Effects of Materials and Riblets on Erosion Mitigation Induced by Multiple Collapses of Cavitation Bubbles

Abstract

:1. Introduction

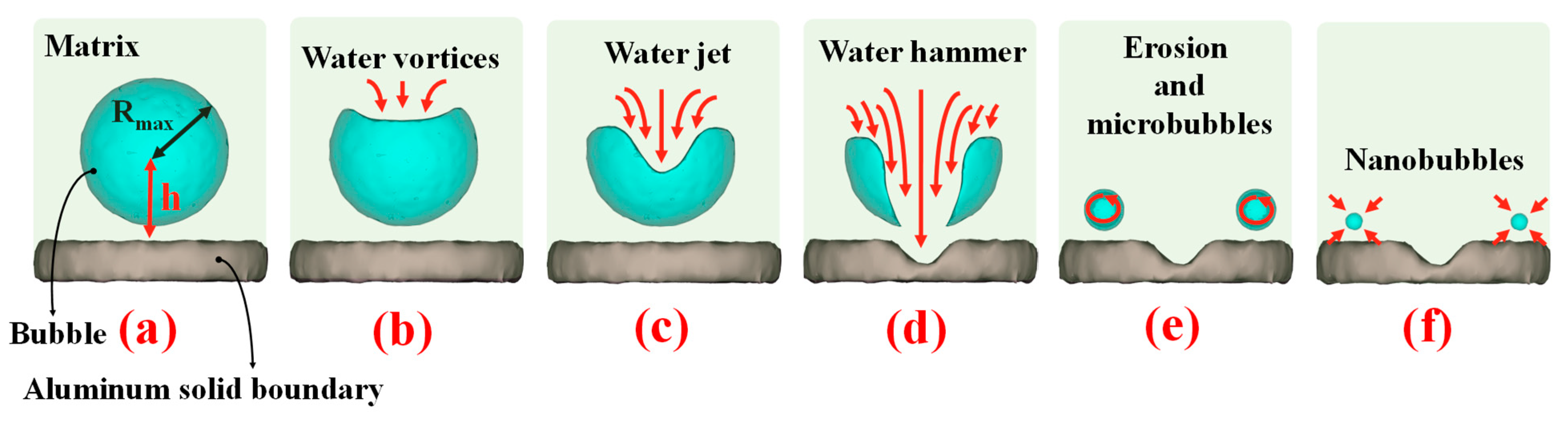

2. Background: Single Cavitation Bubble Near Solid Boundary

3. Experimental Setup

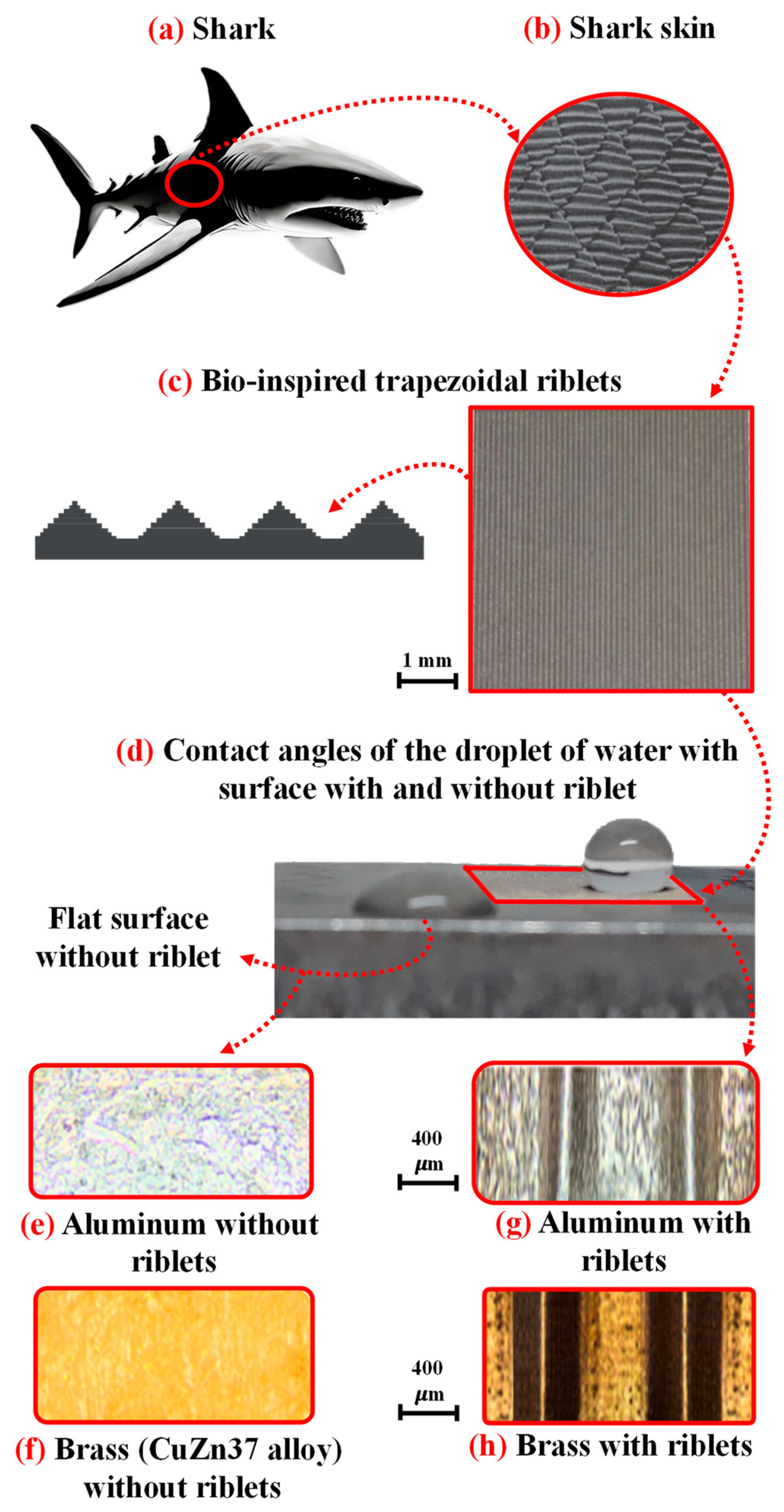

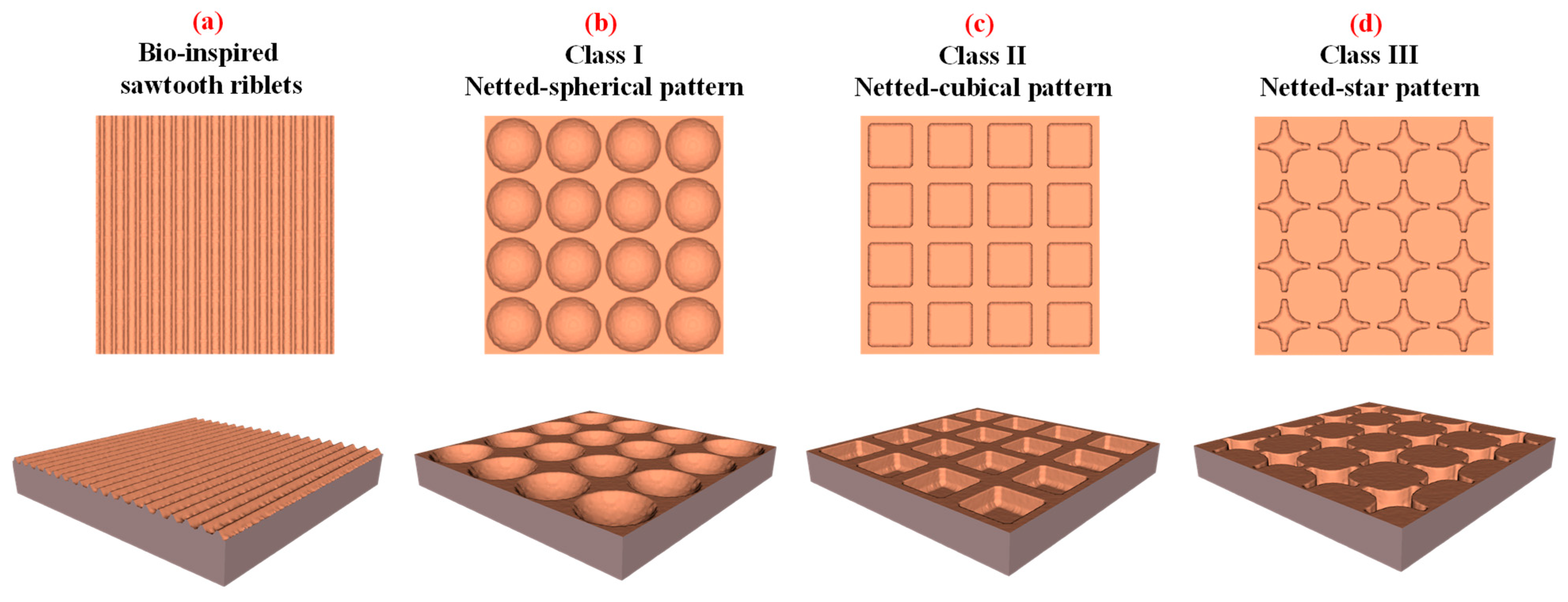

3.1. Solid Boundary without and with Bio-Inspired Sawtooth Riblets

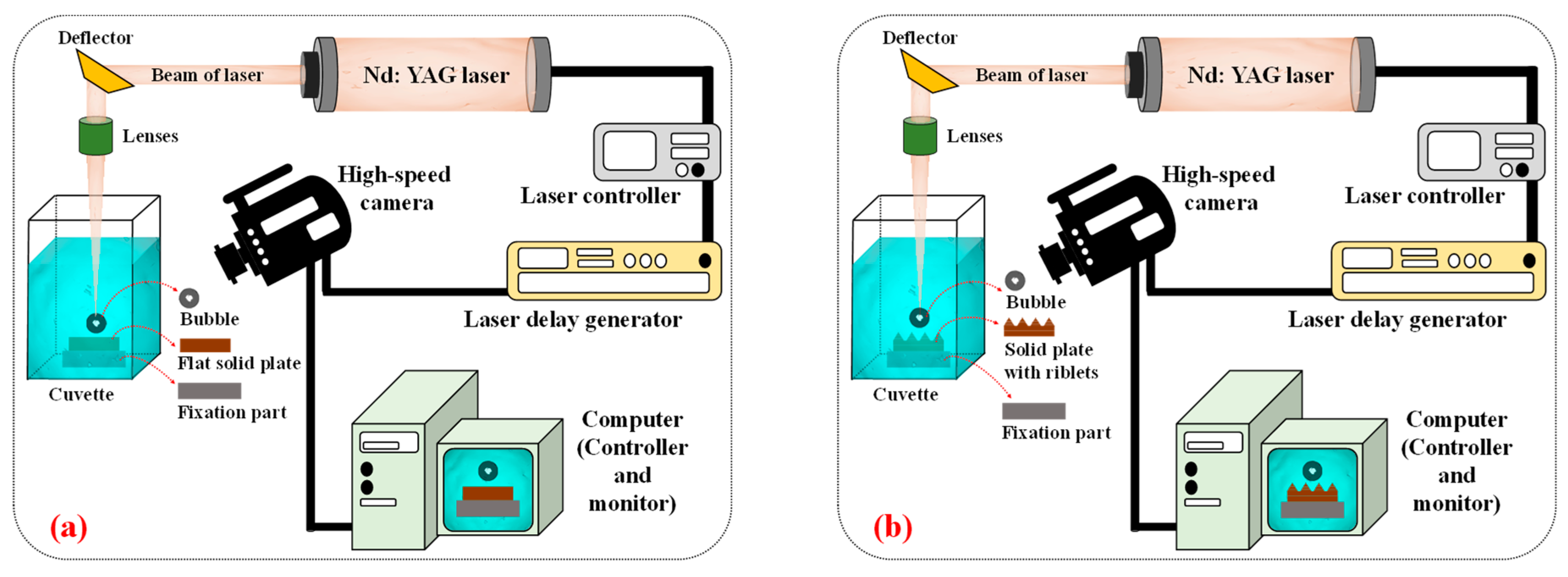

3.2. Experimental Methodology

4. Results and Discussion

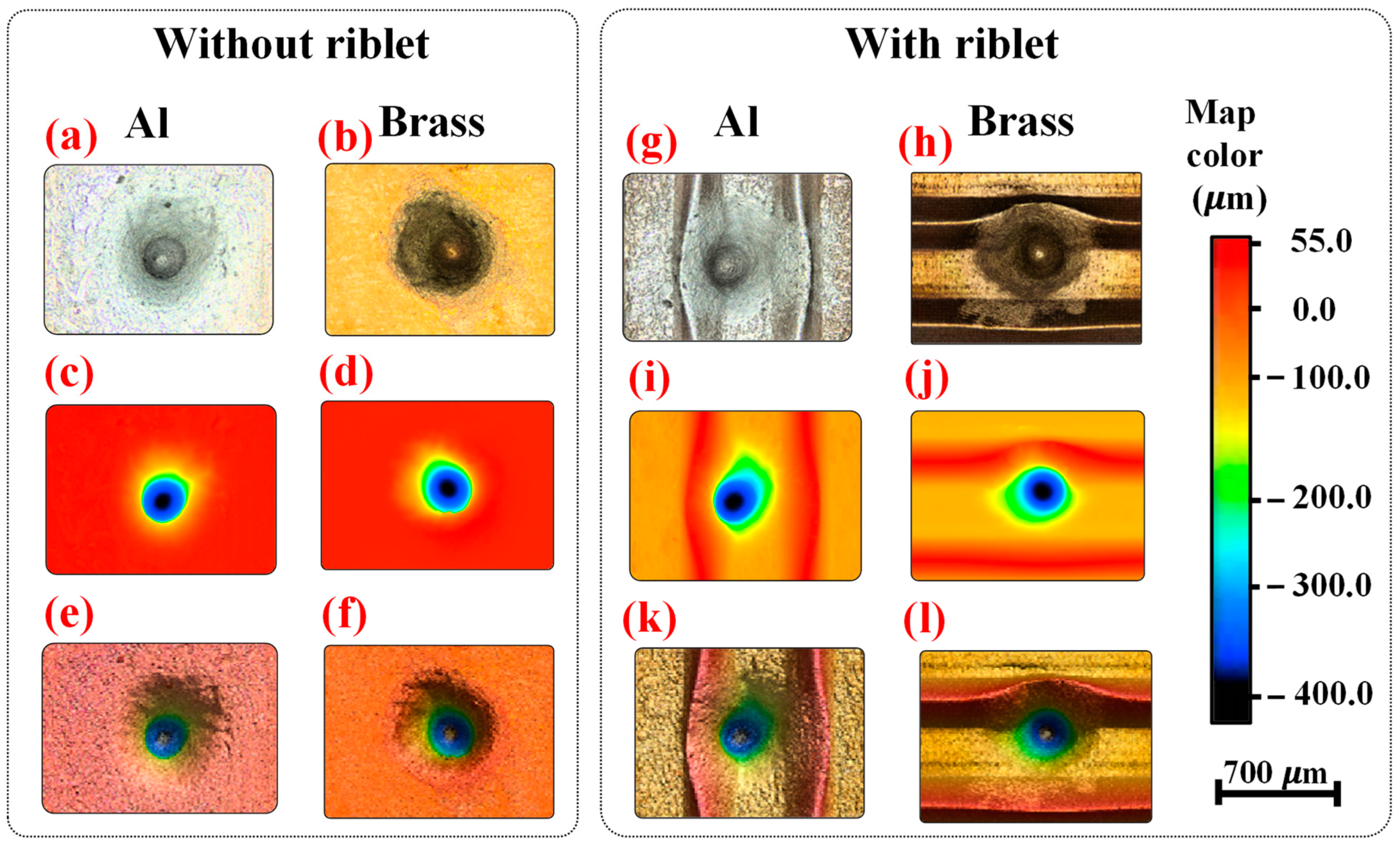

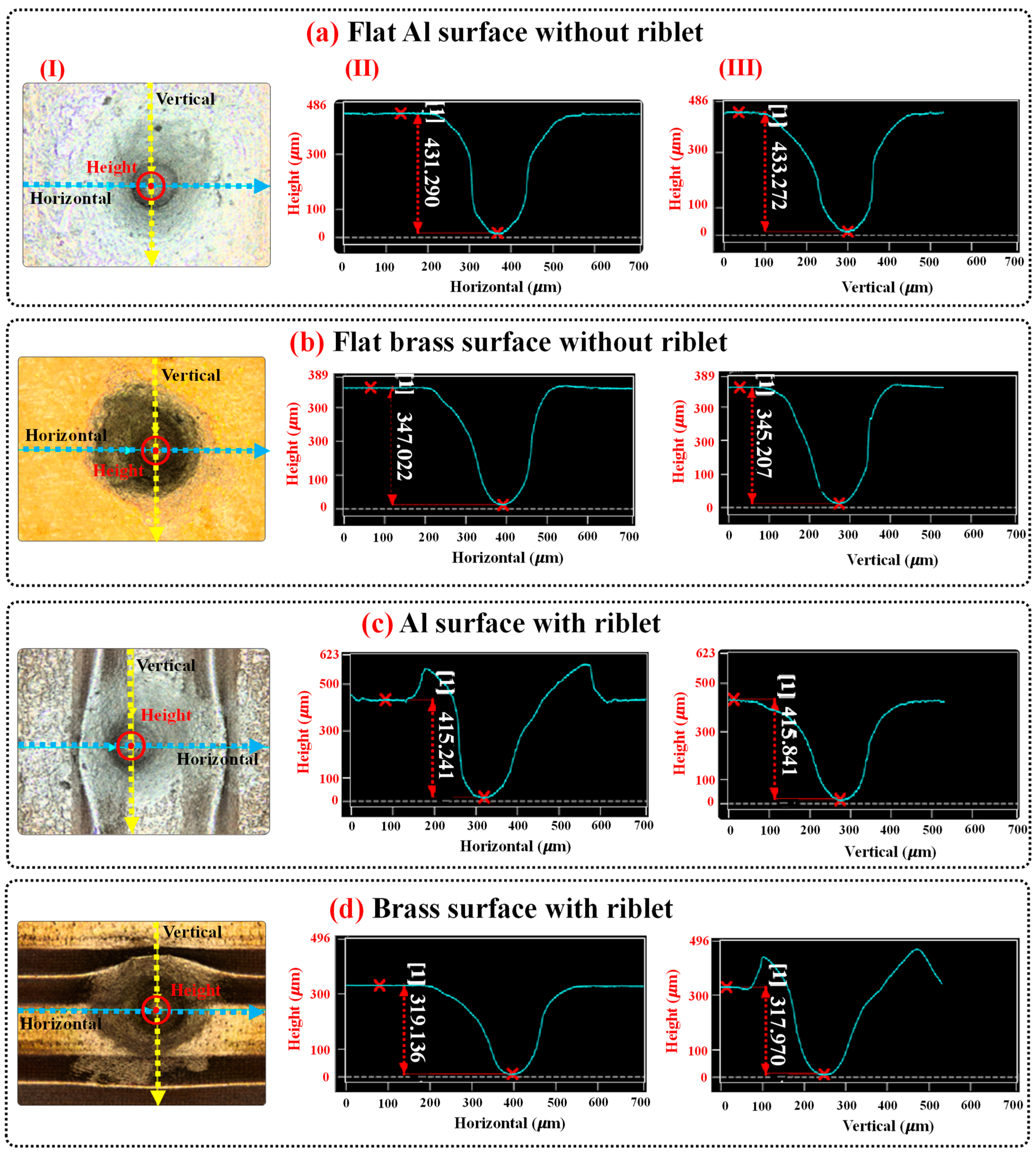

4.1. The Effects of the Material and Riblet on Cavitation-Induced Erosion Morphology

4.2. The Effects of the Material and Riblets on Cavitation-Induced Erosion Depth and Cross-Section

5. Outlook and Perspective

5.1. Comparing Obtained Results with Prior Available Data

5.2. Riblets Morphology

5.3. The Effects of the Cathodic Environment

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kadivar, E.; Ochiai, T.; Iga, Y.; el Moctar, O. An Experimental Investigation of Transient Cavitation Control on a Hydrofoil Using Hemispherical Vortex Generators. J. Hydrodyn. 2021, 33, 1139–1147. [Google Scholar] [CrossRef]

- Kadivar, E.; Timoshevskiy, M.V.; Nichik, M.Y.; El Moctar, O.; Schellin, T.E.; Pervunin, K.S. Control of Unsteady Partial Cavitation and Cloud Cavitation in Marine Engineering and Hydraulic Systems. Phys. Fluids 2020, 32, 052108. [Google Scholar] [CrossRef]

- Fortes Patella, R.; Choffat, T.; Reboud, J.L.; Archer, A. Mass Loss Simulation in Cavitation Erosion: Fatigue Criterion Approach. Wear 2013, 300, 205–215. [Google Scholar] [CrossRef]

- Sadri, M.; Kadivar, E. Numerical Investigation of the Cavitating Flow and the Cavitation-Induced Noise around One and Two Circular Cylinders. Ocean Eng. 2023, 277, 114178. [Google Scholar] [CrossRef]

- Dular, M.; Bachert, B.; Stoffel, B.; Širok, B. Relationship between Cavitation Structures and Cavitation Damage. Wear 2004, 257, 1176–1184. [Google Scholar] [CrossRef]

- Reisman, G.E.; Wang, Y.C.; Brennen, C.E. Observations of Shock Waves in Cloud Cavitation. J. Fluid Mech. 1998, 355, 255–283. [Google Scholar] [CrossRef]

- Lin, Y.; Kadivar, E.; El Moctar, O.; Neugebauer, J.; Schellin, T.E. Experimental Investigation on the Effect of Fluid-Structure Interaction on Unsteady Cavitating Flows around Flexible and Stiff Hydrofoils. Phys. Fluids 2022, 34, 083308. [Google Scholar] [CrossRef]

- Wei, T.; Smith, C.R. Secondary Vortices in the Wake of Circular Cylinders. J. Fluid Mech. 1986, 169, 513–533. [Google Scholar] [CrossRef]

- Kadivar, E.; el Moctar, O.; Sagar, H.J. Experimental Study of the Influence of Mesoscale Surface Structuring on Single Bubble Dynamics. Ocean Eng. 2022, 260, 111892. [Google Scholar] [CrossRef]

- Philipp, A.; Lauterborn, W. Cavitation Erosion by Single Laser-Produced Bubbles. J. Fluid Mech. 1998, 361, 75–116. [Google Scholar] [CrossRef]

- Tomita, Y.; Shima, A. Mechanisms of Impulsive Pressure Generation and Damage Pit Formation by Bubble Collapse. J. Fluid Mech. 1986, 169, 535–564. [Google Scholar] [CrossRef]

- Lauterborn, W.; Bolle, H. Experimental Investigations of Cavitation-Bubble Collapse in the Neighbourhood of a Solid Boundary. J. Fluid Mech. 1975, 72, 391–399. [Google Scholar] [CrossRef]

- Vogeland, A.; Lauterborn, W. Acoustic Transient Generation by Laser-Produced Cavitation Bubbles near Solid Boundaries. J. Acoust. Soc. Am. 1988, 84, 719–731. [Google Scholar] [CrossRef]

- Lindau, O.; Lauterborn, W. Cinematographic Observation of the Collapse and Rebound of a Laser-Produced Cavitation Bubble near a Wall. J. Fluid Mech. 2003, 479, 327–348. [Google Scholar] [CrossRef]

- Tomita, Y.; Robinson, P.B.; Tong, R.P.; Blake, J.R. Growth and Collapse of Cavitation Bubbles near a Curved Rigid Boundary. J. Fluid Mech. 2002, 466, 259–283. [Google Scholar] [CrossRef]

- Dular, M.; Požar, T.; Zevnik, J.; Petkovšek, R. High Speed Observation of Damage Created by a Collapse of a Single Cavitation Bubble. Wear 2019, 418–419, 13–23. [Google Scholar] [CrossRef]

- Kadivar, E.; el Moctar, O.; Skoda, R.; Löschner, U. Experimental Study of the Control of Cavitation-Induced Erosion Created by Collapse of Single Bubbles Using a Micro Structured Riblet. Wear 2021, 486–487, 204087. [Google Scholar] [CrossRef]

- Phan, T.H.; Kadivar, E.; Nguyen, V.T.; El Moctar, O.; Park, W.G. Thermodynamic Effects on Single Cavitation Bubble Dynamics under Various Ambient Temperature Conditions. Phys. Fluids 2022, 34, 23318. [Google Scholar] [CrossRef]

- Murai, Y.; Matsumoto, Y. Numerical Study of the Three-Dimensional Structure of a Bubble Plume. J. Fluids Eng. Trans. ASME 2000, 122, 754–760. [Google Scholar] [CrossRef]

- Xiao, C.; Heyes, D.M.; Powles, J.G. The Collapsing Bubble in a Liquid by Molecular Dynamics Simulations. Mol. Phys. 2002, 100, 3451–3468. [Google Scholar] [CrossRef]

- Ghoohestani, M.; Rezaee, S.; Kadivar, E.; Esmaeilbeig, M.A. Reactive-Dynamic Characteristics of a Nanobubble Collapse near a Solid Boundary Using Molecular Dynamic Simulation. Phys. Fluids 2023, 35, 022003. [Google Scholar] [CrossRef]

- Ghoohestani, M.; Rezaee, S.; Kadivar, E.; el Moctar, O. Thermodynamic Effects on Nanobubble’s Collapse-Induced Erosion Using Molecular Dynamic Simulation. Phys. Fluids 2023, 35, 073319. [Google Scholar] [CrossRef]

- Gao, Z.; Wu, W.; Sun, W.; Wang, B. Understanding the Stabilization of a Bulk Nanobubble: A Molecular Dynamics Analysis. Langmuir 2021, 37, 11281–11291. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.; Lin, X.; Zhang, Z.; Gu, N. Impact of Shock-Induced Lipid Nanobubble Collapse on a Phospholipid Membrane. J. Phys. Chem. C 2016, 120, 18803–18810. [Google Scholar] [CrossRef]

- Nan, N.; Si, D.; Hu, G. Nanoscale Cavitation in Perforation of Cellular Membrane by Shock-Wave Induced Nanobubble Collapse. J. Chem. Phys. 2018, 149, 074902. [Google Scholar] [CrossRef]

- Santo, K.P.; Berkowitz, M.L. Shock Wave Induced Collapse of Arrays of Nanobubbles Located Next to a Lipid Membrane: Coarse-Grained Computer Simulations. J. Phys. Chem. B 2015, 119, 8879–8889. [Google Scholar] [CrossRef] [PubMed]

- Adhikari, U.; Goliaei, A.; Berkowitz, M.L. Mechanism of Membrane Poration by Shock Wave Induced Nanobubble Collapse: A Molecular Dynamics Study. J. Phys. Chem. B 2015, 119, 6225–6234. [Google Scholar] [CrossRef]

- Rezaee, S.; Kadivar, E.; el Moctar, O. Molecular Dynamics Simulations of a Nanobubble’s Collapse-Induced Erosion on Nickel Boundary and Porous Nickel Foam Boundary. J. Mol. Liq. 2024, 397, 124029. [Google Scholar] [CrossRef]

- Rezaee, S.; Kadivar, E.; el Moctar, O. The Role of Sawtooth-Shaped Nano Riblets on Nanobubble Dynamics and Collapse-Induced Erosion near Solid Boundary. J. Mol. Liq. 2024, 405, 124947. [Google Scholar] [CrossRef]

- Peters, A. Numerical Modelling and Prediction of Cavitation Erosion Using Euler-Euler and Multi-Scale Euler-Lagrange Methods. Ph.D. Thesis, Universität Duisburg-Essen, Duisburg, Germany, 2020. [Google Scholar]

- Liang, L.; Pang, Y.; Tang, Y.; Zhang, H.; Liu, H.; Liu, Y. Combined Wear of Slurry Erosion, Cavitation Erosion, and Corrosion on the Simulated Ship Surface. Adv. Mech. Eng. 2019, 11, 1687814019834450. [Google Scholar] [CrossRef]

- Pap, A.E.; Dücso, C.; Kamaras, K.; Battistig, G.; Bársony, I. Heavy Water in Gate Stack Processing. In Proceedings of the Materials Science Forum; Trans Tech Publ: Bäch, Switzerland, 2008; Volume 573–574, pp. 119–131. [Google Scholar]

- Hutson, J.; Lively, J.; Robertson, B.; Cotroneo, P.; Lang, M. Expanding Horizons: AI Tools and Workflows in Art Practice. In Springer Series on Cultural Computing; Springer: Cham, Switzerland, 2024; Part F1711; pp. 101–132. [Google Scholar]

- Epstein, D.C.; Jain, I.; Wang, O.; Zhang, R. Online Detection of Ai-Generated Images. In Proceedings of the IEEE/CVF International Conference on Computer Vision, Paris, France, 2–6 October 2023; pp. 382–392. [Google Scholar]

- Healy, M. Approaches to Generative Artificial Intelligence, A Social Justice Perspective. arXiv 2023, arXiv:2309.12331. [Google Scholar] [CrossRef]

- Sagar, H.J.; el Moctar, O. Dynamics of a Cavitation Bubble near a Solid Surface and the Induced Damage. J. Fluids Struct. 2020, 92, 102799. [Google Scholar] [CrossRef]

- Kadivar, E.; Phan, T.H.; Park, W.G.; El Moctar, O. Dynamics of a Single Cavitation Bubble near a Cylindrical Rod. Phys. Fluids 2021, 33, 113315. [Google Scholar] [CrossRef]

- Kadivar, E.; Rajabpour, A.; El Moctar, O. Nanobubble Collapse Induced Erosion near Flexible and Rigid Boundaries: A Molecular Dynamics Study. Fluids 2023, 8, 154. [Google Scholar] [CrossRef]

- Sagar, H.J. Numerical and Experimental Investigation of Laser-Induced Cavitation Bubbles and Induced Damage. Ph.D. Thesis, Universität Duisburg-Essen, Duisburg, Germany, 2018; pp. 430–439. [Google Scholar]

- Hussein, N. Materials Science and Engineering; CreateSpace Independent Publishing Platform: Scotts Valley, CA, USA, 2017; Volume 7, ISBN 978-1544083803. [Google Scholar]

- Choubey, A.; Vedadi, M.; Nomura, K.I.; Kalia, R.K.; Nakano, A.; Vashishta, P. Poration of Lipid Bilayers by Shock-Induced Nanobubble Collapse. Appl. Phys. Lett. 2011, 98, 23701. [Google Scholar] [CrossRef]

- Vedadi, M.; Choubey, A.; Nomura, K.; Kalia, R.K.; Nakano, A.; Vashishta, P.; Van Duin, A.C.T. Structure and Dynamics of Shock-Induced Nanobubble Collapse in Water. Phys. Rev. Lett. 2010, 105, 14503. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Zhang, Q.; Zhou, Q.; Gao, S.; Wang, B.; Wang, X.; Huang, Y. Flow Accelerated Corrosion and Erosion−corrosion Behavior of Marine Carbon Steel in Natural Seawater. npj Mater. Degrad. 2021, 5, 56. [Google Scholar] [CrossRef]

- Googan, C. Marine Corrosion and Cathodic Protection; CRC Press: London, UK, 2022; ISBN 9781000536492. [Google Scholar]

- Yan, Y.; Zhu, H.; Fan, Z.; Zhao, J.; Jiang, S. Corrosion Behavior of Reinforcing Steel in the Immersed Tube Tunnel (ITT) under Submarine Environment. Materials 2023, 16, 3300. [Google Scholar] [CrossRef] [PubMed]

- Ge, M.; Manikkam, P.; Ghossein, J.; Kumar Subramanian, R.; Coutier-Delgosha, O.; Zhang, G. Dynamic Mode Decomposition to Classify Cavitating Flow Regimes Induced by Thermodynamic Effects. Energy 2022, 254, 124426. [Google Scholar] [CrossRef]

- Ge, M.; Zhang, G.; Petkovšek, M.; Long, K.; Coutier-Delgosha, O. Intensity and Regimes Changing of Hydrodynamic Cavitation Considering Temperature Effects. J. Clean. Prod. 2022, 338, 130470. [Google Scholar] [CrossRef]

- Ge, M.; Petkovšek, M.; Zhang, G.; Jacobs, D.; Coutier-Delgosha, O. Cavitation Dynamics and Thermodynamic Effects at Elevated Temperatures in a Small Venturi Channel. Int. J. Heat Mass Transf. 2021, 170, 120970. [Google Scholar] [CrossRef]

- Naudé, C.F.; Ellis, A.T. On the Mechanism of Cavitation Damage by Nonhemispherical Cavities Collapsing in Contact with a Solid Boundary. J. Basic Eng. Trans. 1961, 83, 648–656. [Google Scholar] [CrossRef]

- Neville, A.; McDougall, B.A.B. Erosion—And Cavitation—Corrosion of Titanium and Its Alloys. Wear 2001, 250, 726–735. [Google Scholar] [CrossRef]

- Dular, M.; Delgosha, O.C.; Petkovšek, M. Observations of Cavitation Erosion Pit Formation. Ultrason. Sonochem. 2013, 20, 1113–1120. [Google Scholar] [CrossRef] [PubMed]

- Chahine, G.L.; Franc, J.P.; Karimi, A. Mass Loss and Advanced Periods of Erosion. Fluid Mech. Appl. 2014, 106, 97–121. [Google Scholar] [CrossRef]

- Chiu, K.Y.; Cheng, F.T.; Man, H.C. Evolution of Surface Roughness of Some Metallic Materials in Cavitation Erosion. Ultrasonics 2005, 43, 713–716. [Google Scholar] [CrossRef] [PubMed]

- Usta, O.; Korkut, E. Prediction of Cavitation Development and Cavitation Erosion on Hydrofoils and Propellers by Detached Eddy Simulation. Ocean Eng. 2019, 191, 106512. [Google Scholar] [CrossRef]

- Ge, M.; Sun, C.; Zhang, G.; Coutier-Delgosha, O.; Fan, D. Combined Suppression Effects on Hydrodynamic Cavitation Performance in Venturi-Type Reactor for Process Intensification. Ultrason. Sonochem. 2022, 86, 106035. [Google Scholar] [CrossRef]

- Sadri Mofakham, A.; Rasteh, M. CFD Simulation of Gas-Solid Fluidized Bed Hydrodynamics; Prediction Accuracy Study. Int. J. Chem. React. Eng. 2023, 21, 391–407. [Google Scholar] [CrossRef]

- Hasan, M.; Zhao, J.; Jiang, Z. A Review of Modern Advancements in Micro Drilling Techniques. J. Manuf. Process. 2017, 29, 343–375. [Google Scholar] [CrossRef]

- Howitt, D.G.; Chen, S.J.; Gierhart, B.C.; Smith, R.L.; Collins, S.D. The Electron Beam Hole Drilling of Silicon Nitride Thin Films. J. Appl. Phys. 2008, 103, 024310. [Google Scholar] [CrossRef]

- Johnson, P.A.; Bartolotti, L.J.; Ayers, P.W.; Fievez, T.; Geerlings, P. Charge Density and Chemical Reactions: A Unified View from Conceptual DFT. In Modern Charge-Density Analysis; Springer: Dordrecht, The Netherlands, 2012; pp. 715–764. ISBN 9789048138364. [Google Scholar]

- Qiu, P.; Leygraf, C. Initial Oxidation of Brass Induced by Humidified Air. Appl. Surf. Sci. 2011, 258, 1235–1241. [Google Scholar] [CrossRef] [PubMed]

| Research | App. | Material Features | γ | Results | Year | Ref. | ||

|---|---|---|---|---|---|---|---|---|

| Erosion | ||||||||

| Material | Surface | Depth (μm) | Diameter (mm) | |||||

| Damaging effects of the various cavities | Exp. & The. | 2S Al | Flat | 0.23 | - | 0.350 | 1961 | [49] |

| Cavitation bubble in water and the resulting surface damage | Exp. | Al | Flat | 0.30 | 8 | 0.570 | 1998 | [10] |

| Probing the erosion–corrosion and cavitation–corrosion of Ti alloys | Exp. | Ti alloys | Flat | The cavitation–corrosion resistance of Ti alloys are in the sequence of: Ti–6Al–4V ELI/Ru > Ti–6Al–4V ELI > Ti 5111 > CP-Ti | 2001 | [50] | ||

| Evolution of metallic materials (316L stainless steel (SS), CP Ti, and brass) in regards to cavitation erosion | Exp. | 316L SS Ti Brass | Roughened | The erosion resistance of metallic materials is in the sequence of: 316L SS > Ti > Brass | 2005 | [53] | ||

| Investigation of the erosion effects of ultrasonic cavitation | Exp. | Al | Flat | - | 40 | 1.500 | 2013 | [51] |

| Probing the advanced stages of erosion characteristics | Exp. | Ni-Al bronze alloy | Flat | - | 450 | 5.000 | 2014 | [52] |

| Prediction of cavitation erosion on propellers | CFD | Erosive Power Method (EPM) was proposed to predict of cavitation erosion on propellers | 2019 | [54] | ||||

| Control of cavitation-induced erosion created by collapse of bubbles using riblets | Exp. | Al | Riblet | 0.9 | 32 | 200.000 | 2021 | [17] |

| Offering a passive control method to control the dynamics of cavitation | Exp. | Al | Riblet | 0.6–1.8 | The riblets can suppress the impact of water jets, thereby decreasing erosion | 2022 | [9] | |

| Examination the temperature effects on hydrodynamic cavitating flows and intensity of cavitation | Exp. | ✓ The pressure drop, inertial/viscous, and temperature condition influence on cavitation lengths and regimes. ✓ Elevated temperatures (over 58 °C) have significant effects on thermodynamic of cavitation. | 2022 | [46,47] | ||||

| Evaluating the effects of materials on erosion | Exp. | Al | Flat | 1.8 | 432.281 | 0.350 | 2024 | Present work |

| Evaluating the effects of riblets on erosion | Exp. | Al | Riblet | 1.8 | 415.541 | 0.245 | 2024 | Present work |

| Evaluating the effects of materials on erosion | Exp. | Brass (CuZn37) | Flat | 1.8 | 346.115 | 0.320 | 2024 | Present work |

| Evaluating the effects of riblets on erosion | Exp. | Brass (CuZn37) | Riblet | 1.8 | 318.553 | 0.225 | 2024 | Present work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kadivar, E.; Rezaee, S.; Löschner, U.; el Moctar, O. Effects of Materials and Riblets on Erosion Mitigation Induced by Multiple Collapses of Cavitation Bubbles. Appl. Sci. 2024, 14, 6452. https://doi.org/10.3390/app14156452

Kadivar E, Rezaee S, Löschner U, el Moctar O. Effects of Materials and Riblets on Erosion Mitigation Induced by Multiple Collapses of Cavitation Bubbles. Applied Sciences. 2024; 14(15):6452. https://doi.org/10.3390/app14156452

Chicago/Turabian StyleKadivar, Ebrahim, Sasan Rezaee, Udo Löschner, and Ould el Moctar. 2024. "Effects of Materials and Riblets on Erosion Mitigation Induced by Multiple Collapses of Cavitation Bubbles" Applied Sciences 14, no. 15: 6452. https://doi.org/10.3390/app14156452

APA StyleKadivar, E., Rezaee, S., Löschner, U., & el Moctar, O. (2024). Effects of Materials and Riblets on Erosion Mitigation Induced by Multiple Collapses of Cavitation Bubbles. Applied Sciences, 14(15), 6452. https://doi.org/10.3390/app14156452