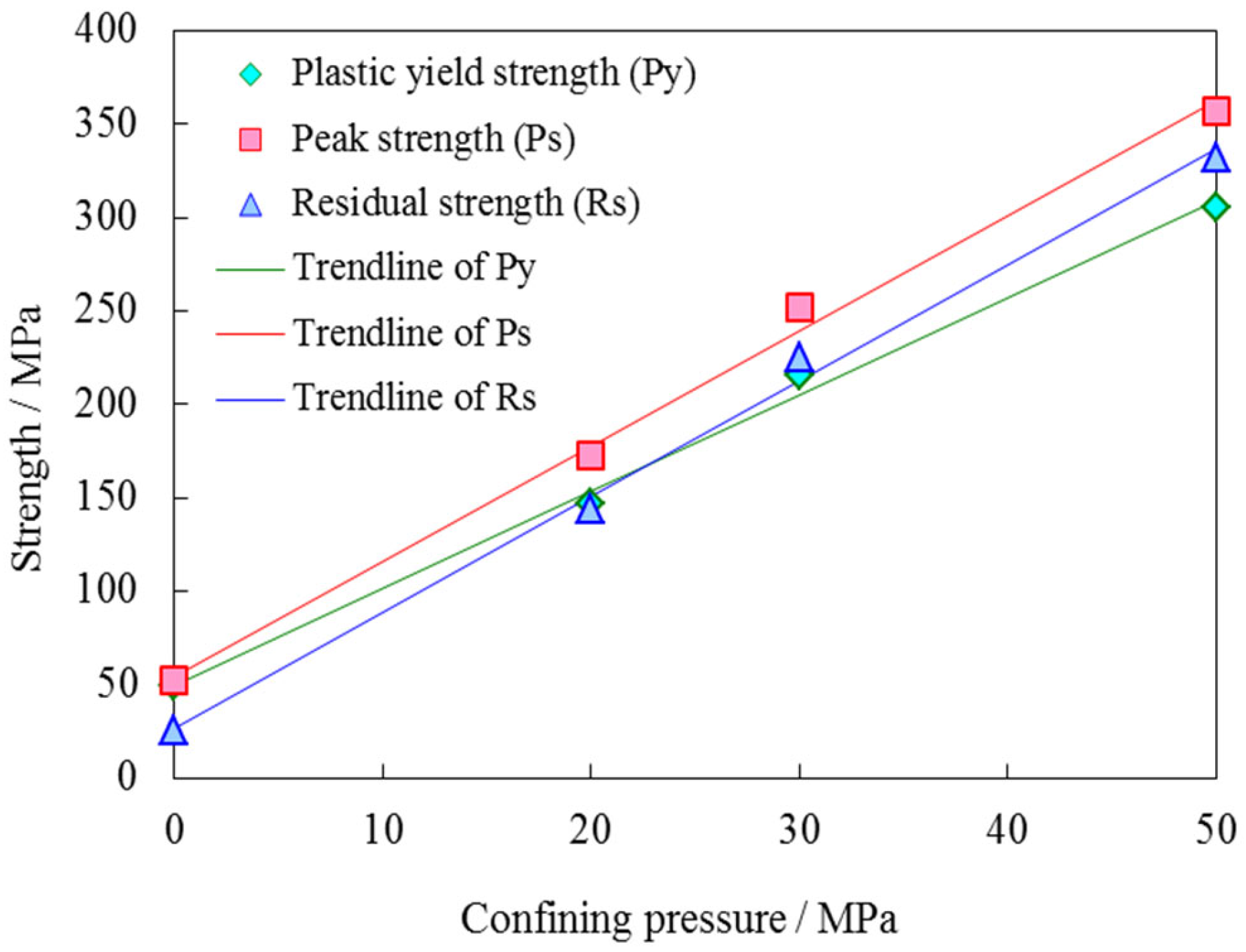

3.1. Core Mechanical Parameters of Carbonate Reservoir

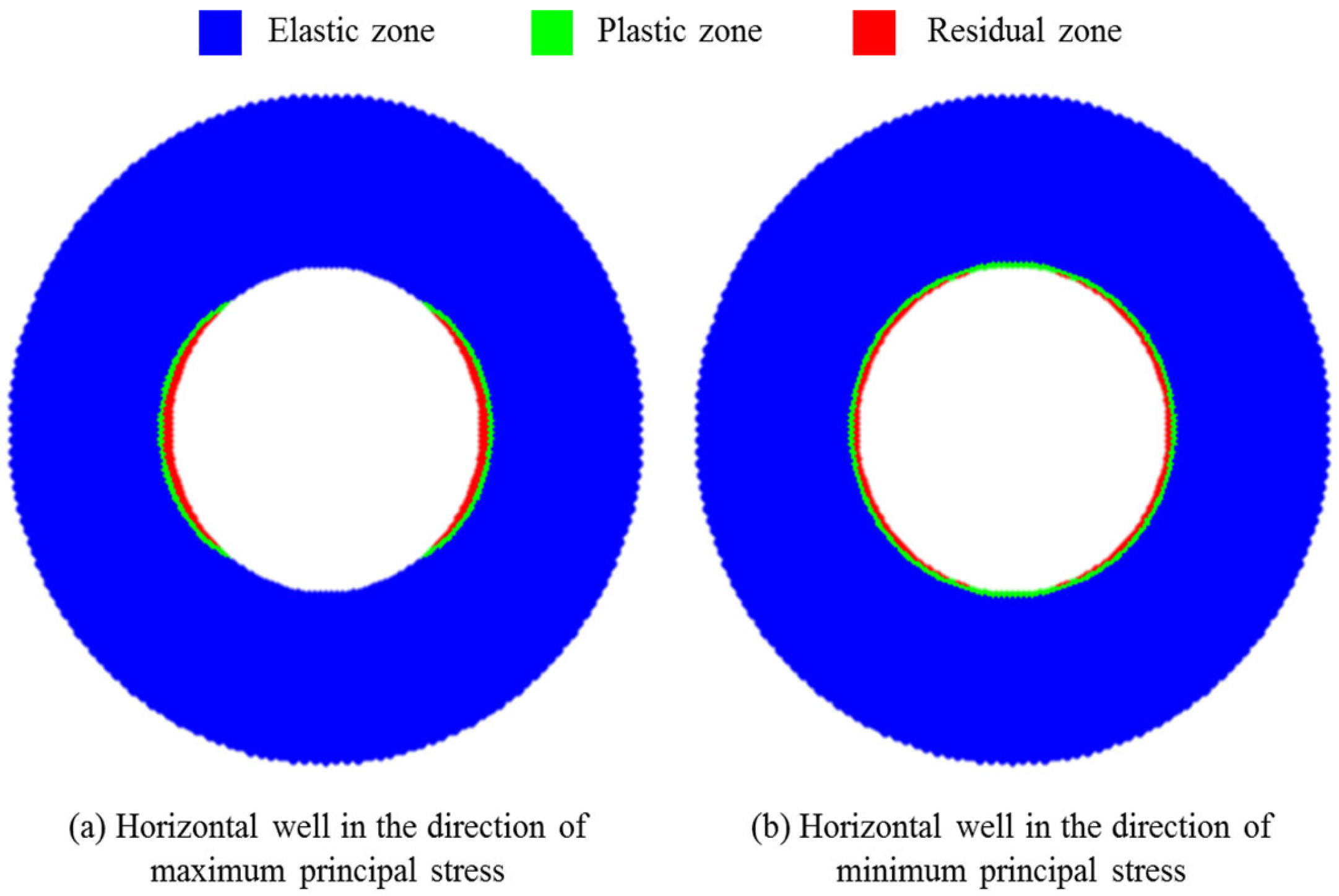

3.2. Description of Wellbore Conditions

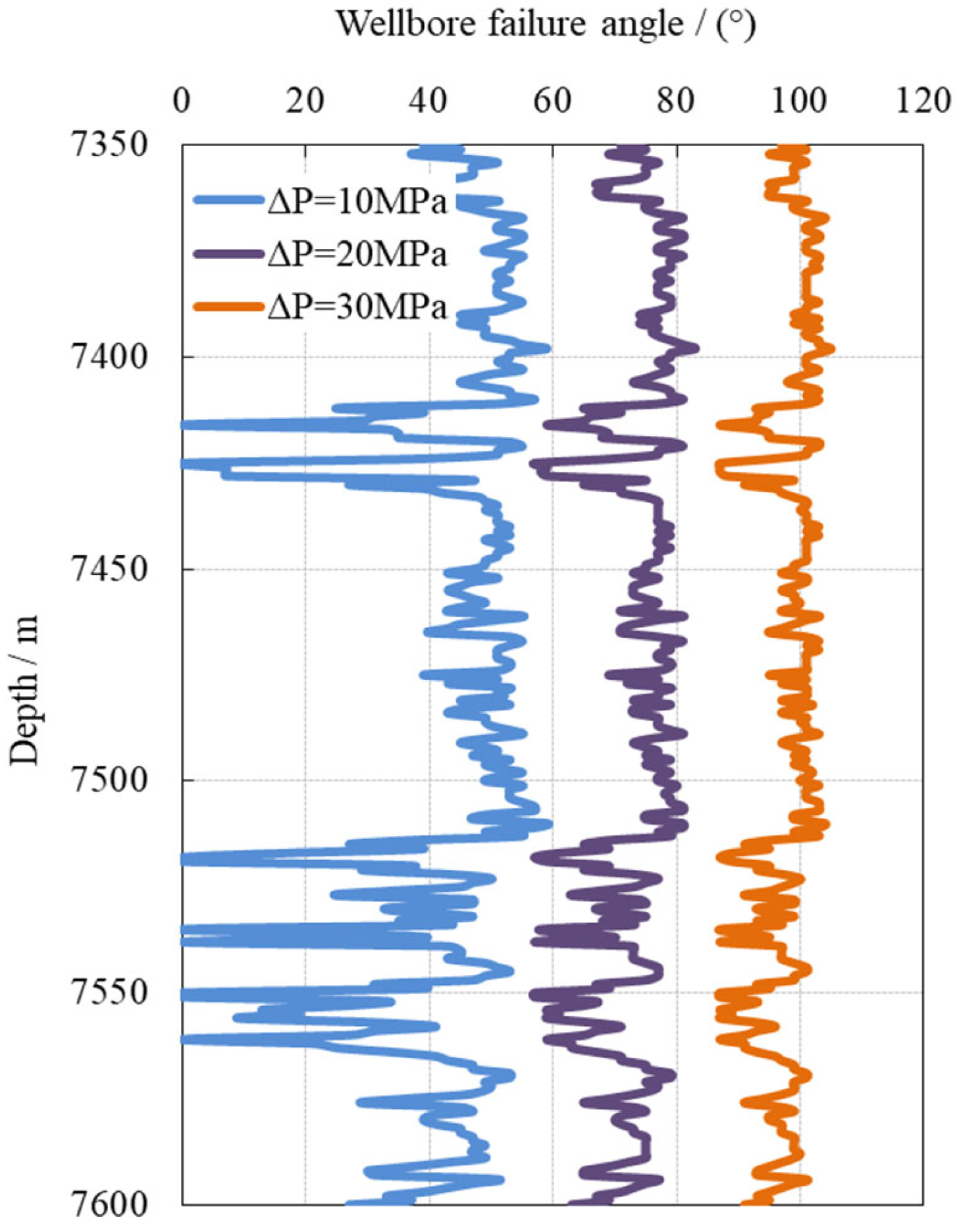

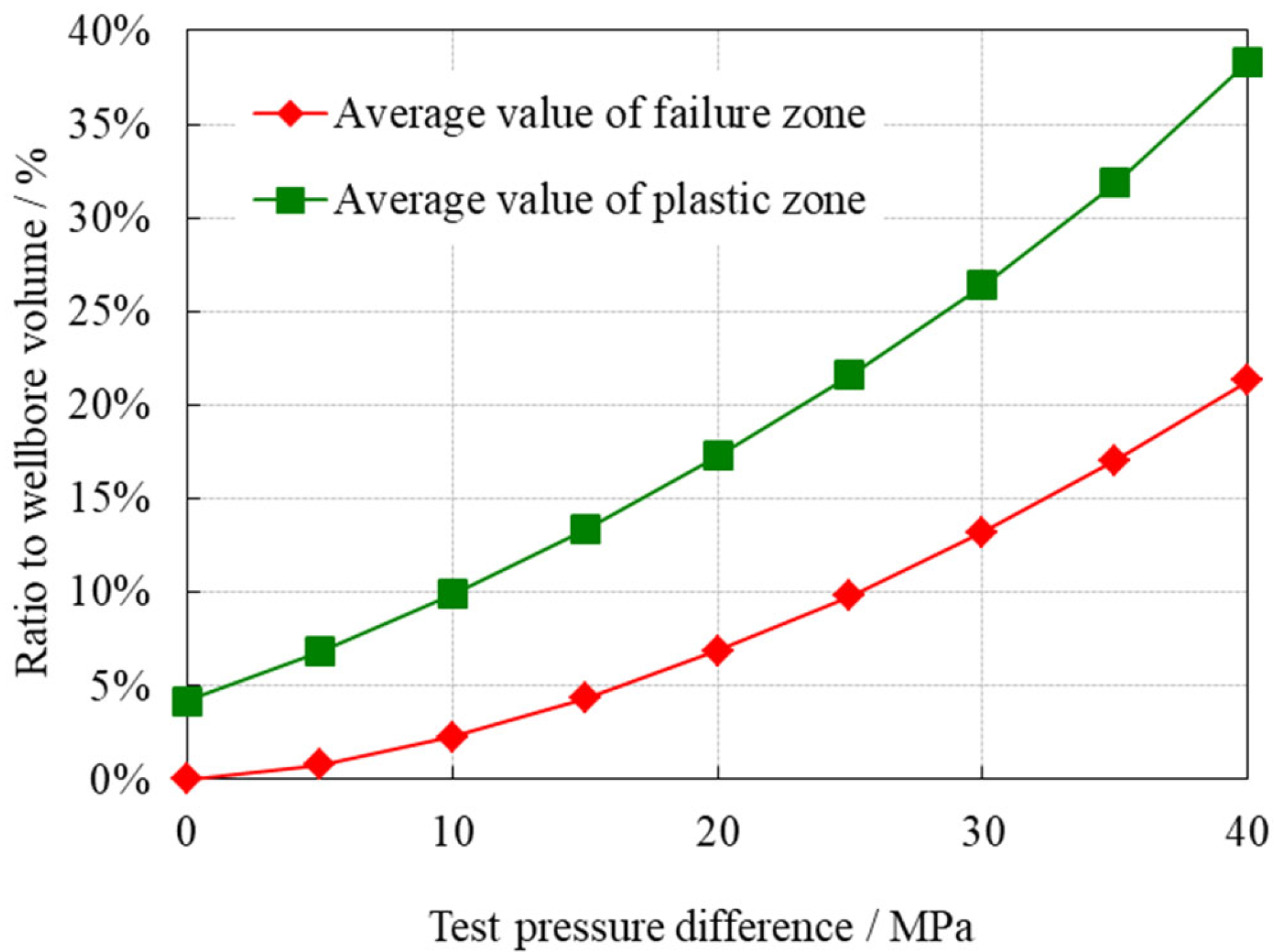

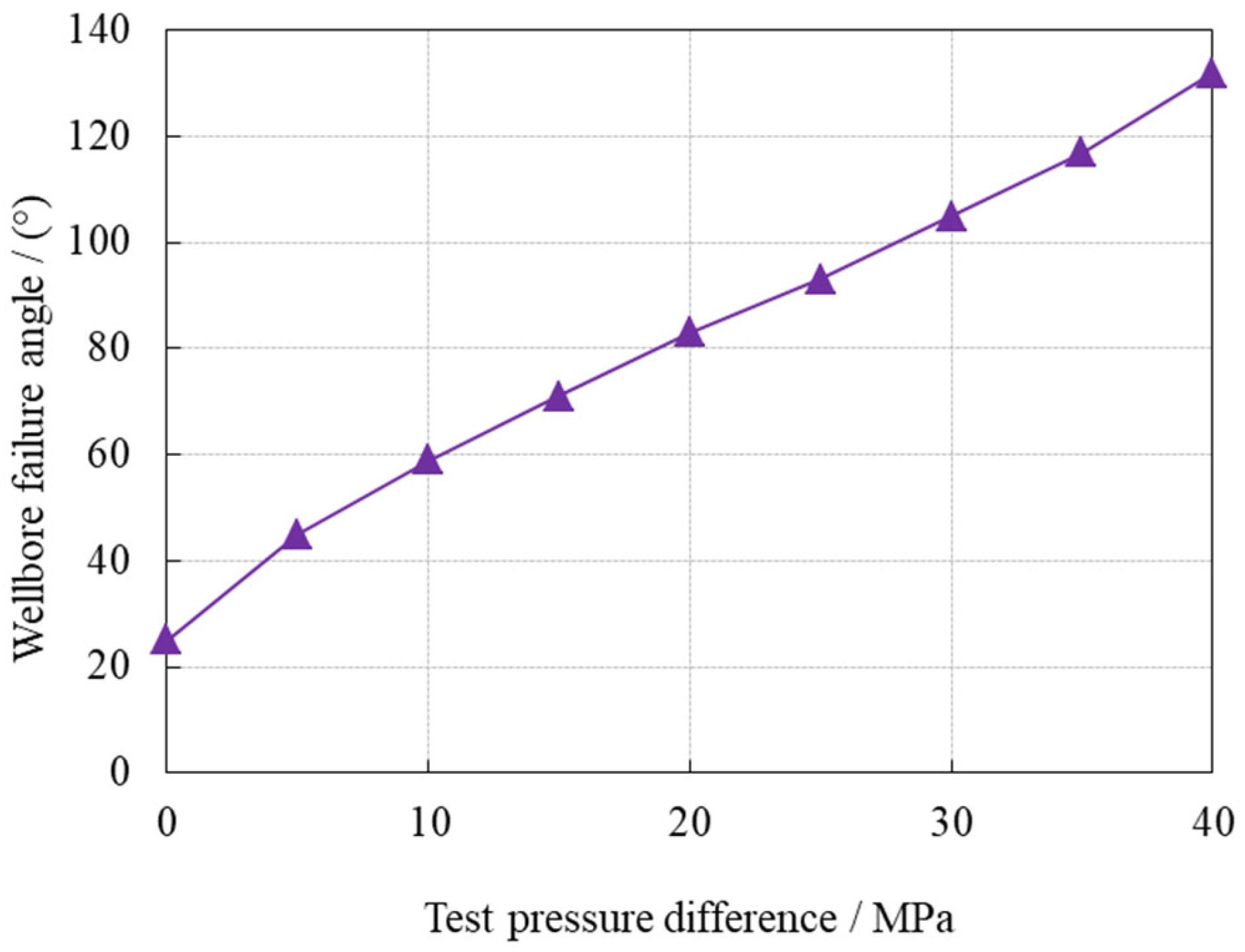

4. Determination of Limit Test Pressure Differential

- The average ratio of the failure zone volume to wellbore volume should be less than 10%;

- The average ratio of the plastic zone volume to wellbore volume should be less than 20%;

- The maximum failure angle on the wellbore wall should be less than 90°.

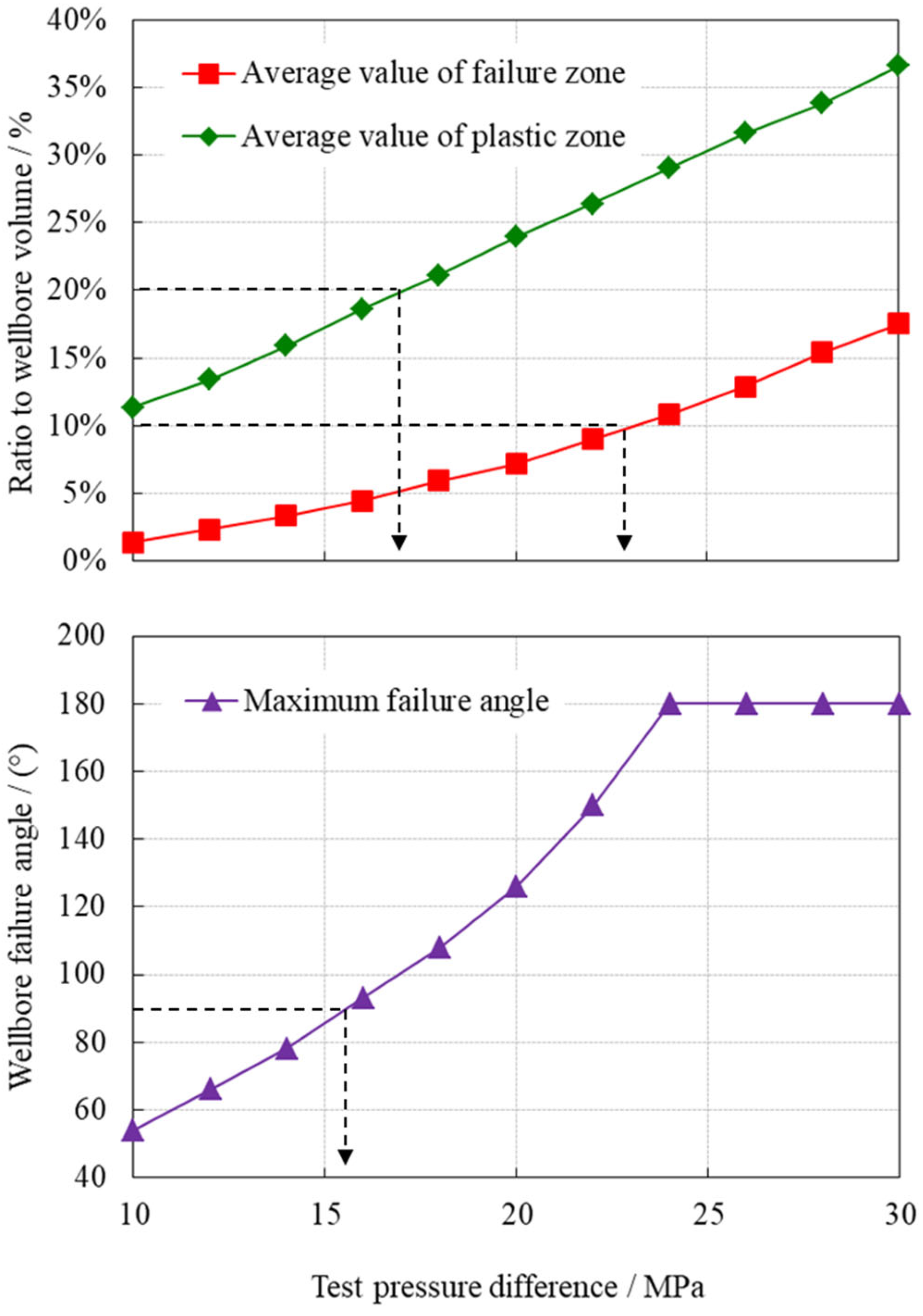

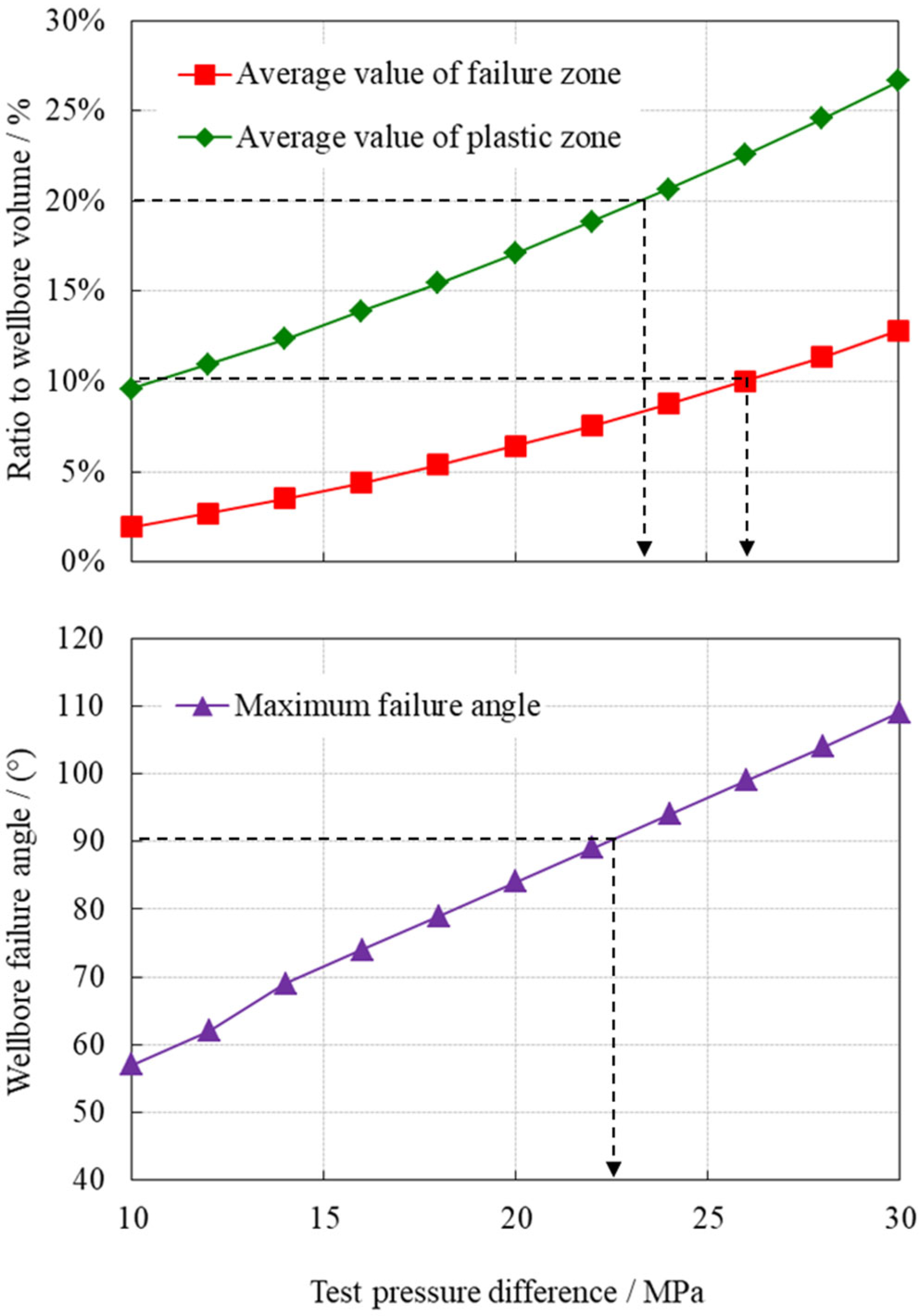

5. Field Application Examples

6. Discussion

- This study proposes three criteria for maintaining wellbore stability during testing: (i) the average ratio of the total plastic zone volume in the open-hole section to the wellbore volume should not exceed 20%; (ii) the average ratio of the failure zone volume to the wellbore volume must remain under 10%; and (iii) the maximum failure angle on the wellbore wall should be less than 90°. Each criterion approaches defining the critical drawdown pressure from a distinct perspective and with varied considerations, reflecting differing margins of safety. The disparities among these criteria stem from their varied emphasis on the mechanisms of wellbore failure; the first criterion prioritizes accumulated plastic deformation, while the second and third directly address the extent and morphology of failure occurrences. Consequently, due to their divergent focuses and definitions, discrepancies exist in the numerically determined critical pressure differences according to these three criteria. Practically, to ensure wellbore stability, the minimum value among these is often adopted as the limiting figure. This conservative approach acknowledges the complexity of wellbore stability assessment and aims to mitigate risk during operational implementation;

- The proposed stability criteria for open-hole sections, derived from carbonate reservoir mechanics and borehole stress profiles, show broad applicability in the study area. These criteria can serve as a foundation for other lithologies with necessary adaptations. Sandstone applications require a focus on granular stresses, structure stability, and sensitivity issues while accounting for brittle fracture tendencies. Shale stability assessment necessitates significant adjustments, emphasizing water content, swelling pressures, and plastic deformation, indicating fundamental differences from carbonate-based criteria.

7. Conclusions

- The analysis of stress distributions in deep carbonate reservoirs during open-hole testing has been conducted, employing principles of elasticity theory. It revealed a dichotomy in wellbore angles influenced by stress anisotropy: those oriented toward lesser differential stresses, deemed safe, and those aligned with higher differentials, posing a risk;

- Laboratory rock mechanics assays were instrumental in delineating the failure attributes and mechanical characteristics of carbonate reservoirs. Deep carbonate core specimens displayed brittle fracture under reduced confining pressures, transitioning to marked plastic behavior en route to peak strength at elevated pressures, and retained considerable residual strength post-failure;

- Incorporating the peak, yield, and residual strength profiles of carbonate rocks, the zones surrounding the wellbore were delineated into elastic, plastic, and residual failure regions, guided by the Mohr–Coulomb criterion. The transition of the adjacent rocks into the residual failure regime signifies impending wellbore collapse and block detachment;

- To establish the analysis method for the limit testing pressure differential, we used criteria such as the ratio of the total volume of the plastic region to the wellbore volume not exceeding 20%, the ratio of the volume of the failure region to the wellbore volume not exceeding 10%, and the maximum failure angle of the wellbore of less than 90°. Implemented in ultra-deep carbonate reservoir field settings, this approach yielded congruent and satisfactory outcomes, affirming its alignment with practical engineering realities.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kang, Z.; Li, Y.; Ji, B.; Zhang, Y. Key technologies for EOR in fractured-vuggy carbonate reservoirs. Oil Gas Geol. 2020, 41, 434–441. [Google Scholar]

- Dai, C.; Fang, J.; Jiao, B. Development of the research on EOR for carbonate fractured-vuggy reservoirs in China. J. China Univ. Pet. (Ed. Nat. Sci.) 2018, 42, 67–78. [Google Scholar]

- Li, Y. The theory and method for development of carbonate fractured-cavity reservoirs in Tahe oilfield. ACTA Pet. Sin. 2013, 34, 115–121. [Google Scholar]

- Jiao, F. Significance and prospect of ultra-deep carbonate fault-karst reservoirs in Shunbei area, Tarim basin. Oil Gas Geol. 2018, 39, 207–216. [Google Scholar]

- Li, X.; Feng, Y.; El Mohtar, C.S. Transient modeling of borehole breakouts: A coupled thermo-hydro-mechanical approach. J. Pet. Sci. Eng. 2019, 172, 1014–1024. [Google Scholar] [CrossRef]

- Xiao, Z.; Jia, S.; Qi, X. Hydraulic-mechanical-chemical coupling evaluation for progressive failure of hard brittle shale wellbore. J. Cent. South Univ. (Sci. Technol.) 2019, 50, 2464–2480. [Google Scholar]

- Jin, Y.; Chen, M. Wellbore Stability Mechanics; Science Press: Beijing, China, 2012; pp. 11–14. [Google Scholar]

- Yang, G. Introduction to Elasticity and Plasticity; Tsinghua University Press: Beijing, China, 2004; pp. 20–25. [Google Scholar]

- Cheng, L. Advanced Seepage Mechanics; Petroleum Industry Press: Beijing, China, 2011; p. 173. [Google Scholar]

- McLellan, P.; Hawkes, C. Borehole stability analysis for underbalanced drilling. J. Can. Pet. Technol. 2001, 40, 31–38. [Google Scholar] [CrossRef]

- Zoback, M.D. Reservoir Geomechanics; Cambridge University Press: Cambridge, Britain, 2007; pp. 135–137. [Google Scholar]

- Ma, T.; Chen, P.; Yang, C. Wellbore stability analysis and well path optimization based on the breakout width model and Mogi-Coulomb criterion. J. Pet. Sci. Eng. 2015, 135, 678–701. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Vertical depth/m | 7735 |

| Pore pressure/MPa | 89.0 |

| Overburden pressure/MPa | 185.6 |

| Max horizontal principal stress/MPa | 193.4 |

| Min horizontal principal stress/MPa | 135.4 |

| Effective stress coefficient | 0.6 |

| Poisson’s ratio of formation | 0.20 |

| Viscosity/mPa·s | 3.06 |

| Fracture permeability/mD | 1.44 |

| Reservoir thickness/m | 100 |

| Coefficient of compressibility/MPa−1 | 0.41 × 10−4 |

| Reservoir porosity/% | 0.6 |

| Testing time/h | 72 |

| Confining Pressure (MPa) | Plastic Yield Strength (MPa) | Peak Strength (MPa) | Residual Strength (MPa) |

|---|---|---|---|

| 0 | 49.2 | 52.2 | 24.9 |

| 20 | 147.0 | 172.8 | 144.0 |

| 30 | 215.1 | 251.8 | 224.7 |

| 50 | 305.4 | 357.0 | 331.8 |

| Parameter | Value |

|---|---|

| Vertical depth/m | 7655–8124 |

| Measured depth/m | 7655–8385 |

| Maximum deviation angle/(°) | 65.85 |

| Borehole azimuth/(°) | 270 |

| Pore pressure/MPa | 84.2–89.4 |

| Overburden pressure/MPa | 183.5–196.2 |

| Maximum horizontal principal stress/MPa | 169.3–181.7 |

| Minimum horizontal principal stress/MPa | 126.3–135.9 |

| Effective stress coefficient | 0.6 |

| Plastic yield strength/MPa | 58.9–71.6 |

| Peak strength/MPa | 63.0–80.5 |

| Parameter | Value |

|---|---|

| Vertical depth/m | 7478–7839.6 |

| Measured depth/m | 7478–7884 |

| Maximum deviation angle/(°) | 44.5 |

| Borehole azimuth/(°) | 40–45 |

| Pore pressure/MPa | 81.5–91.7 |

| Overburden pressure/MPa | 173.7–183.5 |

| Maximum horizontal principal stress/MPa | 175.5–192.3 |

| Minimum horizontal principal stress/MPa | 122.5–151.3 |

| Effective stress coefficient | 0.6 |

| Plastic yield strength/MPa | 53.9–72.8 |

| Peak strength/MPa | 56.3–82.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Su, P.; Tan, Q.; Li, K.; Hu, N. Borehole Condition and Limit Pressure Differential Analysis in Carbonate Reservoirs. Appl. Sci. 2024, 14, 5676. https://doi.org/10.3390/app14135676

Wang L, Su P, Tan Q, Li K, Hu N. Borehole Condition and Limit Pressure Differential Analysis in Carbonate Reservoirs. Applied Sciences. 2024; 14(13):5676. https://doi.org/10.3390/app14135676

Chicago/Turabian StyleWang, Long, Peng Su, Qiang Tan, Ke Li, and Naikun Hu. 2024. "Borehole Condition and Limit Pressure Differential Analysis in Carbonate Reservoirs" Applied Sciences 14, no. 13: 5676. https://doi.org/10.3390/app14135676

APA StyleWang, L., Su, P., Tan, Q., Li, K., & Hu, N. (2024). Borehole Condition and Limit Pressure Differential Analysis in Carbonate Reservoirs. Applied Sciences, 14(13), 5676. https://doi.org/10.3390/app14135676