Coffee Silverskin as a Fat Replacer in Chicken Patty Formulation and Its Effect on Physicochemical, Textural, and Sensory Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Production of Chicken Patties

2.2. Physicochemical Analysis

2.3. Texture Profile Analysis (TPA)

2.4. Sensory Analysis

2.5. Statistical Analysis

3. Results and Discussion

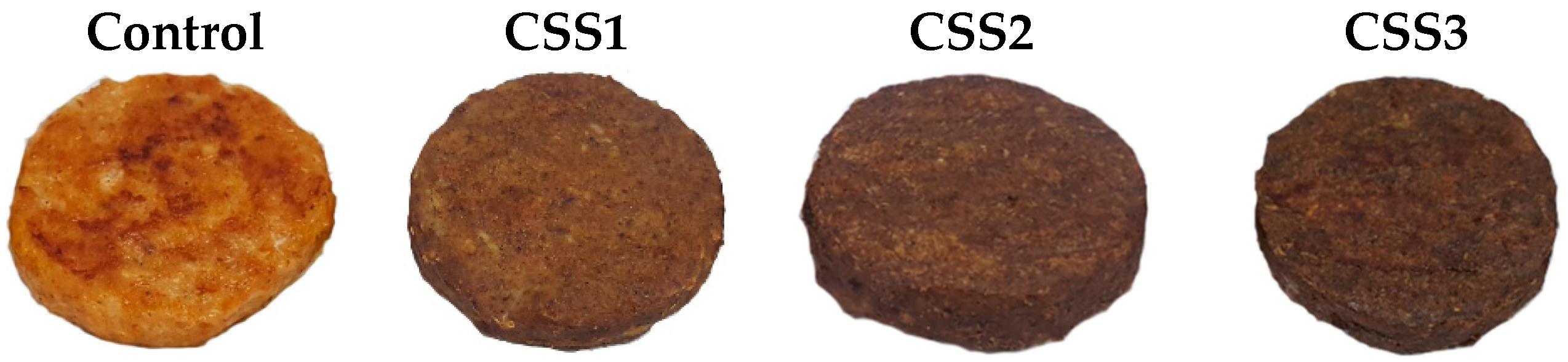

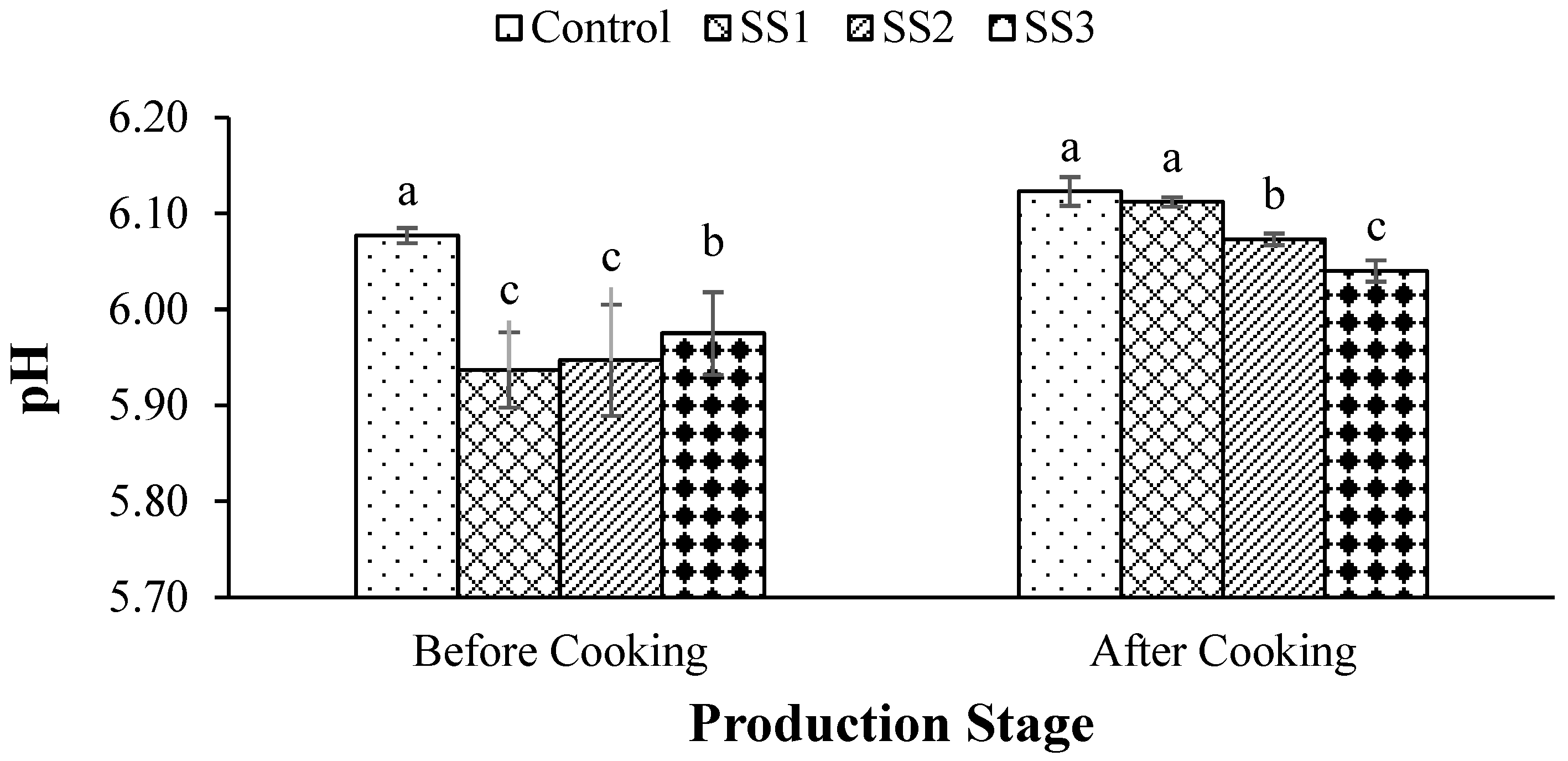

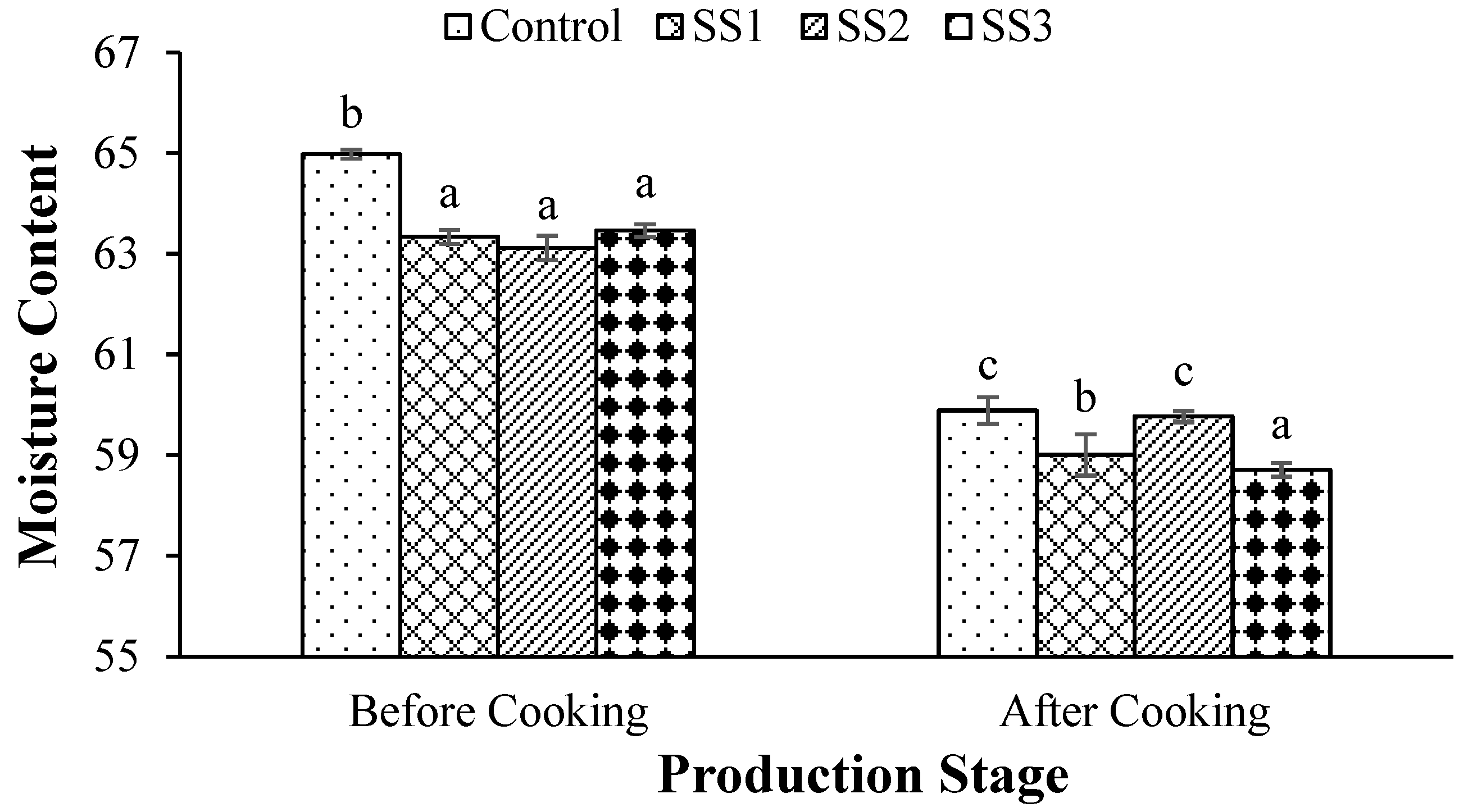

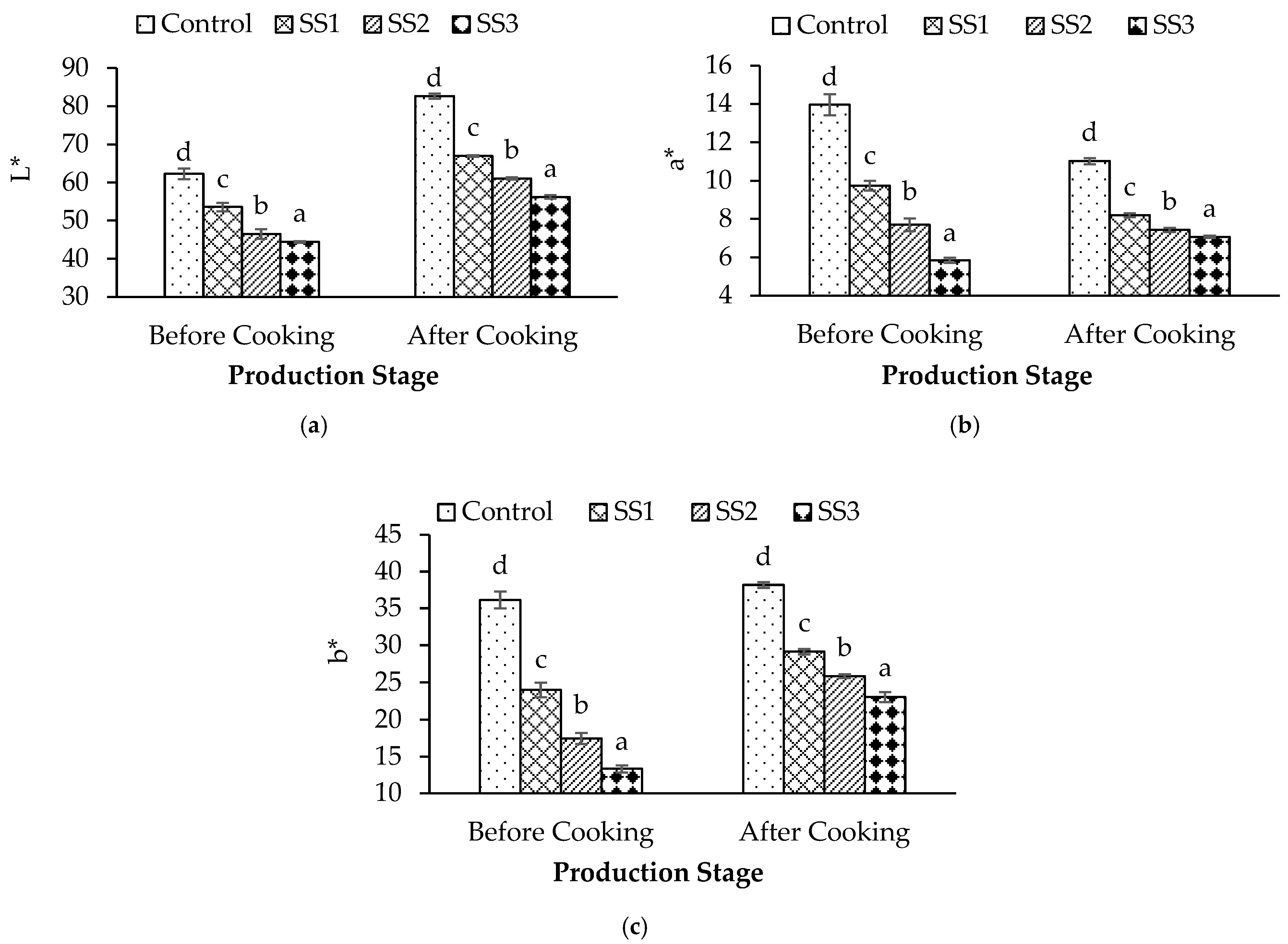

3.1. Physicochemical Properties

3.2. Textural Properties

3.3. Sensory Evaluation

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Coffee Organization (ICO). Coffee Report and Outlook; December 2023. Available online: https://icocoffee.org/documents/cy2023-24/Coffee_Report_and_Outlook_December_2023_ICO.pdf (accessed on 17 January 2024).

- Martuscelli, M.; Esposito, L.; Di Mattia, C.D.; Ricci, A.; Mastrocola, D. Characterization of Coffee Silver Skin as Potential Food-Safe Ingredient. Foods 2021, 10, 1367. [Google Scholar] [CrossRef]

- Alves, R.C.; Rodrigues, F.; Nunes, M.A.; Vinha, A.F.; Oliveira, M.B.P.P. State of the art in coffee processing by-products. In Handbook of Coffee Processing By-Products; Academic Press: Cambridge, MA, USA, 2017; pp. 1–26. [Google Scholar]

- Farah, A.; Santos, T.F.D. The Coffee Plant and Beans: An Introduction. In Coffee in Health and Disease Prevention; Preedy, V.R., Ed.; Academic Press: London, UK, 2015; pp. 5–10. [Google Scholar] [CrossRef]

- Saenger, M.; Hartge, E.-U.; Werther, J.; Ogada, T.; Siagi, Z. Combustion of coffee husks. Renew. Energy 2001, 23, 103–121. [Google Scholar] [CrossRef]

- Narita, Y.; Inouye, K. Review on utilization and composition of coffee silverskin. Food Res. Int. 2014, 61, 16–22. [Google Scholar] [CrossRef]

- Bessada, S.; Alves, R.C.; Oliveira, M.B.P.P. Coffee Silverskin: A Review on Potential Cosmetic Applications. Cosmetics 2018, 5, 5. [Google Scholar] [CrossRef]

- Ateş, G.; Elmacı, Y. Coffee silverskin as fat replacer in cake formulations and its effect on physical, chemical and sensory attributes of cakes. Lebensm. Wiss. Technol./Food Sci. Technol. 2018, 90, 519–525. [Google Scholar] [CrossRef]

- Iriondo-DeHond, A.; Iriondo-DeHond, M.; Del Castillo, M.D. Applications of Compounds from Coffee Processing By-Products. Biomolecules 2020, 10, 1219. [Google Scholar] [CrossRef]

- Arya, S.S.; Venkatram, R.; More, P.R.; Vijayan, P. The wastes of coffee bean processing for utilization in food: A review. J. Food Sci. Technol. 2021, 59, 429–444. [Google Scholar] [CrossRef]

- Nzekoue, F.K.; Borsetta, G.; Navarini, L.; Abouelenein, D.; Xiao, J.; Sagratini, G.; Vittori, S.; Caprioli, G.; Angeloni, S. Coffee silverskin: Characterization of B-vitamins, macronutrients, minerals and phytosterols. Food Chem. 2022, 372, 131188. [Google Scholar] [CrossRef] [PubMed]

- Borrelli, R.C.; Esposito, F.; Napolitano, A.; Ritieni, A.; Fogliano, V. Characterization of a New Potential Functional Ingredient: Coffee Silverskin. J. Agric. Food Chem. 2004, 52, 1338–1343. [Google Scholar] [CrossRef] [PubMed]

- Napolitano, A.; Fogliano, V.; Tafuri, A.; Ritieni, A. Natural Occurrence of Ochratoxin A and Antioxidant Activities of Green and Roasted Coffees and Corresponding Byproducts. J. Agric. Food Chem. 2007, 55, 10499–10504. [Google Scholar] [CrossRef] [PubMed]

- Pourfarzad, A.; Mahdavian-Mehr, H.; Sedaghat, N. Coffee silverskin as a source of dietary fiber in bread-making: Optimization of chemical treatment using response surface methodology. Lebensm. Wiss. Technol./Food Sci. Technol. 2013, 50, 599–606. [Google Scholar] [CrossRef]

- Dauber, C.; Romero, M.; Chaparro, C.; Ureta, C.; Ferrari, C.; Lans, R.; Frugoni, L.; Echeverry, M.V.; Calvo, B.S.; Trostchansky, A.; et al. Cookies enriched with coffee silverskin powder and coffee silverskin ultrasound extract to enhance fiber content and antioxidant properties. Appl. Food Res. 2024, 4, 100373. [Google Scholar] [CrossRef]

- Sia, C.E.S.; Yuliantara, A.; Rizkaprilisa, W.; Paramastuti, R. Potential of Dietary Fiber and Antioxidants from Coffee Skin as a Food Product in Preventing Obesity: Systematic Review. Sci. Technol. Manag. J. 2024, 4, 16–21. [Google Scholar] [CrossRef]

- Singh, M.; Liu, S.X.; Vaughn, S.F. Effect of corn bran as dietary fiber addition on baking and sensory quality. Biocatal. Agric. Biotechnol. 2012, 1, 348–352. [Google Scholar] [CrossRef]

- Longato, E.; Lucas-González, R.; Peiretti, P.G.; Meineri, G.; Pérez-Alvarez, J.A.; Viuda-Martos, M.; Fernández-López, J. The Effect of Natural Ingredients (Amaranth and Pumpkin Seeds) on the Quality Properties of Chicken Burgers. Food Bioprocess Technol. 2017, 10, 2060–2068. [Google Scholar] [CrossRef]

- Angeloni, S.; Scortichini, S.; Fiorini, D.; Sagratini, G.; Vittori, S.; Neiens, S.D.; Steinhaus, M.; Zheljazkov, V.D.; Maggi, F.; Caprioli, G. Characterization of Odor-Active Compounds, Polyphenols, and Fatty Acids in Coffee Silverskin. Molecules 2020, 25, 2993. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Lee, H.J.; Lim, E.-J.; Imm, J.-Y.; Suh, H.J. Physical and sensory characteristics of fibre-enriched sponge cakes made with Opuntia humifusa. Lebensm. Wiss. Technol./Food Sci. Technol. 2012, 47, 478–484. [Google Scholar] [CrossRef]

- Cantele, C.; Tedesco, M.; Ghirardello, D.; Zeppa, G.; Bertolino, M. Coffee Silverskin as a Functional Ingredient in Vegan Biscuits: Physicochemical and Sensory Properties and In Vitro Bioaccessibility of Bioactive Compounds. Foods 2022, 11, 717. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Yao, Y. Carbohydrates as Fat Replacers. Annu. Rev. Food Sci. Technol. 2017, 8, 331–351. [Google Scholar] [CrossRef]

- Montoya, L.; Quintero, N.; Ortiz, S.; Lopera, J.; Millán, P.; Rodríguez-Stouvenel, A. Inulin as a Fat-Reduction Ingredient in Pork and Chicken Meatballs: Its Effects on Physicochemical Characteristics and Consumer Perceptions. Foods 2022, 11, 1066. [Google Scholar] [CrossRef]

- Esquivel, P.; Jiménez, V.M. Functional properties of coffee and coffee by-products. Food Res. Int. 2012, 46, 488–495. [Google Scholar] [CrossRef]

- Gemechu, F.G. Embracing nutritional qualities, biological activities and technological properties of coffee byproducts in functional food formulation. Trends Food Sci. Technol. 2020, 104, 235–261. [Google Scholar] [CrossRef]

- Gocmen, D.; Sahan, Y.; Yildiz, E.; Coskun, M.; Aroufai, I.A. Use of coffee silverskin to improve the functional properties of cookies. J. Food Sci. Technol. 2019, 56, 2979–2988. [Google Scholar] [CrossRef] [PubMed]

- Bertolino, M.; Barbosa-Pereira, L.; Ghirardello, D.; Botta, C.; Rolle, L.; Guglielmetti, A.; Borotto Dalla Vecchia, S.; Zeppa, G. Coffee silverskin as nutraceutical ingredient in yogurt: Its effect on functional properties and its bioaccessibility. J. Sci. Food Agric. 2019, 99, 4267–4275. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Serna, E.; Martinez-Saez, N.; Mesias, M.; Morales, F.; del Castillo, M. Use of Coffee Silverskin and Stevia to Improve the Formulation of Biscuits. Pol. J. Food Nutr. Sci. 2014, 64, 243–251. [Google Scholar] [CrossRef]

- Martuscelli, M.; Esposito, L.; Mastrocola, D. The Role of Coffee Silver Skin against Oxidative Phenomena in Newly Formulated Chicken Meat Burgers after Cooking. Foods 2021, 10, 1833. [Google Scholar] [CrossRef] [PubMed]

- Thangavelu, K.P.; Tiwari, B.; Kerry, J.P.; McDonnell, C.K.; Álvarez, C. Phosphate replacing potential of apple pomace and coffee silver skin in Irish breakfast sausage using a mixture design approach. Meat Sci. 2022, 185, 108722. [Google Scholar] [CrossRef] [PubMed]

- Coşkun, M. Bisküvide Yağ Ikamesi Olarak Kahve Çekirdeği Zarı Kullanımı. Available online: http://hdl.handle.net/11452/14887 (accessed on 12 July 2024).

- AOAC International. Official Methods of Analysis of AOAC International, 18th ed.; AOAC International: Rockville, MD, USA, 2005; Available online: https://www.researchgate.net/publication/292783651_AOAC_2005 (accessed on 17 January 2024).

- Lemon, D.W. An Improved TBA Test for Rancidity; Halifax Fisheries and Marine Service: Ottawa, ON, Canada, 1975. [Google Scholar]

- Choi, Y.-S.; Sung, J.-M.; Park, J.-D.; Hwang, K.-E.; Lee, C.-W.; Kim, T.-K.; Jeon, K.-H.; Kim, C.-J.; Kim, Y.-B. Quality and Sensory Characteristics of Reduced-fat Chicken Patties with Pork Back Fat Replaced by Dietary Fiber from Wheat Sprout. Korean J. Food Sci. Anim. Resour. 2016, 36, 799–806. [Google Scholar] [CrossRef] [PubMed]

- Guedes-Oliveira, J.M.; Salgado, R.L.; Costa-Lima, B.R.; Conte-Junior, C.A. Washed cashew apple fiber (Anacardium occidentale L.) as fat replacer in chicken patties. Lebens. Wiss. Technol./ Food Sci. Technol. 2016, 71, 268–273. [Google Scholar] [CrossRef]

- Choi, Y.-S.; Kim, H.-W.; Hwang, K.-E.; Song, D.-H.; Jeong, T.-J.; Kim, Y.-B.; Jeon, K.-H.; Kim, C.-J. Effect of Dietary Fiber Extracted from Algelica keiskei Koidz on the Quality Characteristics of Chicken Patties. Korean J. Food Sci. Anim. Resour. 2015, 35, 307–314. [Google Scholar] [CrossRef]

- Kirkyol, M.; Akköse, A. Effects of animal fat replacement with almond flour on quality parameters of beef patties. Food Sci. Nutr. 2023, 11, 7091–7099. [Google Scholar] [CrossRef]

- McGlynn, W. The Importance of Food pH in Commercial Canning Operations. Food Technology Fact Sheet. 2003. Available online: https://shareok.org/bitstream/handle/11244/50205/oksd_fapc_118_2010-07.pdf?sequence=1 (accessed on 17 January 2024).

- Botella-Martinez, C.; Lucas-González, R.; Lorenzo, J.M.; Santos, E.M.; Rosmini, M.; Sepúlveda, N.; Teixeira, A.; Sayas-Barberá, E.; Pérez-Alvarez, J.A.; Fernandez-Lopez, J.; et al. Cocoa Coproducts-Based and Walnut Oil Gelled Emulsion as Animal Fat Replacer and Healthy Bioactive Source in Beef Burgers. Foods 2021, 10, 2706. [Google Scholar] [CrossRef]

- Murthy, P.S.; Naidu, M.M. Sustainable management of coffee industry by-products and value addition—A review. Resour. Conserv. Recycl. 2012, 66, 45–58. [Google Scholar] [CrossRef]

- Kılınççeker, O.; Kurt, S. Effects of inulin, carrot and cellulose fibres on the properties of raw and fried chicken meatballs. S. Afr. J. Anim. Sci. 2018, 48, 39. [Google Scholar] [CrossRef]

- Costa, A.S.; Alves, R.C.; Vinha, A.F.; Costa, E.; Costa, C.S.; Nunes, M.A.; Almeida, A.A.; Santos-Silva, A.; Oliveira, M.B.P. Nutritional, chemical and antioxidant/pro-oxidant profiles of silverskin, a coffee roasting by-product. Food Chem. 2018, 267, 28–35. [Google Scholar] [CrossRef]

- Wood, J.D.; Richardson, R.I.; Nute, G.R.; Fisher, A.V.; Campo, M.M.; Kasapidou, E.; Sheard, P.R.; Enser, M. Effects of fatty acids on meat quality: A review. Meat Sci. 2004, 66, 21–32. [Google Scholar] [CrossRef] [PubMed]

- Campo, M.M.; Nute, G.R.; Hughes, S.I.; Enser, M.; Wood, J.D.; Richardson, R.I. Flavour perception of oxidation in beef. Meat Sci. 2006, 72, 303–311. [Google Scholar] [CrossRef] [PubMed]

- Fraqueza, M.J.; Barreto, A.S. The effect on turkey meat shelf life of modified-atmosphere packaging with an argon mixture. Poult. Sci. 2009, 88, 1991–1998. [Google Scholar] [CrossRef] [PubMed]

- Choi, M.-S.; Choi, Y.-S.; Kim, H.-W.; Hwang, K.-E.; Song, D.-H.; Lee, S.-Y.; Kim, C.-J. Effects of Replacing Pork Back Fat with Brewer’s Spent Grain Dietary Fiber on Quality Characteristics of Reduced-fat Chicken Sausages. Korean J. Food Sci. Anim. Resour. 2014, 34, 158–165. [Google Scholar] [CrossRef]

- Pintado, T.; Herrero, A.; Jiménez-Colmenero, F.; Ruiz-Capillas, C. Strategies for incorporation of chia (Salvia hispanica L.) in frankfurters as a health-promoting ingredient. Meat Sci. 2016, 114, 75–84. [Google Scholar] [CrossRef]

- Barros, J.C.; Munekata, P.E.S.; Pires, M.A.; Rodrigues, I.; Andaloussi, O.S.; Rodrigues, C.E.d.C.; Trindade, M.A. Omega-3- and fibre-enriched chicken nuggets by replacement of chicken skin with chia (Salvia hispanica L.) flour. Lebens. Wiss. Technolog./Food Sci. Technol. 2018, 90, 283–289. [Google Scholar] [CrossRef]

- A Kalaikannan, D.S.A. The Effect of the Addition of Oat Flour in Low-Fat Chicken Nuggets. J. Nutr. Food Sci. 2014, 4, 2. [Google Scholar] [CrossRef]

- Ferjančič, B.; Kugler, S.; Korošec, M.; Polak, T.; Bertoncelj, J. Development of low-fat chicken bologna sausages enriched with inulin, oat fibre or psyllium. Int. J. Food Sci. Technol. 2020, 56, 1818–1828. [Google Scholar] [CrossRef]

| Control | SS1 | SS2 | SS3 | Significance | ||

|---|---|---|---|---|---|---|

| pH | 6.10 ± 0.01 a | 6.02 ± 0.03 b | 6.01 ± 0.03 c | 6.01 ± 0.02 c | ** | |

| Moisture content (%) | 62.43 ± 0.78 a | 61.17 ± 0.69 bc | 61.44 ± 0.52 b | 61.09 ± 0.72 c | ** | |

| aw | 0.979 ± 0.001 a | 0.976 ± 0.001 b | 0.976 ± 0.001 b | 0.974 ± 0.001 c | ** | |

| TBARS (μmol MDA/kg) | 11.75 ± 0.67 d | 18.48 ± 0.70 c | 25.91 ± 0.47 b | 32.92 ± 1.00 a | ** | |

| Moisture retention (%) | 81.41 ± 1.30 b | 85.59 ± 1.27 a | 87.34 ± 0.58 a | 86.16 ± 0.91 a | ** | |

| Color | L* | 72.48 ± 3.16 a | 60.27 ± 2.10 b | 53.80 ± 2.29 c | 50.32 ± 1.80 d | ** |

| a* | 12.50 ± 0.52 a | 8.97 ± 0.27 b | 7.56 ± 0.17 c | 6.46 ± 0.20 d | ** | |

| b* | 37.14 ± 0.65 a | 26.58 ± 0.91 b | 21.64 ± 1.31 c | 18.20 ± 1.52 d | ** | |

| Before Cooking | After Cooking | Significance | ||

|---|---|---|---|---|

| pH | 5.98 ± 0.02 a | 6.09 ± 0.01 b | ** | |

| Moisture content (%) | 63.73 ± 0.17 b | 59.34 ± 0.16 a | ** | |

| aw | 0.978 ± 0.001 b | 0.974 ± 0.001 a | ** | |

| TBARS (μmol MDA/kg) | 20.69 ± 1.70 a | 23.84 ± 1.70 b | ** | |

| Color | L* | 51.69 ± 1.55 a | 66.74 ± 2.08 b | ** |

| a* | 9.31 ± 0.65 b | 8.43 ± 0.33 a | ** | |

| b* | 22.74 ± 1.84 a | 29.04 ± 1.20 b | ** | |

| Control | SS1 | SS2 | SS3 | Significance | |

|---|---|---|---|---|---|

| Hardness (N) | 55.08 ± 1.39 a | 69.85 ± 1.22 b | 71.10 ± 1.32 b | 78.21 ± 2.19 c | ** |

| Adhesiveness (mJ) | 0.24 ± 0.05 a | 0.16 ± 0.03 a | 0.22 ± 0.05 a | 0.12 ± 0.03 a | ns |

| Resilience | 0.13 ± 0.00 d | 0.12 ± 0.00 c | 0.10 ± 0.00 b | 0.09 ± 0.00 a | ** |

| Cohesiveness | 0.42 ± 0.01 c | 0.42 ± 0.00 c | 0.37 ± 0.01 b | 0.35 ± 0.01 a | ** |

| Springiness (mm) | 5.64 ± 0.07 b | 5.04 ± 0.05 a | 4.72 ± 0.24 a | 5.06 ± 0.06 a | * |

| Chewiness (mJ) | 132.09 ± 4.50 a | 147.46 ± 3.15 b | 130.03 ± 3.35 a | 137.13 ± 4.60 a | * |

| Control | SS1 | SS2 | SS3 | Significance | |

|---|---|---|---|---|---|

| Odor | 4.08 ± 0.17 b | 3.75 ± 0.14 b | 3.04 ± 0.11 a | 2.75 ± 0.15 a | ** |

| Color | 3.71 ± 0.22 c | 4.00 ± 0.15 c | 3.17 ± 0.17 b | 2.58 ± 0.20 a | ** |

| Taste | 4.33 ± 0.16 d | 3.38 ± 0.16 c | 2.50 ± 0.16 b | 2.04 ± 0.15 a | ** |

| Texture | 3.92 ± 0.17 b | 3.67 ± 0.10 b | 3.13 ± 0.16 a | 2.75 ± 0.20 a | ** |

| General Acceptability | 4.13 ± 0.14 c | 3.54 ± 0.12 b | 2.71 ± 0.14 a | 2.42 ± 0.15 a | ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Özhamamcı, İ. Coffee Silverskin as a Fat Replacer in Chicken Patty Formulation and Its Effect on Physicochemical, Textural, and Sensory Properties. Appl. Sci. 2024, 14, 6442. https://doi.org/10.3390/app14156442

Özhamamcı İ. Coffee Silverskin as a Fat Replacer in Chicken Patty Formulation and Its Effect on Physicochemical, Textural, and Sensory Properties. Applied Sciences. 2024; 14(15):6442. https://doi.org/10.3390/app14156442

Chicago/Turabian StyleÖzhamamcı, İzzet. 2024. "Coffee Silverskin as a Fat Replacer in Chicken Patty Formulation and Its Effect on Physicochemical, Textural, and Sensory Properties" Applied Sciences 14, no. 15: 6442. https://doi.org/10.3390/app14156442